3D printing pvc

Is it possible to 3D print PVC?

Category Engineering

In the ever flourishing and well established world of advanced manufacturing working with materials such as PVC is a staple. But the question we answer here is: can you 3D print PVC? Well let us find out.

Polyvinyl chloride also known as PVC is a very durable material which serves multiple functions. It finds application in a vast number of industries such as health care, automotive, and the construction sector. As it can be manufactured without using oil, it has become a more viable option compared to most other thermoplastics.

Another reason for it’s popularity is its widespread use in so many products, ranging from electric cables and industrial piping to credit cards and toys. Is its resistance to chemical corrosion.

But can you 3D Print it?The answer to that is not a very simple one. There are various facets to it. While it is undoubtedly possible, there are visible limitations to using it as a filament.

PVC contains chlorine, which makes it problematic and potentially hazardous to work with. Working with a material containing chlorine means strict safety measures must be followed which include proper ventilation of the workplace. Trust me you don’t want to be inhaling that in and it definitely won’t give you any superpowers!

3D Printing Companies working with PVC right nowHere in this article, let us first make a few introductions. You need to acquaint yourself with a few companies that have explored the possibilities of making PVC available for printing with both filament and a machine. We’ll see they are faring with it, then we will conclude by exploring all the options available in the market right now.

So first up - The companies working to 3D print PVC!

1.ChemsonChemson, estb. 1986 has its headquarters in Arnoldstein, Austria. It is one of the premier manufacturers of polymer additives in the global plastic market. They create products ranging from auxiliaries to additives, used in all kinds of everyday consumer products.

They create products ranging from auxiliaries to additives, used in all kinds of everyday consumer products.

What Did They Create?

Chemson announced that it had developed a PVC filament for the manufacturing industry, in September 2016. They claimed that theoretically it could be used for standard 3D printing service in india. The filament was of high enough quality to be adequate for the 3D printing of prototypes and end components. It also showed its capabilities when printing support structures.

The company described it as its “3D Vinyl” formula. This PVC filament had all the beneficial properties of polyvinyl chloride and also burned 40% less fossil fuel compared to other filaments. A major breakthrough in terms of combating global warming.

The Filament

This 3D Vinyl developed by Chemson was dubbed as a wonder material to suit the polymer-based 3D printing market while also being a more sturdy and sustainable option. This PVC material possessed all the necessary thermoplastic qualities required for online 3D printing services and could have been a great option for those seeking high-quality prints. Some of its other remarkable qualities included it being impermeable to water, greater rigidity, UV, solvent and fire retardancy.

Some of its other remarkable qualities included it being impermeable to water, greater rigidity, UV, solvent and fire retardancy.

There was a great deal of hype surrounding this announcement about the filament. But, unfortunately,it has been years since the announcement and there has been no concrete news as to when this special filament would become widely available to the public. We, ourselves are still waiting to buy some and try it out.

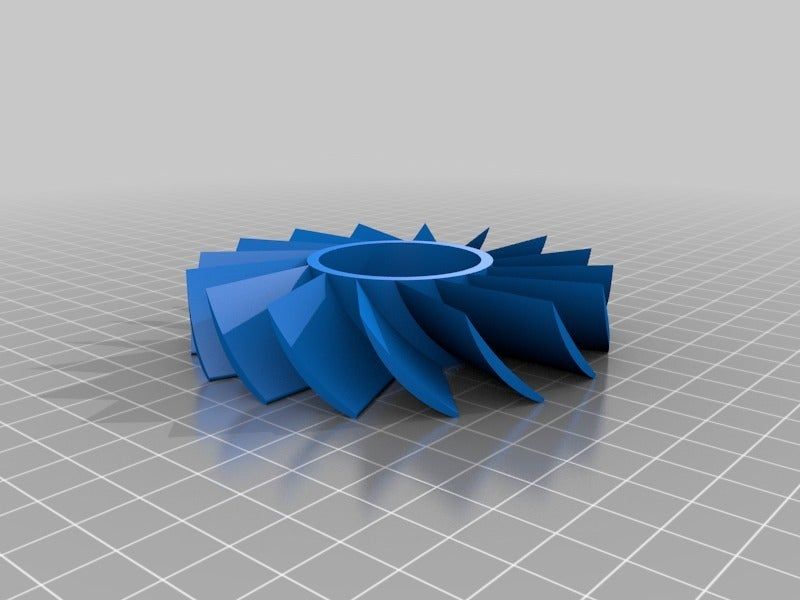

2.AoniqAoniq, an Australian based company entered the 3D printing technoverse in 2017. It promised to revolutionise the industry with its novel line of 888 printers. According to their claims these printers were capable of 3D printing PVC. These produced parts would be on par to those produced by injection molds. Aoniq also claimed that PVC could be used in the same way as conventional 3D polymers like ABS and PLA. it would also give the freedom to tinker around and create prototypes using a honeycomb infill.

What Did They Create?

The 888 was based on the earlier released 3DGence printer. Michael Slavica, Aoniq’s CEO at that time, stated that the 888 printers would work just like any other regular FFF 3D printers. They will be capable of printing several materials including ABS, TPU, and PLA. He also assured that Aoniq PVC prints would even be better than PLA and ABS prints in terms of intricacy and quality.

Michael Slavica, Aoniq’s CEO at that time, stated that the 888 printers would work just like any other regular FFF 3D printers. They will be capable of printing several materials including ABS, TPU, and PLA. He also assured that Aoniq PVC prints would even be better than PLA and ABS prints in terms of intricacy and quality.

The Filament

Aoniq also developed a PVC filament, to accompany the machine. After conducting tests they found out that the filament didn’t emit any corrosive hydrochloric fumes, unless it was exposed to 210 °C for longer than 11 minutes. So, it was evident that the corrosive effect on metal surfaces would be virtually insignificant during regular printing.

Using the filament seems practical, but there were some concerns about users not following the usage guidelines. Such as, allowing the PVC filament to sit idle at high temperatures for more than 11 minutes, is a serious safety hazard. Mr. Slavica also cleared any concerns regarding this by stating that this would only be an issue when using hobbyist-type 3D printers, and not the 888.

Aoniq made an announcement in 2017 stating that it planned to set the price of their PVC filament at around $1,490 and the 888 printer for around $10,499. But since then, as far as we can tell, the company seems to have gone under the radar just like Chemson. We’re still eagerly waiting to get our hands on the Aoniq filament and printer.

So, what's in the market right now?There is a certain Czech-based company called Fillamentum, estb. 2011. It specializes in manufacturing top of the line filaments. They are experienced players in the plastics industry and are interested in bringing new trends to the market.

Fillamentum launched a novel FFF filament they dubbed as Vinyl 303 made from PVC simulating the qualities of PVC. It possessed qualities such as fire retardancy, resistance to chemical corrosion, and optimum mechanical performance. They also claim, in our opinion rightly, that Vinyl 303 is one of the first filaments to repurpose polyvinyl chloride for 3D printing service.

As mentioned previously, working with this type of filament involves following a strict set of safety measurements.

- The room be properly ventilated and the printer should possess a closed chamber to eliminate any harmful gases including HCl acid.

- Steel parts are prone to erosion, so brass nozzles are prefered.

- The printer should also be fitted with an industrial grade HEPA filter,

- It should have an 80 °C bed temperature and print at the recommended speed of 40-60 mm/s, to prevent it from overheating quickly.

- Layers should be high enough to prevent any nozzle clogging which can increase harmful fumes.

According to the manufacturers this filament can be used with electronic equipment and any other application that involves long-term exposure to water, salts, and oil. However care should be taken to avoid any Vinyl 303 printed parts from coming into contact with consumable items, just like with all PVC. Unfortunately, this product may not be readily available for procurement easily.

Unfortunately, this product may not be readily available for procurement easily.

So printing PVC is possible, it hasn’t yet been developed properly to make it widely available. With the resources at disposal right now, it is believed that the time, filament, and electricity required for printing with it may not be worth it.

It is also believed that this product if made commercially available, ordinary hobbyist printers will simply not be able to follow the strict safety standards required for it. This poses serious health hazards and contaminates the environment too.

Right now it is evident that there is a long way to go in modifying 3D printing technology with PVC and prepare for its widespread commercialization.

Read More : Ways of 3D Printing usage in Biotechnology

Ultimate Beginner's Guide To PVC 3D Printing

ADVERTISEMENT

Table of Contents

Amongst the very many thermoplastics that can be 3D printed, one is PVC. Although been discovered decades ago, to date polyvinyl chloride remains a very popular industrial material with which we can 3D print and use it to make consumer and industrial parts and functional prototypes.

Although been discovered decades ago, to date polyvinyl chloride remains a very popular industrial material with which we can 3D print and use it to make consumer and industrial parts and functional prototypes.

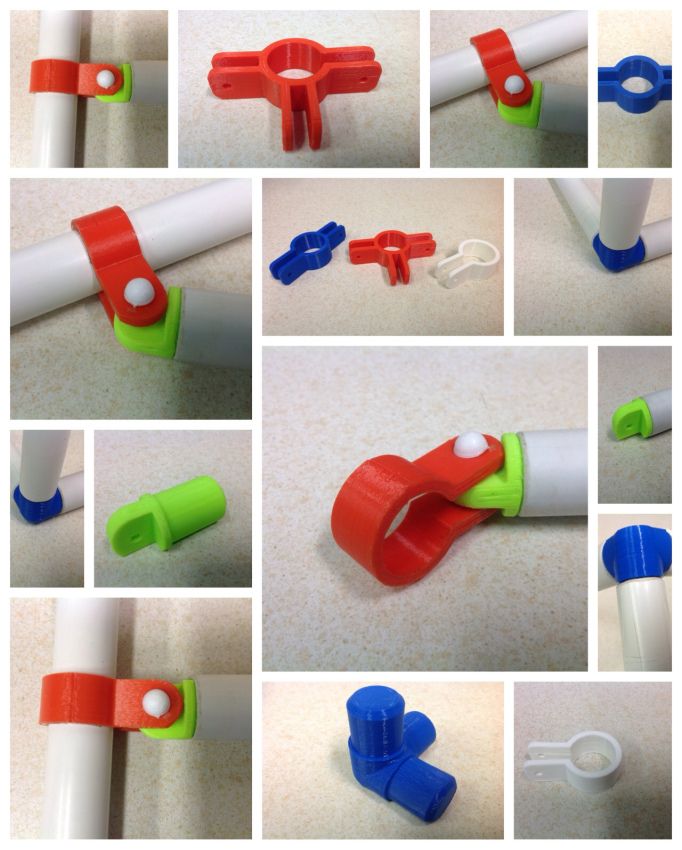

Remember those white pipes, they have been made from polyvinyl chloride. This might generate a question in the mind of all those who have a desktop printer in place at their homes i.e. Can you 3D print PVC using your 3D printer?

To answer this question, we would like to mention two innovations that have happened to date concerning PVC.

The first one is by a company that has successfully developed a 3D printer that manufactures parts and functional prototypes using PVC material.

This is by a company named AONIQ 888. The machine developed by this company was launched in the year 2017 and it offered not only printing with PVC but also, printing with other industrial materials.

The PVC material that is used by this printer can be used in the same way as we do PLA and ABS and other polymers for 3D printing parts and functional prototypes.

It gives you the ability to create rapid prototypes by giving it a honeycomb infill. The greatness of this technique should be realized as it does not generate any waste material.

While printing a solid object compared to injection molded parts, you realize the amazing nature of AONIQ PVC while it is subjected to breakage testing, all other filaments that are put to this test positive to date fracture at the layer except for AONIQ PVC. This is proof of how PVC is good material in terms of being functional.

ADVERTISEMENT

PVC Filament Produced by Chemson- Is It Safe?

Another option for printing polyvinyl chloride is by a company named Chemson. And theoretically, this filament can be used in desktop 3D printers that are filament-based or FDM 3D printers.

But there is another side to using PVC and this one concerns the safety issues regarding PVC.

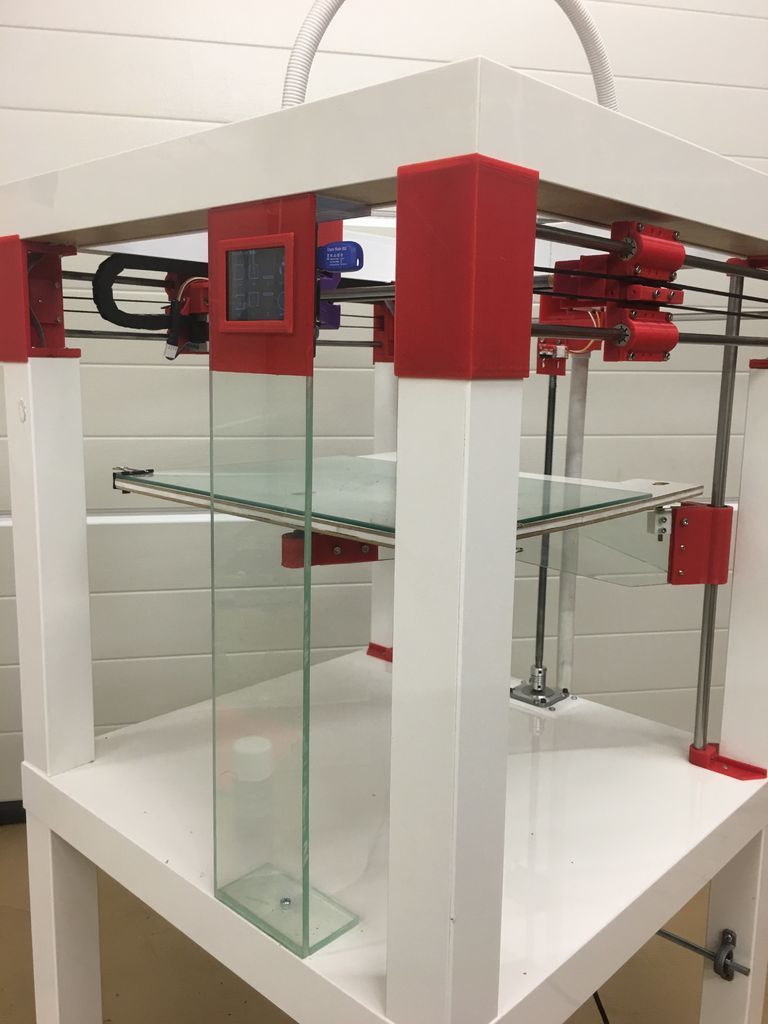

The first concern is regarding the components which are produced whenever PVC is burnt i. e. Dioxins. So, if you are producing a part or functional prototype based on PVC on a desktop printer, you are the one who is sure to be encountered with this by-product. AONIQ is said to have handled this issue with its unique air filtration system in its 888 machines.

e. Dioxins. So, if you are producing a part or functional prototype based on PVC on a desktop printer, you are the one who is sure to be encountered with this by-product. AONIQ is said to have handled this issue with its unique air filtration system in its 888 machines.

The machine comes in an enclosure that has been custom-designed, especially for PVC to provide a safe PVC print operating environment.

What this enclosure does is, eliminates any fumes using the inbuilt carbon filtration system.

And this does not go with other machines where you’re simply using the PVC filament, to 3D print PVC parts and functional prototypes, like for example from Chemson.

The fear here is that anyone with an unfiltered desktop 3D printer, who is using PVC filament to print parts or functional prototypes in an enclosed, unventilated area and introduces some contaminant into the air.

For this, it is strongly recommended to use PVC filament only on air-filtered 3D printers and even then, would insist on external air ventilation.

ADVERTISEMENT

What is 3D Vinyl?

The 3D printing industry is an instantaneous growth-making industry. Every half an hour, you get news of something new that has happened in the industry.

While all the corners of the world are getting associated with this industry, one corner of the world i.e. PVC, how can that remain unassociated?

The PVC-based filament that has no such safety concerns as mentioned before with Clemson or as many complications as many as in AONIQ, is called 3D Vinyl.

It is claimed to be the industry’s first development, testing, and proof of a PVC-based filament.

Suited for the polymer-based 3D printing market, 3D Vinyl is the new wonder material that has been branded as a pioneering invention.

3D printing polymers are now being commercialized and the reason for this commercialization is given to the long-felt need to produce a more durable and sustainable alternative to incumbent 3D printing polymers.

3D Vinyl is meant to be unique with a lot to offer in the industry and it also opens the way to 3D print PVC and burgeons the world of advanced manufacturing.

Characteristics of 3D Vinyl:

This new PVC material has the thermoplastic qualities that are required for 3D printing.

Not only it allows everyone, from hobbyists to pros, to dive into more advanced manufacturing, but also helps move past previous limitations that were imposed by the traditional materials which were used in prototyping and low-volume production.

Additionally, this material will also most likely garner a great deal of attention from all sectors of the 3D printing industry that are seeking a high quality and versatile new material.

3D Vinyl is UV resistant, it has weatherproof qualities that safeguard itself from the surroundings, and the material resists solvent and retards fire.

3D Vinyl has an improved rigidity to the previously made PVC filament, it has low embodied energy content and most importantly, it is sustainable.

3D Vinyl requires only 50 percent fewer fossil fuel inputs, as it uses abundant natural gas. This new material has been introduced by Chemson Pacific.

This new material has been introduced by Chemson Pacific.

ADVERTISEMENT

Apart from Chemson and AONIQ

Fillamentum, the company that was established in 2011, a Czech-based company that manufactures top-quality filaments.

With their few years of experience in the plastics industry, they and are currently focused on bringing new trends and materials to the market.

The company launched an FFF filament called Vinyl 303 which was made from PVC and it exhibited the qualities of PVC, such as fire retardancy, chemical corrosion, and high mechanical performance.

Claims are made by this company saying how Vinyl 303 is one of the first filaments used to 3D print PVC parts and functional prototypes.

Expanding on their claims, anything printed with this material has the same hardness as that of a construction helmet.

Can you 3D Print PVC Parts and Functional Prototypes?

One of the questions that might have aroused in your mind after reading about the companies field of PVC printing is,” whether it is possible to 3D print PVC or not?”

This question is not an easy one to answer and even experts are debating around it. Limitations are surrounding safe 3D printing with PVC filament, that is for sure, but it is certainly possible.

Limitations are surrounding safe 3D printing with PVC filament, that is for sure, but it is certainly possible.

One of the biggest challenges is the fact that PVC contains chlorine, carbon, and hydrogen, and all of these make it problematic and potentially dangerous to work with.

Especially the containment of chlorine in it means proper safety procedures which must be observed and include keeping work areas well-ventilated – because you don’t want yourself to be breathing that in!

And all of these was claimed to offer by AONIQ 888

ADVERTISEMENT

AONIQ888

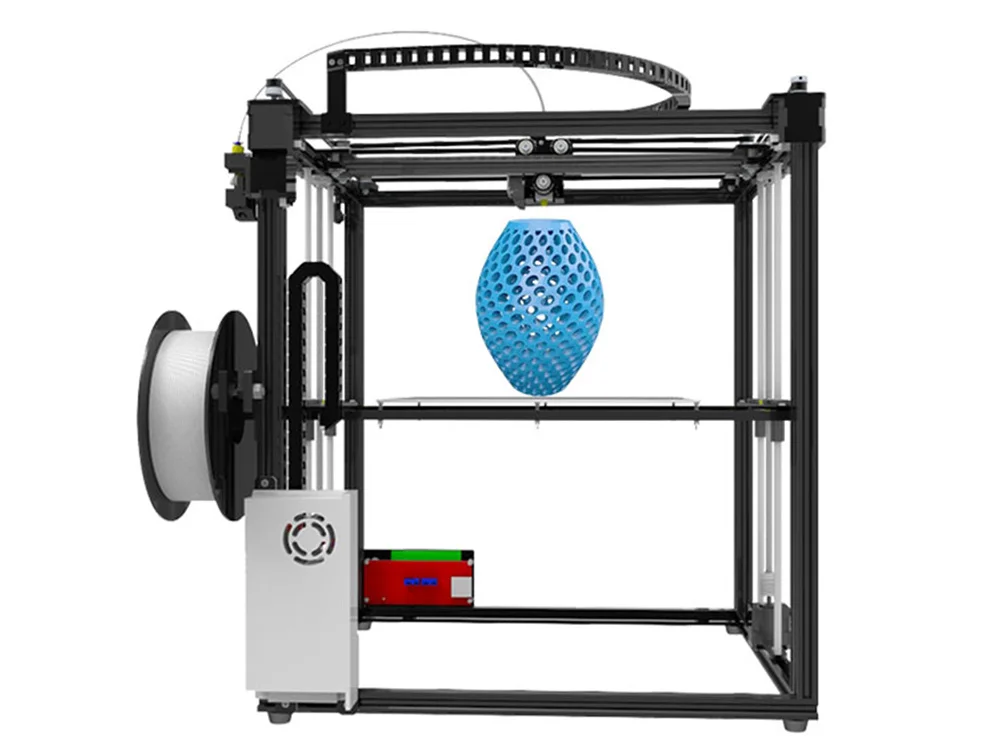

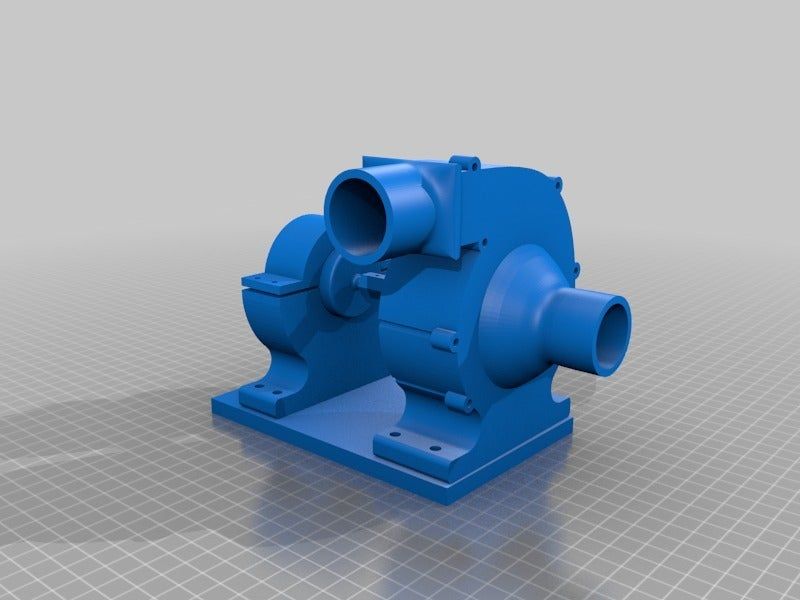

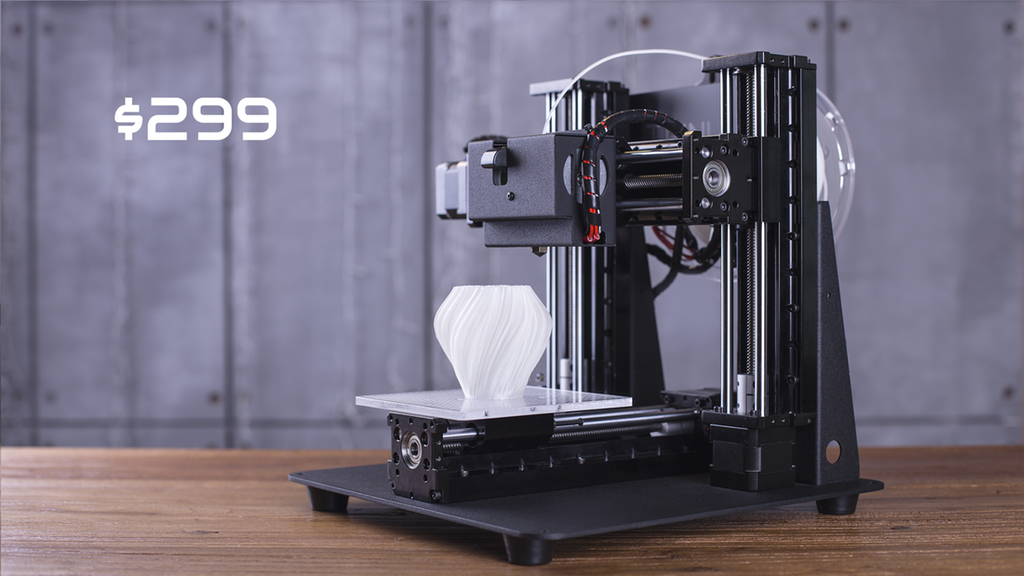

AONIQ 888 is an FDM 3D printer that claims to print with PVC as well as with standard 3D printing materials.

The manufacturer of this printer has also created its own PVC 3D printing formula for this machine that claims to print prototypes including a “honeycomb infill.”

CEO of this manufacturing company Michael Slavica says that with this 3D printer they are giving the average person the ability to not only take on the large corporations but also beat them.

In addition to it, he says how in the next stage of 3D printing, most people who are already using 3D printers for deciding whether they want to continue to tinker on the sidelines or to join the latest industrial revolution.

Apart from the claims to capture the market with its innovation, the company claims the PVC 3D printing to bring reliability to it.

Other aspects to it are the printer’s ability to run continuously for 8 hours a day, 5 days a week without compromising on the quality, even during long printing jobs.

AONIQ also claims about the machine’s ability to have the accuracy of printing parts that have the width of a human hair and includes a printing surface with the most superior surface quality ever available in the market.

Specifications of printer

AONIQ 888 has a build volume of 235 x 255 x 195 mm, a layer height of between 100 and 400 microns, and an X-Y resolution of 100 microns.

The specialty of 3D printing with this machine is that it can print with four print heads that have a size of 2 x 0. 4 mm, 1 x 0.3 mm, and 1 x 0.5 mm. The printer also includes a direct drive extruder.

4 mm, 1 x 0.3 mm, and 1 x 0.5 mm. The printer also includes a direct drive extruder.

And as for the software, the printer claims to run on Simplify3D and Cura.

ADVERTISEMENT

Safety and Printing Considerations Using PVC

Credit: infinityplaysAs we have been mentioning time after time in this article, to 3D print PVC is to give an invitation to a lot of precautions.

To start with, it is strongly recommended that the room be well ventilated and the printer should have a closed chamber.

This would eliminate any harmful fumes including hydrochloric acid. It is for this reason that a brass nozzle instead of the steel one can erode after using it for some time.

Whichever printer you are using, should have a HEPA filter, and then the printer is recommended to at least have 80 °C bed temperature.

The print speed of the printer as recommended by experts should be 40-60 mm/s. The layers of parts or functional prototypes should be high enough that they prevent nozzle clogging.

In the filaments that we talked about in the article, manufacturers of those filaments claim them to be used with electronic equipment prototyping and any other application that involves long-term exposure to water, salts, and oil.

However, talking specifically about Vinyl 303 printed parts, it should not come into contact with food, or other consumable items, just like with all PVC.

And if you are looking for this product urgently, we are sorry to say that this product may not be readily available everywhere.

ADVERTISEMENT

Websites that Offer 3D Printing Services

Yes. Even if you do not have a 3D printer, you can 3D print parts and functional prototypes by uploading your files to websites that offer this kind of service.

So, you can check them out to see if they offer 3D print PVC parts and functional prototypes. A little brief about such websites is given below.

- Craftcloud: The complete process of Craftcloud is based on four steps.

To start with, you need your 3D file which you will have to upload on this website. Then the website will ask you to select a material, and then select an offer, if available on the website, and then within a specifically determined time, you can receive your parts.

To start with, you need your 3D file which you will have to upload on this website. Then the website will ask you to select a material, and then select an offer, if available on the website, and then within a specifically determined time, you can receive your parts. - i.Materialise: Like Craftcloud i.Materialise too, requires you to have a 3D model of the part or functional prototype that you wish to 3D print. As soon as you upload that on the website, it will give you pricing and the options to print with 20 different ranges of materials and 100 colors that are possible to 3D print with. The part that remains hence is production and shipping.

- Sculpteo: A service provider of 3D printing, rapid prototyping, production with additive manufacturing, providing you with pricing, and hence results. Sculpteo also has its own AM studio which you can use, you can consult the company for your design, and a lot more. Apart from 3D printing, you can also laser cut, etc.

The Conclusion

As can be seen from the article to 3D print PVC is possible, but to date, the area has not been touched upon as much as other areas have been.

Now, this can be for various reasons, the most obvious ones amongst them are because of the pricing of the filament, electricity that goes to drive a 3D printer, etc.

Another obvious reason could be safety concerns surrounding the area and because of that its non-compatibility issue with hobbyist printers.

So, more work needs to be done in this area to make PVC as normal as ABS or PLA.

Chemson Pacific prepares 3DVinyl, the first PVC-based 3D printing filament

News

While most of the materials used in 3D printing come from a range of industrial polymers that already exist, one popular thermoplastic has yet to find acceptance in additive manufacturing. His name is polyvinyl chloride (PVC or PVC), and in everyday life he is familiar from plastic pipes, leather substitutes, protective films on washable wallpaper and stretch ceilings, and from gramophone records.

Polyvinyl chloride has a lot of attractive properties: it is durable, cheap, resistant to the external environment and even fire. As a result, PVC ranks third among thermoplastics in terms of industrial use. Why hasn't PVC found its place in 3D printing?

Polyvinyl chloride has a lot of attractive properties: it is durable, cheap, resistant to the external environment and even fire. As a result, PVC ranks third among thermoplastics in terms of industrial use. Why hasn't PVC found its place in 3D printing? It's all about toxicity. While this plastic is harmless when stable, when burned, it releases a bunch of toxic and carcinogenic organochlorine compounds, including phosgene (an asphyxiant gas used as a chemical weapon in World War I) and dioxins (which disrupt all kinds of metabolic processes), which complicates recycling. In addition, lead (as a stabilizer) and phthalates (as plasticizers) are often added to industrial PVC. The latter accumulate in the finished product and for some time are released in gaseous form. However, toxic materials in the composition of thermoplastics are not new to printers, because the “C” in “ABS” means styrene, a poison that affects the nervous system. The same applies to polystyrene (HIPS). Polycarbonate, on the other hand, can become a source of carcinogenic bisphenol A: this substance is used as a hardener, and in finished products it can be present in relatively small residual volumes, released when heated. That is why it is not recommended to use polycarbonate for the manufacture of containers for hot food or drinks.

Polycarbonate, on the other hand, can become a source of carcinogenic bisphenol A: this substance is used as a hardener, and in finished products it can be present in relatively small residual volumes, released when heated. That is why it is not recommended to use polycarbonate for the manufacture of containers for hot food or drinks.

Although the concentrations of harmful substances in the air during 3D printing are in most cases quite small, many of them have a cumulative effect, accumulating in the body, and therefore good ventilation should not be neglected. As a last resort, one should not forget about such relatively safe options as polylactide or polycaprolactone, although their physical and mechanical characteristics in many respects leave much to be desired.

Now Australian company Chemson Pacific claims they have created a safer version of PVC for 3D printing, dubbed "3DVinyl". The development of the material was carried out over two years with the participation of experts from DuPont, PMMCO and AIO Robotics. According to the creators, the finished product has taken over the resistance to chemical attack and the high ignition temperature of industrial analogues. UV resistance is also indicated as an advantage, which is a bit strange, since photodegradation has always been considered one of the main disadvantages of PVC. However, in the industry they cope with this problem due to light-absorbing dyes: apparently, this moment was also taken into account by the developers from Chemson Pacific. In addition, the company claims a relatively environmentally friendly manufacturing process using natural gas instead of crude oil, and the finished material is strong, has good fluidity during extrusion and low shrinkage.

According to the creators, the finished product has taken over the resistance to chemical attack and the high ignition temperature of industrial analogues. UV resistance is also indicated as an advantage, which is a bit strange, since photodegradation has always been considered one of the main disadvantages of PVC. However, in the industry they cope with this problem due to light-absorbing dyes: apparently, this moment was also taken into account by the developers from Chemson Pacific. In addition, the company claims a relatively environmentally friendly manufacturing process using natural gas instead of crude oil, and the finished material is strong, has good fluidity during extrusion and low shrinkage.

Polyvinyl chloride commercialization as a filament will begin in Australia, where the company is entering into alliances with local manufacturers Welvic and CSIRO for the Australian, New Zealand and Asian markets. The new material is set to premiere on May 19 at the Australian Vinyl Industry Conference. In Europe and the US, the company will be represented by the American filament manufacturer Functionalize, known for its conductive composites. Prototypes have already been tested on AIO Robotics' Zeus 3D printers.

In Europe and the US, the company will be represented by the American filament manufacturer Functionalize, known for its conductive composites. Prototypes have already been tested on AIO Robotics' Zeus 3D printers.

Regarding the performance of the new filament, Functionalize CEO Michael Tutongi was quick to say, “3DVinyl does not contain lead or phthalates. It is a plastic similar to that used in blood transfusion bags. At the same time, Chemson added plasticizers and stabilizers to turn PVC into a 3D-printable thermoplastic, while eliminating the formation of organochlorines. The result is a material that does not emit unpleasant odors and does not require high extrusion temperature or platform heating, like ABS. The material looks and prints great, and the stabilization of the chemical composition is based on new methods developed at Clemson. We are currently working on creating a finished commercial product.” We only note that over the past ten years, several large American medical institutions have decided to abandon the use of PVC containers.

Delivery dates and retail prices for 3DVinyl PVC filament have not yet been announced.

Follow author

Follow

Don't want

3

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

Scientists from the Ural Federal University and the Ural Branch of the Russian Academy of Sciences determine...

Read more

5

Subscribe to the author

Subscribe

Don't want

Cosmonaut Oleg Artemiev, who recently returned from the International Space Station, spoke about the experimental...

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci. ..

..

Read more

What you need to know about 3D printing

China's dominance of the world's manufacturing industries dates back to the late 1980s when Western companies found that any import or shipping costs were offset by startlingly lower labor costs and government regulations, but it wasn't until the turn of the century that they really came into their own. . For decades, China has dominated industries as diverse as textiles, personal electronics, toys, iron and metal manufacturing, and even aircraft and automobiles. They finally displaced the United States from the lead in manufacturing a few years ago and have continued to be at the top ever since.

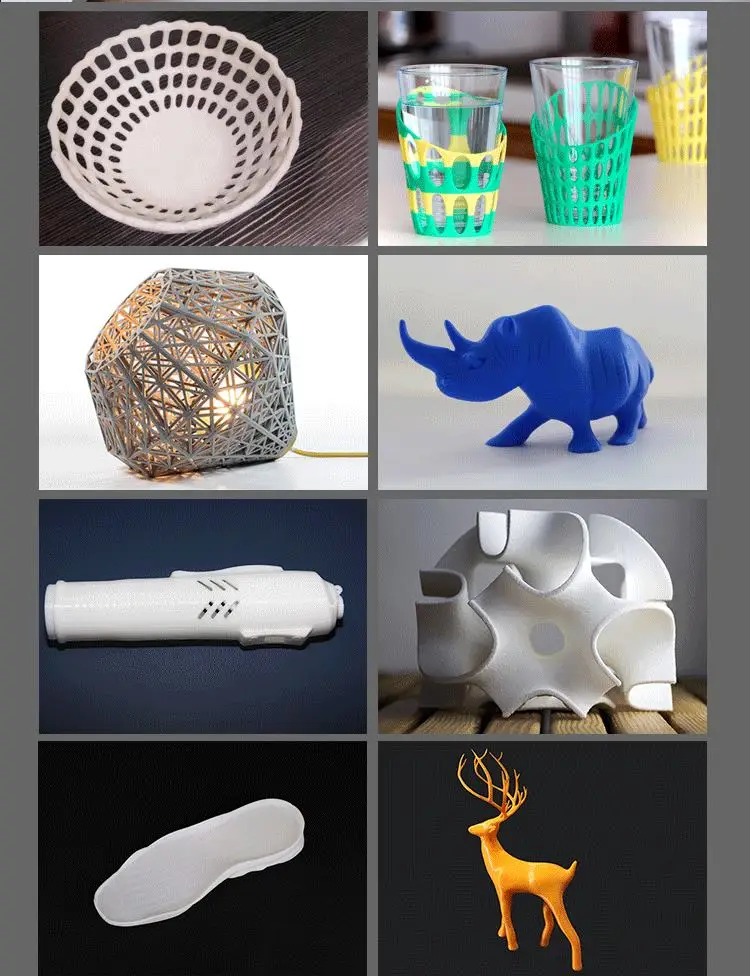

While Asia as a whole has been slow to embrace 3D printing technology, it didn't take long for China to catch up as it is the world's top seller of 3D printers this year. Since 2011, the Chinese 3D printing market has doubled every year and is expected to reach $1.5 billion in 2016. Their growth rate is outpacing the rest of the world and is likely to surpass the United States as the world's largest 3D printing market by 2018 if this growth continues. A 3D printer can produce one part at a time with an accuracy of 0.1mm or less. Desktop printers are already available on the market and allow you to produce small products in almost any shape. The Chinese 3D market is developing at a breakneck pace, which means that the production of PVC toys is also being created faster, more beautiful, better quality, and the price is able to satisfy any client.

A 3D printer can produce one part at a time with an accuracy of 0.1mm or less. Desktop printers are already available on the market and allow you to produce small products in almost any shape. The Chinese 3D market is developing at a breakneck pace, which means that the production of PVC toys is also being created faster, more beautiful, better quality, and the price is able to satisfy any client.

In this article, we want to highlight for you in detail what 3D toy printing is, what are its main advantages and types, and how to use them.

The 3D Printer is a manufacturing tool used to create 3D objects (artifacts) and in our case computer generated toys. 3D printers come in a wide range of shapes, sizes, and types, but at their core, they are all computer-controlled additive manufacturing machines. Just as paper printers apply ink in a single layer to create an image, 3D printers apply material layer by layer to create a 3D object.

Key benefits

3D printers can produce custom parts relatively quickly and cheaply, making 3D printers one of the best tools for rapid prototyping.

3D printing allows designers of toy manufacturers to immediately move from idea to reality, with the help of 3D printing they can quickly change designs and can easily create complex geometric shapes of a toy. In short, at the push of a button, manufacturers can create whatever the customer likes.

With a 3D printer, a part can be designed and manufactured at low cost, and then the design can be modified, printed, and tested multiple times in rapid succession before the part goes into mass production.

Just by pressing a button, whatever you create will be created. Other production methods such as drilling machine, lathe or milling machine should take longer, and the shapes may be slightly different from your desires. Because of the way the parts are created, 3D printers can produce many complex geometries, including natural shapes such as prosthetic limbs or animal models, or more complex shapes such as polyhedra or replicas of scale buildings. 3D printers open up a lot of opportunities for manufacturers simply because they allow people to create things they couldn't before.

A 3D design can be easily modified on a computer and then reprinted. This means that files can be customized for specific people or things and easily printed without changing device settings. The ability to create personalized content is appreciated by both small businesses and large manufacturers as it allows them to create designs. The design can be printed and modified according to the needs of the recipient.

How to work with a 3D printer?

To more specifically understand how 3D printers work and how to design them, you need to understand the different types of 3D printers on the market. Although materials and methods for creating parts vary greatly, all 3D printers create parts by adding material layer by layer, fusing each layer together to create a solid object.

There are several different types of 3D printing processes: some are more suitable for large scale production, others allow multiple materials or colors to be used during printing, and some types of printers can even be built fairly easily due to the way they work.

1 Type: Fused Deposition Modeling ( FDM ). Probably one of the most common types of 3D printing and the easiest to understand. In this type of 3D printing, a material, usually ABS or PLA plastic, is melted by the printer head and extruded onto the base of the printer, similar to how ink is applied to a page on a paper printer. The printer's extruder head lays down material layer by layer to build a 3D model, and each layer fuses with the previous one as it cools.

FDM printers are very common desktop printers because they are inexpensive and easy to build. Their accuracy depends on the quality of the motors that control the position of the extruder head relative to the assembly platform, as well as the thinness of the extruder head when extruding the material. As the material is built up layer by layer, the printed parts tend to be weak along their horizontal cross sections. In addition, any protrusions of 3D printed parts on FDM printers require a support material to hold the protrusion. Multi-head FDM printers can print on soluble media that dissolves when immersed in certain chemicals, while single-extruder printers print on less dense material that can break off after printing is complete. Multiple extruder heads also allow FDM printers to print in different colors or materials, expanding their capabilities.

Multi-head FDM printers can print on soluble media that dissolves when immersed in certain chemicals, while single-extruder printers print on less dense material that can break off after printing is complete. Multiple extruder heads also allow FDM printers to print in different colors or materials, expanding their capabilities.

Type 2: Stereolithography( SLA ) is the oldest 3D printing method that uses a laser to cure a liquid resin with UV light. While FDM printers draw out layers of filament to form a 3D model, an SLA printer's laser beam draws out a section of the part to solidify liquid resin layer by layer, creating a 3D part. While most other 3D printers print from the bottom of the part and work their way up, SLA printers can print from top to bottom. The laser and resin bath is at the base of the printer, and the part is attached to the lower build platform and rises up as it prints.

SLA printers can be very fast and accurate due to their nature. However, the resin itself is expensive, and because it is photocurable, it must be stored in special containers. Most resins are usually very brittle after curing and won't withstand much force, so SLA printing is usually useful when it comes to prototyping but not manufacturing. Like FDM printers, SLA printers require support structures for printed parts, but their materials are limited because they can only print on cured resin and cannot print on multiple media types at once. However, the accuracy of SLA printers allows them to print very complex and fine structures.

However, the resin itself is expensive, and because it is photocurable, it must be stored in special containers. Most resins are usually very brittle after curing and won't withstand much force, so SLA printing is usually useful when it comes to prototyping but not manufacturing. Like FDM printers, SLA printers require support structures for printed parts, but their materials are limited because they can only print on cured resin and cannot print on multiple media types at once. However, the accuracy of SLA printers allows them to print very complex and fine structures.

Type 3: Selective ( SLS ) Laser Sintering is very similar to stereolithography in that a laser is used to solidify the material and form a solid shape. The biggest difference between the two technologies is that SLA printing uses liquid resin, while laser sintering cures the powder material. Layers of powder are laid down on a print bed and the particles of each layer are laser cured.