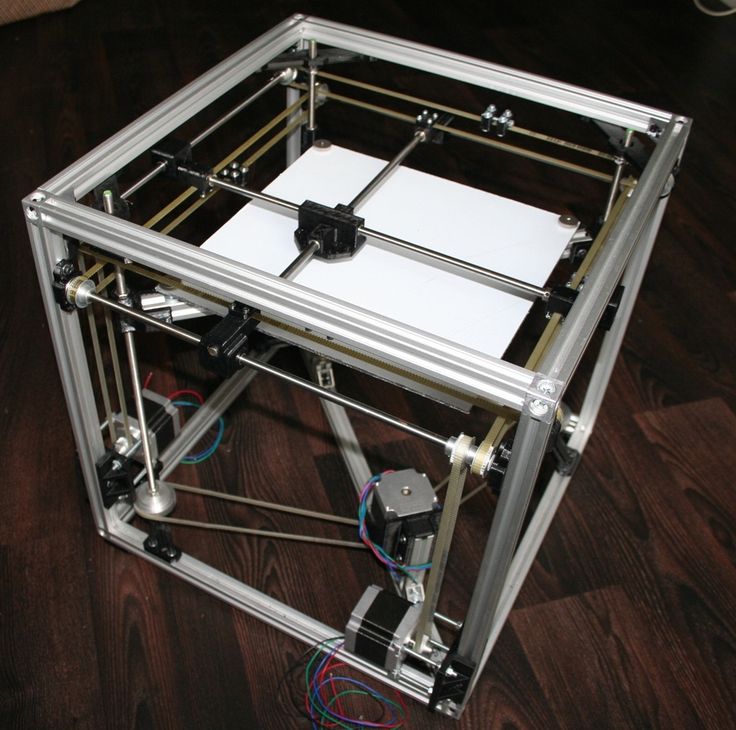

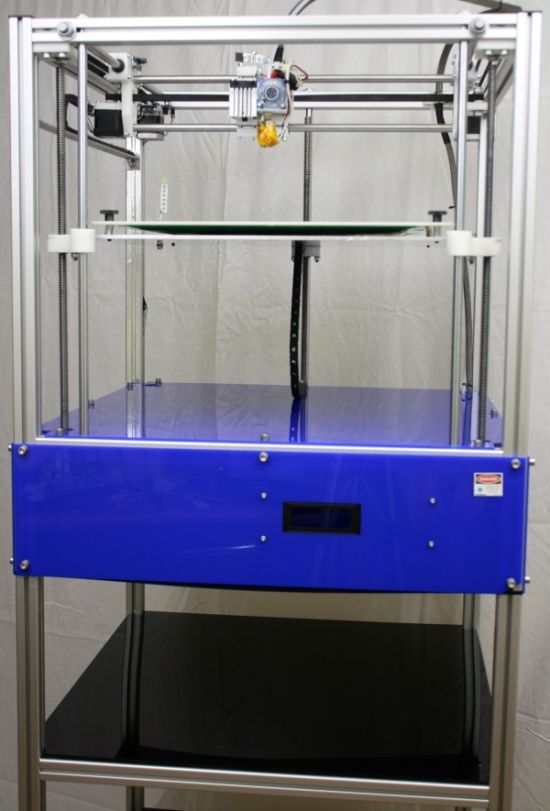

Large reprap 3d printer

The 6 Best RepRap 3D Printers in 2022

Back in the early 2000s, 3D printers were elephant-sized behemoths that cost tens of thousands of dollars. Now, FDM 3D printer giants like Ultimaker and Makerbot, and low cost 3D printer manufacturers like Creality and Prusa exist — because of one sector-defining innovation. That was the RepRap 3D printer movement.

What is a RepRap 3D Printer? And What Does RepRap Mean?

RepRap is short for “replicating rapid prototyper” — aka a self-replicating 3D printer.

A RepRap 3D printer is one designed in line with the RepRap ethos: 3D printers that can self-replicate and print parts to make more RepRap 3D printers. These new RepRap printers can then print more RepRap printers, and so on.

The RepRap movement has done more to democratize 3D printing than anything else. RepRap 3D printers preempted the first DIY 3D printer kits, with these open source 3D printers encouraging tinkering and innovation, advancing the technology.

| Name | Max Build Volume (mm) | Price | Where to buy for the best price? | Alternative Purchase Option |

|---|---|---|---|---|

| Prusa i3 MK3S | 250 x 210 x 200 | $749 / $999 | Kit available on Prusa store here | Fully assembled on Prusa store here |

| Creality Ender 3 Pro | 220 x 220 x 250 | $190 | Creality Store here | Amazon here |

| Prusa Mini | 180 x 180 x 180 | $399 | Prusa Store here | |

| Anet A8 | 220 x 220 x 240 | $159 | Amazon here | |

| Creality CR-10 / V3 | 300 x 300 x 400 | $369-499 | Amazon here | 3DJake UK & Europe |

| FLSUN QQ-S Pro | 255 x 255 x 360 | $369 | Amazon here |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

History of the RepRap movement and RepRap 3D Printing

The RepRap movement was founded by Dr Adrian Bowyer, then a Senior Lecturer at the University of Bath, during 2004 and 2005. He was awarded an MBE by Queen Elizabeth II in 2019 for his services to 3D printing.

The first RepRap 3D printer invented by Dr Bowyer was the RepRap Dawin, named after Charles Darwin who first theorized evolution. You could build one for a few hundred dollars if you got the plastic parts printed and then bought the electronics.

These were the first ever low cost 3D printers; DIY 3D printers you could build yourself. What was previously inaccessible became possible for anyone to have at home if you had enough tech know-how.

And if you were given the plastic parts 3D printed by a friend or someone else, you were morally obliged to print more plastic parts for anyone else who wanted a RepRap. That way, the RepRap movement could spread exponentially, with more printers in service to help others make their own 3D printers.

The first RepRap 3D printer — RepRap Darwin

It was basic, it looked like it was from the 80s, but it worked. It worked for $200 while other 3D printers costed $10,000+. This spurred on the open source 3D printing revolution that has led us to the cutting-edge FDM 3D printers we have today.

Named after Charles Darwin, this is the 3D printer that really kickstarted the RepRap movement.The Darwin plays an important part in the history of 3D printing, and allowed people to now 3D print from home provided they had the technological know-how. It wasn’t pretty and it doesn’t hold up against the far superior RepRap 3D printers that are about today, but in 2008 the Darwin was a big deal, and is looked back upon fondly today.Dr Bowyer’s RepRap printer with its “child”, another RepRap 3D printer it printed the plastic parts for.

If you’re interested in finding out more about the history of 3D printing, click here.

Best RepRap 3D Printer: The Criteria

Judging these printers was different to how we usually rank our printers. This is because many printers that were revolutionary in their time have since been outclassed by newer and more powerful machines. We therefore graded these RepRap printers on:

This is because many printers that were revolutionary in their time have since been outclassed by newer and more powerful machines. We therefore graded these RepRap printers on:

- Price-performance ratio: does it perform well for the price?

- Versatility: can it print many materials?

- Reliability

- Must be a RepRap printer or inspired by the RepRap movement.

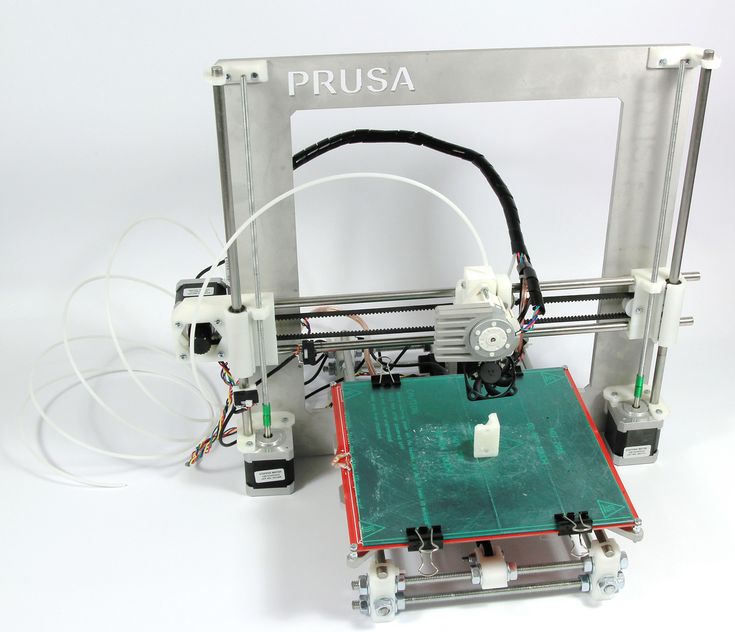

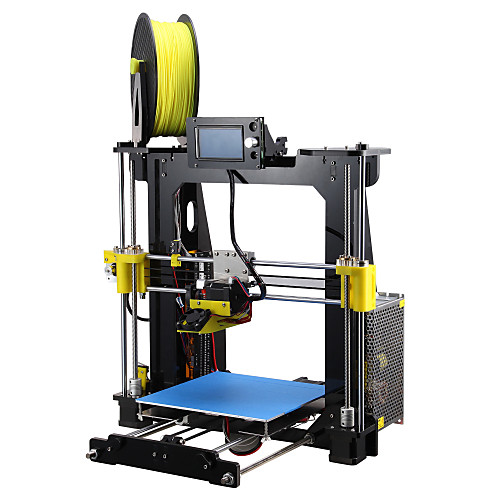

1. Prusa i3 MK3S

- Company based: Czechia

- Price: $749 as a kit — Available on Prusa store here / $999 fully assembled — Available on Prusa store here

- Build volume: 250 x 210 x 200 mm

The myth. The printer. The legend. The Prusa RepRap kit is the unmistakable king of RepRap 3D printers. There’s a reason why Josef Prusa’s invention shot him into the 3D printing stratosphere and landed him a place on Forbes’ 30 under 30 list — the printer is incredible.

Sporting a 250 x 210 x 200 mm print volume as well as up to 50-micron layer resolution, the Prusa i3 is accurate and reliable. It’s designed to be simple to use, and true to the RepRap philosophy can print all its plastic components. As a result of its success, Josef Prusa has had to print over 200 more Prusa 3D printers, so this Prusa farm can print enough Prusa 3D printers to keep up with demand! Prusaception.

It’s designed to be simple to use, and true to the RepRap philosophy can print all its plastic components. As a result of its success, Josef Prusa has had to print over 200 more Prusa 3D printers, so this Prusa farm can print enough Prusa 3D printers to keep up with demand! Prusaception.

If you’re looking for a consistent and high-quality RepRap 3D printer or 3D printer kit, look no further. You can buy your Prusa 3D printer pre-assembled, or build your own to save a few hundred dollars. It prints with layers up to 0.05mm for great precision and surface finish, features a spring metal build plate for changeable PEI sheets, and is also a fast 3D printer, able to travel at over 200mm/s.

For business who want to print tougher filaments like Polycarbonate or Nylon, the Prusa i3 MK3S can handle that, too. The extruder heats up to 300C, and the high quality E3D V6 nozzle can handle even abrasive filaments. You can even upgrade the Prusa to print 5 different color filaments simultaneously with the $300 Multi Material Upgrade kit.

- You can purchase Prusa’s Multi Material Upgrade Kit here.

Overall, we cannot recommend it enough, and it will go down in the 3D printer hall of fame in years to come.

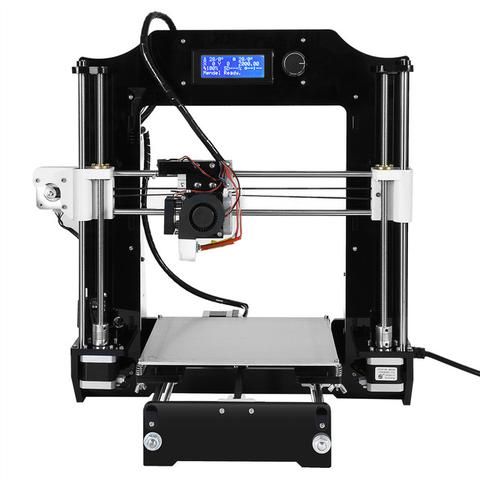

The Prusa i3, encompassing printers such as the MKS3 shown above, is the undisputed king of RepRap 3D printers.2. Creality Ender 3 Pro

- RepRap 3D printer price: $190 — Available on Creality Official Store here / Available on Amazon here / 3DJake UK & Europe here

- Print volume: 220 x 220 x 250 mm

Creality 3D printers are known for their simplicity to assemble, and the Ender 3 Pro is a great example of that. Creality say that you can completely assemble it from package to print-ready in 10 mins using 20 screws, though for new makers this is likely to be quite optimistic.

- View the full specs in our Ender 3 review.

The high quality extruder reduces the chances of the Ender 3 clogging during printing, and Creality have upgraded a number of key areas in the Pro version of the Ender 3. These include an upgraded power supply, improvements to print bed leveling, and a new print bed system to prevent warping and make finished prints easier to remove.

These include an upgraded power supply, improvements to print bed leveling, and a new print bed system to prevent warping and make finished prints easier to remove.

Experienced makers know that the Ender 3 Pro is absolutely up there with the best low cost RepRap kits. It’s very accurate for the price, with precision of up to 100 microns, and it combines this with workhorse-like reliability. You get a good size print volume, fairly fast print speed (up to 180 mm/s), and it’s also fairly quiet. You get very good quality prints and reliability for a 3D printer under $300, and we highly recommend it to anyone willing to invest the time to master it.

3. Prusa Mini

- Company based: Czech Republic

- Price: $399 — Available on Prusa Store here

- Build volume: 180 x 180 x 180 mm

For those who want most of the Prusa MK3S’s main benefits, but in a more compact package and for cheaper, the Prusa Mini could be perfect for you. With a smaller 180 x 180 x 180 mm build area, it’s a smaller printer that can fit on most desktops, but it can still calibrate itself, and offers the same 0. 05mm precision for great quality prints.

05mm precision for great quality prints.

Whereas the MK3S comes with a filament sensor, for the Mini this is an optional upgrade. Moreover, with slightly lower extruder temperatures, you can’t print tougher filaments like Polycarbonate on the Mini, but you can still print filaments like PETG, PLA, ABS, ASA and flexible filaments.

The Mini comes with Prusa’s own PrusaSlicer 3D slicer, and if you run into any problems, you can speak with Prusa’s support team 24/7. Overall, it’s a great lower cost RepRap 3D printer for great quality, reliable prints at a lower price.

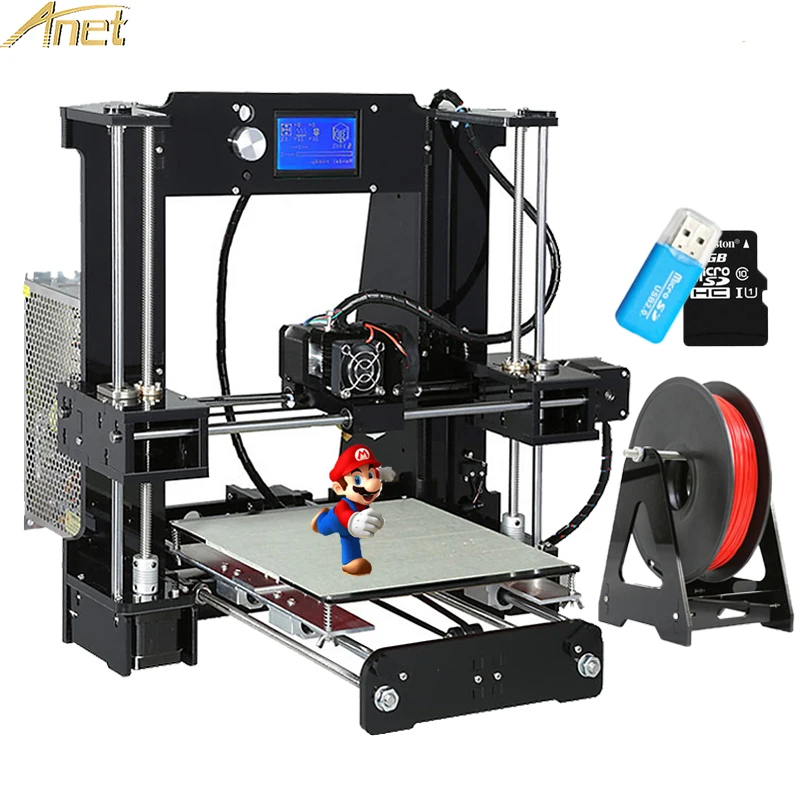

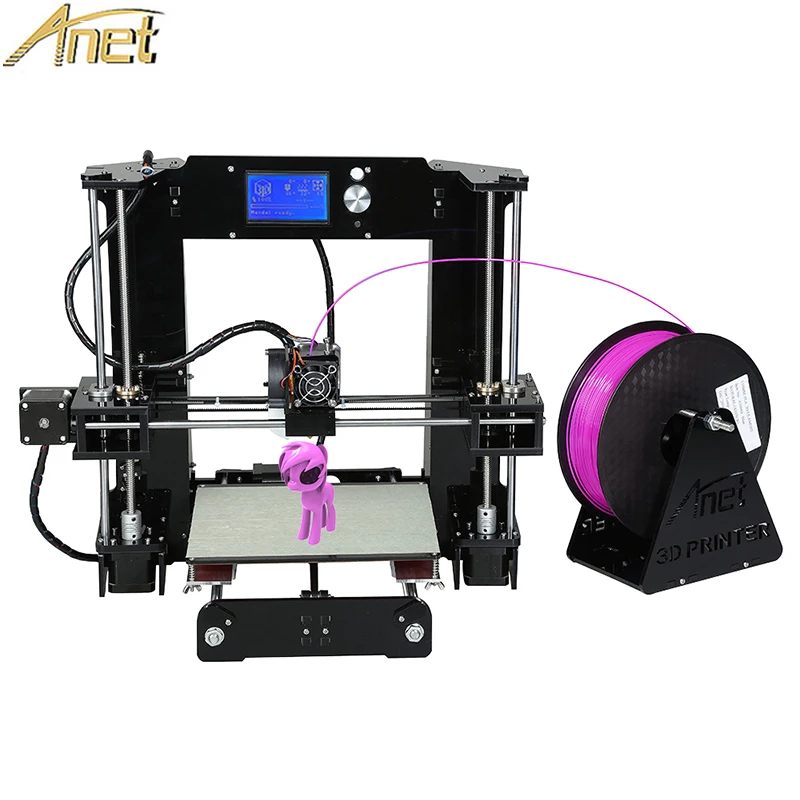

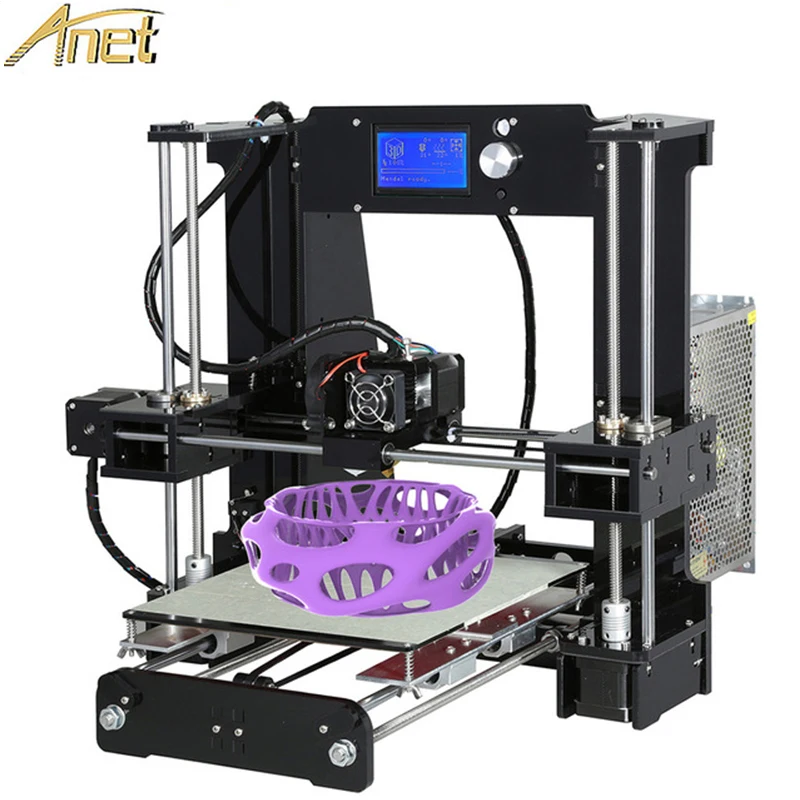

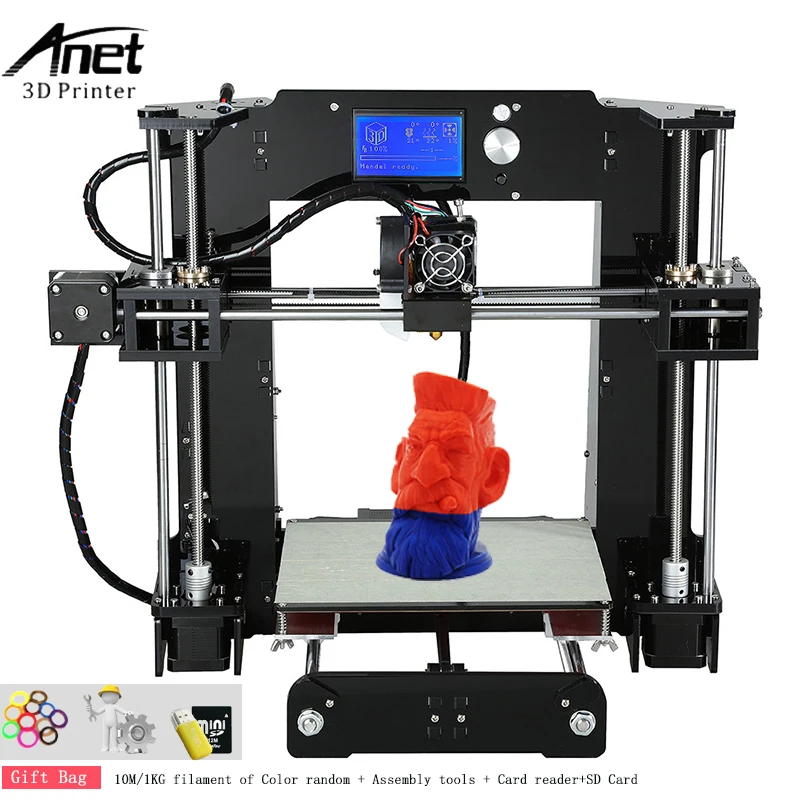

4. Anet A8

- Company based: China

- 3D printer price: $160 — Available on Amazon here

- Print volume: 220 x 220 x 240 mm

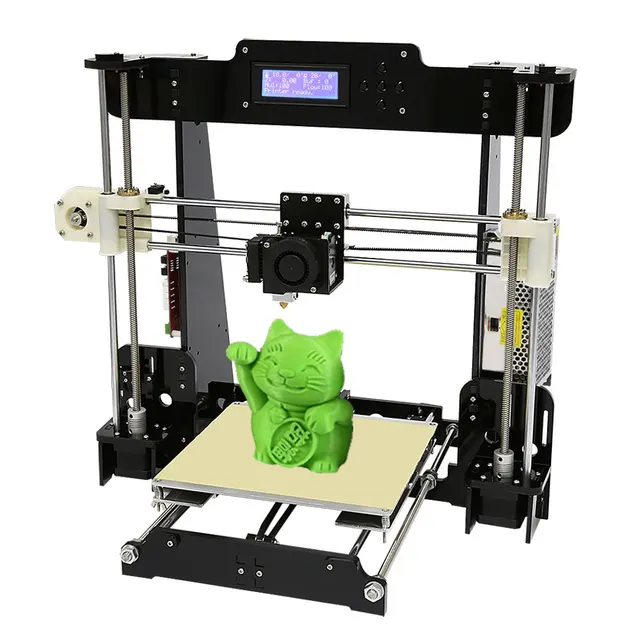

We feel the Anet A8 counts as a RepRap 3D printer since it is Anet’s spin on the Prusa, one of the most famous RepRap kits. It’s cheap and cheerful — you get what you pay for with this DIY 3D printer kit, with extra marks for its consistency and versatility. It’s versatile as it can print so many 3D printer filaments: PLA, ABS, PVA, Nylon, PP, wood and more.

It’s versatile as it can print so many 3D printer filaments: PLA, ABS, PVA, Nylon, PP, wood and more.

For under $200 you can’t expect peak performance, though the minimum layer height of 0.1mm is fine for most printing. Despite not having a weighed down aluminium frame or a dual extruder, the Anet A8 is fairly precise. The stainless steel rail rods, gears and bearings make the printing process more steady, though stability will be slightly worse than if the structure was made of metal.The different parts of the Anet A8 to assemble this DIY kit.

The Anet A8 does not come assembled; you’ll need to build it yourself following Anet’s step-by-step instructions. Most find this more rewarding than buying a plug & play 3D printer, and it’s a great way to learn more about how they function. You can print with your Anet A8 using 3D slicers including Cura and Repetier-Host, and transfer your 3D printer models over via SD card.

Despite the cheap price, the Anet A8 comes with a few neat features. It comes with a heated bed, meaning it can print ABS and PETG, rather than just PLA. It’s also got quite a large printing volume: 220 x 220 x 240 mm. Overall, if you’re looking for a RepRap 3D printer which doesn’t break the bank and gets you started in 3D printing, the Anet A8 is a great option at just $200.

It comes with a heated bed, meaning it can print ABS and PETG, rather than just PLA. It’s also got quite a large printing volume: 220 x 220 x 240 mm. Overall, if you’re looking for a RepRap 3D printer which doesn’t break the bank and gets you started in 3D printing, the Anet A8 is a great option at just $200.

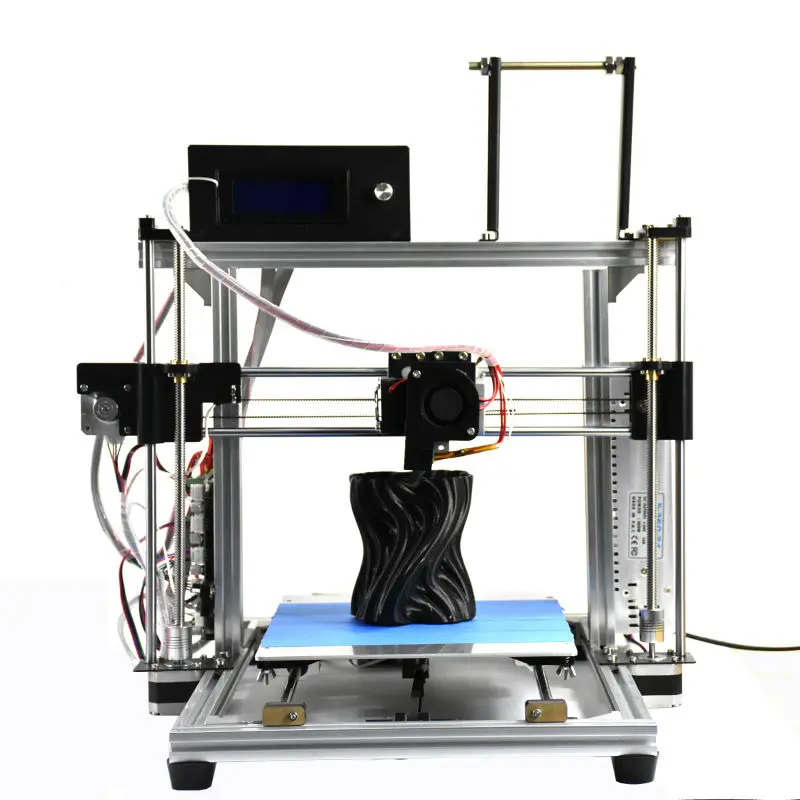

5. Creality CR-10 / CR-10 V3

- Price: $369 / $499 — Available on Amazon here / 3DJake UK & Europe here

- Build volume: 300 x 300 x 400 mm

Creality are known for releasing some of the most highly rated and reliable low cost RepRap 3D printer kits in recent years, with multiple iterations of the popular CR-10 available. We’ve picked both the original CR-10 and the V3, so you can choose between the upgraded but more expensive version, or the lower cost and classic original.

Though a RepRap kit at heart, the CR-10 can be assembled in under an hour without much DIY skill, making it a good 3D printer for beginners.

Not only is it reliable, but for the price it can print huge models, at up to 300 x 300 x 400 mm. It truly is a large 3D printer. In addition, the ability to print with a minimum layer thickness of just 0.05mm is very precise for a RepRap 3D printer kit for $500.

It truly is a large 3D printer. In addition, the ability to print with a minimum layer thickness of just 0.05mm is very precise for a RepRap 3D printer kit for $500.

Complementing this printing precision is the stronger and heavier frame supported by triangular z-axis beams that feature on the CR-10 V3 — but not on the standard CR-10. The frame shape has changed to a more triangular shape — more similar looking to the original RepRap Mendel! — in order improve print stability and reduce the Z axis wobble, key to improving print quality.

The CR-10 also has a filament breakage detector that pauses if it detects any issues without ruining your print, and can automatically resume printing in the event of a power outage. These are key features that you really don’t appreciate until disaster strikes 49 hours into a 50 hour print and they save you — but are an absolute life-saver. Overall, we highly recommend the Creality CR-10 V2.

All the Creality CR-10 source files are available here.

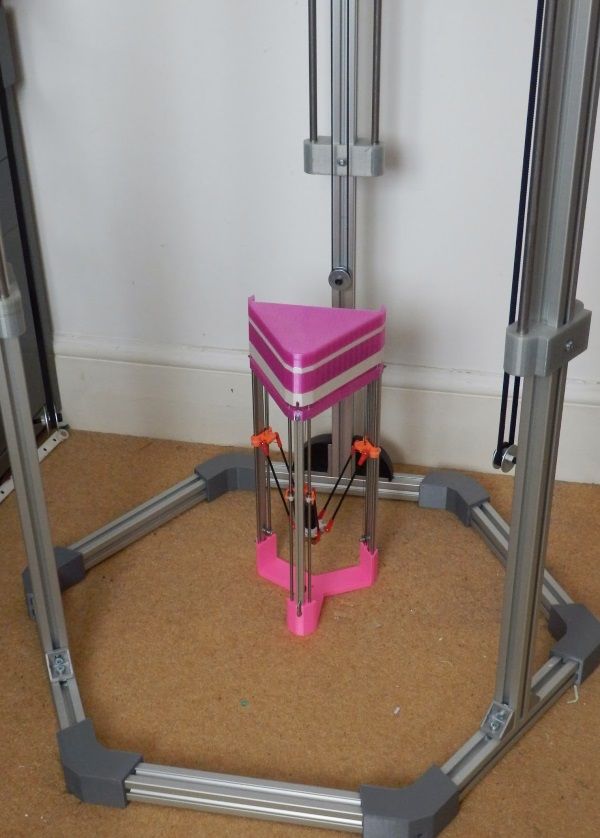

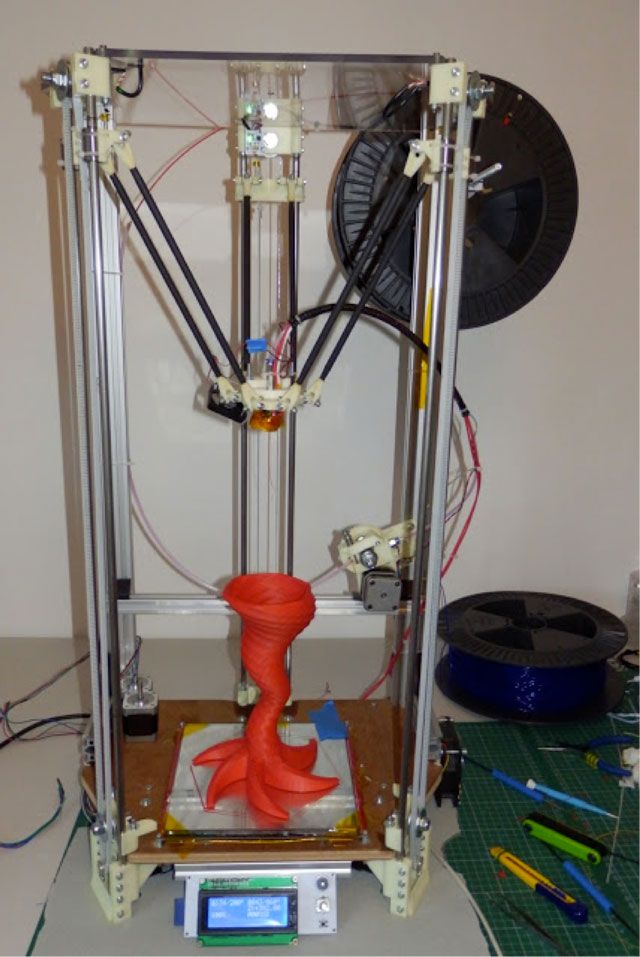

6. FLSUN QQ-S Delta — Upgrade on the RepRap Kossel

- Price: $369 — Available on Amazon here

- Build volume: 255 x 255 x 360 mm

- We have also tested and reviewed the FLSUN QQ-S, which you can view if you click our FLSUN QQ-S review.

There are a number of great RepRap Kossel 3D printers, including the FLSUN QQ-S that we were very impressed with in our 3D printer review. The FLSUN QQ-S is a delta 3D printer that you can buy almost fully pre-assembled for $369. Delta 3D printers are typically tall and thin, with the FLSUN QQ-S able to print up to 360 mm tall prints, with an XY axis of 255 mm.

Kossel RepRap machines were thought of as tougher to master 3D printers for more experienced makers. Now with the FLSUN QQ-S the learning curve is far reduced, especially since the RepRap upgrade ships to you almost completely assembled. The 3.2-inch touchscreen is very easy to use, and the printer comes with an SD card with the 3D slicer software on it, though you can also connect to the printer via WiFi.

Another main selling point is that it’s noticeably (or perhaps unnoticeably!) quiet — FLSUN claim it prints at under 50 dB. This, coupled with the fans and cooling system to avoid overheating and reduce any bad smells, makes the FLSUN QQ-S a great RepRap printer for your home. It retains the quick printing, around 30% faster than the average printer, so if time is of the essence, you could do worse than go with the FLSUN QQ-S.

It’s accurate, quiet, fast and doesn’t take up too much space on a desktop. We recommend it highly. The only drawback is that it may not seem as truly RepRap as it comes more or less pre-assembled, but it evolved from the original RepRap Kossel design so we feel it is worthy of inclusion.

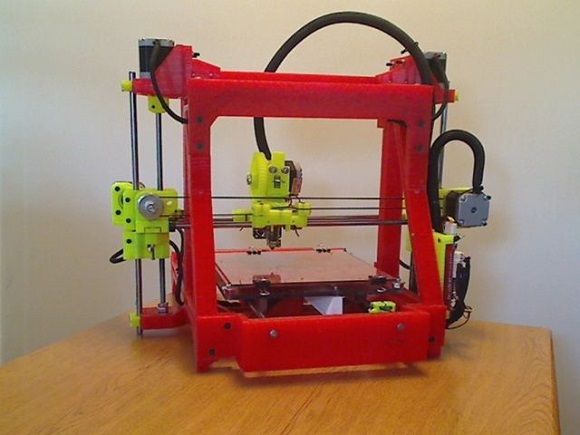

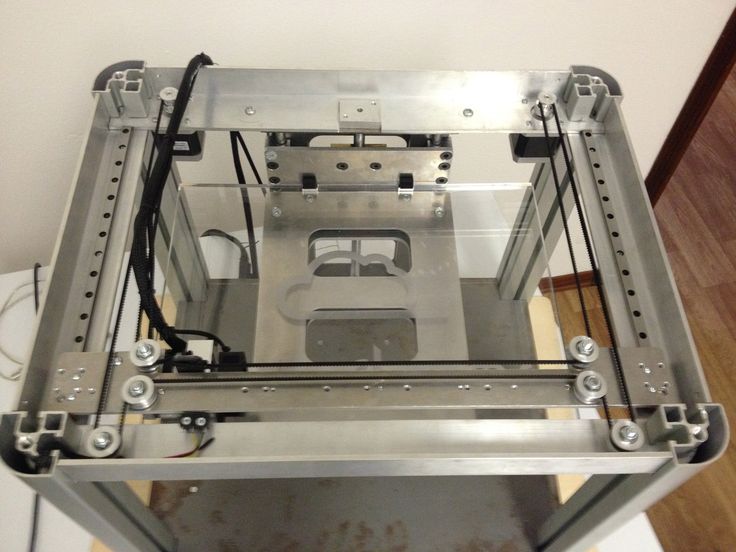

BONUS — RepRap Mendel — Legendary RepRap 3D Printer

The first RepRap 3D printer on this list chosen because of its legacy rather than present performance, the RepRap Mendel is a true veteran of the game. The second iteration of the RepRap machines, the Mendel was the successor to the Darwin machine. It was designed and created by Ed Sells, a student of Dr Adrian Bowyer.

It was designed and created by Ed Sells, a student of Dr Adrian Bowyer.

Named after Gregor Mendel, the ‘father of genetics’, this RepRap 3D printer weighs around 7kg and can print a fairly large 200 x 200 x 140 mm. Though it has a number of improvements over the Darwin, the sheer nostalgia and impact the Darwin has had since its introduction over a decade ago puts it above the Mendel for us.

The RepRap Mendel, the second iteration of the original Darwin 3D printer.For more RepRap-related information and further reading:

Our interview with Dr Adrian Bowyer, discussing founding the RepRap movement

Our long-form feature story on the entire history of 3D printing

Our ranking of the best DIY 3D printer kits

Ways to get a free 3D printer

Build a reprap - RepRap

This page has been flagged as containing duplicate material that PartsSupplies also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that Darwin/Buyers Guide also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page has been flagged as containing duplicate material that What Tooling Do You Have also attempts to cover.

These pages should be merged such that both pages do not attempt to cover the duplicate topics.

This page is out of date --Sebastien Bailard 04:34, 31 October 2010 (UTC)

This page is not only out of date, but contains in part simply nonsense - especially the "Software installation" section. For the lack of editors, this page should be removed. --Traumflug 21:18, 13 April 2011 (UTC)

Contents

- 1 Build a RepRap

- 2 Overview

- 2.1 Object Creation Software

- 2.2 System control Software

- 2.3 Installing the Software (experimental)

- 2.4 Thermoplast extruder

- 2.5 Positioning system

- 2.

6 Shopping list

6 Shopping list

There are multiple ways to build a RepRap or RepStrap; the method selected for these instructions has been chosen to minimize skills and tools needed. If you wish to explore other options click Alternative Build Documentation.

The Classic RepRap Design is "Darwin" pictured on the right. There are very full and accurate building instructions in Make Your Own RepRap.

The RepRap was carefully designed to use only parts that can be made on a RepRap and other cheap parts that you can get anywhere. It was also designed to require few skills to assemble. The one snag is you have to find someone to supply you with the parts that must be made on a RepRap.

RepStrap Darwin Clones are RepRap designs which are fairly accurately copies of the Darwin design but the RepRapped parts are replaced by parts created some other way, Perhaps molded plastic or laser cut acrylic or plywood. Generally parts of one of these machines are interchangeable with RepRapped Darwin parts. Here are some Parts Suppliers.

Here are some Parts Suppliers.

Other RepStraps, these are 3D printers capable of making RepRap (Darwin) parts but are not structurally similar to Darwin. These machines may vary a lot but may be separated into two kinds. Those like Darwin in which the extruder (print head) is moved in the x and y directions and the work is slowly lowered as the print progresses and others where the work is moved in the x and y directions under a stationary head which gradually moves upwards as the print progresses. Here are some references to various RepStrap Machines.

If this is your first RepRap that you are building, here is a basic guide of which build option you should choose:

- If you have a friend nearby that can print out the RepRap part on their RepRap or some other 3D printer. Choose the Classic Darwin

- If you don't have access to a 3d printer then you have 3 options.

- You can build a Classic Darwin, but this means you will have to use a commercial service to print out parts for you; it can easily cost over $1000 for just those parts depending on what deals you can get.

This option is probably the most expensive option.

This option is probably the most expensive option. - You can build a RepStrap Darwin Clone. This means you can either buy a lasercut acrylic kit from Bits from Bytes or make some part yourself by machining them. This option is becoming the more common option especially because soon you will be able to buy a lasercut kit from Ponoko which has offices in the US. This is also usually cheaper than the first option.

- The third option is to build non-clone RepStrap that does not have the same frame as a Darwin, such as McWire which uses pipes for the frame. This option is usually the cheapest, but each RepStrap has it own weaknesses. The good thing is that when complete they can print out parts so that you can build a Classic Darwin. The electronics are compatible with Darwin so you only have to buy them once.

- You can build a Classic Darwin, but this means you will have to use a commercial service to print out parts for you; it can easily cost over $1000 for just those parts depending on what deals you can get.

A RepRap or RepStrap (A RepRap can build itself, a RepStrap can build something that can build itself) can be divided into several key areas:

- Object creation Software

- System control Software

- Thermoplastic extruder

- Positioning system (the Cartesian Bot)

- The electronics to control the positioning system

Object Creation Software

Art of Illusion is currently the software most recommended for designing objects to be printed. It's not a CAD package but it is easy to use. The software allows you to create and manipulate 3D shapes. You can store these shapes in STL file format. STL files are object files that are used in Rapid Prototyping. These STL files can be printed off into real 3D objects using your 3D printer (RepRap).

It's not a CAD package but it is easy to use. The software allows you to create and manipulate 3D shapes. You can store these shapes in STL file format. STL files are object files that are used in Rapid Prototyping. These STL files can be printed off into real 3D objects using your 3D printer (RepRap).

The software is free (GNU GPL version 2) and it is available for Mac OS X, Windows and Linux. If you want to try it out without installing it's available bundled in the Linux distribution liveCD with the rest of the hosted software for the RepRap project.

System control Software

RepRap is controlled via USB or an RS232 interface. You may find a description or download from RepRap Host Software.

There is a RepRap variant which allows you to print an object from a file saved onto a SD card.

Installing the Software (experimental)

This set of instructions tells you how to set up all the software you need for a Reprap in one big blow under Linux Debian.

It involves 5 steps that anyone should be able to complete in a few hours of his/her spare time.

It's easy.

Really.

Warning: Proceed at your own risk. The instructions are not double checked yet.

Prerequisites

You'll need

- a PC (not too old)

- broadband internet access

- some time

Step 1: If you have Windows, go to [Here], get your copy of the Debian installer with one click and start it.

If you already have Linux: Install Debian Lenny some way or the other (you know how to do that ;-)) and continue with Step 3.

Step 2: Follow the instructions. I suggest installing on a 4GB USB stick - but you can also install it all on your hard disk. Be careful to select "testing" instead of stable - this installs Lenny instead of etch. Otherwise the standard settings should be ok in most cases. Don't say "yes" to things you might regret. After a while, a standard system should be installed. Don't forget to install the GRUB boot loader.

Don't forget to install the GRUB boot loader.

Step 3: Log in and say

sudo apt-get install firefox

on the command line.

Step 4: Start firefox and download this Media:Reprap_setup.sh script.

Step 5: Run the script from the shell with

sudo ./Reprap_setup.sh"

Now all the software specific to Reprap is retrieved and installed.

This includes the AVR-Tools, Subversion, Java3d, the Reprap-source tree etc. Installing all that will take some time.

Having successfully reached this point you should try to start the software in reprap-host with:

ant run

If you now see the main window of the host software, you're done.

Congrats! You have made it!

You still have to learn how to use it - but that is another story and another tutorial.

Thermoplast extruder

There are three different extruders all of which, in the end, perform the same function. There is the "official" extruder that can be made by another RepRap. Then there are the kits which are mass produced so it is easier to start printing your first parts. Both kits are designed to be interchangeable with the official extruder.

Then there are the kits which are mass produced so it is easier to start printing your first parts. Both kits are designed to be interchangeable with the official extruder.

- RepRapable Thermoplast Extuder

Can be made by another RepRap or commercial rapid prototyper. These are not the only ways the parts can be made but are the easiest. Some builders have made them from machining aluminum or plastic. Others by making molds and casting from resin. This is only for the main pieces of the extruder. The drive screw and other mechanics must be bought or machined. - Kit from Bits from Bytes (laser cut acrylic)

There is an extruder kit currently available from Bits from Bytes who are based in the UK. The kit is part of the silver or gold kits and doesn't need ordering separately unless you want a spare. Assembly instructions are available on the Bits from Bytes website in the 'Assembly Instructions' area:

Bits from Bytes Extruder Assembly instructions

Bits from Bytes Extruder 3d Model - the model requires a recent copy of Adobe Acrobat.

There are videos of the construction process, in the 'Tutorials' section of the website.

Bits from Bytes Heater Barrel Assembly

Bits from Bytes Extruder Drive Assembly

- Kit from Ponoko (laser cut plywood)

A kit will soon be available via Ponoko which has offices in the US.

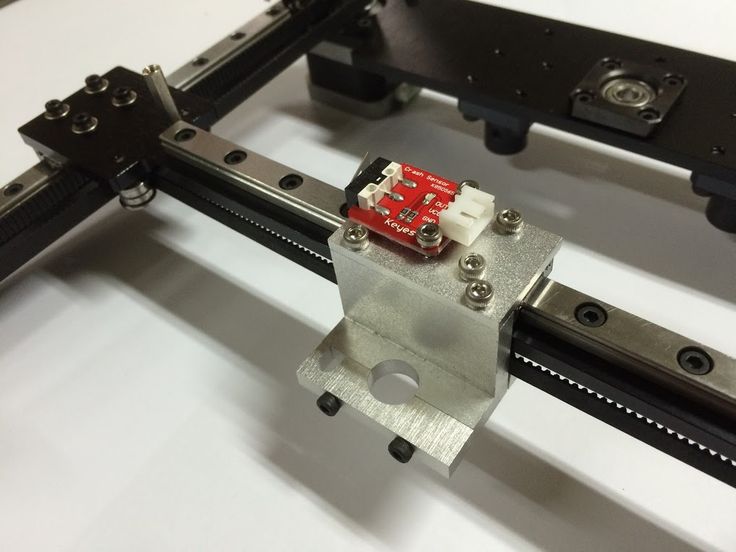

Positioning system

The positioning system is the greatest part of the size of a RepRap. It is what moves the extruder head from place to place. Kits are available from Bits from Bytes, either the FULL Mechanical Kit - Silver or Gold contain all the components necessary to build a positioning system and extruder. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Assembly Instructions

Shopping list

The following list contains all the components necessary to build a RepStrap and enough plastic to print a RepRap. Some handtools are required for assembly, but the only power tool used is a soldering iron.

Extruder and Positioning System

Bits from Bytes - FULL Mechanical Kit - Silver or Gold

Ponoko - coming soon

(only one required)

Electronics

Plastic

The extruders all use 3mm diameter plastic filament/wire. ABS is the recommended plastic for its combination of strength, availability and dimensional stability. Suitable plastic is available from RRRF in 5lb reels. It is also available by request from plasticweldingrod.com.

Total

Shipping and tax vary by country of order but $1000 total is a reasonable approximation.

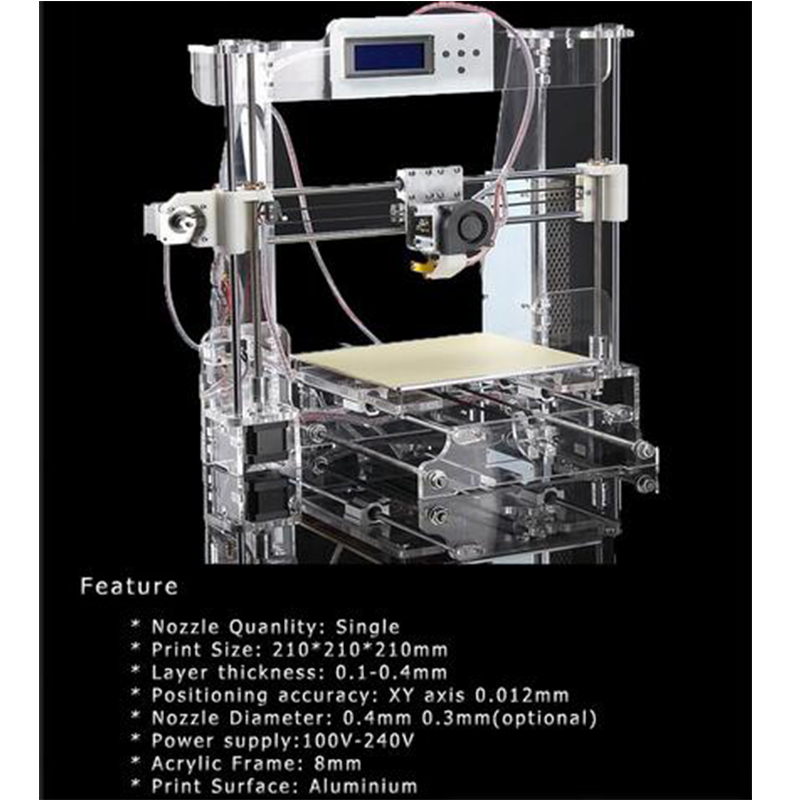

RepRap Prusa i3, reviews and customer reviews.

The third version of the i3 3D printer from Prusa received a more rigid frame and became easier to assemble. It is designed to print all kinds of plastic.

Here, as in other Prusa RepRap printers, a modern E3D extruder is used. The printer is equipped with an LCD display with a standalone function that allows you to work with it without using a computer. The necessary parts for assembling the printer can be purchased separately or as a ready-made kit that contains all the necessary tools for assembly and detailed instructions. nine0003

The necessary parts for assembling the printer can be purchased separately or as a ready-made kit that contains all the necessary tools for assembly and detailed instructions. nine0003

- AliExpress

- Hobby

- Made by hands

Tronxy P802MHA Large Black 3D Printer

I must say that I approached the choice of a 3D printer with all possible irresponsibility. Namely, having read all sorts of horror stories about customs and alignment (more about alignment), I was guided by models that had automatic print head alignment. nine0003

This is the first one. And the second issue on the agenda was delivery, which, as they were afraid, could be a problem. So it's no surprise that I was overjoyed when I discovered that some sellers on Aliexpress ship "from Russia to Russia". In fact, of course, no: they just somehow transport goods to the nearest Russian city, and from there they send them out by forwarding companies.

In fact, of course, no: they just somehow transport goods to the nearest Russian city, and from there they send them out by forwarding companies.

read more nine0003

I plan to buy +79 Add to favorites Liked the review

+153 +251 nine0003

- 3d printers,

- RepRap,

- RepRap Prusa i3

- AliExpress

- Goods prof.

use

use

Reprap Prusa i3 3D Printer Cabinet Base

Hello everyone!

There have already been many reviews of 3D printers on the site, but this one has not yet been reviewed. nine0020 Essentially the same well-known Reprap Prusa i3, but almost ready to use.

There will be no dismemberment, tracking tracks, a photo of a packed package, and any cats :-) Briefly and to the point

read more

I plan to buy +64 Add to favorites Liked the review nine0003

+58 +115

- 3d printers,

- RepRap,

- RepRap Prusa i3

- AliExpress

- Hobby

- Tools nine0013

- 3d printers,

- RepRap,

- RepRap Prusa i3

Prusa i3 3D printer kit

The idea of buying a 3D printer, I caught fire for a long time. Almost as soon as they were announced. Well, or rather, 3D printers have been around for a long time, but they appeared in the domestic sector relatively recently. And it all started with the Rep Rap model. the first repraps looked very scary, they were assembled half from building materials (studs and bolts) and half from plastic parts printed on another printer. It only remained to add stepper motors, HotEnd and control electronics. These are the parts that you cannot buy in a regular store and accounted for the bulk of the cash costs. Ready-made models from the moment RepRap appeared on the lips of ordinary people and almost until last year cost quite significantly. prices were, and still are, in the region of $5,000 to $1,000. To the cherished mark of 300 bucks, the price did not want to fall. There were some projects on Kickstarter, but all this was not the same. nine0020 And now, finally, a wave of 3D printers has reached Chinese manufacturers. A company has emerged that has put on stream kits "build it yourself" 3D printers at a very competitive price: $ 300-270.

Almost as soon as they were announced. Well, or rather, 3D printers have been around for a long time, but they appeared in the domestic sector relatively recently. And it all started with the Rep Rap model. the first repraps looked very scary, they were assembled half from building materials (studs and bolts) and half from plastic parts printed on another printer. It only remained to add stepper motors, HotEnd and control electronics. These are the parts that you cannot buy in a regular store and accounted for the bulk of the cash costs. Ready-made models from the moment RepRap appeared on the lips of ordinary people and almost until last year cost quite significantly. prices were, and still are, in the region of $5,000 to $1,000. To the cherished mark of 300 bucks, the price did not want to fall. There were some projects on Kickstarter, but all this was not the same. nine0020 And now, finally, a wave of 3D printers has reached Chinese manufacturers. A company has emerged that has put on stream kits "build it yourself" 3D printers at a very competitive price: $ 300-270.

read more

I plan to buy +172 Add to favorites Liked the review nine0003

+170 +337

Category "RepRap" - a community of 3D printer owners 3DToday

A section for real do-it-yourselfers: all sorts of information on building and improving handicraft printers.

xolodny

Loading

12/17/2022

341

RepRap

nine

Subscribe to the author

Subscribe

Don't want

From such a device I have

A compact, easy-to-use feeder for a "short" feed of a bar into a hot end. It was originally designed with a cable drive as an alternative to the Zesty Nimble for Delta Cybenimatic typewriters. Then, after rethinking, it was finalized to install Nema8 with a feeding unit with a "groove". nine0003

And when I ran into the limitations of this drive (it turned out to be a very demanding assembly for manufacturing accuracy) - I remade it into a "drum" ...

Read more

Mix_vrn

Loading

12/16/2022

1442

RepRap

24

Subscribe to the author

Subscribe

Don't want

Good day to all!

Do not judge strictly. This is my first note and the first product of this kind. nine0003

This is my first note and the first product of this kind. nine0003

It all started this spring. There was an acute desire to do something interesting and necessary. And at the same time CNC. Well, it was really interesting to try it, everything was itchy. And the choice initially fell on a portal milling cutter. Despite the fact that there was a chance to somehow monetize this product. And even drew a machine tool in the Compass. Counted everything. And wept. I didn't want to make a toy...

Read more

xolodny

Loading

03.12.2022

2587

RepRap

fifteen

Subscribe to the author

Subscribe

Don't want

I had SUCH a project that went to be rethought and then on the shelf.

SOURCES are here. You will have to deal with them on your own. The most current version has been lost somewhere, but it will be possible to do something from a frame with the Z axis from one file and X beam details from another.

You will have to deal with them on your own. The most current version has been lost somewhere, but it will be possible to do something from a frame with the Z axis from one file and X beam details from another.

The reason for sending to the shelf - over-engineering. Some solutions included in this unit, even taking into account the prospects for modernization, turned out to be redundant and expensive....

Read more

RepRap

79

Subscribe to the author

Subscribe

Don't want

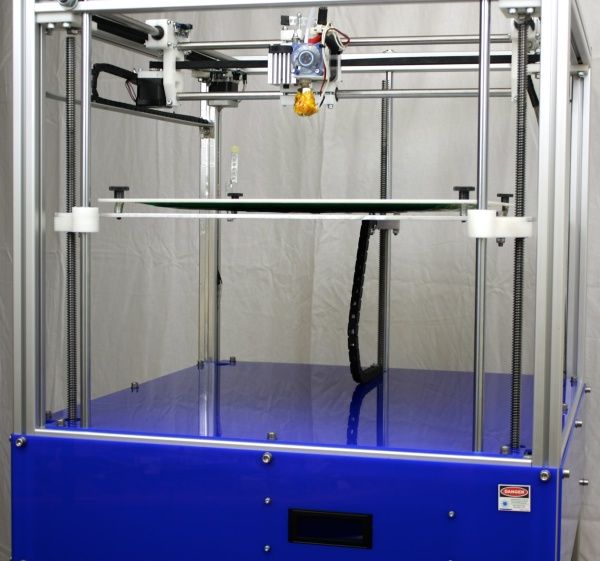

Good afternoon, dear friends. I decided to tell you a little about my giant, which I put on a laptop with the help of "solid" and assembled it in a room from which it cannot be pulled out :) :) nine0003

Chinese classical head, the only water-cooled head. Brass block, nozzles from 0.6 to 1.2.

Table for 4 ball screws and 4 screws 23

Var. ..

..

Read more

xolodny

Loading

11/30/2022

1911

RepRap

27

Subscribe to the author

Subscribe

Don't want

Even when I was posting the first reports on the creation of this fat man, some of the candy lovers asked when it would be possible to purchase something like this

In short, this is IDEX. "IDYOKH" in our opinion. Indypendent extruder. Independent all of himself, krch. A printer that has two print heads at once or one at a time. He can do anything.

It can print with two multicolor printing materials:

It can print with easily detachable and soluble...

Read more

xolodny

Loading

11/26/2022

1128

nine0004 RepRap17

Subscribe to the author

Subscribe

Don't want to

I deliberately postponed this publication until the end of the contest, so to speak, to stay out of it)))

In September I reported ON THE END OF THE PROJECT, I should tell you how he is doing now.

In general, it all started a long time ago - when I was just about to get my first printer in 2017, I literally fell ill with an E3d device called "BigBox". nine0003

Then I had a sheet of composite in an interesting color, a bunch of spare parts...

Read more

RepRap

thirty

Subscribe to the author

Subscribe

Don't want

It's been a while since I've written anything about bringing Imprint's creative work back to normal. Basically, my hands didn’t reach to model the head, so that in addition to blowing from the second side (which I originally wanted, but the priority was normal stable operation, and then fans, lights and other fun and blinking) add a new interesting sensor for removing the table map. nine0003

Let's just say that as soon as I started typing the octopus, I realized that the table was terribly. ..

..

Read more

M448

Loading

11/16/2022

2845

RepRap

nine

Subscribe to the author

Subscribe

Don't want

Good day, dear colleagues.

FB902 was bought a long time ago and various models were printed on it, including PLA (recently), ABS (initially), but the print quality was not satisfactory, and the table dimensions 220x220 left no room for creativity. nine0003

I decided to make a printer with a print area larger than 310x310 mm.

Dashing trouble, the beginning.

What's so complicated, now we'll do everything.

It seems that the most difficult p...

Read more

RepRap

28

Subscribe to the author

Subscribe

Don't want to

I began to miss Mitya's print area, and the features of delta kinematics involve scaling with reference to the diameter, but here the places in my workshop turned out to be only 480 * 380 - the delta is not suitable in any way climbs. I don't need two printers either, so the delta is either for sale or for spare parts. I did not want to sell my favorite machine for nothing, so it was decided to put it on the organs. Of the organs, the 12th Khiva rails and the brain of Duet2 Wifi seemed the most valuable. Plus...

I don't need two printers either, so the delta is either for sale or for spare parts. I did not want to sell my favorite machine for nothing, so it was decided to put it on the organs. Of the organs, the 12th Khiva rails and the brain of Duet2 Wifi seemed the most valuable. Plus...

Read more

petez

Loading

11/07/2022

3523

RepRap

fifteen

Subscribe to author

Subscribe

Don't want to

The Voron V0 is a great printer. However, there are a few things I didn't like about it. And there are a couple of tasks that I would like to implement in an FDM 3D printer, and, in particular, high-precision printing from thermoplastics. nine0003

The main thing that annoyed me on my V0 was the need to turn the bolts in order to level the table.