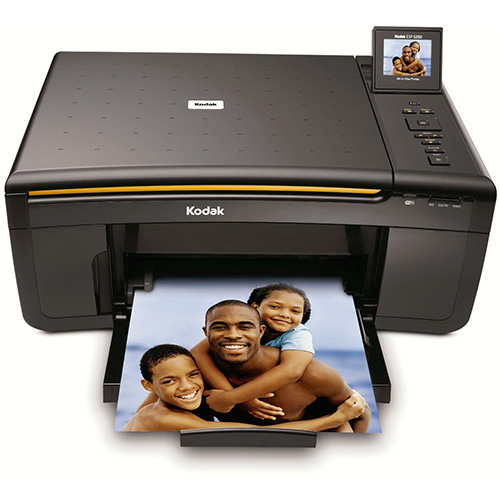

Kodak 3d printer

KODAK Portrait 3D Printer is now available in North America…

Kodak and Smart International, the authorized global brand licensee of 3D printing, are pleased to announce North American and European availability of the KODAK Portrait 3D Printer. In conjunction with this announcement, The KODAK Portrait 3D Printer will be on display at the Formnext industry tradeshow in Frankfurt, Germany, November 13th – November 15th.

Positioned for the 3D desktop professional market, the KODAK Portrait Printer consistently delivers accurate results and remains user-friendly. The KODAK 3D Printer will approach this growing arena of imaging with distinctive features such as the dual extrusion system and a fully enclosed all-steel structure, allowing high-temperature builds, and is complemented with enabling software and a wide range of high-quality materials.

The dual extrusion system features automatic nozzle lifting and swappable PTFE and all-metal hotends for optimal material compatibility. Featuring an intuitive touchscreen, automatic leveling and calibration, and preset print parameters for every material, the KODAK Portrait 3D Printer is ready to use straight from the box for those already familiar with the technology or newcomers with creative needs.

With free access to the KODAK 3D Cloud, an IT-compliant printer management software created by 3DprinterOS, it is now possible to manage a print farm for any number of machines, in any number of locations, from anywhere in the world. Users can access via Wi-Fi or LAN port and slice online, monitor their prints and receive over-the-air updates.

Using the 3D printer, environments ranging from classroom, laboratory, office or studio, users can print highly-precise creative designs. The KODAK Portrait 3D Printer has a fully-enclosed print chamber with HEPA and activated carbon filter, reducing unwanted odors and keeping fingers away from hot moving parts. The wide range of filaments are not limited to different grades of PLA, but also offer ABS, Flex 98, HIPS, PETG, water soluble PVA and two grades of Nylon. They are specially manufactured and packaged to ensure low moisture and high dimensional accuracy, and come in a wide color palette, including, of course, Kodak’s Trade Dress Yellow.

They are specially manufactured and packaged to ensure low moisture and high dimensional accuracy, and come in a wide color palette, including, of course, Kodak’s Trade Dress Yellow.

The KODAK Portrait 3D Printer will be shown at Formnext in Booth J71 in Hall 3.1, where there will also be a press conference in Room Fragment on Thursday 15th November at 4:00pm.

“We are looking at the future of 3D printing and manufacturing, and our KODAK Portrait 3D Printer has been designed to be best-in-class, with capabilities that have the potential to disrupt the traditional manufacturing systems, leading to cost-effective solutions which can reduce environmental impact, with printers speaking to each other across the globe. We are very happy to have collaborated with Kodak and look forward to many future endeavors.’’ said Roberto Gawianski, CEO, Smart International.

“We are delighted to launch the new 3D printer with Smart International and build upon our excitement about this growth industry and the impact that it can have on professional 3D printing and imaging overall,” said Joel Satin, Director of Brand Licensing and Vice-President, Consumer and Film Division, Kodak.

To learn more about the printer and its capabilities, go to www.kodak.com/go/3dprinting.

And watch the full-length video of the printer in action here: https://youtu.be/9mHo-2Moar0.

About Smart International

Smart International has developed an ecosystem of solutions for professional 3D printing. Years of collaboration with engineers, designers, architects, artists, educators, have set the bar high. Only accurate and reliable technology with materials developed for a wide range of applications will help their creations endure and shine. Visit smart3d.tech for more information and Twitter @Kodak3dprinting, Facebook and Instagram.

About Kodak

Kodak is a technology company focused on imaging. We provide – directly and through partnerships with other innovative companies – hardware, software, consumables and services to customers in graphic arts, commercial print, publishing, packaging, entertainment and commercial films, and consumer products markets. With our world-class R&D capabilities, innovative solutions portfolio and highly trusted brand, Kodak is helping customers around the globe to sustainably grow their own businesses and enjoy their lives. For additional information on Kodak, visit us at kodak.com, follow us on Twitter @Kodak, or like us on Facebook at Kodak.

With our world-class R&D capabilities, innovative solutions portfolio and highly trusted brand, Kodak is helping customers around the globe to sustainably grow their own businesses and enjoy their lives. For additional information on Kodak, visit us at kodak.com, follow us on Twitter @Kodak, or like us on Facebook at Kodak.

Kodak 3D Printers | MatterHackers

The Kodak Portrait 3D Printer is a great machine for schools, offices, or any manufacturing environment. It has a build volume of 200x200x235mm, is fully enclosed, and has a HEPA filter. The 32-bit controller board with 5" color touchscreen makes it easy to control all 3D print settings. The printer is also WiFi capable, making it the perfect 3D print farm machine.

- Build volume: 200x200x235mm

- Fully enclosed

- HEPA filter

- 32-bit controller board with 5" color touchscreen

- WiFi capability

- Filament runout sensor

Guides & Articles

Tech Breakdown: Ultimaker S5 3D Printer Review

The Pros at MatterHackers break down and review all the new and improved tech in the first 3d printer from Ultimaker in their new 'S' line of products.

Tech Breakdown: Raise3D E2 3D Printer Review

The E2 is the first Raise3D 3D printer to feature independent dual extrusion for clean multi-material prints and duplicated print jobs.

Tech Breakdown: Lulzbot TAZ Workhorse 3D Printer Review

MatterHackers' pros take a look at why the Lulzbot TAZ Workhorse lives up to its name, making it a 3D printer to be reckoned with.

Tech Breakdown: Ultimaker S5 Pro Bundle Review

Building off the success of the Ultimaker S5, the Pro Bundle takes the printing experience to the next level.

Tech Breakdown: Ultimaker S3 3D Printer Review

A machine you can trust is absolutely essential for any professional, and the Ultimaker S3 passes with flying colors. Read on to see what makes it so reliable.

Tech Breakdown: Creality Ender 3 V2 Bundle 3D Printer Review

From the creators of the CR-10 and the ubiquitous Ender 3, the Ender 3 V2 improves on its predecessor in every way.

Tech Breakdown: BCN3D Epsilon W27 and W50 3D Printer Review

When you need to 3D print something big and in two materials, considering any of the BCN3D Epsilon 3D printers is a smart choice.

Tech Breakdown: Ultimaker 2+ Connect 3D Printer Review

The 3D printer that laid the foundation for Ultimaker gets spruced up and modernized. Let's take a look at the Ultimaker 2+ Connect and what makes it so special.

Tech Breakdown: Peopoly Phenom Resin 3D Printer Review

Building on the success of their other printers, Peopoly unveils the next edition to their resin 3D printer lineup.

Tech Breakdown: Craftbot FLOW 3D Printer Review

The latest line of 3D printers from the company known for their robust machines has a lot going on under the hood, read more to find out.

Tech Breakdown: Zmorph FAB All-In-One 3D Printer Review

The latest machine from Zmorph is more than just a 3D printer, it's a full-fledged workbench in one platform.

Tech Breakdown: BCN3D Sigma D25 3D Printer Review

BCN3D has done it again with the inaugural Sigma D25, the first entry into BCN3D's Desktop series of 3D printers and continuing their IDEX legacy.

Rapidia Metal Extrusion 3D Printers Enter European Market

News

The technology is based on extrusion 3D printing with metal pastes followed by sintering into finished products.

Rapidia was founded by engineer Daniel Gelbart, an inventor with over 100 patents, founder and former CEO of Creo, a developer and manufacturer of digital printing solutions, acquired by Kodak Corporation in 2005 for about a billion dollars. Daniel's next project was a startup with a rather unusual approach to metal 3D printing. nine0003

The proprietary technology is based on a step-by-step process that involves 3D printing blanks and then sintering them into solid metal parts. Typically, extrusion printing in this area uses polymer-metal filaments, but Rapidia prefers to rely on water-based metal pastes. Alternatively, ceramics can be printed. The process eliminates the need for an intermediate debinding step and is highly safe due to the absence of toxic chemicals and flammable fine powders. nine0003

Alternatively, ceramics can be printed. The process eliminates the need for an intermediate debinding step and is highly safe due to the absence of toxic chemicals and flammable fine powders. nine0003

Last year, Rapidia entered the US market by signing a distribution agreement with ExOne, another developer and manufacturer of additive systems, but using sand and metal inkjet-powder 3D printing technology. Shortly thereafter, ExOne came under the control of Desktop Metal, which offers 3D printers using the competitive FDM 3D printing technology with polymer-metal filaments, and the agreement was terminated. Now the startup is ready to explore the European market: Rapidia developments were demonstrated at the recent Formnext 2022 exhibition, and will go on open sale next year. nine0003

The set of equipment consists of a dual-extruder 3D printer with IDEX kinematics (independent positioning along the X axis) and a vacuum argon furnace with a temperature of up to 1400°C. The second head is used to apply the support material. The equipment allows growing parts up to 200x200x150 mm in size with a productivity of up to 50 g/h. Consumables are 316L and 17-4PH stainless steels.

The second head is used to apply the support material. The equipment allows growing parts up to 200x200x150 mm in size with a productivity of up to 50 g/h. Consumables are 316L and 17-4PH stainless steels.

Additional information is available on the manufacturer's website. nine0003

rapidia robocasting

Follow author

Follow

Don't want

4

Article comments

More interesting articles

nine

Subscribe to the author

Subscribe

Don't want to

Bioactive and bioinert coatings for titanium implants, developed by scientists from the Tomsk Polytechnic. ..

..

Read more

four

Subscribe to the author

Subscribe

Don't want

Tomsk State University scientists launch a project to study new compositions for 3D printing...

Read more

59

Follow author

Subscribe

Don't Want

3Dtoday, sponsored by Creality and Bestfilament invites everyone to participate in...

Read more

Read the blogs

The KODAK 3D Printer is back in motion with 40 unique features

We haven't heard much from Kodak on their new 3D printer for a while, but now they're back in action.

We first saw their machine earlier this year at CES, where they showed off their portrait 3D printer. At the time, we noted that the machine has a number of exciting features that have been designed to make life much easier for the operator, such as their dual tilt nozzle which helps avoid collisions during 3D printing. nine0003

nine0003

We were told that they were slightly behind on obtaining specific regulatory approvals for the equipment, which are now complete. Now they are fully prepared to sell cars.

But in the meantime they have added even more useful features to the machine, one of which is quite unique.

Successful 3D printing of an object with pathological ABS geometry on a Kodak Portrait 3D printer [Source: Fabbaloo] 1. Fully closed

The device is now completely closed, which means that it can easily capture dissipated heat from the heated print surface to increase the ambient temperature in the print chamber. This will help a lot in 3D printing some deformable materials like ABS plastic. nine0003 Screenshot of Kodak 3D Printing Cloud [Source: Fabbaloo]

2. KODAK 3D Cloud

The machine is now connecting to Kodak. A 3D printing ecosystem that can, for example, queue print jobs, cut them in the cloud, store GCODE files for future reprints, and monitor print operations in real time using the built-in camera in a portrait 3D printer. The cloud service is based on Microsoft Azure and we believe it is actually a variant of 3DPrinterOS.

The cloud service is based on Microsoft Azure and we believe it is actually a variant of 3DPrinterOS.

3. Double hot end

But the latest improvement is quite unique: they have equipped E3D-Online's double hot ends differently. One hot end has a PTFE feed tube and the other is all metal.

Why do this?

Flexible nylon 3 6D printed on a Kodak Portrait [Source: Fabbaloo]PTFE nozzle is ideal for softer materials and in particular for flexible filaments like TPU. They must be printed at much slower speeds than conventional rigid filaments, and too much friction will be generated when passing through the all-metal nozzles. nine0003

Meanwhile, the second nozzle is all-metal, meaning it can be heated to very high temperatures. PTFE nozzles have a temperature limit because the PTFE material starts to break down at around 260°C - and some nasty chemicals are released in the process. Thus, Kodak has created a second hot end capable of printing high-temperature materials on a 3D printer.

Both of these hot end scenarios are well known. However, the Kodak implemented BOTH on the same machine. . This means that if you want to print a TPU today, for example, you simply print it on nozzle 1. You don't have to take the machine apart to change nozzles, as is done with many other 3D printers. Similarly, the second nozzle is ready to print on high temperature materials at any time without changing equipment.

It is downloaded and sent to the Kodak Portrait 3D printer for flexible or high temperature materials [Source: Fabbaloo]This is a very handy feature for 3D printer operators that we haven't seen before. It's actually quite a simple idea and I'm wondering why it hasn't become more popular.

4. 4 year warranty.

Kodak also explained its warranty program. For $400/year, you get a 4-year hardware warranty.