Kinect one 3d scanner

Validation of a novel Kinect-based device for 3D scanning of the foot plantar surface in weight-bearing | Journal of Foot and Ankle Research

- Methodology

- Open Access

- Published:

- Giulia Rogati1,

- Alberto Leardini1,

- Maurizio Ortolani1 &

- …

- Paolo Caravaggi ORCID: orcid.org/0000-0002-8994-80621

Journal of Foot and Ankle Research volume 12, Article number: 46 (2019) Cite this article

-

4682 Accesses

-

12 Citations

-

7 Altmetric

-

Metrics details

Abstract

Background

Advancements in additive manufacturing, along with new 3D scanning tools, are increasingly fulfilling the technological need for custom devices in personalized medicine. In podiatry and in the footwear industry, custom orthotic and footwear solutions are often required to address foot pathologies or morphological alterations which cannot be managed with standard devices. While laser scanners are the current gold-standard for 3D digitization of the foot shape, their costs limit their applications and diffusion, therefore traditional operator-dependent casting methods are still in use. The aim of this study was to design and validate a novel 3D foot scanner based on the Microsoft Kinect sensor, allowing a 3D scan of the plantar shape of the foot to be acquired in weight-bearing.

Methods

The accuracy and repeatability of the prototypal foot scanner were investigated in a population of 14 asymptomatic healthy subjects, with no history of foot or lower limb injuries. The accuracy was estimated by comparing the Kinect foot scans with those obtained with a high-resolution laser scanner used as reference. The repeatability was assessed by comparing scans of the same foot acquired in different sessions.

Results

The inter-subject average Root Mean Square Error (RMSE) of the Kinect scans was lower than 3 mm for the whole plantar surface, and lower than 1.6 mm for the arch region alone, both in left and right feet. The repeatability, quantified as the average RMSE of pairwise comparisons between sessions, was 1.2 ± 0.4 mm.

Conclusions

The present Kinect-based 3D foot scanner showed optimal intra-operator repeatability and its accuracy appears adequate to obtain 3D scans of the foot plantar surface suitable for different clinical applications. This device could represent a valid low-cost alternative to expensive laser-based scanners and could be used for automatic foot measurements, supporting the design of custom insoles and footwear.

Peer Review reports

Background

There is an increasing interest in the research and development of new tools for 3D scanning and modelling of body parts to address the requirements of personalized orthotic devices and treatments [1]. In podiatry and in the footwear industry, an accurate geometrical characterization of the foot shape is critical to designing custom orthoses and footwear for different categories of people, from healthy workers [2, 3] and athletes [4], to patients with foot or lower limb issues [5], such as patients with diabetes [6, 7]. The medial longitudinal arch, the most notable morphological feature used to characterize the foot type [8, 9], allows the foot to act like a spring: when loaded vertically, it stores energy in several visco-elastic structures, such as the plantar aponeurosis, that can be recovered through elastic return [10]. The foot shape resulting from the mechanical interaction with footwear and orthoses is revealed in weight-bearing conditions, when body weight and ground reaction forces act to deform the foot joints and soft tissues spanning the medial longitudinal arch. It is widely reported that significant peak pressure reduction can be obtained with custom orthoses with respect to non weight-bearing designs [11], and to off-the-shelf insoles [12, 13].

In podiatry and in the footwear industry, an accurate geometrical characterization of the foot shape is critical to designing custom orthoses and footwear for different categories of people, from healthy workers [2, 3] and athletes [4], to patients with foot or lower limb issues [5], such as patients with diabetes [6, 7]. The medial longitudinal arch, the most notable morphological feature used to characterize the foot type [8, 9], allows the foot to act like a spring: when loaded vertically, it stores energy in several visco-elastic structures, such as the plantar aponeurosis, that can be recovered through elastic return [10]. The foot shape resulting from the mechanical interaction with footwear and orthoses is revealed in weight-bearing conditions, when body weight and ground reaction forces act to deform the foot joints and soft tissues spanning the medial longitudinal arch. It is widely reported that significant peak pressure reduction can be obtained with custom orthoses with respect to non weight-bearing designs [11], and to off-the-shelf insoles [12, 13]. However, traditional foot casting methods can not always model the foot in weight-bearing, do not provide automatic foot measurements [14], and have been shown to be less reliable than digital scanning [15, 16]. In this respect, structured-light and laser- based scanners are currently the gold-standard for acquiring 3D high spatial-resolution images of the foot shape. In the former, a pattern of light is projected onto the foot, and cameras located at different positions detect the distortion of the pattern [17]. Laser scanners use an emitter to project a laser line on the foot and capture its reflection with one or more sensors. Both scanners use the triangulation process to reconstruct the 3D shape of the foot.

However, traditional foot casting methods can not always model the foot in weight-bearing, do not provide automatic foot measurements [14], and have been shown to be less reliable than digital scanning [15, 16]. In this respect, structured-light and laser- based scanners are currently the gold-standard for acquiring 3D high spatial-resolution images of the foot shape. In the former, a pattern of light is projected onto the foot, and cameras located at different positions detect the distortion of the pattern [17]. Laser scanners use an emitter to project a laser line on the foot and capture its reflection with one or more sensors. Both scanners use the triangulation process to reconstruct the 3D shape of the foot.

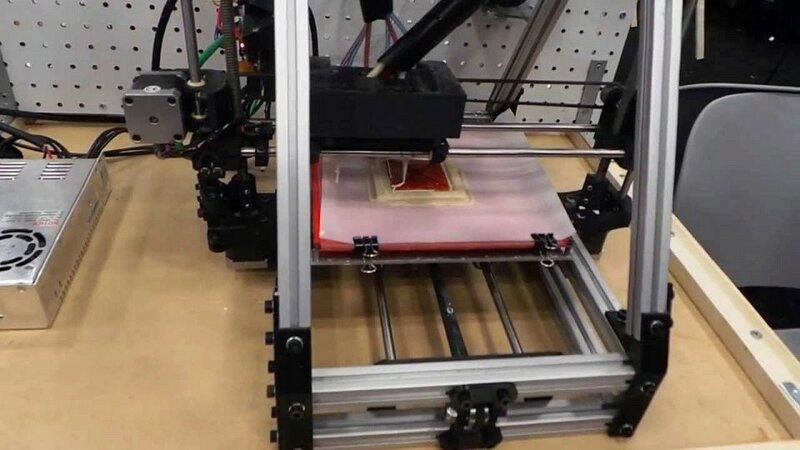

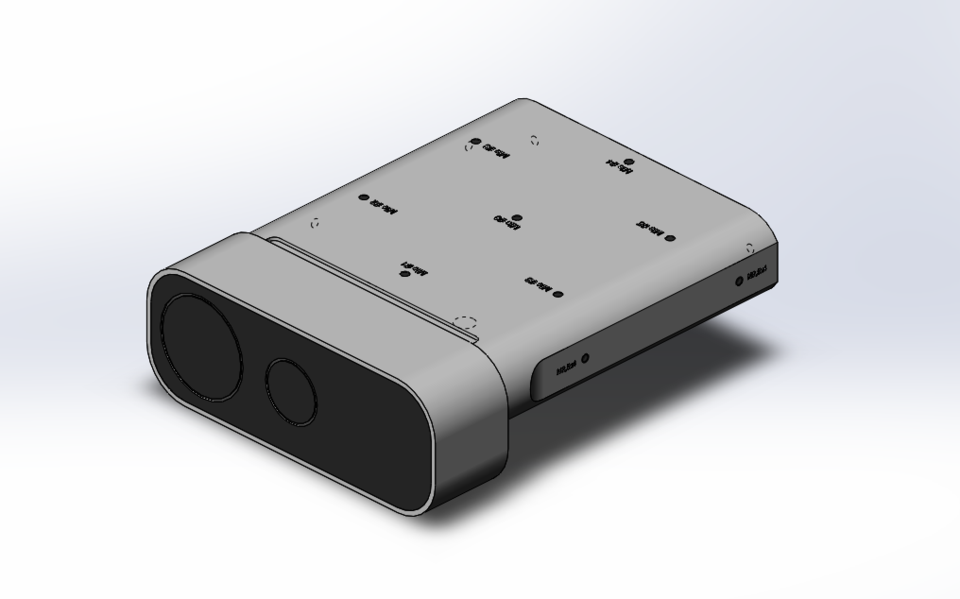

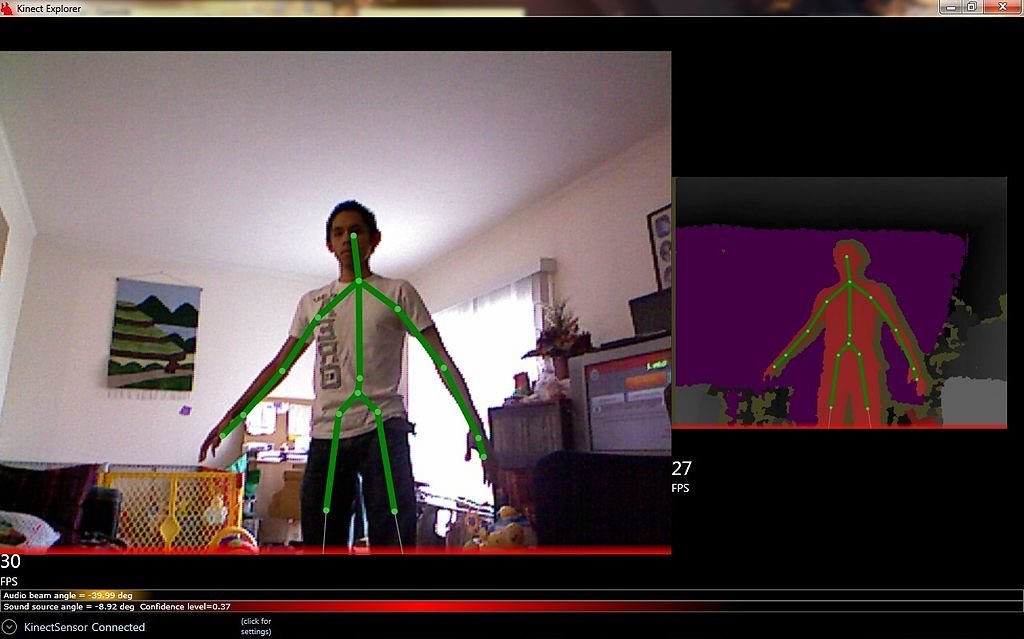

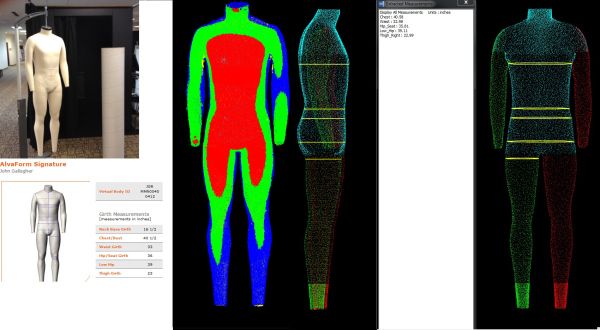

Although 3D scans are significantly cost-effective compared to the consumable costs of plaster casts [18, 19], commercial 3D foot scanners are still rather expensive (6.000–15.000€) thus strongly limiting their applications and diffusion. For this reason, the Kinect sensor, a RGB-depth camera developed by Microsoft for the videogame industry, appears to be a viable low-cost solution for 3D scanning of the foot shape. The sensor has found application as a static body scanner, e.g. in the assessment of postural control [20] and spinal deformity [21], and as a motion analysis tool [22,23,24,25,26]. While the Kinect has been used to analyse foot posture and morphology [27,28,29], a thorough validation study as a 3D foot scanner has yet to be reported.

The sensor has found application as a static body scanner, e.g. in the assessment of postural control [20] and spinal deformity [21], and as a motion analysis tool [22,23,24,25,26]. While the Kinect has been used to analyse foot posture and morphology [27,28,29], a thorough validation study as a 3D foot scanner has yet to be reported.

The purpose of this study was to validate, in terms of accuracy and repeatability, a novel 3D foot scanner based on the low-cost Microsoft Kinect sensor to obtain 3D images of the foot plantar surface in weight-bearing.

Methods

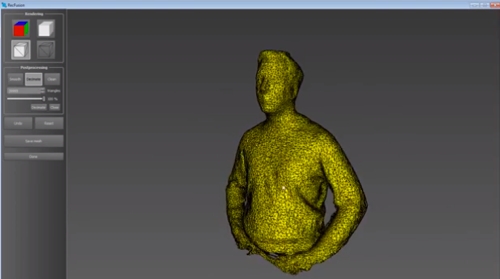

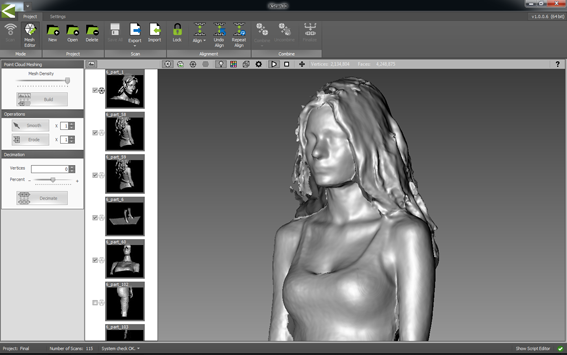

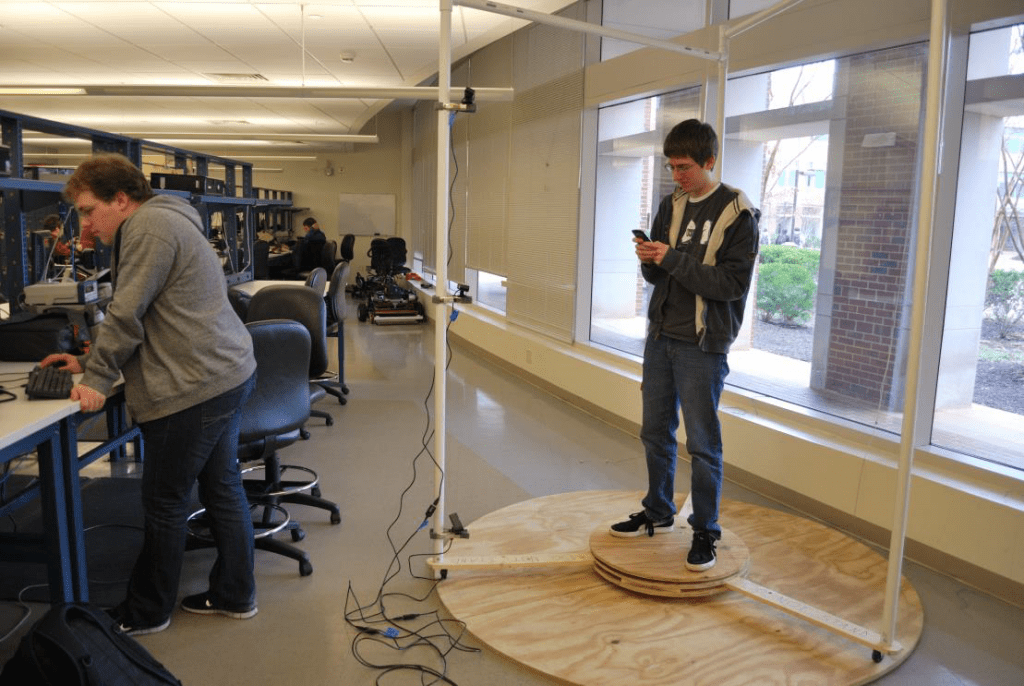

The Kinect sensor is an RGB-depth camera, developed by Microsoft (Redmond, US), which captures simultaneous depth and colour images of the surrounding environment [30]. Initially developed to enhance the gaming experience of the Xbox 360 console, the Kinect sensor has also been employed outside the gaming industry due to the release of a Software Development Kit running on MS Windows. In this investigation, a Kinect-based (Kinect for Windows, 2012 version) foot scanner was designed and tested for accuracy and repeatability. The Kinect sensor combines a laser emitter, an infrared and an RGB camera to obtain a 300.000 point-cloud 3D image of the scanned object via triangulation process [31], at a maximum of 30 fps. The scanner consists of a 0.82 m tall wood box, comprising a scanning glass plate at the top and the Kinect sensor at the bottom (Fig. 1a). The sensor is positioned above a rotating plate, manually rotated during scanning, which allows the plantar aspect of the foot to be visualized from different angles, while preserving the focus distance at 0.55 m. The scanning plate consists in a 400 × 350 × 15 mm glass plate allowing the foot plantar surface to be visualised by the depth sensor. In order to minimize light reflections, the interior walls of the wood box are painted in black and external light sources were reduced during scanning. The acquisition time was set to 25 s, to allow a slow 360 deg. rotation of the sensor. The software Skanect for Windows (Skanect by Occipital, version 1.8) was used to acquire and pre-process the raw 3D depth-data of the scanned feet (Fig.

The Kinect sensor combines a laser emitter, an infrared and an RGB camera to obtain a 300.000 point-cloud 3D image of the scanned object via triangulation process [31], at a maximum of 30 fps. The scanner consists of a 0.82 m tall wood box, comprising a scanning glass plate at the top and the Kinect sensor at the bottom (Fig. 1a). The sensor is positioned above a rotating plate, manually rotated during scanning, which allows the plantar aspect of the foot to be visualized from different angles, while preserving the focus distance at 0.55 m. The scanning plate consists in a 400 × 350 × 15 mm glass plate allowing the foot plantar surface to be visualised by the depth sensor. In order to minimize light reflections, the interior walls of the wood box are painted in black and external light sources were reduced during scanning. The acquisition time was set to 25 s, to allow a slow 360 deg. rotation of the sensor. The software Skanect for Windows (Skanect by Occipital, version 1.8) was used to acquire and pre-process the raw 3D depth-data of the scanned feet (Fig. 1b). The laptop computer used for data acquisition (Intel Core i5 6300 HQ @2.30 GHz, 12GHz RAM) allowed to acquire high-quality 3D images up to 21 fps.

1b). The laptop computer used for data acquisition (Intel Core i5 6300 HQ @2.30 GHz, 12GHz RAM) allowed to acquire high-quality 3D images up to 21 fps.

a The Kinect-based 3D foot scanner. The Kinect sensor is located on a rotating platform at the bottom of the wood box. On top, a 15 mm thick glass plate allows to scan the foot plantar surface in different loading conditions. b 3D point cloud of the plantar foot shape of one subject in bipedal standing, visualised in Skanect

Full size image

Fourteen asymptomatic healthy volunteers (age 21–61 years; BMI 23 ± 3 kg/m2; shoe size 37–43 EU) with no history of foot and lower limb trauma or surgery were recruited for this study. According to the podoscopic evaluation the subjects were classified as having slightly flat feet (n = 5), rectus feet (n = 6) and slightly cavus feet (n = 3). A plexiglass box for foot measurements (PodoBox), featuring transparent rulers on the sides and in the bottom surface, was used to measure the foot main morphological parameters (Fig. 2). The accuracy of the device was assessed by comparing the scans of 28 feet from 14 subjects with those obtained with a high-resolution commercial 3D foot scanner (i-Qube, Delcam, UK). The scans were taken in bipedal standing - or full weight-bearing; this posture was preferred over other weight-bearing conditions for it is highly repeatable, thus helping to reduce differences in the foot shape on the two scanning devices. The 3D modelling software Geomagic Control™ (3D Systems, Rock Hill, USA) was used for spatial alignment and to calculate the average distance between the Kinect and i-Qube scans. The alignment was achieved via the “Best Fit Alignment” procedure: a preliminary gross alignment is performed by matching 5000 random points, and finer adjustments can be obtained by using 25.000 random points, until the average deviation between scans is minimized [32]. Distance Maps - i.e. the point-by-point graphical representation of the distance between the two 3D data sets - and the Root Mean Square Error (RMSE) of the distances were used to quantify the accuracy of the Kinect scans in the whole plantar surface and in the medial arch region alone.

2). The accuracy of the device was assessed by comparing the scans of 28 feet from 14 subjects with those obtained with a high-resolution commercial 3D foot scanner (i-Qube, Delcam, UK). The scans were taken in bipedal standing - or full weight-bearing; this posture was preferred over other weight-bearing conditions for it is highly repeatable, thus helping to reduce differences in the foot shape on the two scanning devices. The 3D modelling software Geomagic Control™ (3D Systems, Rock Hill, USA) was used for spatial alignment and to calculate the average distance between the Kinect and i-Qube scans. The alignment was achieved via the “Best Fit Alignment” procedure: a preliminary gross alignment is performed by matching 5000 random points, and finer adjustments can be obtained by using 25.000 random points, until the average deviation between scans is minimized [32]. Distance Maps - i.e. the point-by-point graphical representation of the distance between the two 3D data sets - and the Root Mean Square Error (RMSE) of the distances were used to quantify the accuracy of the Kinect scans in the whole plantar surface and in the medial arch region alone. The latter was investigated independently because of its relevance to foot type classification and custom orthotics design.

The latter was investigated independently because of its relevance to foot type classification and custom orthotics design.

The PodoBox: a plexiglass-made foot measuring tool. Adhesive rulers on the sides and bottom surface for arch height and arch length measurement (a), and transparent mobile rulers for foot length and foot width measurement (b)

Full size image

The repeatability of the Kinect scans across different sessions was also assessed on 28 feet of 14 subjects. The feet of each subject were scanned in three sessions a few days apart, and pairwise comparisons were performed to calculate the RMSE between scans of the same foot. Three RMSE were therefore calculated, for both right and left foot of each subject - session#1 vs. session#2, session#1 vs. session#3 and session#2 vs. session#3 - and the average RMSE for each subject’s foot was averaged across all subjects. The Coefficient of Variation of the RMSE distribution across comparisons was also used to assess the scans repeatability.

In order to assess the scanner effectiveness in detecting differences between foot types, the main morphological parameters of six sample subjects - two with flat, two with rectus and two with cavus feet - were analysed (Fig. 3). Custom software was developed in Matlab (MathWorks, R2016a) for the automatic analysis of the Kinect foot scans to estimate foot length, foot width, arch height, arch width, arch length and the Arch Index. The arch width refers to the maximum penetration of the foot arch in the medio-lateral direction, expressed as a percentage of the foot width at the same position. The Arch Index is computed as the ratio between the area of the middle third of the footprint and the total area of the footprint - toes excluded [33]. Furthermore, manual measurements of foot length and foot width, obtained using the PodoBox, were compared to the corresponding estimated by the software on the 3D scans, and the average % errors were computed.

Fig. 3

3Sample flat (a), rectus (b) and cavus (c) feet scanned in bipedal standing posture. Top, podoscope visualization; bottom, corresponding Kinect scans displayed in Geomagic

Full size image

Results

Kinect-scans accuracy

The accuracy in the 3D scan of the arch region was higher than that of the whole plantar surface. The comparison between 3D scans of the whole plantar surface obtained with the Kinect and with the high-resolution laser scanner (Fig. 4, top), resulted in an inter-subject average RMSE of 2.8 ± 0.6 mm and 2.9 ± 0.4 mm, respectively across left and right feet. Corresponding errors in the arch region alone (Fig. 4, bottom) were 1.4 ± 0.4 mm and 1.6 ± 0.5 mm (Table 1).

Fig. 4Color maps of the distances [mm] between laser scanner and Kinect foot scans for the right foot of one subject in weight-bearing, following the Geomagic “Best Fit Alignment” procedure. Top, error in the whole plantar region; bottom, error in the arch region alone

Full size image

Table 1 RMSE [mm] between Kinect-based and reference foot scans for each left and right foot of the 14 subjects. The inter-subject average RMSE is reported at the bottom of the table

The inter-subject average RMSE is reported at the bottom of the tableFull size table

Kinect-scans repeatability

Good repeatability of the Kinect scans was observed across all trials. The inter-subject average RMSE of the pairwise comparisons between scans acquired in three sessions was 1.2 ± 0.4 mm, both for left and right feet (Table 2). The inter-subject average Coefficient of Variation was 24.3 ± 12.3% and 17.4 ± 10.5%, respectively across left and right feet.

Table 2 RMSE [mm] of the distances calculated in the pairwise comparisons between the three scans of each left and right foot of the 14 subjectsFull size table

Morphological parameters of sample flat, rectus and cavus feet

The automatic analysis of the foot scans allowed estimation of the foot main morphological parameters for the 12 feet of the six sample subjects (Table 3). The main foot dimensions, foot length and foot width, were similar to the corresponding PodoBox measurements: the inter-subject average error was 1. 2 ± 1.1% and 0.9 ± 0.7%, in foot length and 9.0 ± 4.1% and 10.2 ± 3.2% in foot width, respectively across left and right feet. Arch Index and arch width values were consistent with the clinical classification; the largest Arch Index and lowest arch width were found for the four flat feet, whereas the lowest Arch Index and the largest arch width were found for the four cavus feet.

2 ± 1.1% and 0.9 ± 0.7%, in foot length and 9.0 ± 4.1% and 10.2 ± 3.2% in foot width, respectively across left and right feet. Arch Index and arch width values were consistent with the clinical classification; the largest Arch Index and lowest arch width were found for the four flat feet, whereas the lowest Arch Index and the largest arch width were found for the four cavus feet.

Full size table

Discussion

In podiatry, foot impression foams are still the preferred method to design semi weight-bearing custom insoles. Most of the current optical and laser-based foot scanning devices are either expensive for small clinics and non-commercial applications, or do not allow foot scanning in weight-bearing. Moreover, no automatic tool is currently available to estimate the foot’s main morphological parameters from 3D foot scans. The advent of depth sensors, associated to infrared cameras and projectors, represent a cost-effective scanning tool with respect to laser-based devices. The purpose of this study was to assess the accuracy and the reliability of a novel low-cost 3D foot scanner based on the Microsoft Kinect sensor.

The advent of depth sensors, associated to infrared cameras and projectors, represent a cost-effective scanning tool with respect to laser-based devices. The purpose of this study was to assess the accuracy and the reliability of a novel low-cost 3D foot scanner based on the Microsoft Kinect sensor.

Preliminary tests were performed to choose the optimal scanning parameters, with the subject in bipedal standing on the scanning plate. A 360 deg. rotation of the Kinect sensor was chosen as the optimal method to guarantee the best quality of the plantar foot scans, and was preferred to a fixed position or to sensor translation.

The accuracy of the Kinect-based foot scanner was assessed on 14 subjects, using a commercial high-resolution 3D laser scanner as reference. The inter-subject average RMSE in the 3D shape of the whole plantar surface was about 3 mm, and this was very similar in the left and the right foot. The largest errors were located at the toes and in the lateral aspect of the midfoot region, approximately along the fifth metatarsal bone (see Fig. 4). It should however be highlighted that some differences in foot posture were expected especially at the toes region, as Kinect-based and reference foot scans could not be acquired simultaneously and thus may be affected by small postural differences. Therefore, the error in scanning the arch region alone, which is the foot’s most prominent morphological feature, was also investigated. The inter-subject average RMSE in the 3D shape of the medial arch was about 1.5 mm, and very consistent between left and right foot. This error, albeit rather small and consistent with the repeatability of the measurements, should be accounted for when designing personalized orthoses or in the statistical comparison of morphological data from different groups.

4). It should however be highlighted that some differences in foot posture were expected especially at the toes region, as Kinect-based and reference foot scans could not be acquired simultaneously and thus may be affected by small postural differences. Therefore, the error in scanning the arch region alone, which is the foot’s most prominent morphological feature, was also investigated. The inter-subject average RMSE in the 3D shape of the medial arch was about 1.5 mm, and very consistent between left and right foot. This error, albeit rather small and consistent with the repeatability of the measurements, should be accounted for when designing personalized orthoses or in the statistical comparison of morphological data from different groups.

While the novel scanner showed very good inter-session repeatability (range 0.5 ÷ 2.2 mm), the inter-operator repeatability was not investigated in the present study. However, since the acquisition process is almost fully automatic, inter-operator errors are expected to have similar magnitude.

Further geometrical analysis of the plantar foot scans via custom Matlab scripts showed good agreement between the acquired 3D data sets and the clinical observations. In particular, the estimated Arch Index of the flat feet was larger than that of the cavus feet, while the arch width was the smallest in the flat feet and the largest in the cavus feet. The morphological measurements based on the Kinect foot scans appeared consistent with the real foot morphology and may represent a useful objective tool, in addition to the clinical evaluation, for foot type classification. While the average error in measuring foot length was approximately 1%, the scan-based foot width measurements were about 10% larger than the corresponding measurement from the PodoBox. This small overestimation of the real foot width may be explained by the compression of the soft tissues between the mobile ruler and the side of the PodoBox, compression that was not present during the Kinect scanning (see Fig. 2b).

From an economical perspective, the total cost of the present prototypal 3D foot scanner is about 200–300€, which is at least one order of magnitude lower than that of commercial laser-based foot scanners currently available. This should also allow clinics and research groups with limited resources to perform foot scans to support objective diagnosis of foot pathologies. Moreover, the non-invasive and automatic procedure proposed here allows foot scanning in different loading conditions, and the operator’s influence is minimal. However, the present study and its outcome should be considered in light of some limitations. While accuracy and repeatability results were largely consistent across subjects, and between left and right foot intra-subject, the sample of feet analysed is rather small. In addition, only adult feet were included, thus no information is available on the applicability and reliability of the device in scanning children’s feet. Finally, all acquisitions were performed in ideal low-light conditions with a rather powerful portable computer; lower resolution scans could be obtained and some noise may be present in real-case scenarios.

Conclusions

This study has shown that the accuracy of the Kinect sensor, within the setup specifically designed for this investigation, is comparable to that of laser-scanner devices. The sensor, therefore, may be reasonably used to obtain 3D scans of the foot plantar surface suitable for different clinical and biomechanical applications. The novel low-cost foot scanner may represent a valid alternative to more expensive laser scanners currently on the market and suitable to support the design of custom insoles and orthoses. The scans geometry can be further analysed and measured by specific software applications, as shown in the present manuscript. The combination of the Kinect-based foot scanner and of relevant analysing code presented here may represent a useful tool for automatic foot measurement, providing podiatrists and clinicians with quantitative parameters for foot type classification and diagnosis of foot morphological alterations.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Chen RK, Y-a J. Wensman J, Shih a. additive manufacturing of custom orthoses and prostheses—a review. Additive Manufact. 2016;12:77–89.

Article CAS Google Scholar

Sobel E, Levitz SJ, Caselli MA, Christos PJ, Rosenblum J. The effect of customized insoles on the reduction of postwork discomfort. J Am Pod Med Assoc. 2001;91(10):515–20.

Article CAS Google Scholar

Shabat S, Gefen T, Nyska M, Folman Y, Gepstein R. The effect of insoles on the incidence and severity of low back pain among workers whose job involves long-distance walking. Euro Spine J. 2005;14(6):546–50.

Article CAS Google Scholar

Mündermann A, Nigg BM, Humble RN, Stefanyshyn DJ.

Foot orthotics affect lower extremity kinematics and kinetics during running. Clin Biomech. 2003;18(3):254–62.

Foot orthotics affect lower extremity kinematics and kinetics during running. Clin Biomech. 2003;18(3):254–62.Article Google Scholar

Skou ST, Hojgaard L, Simonsen OH. Customized foot insoles have a positive effect on pain, function, and quality of life in patients with medial knee osteoarthritis. J Am Pod Med Assoc. 2013;103(1):50–5.

Article Google Scholar

Owings TM, Woerner JL, Frampton JD, Cavanagh PR, Botek G. Custom therapeutic insoles based on both foot shape and plantar pressure measurement provide enhanced pressure relief. Diab Care. 2008;31(5):839–44.

Article Google Scholar

Paton JS, Stenhouse EA, Bruce G, Zahra D, Jones RB. A comparison of customised and prefabricated insoles to reduce risk factors for neuropathic diabetic foot ulceration: a participant-blinded randomised controlled trial.

J Foot Ankle Res. 2012;5(1):31.

J Foot Ankle Res. 2012;5(1):31.Article Google Scholar

Balsdon ME, Bushey KM, Dombroski CE, LeBel M-E, Jenkyn TR. Medial longitudinal arch angle presents significant differences between foot types: a biplane fluoroscopy study. J Biomech Eng. 2016;138(10):101007.

Article Google Scholar

Saltzman CL, Nawoczenski DA, Talbot KD. Measurement of the medial longitudinal arch. Arch Phys Med Rehab. 1995;76(1):45–9.

Article CAS Google Scholar

Ker R, Bennett M, Bibby S, Kester R, Alexander RM. The spring in the arch of the human foot. Nature. 1987;325(6100):147.

Article CAS Google Scholar

Tsung BYS. Zhang M. Mak AFT: Wong MWN. Effectiveness of insoles on plantar pressure redistribution.

J Rehabil Res Dev; 2004.

J Rehabil Res Dev; 2004.Google Scholar

Caravaggi P, Giangrande A, Lullini G, Padula G, Berti L. Leardini A. In shoe pressure measurements during different motor tasks while wearing safety shoes: The effect of custom made insoles vs prefabricated and off-the-shelf. Gait Posture. 2016;50:232–8.

Article Google Scholar

Lucas-Cuevas AG, Pérez-Soriano P, Llana-Belloch S, Macián-Romero C, Sánchez-Zuriaga D. Effect of custom-made and prefabricated insoles on plantar loading parameters during running with and without fatigue. J Sports Sci. 2014;32(18):1712–21.

Article Google Scholar

Losito J. Impression casting techniques. In: Clinical Biomechanics of the Lower Extremities. Valmassey R, editor. St Louis: CV Mosby; 1996. pp. 280–94.

Trotter LC, Pierrynowski MR. Ability of foot care professionals to cast feet using the Nonweightbearing plaster and the gait-referenced foam casting techniques. J Am Pod Med Assoc. 2008;98(1):14–8.

Article Google Scholar

Carroll M, Annabell M-E, Rome K. Reliability of capturing foot parameters using digital scanning and the neutral suspension casting technique. J Foot Ankle Res. 2011 March 04;4(1):9.

Article Google Scholar

Geng J. Structured-light 3D surface imaging: a tutorial. Adv Opt Photon. 2011;3(2):128–60.

Article CAS Google Scholar

Telfer S, Woodburn J. The use of 3D surface scanning for the measurement and assessment of the human foot. J Foot Ankle Res. 2010;3(1):19.

Article Google Scholar

Payne C. Cost benefit comparison of plaster casts and optical scans of the foot for the manufacture of foot orthoses. Aus J Am Pod Med. 2007;41:29–31.

Google Scholar

Clark RA, Pua Y-H, Fortin K, Ritchie C, Webster KE, Denehy L, et al. Validity of the Microsoft Kinect for assessment of postural control. Gait & Posture. 2012;36(3):372–7.

Article Google Scholar

Grant CA, Johnston M, Adam CJ, Little JP. Accuracy of 3D surface scanners for clinical torso and spinal deformity assessment. Med Eng Physics. 2019;63:63–71.

Article Google Scholar

Mentiplay BF, Perraton LG, Bower KJ, Pua YH, McGaw R, Heywood S, et al. Gait assessment using the Microsoft Xbox one Kinect: concurrent validity and inter-day reliability of spatiotemporal and kinematic variables.

J Biomech. 2015;48(10):2166–70.

J Biomech. 2015;48(10):2166–70.Article Google Scholar

Dutta T. Evaluation of the Kinect™ sensor for 3-D kinematic measurement in the workplace. Appl Ergon. 2012;43(4):645–9.

Article Google Scholar

Weiss A, Hirshberg D, Black MJ. Home 3D body scans from noisy image and range data. In: Int. Conf. on Computer Vision (ICCV). Barcelona: IEEE; 2011. pp. 1951–58.

Stone EE, Skubic M, Passive in-home measurement of stride-to-stride gait variability comparing vision and Kinect sensing. 33rd Annual International Conference of the IEEE EMBS Boston, Massachusetts USA; 2011.

Chang CY, Lange B, Zhang M, Koenig S, Requejo P, Somboon N. Towards pervasive physical rehabilitation using Microsoft Kinect, International Conference on Pervasive Computing Technologies for Healthcare (Pervasive Health), San Diego, CA, USA; 2012.

Taha Z, Aris MA, Ahmad Z, Hassan MHA, Sahim NN. A low cost 3D foot scanner for custom-made sports shoes. J Appl Mech Mat. Trans Tech Publ. 2014;440:369–72.

Article Google Scholar

Algar D, Guldberg A. Insole modeling using kinect 3d sensors. Gothenburg: Chalmers University of Technology; 2013.

Google Scholar

Mentiplay BF, Clark RA, Mullins A, Bryant AL, Bartold S, Paterson K. Reliability and validity of the Microsoft Kinect for evaluating static foot posture. J Foot Ankle Res. 2013;6(1):14 PubMed PMID: 23566934. Pubmed Central PMCID: 3639226.

Article Google Scholar

Microsoft Kinect. Available from: https://developer.microsoft.com/en-us/windows/kinect. Accessed 15 Mar 2019.

Khoshelham K, Elberink SO.

Accuracy and resolution of kinect depth data for indoor mapping applications. Sensors. 2012;12(2):1437–54.

Accuracy and resolution of kinect depth data for indoor mapping applications. Sensors. 2012;12(2):1437–54.Article Google Scholar

Hammett PC, Garcia-Guzman LM, Geddes SW, Walsh PT. Quantifying alignment effects in 3D coordinate measurement: University of Michigan Transportation Research Institute; 2009.

Cavanagh PR, Rodgers MM. The arch index: a useful measure from footprints. J Biomech. 1987;20(5):547–51.

Article CAS Google Scholar

Download references

Acknowledgements

Not applicable

Funding

The study is partially funded by the Italian 5 × 1000 funding scheme.

Author information

Authors and Affiliations

Movement Analysis Laboratory, IRCCS Istituto Ortopedico Rizzoli, Via di Barbiano 1/10, 40136, Bologna, Italy

Giulia Rogati, Alberto Leardini, Maurizio Ortolani & Paolo Caravaggi

Authors

- Giulia Rogati

View author publications

You can also search for this author in PubMed Google Scholar

- Alberto Leardini

View author publications

You can also search for this author in PubMed Google Scholar

- Maurizio Ortolani

View author publications

You can also search for this author in PubMed Google Scholar

- Paolo Caravaggi

View author publications

You can also search for this author in PubMed Google Scholar

Contributions

GR assisted with designing the study, recruited the participants, performed the data analysis, helped with the interpretation of the results and the preparation of the manuscript. AL assisted with designing the study, helped with the interpretation of the results and the preparation of the manuscript. MO helped designing the scanning device and with the interpretation of the results. PC designed the study, designed the scanning device, assisted with data analysis, helped with the interpretation of the results and the preparation of the manuscript. All authors read and approved the final manuscript.

AL assisted with designing the study, helped with the interpretation of the results and the preparation of the manuscript. MO helped designing the scanning device and with the interpretation of the results. PC designed the study, designed the scanning device, assisted with data analysis, helped with the interpretation of the results and the preparation of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Correspondence to Paolo Caravaggi.

Ethics declarations

Ethics approval and consent to participate

Acknowledgment of the IRCCS Istituto Ortopedico Rizzoli was granted and informed consent was obtained for all participants recruited in the study.

Consent for publication

Participants’ consent to publish was granted.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

Reprints and Permissions

About this article

Microsoft Kinect 3D Scanner In-Depth Review

8Expert Score

Microsoft Kinect

Microsoft Kinect is a simple scanner that’s able to produce decent quality 3d scans at a reasonable price.

Affordability

9

Quality

8

Speed

7

Capability

7

Practicality

7

User Expectations

10

PROS

- High-resolution scans

- Extremely compatible software

- Easy scanning process

CONS

- Need good lighting to produce good quality scans

Table of Contents

The Kinect 3D scanner uses similar 3D scanning technology to photogrammetry. The process consists of taking multiple pictures from different angles of an object. The scanner comprises a camera, an infrared camera that is meant for calculating the field of depth of object as well as around.

The process consists of taking multiple pictures from different angles of an object. The scanner comprises a camera, an infrared camera that is meant for calculating the field of depth of object as well as around.

Both the cameras used by Kinect permits users to make a decently accurate 3D scan of almost any object that they wish to scan. But how does the scanner rank when seen in terms of value: money ratio? We can only tell by looking at it in-depth. So, let’s get started.

Features

Some of the most valuable features of the scanner are mentioned and explained below.

Affordable

Because Kinect can be constructed easily and its complete information is available online for free, you don’t need to undergo any complex process of setting it up and shipping it from anywhere. Also, the parts of which Kinect is made up, are comparatively cheaper.

So, if you have a 3D printer all you have to do is buy the components that are necessary to make the scanner run and that’s it. You need not spend much on this scanner.

You need not spend much on this scanner.

DIY Kit

The complete assembly of components, as well as 3D printing of the necessary parts, can be done on your own. Just refer to the online instructions available to complete the setup.

Kinect can be constructed as other DIY kits and this makes up a great opportunity for all those who are willing to invest time in learning a little deeper about 3D scanning technology.

Easy to use software

Skanect as well as the other software that is compatible with the scanner are extremely user-friendly. Their interface allows you to reach the tool that you are searching for, extremely fast.

Also, the entire system is relatively easy to grasp. Even if you do not have any sort of technical background, it’s fine. You will still be able to operate the scanner pretty easily.

Open-source

Kinect is an open-sourced 3D scanner. This presents a great opportunity for those who wish to innovate and use a machine for obtaining the kind of work they wish to achieve. Also, it means that nothing is fixed.

The scanner can be scaled according to your project. Moreover, everything is accessible to everyone from the internet.

Specifications

Kinect is equipped with two cameras that take multiple images of an object that you wish to scan. It needs a PC adapter and a PC to produce high-quality scans of parts and functional prototypes. The device can be connected using a USB port.

Price

Since it’s available as a DIY and needs to be purchased in terms of components, there isn’t any fixed cost for this scanner.

First Impression

Credit: all3dp

The first thing that you need to do is acquire the required hardware i.e. three things in order to start with the scanner:

- The Kinect: can be bought either from Xbox 360 or Xbox One. These are available from almost any electronics shop.

- The PC adapter: Because Kinect is made to be used in its respective Xbox and not in a PC like other scanners, you’ll have to obtain a Kinect 360 to PC adapter.

- A PC: It can be either a laptop or desktop with a free USB port.

The minimum requirement to get you started is:

- Latest Kinect drivers downloaded

- A 64-bit Processor

- Dual-core (3.1Ghz) or faster CPU

- A 4GB of Ram

- Nvidia CUDA graphic card or a Kinect Fusion compatible GPU

- A compatible USB 3.0 port one that is offered by Intel or Renesas chipset

Setup

Credit: all3dp

Although the Kinect needs to undergo some process before starting 3D scanning with the same, it’s good to say that you can plug it into a power source and start scanning. After having plugged it into your PC, you can download its drivers. These codes will instruct your computer on how to handle the Kinect.

For users who are running it on Windows 10, it’s likely that the drivers inside will get downloaded automatically after the recognition of Kinect by your PC. In case this doesn’t happen, simply download the drivers from Microsoft. Other than this, you will have to download software that allows you to use your Kinect for 3D scanning.

To set up Skanect, open the .exe file as soon as it’s downloaded. A simple interface will await you once the process is completed. The setup will take three steps:

- Clicking on the New section that’s present on the menu under the title “Prepare.” By doing so, you can mess around with various settings depending on which object you wish to scan.

- Choosing the bounding box size that is the most appropriate for the object. Doing so lets you choose from the presets that are already provided. Instead, you can also use a custom one by clicking the slider and moving it with the mouse.

- Choosing a path for saving the scanned object. Note that this would not be the final model, but only the .skn file of the same that can be later opened in the Skanect.

After finishing the setup, click the start button to be taken to the next step of the scanning process.

Scan Type

The process of scanning is quite simple. All you need to do is just hover the Kinect 3D scanner around the object as if it were orbiting the part.

While doing so, the software will use the background to help track the position of the object. So, in case you wish to rotate the object, the background will be scanning and will always be the same. This scenario applies especially to photogrammetry and for normal 3D scanning.

Ensure that there is a good amount of lighting during the entire scanning process because bad lighting won’t just make it harder, but also lead to a final render with the poorly colored model. So, take your time and ensure that the scans are done slowly and with patience.

Also, check that Kinect is passed through the entire object from all the angels. This can be done by keeping an eye on your PC. Moreover, scanning makes certain that all the areas of the object are appearing neatly.

Scan Quality

Credit: all3dp

Kinect’s scan quality is just about average. You can see the brightness is very inconsistent. And this is because of its camera not being locked. This means that the scanner will adapt the brightness based on the direction that you’re pointing to the sensor. Also, because the cameras present on the Kinect are at wide angles to each other.

Such an arrangement makes it extremely appropriate for sensing motion as well as the depth of people present in front of the TV playing games. But it has its own downsides i.e. 3D scanning on a manual turntable is almost impossible because the tracking gets confused as your arm enters the frame.

Software

Credit: all3dp

3D Scan is a free Windows 10 application that uses your Kinect for creating 3D models. It can be downloaded from Microsoft. Other than this, you can use Skanect which is third-party software that is compatible with Kinect. It can be used by subscribing to its free or paid version.

The only difference between both of these is that the latter permits you to export the model with more faces and in color. Skanect can be downloaded from Occipital.

Customer Support

Kinect customer support is all given by its community of active users. All the solutions to your problems are available online and are accessible for free.

Parameters Influencing Buying Decision

The key factors that’ll help you decide upon the scanner are mentioned below.

3D Scanner Cost: Affordable

3D Scanner Speed: Average

3D Scan Quality: Two cameras make it possible for the scanner to deliver high-quality scans even while processing parts with intricate geometries.

3D Scanner Capability: The scanner is capable of taking multiple images of the object and then combining them to produce a single scan.

3D Scanner Practicality: It can be used for scanning everyday objects of small size and not much complex geometry.

3D Scanner User Expectations: Hobbyists, academicians, and even small manufacturers can use the scanner to achieve good results.

The Verdict

In a nutshell, Microsoft Kinect is a simple scanner that’s able to produce decent quality scans at a reasonable price. There isn’t something very fancy about the scanner, at the same time there isn’t something too lacking about the device.

Although it isn’t capable of letting you go in-depth, it doesn’t disappoint by providing bad-quality scans. Even while scanning intricate geometries, the scanner does deliver. So, enjoy the simplicity that suits your pockets.

Free STL file Base for Kinect (3D scanner)・3D print model for download・Cults

Mold for zander pro

0,50 €

One form up

0,50 €

Rogen mold 120

0. 50 €

Flower pot

Free

Carp stencil 2

Free

carp stencil

free

Socket for all types of telephones

Free of charge

Camera phone holder (deeper)

Free

Best 3D Printer Files in the Miscellaneous Category

Covid19 Decathlon mask

Free

Articulated Dragonair

1.99 €

Himiko Toga Scarf Teeth (My Hero Academia)

4.18 €

Snake key ring

Free

Bulldog Boss

2. 65 €

Lionel Messi + update 12/2022

5 €

Bike Handlebar AA Battery Slot

Free

Giant 'Nano' Geocache

Free

Bestsellers in Miscellaneous category

Addams Thing

1.99 €

ingesaurus

2.50 €

4th planet Fighting pre-Olympic god

12 €

Key holder for middle finger

1 €

Gengar pen holder

1,50 €

Eeveelution articulated mega pack

10 €

Mini big red boots

0,95 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

Mobile phone holder printed in one piece with gears

6. 50 €

SlingHAMMER - repeating crossbow pistol for steel balls 6 mm 8 mm 10 mm or 12 mm

12.50 €

flexible volute

2 €

Wolf - Flexi Articulated Animal (printed in place, without supports)

2 €

Gremlin rail 640 mm FPV

0,95 €

Charmander - pokemon with flexible articulation (seal in place, without supports)

2 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2,50 €

hinged shenron

3 €

💖 Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in keeping the activities of and creating future designs for is very simple. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via Ko-Fi here 💜.

-

INVITE FRIENDS: Invite your friends, discover the platform and the amazing 3D files shared by the community!

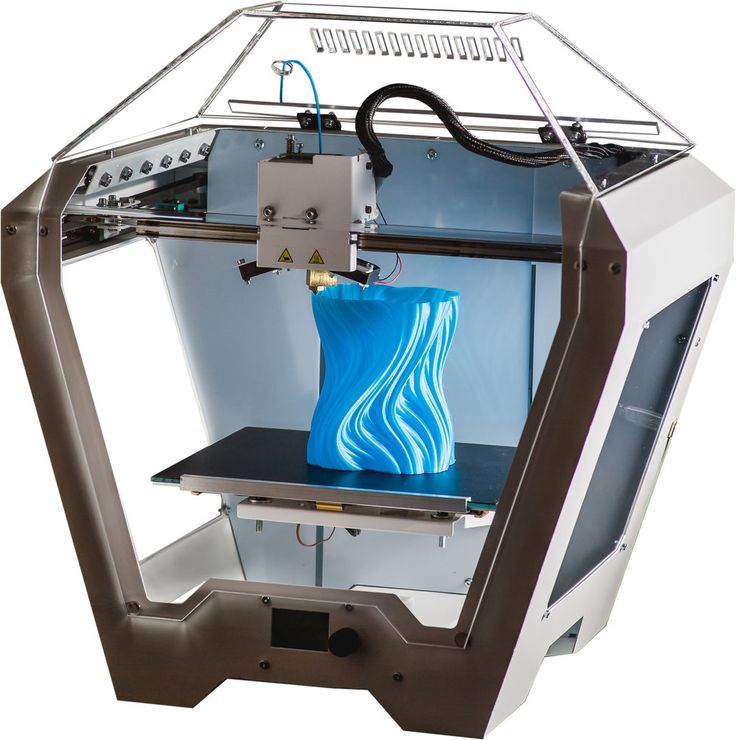

Top Ten 3D Scanners from $100 to $100,000 / Sudo Null IT News There are several ways for you: you can of course create your 3D model from scratch in a 3D modeling program or find a suitable one on the Internet, but you can also scan an existing object! The purpose of this review is to help you understand the variety of 3D scanners available and offer the best in every price segment from a photogrammetric smartphone app to professional 3D scanners.

Scanners are listed in ascending price order so you can choose the one that suits your budget and use the resulting 3D models for both 3D printing and animation.

If you are not satisfied with the suggested solutions, there is an extended overview at this link.

3D scanner in hand:

1. Best smartphone app: Autodesk 123D Catch (free)

Autodesk 123D Catch is a free photogrammetric application. It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them.

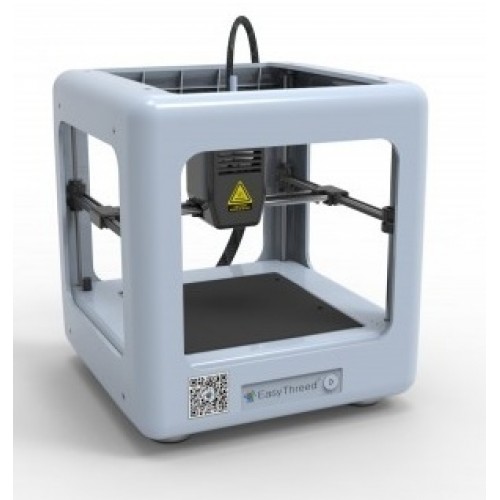

2. Best DIY 3D scanner: Kinect ($99.99)

The Xbox Kinect is designed to expand your gaming experience. It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

Price: $99.99

Resolution: 0.051 mm

)

This scanner can be attached to your tablet or phone (generally designed for iPad, but can be adapted to other devices). Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example.

Price: $ 379

Resolution up to: 0.5 mm

Poom accuracy to: 4 mm

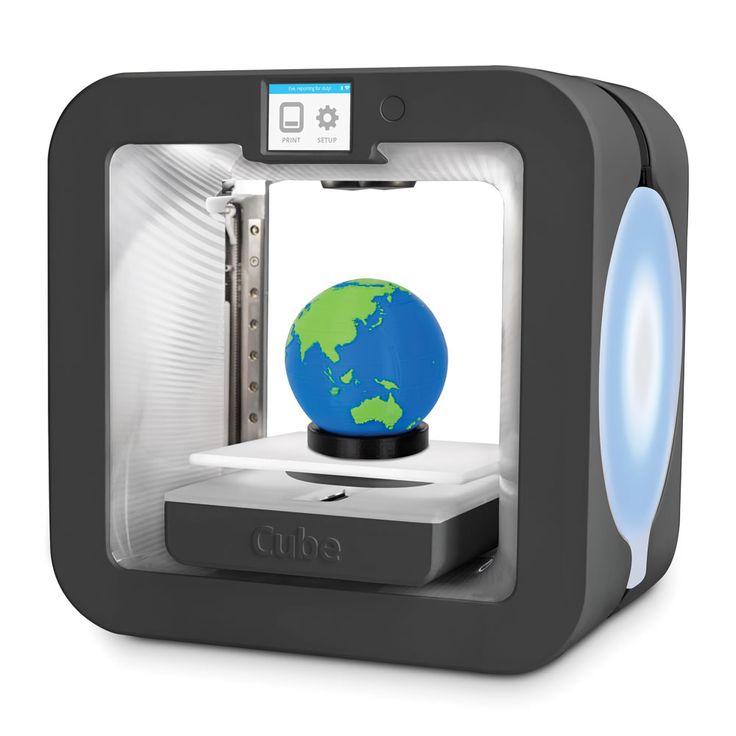

4. The best of cheap manual 3D scanners: Cubify ($ 399) 9000 3D 3D 3D-scanners can be quite affordable and easy to use if you choose from inexpensive portable models. Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models.

Price: $ 399

Resolution: 0.9 mm

Resolution at a distance of 0.5 m: 1 mm

3D scanner on the table:

9000 Scanner: Matter and Form ($519)If you're looking to take your quality to the next level, you can purchase a desktop 3D scanner. This model is compact, easy to use, and delivers good resolution, especially considering the price (not your go-to option if you're looking for perfection, but great for educational and demo purposes). The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object.

Price: $ 519

Resolution: 0. ly combines a 3D scanner and a 3D printer. The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing.

Professional 3D scanners:

7. Best value for money handheld 3D scanner: Fuel3D Scanify ($1490)

Very easy to use, intuitive, and feels good in the hand, this scanner delivers good accuracy and texture quality. The only limitation is that the size of the scanned area is limited, which is great for small objects, but for scanning a full-length person, for example, it will not work.

Price: $ 1490

Resolution: 0.35 mm

accuracy: to 0.3 mm

8. Best price The scanner uses a different scanning technology than others. Instead of a dual laser scanning system, it uses a structured light source and cameras for fast scanning with very fine detail down to 0. 06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing.

Price: $ 3995

Resolution: 0.06 mm

accuracy: 0.5% of the size of the object

9. Best professional 3D scanner: Solutionix Rexcan 4 ($ 79) 9000 The 3D scanner and its price provides much better scanning quality. Solutionix Rexcan is equipped with two cameras for greater accuracy. It uses optical phase shift triangulation technology and two high-resolution CCD cameras to provide high-precision data. The scanner can be used to scan larger objects by increasing productivity with a photogrammetric system. As an option, it can be equipped with an automatically rotating platform capable of supporting up to 50 kg of weight.

Price: $ 79 900

accuracy: from 0.03 to 0.71 mm

10.