Ctc 3d printing

Metal Additive Manufacturing | Concurrent Technologies Corporation

Concurrent Technologies Corporation (CTC) offers a variety of Additive Manufacturing (or 3D Printing) processes to provide our clients both complex part manufacturing and the ability to repair worn or damaged high-cost components.

Whether you need specific part geometry for performance enhancements or a cost-effective repair process for high-dollar components, CTC’s experts offer the Metal Additive Manufacturing process that can get you results in days. Our engineers can move you quickly from concept and design to manufactured product. These processes can also be merged together to provide customized solutions. Contact us today for a free quote.Concurrent Technologies Corporation’s In-House Processes:

Concurrent Technologies Corporation applies its 30-year history in metals and metal

processing solutions to be an all-encompassing service provider for Metal Additive

Manufacturing/3D Printing solutions. We provide a comprehensive suite of services

including reverse engineering, process development, characterization of powder and

substrate, surface profile preparation, material application, post processing, final

machining, and inspection. CTC also provides services to evaluate, validate, and

qualify the part through mechanical and physical property characterization. All

processes are controlled in-house to ensure quality results.

What We Can Do for You:

- Applicable Part Identification

- Reverse Engineering/Solid Modeling

- Prototype and Part Mfg

- Physical/Mechanical Testing

- Design Allowables and Qualification

- Equipment Selection and Transition

- Modeling and Simulation

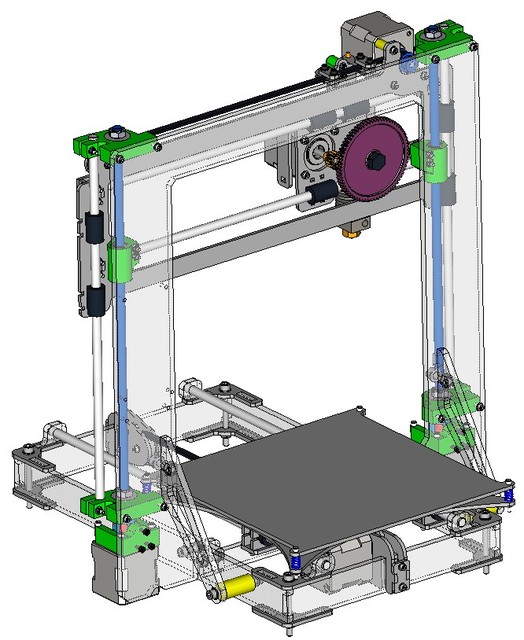

- Fused Deposition Modeling for Plastics

Materials:

- Titanium

- Aluminum

- Tool Steel

- Copper

- Nickel

- Inconel

- Stainless Steel

- Cobalt-Chromium

- Plastics

- Tantalum, and more

Read our

brochure or watch our video

to learn about some of the innovative projects our AM experts have completed for

our clients.

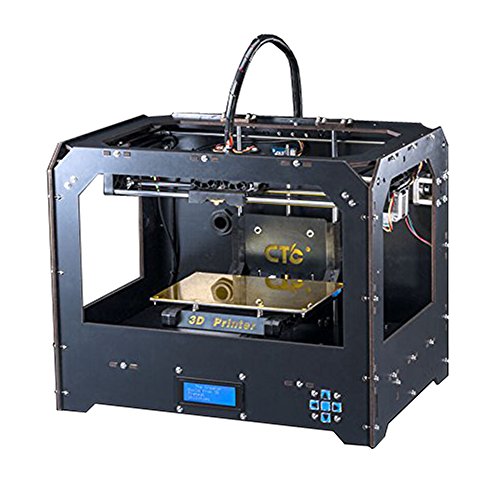

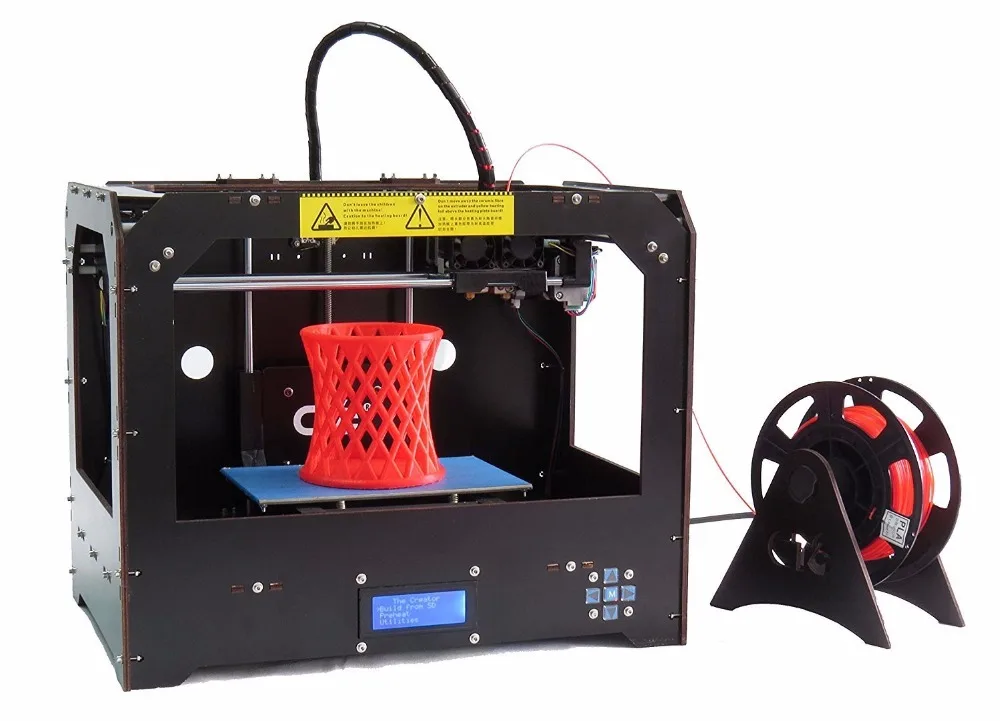

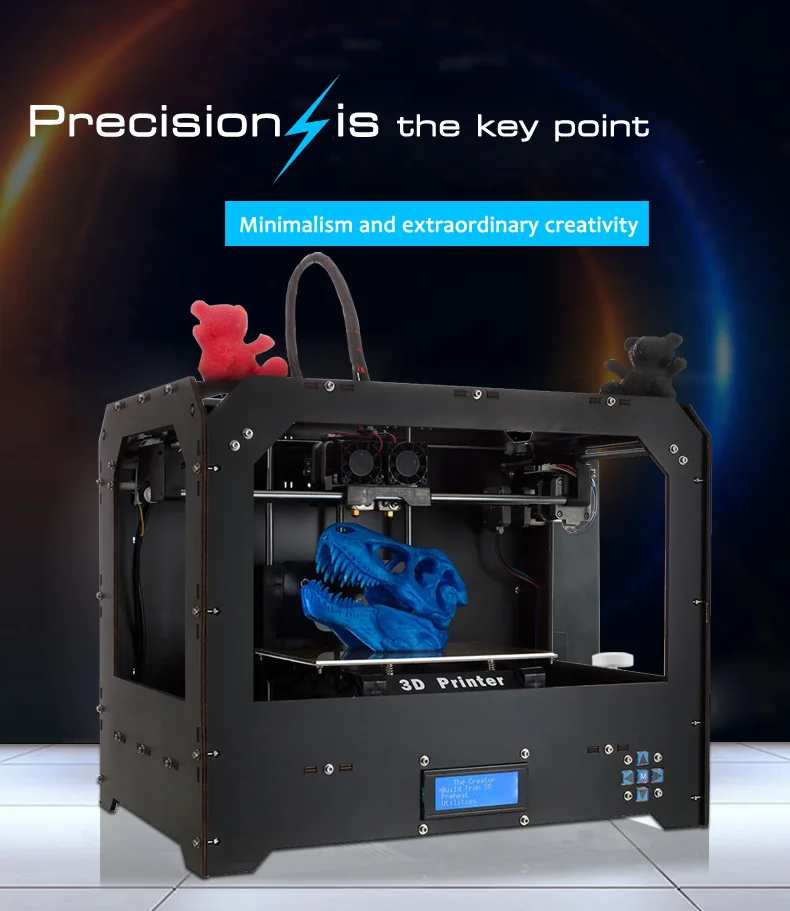

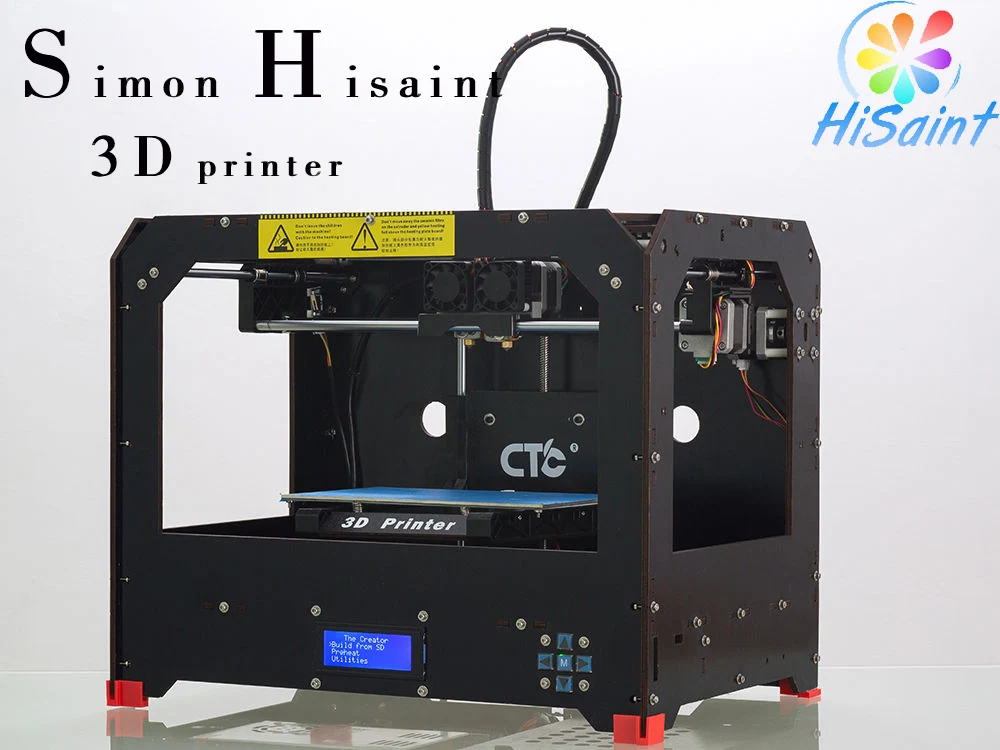

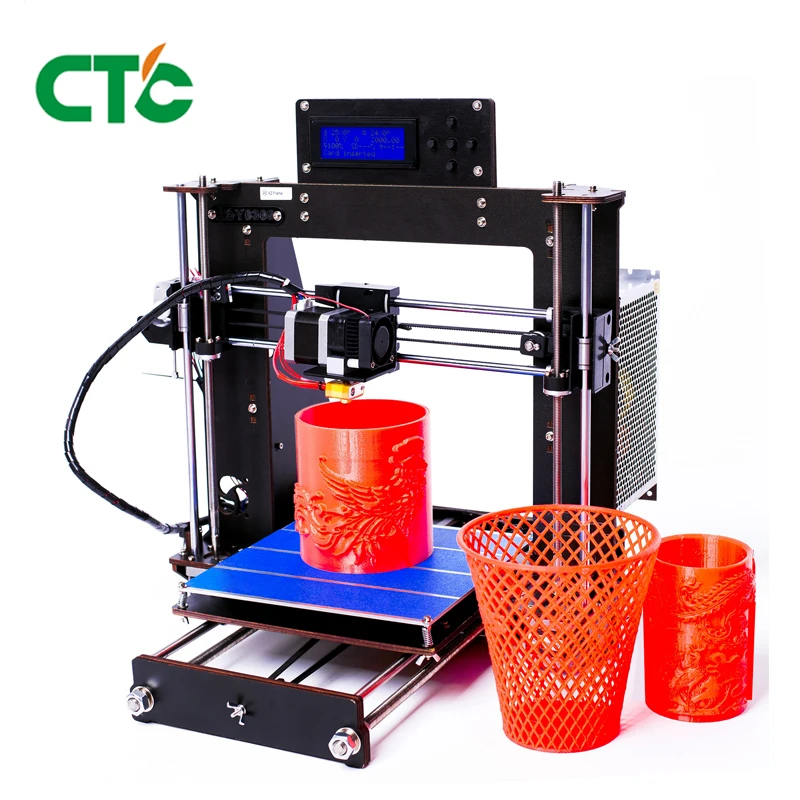

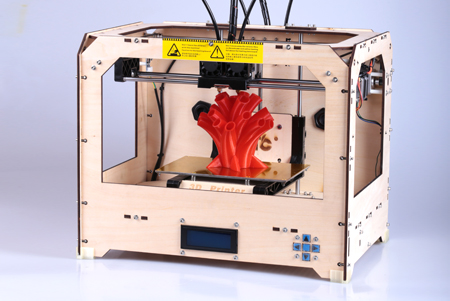

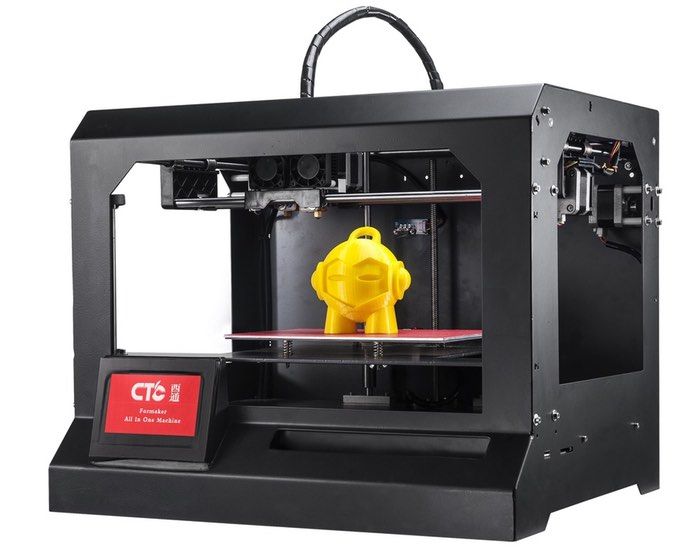

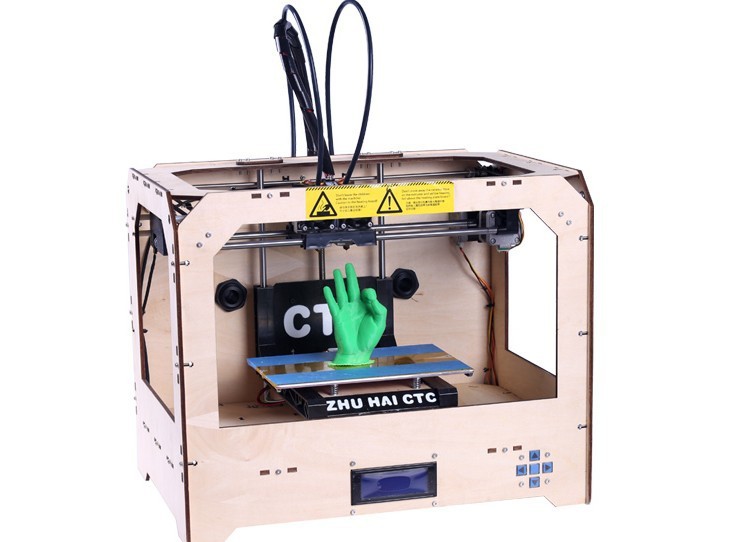

CTC LTD CTC-3D Bizer 3D Printer

| Brand | CTC LTD |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | PVA, PLA, ABS, FLEX (Elastic TPE), Rubber-like (TPU), Flexible Resin, (taulman) PCTPE, PC-ASA, PVDF (PolyvinylideneFluoride), FR-ABS (Flame Retardant) |

| Website | http://www.ctcprinter.com |

| Average Price | $799.00 |

| CTC 3D PRINTER "BIZER" WITH DOUBLE NOZZLE | |

| Model | Bizer |

| Case Material | Wood |

| Input Voltage | AC110V-230V |

| Output Port | USB2. 0, SD Card 0, SD Card |

| Touch Screen | No |

| Printer Dimesion | 320*467*381mm |

| Buidling Size | 225 * 145 * 155mm |

| Packing size | 565 * 430 * 535mm |

| Layer Accuracy | 0.1mm-0.5mm |

| Positioning Accuracy | XY axis 0.011mm |

| Input File Types | stl, gcode |

| Extrusion Nozzle Flow | About 24cc / hour |

| Nozzle diameter | 0.4mm |

| Recommended Nozzle Moving Speed | 35-40 mm / s |

| Print Material | ABS or PLA with 1.75mm diameter filament |

| Drawing Software | Rhino3D, Proe, 3dMAX, CAD, UG, Soliwork |

| Software | ReplicatorG or west to CTC Chinese Version |

| Print Color | Cyan, Magenta, Yellow, black, Write, Green , Clear , etc. |

Reviews 4.

0 2 reviews

0 2 reviews Print Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Nov 7, 2018

fsdfsdfsdfsd

Nov 7, 2018

descr es fsd fs r s

Damen and partners develop 3D printed propeller technology (photo)

A collaborative consortium of DAMEN Shipyards, RAMLAB, Promarin, Autodesk and Bureau Veritas has produced a prototype of the world's first marine propeller using 3D printing technology. The 1350mm propeller, called the WAAMpeller, has a BV-approved type design class, Damen said.

The 1350mm propeller, called the WAAMpeller, has a BV-approved type design class, Damen said.

The WAAMpeller propeller is manufactured from Nickel Aluminum Bronze (NAB) at RAMLAB (Rotterdam Additive Manufacturing LAB) in the Port of Rotterdam. The prototype was produced using wire arc technology (WAAM) using the Valk welding system and software provided by Autodesk. A three-blade propeller designed by Promarin is used on the DAMEN Stan Tug 1606 series tugs. After receiving the WAAMpeller prototype, the propeller will then be CNC machined at Autodesk's state-of-the-art manufacturing center located in Birmingham, UK.

The production of a prototype propeller marks another step forward for engineers in understanding the properties of materials.

“This is due to the fact that three-dimensional “printed” materials are created in stages, layer by layer. As a consequence, materials exhibit different physical properties in different directions, a characteristic known as anisotropy. On the other hand, steel or cast materials are isotropic - they have the same properties in all directions,” explained Kees Custers, Design Engineer at DAMEN R&D.

On the other hand, steel or cast materials are isotropic - they have the same properties in all directions,” explained Kees Custers, Design Engineer at DAMEN R&D.

Because of this critical difference, one of the first steps was to thoroughly test the material properties of the printed material to ensure it met Bureau Veritas standards.

“This involved printing two simple walls of material and then using a milling machine to produce samples for laboratory testing of tensile and static strength,” he explained.

It can also be said that the production of the WAAMpeller propeller weighing 400 kg was a milestone in the development of 3D printing technology, according to a Damen press release.

“The challenge was to translate a 3D computer file into a physical object. It's more complicated because this propeller has a geometric shape with two curved contours with some complicated overhanging sections," Custers explained.

Yannick Eberhard of Promarin R&D added that “the transition from semi-automatic to robotic machining is a solid foundation for even more complex and robust future propeller designs. ”

”

“Material characterization and mechanical testing was an important part of this project. We must ensure that the material properties meet the needs of the application in the industry. For example, the stiffness of the material that makes a propeller strong can absorb significant impacts without damage,” said Wei Ya, Ph.D. from the University of Twente at RAMLAB.

3D metal overlays that take into account the shape and width of the platen, as well as how quickly the printed material can be applied. Wei Ya noted the ability of RAMLAB to print objects with a maximum size of 7x2x2 meters.

The first WAAMpeller prototype will be used for demonstrations and, according to Kees Custers, the consortium is already planning to start work on a second BV-class propeller next month.

“We aim to install this second example on one of our tugs later this year,” said Kees Custers.

The international shipbuilding group DAMEN Shipyards Group (headquartered in Gorinchem, the Netherlands) unites 40 shipbuilding and ship repair yards. The total number of company employees worldwide is 9thousand people. The company has built more than 6,000 vessels around the world to date, and annually puts into operation about 160 new vessels. DAMEN specializes in the design and construction of tugs, boats, patrol boats, high-speed and cargo vessels, dredgers, offshore service vessels, oil spill response vessels (OSR), frigates and mega-yachts.

The total number of company employees worldwide is 9thousand people. The company has built more than 6,000 vessels around the world to date, and annually puts into operation about 160 new vessels. DAMEN specializes in the design and construction of tugs, boats, patrol boats, high-speed and cargo vessels, dredgers, offshore service vessels, oil spill response vessels (OSR), frigates and mega-yachts.

Related link:

Damen and partners develop the world's first certified 3D printed propeller (graphic) >>>>

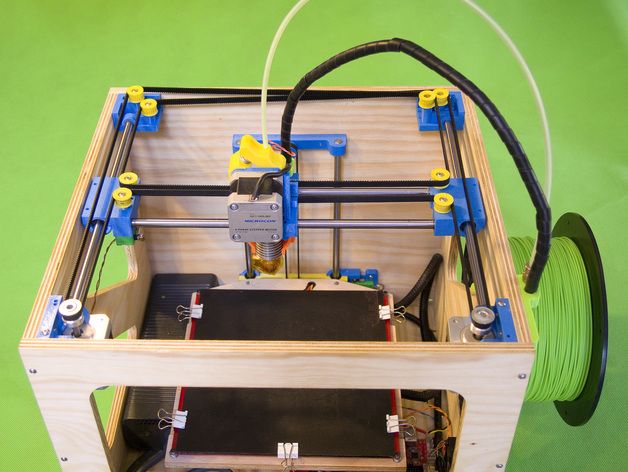

Free 3D File Z-Axis Adjustment・Object for Download and 3D Printing・Cults

Marlin 1.1.9 and 2.0.0 for MKS Gen L (all my versions)

Free

Washer for screws and nuts M3

Free

Fender Stratocaster Back Plate Cover for Stratocaster-3D 9 only0044

Free

CNC feet - Nikodem CNC

Free

Kyosho Pure Ten Alpha 3

Free

CNC Plotter - Plantus

Free

CD - CTC Prusa I3 2018

Free

Dishwasher clip / Bosch

Free

The best files for 3D printers in the Tools category

mask hook

Free

ROLL CARRIER

1. 12 €

12 €

Angular guide for saw (band or oscillating)

0.61 €

Steampunk Cabinet Latch

1.49 €

GoPro bike mount

Free

Plug for ruler

Free

COVID 19 CORONAVIRUS CAP PROTECTION FFCCSE

Free

Coffee mill adapter for filter basket for espresso (Mahlkönig and DeLonghi)

Free

Bestsellers in the Tools category

Creality Sonic Pad Mount for Ender 3 S1

0.99 €

Fan duct Sovol SV06 5015 - CFD optimized

3.75 €

Ratchet holders - magnetic - holders for tool box organization

2,66 €

V3 AIR DUCT FAN 5015, ENDER 3 S1, S1 PRO, SPRITE, ACCELEROMETER, LED strip

€2. -10% 2.27 €  53

53

ENDER 3 S1 PRO STRENGTH GAIN

1.72 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. Printing does not require support

1.54 €

ENDER 3 S1/S1 PRO, PROFILE 2020 ALU, REEL HOLDER AND DEPORTED REEL

2,12 €

.22 LR 250x storage fits in 7.62 NATO ammo container

7.03 €

Pinch Perfect Full Set (12 OZ - 30 OZ) Sublimation Aid Tool on Cup

1.99 €

Printer boxes for Ikea Lack Table

1,99 €

HOT END DUCT 4020 OR 5015 FAN, ENDER 3 S1, S1 PRO, SPRITE, NON-OFFSET Y PROBE, ABL BETA ADAPTER

€2. -10% 2.05 €  27

27

PRECISE DIAL INDICATOR 3D PRINT DIY

€1.90

Creality Ender 3 S1 Pro Advanced Cable Management

1.50 €

SUPERBOX

1,50 €

PET-Machine, make your own plastic bottle filament at home!

50 € -61% 19,50 €

Generativ Design Y-Filamentsplitter Bambulab AMS-Extern RS-CONCEPTS

2,50 €

💖 Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in maintaining the activities of and creating future developments is very simple.