3D printers material

Guide to 3D Printing Materials: Types, Applications, and Properties

3D printing empowers you to prototype and manufacture parts for a wide range of applications quickly and cost-effectively. But choosing the right 3D printing process is just one side of the coin. Ultimately, it'll be largely up to the materials to enable you to create parts with the desired mechanical properties, functional characteristics, or looks.

This comprehensive guide to 3D printing materials showcases the most popular plastic and metal 3D printing materials available, compares their properties, applications, and describes a framework that you can use to choose the right one for your project.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

There are dozens of plastic materials available for 3D printing, each with its unique qualities that make it best suited to specific use cases. To simplify the process of finding the material best suited for a given part or product, let’s first look at the main types of plastics and the different 3D printing processes.

There are the two main types of plastics:

-

Thermoplastics are the most commonly used type of plastic. The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles. Thermoplastics can be heated and formed into the desired shape. The process is reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible. A common analogy for thermoplastics is butter, which can be melted, re-solidify, and melted again. With each melting cycle, the properties change slightly.

-

Thermosetting plastics (also referred to as thermosets) remain in a permanent solid state after curing. Polymers in thermosetting materials cross-link during a curing process that is induced by heat, light, or suitable radiation. Thermosetting plastics decompose when heated rather than melting, and will not reform upon cooling. Recycling thermosets or returning the material back into its base ingredients is not possible. A thermosetting material is like cake batter, once baked into a cake, it cannot be melted back into batter again.

The three most established plastic 3D printing processes today are the following:

-

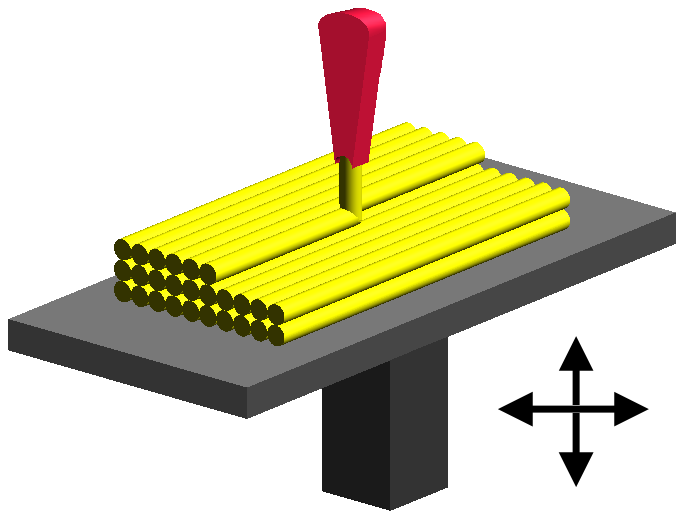

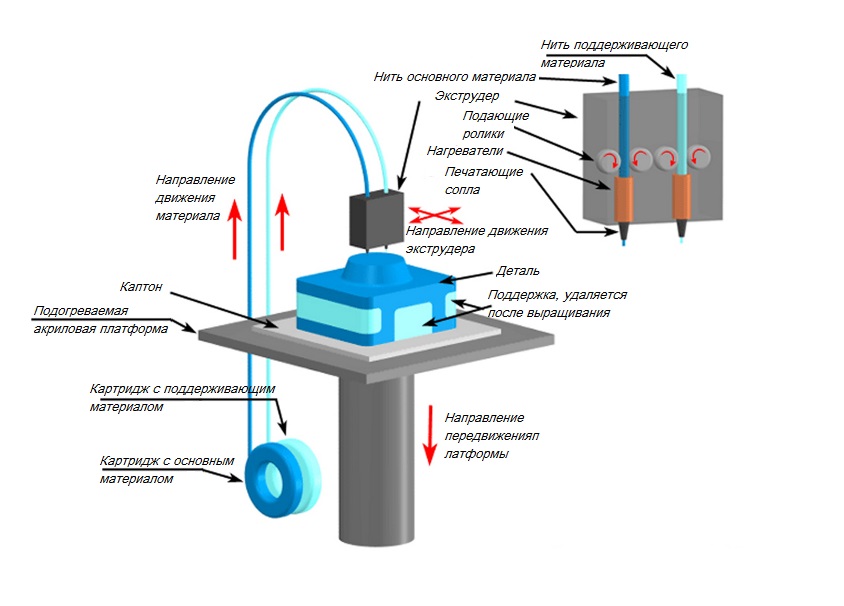

Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filaments, which a printer nozzle deposits layer by layer in the build area.

-

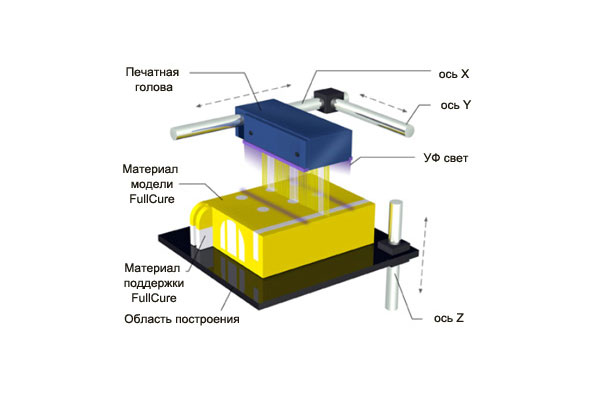

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization.

-

Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

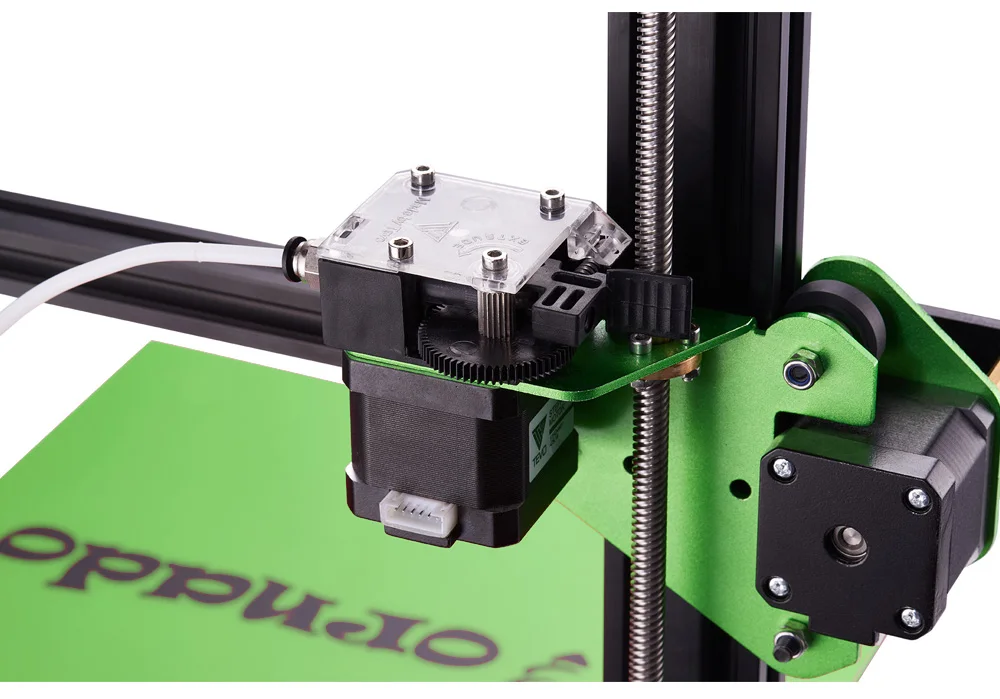

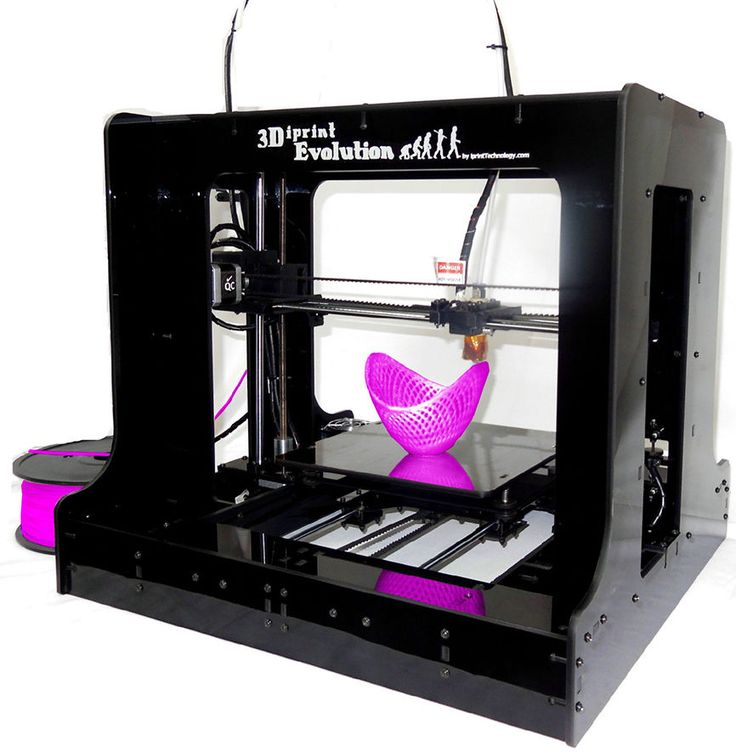

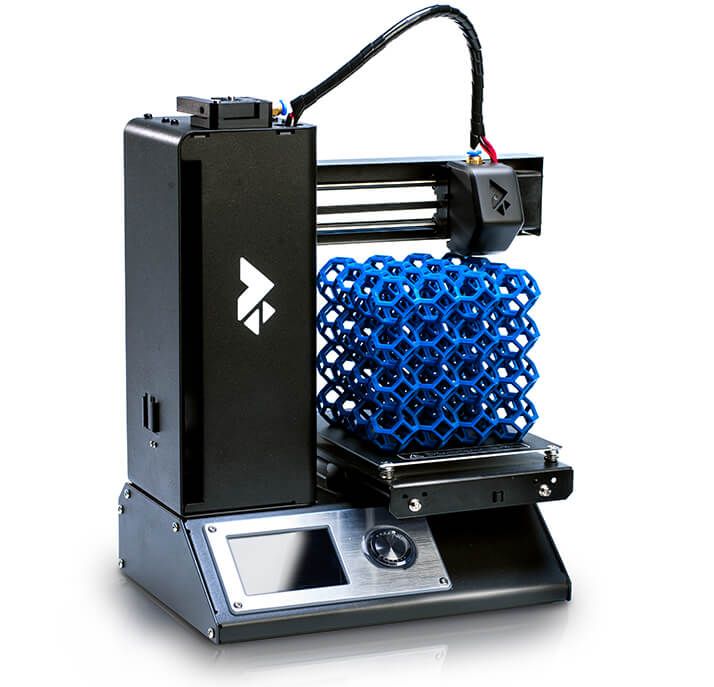

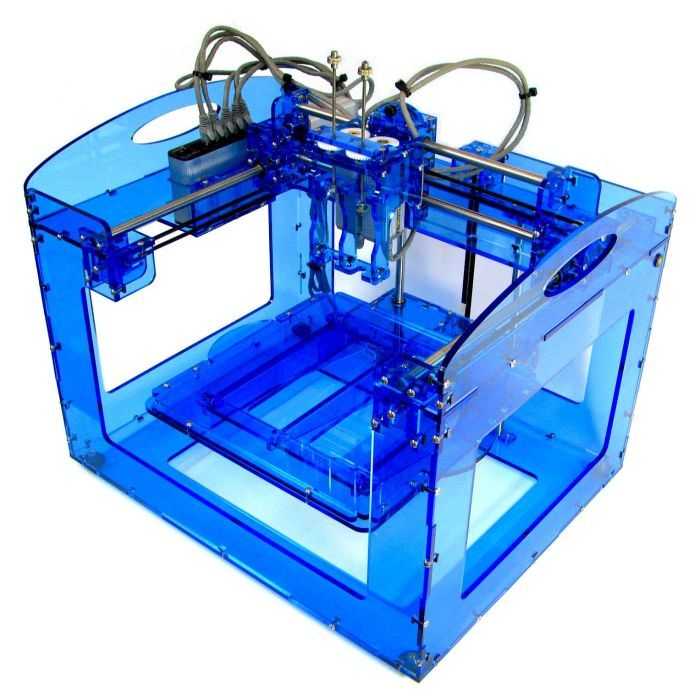

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

This technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

Consumer level FDM has the lowest resolution and accuracy when compared to other plastic 3D printing processes and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

As the melted filament forms each layer, sometimes voids can remain between layers when they don’t adhere fully. This results in anisotropic parts, which is important to consider when you are designing parts meant to bear load or resist pulling.

FDM 3D printing materials are available in a variety of color options. Various experimental plastic filament blends also exist to create parts with wood- or metal-like surfaces.

The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials that offer properties like higher heat resistance, impact resistance, chemical resistance, and rigidity.

| Material | Features | Applications |

|---|---|---|

| ABS (acrylonitrile butadiene styrene) | Tough and durable Heat and impact resistant Requires a heated bed to print Requires ventilation | Functional prototypes |

| PLA (polylactic acid) | The easiest FDM materials to print Rigid, strong, but brittle Less resistant to heat and chemicals Biodegradable Odorless | Concept models Looks-like prototypes |

| PETG (polyethylene terephthalate glycol) | Compatible with lower printing temperatures for faster production Humidity and chemical resistant High transparency Can be food safe | Waterproof applications Snap-fit components |

| Nylon | Strong, durable, and lightweight Tough and partially flexible Heat and impact resistant Very complex to print on FDM | Functional prototypes Wear resistant parts |

| TPU (thermoplastic polyurethane) | Flexible and stretchable Impact resistant Excellent vibration dampening | Flexible prototypes |

| PVA (polyvinyl alcohol) | Soluble support material Dissolves in water | Support material |

| HIPS (high impact polystyrene) | Soluble support material most commonly used with ABS Dissolves in chemical limonene | Support material |

| Composites (carbon fiber, kevlar, fiberglass) | Rigid, strong, or extremely tough Compatibility limited to some expensive industrial FDM 3D printers | Functional prototypes Jigs, fixtures, and tooling |

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA parts can also be highly polished and/or painted after printing, resulting in client-ready parts with high-detailed finishes.

Parts printed using SLA 3D printing are generally isotropic—their strength is more or less consistent regardless of orientation because chemical bonds happen between each layer. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA offers the widest range of material options for plastic 3D printing.

SLA 3D printing is highly versatile, offering resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

| Formlabs Materials | Features | Applications |

|---|---|---|

| Standard Resins | High resolution Smooth, matte surface finish | Concept models Looks-like prototypes |

| Clear Resin | The only truly clear material for plastic 3D printing Polishes to near optical transparency | Parts requiring optical transparency Millifluidics |

| Draft Resin | One of the fastest materials for 3D printing 4x faster than standard resins, up to 10x faster than FDM | Initial Prototypes Rapid Iterations |

| Tough and Durable Resins | Strong, robust, functional, and dynamic materials Can handle compression, stretching, bending, and impacts without breaking Various materials with properties similar to ABS or PE | Housings and enclosures Jigs and fixtures Connectors Wear-and-tear prototypes |

| Rigid Resins | Highly filled, strong and stiff materials that resist bending Thermally and chemically resistant Dimensionally stable under load | Jigs, fixtures, and tooling Turbines and fan blades Fluid and airflow components Electrical casings and automotive housings |

| Polyurethane Resins | Excellent long-term durability UV, temperature, and humidity stable Flame retardancy, sterilizability, and chemical and abrasion resistance | High performance automotive, aerospace, and machinery components Robust and rugged end-use parts Tough, longer-lasting functional prototypes |

| High Temp Resin | High temperature resistance High precision | Hot air, gas, and fluid flow Heat resistant mounts, housings, and fixtures Molds and inserts |

| Flexible and Elastic Resins | Flexibility of rubber, TPU, or silicone Can withstand bending, flexing, and compression Holds up to repeated cycles without tearing | Consumer goods prototyping Compliant features for robotics Medical devices and anatomical models Special effects props and models |

| Medical and dental resins | A wide range of biocompatible resins for producing medical and dental appliances | Dental and medical appliances, including surgical guides, dentures, and prosthetics |

| Jewelry resins | Materials for investment casting and vulcanized rubber molding Easy to cast, with intricate details and strong shape retention | Try-on pieces Masters for reusable molds Custom jewelry |

| ESD Resin | ESD-safe material to improve electronics manufacturing workflows | Tooling & fixturing for electronics manufacturing Anti-static prototypes and end-use components Custom trays for component handling and storage |

| Ceramic Resin | Stone-like finish Can be fired to create a fully ceramic piece | Engineering research Art and design pieces |

Explore Formlabs SLA Materials

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

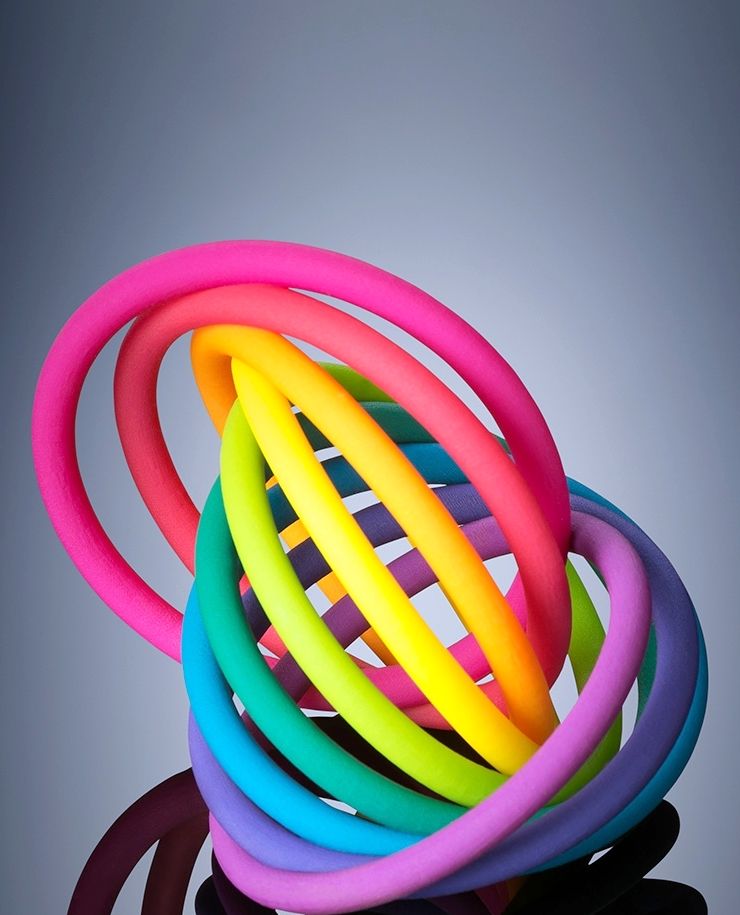

Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Just like SLA, SLS parts are also generally more isotropic than FDM parts. SLS parts have a slightly rough surface finish due to the powder particles, but almost no visible layer lines.

SLS 3D printing materials are ideal for a range of functional applications, from engineering consumer products to manufacturing and healthcare.

The material selection for SLS is limited compared to FDM and SLA, but the available materials have excellent mechanical characteristics, with strength resembling injection-molded parts. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

| Material | Description | Applications |

|---|---|---|

| Nylon 12 | Strong, stiff, sturdy, and durable Impact-resistant and can endure repeated wear and tear Resistant to UV, light, heat, moisture, solvents, temperature, and water | Functional prototyping End-use parts Medical devices |

| Nylon 11 | Similar properties to Nylon 12, but with a higher elasticity, elongation at break, and impact resistance, but lower stiffness | Functional prototyping End-use parts Medical devices |

| TPU | Flexible, elastic, and rubbery Resilient to deformation High UV stability Great shock absorption | Functional prototyping Flexible, rubber-like end-use parts Medical devices |

| Nylon composites | Nylon materials reinforced with glass, aluminum, or carbon fiber for added strength and rigidity | Functional prototyping Structural end-use parts |

Explore Formlabs SLS Materials

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Different 3D printing materials and processes have their own strengths and weaknesses that define their suitability for different applications. The following table provides a high level summary of some key characteristics and considerations.

| FDM | SLA | SLS | |

|---|---|---|---|

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. High performance composites on high cost industrial machines High performance composites on high cost industrial machines | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites, thermoplastic elastomers such as TPU. |

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but use extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

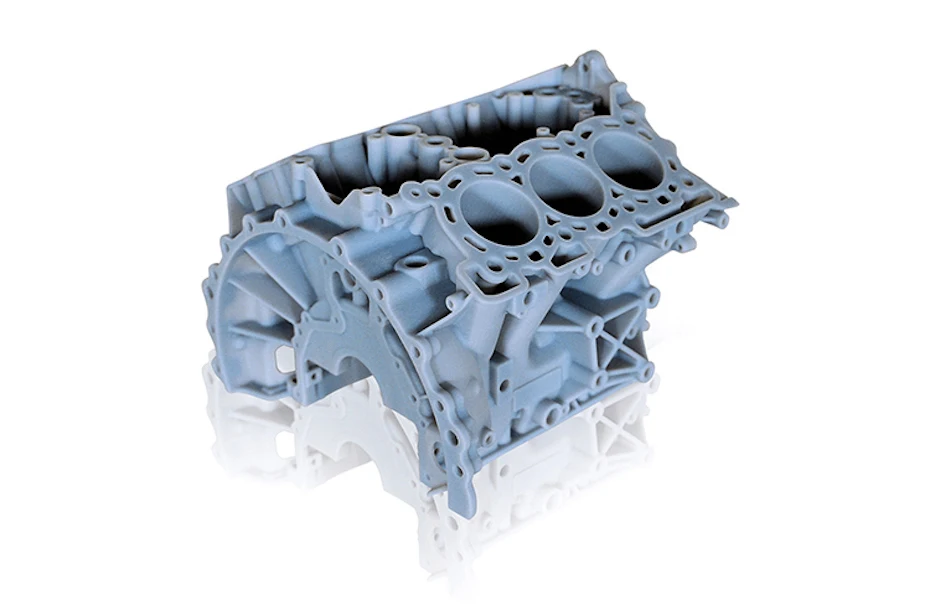

SLM and DMLS printers work similarly to SLS printers, but instead of fusing polymer powders, they fuse metal powder particles together layer by layer using a laser. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

-

Titanium is lightweight and has excellent mechanical characteristics. It is strong, hard and highly resistant to heat, oxidation, and acid.

-

Stainless steel has high strength, high ductility, and is resistant to corrosion.

-

Aluminum is a lightweight, durable, strong, and has good thermal properties.

-

Tool steel is a hard, scratch-resistant material that you can use to print end-use tools and other high-strength parts..

- Nickel alloys have high tensile, creep and rupture strength and are heat and corrosion resistant.

Compared to plastic 3D printing technologies, metal 3D printing is substantially more costly and complex, limiting its accessibility to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Another alternative is electroplating SLA parts, which involves coating a plastic material in a layer of metal via electrolysis. This combines some of the best qualities of metal—strength, electrical conductivity, and resistance to corrosion and abrasion—with the specific properties of the primary (usually plastic) material.

Plastic 3D printing is well-suited to create patterns that can be cast to produce metal parts.

With all these materials and 3D printing options available, how can you make the right selection?

Here’s our three-step framework to choose the right 3D printing material for your application.

Plastics used for 3D printing have different chemical, optical, mechanical, and thermal characteristics that determine how the 3D printed parts will perform. As the intended use approaches real-world usage, performance requirements increase accordingly.

| Requirement | Description | Recommendation |

|---|---|---|

| Low performance | For form and fit prototyping, conceptual modeling, and research and development, printed parts only need to meet low technical performance requirements. Example: A form prototype of a soup ladle for ergonomic testing. No functional performance requirements needed besides surface finish. | FDM: PLA SLA: Standard Resins, Clear Resin (transparent part), Draft Resin (fast printing) |

| Moderate performance | For validation or pre-production uses, printed parts must behave as closely to final production parts as possible for functional testing but do not have strict lifetime requirements. Example: A housing for electronic components to protect against sudden impact. Performance requirements include ability to absorb impact, housing needs to snap together and hold its shape. | FDM: ABS SLA: Engineering Resins SLS: Nylon 11, Nylon 12, TPU |

| High performance | For end-use parts, final 3D printed production parts must stand up to significant wear for a specific time period, whether that’s one day, one week, or several years. Example: Shoe outsoles. | FDM: Composites SLA: Engineering, Medical, Dental, or Jewelry Resins SLS: Nylon 11, Nylon 12, TPU, nylon composites |

Once you’ve identified the performance requirements for your product, the next step is translating them into material requirements—the properties of a material that will satisfy those performance needs. You’ll typically find these metrics on a material’s data sheet.

| Requirement | Description | Recommendation |

|---|---|---|

| Tensile strength | Resistance of a material to breaking under tension. High tensile strength is important for structural, load bearing, mechanical, or statical parts. | FDM: PLA SLA: Clear Resin, Rigid Resins SLS: Nylon 12, nylon composites |

| Flexural modulus | Resistance of a material to bending under load. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. | FDM: PLA (high), ABS (medium) SLA: Rigid Resins (high), Tough and Durable Resins (medium), Flexible and Elastic Resins (low) SLS: nylon composites (high), Nylon 12 (medium) |

| Elongation | Resistance of a material to breaking when stretched. Helps you compare flexible materials based on how much they can stretch. Also indicates if a material will deform first, or break suddenly. | FDM: ABS (medium), TPU (high) SLA: Tough and Durable Resins (medium), Polyurethane Resins (medium), Flexible and Elastic Resins (high) SLS: Nylon 12 (medium), Nylon 11 (medium), TPU (high) |

| Impact strength | Ability of a material to absorb shock and impact energy without breaking. Indicates toughness and durability, helps you figure out how easily a material will break when dropped on the ground or crashed into another object. | FDM: ABS, Nylon SLA: Tough 2000 Resin, Tough 1500 Resin, Grey Pro Resin, Durable Resin, Polyurethane Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Heat deflection temperature | Temperature at which a sample deforms under a specified load. Indicates if a material is suitable for high temperature applications. | SLA: High Temp Resin, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Hardness (durometer) | Resistance of a material to surface deformation. Helps you identify the right “softness” for soft plastics, like rubber and elastomers for certain applications. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

| Tear strength | Resistance of a material to growth of cuts under tension. Important to assess the durability and the resistance to tearing of soft plastics and flexible materials, such as rubber. | FDM: TPU SLA: Flexible Resin, Elastic Resin, Durable Resin SLS: Nylon 11, TPU |

| Creep | Creep is the tendency of a material to deform permanently under the influence of constant stress: tensile, compressive, shear, or flexural. Low creep indicates longevity for hard plastics and is crucial for structural parts. Low creep indicates longevity for hard plastics and is crucial for structural parts. | FDM: ABS SLA: Polyurethane Resins, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Compression set | Permanent deformation after material has been compressed. Important for soft plastics and elastic applications, tells you if a material will return to its original shape after the load is removed. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

For even more details on material properties, read our guide to about the most common mechanical and thermal properties.

Once you translate performance requirements to material requirements, you’ll most likely end up with a single material or a smaller group of materials that could be suitable for your application.

If there are multiple materials that fulfil your basic requirements, you can then look at a wider range of desired characteristics and consider the pros, cons, and trade-offs of the given materials and processes to make the final choice.

Try our interactive material wizard to find materials based on your application and the properties you care the most about from our growing library of materials. Do you have specific questions about 3D printing materials? Contact our experts.

Recommend Me a Material

Ultimate Materials Guide - Tips for 3D Printing with PETG

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 75-90 °C

Heated Bed Recommended

Enclosure Not Required

Build Surface

Glue Stick

Painter’s tape

Extruder

Temperature: 230-250 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model.

These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

- Self-watering Planter

- Water Bottle

- Snap Fit Parts

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

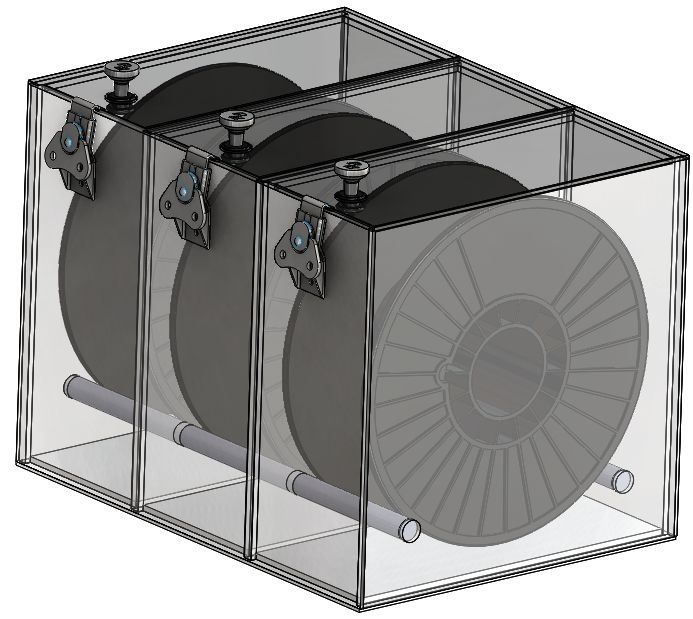

Consumables for FDM printing Plastic filaments

No matter how high-tech 3D printing is, 3D modeling is impossible without such an inexpensive component as consumables. Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place. nine0003

Each 3D prototyping technology has its own pool of consumables - they are developed taking into account compatibility with printers, cost efficiency and quality of output 3D objects. Thus, industrial installations use powder materials, medical 3D printers are biocompatible and neutral, culinary ones work with a wide range of paste-like and viscous food compositions, and the most common in the segment of personal and semi-professional 3D equipment - with plastic thread and photopolymer resins. And since this segment is the most massive, it is on it that we will focus in the first place. nine0003

Of course, you have already studied our range of consumables - in the 3DMall online store it is rightfully considered one of the most worthy and affordable in the whole country. Here you can buy consumables for FDM and other types of printers inexpensively with delivery in Moscow and Russia, including the possibility of picking up at one of the many points of issue. And our Knowledge Base and prompt free consultations with our experts on all issues related to 3D printing will help you make the right choice. nine0003

nine0003

FDM consumables

Most modern personal printers are FDM units, which, like their consumables, are more than affordable. Today, such printers are available not only in offices, design and engineering offices, but also in the homes of many fans of maker and 3D technologies.

There are many varieties of plastics for 3D printing - a far from exhaustive list of materials includes PLA, ABS, PVA, Nylon, PC, HDPE, PP, PCL, PPSU, Acrylic, PET, HIPS, imitation wood, sandstone or metals, the characteristics of which we consider in more detail. nine0003

PLA - polyaktide

The undisputed leader of the modern market of consumables for FDM printers - an environmentally friendly, biocompatible, thermoplastic composition. Its production is based on corn and sugar cane, thanks to which products from this type of plastic are successfully used in everyday life. It is used for the manufacture of toys, dishes, souvenirs, housing elements for household appliances, designer models, food packaging, medicines, surgical thread, and due to its affordability, it is also used for education and hobbies. nine0003

nine0003

Despite the high quality of the surface of PLA products, it is a stretch to call them practical - the material is quite soft and short-lived. The melting temperature is 170-180 about C, the glass transition process begins when cooled to 50 about C.

PLA has proven to be the best type of material for 3D printers with an open build chamber and a heated worktable.

Benefits include low shrinkage so finished objects do not deform during curing, ease of handling and versatility. nine0003

ABS

ABS, or acrylonitrile butadiene styrene, is the most popular heat-resistant plastic in the field of 3D prototyping, which, however, cannot be considered one of the most popular due to the fact that printing with its use is quite problematic.

Advantages - durability, mechanical strength, resistance to moisture, oils, a wide range of acids and elevated temperatures (it withstands heat up to 100-110 about C, responds well to staining). At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

At the same time, some varieties are destroyed by prolonged contact with direct sunlight, and the melting point is about 180 about C - considered low for industrial use. When cooling, the object is subject to significant shrinkage - the first layers can twist, deform and crack. To avoid such problems, the use of ABS is recommended for printing on 3D printers with a heated desktop and a closed body. For a more reliable grip on the work surface, you should also use adhesive tape.

ABS products are absolutely safe at normal air temperatures, however, heat releases toxic acrylonitrile fumes, so it should not be used for printing toys, household items, dishes and food storage containers. nine0003

PVA - polyvinyl alcohol

A truly unique material for special applications. Its main feature is the ability to dissolve in water, which allows it to be used to build support structures (support for particularly filigree elements of the main object) when printing on printers with 2 extruders. The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality. nine0003

The finished model after separation of the support does not require mechanical post-processing - its surface is smooth and of high quality. nine0003

The mechanical properties of this type of plastic are also interesting - in conditions of low humidity it has amazing strength, and with increasing humidity it becomes elastic, however, with a loss of strength. The melting temperature is 165-175 about C, which allows it to be used in combination with PLA and ABS plastics.

Before using PVA, it is recommended to dry it additionally (for example, in an oven) at a temperature not exceeding 80 C for 6-8 hours, even if it was stored in an absolutely sealed dry container. nine0003

Nylon

The main advantage of this material is its resistance to wear due to friction, which makes it very popular in various industries, in particular for coating parts as an alternative to lubrication.

Nylon thread is represented by a fairly large assortment, each variety has its own advantages and disadvantages. The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

The most popular and practical are traditionally considered the nylon-66 created by DuPont in 1935 and its later analogue produced by BASF nylon-6. Their melting points are respectively 265 and 220 about C, which determines the features of their application.

Key features - easily absorbs moisture, fuses with polyimide, which requires special care when choosing a printer, for a more secure fixation to the desktop, use wax-impregnated adhesive tape. Recommended for refilling printers with studded traction mechanisms as part of extruders, as well as for printing solid models, since nylon parts stick together very poorly. nine0003

PC - polycarbonate

The main advantages of polycarbonate plastic filament are its high strength and temperature resistance, it can be cooled and heated without the risk of deformation of the finished object, which cannot be said about the printing process itself. The melting temperature of the material is 265 about C, the safety requirements and risks of deformation during model building will help to optimize equipment with a closed print chamber and a heated platform. You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production. nine0003

You should immediately pay attention to the risks - printing these materials is harmful to health, since bisphenol A, a potentially carcinogenic and toxic substance, is used in the process of its production. nine0003

Due to its high hygroscopicity, RS should be stored in dry and fully sealed containers.

HDPE - High Density Polyethylene

This is one of the world's most sought after plastics for 3D printing. The material melts very easily and hardens in record time - the temperature difference between these processes is only 20-25 degrees, the average melting point is 130-145 about C. (hardening too fast), high shrinkage and deformation activity. The optimal solution for high quality HDPE printing results is high speed prototyping and careful temperature control of the build chamber and work platform to slow down the process of layer curing. However, HDPE is in the category of the cheapest consumables. It is used for the production of plastic bottles and containers, disposable tableware. nine0003

nine0003

An interesting fact is that this type of plastic thread can also be made from plastic waste, there are even 2 professional installations that can cope with this task (universal processing machines FilaBot and RecycleBot.

PP - polypropylene

A versatile and inexpensive material used for production a wide range of plastic products - from dishes and packaging to pipes and fittings.The advantages of PP include low specific gravity, chemical resistance, non-toxicity, moisture resistance, wear resistance and low cost.Unstable with constant contact with direct sunlight and temperatures below -5 o C.

Print shrinkage is as high as 2.4%, 3 times greater than with ABS. Molten material adheres well even to a cold surface, but for high quality printing it is recommended to use equipment with a heated bed.

More popular than the original polypropylene is its imitation, developed by the world famous company Stratasys - Endur.

PCL - polyaprolactone

This is a low temperature biodegradable polyester that melts already at 60 about C, which requires a careful approach when choosing equipment for PLC printing - not all 3D printer models support this mode. Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

Non-toxic - used in the field of medicine, has excellent plasticity, so it can be used an unlimited number of times.

High viscosity and low temperature resistance make this material unsuitable for functional prototypes and objects, but it is ideal for printing food containers and various layouts. nine0003

PPSU - polyphenylsulfone

Thermoplastic material with outstanding strength characteristics, in demand in the aviation industry. Chemically and thermally resistant, does not burn, does not deform in a wide temperature range (-50 o C ... +180 o C). It is used in the production of food containers, dishes, household items. Resistant to corrosion from solvents and household chemicals.

With all the advantages, it is used infrequently, since the melting point is 370 o C.

Acrylic - Plexiglas

Durable, environmentally friendly, moisture resistant material, characterized by excellent adhesion of layers in the prototyping process. The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest construction accuracy, which is very, very difficult to achieve on a classic personal printer.

The objects have a homogeneous flat surface and excellent performance properties. It is rarely used for FDM printing, as it is difficult to store and requires the highest construction accuracy, which is very, very difficult to achieve on a classic personal printer.

Stratasys' VeroClear imitator, which is used in Objet Eden printers, is in much greater demand. nine0003

PET - polyethylene terephthalate

Food and medical containers are mainly made from this material with a very complex name. Its main advantage is its high chemical resistance, it is not subject to the damaging effects of a wide range of acids and alkalis, it is resistant to wear and a wide temperature range (-40 about C ... +75 about C). Shrinkage on cooling is about 2%, which, combined with a high melting point, reaching 260 about C, makes the printing process somewhat problematic. The transparency of the product is achieved by rapid cooling of the model to the glass transition threshold (+70-80 about C). In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

In general, to obtain a consistently high-quality result, it is enough to create the same conditions as when printing ABS.

HIPS Soluble Support Material

This is a polystyrene with amazing durability, used to produce real parts and components used in various industries in real use. It is also used for the manufacture of toys, disposable tableware, a number of building materials. In terms of physical properties (strength and durability), it is similar to ABS plastic, but it dissolves easily in limonene. This feature allows it to be used as a support material for printing ABS plastic products, in comparison with PVA it has a much lower cost and absolute insensitivity to water. nine0003

Printing is recommended in well-ventilated rooms, as toxic volatile substances may be released during melting.

Wood imitators

This category of consumables includes LAYWOO-D3 and BambooFill, products from which both visually and functionally are in no way inferior to analogues made of natural wood - the products even have a characteristic woody aroma. They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable. nine0003

They do not deform and do not require the use of a heated platform. LAYWOO-D3, for example, is made from dusted sawdust and a non-toxic binder polymer, making it safe and highly post-processable. nine0003

An interesting detail is that the use of nozzles with different heating parameters can achieve different decorative effects. For example, as the extrusion temperature increases, this type of material acquires a richer, darker hue.

The only negative is the high cost, which exceeds the price of PLA or ABS by almost 4 times.

Laybrick – sandstone simulant

We owe the appearance of this composite material with high aesthetic and performance characteristics to the inventor Kai Parti. By the way, LAYWOO-D3 is also his creation. The binder used as the basis for creating this type of material is mixed with a mineral filler - this explains the original texture of the resulting products. nine0003

Depending on the selected melting temperature, the surface of the products can be smoother or rougher (the higher it is, the greater the roughness).

One of the easiest materials to work with - it does not need a heated platform, it practically does not shrink or deform. The only drawback is the high cost compared to other filaments.

BronzeFill - metal simulant

Metal is the foundation of additive manufacturing, its use in 3D printing opens up almost unlimited possibilities for humanity. If not for the high cost, of course. Therefore, it is not surprising that a high-quality imitator, BronzeFill, has also been created for the followers of FDM printing. Products printed from it are not inferior to metal ones either visually or operationally. nine0003

This is an almost transparent PLA-based plastic, which also contains a bronze filler. Finished 3D objects respond well to post-processing - grinding, polishing - and visually look like all-metal, but you should not forget that thermoplastic is based on it.

How to choose printing plastic?

The choice of filament for printing should be determined by the following several parameters:

- the capabilities of the 3D printer at your disposal; nine0162

- requirements for surface quality, detailing accuracy and performance of finished products;

- color;

- scope.

We offer you a small comparison table on the key characteristics of the most popular types of plastic in personal 3D printing, which will help you choose the best option.

layer, °С

threads, mm

Consumables printing enables fast and cost-effective prototyping and production of models for a wide range of applications. But choosing the right 3D printing technology is only one side of the coin. Ultimately, the ability to create models with the required mechanical properties, functional characteristics or appearance will depend on the materials. nine0003

Ultimately, the ability to create models with the required mechanical properties, functional characteristics or appearance will depend on the materials. nine0003

This comprehensive guide provides information on the most popular plastic and metal 3D printing materials available, compares their properties and applications, and provides guidance on how to select the most appropriate material for your project.

Interactive material

Need help choosing your 3D printing material? Our new interactive materials wizard will help you select the right material from our growing range of polymers, based on your intended application and the properties that matter most to you. nine0003

Get material recommendations

Dozens of plastic materials are available for 3D printing. Each of them has unique properties suitable for specific applications. To make it easier to find the best material for a particular model or product, let's first look at the main types of plastics and the various 3D printing processes.

There are two main types of plastics:

-

thermoplastics are the most common type of plastics. The main feature that distinguishes them from thermosetting plastics is their ability to withstand multiple melting and solidification cycles. Thermoplastics can be heated and shaped into desired shapes. This process is reversible because no chemical bond is formed. As a result, they can be recycled or melted down and reused. Thermoplastics can be compared to butter: it melts and hardens many times. With each melting cycle, the properties of thermoplastics change slightly. nine0003

-

thermoset plastics (also called thermosets) remain permanently solid after polymerization. The polymers in thermosetting plastics are crosslinked during the polymerization process, which is induced by heat, light, or appropriate radiation. Thermoset plastics decompose when heated, rather than melt. In addition, they do not change their shape when cooled.

It is not possible to recycle thermosetting plastics or restore the material to its original state. Thermosetting is like pie dough: once baked, the pie cannot be melted back into dough. nine0003

It is not possible to recycle thermosetting plastics or restore the material to its original state. Thermosetting is like pie dough: once baked, the pie cannot be melted back into dough. nine0003

The three most common plastic 3D printing processes today are:

-

Fused Deposition Modeling (FDM) 3D printers melt and extrude thermoplastic filaments that are deposited layer by layer by a printer nozzle onto the work area.

-

The Stereolithography (SLA) 3D Printer uses a laser to photopolymerize thermoset liquid polymers into a hardened plastic. nine0003

-

The Selective Laser Sintering (SLS) 3D Printer is equipped with a high power laser to sinter fine particles of thermoplastic powder.

How-To Video

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing. nine0003

nine0003

Watch video

Fused fusion modeling (FDM), also known as fused filament manufacturing (FFF), is the most common form of consumer grade 3D printing, fueled by the rise of hobbyist 3D printers.

This method is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple products, such as parts that are usually machined. nine0003

Consumer grade FDM has the lowest resolution and accuracy of any other plastic 3D printing process, making it unsuitable for printing complex designs or models with intricate features. It is possible to improve the surface quality of models printed using this technology using chemical and mechanical polishing processes. FDM-based industrial 3D printers, which offer a wider range of engineering thermoplastics, can solve these problems, but are also much more expensive. nine0003

Each layer is formed with a thermoplastic thread. Sometimes, if the layers are not completely adjacent to each other, there may be voids between them. As a result, anisotropic models are obtained, which is important to consider when designing products that must withstand load and be resistant to tension.

As a result, anisotropic models are obtained, which is important to consider when designing products that must withstand load and be resistant to tension.

FDM 3D printing materials are available in a variety of colors. There are also various experimental mixtures of thermoplastic threads designed to create models with a surface that mimics wood or metal. nine0003

The most common materials for 3D printing in FDM technology are ABS (acrylonitrile butadiene styrene), PLA (polylactic acid) and various mixtures of these polymers. More advanced FDM printers can also print on other materials with different properties, such as increased temperature and chemical resistance, impact resistance, and rigidity.

| Material | Features | Material for supporting structures |

|---|---|---|

| A shock -resistant polystyrene | Material for the creation of soluble supporting structures, most often used with ABS , is dissolved in Limonen Fiber.  Material for supporting structures Material for supporting structures | Strong, tough and incredibly hard Only compatible with some expensive industrial 3D printers based on FDM technology | Functional prototypes Clamping fixtures, fixtures, tooling |

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular among professionals today.

Models printed with stereolithography printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of any other plastic 3D printing technology. Resin 3D printing is a great option for producing highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates, and functional models. Models printed using SLA technology can be easily polished and/or painted after printing, resulting in highly detailed finished products. nine0003

Models printed on SLA 3D printers are generally isotropic: their strength is more or less constant and independent of orientation, since chemical bonds occur between each layer. This results in models with predictable mechanical characteristics critical for applications such as fasteners, fixtures, finished products, and functional prototypes.

This results in models with predictable mechanical characteristics critical for applications such as fasteners, fixtures, finished products, and functional prototypes.

Stereolithography supports a wide range of plastic 3D printing materials. nine0003

SLA 3D printing is versatile and provides a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

| Materials of Formlabs | Characteristics | Methods of use |

|---|---|---|

| Standard polymers | General resolution Glavo0176 | Initial prototypes Rapid iterations |

| Tough Resin and Durable Resin | Materials that are tough, strong, functional and dynamic Can withstand compression, tension, bending and impact without breaking Various materials with properties similar to ABS | Enclosures and Enclosures Clamps and Fixings Connectors Wear Prototypes |

| Rigid Resins | Highly filled, stiff and durable material that resists bending Resistant to temperature and chemicals Holds size under load | Clamping and clamping fixtures, tooling Turbines and fan blades Fluid/air components Electrical enclosures and enclosures used in the automotive industry |

| High Temp Resin | High temperature resistant High Precision | Hot Air, Gas, and Liquid Components Heat Resistant Fasteners, Enclosures, and Fixtures Molds and Inserts |

| Flexible Resin and Elastic Resin | Flexible Rubber, TPU, or Silicone compression Withstands many successive cycles without wear | Consumer product prototypes Foldable structures for robotics Medical devices and anatomy models Props and models for special effects |

| Medical and dental resins | A wide range of biocompatible resins for the manufacture of medical and dental products | Dental and medical products, including surgical templates, dentures and limb prostheses | 4 Jewelry resins | Lost Wax and Vulcanized Rubber Casting Materials Easy to cast, allows for intricate designs and retains shape well Request a free sample

Selective laser sintering (SLS) 3D printing is a technology trusted by engineers and manufacturers across industries to create durable and functional models. The green powder supports the model during printing and eliminates the need for special support structures. As a result, SLS is ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features. Like stereolithography, SLS produces more isotropic models than FDM models. Models created with SLS technology have a slightly rough surface due to powder particles, but have almost no visible layer lines. nine0003 SLS 3D printing materials are ideal for a range of functional applications, from consumer product design to manufacturing and healthcare applications. Compared to FDM and SLA technologies, SLS technology allows the use of a limited number of materials. However, the available materials have excellent mechanical properties. | Functional Prototypes End-Use Structural Products |

Sample

Experience Formlabs SLS print quality for yourself. We will send a free print sample directly to your office.

Request a free sample

Different 3D printing materials and processes have their own advantages and disadvantages that make them suitable for different scenarios. The following table provides a brief overview of some of the main features and factors to consider. nine0176

Poor detail

Limited conformance to design

High cost of industrial devices if precision and high performance materials are required

Basic experimental models

Production of special end-use products using professional industrial devices and materials

Templates, molds and tooling

Dental products

Prototypes and molds for casting jewelry

Props and models

Small-scale production, production of limited trial runs, creation of products to order

High performance composites on high value industrial applications

High performance composites on high value industrial applications There are several 3D printing processes not only from plastics, but also from metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held in place by a resin binder. The finished models are in an intermediate state and then sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. 3D printers based on SLM and DMLS technologies can create strong, precise and complex metal products, making this process ideal for the aerospace, automotive and medical industries.

-

Titanium is a light metal with excellent mechanical properties. It is strong, hard and highly resistant to heat, oxidation and acids. nine0003

-

stainless steel has high strength, ductility and corrosion resistance.

-

aluminum is a lightweight, durable, strong metal with good thermal properties.

-

Tool Steel is a hard, scratch-resistant material that can be used to print end-use tools and other high-strength products. nine0003

- nickel alloys have high tensile strength, creep and tensile strength, as well as heat and corrosion resistance.

Compared to plastic 3D printing technologies, metal 3D printing is much more expensive and difficult, and thus beyond the reach of most companies.

As an alternative to casting workflows that produce metal models cheaper and faster than traditional methods and provide greater design freedom, SLA 3D printing is well suited. nine0003

nine0003

Another alternative is galvanization of SLA printed models. It involves applying a layer of metal to plastic using electrolysis. This combines some of the best qualities of metal (strength, electrical conductivity, corrosion and abrasion resistance) with the special properties of the base (usually plastic) material.

Plastic 3D printing is well suited for creating templates that can be cast to produce metal models. nine0003

With so many materials and options available for 3D printing, making the right choice can be difficult.

We provide a 3-step process for selecting the right material for 3D printing.

Plastics used for 3D printing have different chemical, optical, mechanical and thermal characteristics that affect the properties of 3D printed models. As you move from the intended use case to the actual operating environment, the performance requirements increase accordingly. nine0003

| Requirement | Description | Recommendations |

|---|---|---|

| Low Efficiency | Example: Prototype mold for a ladle for ergonomic testing. | FDM PLA SLA: Standard Resins, Clear Resin (Clearness), Draft Resin (Fast) |

| Medium Efficiency | For validation or pre-production use, printed models should have properties as close as possible to those of final production models , for functional testing, but do not meet stringent requirements regarding service life. Example: housing for electronic components to protect against sudden impacts. Functional characteristics include the ability to absorb impact energy. In addition, the body must snap into place and retain its shape. nine0003 | FDM ABS SLA: Engineering Resins SLS: Nylon 11 Powder, Nylon 12 Powder, TPU |

| High Efficiency | Final 3D printed models must be highly stable to achieve end use products to wear and tear over a certain period of time, whether it be a day, a week or several years. Example: shoe soles. Functional features include rigorous cycling and unloading life testing, color fastness over many years, and tear resistance, among other things. nine0003 | FDM Composites SLA: Engineering, Medical, Dental or Jewelry Resins SLS: Nylon 11 Powder, Nylon 12 Powder, TPU, Nylon Composites |

material requirements: material properties that will satisfy these requirements. These indicators are usually given in the technical specifications of the material. nine0003

| Requirement | Description | Recommendations | |

|---|---|---|---|

| Tensile strength | Resistance to fracture under tension. High tensile strength is important for structural, load-bearing, mechanical or static models. | FDM PLA SLA: Clear Resin, Rigid Resin SLS: Nylon 12 Powder, Nylon Composites | |

| Flex Module | Material resistance to bending under load. Indicates either rigidity (high value) or flexibility (low value) of the material. Indicates either rigidity (high value) or flexibility (low value) of the material. | FDM PLA (High), ABS (Medium) SLA: Rigid Resin (High), Tough Resin and Durable Resin (Medium), Flexible Resin and Elastic Resin (Low) SLS: Nylon composite materials (high value), Nylon 12 Powder (medium value) | |

| Elongation | Material resistance to tensile failure. Allows you to compare the degree of stretching of flexible materials. It also indicates whether the material is stretched or immediately destroyed. nine0176 | FDM ABS (medium), TPU (high) SLA: Tough Resin and Durable Resin (medium), Flexible Resin and Elastic Resin (high) SLS: Nylon 12 Powder (medium), Nylon 11 Powder (medium), TPU (high) | |

| Impact strength | The ability of a material to absorb impact and its energy without breaking. Shows toughness and durability. Allows you to determine how easily the material breaks when it falls to the ground or collides with another object. nine0176 nine0176 | FDM ABS, Nylon SLA: Tough 2000 Resin, Tough 1500 Resin, Gray Pro Resin, Durable Resin SLS: Nylon 12 Powder, Nylon 11 Powder a certain load. Indicates whether the material is suitable for high temperature applications. | SLA: High Temp Resin, Rigid Resin SLS: Nylon 12 Powder, Nylon composites |

| Hardness (durometer) | Material resistance to surface deformation. Allows you to determine the right degree of plasticity for soft plastics such as rubber and elastomers for a particular application. | FDM TPU SLA: Flexible Resin, Elastic Resin SLS: TPU | |

| Tear resistance | Material resistance to notching under tension. This indicator is important for evaluating the durability and wear resistance of soft plastics and flexible materials such as rubber. nine0176 | FDM TPU SLA: Flexible Resin, Elastic Resin, Durable Resin SLS: Nylon 11 Powder, TPU | |

| Creep | Creep is the tendency of a material to permanently deform under the influence of constant stress: tension or bending, compression, shear . Low creep indicates durability of hard plastics and is very important for structural models. Low creep indicates durability of hard plastics and is very important for structural models. | FDM ABS SLA: Rigid Resin SLS: Nylon 12 Powder, Nylon 9 composites0176 | |

| Compression set | Irreversible deformation after material compression. An important indicator for soft plastics and applications where flexibility is needed. Indicates whether the material will restore its original shape after the load is removed. | FDM TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

For more information on material properties, see our guide to the most common mechanical and thermal properties. nine0003

By converting performance characteristics into material requirements, you can most likely find out which material, or small group of materials, is right for your application.

If several materials meet your basic requirements, a broader range of desired characteristics, as well as the advantages and disadvantages of these materials and processes, can be considered for the final selection.

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance.

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance. With its low model cost, high performance, and use of common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products. nine0003

With its low model cost, high performance, and use of common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products. nine0003  They have strength comparable to die-cast models. The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0176

They have strength comparable to die-cast models. The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0176  Other than surface quality, there are no performance requirements. nine0003

Other than surface quality, there are no performance requirements. nine0003