Kinematics 3d printer

3D Printer kinematic types

There are various 3D printing technologies: Digital Light Processing (DLP), stereolithography (SLA), Selective Laser Sintering (SLS), Selective Heat Sintering (SHS) and the others. In this article we are going to explain the FFF technology and talk about its advantages and disadvantages as well as 3D-printers that use it.

Introduction

FFF printers (Fused Filament Fabrication) are also known as FDM printers (Fused Deposition Modelling). These devices are able to create prints by depositing molten plastic on the print bed layer-by-layer. FFF printers are used both for commercial purposes and at home.

.

Kinematics in 3D printing

Each 3D printer uses its own kinematics that controls the movement of the mechanical parts: print beds and extruders. In this article we will review four types of FDM-printers: Cartesian, Delta, Polar and 3D printers with robotic arms.

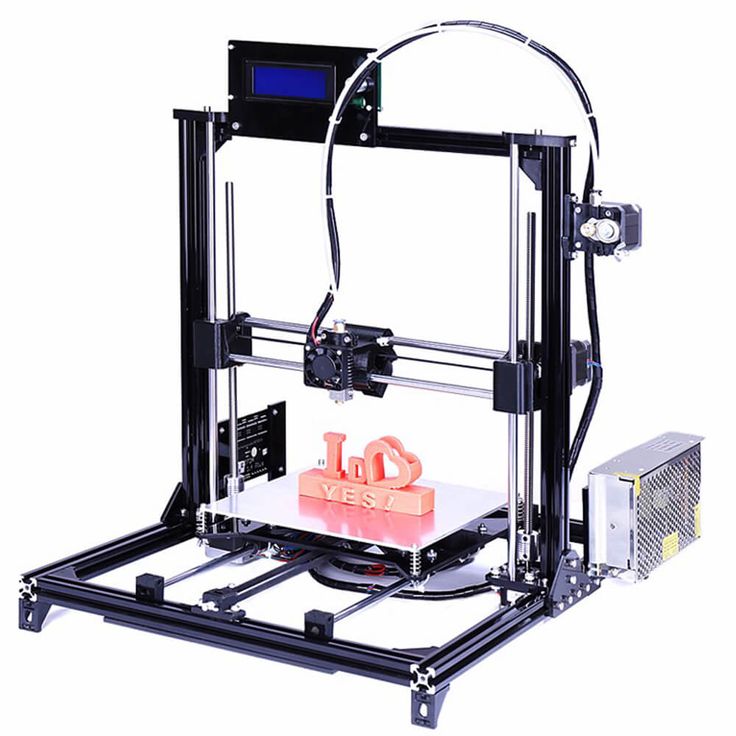

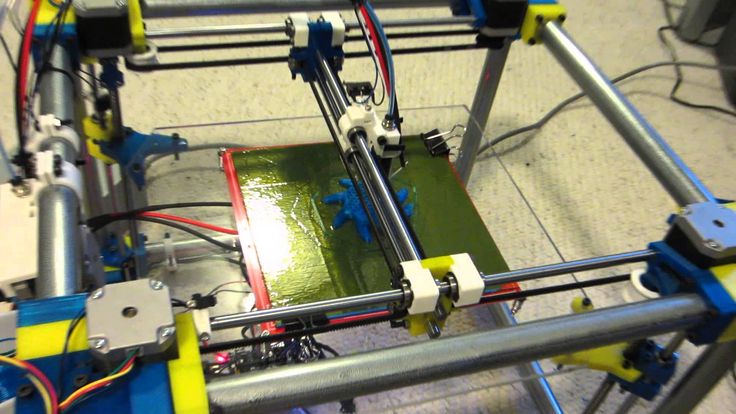

Cartesian printers are the most common FFF/FDM printers on the market. The technology uses three axes – X, Y, Z (Cartesian coordinate system) to determine the movements of mechanical parts: the print head and the bed move according to the coordinates.

There is a limited number of possible ways for platforms and print heads to move:

- The platform moves horizontally along one of the axes — X or Y, the extruder moves vertically along the other axis .

- The platform moves horizontally (Z), the extruder moves two-dimensionally in along the X-Y axes.

- The platform moves vertically and along one of the horizontal axes, the extruder moves horizontally.

- The platform doesn’t move, the extruder moves three-dimensionally.

- The platform moves along the XY axes, the extruder moves vertically.

The second one is the most common — the platform moves vertically and the extruder moves in the XY plane.

Advantages of Cartesian kinematics

Cartesian printers produce some of the most stable results among FDM devices. Consumables for FDM are cheap and available in different colors and materials. Cartesian 3D printers are often used commercially for printing souvenirs, decorations and other custom made things.

Consumables for FDM are cheap and available in different colors and materials. Cartesian 3D printers are often used commercially for printing souvenirs, decorations and other custom made things.

Cartesian 3D printers are popular and well established among enthusiasts and professionals. There are many online communities with lots of information about their design, how they operate and how to build them.

Models printed using Cartesian coordinate system can be taken apart and used to build bigger ones, and it allows to make objects of any given size not limited by printer’s build volume. Many 3D printers are available as kits. For newcomers and those who don’t want to learn about building printers, pre-assembled devices are available. They allow to start printing almost right out of box.

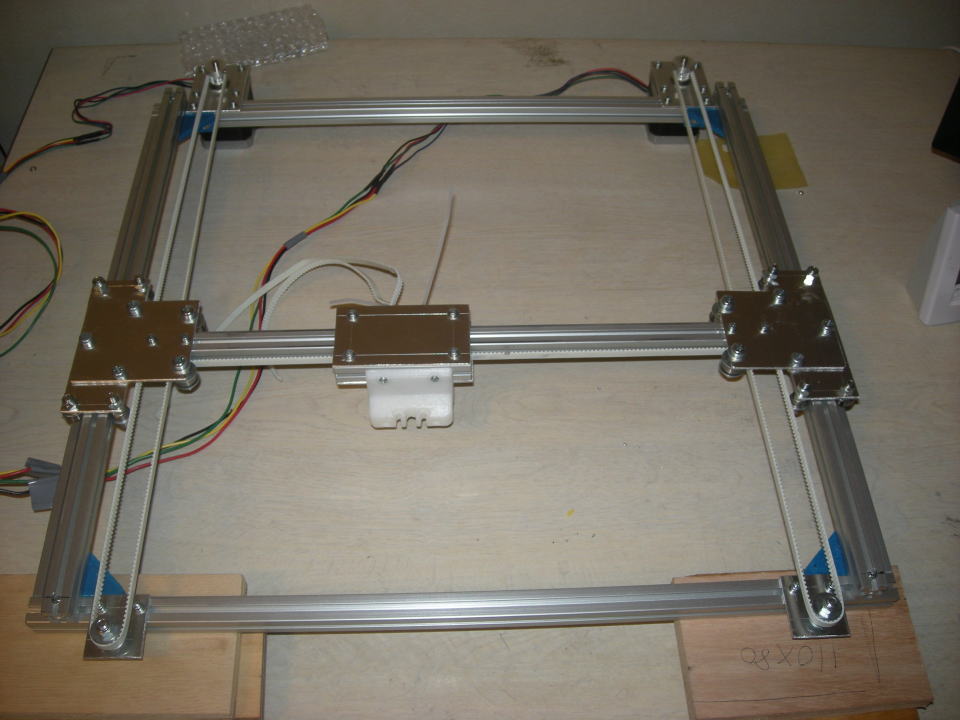

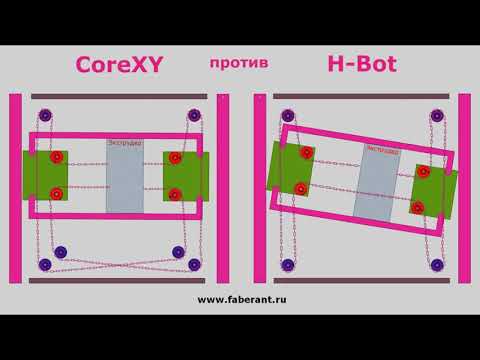

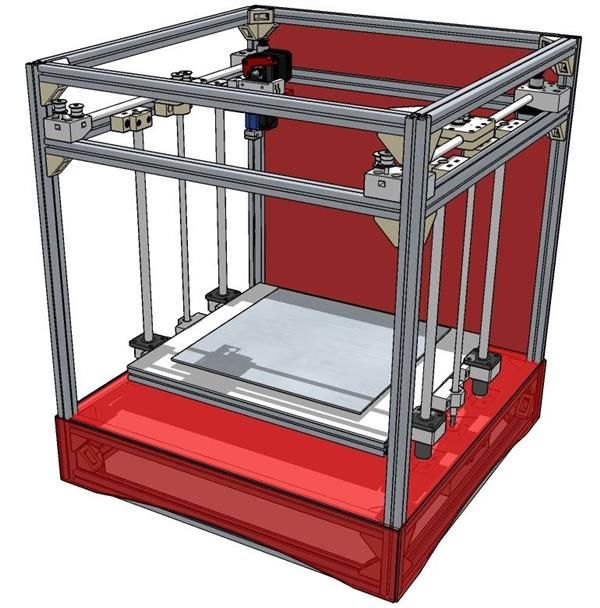

CoreXY and H-Bot Cartesian kinematics

This kinematics is often used for commercial purposes. They have a non-standard extruder movement – it moves vertically.

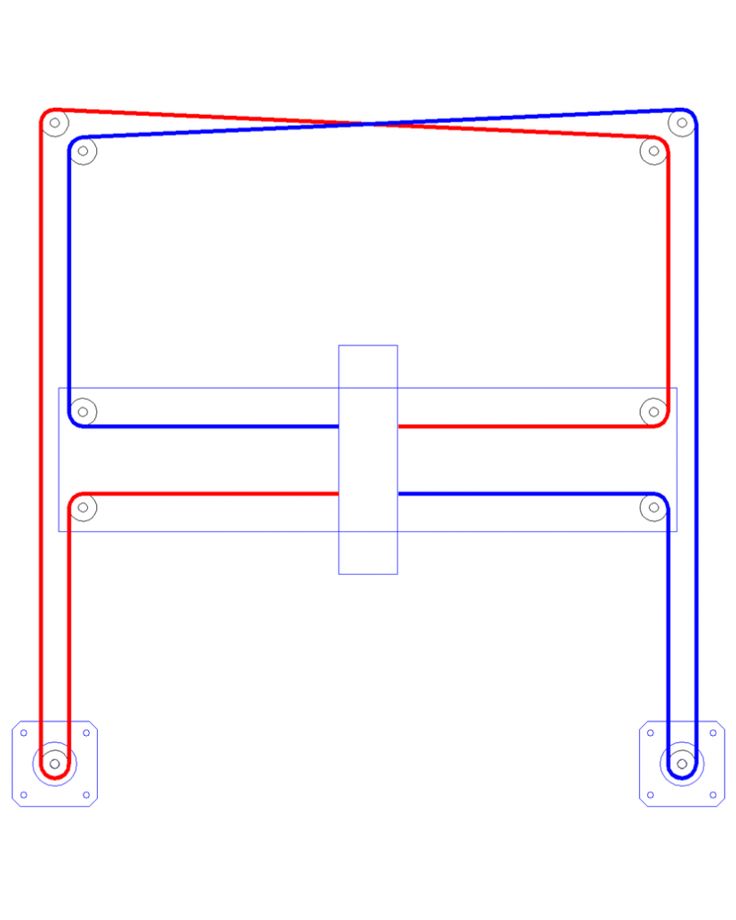

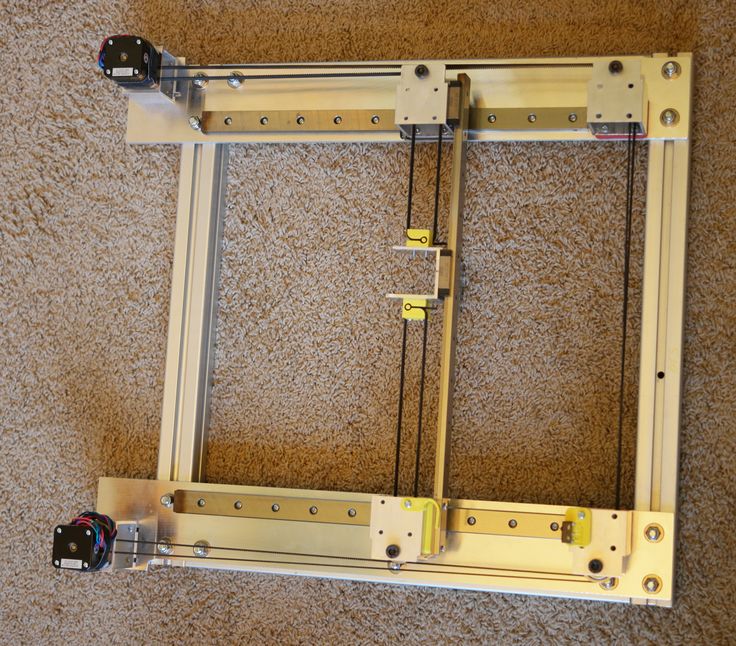

Image source: https://www. pinterest.com

pinterest.com

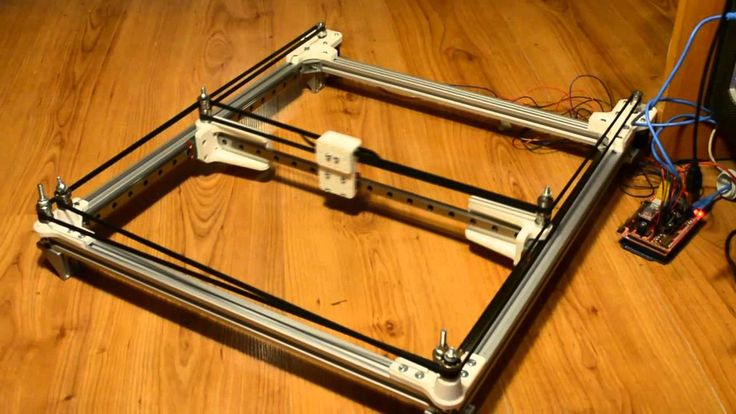

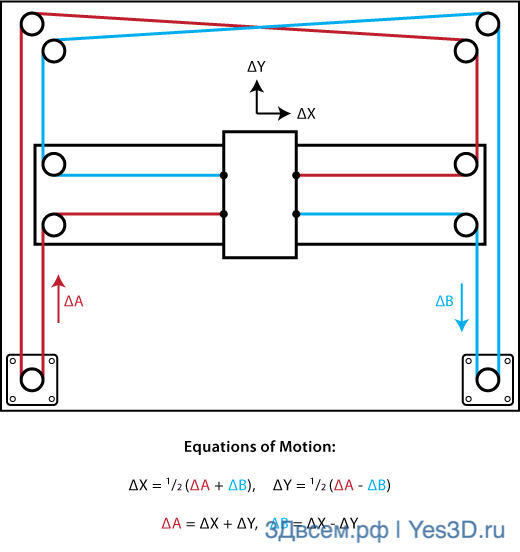

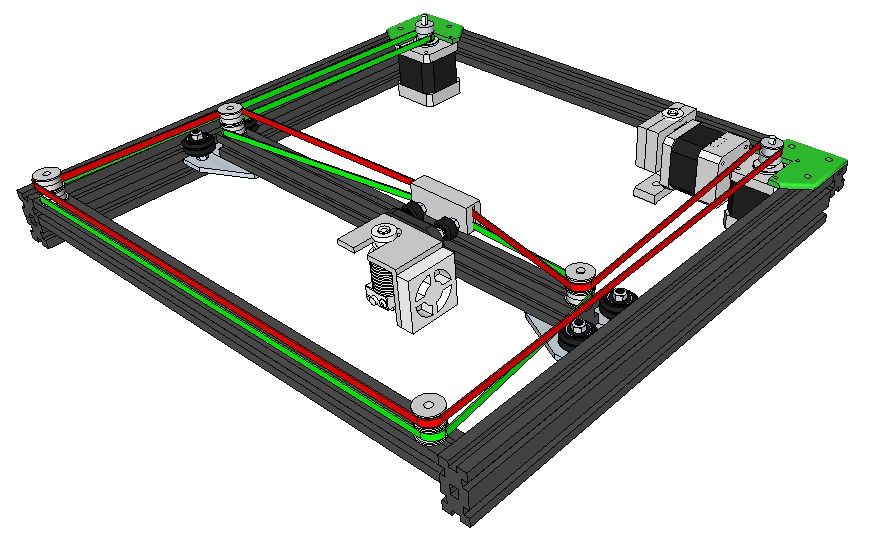

CoreXY features two motors that control two belts moving the extruder in the XY plane.

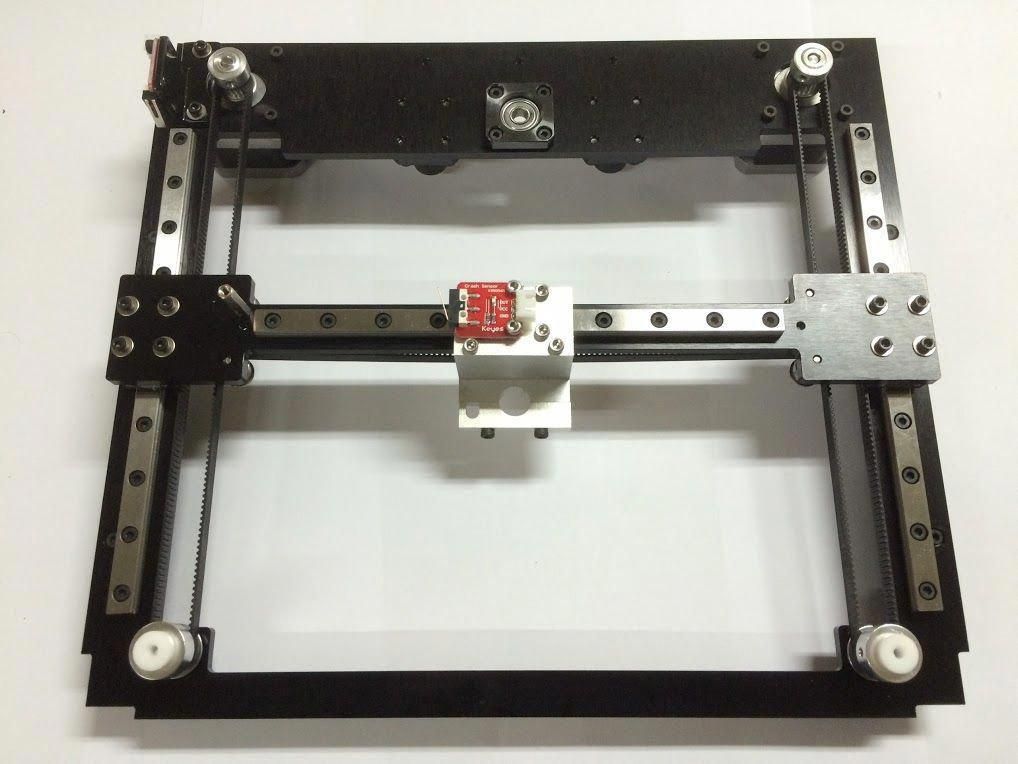

Image source: smoothieware.org

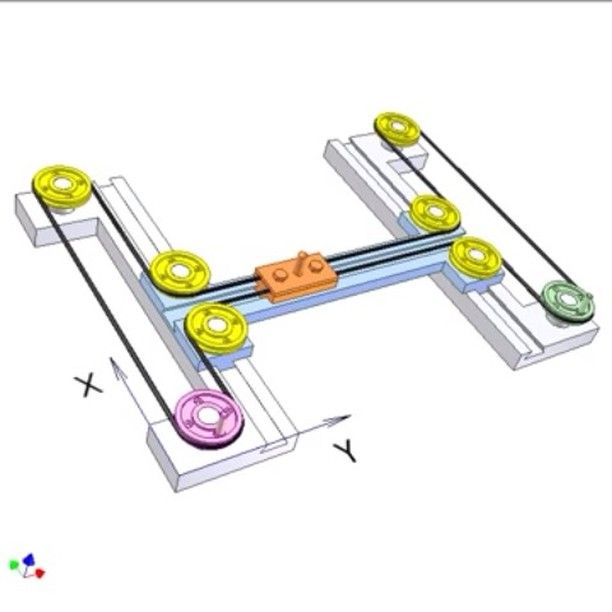

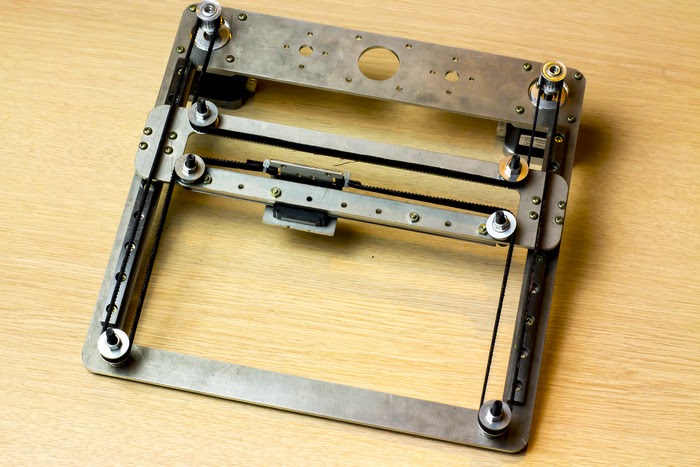

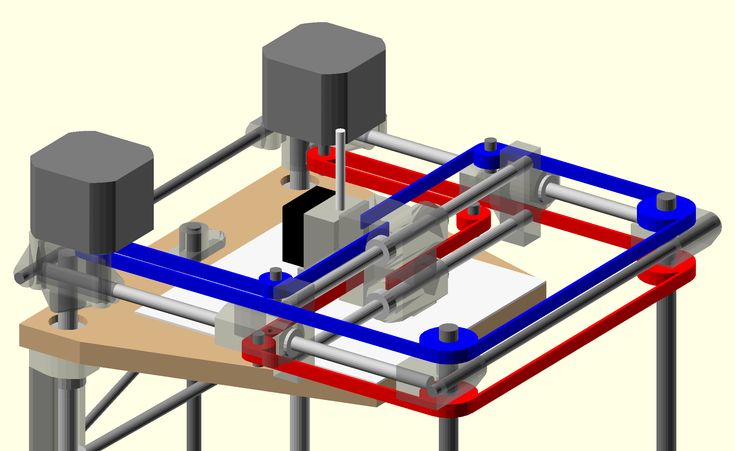

The H-Bot kinematics is similar but uses a different belt drive system. There’s only one belt mounted to a frame that has an H-shape, hence the name of the kinematics.

Image source: smoothieware.org

When both motors rotate in the same direction, the extruder moves along the X-axis, when they rotate in different directions, the extruder moves along the Y-axis. When one of the motors doesn’t move, the extruder moves diagonally.

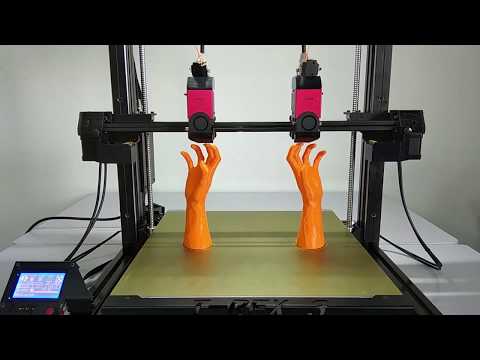

Among 3D printers with this design, there’s Designer X PRO. The printer has a very high speed, since the JetSwitch technology allows for a faster two-material printing (up to 5 seconds faster in normal mode and 250ms in a draft mode). Redesigned print head with 1µm accuracy and new generation platform allow to print high quality models comparable to manufactured goods. It has a two-material printing function. Software fully controls the printing process, which reduces errors and maximizes efficiency.

It has a two-material printing function. Software fully controls the printing process, which reduces errors and maximizes efficiency.

Picaso 3D Designer X Pro 3D printer

- Max extruder temperature 380 °C

- Max heated bed temperature 150 °C

- Max print speed up to 100 cm3/h

- Mechanical arrangement Cartesian-XZ-Head

- Nozzle size, mm 0.

3 mm

3 mm - Number of nozzles 2

- Build volume 200 x 200 x 210 mm

- Layer height 50 - 250 Microns

- Technology FFF FDM

Go to product

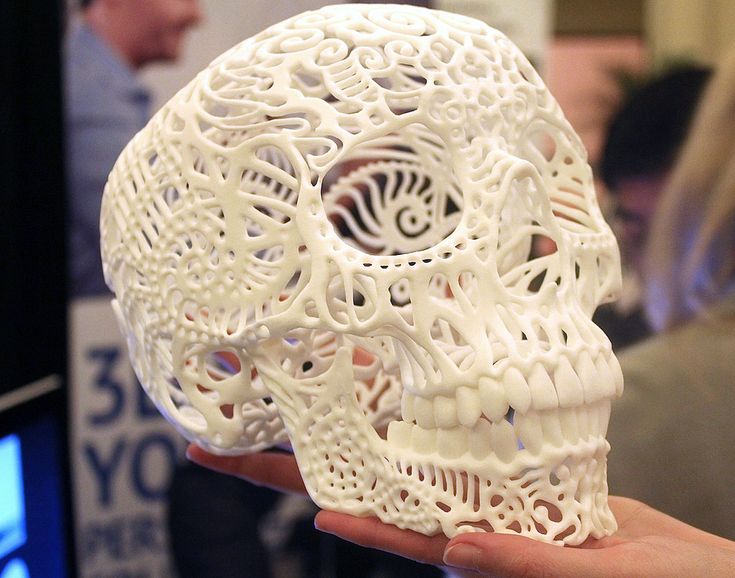

Printed model example:

Image source: top3dshop. com

com

Delta printers

Delta printers are different from Cartesian ones both externally and in work process. The main difference lies in the way the extruder moves in relation to the print bed.

Image source: https://3dprint.com/

DELTA design has an extruder that is mounted to three points connected to a print bed that doesn’t move.

Advantages and disadvantages of Delta printers

Compared to Cartesian printers, Delta kinematics allows for a higher speed but provides less accuracy. The reason is the fact that extruder movement requires all three motors working simultaneously, which leads to errors in coordinate positioning.

Other advantages:

- Small size. A delta printer is tall, but otherwise doesn’t require a lot of space.

- Absence of protruding parts. The user can make the structure more rigid and get an enclosure.

- Ability to print tall models.

Image source: http://rwgresearch. com/

com/

Disadvantages:

- Higher price.

- Difficult to assemble on your own. Entry-level users could have problems with assembling it correctly, so it’s recommended to buy a pre-assembled printer.

- Working with polar coordinates requires less common software and more expensive parts due to higher processing power.

Examples include the Tevo Little monster 3D printer. Its main use is commercial: design, advertising and educational purposes, but it can also be used at home. It is small and fast. Supported materials: PLA, ABS, Flexible PLA, HIPS, WOOD, PVA, Nylon.

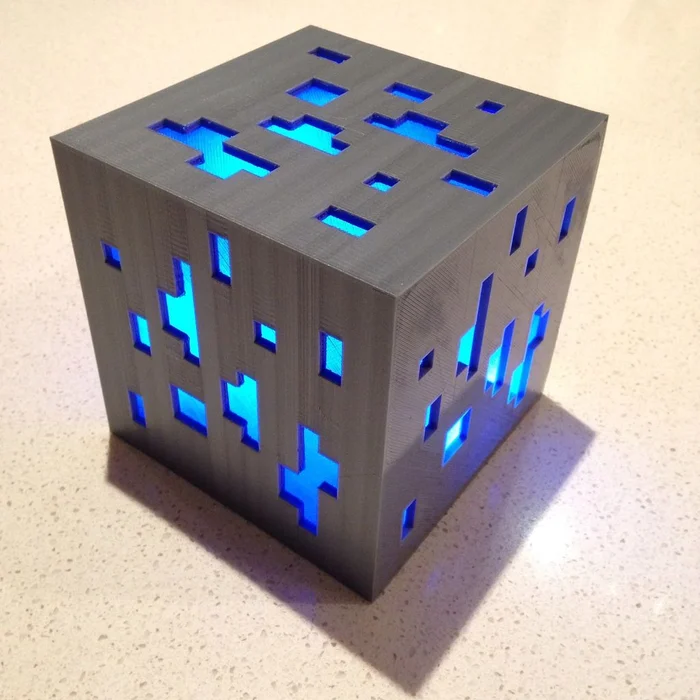

Printed model example:

Image source: https://twitter.com/

Polar 3D printers

This new and interesting polar design is represented on the market by a company named Polar. It uses polar coordinates — it means the positioning is determined by radius and angle instead of commonly used XYZ-axes.

Image source: http://www. purdue3dpc.org

purdue3dpc.org

The platform is circular, it rotates and moves horizontally in one dimension, while the extruder moves up and down. Imagine vinyl record player – print head is like a needle and the platform is like a record. The difference is that the latter not only rotates but also moves, while the former is limited in its movement.

Advantages and disadvantages of the Polar design

3D printers with polar design allow to create large objects, using less space and being energy-efficient. These machines lack accuracy but the manufacturer could probably solve this problem in a foreseeable future.

Image source: https://about.polar3d.com/

Polar 3D is one of these printers. It doesn’t have a heated bed, which makes using Acrylonitrile Butadiene Styrene (ABS) more difficult. The printer is small, efficient but has low accuracy compared to delta and cartesian 3D printers. The manufacturer recommends using the device for educational purposes.

Printed model example:

Image source: https://www.tomsguide.com/

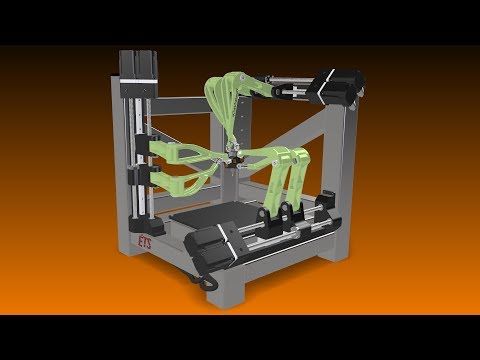

3D printers with robotic arms

They use a programmable mechanical manipulator with an extruder instead of a gripper. Besides their functions as manipulators and 3D printers, large scale industrial robotic arms (the small scale ones also exist) can undertake welding, painting, milling and lots of other functions..

Image source: http://www.dubox.me/

While 3D printing with robotic arms is mainly used in industrial setting, there are models for home use with a broad set of functions.

Dobot Magician Educational robotic arm can do many things. It can draw, write, grip and move objects, laser engrave, etc.

Example:

Image source: https://www.youtube.com/

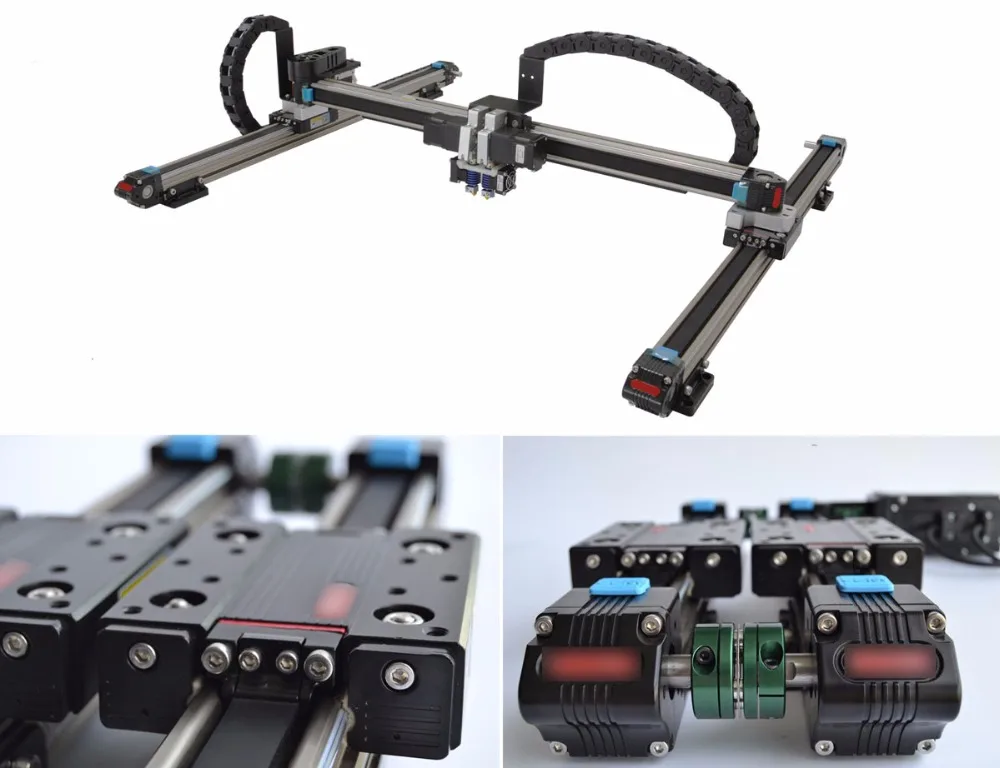

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics design based on a block moving horizontally due to a link lever mechanism.

Devices that use this kinematics are more compact, have very high accuracy and better repeatability than traditional robotic manipulators can provide, lower noise and vibration levels. SCARA robots are not only more accurate but also faster than cartesian robots of similar size and mass.

But these devices are expensive, have limited stiffness along the XY axes, smaller build area and limited movement.

Examples include Dobot M1. It’s a small desktop robot that can be used both as a 3D printer and a manipulator. It’s controlled with software or mobile applications. It has various attachable heads for printing, engraving, soldering and assembling.

Printed model example:

Image source: https://thegadgetflow.com/

Kinematics of robotic systems

The advantages of 3D printers with robotic manipulators are obvious – working area is not limited to the size of a build chamber, since such machines don’t have one. These machines are smaller but have the same printing area.

Image source: https://spectrum.ieee.org/

The extruder is not limited to its moves as in FDM printers, it can move in complex trajectories in three axes with different angles, which simplifies making complex models. Another advantage is that robotic arms can be also used for other purposes, once the extruder is replaced by other modules.

Printing accuracy is not comparable to Cartesian 3D printers but thanks to their versatility and large size, such robots can be used for 3D printing in industrial setting where they become almost irreplaceable.

Small desktop robotic arms are good as a visual aid or as a tool for your hobby.

Conclusion

Before buying a 3D printer, ask yourself why you need one. Would it be for a commercial use, your job or hobby? FFF / FDM 3D printers are versatile because they can be used for different purposes. Whether you want to learn about 3D printing and get a new hobby, turn your creative ideas into reality or start a business – it doesn’t matter. There’s a suitable 3D printer for every purpose but you need to take your time choosing what you really need.

There’s a suitable 3D printer for every purpose but you need to take your time choosing what you really need.

If you need help purchasing a 3D printer, head straight to https://top3dshop.com. We’ll help you choose the best machine to suit your needs.

CoreXY Kinematics - 3D Distributed

Home

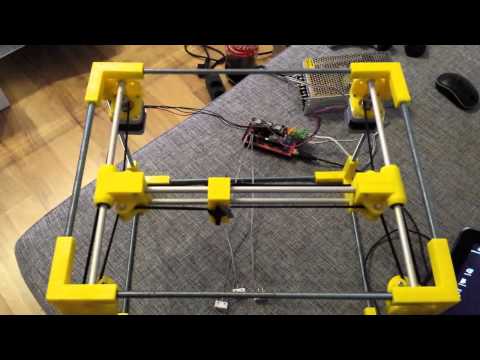

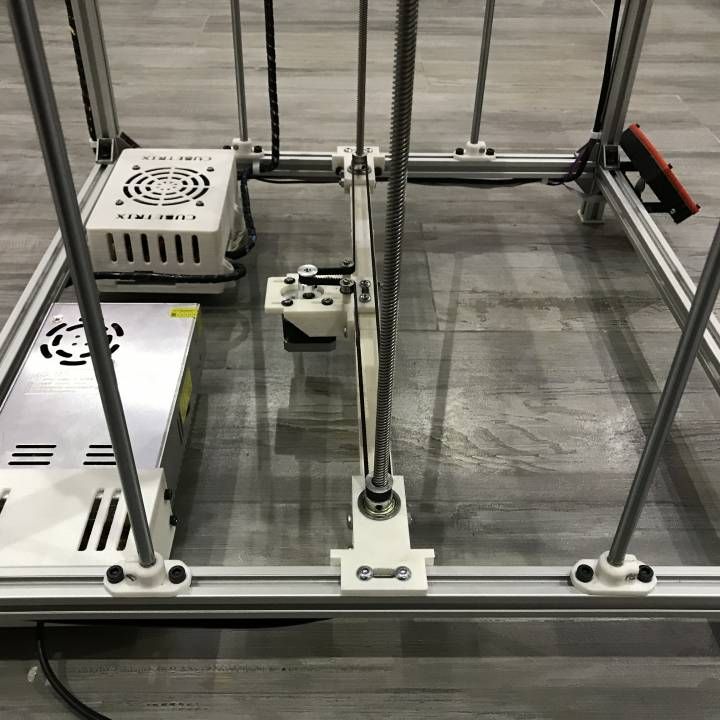

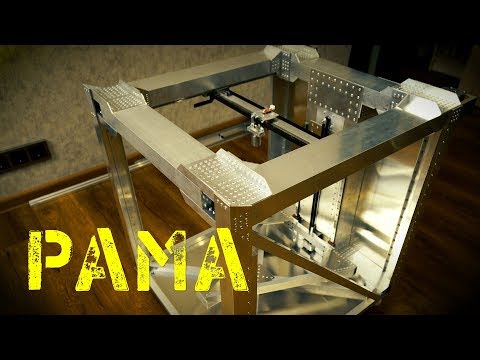

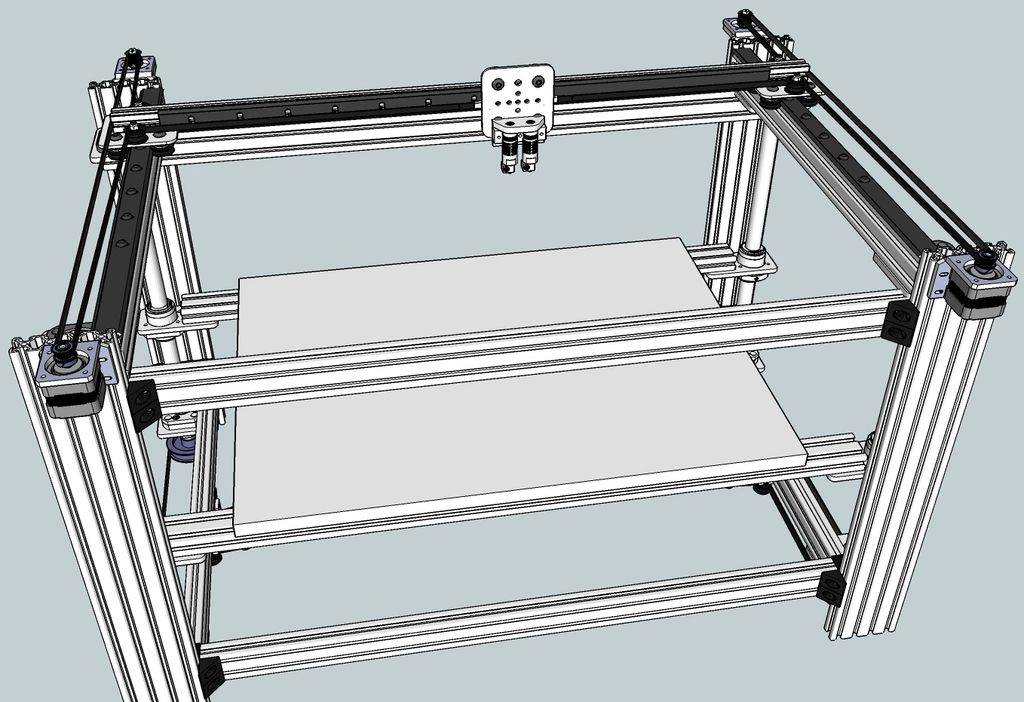

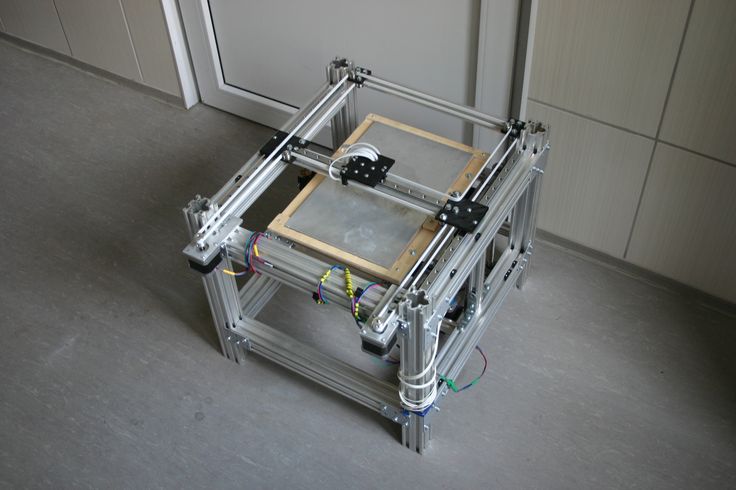

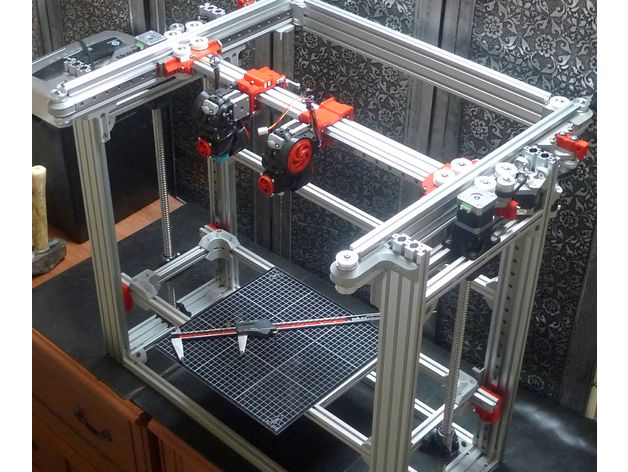

SolidCore CoreXY 3D Printer

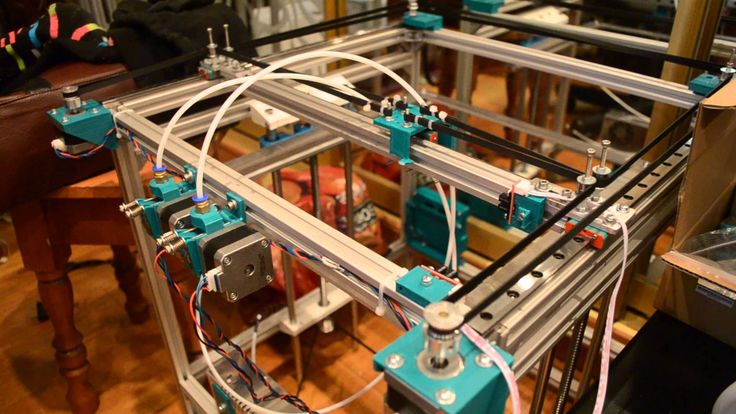

CoreXY Kinematics

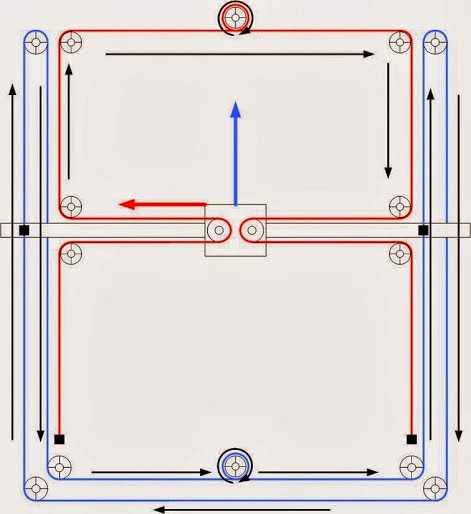

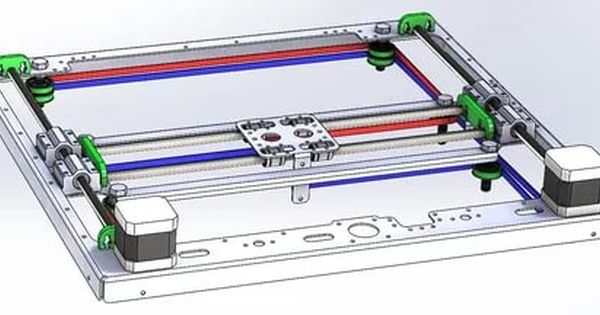

CoreXY Mechanism DiagramCoreXY Kinematics Explained?

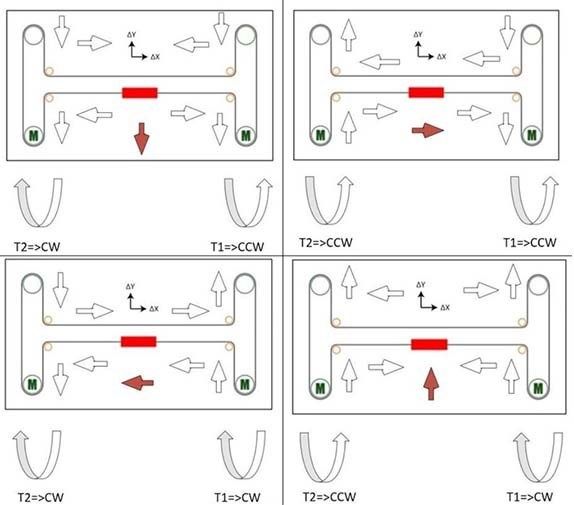

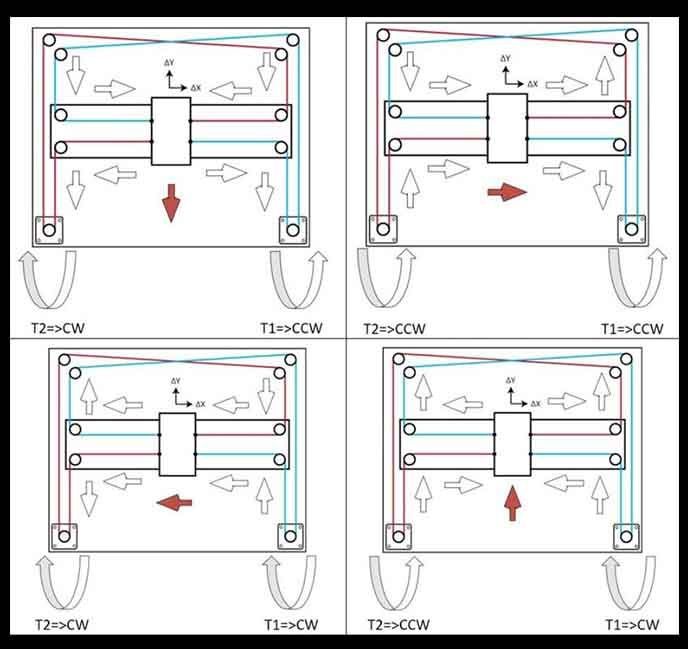

The corexy kinematics mechanical arrangement includes a unique motor movement where the X or Y motor move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal.. If the two motors move opposite of each other the print head will move along the X-axis, If the two motors move in the same direction the carriage will move along the Y-axis.

How Does CoreXY Work?CoreXY-Kinematics-ExplainedThe CoreXY 3d printer design is very different than most common 3d printer motion systems that have dedicated stepper motor for each axis. The core-xy motion system is designed to minimize torque while moving the gantry and carriage.

The core-xy motion system is designed to minimize torque while moving the gantry and carriage.

The corexy parallel kinematics mean’s that the motors are the largest source of inertia within the system, are stationary. This means rapid acceleration because the two stepper motors provide a means of moving both axes independently or simultaneously. The major benefit of the design is that the motors remain in a static position.

The corexy kinematics is a complex motion system where X or Y motor move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal.. If the two motors move opposite of each other the print head will move along the X-axis, If the two motors move in the same direction the carriage will move along the Y-axis.

Two Motors (X and Y)

- Both Motors Move Clockwise >> Carriage Moves Left

- Both Motors Move Counter Clockwise>> Carriage Moves Right

- Both Motors Move Opposite of Each Other>> Carriage Moves Toward & Away

- One Motor Moves>> Carriage Moves Diagonal

see more CoreXY Mechanism Research

CoreXY Motor Movement

| Motor Movement | Direction |

|---|---|

| Both Motors Move Clockwise | Carriage Moves Left |

| Both Motors Move Counter Clockwise | Carriage Moves Right |

| Both Motors Move Opposite of Each Other | Carriage Moves Toward & Away |

| One Motor Moves | Carriage Moves Diagonal |

Is CoreXY Better?

Over the last few years the popularity of the CoreXY kinematics has became a community favorite. New designs, developments and opens source contrubutions have led many to claim it’s the best motion system for 3d printing but that really depends on the user and application.

New designs, developments and opens source contrubutions have led many to claim it’s the best motion system for 3d printing but that really depends on the user and application.

- Higher Print Speeds: The stationary X and Y motors reduce mechanical weight and momentum giving the motion system a mechanical advantage compared to other motor placement configurations.

- Quality: With the reduced weight and momentum the setup also results in reduced vibrations and increased repeatability at higher speeds.

- Mechanicaly Optimized: With the x and y motors out of the way the machine size compared to actual build volume ratio gives you more printing space with a smaller footprint. Unlike the hbot the corexy carriage isn’t problematic to twisting or buckling when x and y motors rotate in the same direction.

- Maintenance: The longer x and y belts introduce belt tensioning issues(belt stretch).

The increased number of belt idlers increase maintance.

The increased number of belt idlers increase maintance. - Scalabilty: The belt stretch and tensioning issues introduces a design constraint as the machine size increases.

CoreXY Advantages

The Advantages of the corexy system is the increased print speeds that can be achieved due to the light weight carriage. While 3d printing is a very slow process any kind of reduction in print time is much needed. In addition to faster print speeds the smooth motion that the core xy uses is also known to reduce artifacts commonly found in 3d printed objects.

see RepRap CoreXY

CoreXY vs Cartesian

Most printers utilize Cartesian or plotter style motion where one or two motors will move the carriage from left to right or towards and away. This is the simplest approach in 3d printer motion. While the core xy setup is more complicated but a more efficient approach. The difference between corexy and the cartesian motion system is the corexy reduces inertia from the static motor positions while the cartesian setup uses at least one motor to drive along each axis. The weight of the motor increases inertia making it more difficult to change direction. Which results in the corexy theoretically being faster in and more accurate than the cartesian.

The weight of the motor increases inertia making it more difficult to change direction. Which results in the corexy theoretically being faster in and more accurate than the cartesian.

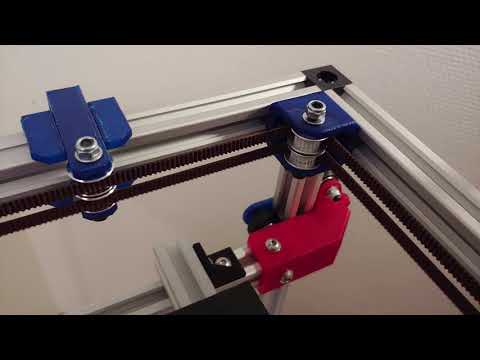

CoreXY Belt Path & Routing

CoreXY Belt Path – Source: Mark RehorstThe corexy 3d printer belt path has been explored in many mechanical arrangements. The main two corexy belt routing methods are belts crossed or not crossed. The main focus should be to keep the belt routing path parallel to the X and Y guide rails. There’s an excellent blog about core xy belt path by Mark Rehorst.

CoreXY vs Hbot

| Type | Pros | Cons |

|---|---|---|

| CoreXY | design balances the forces | more complex beltpath with two crossing belts |

| Hbot | simple design with only one belt | higher orthogonal load known as racking |

A similar mechanical arrangement of the core-xy is the H-bot. The Hbot uses the same concept of carriage motion as the corexy but is much more simple and requires less math. In addition the hbot is harder to “get wrong.” The corexy belt path has it’s pros and cons. The corexy’s disadvantage is that it requires two belts on two separate planes. The coreXY balances the forces while moving the gantry or carriage to minimize “racking’ where the mechanical system is pulled out of square.

The Hbot uses the same concept of carriage motion as the corexy but is much more simple and requires less math. In addition the hbot is harder to “get wrong.” The corexy belt path has it’s pros and cons. The corexy’s disadvantage is that it requires two belts on two separate planes. The coreXY balances the forces while moving the gantry or carriage to minimize “racking’ where the mechanical system is pulled out of square.

What You Need to Know Before Buying a 3D Printer

Every user is different and has different needs. There isn’t one printer for everybody. You have to consider:

Experience: What is your experince with 3d printers or mechanical components and electroncs that may require technical maintance or steep learning curves.

Application: What kind of parts are you going to print? What size? What materials? How many?

Expectations: What kind of quality or user experience do you expect? What kind of maintance can apply?

Budget: How much can you spend or how much are you willing to spend? You get what you pay for but you may not need much.

Related Content

SolidCore DIY 3D Printer

SolidCore CoreXY BOM

SolidCore Documentation

SolidCore CoreXY Frame

SolidCore Thingiverse 3D Printer Build Plans

SolidCore Kinematic Bed Mounting System Setup

CoreXY 3D Printer Kits

3D Printer Parts

Related Content

CoreXY Belt Routing

There are a few different types of 3d printer kinematics to choose from, with cartesian kinematics being the most common. Recently the corexy architecture has become more popular. In this guide, we will compare corexy vs cartesian kinematics in terms of their speed and print quality so that you can understand the difference in each

by Shane Hooper

The CoreXY motion system is a good solution if you’re looking to print faster. The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

by Shane Hooper

CoreXY Belt Routing One of the most important parts for corexy movement is belt routing. Here’s a guide to the mechanics of corexy belt routing pulley layout in order to get accuracy and constant belt tension. Belt Routing Methods There are two main ways to implement the corexy belt path. Either a stacked pulley arrangement

by Shane Hooper

CoreXY Kinematics Explained? The corexy kinematics mechanical arrangement includes a unique motor movement where the X or Y motor move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal..

If you were to move just one motor you would see the print head move diagonal..

by Shane Hooper

CoreXY Scalability The scalability of a core-xy printer can be an issue when it comes to hardware design and implementation. An increased belt path can also introduce problems resulting in artifacts in 3d printed parts. A rigid gantry setup is needed and proper binding is a must. 9mm and 12mm belts are available to account

by Shane Hooper

Loose belts are a common problem for users and cause a variety of issues. It may or may not be obvious that your 3d printer is experiencing issues. Belt tensioning defects can occur.

It may or may not be obvious that your 3d printer is experiencing issues. Belt tensioning defects can occur.

by Shane Hooper

SolidCore CoreXY Z-Axis Bed Leveling We recently started working on the SolidCore 3d printer‘s bed leveling and mounting system. The z-axis uses a 3-point kinematic bed mounting with magnetic pivot spheres on each mount This properly constrains the bed at 3 points of contact. The original SolidCore Z-axis design was somewhat primitive because we only

by Shane Hooper

The CoreXY motion system is a good solution if you’re looking to print faster. The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

The 3d printer kinematics has become more popular in the last couple of years as users and DIY builders agree on an increase in print quality. The motion system is more lightweight compared to other 3d printer kinematics such as cartesian

by Shane Hooper

The latest design update uses three Z-axis stepper motors. In this arrangement the belt routing to the stepper motor drive the lead screw. Each lead screw will be constrained by an MGN12 linear rail. This should also minimize vibrations that might be transferred from the motors to the z-axis. The belt to pulley ratio gives

by Shane Hooper

Modular

Scalable

Linear Rails

Balanced Carriage Pull

Enclosure

BOM utilizes most available parts

All Metal Parts or 3D Printed

Z-Axis: Independent Driven or Shared Belt Routing

by Shane Hooper

While this write up is still a work in progress as I continue to research kinematic mounting and the math used to find the angle that properly constrains the bed to allow for thermal expansion. This is the documented details of how the SolidCore kinematic mounting system should work. So comment or correct me if

This is the documented details of how the SolidCore kinematic mounting system should work. So comment or correct me if

by Shane Hooper

Frame Profile Specs Size 2020 or 20mm x 20mm Style T-Slot Frame BOM Part List Part Quantity Description Source Documentation Folder Frame Extrusions 2020 T-Slot ZylTech Frame Size List Frame Folder 570mm Long 6 Vertical (Tall) ZylTech Frame Size List Frame Folder 430mm Long 3 Vertical (Z-Axis Rail) ZylTech Frame Size List Frame Folder 660mm

by Shane Hooper

Although this page will be used to document and collect resources to implement a toolchanger on the SolidCore printer, we’ve only completed one so far for this case study. The following design analysis is discussing a toolchanger project we prototyped for our customer, Nandan. The majority of the topic currently being discussed is of the

The following design analysis is discussing a toolchanger project we prototyped for our customer, Nandan. The majority of the topic currently being discussed is of the

by Shane Hooper

Like this:

Like Loading...

Kinematics of 3D printers: what are the best types

Kinematics of 3D printers - which device to choose?

The print quality of a 3D printer and how it works depends on several factors. One of the important indicators is kinematics. This article discusses its main types and their features.

- What is the kinematics of 3D printers?

- Kinds and types of kinematics

What is the kinematics of 3D printers?

Each 3D printer has its own kinematics. Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move.

Models are equipped with a platform and an extruder. These parts move in a certain direction relative to each other. Kinematics in such a device means the scheme along which the extruder and platform move.

Types and types

There are five types of 3D printer kinematics. The principle of operation of the device and the method of processing the workpiece depend on their features.

Cartesian 3D printers

The most common are 3D printers with Cartesian kinematics. They are based on the Cartesian coordinate system, they work in the X, Y and Z axes. They set the coordinates by which the print head changes position relative to the platform. The printhead has limitations in terms of movement in three axes.

- The extruder moves up when the platform moves in the horizontal X or Y axis.

- The platform moves up in the Z axis, the extruder can move in the horizontal directions at this moment.

- The platform moves along one of the axes in height, the extruder rises along the other axis.

- The platform is static and does not move, the extruder moves in all three axes.

- The extruder moves along the coordinates in height, and the platform moves along the X and Y axes.

The most common options during operation are the first and second.

Cartesian kinematics has a number of advantages.

- This is a simple motion pattern suitable for hobby printing. Many budget models work on its basis.

- The printer can be produced in any dimensions, if necessary, it is upgraded.

- Consumables are freely available. Users are offered a large number of materials and colors.

- The printers can be shipped unassembled. This feature allows beginners in the world of 3D printing to understand the principle of the mechanism.

- Devices based on the Cartesian system, suitable for mass production of parts. They are designed to create blanks of different sizes.

Among the shortcomings of printers built on the principle of three coordinate systems, there are two factors:

- models are bulky, after assembly they take up a lot of space on the desktop;

- The print speed is slow.

Cartesian kinematic printers suitable for hobby printing. They help beginners understand the process of work and learn how to create models.

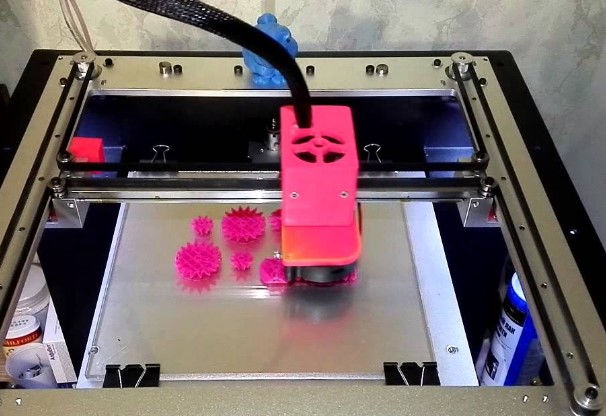

Example of printing on a device with Cartesian kinematics.

Varieties of Cartesian kinematics CoreXY and H-Bot

CoreXY has two feed belts, while H-Bot has only one, but it is long - this is the main difference between the two varieties. The common feature in these devices based on Cartesian kinematics is that the platform moves only along the Z axis. The horizontal X and Y axes are moved by a pair of motors mounted on the frame.

Two motors are responsible for the movement along the horizontal axes, one motor along the vertical ones. Such kinematics is common not only in amateur printers, but also in professional ones.

CoreXY and H-Bot based 3D printers are more expensive than conventional Cartesian models. For the production of their cases, a metal alloy or composite materials are used. Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing.

Rail guides unleash the potential of high-quality printing. This kinematics allows you to achieve good detail with fast printing.

The advantages of CoreXY and H-Bot are:

- high print speed;

- quality detailing of models;

- professional use grade.

But not without drawbacks:

- H-Bot is not implemented on steel shafts;

- the belt tension must be constantly monitored to avoid play;

- high cost of instruments;

- belts can wear out quickly if they rub against neighboring objects during operation, this factor must be taken into account during operation;

- the pulleys on which the belts move must be located strictly perpendicular to each other.

Cartesian kinematic printers are widely used in various industries. They are distinguished by high print detail, a durable metal case, and high-quality components.

Help! Cartesian kinematics allows you to create detailed objects at high speed.

Delta Printers

Delta kinematic printers differ from their competitors in a number of ways. The table remains stationary, and three fixed axes are used to move the print head at once. In such devices, there is no division into the X, Y and Z axis. To move the carriage sideways, you need to lower one axis, and raise the rest.

Help! In the production of 3D printers, the Delta kinematics has not yet found wide distribution. This is a promising direction, which is currently being developed by developers.

Already existing delta printers offer the following advantages.

- Small dimensions. Devices do not take up much space on the desktop, they are tall, but not wide.

- High print speed. Models can process 300–400 mm/s.

- A new approach to blank production. The equipment does not print using the same technology as Cartesian. It is interesting to watch the process of processing the model.

Deltas also have a few disadvantages.

- Calibration complexity. A lens is formed on the printed surface, due to which it is impossible to fully calibrate the printing process. This is the main factor slowing down the mass introduction of kinematics.

- Poor accuracy. High print speeds sacrifice accuracy. All axes perform small movements, errors occur.

- Computing power requirement. Deltas are equipped with 32-bit boards, which is why they do not support interaction with 8-bit systems.

- The frame must be rigid. This is necessary to avoid backlash, deviations and distortions.

- Not all extruders will fit. Deltas have weight restrictions, so direct type extruders are not allowed.

Printing accuracy remains high.

On deltas, you can build high-quality vertical models, even with large dimensions. There are no protruding parts on the body, which allows you to independently increase its rigidity.

Polar

The polar kinematic scheme is presented only by one company - Polar. The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The essence of this technology lies in the fact that it does not have positioning along the X, Y and Z axes. The position of the extruder is set by the angle and radius. The platform of polar 3D printers is round in shape, it moves only along the horizontal axis and only rotates in a circle. The extruder moves up and down.

The advantages of 3D printers based on polar kinematics are:

- the ability to create large objects;

- high energy efficiency;

- material savings;

- small dimensions.

But there are also disadvantages:

- low printing accuracy, which was started by Polar representatives;

- platform does not warm up during operation;

- material handling restrictions - ABS plastic cannot be processed.

Polar printers are less accurate than Cartesian and Delta printers. The manufacturer recommends using such models for educational purposes; they are not yet suitable for professional printing.

Printing example shows that accuracy cannot be achieved. All features are blurred, the figure lacks sharpness and clarity.

With robotic arms

Printers with robotic arms are a design with a mechanically programmable extruder gripper arm. This is a multifunctional robot: it can carry out welding, painting, milling, etc.

The extruder can move in different directions: in layers, along complex paths in three dimensions, at different angles. Thanks to this set of functions, it is possible to create complex structures.

The main advantages are:

- versatility: the device can perform several types of tasks when replacing the extruder;

- are suitable for industrial applications: you can print large objects with almost no size restrictions.

But there are also disadvantages:

- low accuracy: such equipment is inferior to Cartesian kinematics;

- large size: devices take up a lot of work surface space.

These models are not suitable for professional 3D printing. They can be considered as an object for a hobby or a tool for it. For industrial purposes, such devices work only when high precision in the execution of parts is unimportant.

SCARA

SCARA (Selective Compliance Articulated Robot Arm) is a kinematics based on horizontal rotation of the platform. The movement is achieved by the articulation of the linkage mechanism.

These instruments are highly accurate and repeatable, and operate with a minimum of noise and vibration. SCARA also surpassed the Cartesian models in terms of processing detail: the difference is that the former work noticeably faster.

Advantages of such kinematics:

- print accuracy;

- high workpiece processing speed;

- small dimensions and weight.

But there are also disadvantages:

- stiffness restrictions in the area of the X and Y axes;

- high cost;

- is not the widest area of use.

SCARA kinematic devices are devices that combine the functions of a 3D printer and a manipulator. Device actions are programmed through software or an installed mobile application.

The choice of kinematics for 3D printers depends on the requirements for technology and application.

- Cartesian models remain the most common. They combine high accuracy, good speed, small dimensions. They can be used for amateur 3D printing. They work in a Cartesian coordinate system, the platform and the extruder move along the X, Y, Z axes.

- CoreXY and H-Bot are varieties of Cartesian kinematics. They are highly detailed blanks, suitable for professional use. Their disadvantage is the complexity in the process of operation. The user must constantly ensure that the belts do not come into contact with foreign objects and are well tensioned.

- Delta printers are uncommon models whose weak point is print accuracy. In the process of working with the device, there are problems with calibration, as well as with the choice of extruder.

- Polar printers are produced by only one company - Polar. These devices cannot provide high accuracy of the workpiece, so they are used only for educational purposes. During operation, the platform does not warm up, which limits the choice of materials.

- Robotic 3D printers are versatile devices that are used for more than just model making. Such devices can mill, weld, paint. The technique is inferior in accuracy to the Cartesian varieties.

- SCARA is one of the modern kinematics, which can not be used in all areas. It features high precision and good printing speed, it can be used as a professional instrument. The main disadvantage of SCARA is its high price.

- February 17, 2020

- 9954

Get expert advice

3D printing for the newest. From A to Z. Kinematics.

In this article, we will understand what 3D printing is and what the kinematics of 3D printers are.

1. 3D printing. What does she taste like?

There are a lot of printing technologies, from FDM (FFF), which is used by more than 90% of printers on this portal, to SLA / DLP / LCD (with photopolymers) and SLS / SLM (powder sintering using powerful lasers)

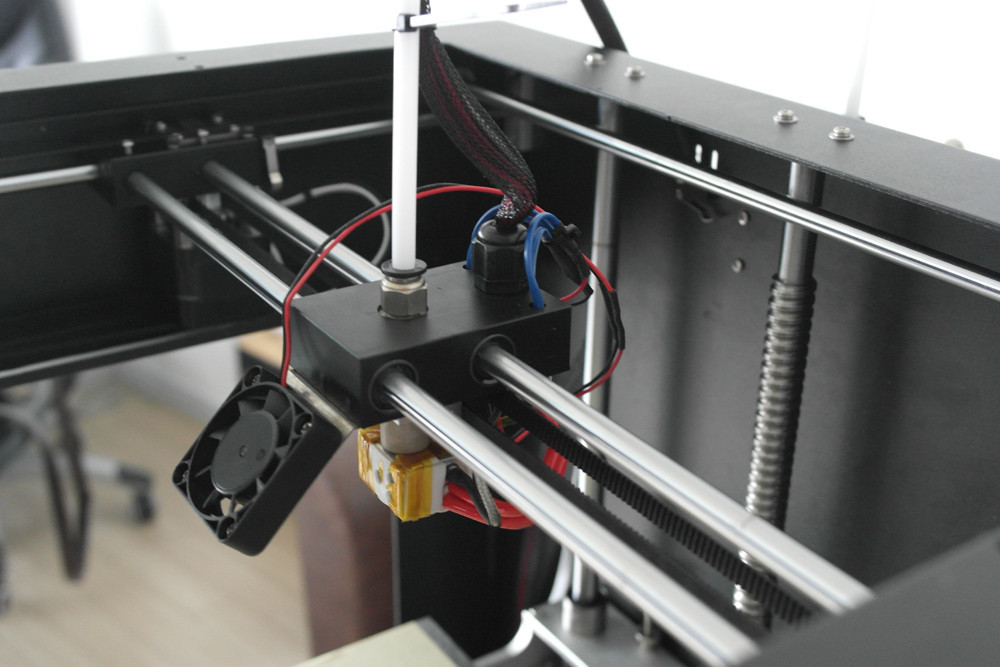

At the initial stage, we are interested in FDM - layer-by-layer deposition of a molten rod. The picture below shows the hot end (Hot end) - that part of the 3D printer extruder where the rod is melted.

The plastic rod is fed through the Teflon tube and radiator into the thermal barrier, and through it into the heating block. It melts there and exits through the nozzle. The nozzle has a certain diameter, which is marked on it.

It is often made of brass, as the material is inexpensive and easy to process. The accuracy of printing depends on the nozzle. The smaller the nozzle, the more threads fit into one mm.

Heater and thermistor provide feedback for temperature control and regulation. That is, the voltage supply to the heater depends on what temperature the thermistor shows, and the processor compares it with the set one.

Next we see the heating block. A nozzle is screwed into it on one side, and a thermal barrier on the other.

The thermal barrier is used to minimize the heating of the plastic above the thermoblock.

[IMG]http://3d-makers.nethouse.ru/static/img/0000/0002/6151/26151635.2ofdbr37y8.W665.jpg[/IMG]

Most often made of stainless steel. It has a lower thermal conductivity than conventional, unalloyed steel. To prevent the rod from melting above the thermal block, a radiator is screwed on top of the thermal barrier and blown by a cooler. Everything is quite simple.

It is very common for melted plastic to leak through threads.

This means that the nozzle has not pressed the thermal barrier in the heater block. Therefore, when disassembling and assembling the hot end, we first screw the thermal barrier into the heating block, and then press it with a nozzle. If, when you twist the nozzle, there is a gap between the end of the nozzle and the heating block, then this is normal, the gap in order to press the thermal barrier with the nozzle.

Therefore, when disassembling and assembling the hot end, we first screw the thermal barrier into the heating block, and then press it with a nozzle. If, when you twist the nozzle, there is a gap between the end of the nozzle and the heating block, then this is normal, the gap in order to press the thermal barrier with the nozzle.

In order to feed the bar at the right time and in the right place, a feeder is needed, that is, a bar feeder.

Sometimes it is performed combined with a hot end, and then this type of extruder (this is all together a hot end + feeder) is called a direct (direct), that is, a direct feed, without tubes.

The same feeder is made separately, and the bar is fed through a fluoroplastic tube. Such a system is called bowden.

This is to lighten the moving part. As for the positive aspects and disadvantages - each design undoubtedly has them.

Direct extruder:

1. Advantages:

Advantages:

a) More reliable due to fewer plastic feed connections;

b) Less picky about the materials it prints on, in particular rubber-based rubber is problematic to print on bowden extruders;

2. Disadvantages:

b) Dimensions. They greatly affect the plot area. Let's say, like in the picture above, a direct with 4 colors would be very huge. And for Bowden, this is just right.

Bowden extruder:

1. Advantages:

b) The coil does not twitch after the model, otherwise when the coil turns with the direct are tangled, we will get a skip of steps, since the carriage will pull the coil along with it.

2. Disadvantages:

a) Retract settings (pulling the rod back during idle movements so that the molten plastic does not ooze out of the nozzle expanding) is more difficult, since the rod is smaller than the inner diameter of the tube, it tends to stretch;

b) It is more difficult than on direct to select all gaps in order to print with various flexible plastics. Everyone who says that printing on Bowden is impossible with flexible plastics is blatantly lying. I am typing. And quite successfully.

Everyone who says that printing on Bowden is impossible with flexible plastics is blatantly lying. I am typing. And quite successfully.

Now we go directly to the mechanics and its calibration.

Part 2. Mechanics. What, how and what pulls?

There is a very limited number of kinematic schemes for which the firmware is written, and which work out movements quite tolerably.

Consider everything, from the most common:

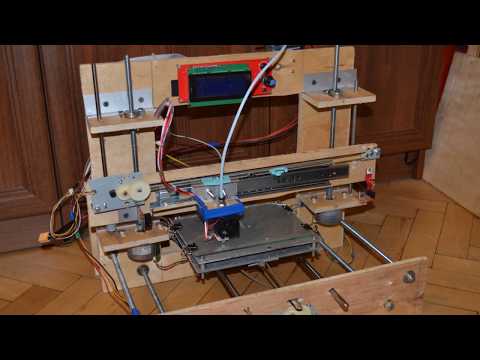

1. Design and kinematics from Joseph Prusha (no need to read Prus, Prasha and so on, this is the name of a person, after all).

Movement along each of the axes is provided by its own independent motor. Movement along the Z axis (up and down) is provided with the help of 2 motors and with the help of a kinematic screw-nut pair. M5 studs are often used; recently, screws with trapezoidal threads have been increasingly installed.

Here is a trapezoidal screw. How studs with metric threads look I will not apply.

How studs with metric threads look I will not apply.

The only thing I will explain about moving along the studs and trapeziums is that for the production of trapeziums they take a calibrated rod and roll it between rollers at an angle. Get helical grooves. This method, a priori, gives better quality and step accuracy than building studs of far from the highest quality.

To connect 2 motors to one axle (and 1 connector) at the same time, the following scheme is used.

Connection in series, 2 wires soldered and the rest crimped. You can ignore the colors, the main thing is that the windings ring. A and B are windings, and 1 and 2 are terminals.

Advantages of this kinematics:

1) Independent movement of each axis. It is easy to catch to understand which axis skips steps. Kinematics migrated to printers from CNC milling, so many manufacturers make desktop milling machines on it; instead of an extruder, they offer to install a laser for engraving or cutting, a spindle for milling boards, an extruder for chocolate or even dough to bake pancakes.

Kinematics migrated to printers from CNC milling, so many manufacturers make desktop milling machines on it; instead of an extruder, they offer to install a laser for engraving or cutting, a spindle for milling boards, an extruder for chocolate or even dough to bake pancakes.

Pictured above is a ZMorph printer. It can be used as a printer (with one or two extruders), as an engraver (Dremel machine), as an engraving laser, and so on. A small presentation video.

Milling machine with this kinematics. I note that for milling it is necessary to use a screw-nut pair to move, and not belts, they are not designed for such loads.

Chocolate and pancake printers according to your design. It is worth noting that it is not recommended to use chocolates like Alenka or Babaevsky, since they already contain cocoa butter and during processing (melting and hardening) the result is unpredictable. It is necessary to use chocolate in galettes, such as the Belgian Callebaut, as it does not contain cocoa butter, and must be added for the final filling. For this type of chocolate, each pack has a graph of its crystallization. It is desirable to take the oil in powder form. For more information, I recommend Google about tempering chocolate.

It is necessary to use chocolate in galettes, such as the Belgian Callebaut, as it does not contain cocoa butter, and must be added for the final filling. For this type of chocolate, each pack has a graph of its crystallization. It is desirable to take the oil in powder form. For more information, I recommend Google about tempering chocolate.

2) The kinematics are as easy as two fingers. Its very easy to assemble. Many even collect on old DVD drives.

3) Easily changed to suit your needs, the size of the extruder is also of little importance, as it protrudes forward and does not interfere with the movement of other parts. Many people put a second extruder, or make the nozzles swing so that the nozzles of one extruder do not remain on the part when printing with the second nozzle.

Therefore, for this kinematics, there are a huge number of extruder variations, for every taste, on a very famous site.

Disadvantages of this kinematics:

1) Complicated calibration. Yes, since the table 'jumps', it is difficult to print with high quality, because the part + table, with a sharp change in the direction of movement by inertia, tend to go further. Ugly print artifacts are obtained. And for high-quality printing, you need a small speed. In general, it all depends on the frame. My first printer was a Chinese pryusha. With acrylic frame.

Acrylic is not very hard. And as you know, the rigidity of the printer, like the CNC, is the most important thing. And it was possible to print more or less qualitatively at speeds of 40-50 mm / s. Then I transplanted it to a steel frame from MZTO.

And after that, without loss of print quality, I was able to print at speeds up to 100 mm / s.

2) Delamination. Due to the open case and the constantly moving platform, hot air, one might say, is constantly blown away, and by cooling the part excessively with drafts, we increase the already large shrinkage of nylons, abs and other capricious plastics. Someone sews a fur coat for a fabric printer, and someone is content with boxes.

Someone sews a fur coat for a fabric printer, and someone is content with boxes.

But the goal, as always, is the same - to reduce the effect of drafts on the shrinkage of the part.

Key points for correct calibration of printers with this kinematics:

1) Place the printer on a level surface. Preferably horizontal. This requires a bubble level. Next, set the level of the position of the X axis.

2) Transfer to the home position. It is done either in the printer menu with the Home / Home command, if you are printing from a computer, then either with the G28 command in the command line, or with special buttons with the house icon.

Next, tighten the table screw so that the nozzle touches the glass. It did not press on the glass, but touched. We look at the light and twist. After that, move the extruder to another corner with the arrows in + X, + Y from the PC, or through menu

Turn the screw in the same way until it touches the nozzle. And repeat the operation for the remaining points.

And repeat the operation for the remaining points.

I will try to save you from mistakes. In the photo of the printer above, the glass on the table is fastened with as many as 8 clamps. And it is quite possible that there will be a hump in the center. To avoid such problems, the glass should be fixed with 3 clamps. The plane is built, as is known from descriptive geometry, by 3 points. And calibration will be easier in this case. Just tighten the screw over the limit switch in Z.

For the nozzle to touch the glass in the middle of the side with 1 clip. Then we distill the hot end into the corner where there is another clamp, tighten the table screw, and repeat the operation with another angle.

Regarding wobble.

Any anti-wobbling systems such as installing a bearing in the upper support do not work.

Just because putting 4 far from perfectly even cylinders in perfect parallel and in the same plane is an unrealistic task. Especially on a flimsy acrylic frame with printed details. Therefore, if we take the straightness of the shafts as a constant, and set them parallel on the frame (purely hypothetically), and release the screws (from below the coupling for attaching to the motor) and nuts for attaching the X axis. Due to their curvature, the screws will spin like a mixer, but on printing will not be affected.

Especially on a flimsy acrylic frame with printed details. Therefore, if we take the straightness of the shafts as a constant, and set them parallel on the frame (purely hypothetically), and release the screws (from below the coupling for attaching to the motor) and nuts for attaching the X axis. Due to their curvature, the screws will spin like a mixer, but on printing will not be affected.

Otherwise, the design will work on who will be stronger in bending resistance. And it will turn out far from a flat wall. Do you need it?

2. Kinematic design of Felix printers.

There are many such printers, such ones are made by MZTO (mz3d.ru), already mentioned by Felix. In fact, the kinematics are the same as those of the Prusa. axes independent of each other. Only now the table does not travel along one axis, but along two at once. Along the Z axis, and along the Y axis.

The design of the table is something like this.

A platform rides on the Z shafts. The engine hangs at the back. The table moves along the rails with the help of a belt. The hotend moves only along one axis. The design is very funny, since the table weighs much more than the hotend, and they try to move it along 2 axes at once.

Advantages of this kinematics:

1) There is no second motor along the Z axis. There is no notorious wobble simply because there are 2 shafts and 1 propeller. The screw should also not be fixed from above. If it's not a ball screw.

Ball screw is a separate issue. If we take a high-quality ball screw, say, from the same Hiwin, then it is manufactured according to at least the 7th accuracy class (if rolled, and if polished, then the class is even higher) and must be installed in bearing supports. On the drive side there are 2 back-to-back angular contact bearings, and on the other end a radial bearing with a loose fit to compensate for thermal expansion.

The purpose of mounting a ball screw is to ensure movement accuracy. If it is installed incorrectly, money is wasted, and the accuracy will not be higher than a screw-nut pair with a trapezoidal thread. For FDM, trapezoidal accuracy is more than enough.

2) Plenty of space for a direct extruder. As in the previous kinematics, there is room for creativity, to select the one and only extruder that you like.

3) Rigid frame. It is possible to make a normal frame. Rigid, durable. Yes, even cast iron. The guys from Felix decided not to bother their heads and sculpt from an aluminum profile. MZTO went further, bent the steel sheet. And the shelf for the installation of the table was milled from a sheet of aluminum.

4) If we take the design of Felix on the profile, then by replacing a pair of pieces of the profile and the Z screw, you can increase the print area.

Just be sure to add stiffness. And it will turn out like a miracle of design thought. Big, meaningless and merciless.

And it will turn out like a miracle of design thought. Big, meaningless and merciless.

Kinematic disadvantages:

1) Undoubtedly large twitching masses. The table back and forth, and if you turn on the movement along Z during idle movements (Z-hope), then there will be a disco.

2) There is no way to make him a normal heat chamber. The table moves back and forth and the temperature gradient simply blows away. Hence the problems when printing with nylons or ABS. Small drafts in the room will easily show you where the crayfish hibernate, how the material shrinks.

The table calibration of this printer is similar to the Prusa table calibration, only a little easier. It is easier due to the fact that you do not need to level the X-axis, it is automatically set when assembling the frame. We bring the nozzle to the table and twist the lambs.

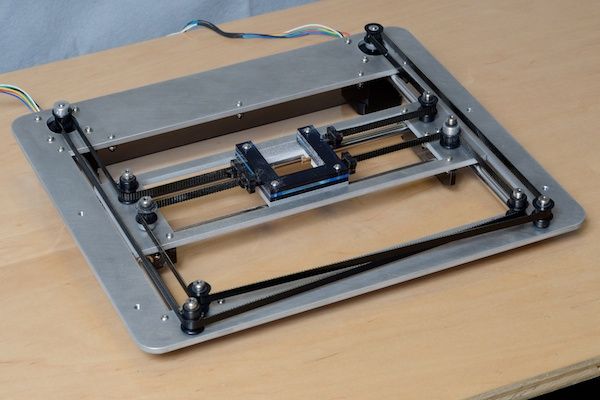

3. Ultimaker kinematics.

One of the most common variations of Cartesian kinematics.

There are not very many such printers, but they do exist. Variation from Zortrax deserves attention. A variant of the same Raise is closer to the classics.

Zortrax has twin shafts, the reason is simple - they have a direct extruder with a full size Nema 17 motor. Raise Dual has a double direct extruder, so the classic 6 mm shafts are replaced by 8 mm. And the total weight of the 'head' is almost 900 grams.

Kinematics built entirely on shafts. They act both as guides and as pulleys. Kinematics also refers to Cartesian kinematics with independent movement along each axis by its own motor. Very picky about the straightness of the shafts. If you use curved shafts, you can get very funny artifacts on the walls of models. And they will be on all 3 coordinates. Most often it looks like a different thickness of the first layer and small waves along the walls. Therefore, all the salt and the high price of the original Ultimaker is only in high-quality components. Namely, in straight shafts. The belts are often used as ring belts, which simplifies their tensioning system, since it is important that all 4 belts are equally tensioned.

Namely, in straight shafts. The belts are often used as ring belts, which simplifies their tensioning system, since it is important that all 4 belts are equally tensioned.

Advantages of this kinematics:

1) The table only moves along one axis. vertical. And the temperature gradient in no way suffers from this. The table is cantilever, so it is desirable to provide stiffeners or take this into account with the thickness of the table.

The metal fold on the table acts as a stiffener.

Many Chinese clones are equipped with such stiffening ribs for the table.

2) Despite the seeming complexity of the kinematic scheme, it is simple and each axis moves with its own motor.

3) The body is closed, which protects against drafts, and therefore delamination. Some put an acrylic door to heighten the effect.

Disadvantages of kinematics:

1) For good printing, it is not enough to buy a pack of even rollers. Collecting all these shafts correctly together is another task. At the same time and buy good bearings. Not that, Chinese junk, which is often sold on Ali, but normal bearings. If the bearings that are placed in the housing rotate poorly, the print will be jerky and with a shift in the layers. The consequences can be asked from Vanya (Plastmaska). Also, when buying leopard bushings, brass bearings with graphite inserts, be prepared for the fact that they will play. And if there is a backlash, the whole structure will knock.

Collecting all these shafts correctly together is another task. At the same time and buy good bearings. Not that, Chinese junk, which is often sold on Ali, but normal bearings. If the bearings that are placed in the housing rotate poorly, the print will be jerky and with a shift in the layers. The consequences can be asked from Vanya (Plastmaska). Also, when buying leopard bushings, brass bearings with graphite inserts, be prepared for the fact that they will play. And if there is a backlash, the whole structure will knock.

And also, the Chinese like to push brass instead of bronze. And with even wear of brass and graphite, there will be an oily sticky black film on the shafts, which will make the movements harder. Ilya (tiger) offers good bushings. He also wrote about these difficulties.

2) All shaft parallels must be set correctly. I suggest using this device.

4 shafts that go along the walls of the body automatically stand up correctly, but it is important to set the crosspiece correctly in order to get angles 90 degrees in the XY plane.

3) The design does not provide for an increase in the printable area with a couple of profile pieces, so the size of the hotend matters. Direct is difficult to put, but you can if you want.

Calibrating the table couldn't be easier. The table is often on 3 attachment points. Move the hot end by 3 points and turn the thumbs.

4. Kinematics used by Makerbot.

Also very widespread. In particular, printers from Makerbot, BQ, BCN3D, Magnum, magnum clone Zenit and quite tolerable makerbot replicas Flashforge and Hori work on this kinematic scheme.

In this case we have independent movement of each of the axes, with a Z table and all the resulting sides.

The main drawback is that the engine hangs on one side of the rolling beam, creating a kind of imbalance. This shortcoming was compensated in a two-extruder version - BCN3D Sigma. There, each bowden head has its own engine to move along the beam. And they are installed at the edges of the beam and balance each other. For uniform movement of each of the edges of the beam, 2 shafts, pulleys and belts are used. Belts must be tensioned equally.

For uniform movement of each of the edges of the beam, 2 shafts, pulleys and belts are used. Belts must be tensioned equally.

Advantages of kinematics:

1) Independent movement of each axis.

2) Z-moving table. The temperature gradient does not suffer from 'blowing'.

3) Enclosed housing. If not closed, then there is a quite normal chance from the point of view of aesthetics to close it.

4) Scalable kinematics possible. Various BigREPs and others with 1m print areas use exactly this kinematics, as various H-bot/CoreXYs will ring like hell due to the presence of 4-5m belts and their stretching during accelerations.

Disadvantages of kinematics:

1) Unbalanced masses on the moving beam, hence the maximum print speed, with acceptable quality no more than 60-80 mm/s. Some manage to balance them and it is not so noticeable.

2) Bulky structures on the shafts to avoid unbalance during movements.

3) Make sure that the belt tensions on the right and left are the same.

4. H-bot/CoreXY kinematics.

Next in distribution. Also Cartesian. Two motors are stationary, but move the carriage along the rails with one long piece of belt, or with two, but shorter. The math is more complicated than the previous ones, as it is necessary to synchronize the rotation of both motor rotors. That is, to move along each axis, you need to rotate both motors, and to move diagonally, only 1.

[IMG]http://www.doublejumpelectric.com/projects/core_xy/pics/hbot.svg[/IMG]

In fact, the mathematics for rotating motors is the same, but the implementation in mechanics is different. One of the biggest disadvantages of the H-bot over the CoreXY is that the belt tends to rotate the beam as it moves.

In the picture on the left, this is noticeable, the forces on the right and the forces on the left create a torque. Therefore, to implement this kinematics, the rigidity of the kinematic scheme is necessary. Most often it is implemented in rails.

Most often it is implemented in rails.

With rigid beam. Some do, of course, on the shafts, but in the end - this is not a fountain.

And then they realize this and move to the rails.

For they are both easier to assemble and set up, and it is not necessary to invent carriages so that the shafts do not need to be fixed well.

CoreXY, unlike the H-bot, is driven by two belts.

And so, for ease of understanding, I will describe the positive and negative aspects of each variation of this kinematics.

H-bot.

Advantages:

1) Only one belt is needed, and the scheme provides for its operation without twisting.

2) It is more convenient to tension one belt than 2, so only one normal tensioner is needed in this scheme.

Even so.

Disadvantages:

1) The belt tends to stretch over time, and since the amount of stretching directly depends on the length, it is necessary to monitor its tension. Otherwise, you will get ugly waves on the surface before the stops.

With a loose belt tension, the carriage will have this play.

2) It is necessary to set the rollers strictly perpendicular to the XY plane, since if the roller is slightly skewed, the belt will be eaten against the roller shoulders. And we will get such a bullshit.

Tested in the skin and ZAV printer. Therefore, I always recommend that the rollers be fixed normally, and not cantilevered, in order to avoid bending the roller axis from belt tension.

3) Complicated mathematics, due to which at speeds above 100 mm/s there may be problems with the lack of resources of 8 bit boards.

CoreXY.

Pros:

1) Two short pieces of strap. They are easier to find than one long one.

2) The forces balance the beam, but do not tend to turn it, so these kinematics can also be assembled on shafts.

Disadvantages:

1) There are schemes with belt twisting and belt transition from one level to another - this is not very pleasant for a belt. Especially when one belt rubs against another. This moment is on video.

:{}

2) The difficulty of tightening the belts. They must be tensioned equally, otherwise the tension forces will tend to turn the carriage.

3) Complexity of assembly and development. It is necessary to maintain the verticality of the rollers, relative to the horizontality of the platform for installing motors and rails. A slight misalignment of the rollers will cause the belt to tend to slide down the roller, and if it rests against the shoulder of the roller, it will creak, if the shoulder is large, and if it is small, it will try to drive into it, as in the photo from the h-bot description .

The general disadvantage of kinematics is poor scalability. That is, it is very problematic to set such a kinematics for a print area larger than 300 * 300 simply because of the lengthening of the belt during printing. For small printers with high print speeds - one of the best kinematics.

5. Delta kinematics.

The kinematics are based on the movements of the delta robot.

Only the hot end is installed instead of grippers. It has its own set-up problems, but it can take a very long time to print. It is rare when direct extruders are installed, since the effector (a platform for installing a hot end) is often mounted on magnets and it is necessary to unload it as much as possible. But to reduce the length of the tube (more specifically, the effect of the length of the tube on the print quality due to the correct adjustment of the retracts (pulling the plastic rod back to reduce its leakage from the expansion)) on the print quality, the extruder is hung on the same carriages, but on separate hangers. This reduces the length of the bowden tube and increases print quality.

This reduces the length of the bowden tube and increases print quality.

Advantages:

1) Easy to customize. To increase the height, it is enough to buy 3 pieces of a longer profile, and increase the maximum height in the settings.

2) Takes up little space. It is more often high than bulky in length and width, due to this compactness.

3) If you make a light effector (carriage on which the hot end is installed), then you can achieve high speeds without losing print quality.

4) Vertical movement is the same as XY movement. Thus, there is no sticking of linear bearings on the table crossings, as in Cartesian printers, no extra motors rolling on the beam...

5) The absence of protrusions makes it possible to close the housing and stiffen the frame.

6) The aesthetic part - it's more interesting to stick to the work of the delta.

Disadvantages:

1) Difficult mathematics of movements, it is recommended to install 32-bit boards at once.

2) Complicated setting. A common problem in tuning is to remove the so-called 'lens', because each rod rotates with a radius, and if the tuning is incorrect, your printed plane will be either a convex or concave lens.

3) It is difficult and expensive to make a rigid frame, so that it would not dangle from the constant jerking of the carriages.

4) Difficulty installing a direct extruder. It turns out to be heavy, and since many deltas are made on magnets, it will not be possible to accelerate. Although, there is one neat and easy solution - installing a ready-made direct extruder with a gearbox. Like E3D Titan Aero or Bondtech BMG.

5) Parts precision problems - any unevenness and misalignment will be visible even if they are on the same axis. And they add up along the axes.

To sum up , do you want a small printer (not larger than 300*300 mm) with nimble kinematics? Then you should go to Ultimaker or H-bot/CoreXY.