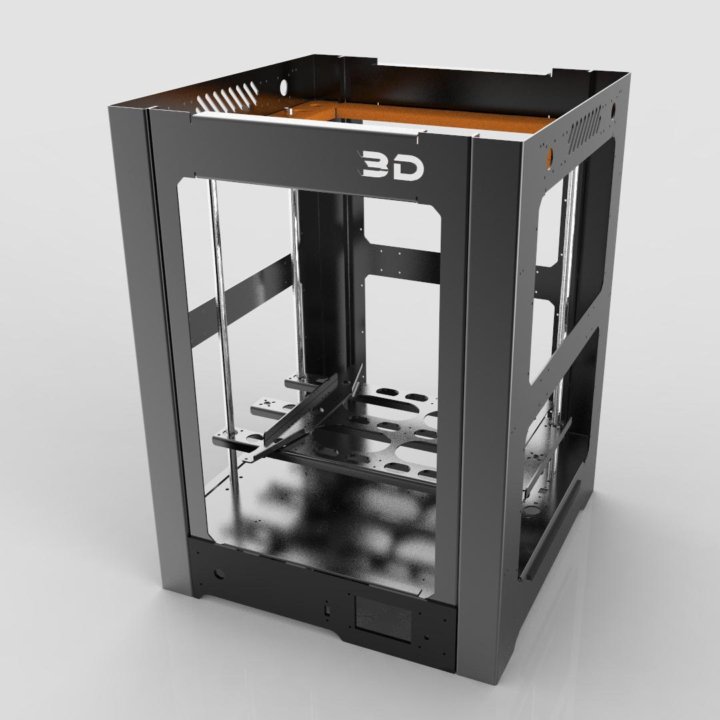

M100 3d printer

Mid-Size Metal 3D Printer for all kind of materials

Get detail information with our whitepapers, which investigate the performance of a standardized test job layout built on three different EOS M 290 systems using EOS Titanium Ti64ELI or a study into the influence of oxygen in the print process chamber and its effect on the critical properties of aluminium alloy AlSi10Mg.

11_modularityThe most extensive materials portfolio on the market

12_laserPowerful 400-watt fiber laser for excellent detail resolution

18_positiveA robust and well-established system with a vast range of applications

The exceptionally high beam quality of the laser spot and the excellent detail resolution are ideal for producing highly complex components with homogeneous properties.

With the most extensive range of validated materials and processes available on the market, all customer needs are covered.

The comprehensive monitoring suite enables quality assurance of all production- and quality-relevant data in real time.

| Construction Volume | 250 x 250 x 325 mm (9.85 x 9.85 x 12.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 400 W | |

| Precision Optics | F-theta lens; high-speed scanner | |

| Scan Speed | up to 7.0 m/s (23 ft./sec) | |

| Focus Diameter | 100 μm (0. 004 in) 004 in) | |

| Power Supply | 32 A / 400 V | |

| Power Consumption | max. 8,5 kW/ average 2,4 kW/with platform heating up to 3,2 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h) | |

| Machine Dimensions (W x D x H) | 2,500 x 1,300 x 2,190 mm (98.4 x 51.2 x 86.2 in) | |

| Recommended Installation Space | min. 4,800 x 3,600 x 2,900 mm (189 x 142 x 114 in) | |

| Weight | approx. 1,250 kg (2,756 lb) 1,250 kg (2,756 lb) | |

| Software | EOSPRINT incl. EOS ParameterEditor, EOSTATE Everywhere, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules |

This whitepaper investigates the performance of a standardized test job layout built on three different EOS M 290 systems using EOS Titanium Ti64ELI. In a nutshell, the results verify that the EOS M 290

- Shows a high capability of more than 4 Sigma for the tensile properties across the three machines located in different facilities

- Proves that the DMLS process remains repeatedly capable and above the ASTM requirements for Ti64 ELI

- Verifies that EOS systems are ready for decentralized serial additive manufacturing

Want to learn more? Get the free Whitepaper and more here.

Download Whitepaper

32_securityform. website_f1.label

website_f1.label

form.website_f2.label

Get your personal link now:

First name

Last name

Zip Code

Company

I have taken note of the Privacy Policy and would like to be contacted by EOS GmbH and its local subsidiaries under the contact data provided above.

Yes, I would like to receive the EOS newsletter and stay up to date with industrial 3D printing innovation. I would like EOS GmbH and its local subsidiaries to send me its newsletter as well as individual communications to the e-mail address provided above.

EOS and Linde combined forces to conduct an important study into the influence of oxygen in the print process chamber and its effect on the critical properties of aluminium alloy AlSi10Mg. This whitepaper describes the study and its findings:

- The EOS M 290 with the EOS Aluminium AlSi10Mg powder and process parameters enable a high-quality, reproducible final part

- An oxygen content below 1000 ppm needs to be maintained during processing to prevent increasing the number and size of pores and ensure high part density and required mechanical properties

- Powder aging is reduced by keeping the O2 level below 1000 ppm which enables more frequent reuse of the powder

- The position of the oxygen sensor influences the measurement, with a sensor placed near to the powder bed giving optimal measurement

Want to learn more? Get the free Whitepaper and more here.

Download Whitepaper

32_securityform. website_f1.label

website_f1.label

form.website_f2.label

Get your personal link now:

First name

Last name

Zip Code

Company

I have taken note of the Privacy Policy and would like to be contacted by EOS GmbH and its local subsidiaries under the contact data provided above.

Yes, I would like to receive the EOS newsletter and stay up to date with industrial 3D printing innovation. I would like EOS GmbH and its local subsidiaries to send me its newsletter as well as individual communications to the e-mail address provided above.

Cross-section of a Conflux Core™ heat exchanger printed in 3D on the EOS M 290

Additively manufactured component for the limited series DS 3 Dark Side: the trim strip with extremely fine titanium grids

Unique and cost-effective: The filigree grid structure of the Hoet spectacle frame is made of titanium from an EOS M 290

Door handle frame with titanium grid: Production of 200 components in one construction job without loss of quality with EOS M 290

Euro-K: Additive manufactured micro burner for the combustion of gaseous and liquid fuels, built on an EOS M 290

Additively manufactured Liebherr valve block, built on the EOS M 290: Same performance, 35 percent lighter

01

02

03

04

05

06

53_individual_production Metal Materials for the EOS M 290

EOS StainlessSteel

Stainless steel alloys are used in many industries, including aerospace, medicine, energy, jewelry, shipbuilding, and the food sector. The chemical and mechanical properties of our alloys meet various international material standards.

The chemical and mechanical properties of our alloys meet various international material standards.

EOS Aluminum

Aluminum alloys are ideal for many applications in the aerospace and automotive industries. The chemical and mechanical properties of our alloys meet various international material standards.

EOS CobaltChrome

Cobalt-chrome is often used in aerospace and medical applications. Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

EOS NickelAlloy

Nickel alloys can be used in a variety of applications: aircraft, gas turbines, and shipbuilding. The chemical and mechanical properties meet various international material standards.

EOS NickelAlloy HAYNES® 282®

This material is a precipitation strengthened nickel-base superalloy with a unique combination of high temperature strength, thermal stability, and fabricability. The alloy was developed for high temperature structural applications.

The alloy was developed for high temperature structural applications.

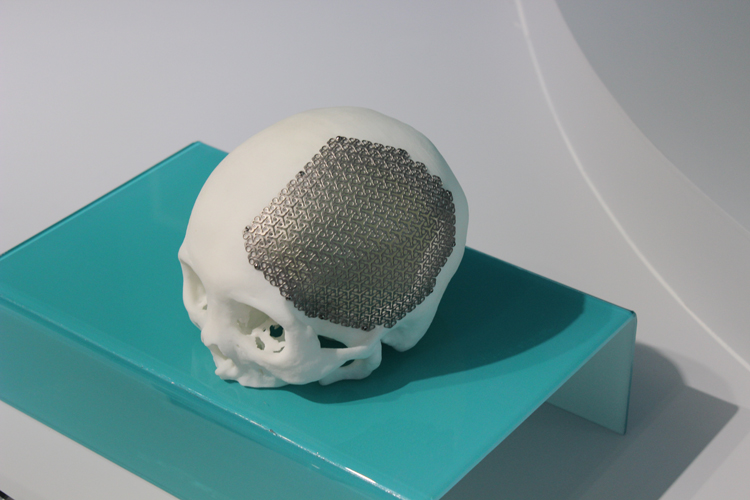

EOS Titanium

Various high-performance applications in the aerospace, automotive, and medical industries use titanium for its properties. The chemical and mechanical properties of our alloys meet various international material standards.

EOS Copper Cu

High purity copper for the EOS M 290 to reach good electrical and thermal conductivity for a wide variety of applications.

EOS CaseHardeningSteel 20MnCr5

Case hardening steel with good hardenability reaching good wear resistance due to high surface hardness after heat treatment.

11_modularity Material Management Metal Materials

IPCM-M extra

The IPCM-M extra is the manual solution that is flexible in use with multiple machines, easy to scale-up with increasing demand and can be used with all EOS metal systems. It includes the following products:

It includes the following products:

IPCM-M pro

The IPCM-M pro is a semi-automatic solution that secures easy, fast and safe handling in a closed system. It reduces the steps in the powder handling workflow while keeping the flexibility to use it with multiple machines. It includes the following products.

13_automation Software

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSTATE comprises 4 modules that can be used individually or in combination.

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

-- loading ... --

Be inpired. Stay up to date.

Join our Monthly Newsletter Now!

Large and ultra-fast 3D Printer with 4 laser

05_incr_productivityUp to 4x more productivity

12_laserFour precise 400-watt fiber lasers

52_construction_spaceBuild volume of

400 x 400 x 400 mm

With a build volume of 400 x 400 x 400 mm and four lasers, the EOS M 400-4 platform achieves up to four-times higher productivity, making it perfect for industrial applications. Four precise 400-watt fiber lasers work over an area of 250 x 250 mm each, with 50 mm overlap.

Four precise 400-watt fiber lasers work over an area of 250 x 250 mm each, with 50 mm overlap.

With its intuitive user interface, flexible software tools and diverse accessories, the system meets every usage requirement of an industrial production environment. Highly automated procedures and processes guarantee ease of operation.

A broad portfolio of materials is available, from light metals to stainless steel, tool steels and super alloys. Any process from the EOS M 290 can be transferred to the EOS M 400-4 to achieve equivalent part properties.

| Construction Volume | 400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 4 x 400 W | |

| Precision Optics | 4 F-theta-lenses; 4 high-speed scanners | |

| Scan Speed | up to 7. 0 m/s (23 ft/s) 0 m/s (23 ft/s) | |

| Focus Diameter | approx. 100 µm (0.004 in) | |

| Power Supply | 3 x 50 A | |

| Power Consumption | max. 45 kW / typical 22 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h)" | |

| Machine Dimensions (W x D x H) | 4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in) | |

| Recommended Installation Space | min. 6.500 x 6.000 x 3.300 mm (256 x 236 x 130 in) | |

| Weight | approx. 4,835 kg (10,659 lb) 4,835 kg (10,659 lb) | |

| Software | EOSPRINT 2, EOSTATE PowderBed, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules |

Source: Václav Jirásek

3D lattice palms ready for microwelding

Challenge:

Bring a goldsmith’s creation to life by printing an intricate and luxurious life-size 3D lattice face mask and palms, to which jewels could be micro welded.

Source: One3D

One3D facility in Mohelnice with EOS M 400-4

Solution:

- One3D AM Engineers

- EOS M 400-4

- EOS StainlessSteel 316L

Source: Václav Jirásek

Post-processed 3D lattice palms

Results:

- Design, print and post-processing of complex parts in just 5 days

- Complete design freedom for artist and One3D engineers

- Rapid printing of 207 cm3 build volume enabled highly detailed and considered 3D lattice palms ready for post-processing

53_individual_production Metal Materials for the EOS M 400-4

EOS Aluminum AlSi10Mg

Parts printed using EOS Aluminum AlSi10Mg offer strength, hardness and dynamic properties as well as excellent thermal properties and low weight.

EOS NickelAlloy IN718

Parts show excellent tensile, fatigue, creep and rupture strength at temperatures up to 700°C, making it ideal for many high temperature applications.

EOS NickelAlloy HX

Parts show high strength and oxidation resistance also at elevated temperatures up to 1200°C making it ideal for applications in aerospace, gas turbines, etc.

EOS NickelAlloy HAYNES® 282®

This material is a precipitation strengthened nickel-base superalloy with a unique combination of high temperature strength, thermal stability, and fabricability. The alloy was developed for high temperature structural applications.

EOS Maraging Steel MS1

Parts have excellent mechanical properties and are heat-treatable using a simple thermal age-hardening process to obtain superior hardness and strength.

EOS StainlessSteel 316L

Parts show a high level of corrosion resistance, toughness and ductility as well as a high resistance to acids.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

EOS Titanium TiCP grade 2

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

11_modularity Material Management Metal Materials

IPM M Powder Station L

The IPM M Powder Station L is the fully-automatic and intelligent material management solution that offers a closed powder cycle in a protective gas atmosphere in just one module.

13_automation Software

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

-- loading ... --

Be inpired. Stay up to date.

Join our Monthly Newsletter Now!

Malyan M100/M150/M200 3D Printer Compatible Pressure Spring

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00 nine0007

Basket 0

Want free shipping? click here Learn more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}} nine0007

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Main Board of 3D Printer M100

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00 nine0007

Basket 0

Want free shipping? click here Learn more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}} nine0007

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9isProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price.