Icon 3d printed house location

Careers – ICON

Career Opportunities

Career Opportunities

Benefits & Perks

ICON is a truly exceptional place to work.

We are as passionate about the success and experience of our team members as we are about our mission to shape the future of homebuilding.

We offer comprehensive health benefits, including medical, dental, vision, disability, life insurance, FSA & HSA.

We offer generous family and parental leave for growing families.

Enjoy our “Use What You Need” time away from work policy.

Includes employee stock options, 401K, and Roth IRA retirement programs.

Daily lunch, snacks, and beverages are provided in-office and on-site.

“We believe that to address the global housing crisis, something radical and courageous needs to happen. To make dignified, resilient and sustainable housing accessible for all and to develop space-age construction systems, we are rapidly building a creative, bold, and diverse team. ”

Jason Ballard / ICON Co-Founder / CEO

Join Team ICON

You’re not just building your career, you’re helping build the future of human shelter.

departmentSelected = event.target.value ? Number(event.target.value) : null" class="appearance-none bg-transparent block border border-moondust leading-10 mb-6 px-2 outline-none w-full focus:border-lightspeed md:hidden md:mb-2" > All DepartmentsProduct Management (0)Accounting & Finance (2)Administrative & Executive Support (0)Architecture & Building Science (6)Business Development (1)Communications (0)Construction (2)Control Systems (2)Design (0)Engineering Support Services (0)Facilities (0)Fleet Support (0)Information Technology (1)Manufacturing (0)Material Operations (0)Material Science (0)Mechanical Engineering (2)People (0)Product Testing (2)Research & Development (3)Software Development (5)Supply Chain (1)Talent Acquisition (0)Talent Community (1)UX (0)Workplace Experience (0)No Department (0)

- All Departments

- Accounting & Finance (2)

- Architecture & Building Science (6)

- Business Development (1)

- Construction (2)

- Control Systems (2)

- Information Technology (1)

- Mechanical Engineering (2)

- Product Testing (2)

- Research & Development (3)

- Software Development (5)

- Supply Chain (1)

- Talent Community (1)

- Printed Construction Specialist

- Director, DOD Research and Development Programs

- Application Test Engineer

- Project Manager, MEP Systems

- Logistics Specialist

- MEP BIM Technologist

- Director of Construction Architecture

- Program Manager, Architecture

- Product Test Technician

- Mechanical Engineer II, Magma

- Print Technician

- Senior UX Researcher

- Supply Chain Manager

- Software Engineer II, Controls

- Sr.

Software Engineer II, Controls

Software Engineer II, Controls - Back End Engineer, BuildOS

- Director of Concrete Sustainability

- Machine Learning Engineer

- Senior Front End Engineer I, BuildOS

- Senior Machine Learning Engineer

- System Administrator

- Mechanical Engineer II, Vulcan

- Finance Associate

- Space Mechanisms Engineer- Off-Planet Robotics

- Staff Accountant

- Structural Engineer

- Systems Engineer and Scheduler, Off-Planet Robotics

- VP, Sales

ICON and Lennar Announce Community of 3D-printed Homes is Now… – ICON

Reservations Begin in 2023 for the 100-home Community Co-designed by BIG-Bjarke Ingels Group

GEORGETOWN, TX – November 10, 2022 – ICON, the leader of advanced construction technologies pioneering large-scale 3D printing, and Lennar, one of the nation’s leading homebuilders, announced today that construction is underway on the largest community of 3D-printed homes and reservations will begin in 2023.![]()

Situated north of Austin in the city of Georgetown’s master-planned community of Wolf Ranch by Hillwood Communities, a Perot company, the 100-home community combines innovative robotics, software and advanced materials to create homes that are technologically advanced, environmentally sustainable and architecturally striking. Each Lennar home in Wolf Ranch is co-designed by the renowned architectural firm BIG-Bjarke Ingels Group. Prices are anticipated to start from the mid-$400,000s.

“We are very pleased to partner with ICON and BIG in building a first-of-its-kind, printed home community that combines innovative designs with sustainable features at an affordable price,” said Stuart Miller, Executive Chairman of Lennar. “Given the housing shortage that persists across the country, it has never been more important to innovate in order to find new methods of construction that will enable greater design flexibility and greater production at affordable prices. ”

”

Blending contemporary Texas ranch style aesthetics, the community of 3D-printed homes features elevated architectural and energy-efficient designs that highlight the benefits of resiliency and sustainability with the digital possibilities of additive construction. Delivered at speed and at scale using a fleet of ICON’s Vulcan robotic construction systems, software and advanced materials, each home’s full wall system - including interior and exterior walls - are produced with less waste and with more design freedom.

“For the first time in the history of the world, what we’re witnessing here is a fleet of robots building an entire community of homes. And not just any homes, homes that are better in every way… better design, higher strength, higher energy performance and comfort, and increased resiliency,” said Jason Ballard, co-founder and CEO, ICON. “In the future, I believe robots and drones will build entire neighborhoods, towns, and cities, and we’ll look back at Lennar’s Wolf Ranch community as the place where robotic construction at scale began. We still have a long way to go, but I believe this marks a very exciting and hopeful turn in the way we address housing issues in the world.”

We still have a long way to go, but I believe this marks a very exciting and hopeful turn in the way we address housing issues in the world.”

Construction at Wolf Ranch deepens a relationship that began with Lennar’s investment in Austin-based ICON’s series B financing round and offers a promising path toward an alternate method of delivering technology-driven homes that meet rising demand in desirable communities. In addition to state-of-the-art homes, Lennar homeowners in Wolf Ranch can enjoy all of the amenities offered in tree-covered hill country – including pools, recreational trails and parks within easy access of downtown Georgetown and a short drive to Austin.

Lennar’s investments are facilitated by LENX, which drives a focused strategy within Lennar to integrate technology solutions across the homebuilding industry. With a clearly defined strategy of investing in technology companies directly adjacent to Lennar’s core homebuilding operations and a disciplined investment process, LENX provides hands-on mentorship and guidance from senior leaders of Lennar’s management team and a marquee opportunity to provide products and technology to Lennar customers, allowing portfolio companies to scale at an unprecedented pace.

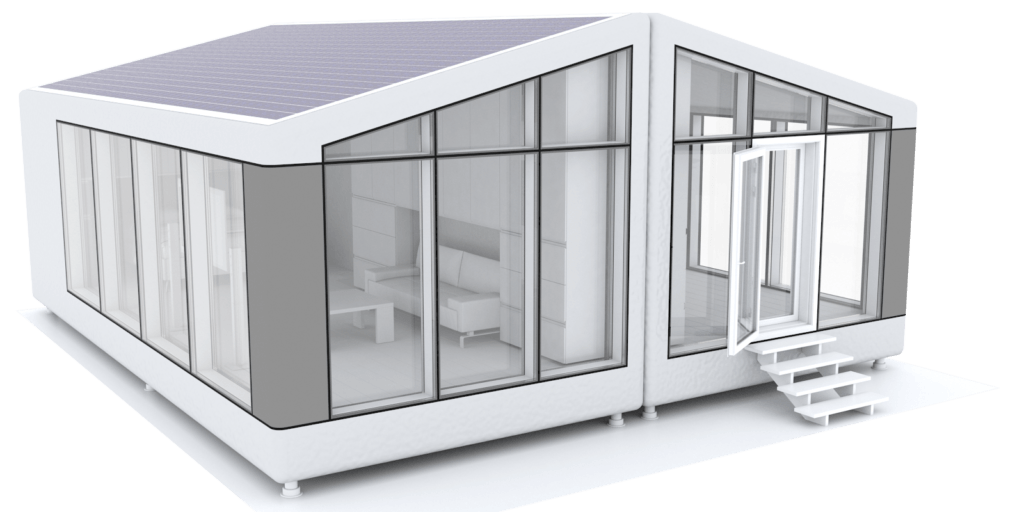

The community will offer eight stunning floorplans with 24 unique elevations ranging from 1,574 to 2,112 square feet of thoughtful living space. The homes will offer three to four bedrooms and two to three baths. All homes will be powered by the sun with rooftop solar panels and will feature components from Lennar’s Connected Home package including a Ring Video Doorbell Pro, a Schlage Encode™ Smart WiFi deadbolt and a Honeywell Home T6 Pro WiFi smart thermostat. Plus, each home will come equipped with the Wolf Ranch security package.

“We are excited to welcome Lennar and ICON's cutting-edge home construction technology to Georgetown,” Georgetown Mayor Josh Schroeder said. “The Georgetown community prides itself on honoring our past and innovating for our future, and we are eager to see the future being built right here.”

"Hillwood Communities is honored that ICON and Lennar chose Wolf Ranch to launch this exciting initiative and we look forward to the positive impact it will bring to the homebuilding industry,” said Fred Balda, president of Hillwood Communities. “This innovative approach aligns with Hillwood’s long history of elevated design and the thoughtful development approach we take to ensure a higher standard of living for the residents of our communities."

“This innovative approach aligns with Hillwood’s long history of elevated design and the thoughtful development approach we take to ensure a higher standard of living for the residents of our communities."

Reservations begin in 2023. Interested homebuyers can join the interest list by clicking here.

About Lennar Corporation

Lennar Corporation, founded in 1954, is one of the nation's leading builders of quality homes for all generations. Lennar builds affordable, move-up and active adult homes primarily under the Lennar brand name. Lennar's Financial Services segment provides mortgage financing, title and closing services primarily for buyers of Lennar's homes and, through LMF Commercial, originates mortgage loans secured primarily by commercial real estate properties throughout the United States. Lennar's Multifamily segment is a nationwide developer of high-quality multifamily rental properties. LENX drives Lennar's technology, innovation and strategic investments. For more information about Lennar, please visit www.lennar.com.

For more information about Lennar, please visit www.lennar.com.

About ICON

ICON develops advanced construction technologies that advance humanity. Using proprietary 3D printing robotics, software and advanced materials, ICON is shifting the paradigm of homebuilding on Earth and beyond. For more information visit www.iconbuild.com or follow the conversation on Instagram, Twitter, Facebook, YouTube (@ICON3DTech).

About BIG – Bjarke Ingels Group

BIG-Bjarke Ingels Group is a Copenhagen, New York, London, Barcelona, and Shenzhen-based group of architects, designers, urbanists, landscape professionals, interior and product designers, researchers, and inventors. Led by Bjarke Ingels, the studio is currently involved in projects throughout Europe, the Americas, Asia, and the Middle East. BIG’s architecture emerges out of a careful analysis of how contemporary life constantly evolves and changes. BIG believes that by hitting the fertile overlap between pragmatic and utopia, architects can find the freedom to change the surface of our planet, to better fit contemporary life forms.

About Hillwood

Hillwood, a Perot company, is a premier commercial and residential real estate developer, investor and advisor of properties throughout North America and Europe. Through its Communities division, Hillwood has delivered more than 40,000 single-family lots in more than 100 master-planned communities across 13 states and Costa Rica. These communities continue to raise the bar in terms of quality, innovation and the unmistakable sense of community that sets each property apart. Before laying the physical groundwork for any new residential development, Hillwood Communities takes the time to focus on the ideals that draw people together — and the everyday interactions that strengthen those bonds. By purposefully designing its walkways, gathering spaces, and structural amenities to spark spontaneous encounters and foster shared interests, Hillwood Communities believes in the power of community. For more information, please visit http://www. hillwoodcommunities.com.

hillwoodcommunities.com.

About the City of Georgetown

Georgetown is a welcoming, vibrant city that has been ranked No. 1 in Southern Living Magazine’s “South’s Best Cities to Live in” and is home to the “Most Beautiful Town Square in Texas.” Georgetown has a rich history, with Victorian storefronts and a cultural district with a wide selection of restaurants, wineries, shops, art galleries, theaters, and museums, as well as Southwestern University, tied for the No. 1 National Liberal Arts College in Texas in the latest U.S. News & World Report ranking. Outdoor recreation includes 40 parks, 16 miles of hiking and cycling trails, and Lake Georgetown. Georgetown is the fastest growing city in the U.S. with a population of more than 50,000.

ICON builds the first building in a new series of 3D printed dwellings

You are here

Home

Texas-based ICON has released another redesign of its Vulcan 3D construction printer and launched the construction of a new series of 3D printed residential buildings, scaling up and exploring new approaches to architectural design.

Austin-based ICON is the most productive building 3D printing company, with the possible exception of China's WinSun. Texans have a lot of already successful and so far only promising projects using 3D printing technologies: a demonstration 3D printed house, projects to build affordable housing for the poor in their native Austin (pictured below) and the Mexican state of Tabasco, training of US Marines 3D - printing of caponiers for ground equipment. nine0005

In March of this year, several residential buildings designed by ICON were put up for sale on the US real estate market. The company is even working with NASA on 3D printing technologies for habitable structures on the Moon, but space is a long-term prospect, but for now, you need to continue working on Earth, which the company is doing, taking up the construction of an object called House Zero.

The name "Zero House" owes its name to ICON's intention to build a series of structures to test new building methods, integrate smart and energy-saving technologies, and test new approaches to architectural design. The layout of the first or "zero" building (in the title illustration) provides for three bedrooms and three bathrooms - two full and one incomplete. The size of the living space will reach 220 square meters, although this is not the limit for the new additive system. nine0005

The layout of the first or "zero" building (in the title illustration) provides for three bedrooms and three bathrooms - two full and one incomplete. The size of the living space will reach 220 square meters, although this is not the limit for the new additive system. nine0005

3rd Generation Vulcan 3D Printer

Not only is the company building the first house in a new series, but also testing a new generation 3D construction printer, the third modification of the Vulcan system. The first version has been in operation since at least 2018, and the next year ICON rolled out an improved version of the Vulcan II. The third-generation 3D printer still prints with cement mortars, but it works twice as fast as previous models and covers one and a half times the working area - up to 280 square meters. Equipment weighing 4.3 tons is maximally automated and controlled using a mobile application. nine0005

Vulcan II 3D printer in action

“House Zero will be the most incredible 3D printed house in the world because it is designed and optimized specifically for additive manufacturing. This is the moment when people around the world will see the increased freedom of architectural design and the benefits of 3D printed houses, and will want to live in such buildings themselves. We hope that this project will serve as a catalyst for a general enthusiasm for the building technologies and architecture of the future. We are preparing to launch production at our new facilities and are ready to participate in even larger projects,” said ICON co-founder and CEO Jason Ballard. nine0005

This is the moment when people around the world will see the increased freedom of architectural design and the benefits of 3D printed houses, and will want to live in such buildings themselves. We hope that this project will serve as a catalyst for a general enthusiasm for the building technologies and architecture of the future. We are preparing to launch production at our new facilities and are ready to participate in even larger projects,” said ICON co-founder and CEO Jason Ballard. nine0005

Source

Other materials:

- Wilting and 3D Systems Accelerate Adoption of Metal Additive Manufacturing

- Introducing 4 Forward AM Innovation Award Finalist Startups

- Airbus Polymer Sintered Parts Ready to Fly

- International Conference on Digital Foundry Solutions

- Perm High Temperature FDM Line printers

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

Building 3D printing awaiting a breakthrough The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0005

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades.![]() The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0005

The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0005

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0005

So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0005

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0070

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0097

2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0097

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry. nine0097

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, an increase of 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0005

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0005

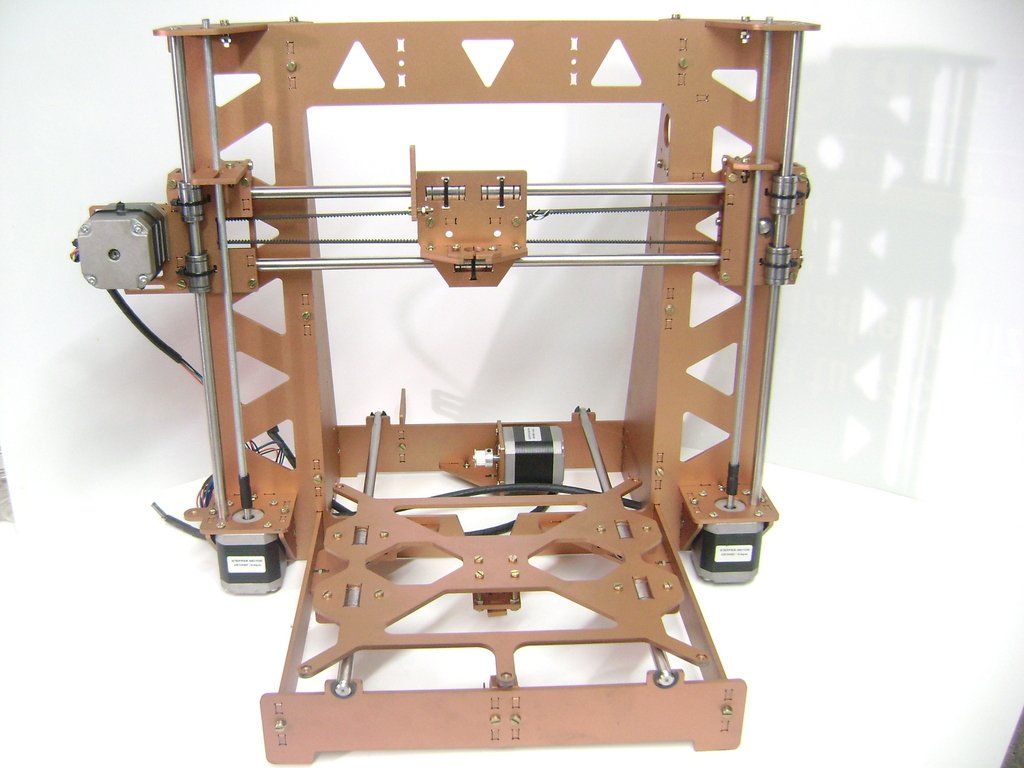

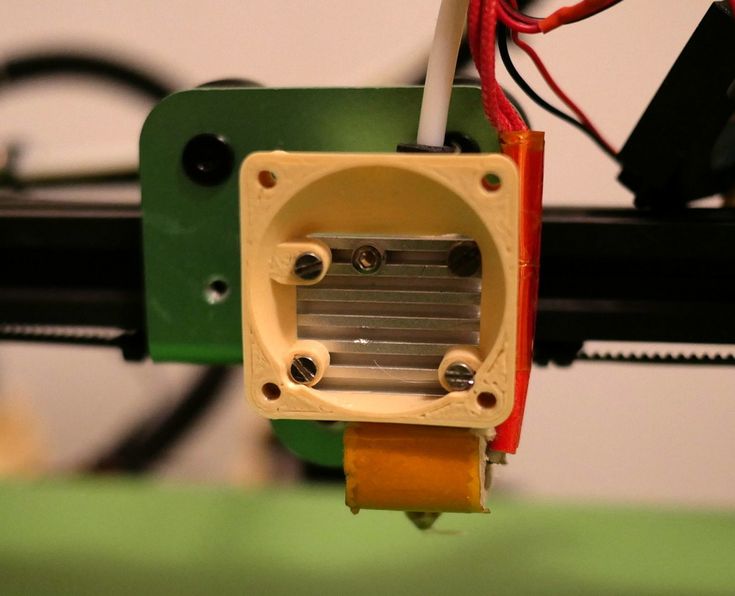

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.![]() nine0005 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

nine0005 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers, as well as participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

There is little that unites developed, developing and poor countries, everywhere their problems and tasks, but The lack of affordable housing is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people.![]() And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0005

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0005

At the same time, the trend towards “green agenda ”, CO2 emission reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0005 3D printed walls.

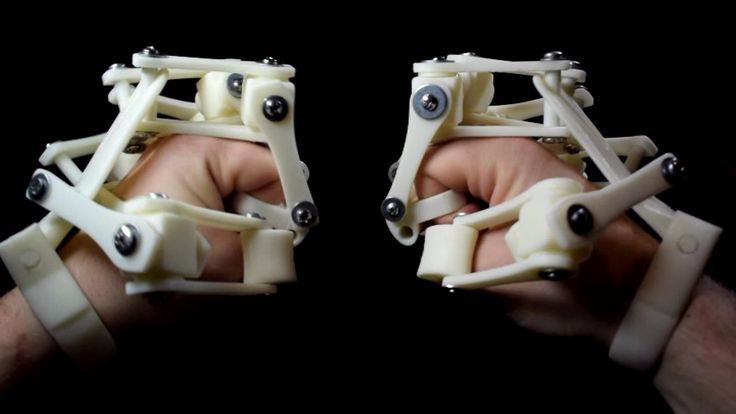

Today, when we talk about 3D printing of houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used, which in turn reduces construction costs and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0005

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0005

eco-concrete with the addition of polymers is currently being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0005

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0005

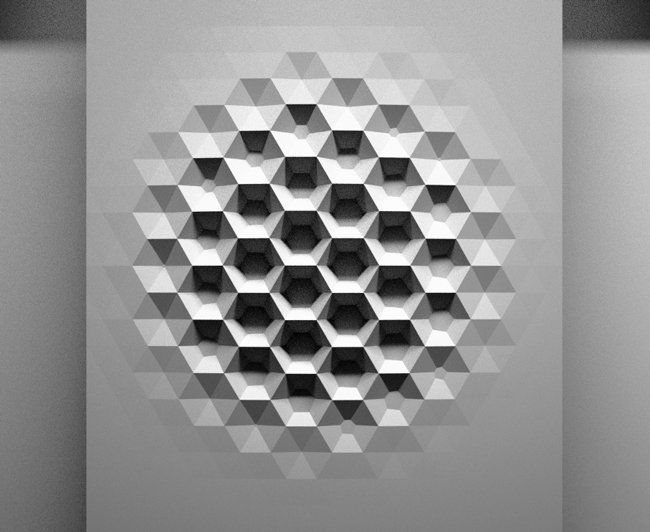

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0005

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

nine0005

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0005

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop.