Mcor 3d printer

Mcor IRIS 3D Printer Review 2022

3

See Price

Here at 3D Beginners, we cover basically any printer under the sun, and today we take a look at the rather remarkable Mcor IRIS, unique in that it steps away from traditional 3D printing techniques in favor of bringing a full-color spectrum to printing.

How does it stack up in terms of quality against additive printers? Let’s find out as we wade through the tantalizing marketing spiel to determine precisely how this ostensibly revolutionary printer stacks up.

| Printing Area | 256 mm x 169 mm x 150 mm |

| Layer Resolution | 100 Microns |

| Color Resolution | 5760 x 1440 x 508 dpi |

| Supported Filament | A4 Paper |

| Printing Technology | Selective Deposition Lamination |

Table of ContentsShow

Design & Features

When talking about 3D printers, we are tacitly referring to additive manufacturing techniques such as FDM, or if not, to other technology such as SLA. With the Mcor IRIS, the whole idea of a 3D printer as a unit designed to melt and mold plastic material, powder, or resin into a 3D model is thrown on its head.

The IRIS uses your run of the mill white office paper, the very stuff used in traditional inkjet printers. That’s right, the modern descendent of the world changing papyrus the Ancient Egyptians invented thousands of years ago.

How does it work? A stack of paper is fed into a traditional Epson printer located in the shelf unit below the IRIS one sheet at a time. The printer prints ‘’slices’’ similar to an additive counterpart but as a color outline on the borders of the soon to be model. The stack then goes through a deposition lamination process whereby each sheet is fed into the IRIS, and a multi-function head cuts a 2D profile.

From here, a nozzle on the head selectively applies a water-based adhesive that ensures the layers stick together to form the 3D model as they stack up and are pressed together by way of a heat plate to aid adhesion. The IRIS then applies a finish, or coating, that can differ based on functional needs from hardened outer layers to glossier, lacquer-like veneers. The model exits the printer as a stack of paper. The waste, excess paper is easily removed in blocks to reveal the model beneath.

The IRIS then applies a finish, or coating, that can differ based on functional needs from hardened outer layers to glossier, lacquer-like veneers. The model exits the printer as a stack of paper. The waste, excess paper is easily removed in blocks to reveal the model beneath.

The use of paper as the raw material behind the prints also means that the IRIS can print in an array and complexity of colors unheard of in 3D printing circles. By color, we mean true color as in over 1 million different hues pulled straight from the International color consortium with rich, vibrant, photo-realistic, and high definition subtleties. On the models themselves, colors are also possible in 360 degrees.

The benefits don’t stop there though as the functional cost of printing is drastically reduced compared to plastic materials. A stack of paper is markedly cheaper than multiple spools of PLA for example. Additionally, the IRIS is pretty much as environmentally friendly as 3D printers can get with fully recyclable paper waste and the ability to source paper from responsible distributors.

As for specific features and specifications, we need to start by stressing that the Mcor IRIS is through and through an industrial grade printer acting as a counterpart to the Irish company’s smaller, office-friendly, prosumer version called the ARKE.

The IRIS is no small machine measuring in at 950 mm x 700 mm x 800 mm with a total weight of 160 kg. The build volume is 256 mm x 169 mm x 150 mm with a layer resolution of 100 microns (the thickness of a piece of paper) with a color resolution of 5760 x 1440 x 508 dpi.

The Mcor IRIS uses any standard variant of A4 office paper alongside Mcor designed ink cartridges that fit into the inkjet part of the unit. The ink is designed to seep through the whole thickness of the sheet creating the colored outer layer of the finished prints.

Connectivity is assured via Ethernet. Software-wise, the IRIS uses a tandem of SliceIT and ColourIT, used for slicing models before printing and applying color respectively. The software is compatible with STL, WRL, OBJ, 3DS, FBX, DAE and PLY file types.

Printing

When eyeing up a finished print from the Mcor IRIS, we had to keep reminding ourselves that it was made of paper. The results are surprisingly solid especially when used in conjunction with a robust coating option, and the colors will charm even the most versed 3D printer. They aren’t perfect by any stretch of the imagination it must be said.

Although the color spectrum is baffling, the quality of the finished products is defined by an evident lack of detail in terms of texture on the models. In most cases, there is a distinct absence of features beyond general shapes and surfaces are flat, dull even.

The quality of the color rendering leaves something to be desired too with a slightly blurred, drab quality that is at odds with the vibrancy of plastic 3D printing, albeit in the few colors additive printing can produce. Layers are incredibly apparent throughout most models which can significantly affect the appearance of the coloring.

For the reasons above, the Mcor IRIS doesn’t stack up to the functional results of standard 3D printers where prints can be used as pre-production stress test models or serious prototyping. In our estimation, the Mcor IRIS is far better suited to artistic pursuits for sculptures, display models, ornaments and as parts of a larger art piece.

In our estimation, the Mcor IRIS is far better suited to artistic pursuits for sculptures, display models, ornaments and as parts of a larger art piece.

Alternatively, architectural firms will find the IRIS a suitable device to print 3D mock-ups of potential buildings, but as above the lack of detail means these won’t be suited to life-like renditions. The paper is quite simply not robust enough to weather the demands of a mechanical setting, pre-build testing, or as a pre-molding prototype.

Support

Mcor has seized production of the IRIS in favor of the newer ARKE and ARKEPRO, as such technical support for the IRIS is limited. The company’s website offers very little in terms of articles or tutorials and finding any support help is an arduous task in itself.

Most resellers offer a standard one-year warranty, a reasonably standard offering for these types of units.

Verdict

The Mcor IRIS has a lot going for it particularly when it comes to the full-color features and the low cost of production, but the near $50,000 price tag is a hard pill to swallow.

We weren’t disappointed with the results (the array of colors and the way they can shift effortlessly from one side of a model to the other is astounding), but instead, we felt they were at odds with the claims made by Mcor.

Beyond artistic and educational purposes, the IRIS doesn’t provide enough detail and solidity for industrial-grade uses making it a rather expensive gimmick for any serious R&D department or design studio.

The End of Mcor Technologies? « Fabbaloo

By Kerry Stevenson on May 30th, 2019 in Corporate

Tags: bankrupt, color, financial, mcor, paper, receiver

The ArkePro, likely the last device produced by Mcor Technologies [Source: Fabbaloo]It appears the end is near for Mcor Technologies, as we have indications they are in receivership.

The Irish company was one we’ve tracked for many years, beginning with one of our most popular stories describing their radical paper-based 3D printing technology way back in 2007. The technology involved gluing sheets together and neatly cutting off non-object material, sheet by sheet. This allowed them to produce inexpensive 3D prints made from paper, and even full color 3D prints with their most recent device.

This allowed them to produce inexpensive 3D prints made from paper, and even full color 3D prints with their most recent device.

Since then we’ve carefully followed their progress with the technology, announced with flair at CES a few years ago. Their most recent product is the Arke, an ingenious device that pre-prints full color “edges” on paper before entering the layer-cutter. This process is one of the few that could produce full color textured 3D prints.

Sample full color 3D print from the Mcor ArkePro [Source: Fabbaloo]More recently, Mcor has spent considerable time tuning the Arke’s design to enable it be manufactured as efficiently as possible. Our interview with their then-CEO, Conor MacCormack, showed the company was working with a noted contract product manufacturer, Flextronics.

In the past year the company took on a new CEO, and we were looking forward to speaking with them. But somehow that never happened.

Since then we’ve noted that Mcor no longer appeared at any trade shows we attended, save for the occasional machine in a reseller’s booth. This caused us some concern there were issues, and apparently that was indeed the case.

This caused us some concern there were issues, and apparently that was indeed the case.

We recently received a notice from the company’s receiver. (A receiver is an accounting firm that takes over operations of a financially bankrupt company, usually with intentions of selling the assets or entire operation to interested buyers.)

Obviously, that’s not good.

The receiver, Deloitte in this case, explains Mcor was unable to secure further investment to pay for growth and expansion, leading to the current situation.

Deloitte intends on operating the company for a short period during which they offer for sale the intellectual property, physical assets and customer base for any who are interested.

These include the ArkePro 3D printer, an office-friendly, full color and low-cost device ready for manufacture by Flextronics, including 12 months of manufacturing materials and the associated consumables business.

I’m not sure who might be interested in purchasing all or part of this operation, but if such parties exist, they likely read this publication.

This may be an opportunity for a new management to take over the operations and immediately get into the color 3D printing business, which is still an emerging market served by only a few parties. A 3D printer manufacturer wishing to add a new product line could be a possible buyer, as well as a 3D print reseller wishing to establish their own hardware operation. We don’t know the price, but it could be at a discount over inventing such technology on your own.

Anyone interested should contact Deloitte as soon as possible, as we don’t know how long they will continue operations. Deloitte suggests interested parties should contact:

David Van Dessel

Partner, Restructuring, Deloitte

Email: [email protected]

Telephone: +353 1 417 8805

A note on Mcor’s site provides little further detail:

“By Deed of Appointment, effective 21 March 2019, David Van Dessel was appointed Receiver and Manager over the assets and undertaking of MCOR Technologies Limited on foot of the powers contained in a Debenture.

”

Via Mcor Technologies

Mcor Sneaks Out The ARKePro

Call us surprised; Mcor Technologies seems to have released a new 3D printer without a lot of fanfare.

One on One With Mcor’s Conor MacCormack, Part 2

We had the rare opportunity to sit down with Mcor Technology’s CEO, Conor MacCormack at CES and find out what’s been happening with the company in recent months.

One on One With Mcor’s Conor MacCormack, Part 1

We had the rare opportunity to sit down with Mcor Technology’s CEO, Conor MacCormack at CES and find out what’s been happening with the company in recent months.

If MCOR Was Not Exhibiting At CES, Why Were They There?

This year’s CES exhibition in Las Vegas was notable in the 3D space primarily by the missing presence of several large industrial vendors. Except one, sort of.

MCOR Shifts Gears on their Color 3D Printer

MCOR Technologies announced a very attractive full-color 3D printer based on their paper technology last January, but a recent announcement describes some key changes.

MCOR Announces A Low-Price Full Color Desktop 3D Printer: The Arke

Yesterday at the Consumer Electronics Show MCOR announced the Arke, a full RGB color desktop 3D printer, capable of producing intricately color textured objects at low cost.

Kerry Stevenson, aka "General Fabb" has written over 8,000 stories on 3D printing at Fabbaloo since he launched the venture in 2007, with an intention to promote and grow the incredible technology of 3D printing across the world. So far, it seems to be working!

View all of Kerry Stevenson's posts.

AM-COR. Distributor and integrator of additive technologies. 3D printers SLS, Gypsum, DLP, FDM.

3D printers made in China, Thailand.

Without sanctions

Our brands

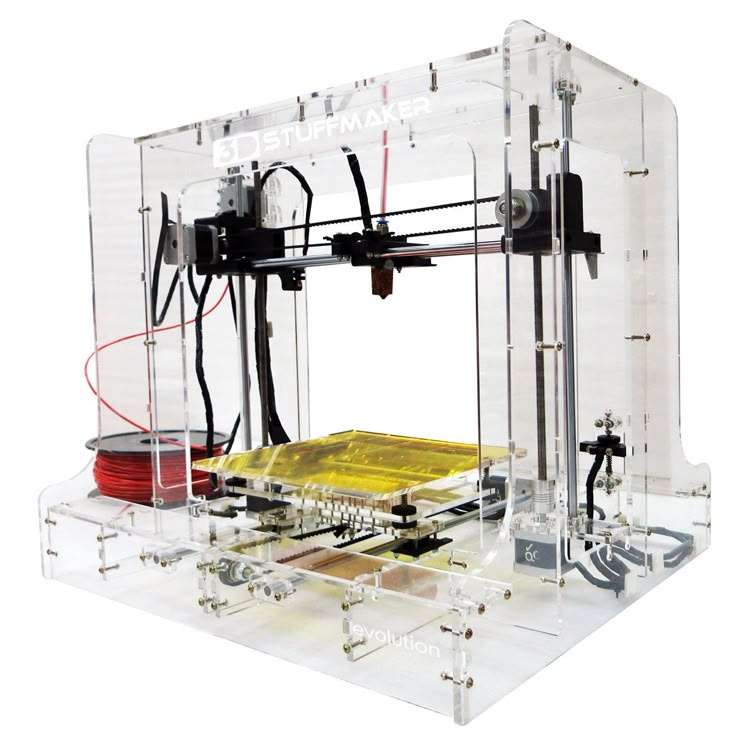

AMcore is the exclusive supplier of the world's leading manufacturers of 3D printers in the territory of the Customs Union. In the product catalog of 3D printers you will find products of recognized leaders in the production of devices for three-dimensional printing and scanning and consumables for them. Here you will find professional and desktop 3D printing solutions. We will help you choose the device that will perfectly fulfill your tasks!

To go to the catalog of the brand you are interested in, please click on the corresponding manufacturer's logo below.

01.XYZprinting PRO

For professionals

XYZprinting, one of the world's largest manufacturers of 3D printers. The professional line of 3D printers is based on the following technologies:

SLS (Selective Laser Sintering) 3D printers

Selective Laser Sintering (SLS) technology has long been the platform of choice for producing 3D printed parts with strong mechanical properties. MfgPro230 xS allows you to organize small-scale production and production of functional prototypes, at an affordable price. DETAILS...

3D printers BINDER JET (gypsum)

3D printerPARTPRO 350 XS is a high-speed 3D printer for printing full-color gypsum products at an affordable price. MORE...

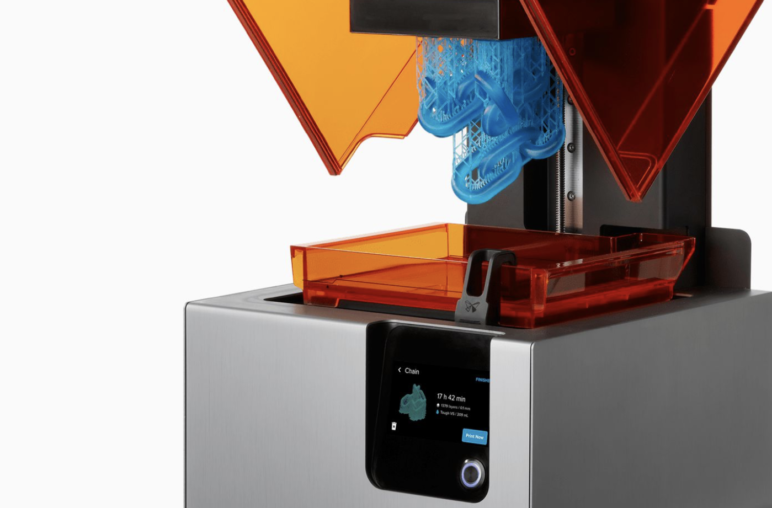

DLP and SLA 3D printers

The line of photopolymer 3D printers is represented by three models, including the ultra-fast PARTPRO120 XP DLP 3D printer, which allows you to print at speeds up to 30 cm/hour! MORE...

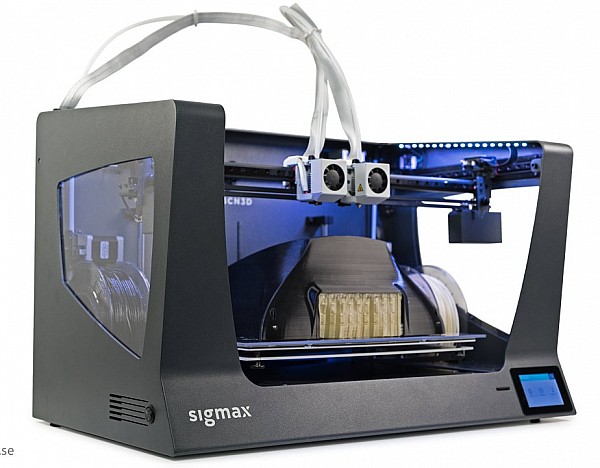

FDM and Color fdm 3D printers

In addition to the traditional two-head FDM 3D printer, XYZprinting offers a unique PARTPRO200 XTCS full color FDM 3D printer with a large print area. DETAILS...

DETAILS...

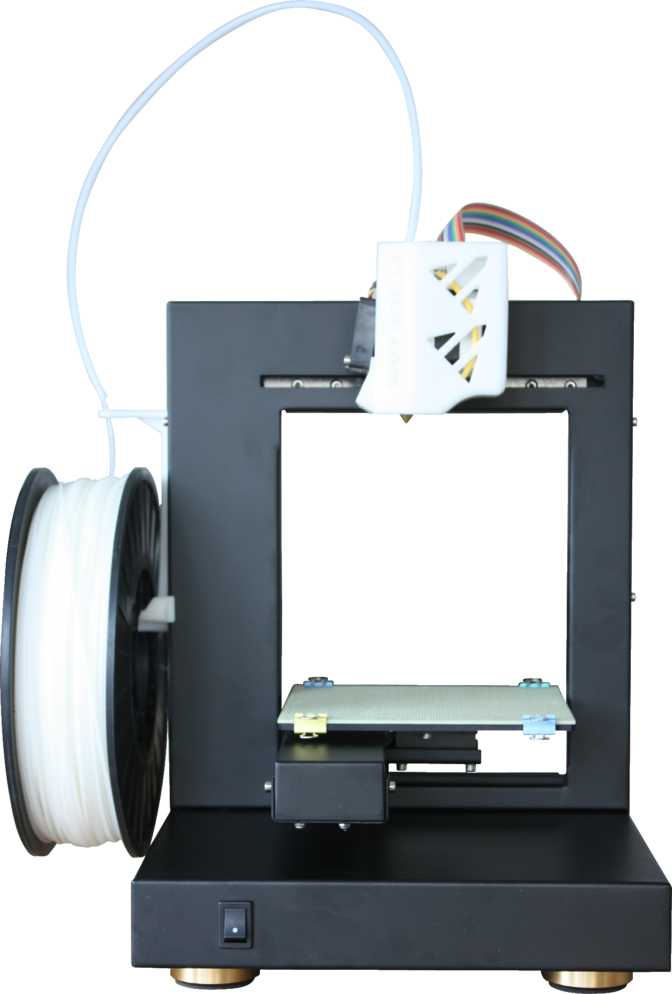

02.XYZprinting DeSKTOP

for Education and Prototyping

XYZprinting, a leading manufacturer of 3D printing technology, has grown rapidly since its founding in 2013, with offices in Taiwan (Head Quarter), China, Japan, South Korea, the United States and Europe. With proven industry expertise and an innovative spirit, it is becoming a leading global brand in desktop 3D printing products and services. XYZprinting is backed by the world's leading electronics manufacturing conglomerate New Kinpo Group, which generates over 36 billion euros in revenue annually and has over 8,500 R&D engineers across four continents. Kinpo Group has over 17 years of experience designing and manufacturing printers for personal and commercial use.

3D printers for education

Bring the future into the classroom and into your home! Inspire the next generation by standing on the shoulders of giants. Teach the skills and professions of the future with XYZprinting 3D printers, LEARN MORE. ..

..

3D printers for design and prototyping

New frontiers in 3D printing. Take 3D printing to the next level with the da Vinci Color series. DETAILS...

03. WEBER granular 3D printers

for large items

“Direct extrusion” involves creating components layer by layer from plasticized granules. The fact that no filament is used has a number of advantages:

WEBER SINGLE SCREW EXTRUDER

Can be used to process highly filled, fiber reinforced or even soft materials. MORE...

HIGH CAPACITY UP TO 20 KG/H

The high output of the extruder provides faster printing (up to 20 kg/h), which is very important for large volume products. DETAILS...

PELLETS 10 TIMES CHEAPER!

Pellets are much more economical than using a plastic thread (filament). DETAILS...

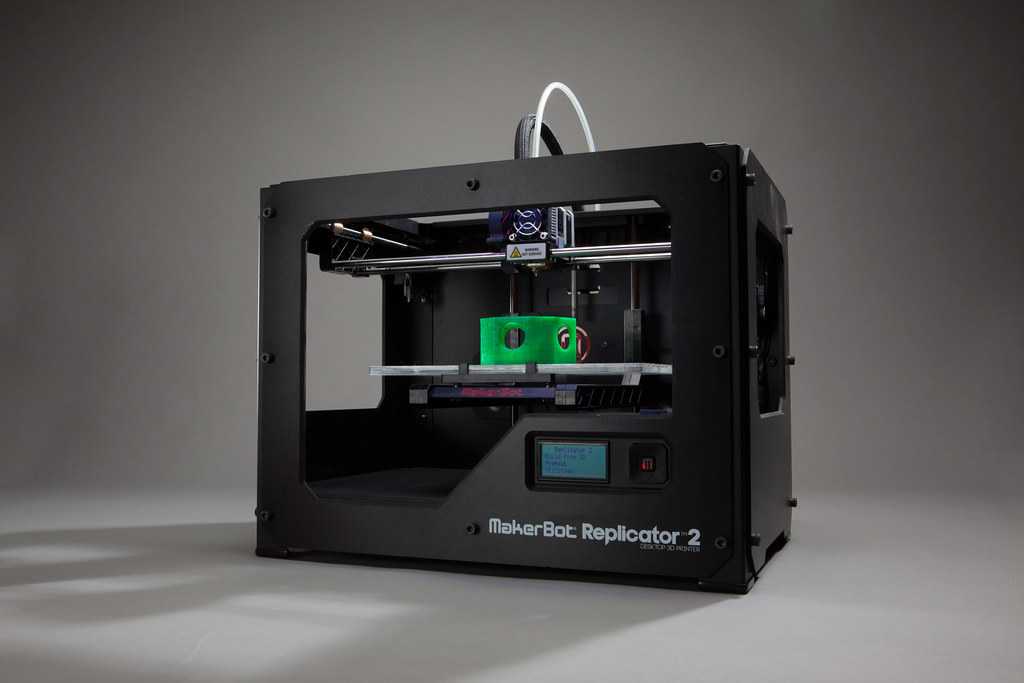

04. Makerbot (Stratasys)

for FUNCTIONAL

prototyping

Makerbot is a division of the world leader Stratasys - manufacturer of professional 3D printers.

3D printer FOR PROFESSIONALS

Modernize manufacturing and accelerate product development with the powerful METHOD Additive Platform. DETAILS...

Professional Education 3D Printers

Bring ideas to life with Makerbot 3D printing solutions designed for students and educators. DETAILS...

TECHNOLOGIES

Additive Manufacturing (AM) is a term to describe a set of technologies that create 3D objects by adding material layer by layer. Materials may vary from technology to technology. But there are some common features for all additive manufacturing, such as the use of a computer along with special 3D modeling software. The first thing to do to start this process is to create a CAD sketch. The AM device then reads the data from the CAD file and creates the structure layer by layer from the printed material, which can be plastic, liquid, flux-cored filaments, or even a sheet of paper.

XYZprinting SLA Printer

SLA technology produces smooth surfaces and fine details.

Package body

Functional product.

Jewelry

SLA 3D printers are widely used by jewelers to make burnt-out models.

Functional prototypes

Prefabricated products - this is the calling of SLA technology in prototyping.

Stereolithography is a 3D printing technique that can be used to complete your 3D printing projects. Although this method is the oldest in the history of 3D printing, it is still in use today. The idea and application of this method is amazing. Whether you're a mechanical engineer who needs to check if a part fits your design, or a creative person who wants to create a plastic prototype for a new future project, stereolithography can help you turn your models into a real 3D printed object.

Brands: XYZprinting

DLP 3D printers, like SLA, work with photopolymers. But what makes SLA and DLP processes different is the different type of light source. For fans of DLP 3D, more traditional light sources such as arc lamps are commonly used. Another important part of the process is the liquid crystal display panel, which illuminates the entire printable area at once. Therefore, DLP 3D printers print faster than SLA 3D printers. The material used for printing is liquid plastic resin, which is placed in a transparent resin container. The resin hardens quickly when exposed to light. The print speed is pretty impressive. A layer of cured material can be created with such a printer in seconds. When a layer is finished, it moves up and work begins on the next layer.

Another important part of the process is the liquid crystal display panel, which illuminates the entire printable area at once. Therefore, DLP 3D printers print faster than SLA 3D printers. The material used for printing is liquid plastic resin, which is placed in a transparent resin container. The resin hardens quickly when exposed to light. The print speed is pretty impressive. A layer of cured material can be created with such a printer in seconds. When a layer is finished, it moves up and work begins on the next layer.

Brands: XYZprinting

Casting

Casting of medium and large parts with metals and polymers

Cylinder head block

DLP technology is ideal for medium and large parts.

Aligners

Making master models for vacuum crimping - making aligners

Marketing group

Nunc ullamcorper, justo a iaculis elementum, enim orci viverra eros, fringilla porttitor.

Impeller

Complex geometry and engineering, high temperature plastics are the main advantages of FDM technology.

Drone body

Carbon-filled plastics are ideal for making strong, lightweight structures.

Uppers

Stretch printing of shoe elements.

Medical devices

Bio-inert and engineering plastics - widely used in the manufacture of individual medical devices.

With FDM you can print not only functional prototypes, but also concept models and functional products. What's great about this technology is that all FDM printed parts can be made from high performance engineering grade thermoplastics, which is very beneficial for mechanical engineers and manufacturers. FDM is the only 3D printing technology that allows parts to be produced from production quality thermoplastics, so the printed products have excellent mechanical, thermal and chemical properties.

Brands: Weber, MakerBot, Dremel, XYZprinting PRO, XYZprinting Desktop

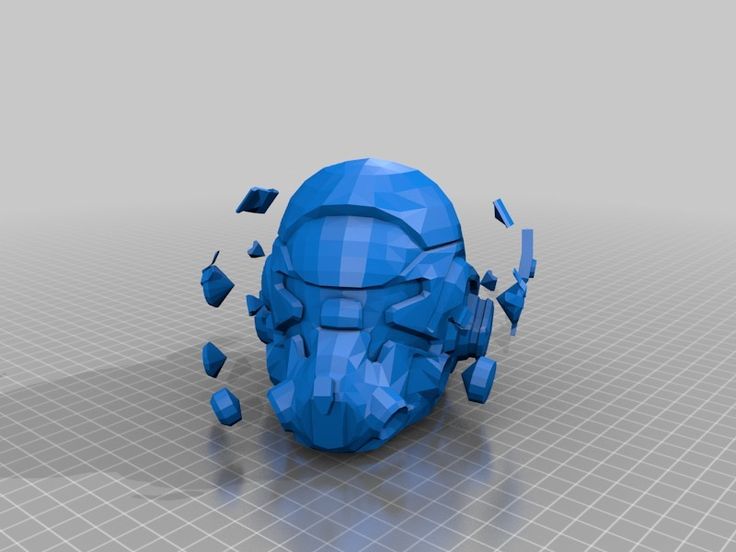

SELECTIVE LASER SINTERING (SLS) uses a 3D printing process called Power Bed Fusion.

Common applications for SLS are functional parts, complex ductwork requiring hollow structures, and light production.

His strength lies in the creation of functional parts, parts with good mechanical properties and complex geometries.

Brands: XYZprinting PRO

Chain mail

SLS technology allows printing non-separable structures without supports

Case

Cased, thin-walled products with complex geometry - an ideal application for SLS printing technology.

Cylinder head

Functional products

Three-dimensional picture

Full-color full-fledged three-dimensional picture printed on a plaster 3D printer.

Antique vase

Antique vase - an exact full-color copy of the museum exhibit.

Gypsum plaster

Your imagination is not limited

Souvenirs

Binder Jetting technology — layer-by-layer bonding of a composite powder with a binder (usually based on gypsum or quartz sand).

Plaster 3D printers are used in architecture, model making, archaology, design and art.

Sand-based 3D printers find their way into foundries and are used to make molds and cores.

Brands: XYZprinting PRO

Industries

Additive technologies are already widely used in various industries, education and workshops.

AVIATION

The aerospace engine, air duct, low volume interior and cockpit industries demand stronger, lighter, and more durable components. Modern additive manufacturing technologies open up new possibilities for solving these problems.

AUTOMOTIVE

Additive manufacturing is a revolutionary and rapidly advancing technology that allows designers to create rapid or rapid prototypes as well as complex designs that would otherwise be impossible with legacy manufacturing processes. The new technology provides the automotive industry with innovative design, the freedom to innovate and professionalism in the supply chain. This technology is also being used to test, manufacture and assemble automotive parts and components with higher efficiency, optimization and cost effectiveness.

This technology is also being used to test, manufacture and assemble automotive parts and components with higher efficiency, optimization and cost effectiveness.

INSTRUMENT MAKING

Small-scale production of housings, connectors, tooling allows you to reduce time costs and production costs. rapid prototyping using additive technologies significantly reduces the time to bring products to market.

JEWELERY

Additive manufacturing is the perfect fit for jewelry making, with the ability to produce complex shapes and be COST-EFFICIENT in small to medium batch production.

DENTISTRY

Dental labs can now digitally design and process a large volume of customized products. This technology is easily integrated into the dental laboratory workflow without any disruption to the current flow or standard protocols. With no costly upfront costs or set up and minimal training time, this is turnkey technology.

MEDICAL

manufacture of custom implants and scaffolds for rehabilitation, models for preoperative surgical planning, anatomical models for mechanical testing and examination of human bones or new medical technologies, manufacture of drug delivery devices, and the development of new manufacturing methods specifically designed for medical applications.

ARCHITECTURE

and DESIGN

Additive technologies in design and architecture are the endless possibilities of geometry. Modern technologies make it possible to create unique shapes and structures, light and durable details, unique and functional interior items and models of future buildings.

EDUCATION

training of future personnel for additive manufacturing and technologies of the near future - this is the main task of education and we have something to offer.

COMPANY INFO

AMcore specializes in the distribution of equipment and the sale of industrial solutions for 3D printing, 3D scanning and consumables. In our product portfolio you will find manufacturers that are world leaders in their segments. On the territory of the Russian Federation and the countries of the customs union, we are the official exclusive supplier (distributor): XYZprinting, MakerBot, Dremel, Weber.

In the product catalog of 3D printers you will find products of recognized leaders in the production of devices for three-dimensional printing and consumables for them. DETAILS...

DETAILS...

Large-format 3D printers from Weber for printing with granulates enter the Russian market

News

large-format additive systems for 3D printing with granular polymer and composite materials.

Weber commercial director Manuel Kolb (left) and general director of AM-KOR LLC Vladislav Kurbatov (right)

Weber (Hans Weber Maschinenfabrik GmbH) has been operating for about a hundred years and is known, among other things, as a manufacturer of extrusion equipment for the production of polymer pipes, which suggests a high competence in the production of extruders, including for 3D printers.

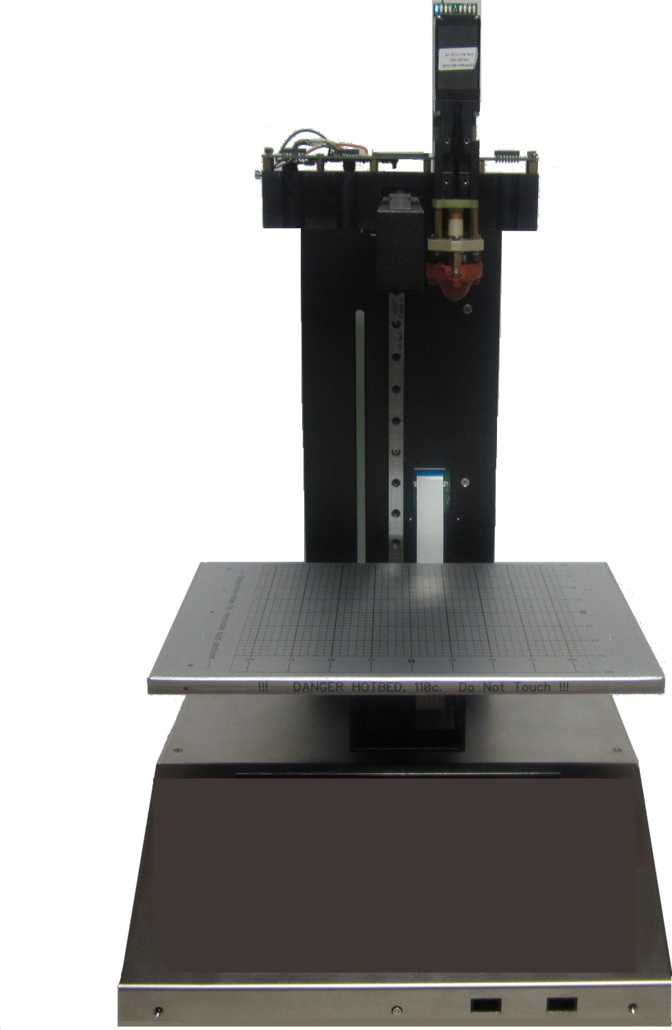

Weber DX 025 Portal Industrial 3D Printer

Weber's industrial additive solutions are based on the use of granular polymers, 3D portal printers and robotic systems with working volumes up to three cubic meters and print speeds up to 8 kg/h. The use of plastic granulates makes it possible to reduce the cost of manufactured products by up to ten times in comparison with polymer filaments, as well as to create specialized composite compositions.

Weber DXR 25 Robotic Additive System

Weber Granular Plastic 3D Printing Extruders

The AE extruder series for additive manufacturing is designed with dynamism in mind: the lightweight design is optimized for variable throughputs and is equipped with powerful servo motors and compact material feeders.

Weber single screw extruder diagram

These extruders are used in Weber additive solutions, delivering high productivity and cost efficiency through the use of granular plastic consumables.

Weber screw extruders: AE16 up to 2 kg/h, AE20 up to 4.5 kg/h, AE30 up to 8 kg/h

Detailed information about industrial additive solutions from Weber is available on the special website "AM-KOR" and on the website of the manufacturer.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru

ru

industrial granulate AM-KOR Weber

Follow author

Subscribe

Don't want

5

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want to

The project is experimental and symbolic: the structure was erected by 3D4Art to celebrate...

Read more

5

Subscribe to the author

Subscribe

Don't want

The World Nuclear Association (WNA) published a report on the application of advanced manufacturing technologies.