3D printing dental models

Resin Library and 3D Printing Materials

Resin Library and 3D Printing MaterialsSkip to Main Content

Dental Resins

Bring production in-house or improve existing workflows with industry-leading Formlabs 3D printers. Our Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.

Visit the Formlabs Store

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your lab or practice.

Request a Free Sample Part

The Form 3B+ and Form 3BL are compatible with the complete Formlabs resin library of more than 20 general purpose and speciality materials.

Explore All Formlabs Materials

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 12Permanent CrownRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

For more information, help choosing a material, or bulk orders, we're here to help.

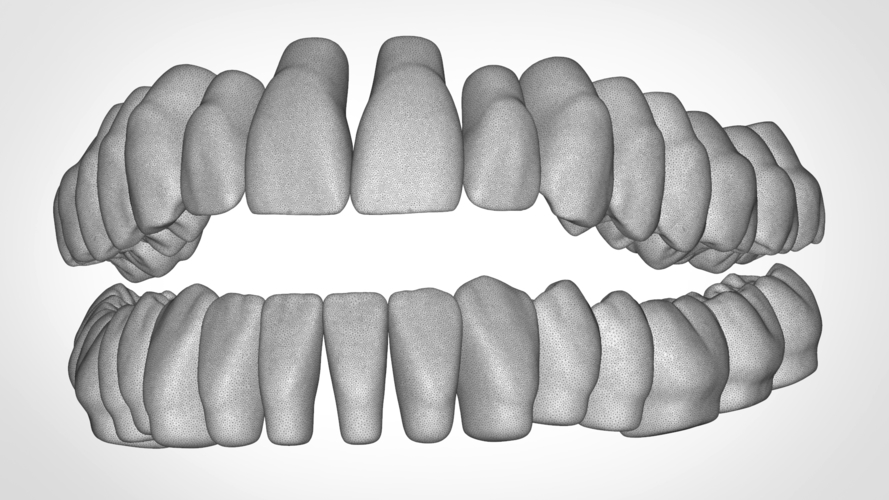

3D Print Dental Models for Study, Patient Presentation, and more.

Fabricate restorative study models, removable dies, digital wax up models, and models for thermoforming clear aligners.

Digital Workflow

Pro 3D Printer

Materials

Fabricate accurate models for orthodontic and restorative study in-office in less than an hour. 3D print dental models for before-and-after patient presentation to help increase case acceptance. Pint large quantities of models rapidly for use in the production of clear aligner therapy.

Available in your choice of color, all with outstanding dimensional accuracy and speed. SprintRay Die & Model resins are extremely reliable and easy to work with.

Key Benefits

- Rapidly print up to 22 models in under an hour

- Shown to be more accurate than traditional methods

- Print models for an estimated $2 each in materials cost

Dental Study Models

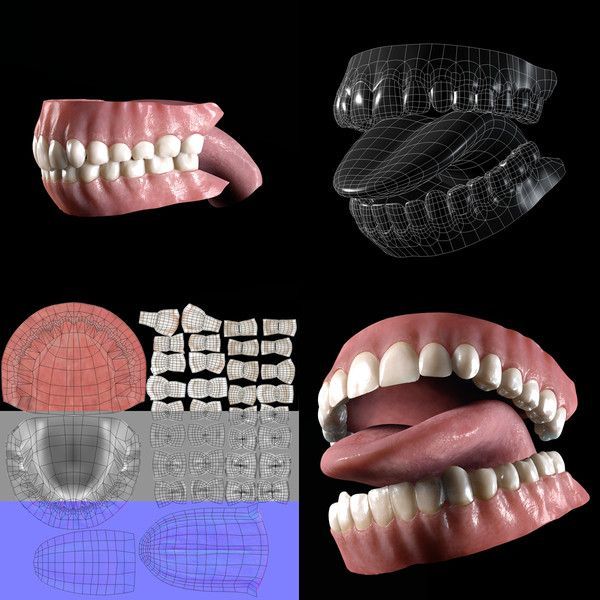

3D print dental study models and digital wax ups to show beautiful anatomical detail. This precision allows for exceptional measurements, patient education, and laboratory collaboration. The color options allow for clinicians to choose the shade that most clearly shows detail.

This precision allows for exceptional measurements, patient education, and laboratory collaboration. The color options allow for clinicians to choose the shade that most clearly shows detail.

Study Models for Presentation

Models for Aligners

Full-arch orthodontic model play an integral role in clear aligner therapy. Sequential models can be printed and used to thermoform clear aligners. In addition, complete orthodontic model can be used in conjunction with spray separators and laser soldering to fabricate orthodontic appliances.

About Clear Aligners

Digital Wax Up Models

Digitally build wax up models to show patients the results they can look forward to based on your treatment plans. Gather anatomical data using your intraoral scanner, then enhance with CAD software.

About Wax Up Models

Image courtesy of Dr. Marko Tadros, DMD

Marko Tadros, DMD

Removable Dies

Useful for visual aids in dental surgery and anatomical education, SprintRay's 3D printers produce parts with tight tolerances so that your removable dies come out perfect with each print.

Connect with Digital Dentistry Experts

Whether you’re new to digital dentistry and are looking for guidance or you have specific needs you’d like addressed, our expert sales team would love to connect.

Schedule an Appointment

Materials

Our large library of dental printing materials are designed to get the most out of SprintRay 3D printers. Whether you're using resins from SprintRay or one of our growing list of materials partners, you’ll receive highly-accurate, outstanding results thanks to our extensive validation process.

See SprintRay Materials

See Open Certified Materials

SprintRay Die and Model 2

Rapidly 3D Print High-contrast Dental ModelsApplications

Brochure

Read IFU

- Improved flexural modulus and strength

- Up to 10% faster print speeds

- Print up to eight full arch models in just 15 minutes*

- Fantastic color and finish that mimics dental stone

- Easy to separate from thermoforming materials

- Biocompatible, FDA-compliant material

SprintRay Die & Model 2 represents a big step forward in dental modelling materials. Our new colors mimic classic dental stone and feature almost no pigment settling, which means you can spend more time printing and less time mixing. Improved adhesion to the build plate is matched by an increase in flexural modulus and strength, providing higher success rates and a reduced chance of breakage.

Our new colors mimic classic dental stone and feature almost no pigment settling, which means you can spend more time printing and less time mixing. Improved adhesion to the build plate is matched by an increase in flexural modulus and strength, providing higher success rates and a reduced chance of breakage.

A reduced odor improves the quality of life for 3D printing models for an overall experience that your practice staff will love. Plus, Die & Model 2 resins are easier to separate from thermoforming materials, saving time and labor for more efficient in-office fabrication workflows. With rapid, repeatable results that are easier than ever to use, Die & Model 2 is helping to bring dental 3D printing into dental practices everywhere.

* When printed on SprintRay Pro with Ludicrous Speed profile. Learn More

FLEXURAL MODULUS

Higher flexural modulus prevents the model from distorting, which can impact accuracy.

Die and Model 2

2650 MPa

Die and Model

1700 MPa

FLEXURAL STRENGTH

Higher flexural strength ensures that the model doesn't break during normal use.

Die and Model 2

91.5 MPa

Die and Model

66.7 MPa

SprintRay Study Model White 2

Rapid, pure-white models for patient presentationApplications

Read IFU

SprintRay Study Model White 2 is a special material formulation that provides outstanding color, clarity, and production speed, making it perfect for patient presentation. With a 20% increase in curing efficiency, you can offer same-day mockups and waxups. Plus, get pure white prints every time thanks to an improved color formulation that doesn’t discolor during post-processing.

- Wow patients with same-visit mockups and waxups

- 20% faster; print full-arch models in just 18 minutes

- Pure white color, even after post-curing

PRODUCTION TIME

Higher speed means faster model production, allowing for same-day waxup and diagnostic models.

Study Model White 2

17 Minutes

Die & Model 2 Gray

24 Minutes

Digital Workflow Explained

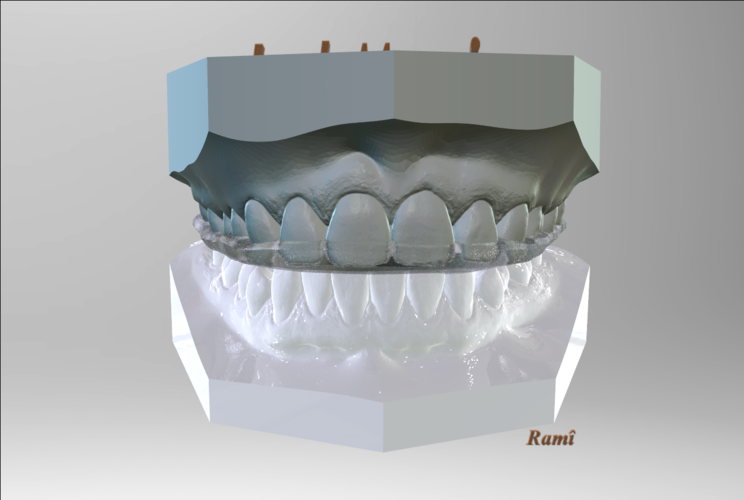

3D Printing Dental ModelsUsing an intraoral scan and optional CBCT data, you can use 3rd-party software or RayWare to complete the edges and fill the holes of your scan. Because horizontal space doesn't add time to your print, feel free to stack as many models horizontally along the platform as you'd like.

View Workflow

Capture Data

First capture and record a patient's anatomy using an intraoral scanner or other scanned data.Design and Plan

Design the appliance using dental CAD software or outsource design to a digital lab and recieve print files.Image courtesy of 3Shape

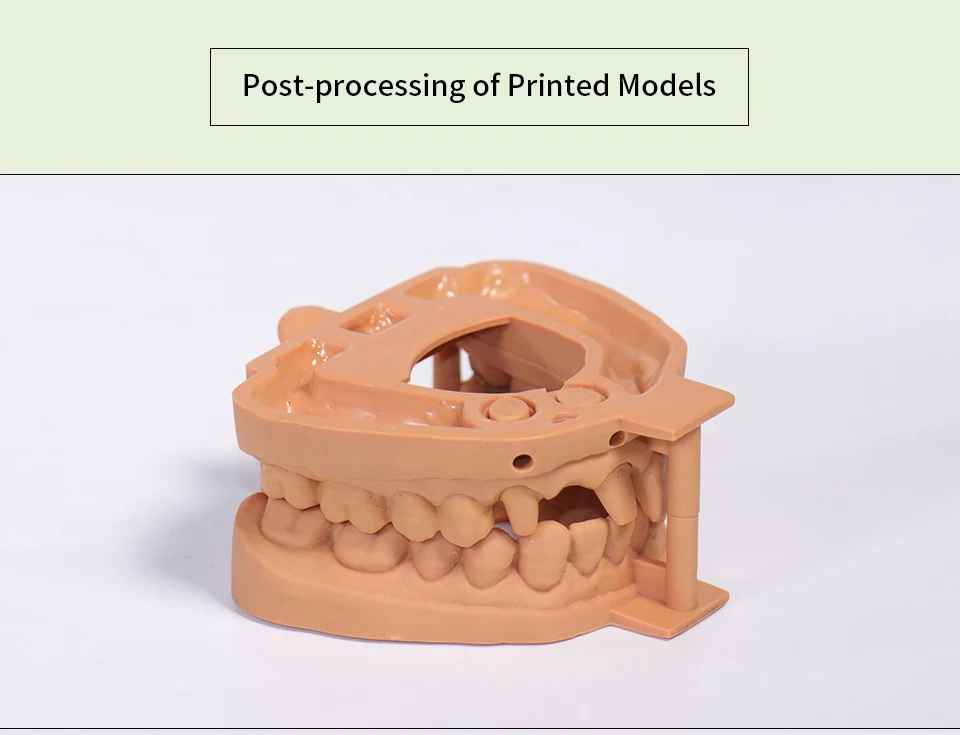

Print and Process

Prepare 3D models, print them, and post-process according to requirements.Place

Deliver appliance as recommended.

SprintRay Pro 3D Printer

More Accurate than Stone

A recent university study found SprintRay Pro more accurate and consistent than traditional alginate methods. With an average RMS of 129±16μm for 3D printing compared to 177±25μm for alginate methods, SprintRay Pro is ready to meet the clinical demands of contemporary dentistry

Read About Accuracy

About SprintRay Pro

SprintRay vs Others

Dental 3D Printing Control Center

RayWare is the 3D printing software that’s designed specifically for dental professionals. It’s easy to learn, and our California-based support team is just a phone call away. In addition to nesting printable files, RayWare allows you to fix, close, and base raw intraoral scans from any scanner with a click of a button.

Test Drive RayWare

Compatible 3D Scanners

You can use any scanner type you’d like with RayWare. We accept any .STL formatted scan data. This list of scanners shows many options that our customers often use, but it is not an exclusive list.

We accept any .STL formatted scan data. This list of scanners shows many options that our customers often use, but it is not an exclusive list.

- 3Shape - Desktop & IOS

- Planmeca - IOS

- Cerec - IOS

- 3M - IOS

- iTero - IOS

- Medit - Desktop & IOS

- Dental Wings - Desktop & IOS

- Carestream - IOS

- Shining 3D - Desktop & IOS

- Condor - IOS

- Heron - IOS

- Open Technologies - Desktop

Compatible Design Software

RayWare allows you to choose a dental design software that meets your clinical needs. This list shows our recommended options, but RayWare accepts any design file formatted in .STL, which means you can use whatever you’re most comfortable with.

This list shows our recommended options, but RayWare accepts any design file formatted in .STL, which means you can use whatever you’re most comfortable with.

- 3Shape

- BlueSkyBio

- Exocad

- Archform

- Orthoselect

- eXceed Ortho

Request a Sample Today

Order your free dental sample and learn how SprintRay 3D products can revolutionize your practice.Request a Free Dental Sample

Cutting-edge Digital Dentistry Powered by SprintRay

The SprintRay 3D printing ecosystem is designed for the unique needs of dental professionals. With SprintRay as your partner, pushing the boundaries of what’s possible in dentistry has never been easier.

Schedule Consultation

Desktop 3D Printer

Automated Wash/Dry

Automated Post-processing

3D Printing Materials

3D Printing Software

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar. nine0003

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary. nine0003

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery. nine0034

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks. nine0003

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

Digital LED projection (DLP). nine0014 Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

nine0014 Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay. nine0003

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality. nine0003

Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality. nine0003

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D. nine0003

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic. nine0003

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

nine0003

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here. nine0003

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here. nine0003

← General requirements for the placement of portable X-ray machines | TOP 5 Illuminated Physiodispensers →

3D printers in dentistry

3D printers are becoming increasingly important in the work of any dental clinic, dental laboratory, research centers. With their help, dentists not only improve the quality of their products and services, but also save significant money. In addition, 3D printers in dentistry guarantee accelerated production volumes and incredible accuracy of finished products. nine0003

- How to improve business

- Advantages 3D prints

- How it works

- video

- Select 3D printer

- How to improve business

- Advantages 3D printing

- How it works

- Video

- 3D printer

How 3D printers improve the dental business

3D printers save dentists from a very complex and time-consuming process in their work - manual modeling of prostheses, crowns and other products. Clients no longer need to wait and go through the entire complex process from the first visit to the installation of the final structure, passing through a series of fittings and improvements. Now they just need to do a mouth scan - and soon get a great result. nine0003

Clients no longer need to wait and go through the entire complex process from the first visit to the installation of the final structure, passing through a series of fittings and improvements. Now they just need to do a mouth scan - and soon get a great result. nine0003

Dental technicians usually rely on a steady hand and good eyesight, and their work is very laborious and time consuming to get an acceptable result. 3D printing brings the dental business to production capacity and ensures consistent accuracy. Now you can use oral imaging and scanning for fast CAD/CAM modeling and 3D printing of crowns, bridges, plaster models and unique orthodontic instruments. nine0003

Each client's unique tooth shape is incredibly difficult to capture with hand or milling. However, dental 3D printers make complicated and outdated manufacturing methods unnecessary. Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

How 3D printers are improving the dental business

3D printers relieve dentists of a very complex and time-consuming process in their work - manual modeling of prostheses, crowns and other products. Clients no longer need to wait and go through the entire complex process from the first visit to the installation of the final structure, passing through a series of fittings and improvements. Now they just need to do a mouth scan - and soon get a great result.

Dental technicians usually rely on firm hands and good eyesight, and their work is very laborious and time consuming to get an acceptable result. 3D printing brings the dental business to production capacity and ensures consistent accuracy. Now you can use oral imaging and scanning for fast CAD/CAM modeling and 3D printing of crowns, bridges, plaster models and unique orthodontic instruments. nine0003

Each client's unique tooth shape is incredibly difficult to capture with hand or milling. However, dental 3D printers make complicated and outdated manufacturing methods unnecessary. Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

Thanks to the latest technologies and the most modern materials, you get finished products several times faster than before. But the main thing is that dental models printed on a 3D printer exactly repeat all the nuances of the original sample.

Cobalt Chromium bridge blank printed on 3DLAM Mini 9 3D printer0003

Biocompatible Resin Surgical Guide

3DLAM Mini Cobalt Chromium Bridge Blank

Biocompatible Resin Surgical Guide

Benefits of 3D Printing for Dentists

2 You Can Store Everything patient data in digital form, no more impressions and samples - just print the desired model on a 3D printer.

Benefits of 3D printing for dentists

- You can store all patient anatomy data digitally, no more impressions and specimens – just 3D print the model you need.

- Significantly speed up the production of the desired items.

- Fully automatic printing process that eliminates the human factor.

- Increasing production without additional staff - your customers no longer have to wait weeks for a master to become available.

- Incredible manufacturing precision - no more mistakes and no need to make new samples. nine0034

- The use of the most advanced technologies will favorably reflect on the image of your company.

How it works: Using a 3D printer to make a denture

How it works: Using a 3D printer to make a denture

1.