Is 3d printer stock a good investment

5 3D Printing Stocks to Consider in 2022

Back in the early 2010s, stocks were booming for 3D printing -- also known as additive manufacturing, a computer-controlled process in which three-dimensional objects are made. But the boom was followed by a bust as many pure-play 3D printing companies didn't immediately deliver on lofty expectations.

Rumors of the manufacturing technology's demise are clearly premature. These days, 3D printing is a high-growth niche that is steadily reshaping the manufacturing and industrial sectors. Some estimates point to a doubling in annual revenue from additive manufacturing between 2022 and 2026. Even growth investor Cathie Wood has launched a fund focused on manufacturing tech, The 3D Printing ETF (NYSEMKT:PRNT), via her company ARK Invest.

Here's what you need to know about 3D printing and additive manufacturing stocks for 2022:

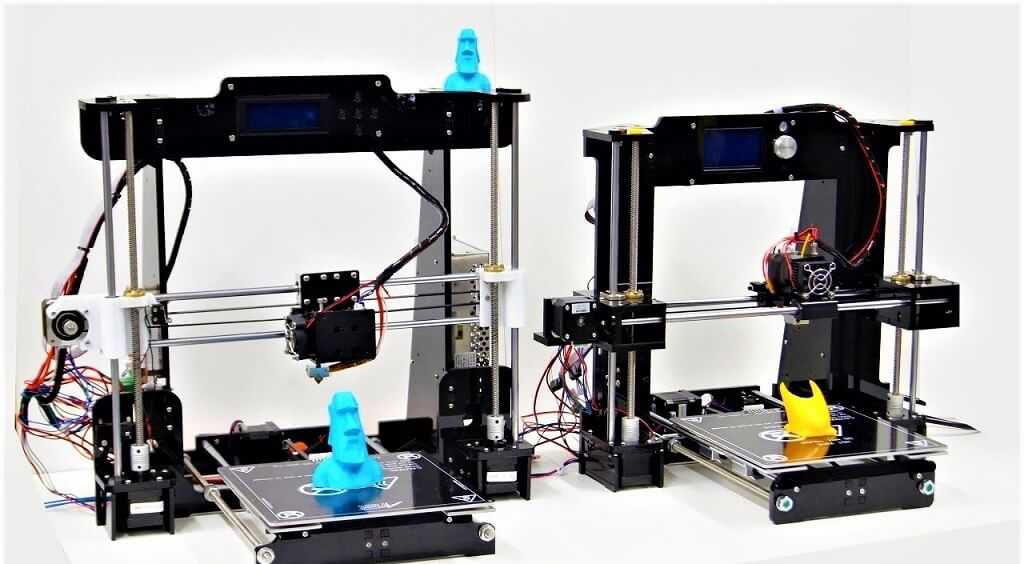

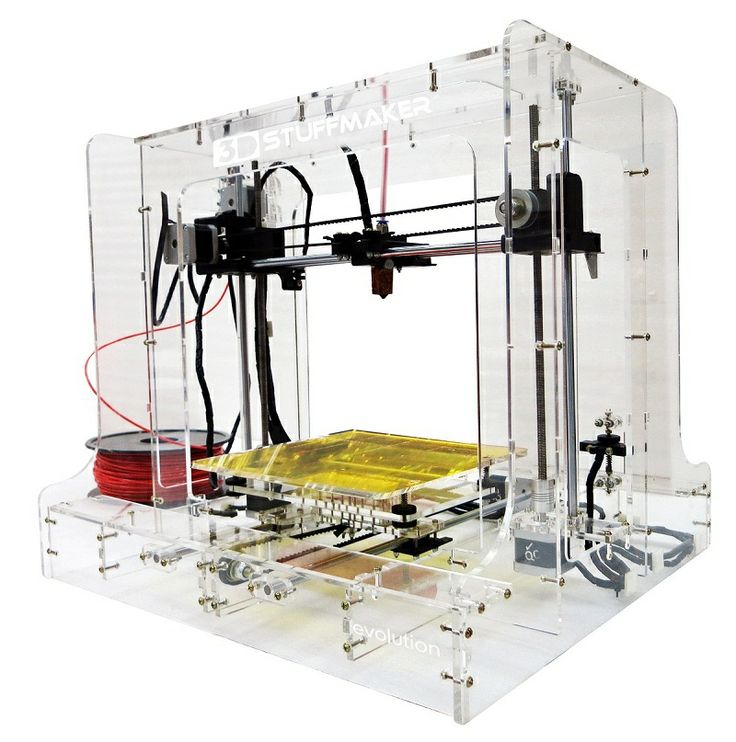

Image source: Getty Images.

Investing in 3D printing stocks

The manufacturing of products in all corners of the economy is being revolutionized by 3D printing, from healthcare equipment to metal fabrication to housing construction. It's invading so many sectors that tech giants such as Microsoft (NASDAQ:MSFT), Autodesk (NASDAQ:ADSK), and HP (NYSE:HPQ) have launched products aimed at 3D printing and additive manufacturing. Other engineering and software outfits such as Dassault Systemes (OTC:DASTY), ANSYS (NASDAQ:ANSS), and Trimble (NASDAQ:TRMB) have also gotten involved in 3D printing technology.

Here are five key players to consider for 2022 that are a more focused bet on 3D printing:

| Company | Market Cap | Description |

|---|---|---|

| Desktop Metal (NYSE:DM) | $1. 3 billion 3 billion | Recent IPO that focuses on metal fabrication technology. |

| Stratasys (NASDAQ:SSYS) | $1.5 billion | One of the original 3D printing pioneers, with a wide array of printers and supporting design software. |

| Xometry (NASDAQ:XMTR) | $1.9 billion | A manufacturing marketplace, including access to on-demand 3D printing services. |

| 3D Systems (NYSE:DDD) | $1.9 billion | Another original 3D printing pioneer and the largest pure-play stock on 3D printing technology. |

| PTC (NASDAQ:PTC) | $11.7 billion | A manufacturing technology provider with a suite of software and related services for industrial businesses. |

1. Desktop Metal

This company is a recent entry into the 3D printing space after going public via a SPAC at the end of 2020. The stock has been a terrible market underperformer since then, losing three-quarters of its value as of spring 2022. However, Desktop Metal could still be a promising investment for the long term.

However, Desktop Metal could still be a promising investment for the long term.

As its name implies, Desktop Metal develops 3D printing hardware and accompanying design software for metal and carbon fiber parts. The company's smaller systems can handle prototyping and one-off parts, and larger printers are production grade-designed for manufacturing facilities. Desktop Metal serves companies operating in automotive, consumer goods, and heavy industrial equipment businesses.

Despite a tenuous start as a public company, Desktop Metal was actually increasing revenue at a torrid triple-digit pace in 2021. Gross profit margins are thin, and the company generated a steep net loss, but that should improve over time as the business scales its operation. Desktop Metal also has several hundred million dollars in cash and investments to fund its expansion. It used some of these funds to acquire additive manufacturing peer ExOne at the end of 2021.

2. Stratasys

Stratasys was part of the early 2010s 3D printing stock boom and bust, but its business has endured. Sales took a dip early in the COVID-19 pandemic but are rebounding as the Israel-based company picks up new manufacturing contracts.

Stratasys serves a diverse set of customers, including aerospace and automotive parts manufacturers, medical and dental companies, and makers of basic consumer products. In addition to a wide array of 3D printer models, Stratasys develops software to help users accelerate the time between design and final printing.

It isn't the highest-growth name on this list, but Stratasys is profitable (on a free cash flow basis) and has more than $500 million in cash and investments on its balance sheet, as well as no debt. Management thinks its payoff from years of research and development into additive manufacturing will accelerate in 2022.

3. Xometry

This is another newcomer to public markets. Xometry completed its initial public offering (IPO) over the summer of 2021, raising almost $350 million in cash in the process. As is often the case with new IPOs, the stock has underperformed since then. It has lost over half of its value from the time it started trading on public markets, but the business itself is rapidly growing.

Xometry is a marketplace for on-demand manufacturing of prototyping and mass production. It has a network of more than 5,000 suppliers that companies can call on to meet their fabrication needs. Among the suppliers on the Xometry platform are 3D printing companies, injection molding, and automated machining. The company reported having more than 28,000 active buyers utilizing its platform at the end of 2021.

Although it isn't profitable yet, Xometry's unique approach to the 3D printing and additive manufacturing industry is growing fast. Like other names on this list, it has a sizable war chest of cash and short-term investments that it can spend on research and marketing as it tries to attract more suppliers and buyers to its marketplace.

Like other names on this list, it has a sizable war chest of cash and short-term investments that it can spend on research and marketing as it tries to attract more suppliers and buyers to its marketplace.

4. 3D Systems

3D Systems was another early player in the 3D printing industry, and while it suffered through the boom-and-bust period of the early 2010s, its business has held steady for much of the past decade. After a brief dip during the early days of the pandemic, 3D Systems is back in growth mode.

The company develops printers and design software for all sorts of materials and industries (medical device makers, dental labs, semiconductor designers, aerospace, and automotive manufacturers). It claims leadership among independent 3D printing companies (as measured by sales). As the 3D printing industry expands in the coming years, 3D Systems thinks it will be able to attract lots of new business with its extensive experience and global reach.

As an established tech outfit in the manufacturing sector, 3D Systems offers investors the prospect of more stable growth, along with profitability. It also has a large net cash position from which it can consolidate its lead in 3D printers and software technology.

5. PTC

By far the largest company on this list, PTC is a longtime technology partner of manufacturing and industrial enterprises. Fast approaching $2 billion in annualized sales and highly profitable, PTC has all the tools needed to digitally transform industrial businesses.

Besides 3D printing computer-aided design software (ANSYS is a peer and software partner that also operates in this space), PTC specializes in augmented reality, industrial IoT (Internet of Things), and product life-cycle management software. Most of its revenue is subscription-based (including its Creo software that enables 3D printing), making for a stable and steadily growing business model that generates ample cash flow. PTC puts spare cash to work developing new products for its partners and makes bolt-on acquisitions of other software companies that enhance its overall portfolio.

PTC puts spare cash to work developing new products for its partners and makes bolt-on acquisitions of other software companies that enhance its overall portfolio.

As a larger company, PTC won't be the fastest-growing stock in the additive manufacturing and 3D printing space. However, the company has established itself as a leader in industrial technology and should be a primary beneficiary as the production of manufactured goods gets more efficient.

The future of 3D printing

Manufacturing technology is making inroads throughout the global economy by reducing the cost of production and localizing and speeding up the time it takes to deliver customer orders. This is far from mere hype. Nevertheless, as is the case with all technology investments, progress won't go straight up. Expect twists and turns in these stocks as they develop new methods to design and make products.

If you decide to invest, do so in a measured way. Maintain a diversified portfolio, be wary of stocks benefiting from investor over-optimism, and always leave spare cash to invest more when there are inevitable dips. Given enough time -- years and decades -- investing in 3D printing could eventually provide a big payoff.

Maintain a diversified portfolio, be wary of stocks benefiting from investor over-optimism, and always leave spare cash to invest more when there are inevitable dips. Given enough time -- years and decades -- investing in 3D printing could eventually provide a big payoff.

Related communication stocks topics

Investing in 5G Stocks

As the 5G technology rollout continues, these companies look like winners.

Investing in Top Telecommunications Stocks

Our world is increasingly interconnected, and these companies make it happen.

Investing in Communication Stocks

Communications has a broad definition. These companies are the leaders in the space.

Investing in Top Consumer Discretionary Stocks

When people have a little extra cash, they indulge in offerings from these companies.

Nicholas Rossolillo has positions in Autodesk and PTC. The Motley Fool has positions in and recommends Autodesk, HP, and Microsoft. The Motley Fool recommends 3D Systems, ANSYS, Dassault Systemes, PTC, and Trimble Inc. The Motley Fool has a disclosure policy.

The Motley Fool recommends 3D Systems, ANSYS, Dassault Systemes, PTC, and Trimble Inc. The Motley Fool has a disclosure policy.

Top 3D Printing Stocks for Q4 2022

Table of Contents

Table of Contents

-

Best Value 3D Printing Stocks

-

Fastest Growing 3D Printing Stocks

-

3D Printing Stocks With the Best Performance

SSYS is top for value and performance and NNDM is top for growth

By

Noah Bolton

Full Bio

Noah has about a year of freelance writing experience. He's worked on his investing website dealing with topics such as the stock market and financial advice for beginners.

Learn about our editorial policies

Updated October 06, 2022

The 3D printing industry is made up of companies that provide products and services capable of manufacturing a range of products. 3D printing, also known as additive manufacturing, creates physical objects from digital designs. The printing process works by laying down thin layers of material in the form of liquid or powdered plastic, metal, or cement, and then fusing the layers together. Though still too slow for mass production, it is a revolutionary technology that has the potential to disrupt the manufacturing logistics and inventory management industries. The 3D printing industry is comprised of only a handful of companies, including players such as Proto Labs Inc., Faro Technologies Inc., and Desktop Metal Inc.

3D printing, also known as additive manufacturing, creates physical objects from digital designs. The printing process works by laying down thin layers of material in the form of liquid or powdered plastic, metal, or cement, and then fusing the layers together. Though still too slow for mass production, it is a revolutionary technology that has the potential to disrupt the manufacturing logistics and inventory management industries. The 3D printing industry is comprised of only a handful of companies, including players such as Proto Labs Inc., Faro Technologies Inc., and Desktop Metal Inc.

The industry is so young that it has no meaningful benchmark index. But the performance of these stocks can be compared to the broader market as represented by the Russell 1000 Index. These stocks have not performed well. Stratasys Ltd. (SSYS), the best performing 3D printing stock, has dramatically underperformed the Russell 1000, which has provided a total return of -12.5% over the past 12 months. This market performance number and all statistics in the tables below are as of Sept. 20, 2022.

This market performance number and all statistics in the tables below are as of Sept. 20, 2022.

Here are the top three 3D printing stocks with the best value, fastest sales growth, and the best performance.

These are the 3D printing stocks with the lowest 12-month trailing price-to-sales (P/S) ratio. For companies in early stages of development or industries suffering from major shocks, this metric can be substituted as a rough measure of a business's value. A business with higher sales could eventually produce more profit when it achieves (or returns to) profitability. The price-to-sales ratio shows how much you're paying for the stock for each dollar of sales generated.

| Best Value 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing P/S Ratio | |

Stratasys Ltd. (SSYS) (SSYS) | 15.49 | 1.0 | 1.6 |

| 3D Systems Corp. (DDD) | 9.00 | 1.2 | 2.0 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | 2.1 |

Source: YCharts

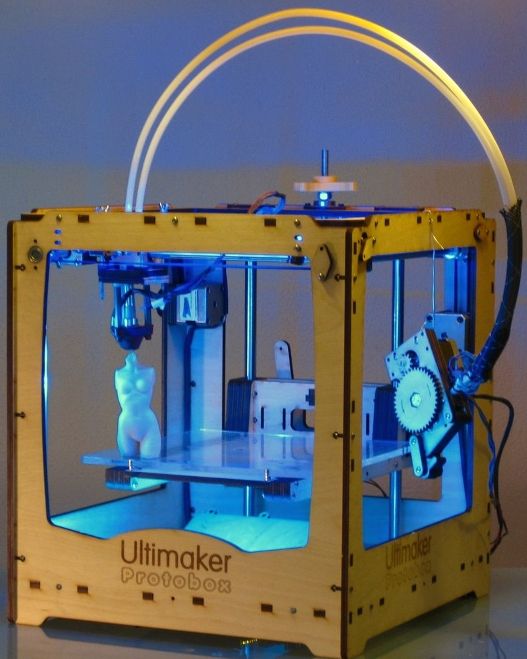

- Stratasys Ltd.: Stratasys offers 3D printing solutions, such as 3D printers, polymer materials, a software ecosystem, and related parts. It serves a variety of industries, including aerospace, automotive, consumer products, and healthcare. On Sept. 13, Stratasys completed the merger of its MakerBot subsidiary with Ultimaker, which offers platforms used to make 3-D printers. Ultimaker is backed by NPM Capital. The merged company will keep the Ultimaker name and focus on providing solutions, hardware, software and materials to the industry. NPM Capital will have majority ownership of the new company at 53.5%, and Stratasys will own 46.5%.

- 3D Systems Corp.: 3D Systems provides 3D printing solutions.

The company offers a range of hardware, software, and materials designed for additive manufacturing. Its products and services are used in a variety of industries and sectors, including aerospace, automotive, semiconductor, healthcare, and more.

The company offers a range of hardware, software, and materials designed for additive manufacturing. Its products and services are used in a variety of industries and sectors, including aerospace, automotive, semiconductor, healthcare, and more. - Proto Labs Inc.: Proto Labs is an e-commerce-based company that provides digital manufacturing services. It offers 3D printing, injection molding, CNC machining, and sheet metal fabrication. On Aug. 5, Proto Labs announced financial results for Q2 2022, the three-month period ending on June 30, 2022. Net income fell more than 80% to $2.6 million from the prior-year quarter while revenue rose 3.1%.

These are the 3D printing stocks with the highest YOY sales growth for the most recent quarter. Rising sales can help investors identify companies that are able to grow revenue organically or through other means and find growing companies that have not yet reached profitability. In addition, accounting factors that may not reflect the overall strength of the business can significantly influence earnings per share. However, sales growth can also be potentially misleading about the strength of a business, because growing sales on money-losing businesses can be harmful if the company has no plan to reach profitability.

However, sales growth can also be potentially misleading about the strength of a business, because growing sales on money-losing businesses can be harmful if the company has no plan to reach profitability.

| Fastest Growing 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | Revenue Growth (%) | |

| Nano Dimension Ltd. (NNDM) | 2.45 | 0.6 | 1,270 |

| Desktop Metal Inc. (DM) | 3.07 | 1.0 | 203.9 |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | 13.3 |

Source: YCharts

- Nano Dimension Ltd.: Nano Dimension is an Israel-based 3D printing company focused on developing equipment and software for 3D-printed electronics. It develops printers for multilayer printed circuit boards and nanotechnology-based inks.

The company serves a range of industries, including consumer electronics, healthcare, aerospace, and automotive. On Sept. 1, Nano Dimension released Q2 2022 results. The company's net loss widened sharply to $40.0 million from a loss of $13.6 million in the same quarter a year earlier even as revenue soared more than 13-fold. The larger second-quarter loss was fueled partly by $10.9 million in non-cash adjustments for depreciation and amortization expenses, and share-based payments.

The company serves a range of industries, including consumer electronics, healthcare, aerospace, and automotive. On Sept. 1, Nano Dimension released Q2 2022 results. The company's net loss widened sharply to $40.0 million from a loss of $13.6 million in the same quarter a year earlier even as revenue soared more than 13-fold. The larger second-quarter loss was fueled partly by $10.9 million in non-cash adjustments for depreciation and amortization expenses, and share-based payments. - Desktop Metal Inc.: Desktop Metal manufactures 3D printers and related equipment used to build complex parts from metal. It also offers 3D printing software. The company serves a range of industries, including automotive, consumer products, education, and heavy industry. On Aug. 08, the company reported Q2 2022 results. Desktop Metals' net loss increase nearly seven-fold to $297.3 million compared to the same quarter a year earlier even as revenue tripled.

- Stratasys Ltd.

: See above for company description.

: See above for company description.

These are the 3D printing stocks that had the smallest declines in total return over the past 12 months out of the companies we looked at.

| 3D Printing Stocks With the Best Performance | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing Total Return (%) | |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | -34.5 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | -50.6 |

| Materialise NV (MTLS) | 10.95 | 0.6 | -53.9 |

| Russell 1000 | N/A | N/A | -12.5 |

Source: YCharts

- Stratasys Ltd.: See above for company description.

- Proto Labs Inc.: See above for company description.

- Materialise NV: Materialise is a Belgium-based provider of additive manufacturing software and 3D printing services. It serves a range of industries, including healthcare, aerospace, and automotive. On Sept. 7, Materialise completed its acquisition of Identity3D, which makes products that encrypt, distribute, and track digital parts as they move through supply-chains. The value of the deal was not specified in the announcement.

The comments, opinions, and analyses expressed herein are for informational purposes only and should not be considered individual investment advice or recommendations to invest in any security or to adopt any investment strategy. Though we believe the information provided herein is reliable, we do not warrant its accuracy or completeness. The views and strategies described in our content may not be suitable for all investors. Because market and economic conditions are subject to rapid change, all comments, opinions, and analyses contained within our content are rendered as of the date of the posting and may change without notice. The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "Financial Data."

Stratasys Ltd. "Stratasys Completes Merger of MakerBot with Ultimaker."

Proto Labs Inc. "Proto Labs Q2 2022 Earnings Release."

Nano Dimension Ltd. "Earnings Press Release for Q2 2022."

Desktop Metals Inc. " Desktop Metals Second Quarter 2022 Earnings."

Materialise NV. "Materialise Acquires Indenity3D."

Business using a desktop 3D printer, is it real?

Home » Articles » 3D printers, 3D scanners and CNC machines » Business using a desktop 3D printer, is it real?

Business using a desktop 3D printer, is it real?

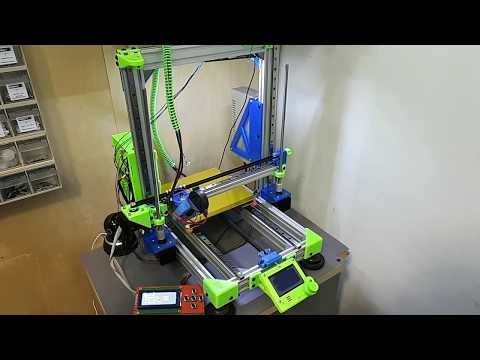

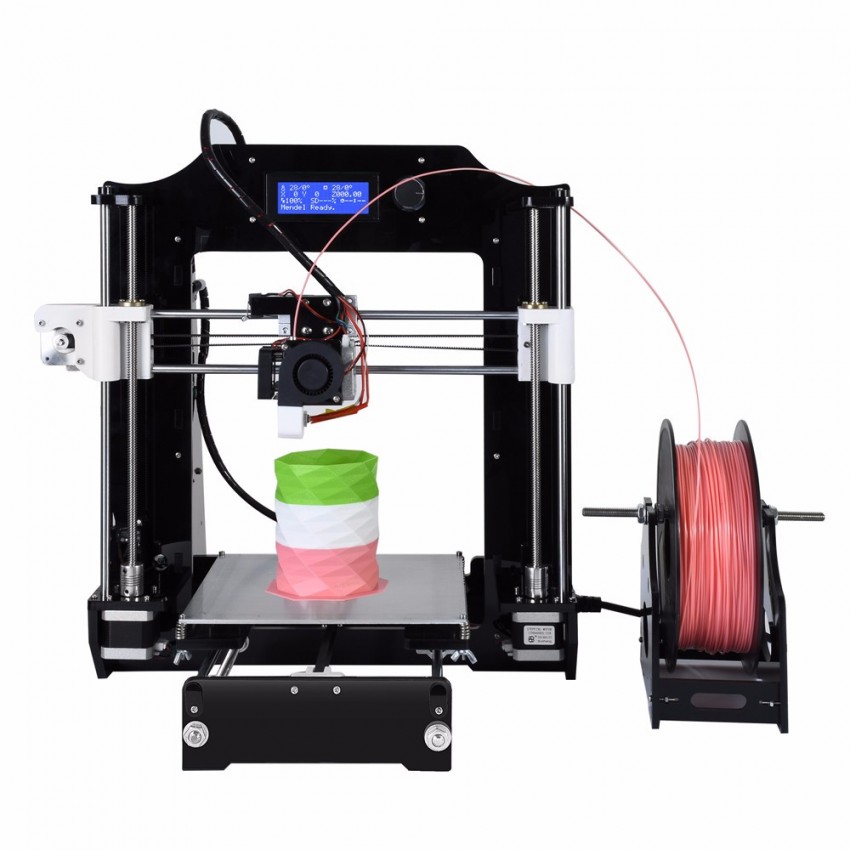

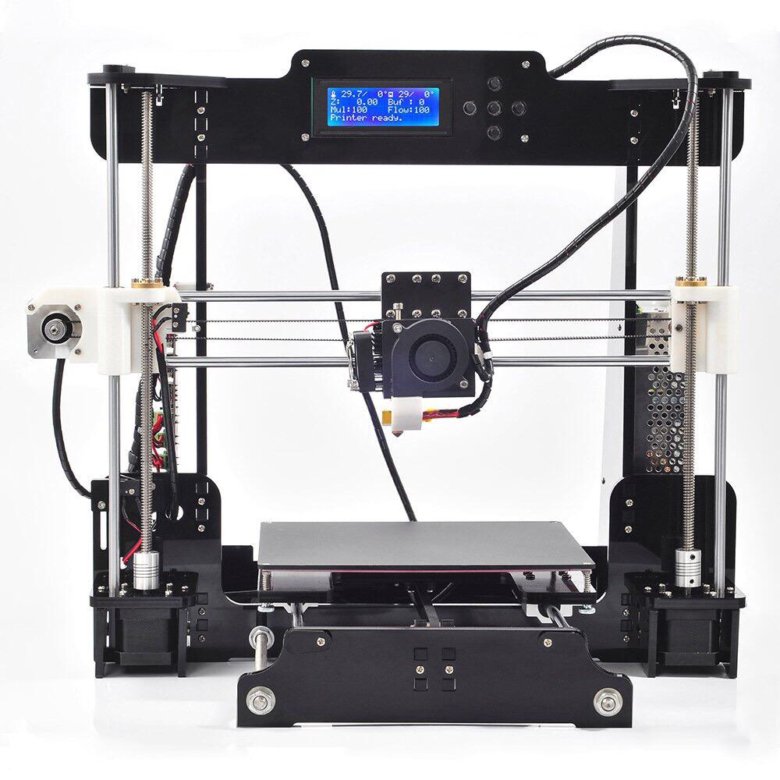

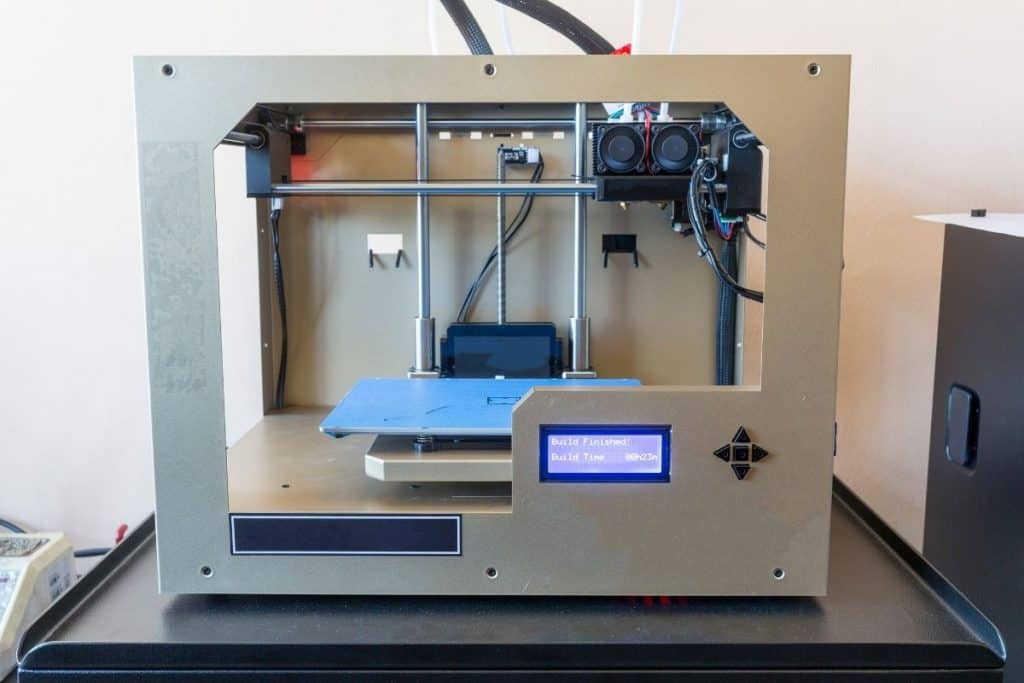

3D printers have firmly entered our lives and have taken their rightful place in it. These units are designed for 3D modeling of various objects: from toys and souvenirs to complex parts and high-precision tools. With their help, you can create a model of any product. This explains their demand and popularity. 3D printers these days are actively used not only for amateur purposes. For businesses, professional additive installations with FDM technology are purchased, which involve the use of various types of materials for 3D printing. And these will not necessarily be bulky expensive devices, the operation of which requires separate laboratories with forced ventilation. Today, even open source desktop 3D printers are equipped with FDM technology. They allow anyone who wants to start their 3D business not just from scratch, but in a constantly changing market. nine0003

These units are designed for 3D modeling of various objects: from toys and souvenirs to complex parts and high-precision tools. With their help, you can create a model of any product. This explains their demand and popularity. 3D printers these days are actively used not only for amateur purposes. For businesses, professional additive installations with FDM technology are purchased, which involve the use of various types of materials for 3D printing. And these will not necessarily be bulky expensive devices, the operation of which requires separate laboratories with forced ventilation. Today, even open source desktop 3D printers are equipped with FDM technology. They allow anyone who wants to start their 3D business not just from scratch, but in a constantly changing market. nine0003

Risk or not?

Own business is always a certain risk, to a greater extent it is present at the stage of formation. In order not to burn out immediately after launch, you should already have a developed working strategy based on:

- Budget allocated for business development;

- Existing 3D modeling skills;

- Features of a 3D installation that provides business.

nine0020

nine0020

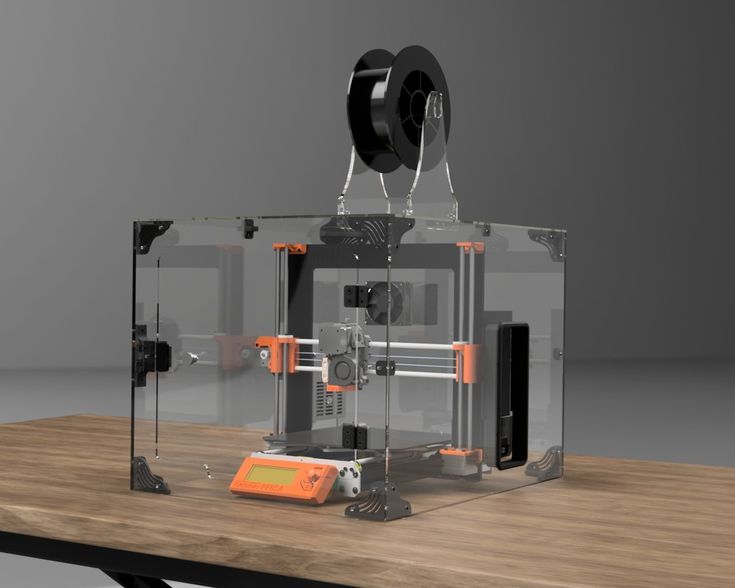

If you're only looking to buy a desktop 3D printer for professional use and make money with it, don't be fooled by the low cost. A good thing, a priori, cannot be cheap. Keep in mind, however, that the price of desktop additive rigs has come down significantly in recent times.

Buying a 3D printer will not be your only investment in your own business. As it develops, the need for additional investments will also increase. Therefore, the more powerful and functional the additive installation you bought, the less money will be required to refine the parts performed on it. A high-quality 3D printer will ensure high-quality products, an expansion of the customer base and a rapid increase in orders, which guarantees a quick return on investment. nine0003

Business options using a desktop 3D printer

With a desktop 3D printer, you can realize a number of business ideas that will bring not only good income, but also satisfaction from what you do. Even a small additive installation will allow you to make unique things. This will be the #1 idea for your business.

Even a small additive installation will allow you to make unique things. This will be the #1 idea for your business.

1. Manufacturing

Making rare and unique gizmos with a 3D printer may well become your additional income. This idea should be used by those who already have their own well-known brand. The additive device will allow you to produce a series of rare products in a limited edition in a unique design and with non-standard design elements. It can be souvenirs, jewelry, accessories, toys, reduced copies of cars, planes, spaceships and much more. nine0003

2. Prototyping

Having a desktop 3D printer will allow you to forget about time-consuming manual modeling that takes a lot of effort, money and energy. Using this device, you will produce high-precision three-dimensional models that are in demand in various sectors of the national economy - mechanical engineering, shipbuilding and aircraft building, dentistry and cosmetology, light industry, etc. They will be a worthy alternative to plaster and clay models, which are used less and less these days. nine0003

They will be a worthy alternative to plaster and clay models, which are used less and less these days. nine0003

3. Graphic design

This area of 3D modeling is rapidly developing these days. In order to succeed in it, you need to have good taste, be diligent, painstaking and accurate, as well as have computer skills and basic knowledge in the field of 3D modeling. Graphic design is used to create sketches of 3D layouts and models grown on a 3D printer.

To practice graphic design skills, you can use one of the free programs that are available on the World Wide Web. The software installed on the PC, with the accumulation of experience, knowledge and practical skills, can be improved with the help of additional plug-ins. Not a single 3D printing is complete without graphic design, so this line of business in the field of 3D is guaranteed to become popular and successful. nine0003

4. Courses and master classes in 3D modeling

If you are sure that your knowledge and skills are enough to teach the intricacies of three-dimensional modeling to other people, then this line of business is especially for you. You can organize training courses on the basics of 3D or modeling techniques known to you, conduct master classes and trainings, participate in competitions held in this area. This will allow you not only to do your favorite thing at a professional level, while receiving a good income, but also to constantly improve your own level of knowledge, hone your skills, develop and grow to become a true expert in the field of 3D and a leader in your niche. nine0003

You can organize training courses on the basics of 3D or modeling techniques known to you, conduct master classes and trainings, participate in competitions held in this area. This will allow you not only to do your favorite thing at a professional level, while receiving a good income, but also to constantly improve your own level of knowledge, hone your skills, develop and grow to become a true expert in the field of 3D and a leader in your niche. nine0003

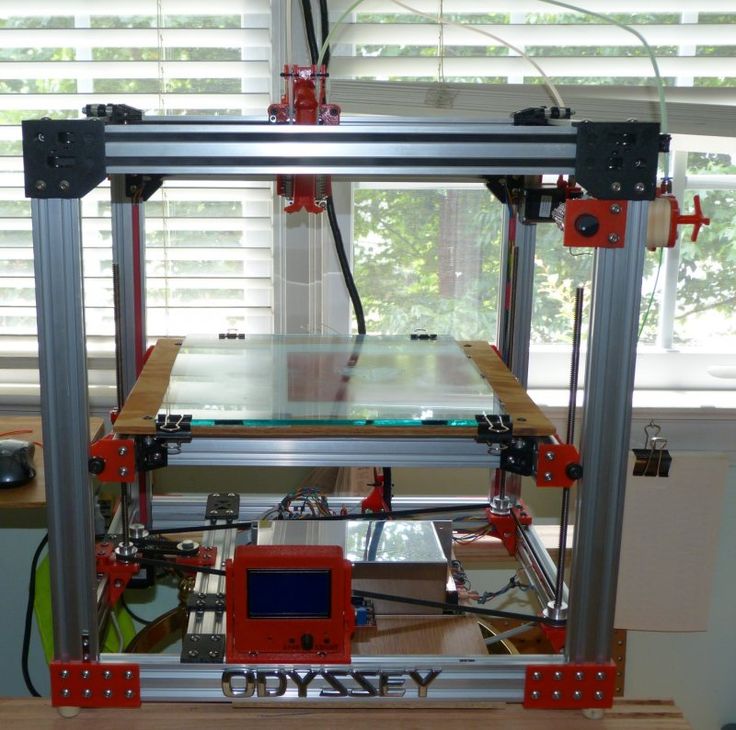

5. Engineering design

This line of business in the field of 3D will be of interest to "techies" who prefer to study three-dimensional modeling "from the inside". It involves the design and creation of new 3D printers and their components, the improvement of existing ones. This niche has not yet been fully occupied, and not only in our country, but throughout the world, so the prospects that will open before you will be simply colossal.

7. 3D printing services

Similar services in major cities of our country are growing like mushrooms after rain. Therefore, if you decide to offer 3D printing services to consumers, be prepared to offer them something new and interesting in order to beat the competition. Fresh ideas in the field of 3D will allow you to stand out among similar companies and attract the interest of the target audience. This will help you become a leader in your niche and regularly make good profits.

Therefore, if you decide to offer 3D printing services to consumers, be prepared to offer them something new and interesting in order to beat the competition. Fresh ideas in the field of 3D will allow you to stand out among similar companies and attract the interest of the target audience. This will help you become a leader in your niche and regularly make good profits.

If high competition does not scare you, and you intend to get into the provision of 3D printing services, be prepared for the fact that this business will require significant investments from you at the initial stage. You will not only have to purchase a high-tech desktop 3D printer, but also a number of additional installations, as well as high-quality materials for growing three-dimensional parts, otherwise you will not achieve success in your business. nine0003

8. Software development for 3D printing

Despite the fact that there are a huge number of 3D printing programs on the World Wide Web, both paid and free, new, improved software will never be superfluous. To create it, of course, professional skills and knowledge are needed. If you have them, go ahead. Your startup can bring you a solid income with a minimum investment in its development.

To create it, of course, professional skills and knowledge are needed. If you have them, go ahead. Your startup can bring you a solid income with a minimum investment in its development.

9. Organization of a fab lab

Fab labs are popular among those who are just learning the basics of 3D modeling, but are already showing good skills in this area. In them, novice users can hone their professional skills on the latest high-tech equipment with specialized technical support. To organize a fab lab, you need funds and special permissions.

And in conclusion, I would like to write that a desktop 3D printer can be used to develop your business. It, together with your skills and knowledge, will bring you a stable income and very tangible benefits to consumers. nine0003

12 common 3D printing mistakes from easy to hard. How to avoid them?

1. Underestimation of the importance of the first layer. 2. Don't ask the 3D printing communities for help. 3. Random entanglement of the filament. 4. Fast assembly of your 3D printer. 5. Incorrect table and nozzle height calibration. 6. Using the wrong slicer settings. 7. Using a high % infill to reinforce details instead of walls/shells. 8. Don't use support when needed. nine. Never replace worn parts. 10. Lack of 3D printing monitoring. 11. Neglect of safety rules in 3D printing. 12. Buying a bad 3D printer out of over-enthusiasm. Output.

Don't ask the 3D printing communities for help. 3. Random entanglement of the filament. 4. Fast assembly of your 3D printer. 5. Incorrect table and nozzle height calibration. 6. Using the wrong slicer settings. 7. Using a high % infill to reinforce details instead of walls/shells. 8. Don't use support when needed. nine. Never replace worn parts. 10. Lack of 3D printing monitoring. 11. Neglect of safety rules in 3D printing. 12. Buying a bad 3D printer out of over-enthusiasm. Output.

There's nothing worse than 3D printing for days, weeks, months and years only to find out you're making common mistakes.

We're sure many of you are familiar with that feeling, which is why we've written this post to get you back on the road to success by outlining some common mistakes to avoid on your 3D printing journey. nine0003

Here you will find both small errors that you did not pay attention to before, and serious errors that can lead to a complete cessation of 3D printing.

Join our research to identify the most common 3D printing mistakes, as well as simple solutions to fix them quickly.

1. Underestimation of the importance of the first layer.

Too often 3D printing fails in the middle of the process due to poor adhesion of the first layer.

Definitely keep this important factor in mind if you want a successful print. nine0115 This is a mistake that is made too often, and it makes people chase ghosts, trying to figure out what the problem is.

All this time, the reason was the bad first layers, which did not have a strong enough connection with the working platform.

Although your first layer is held at the start of printing, adhesion decreases as the print head moves. It is likely that your print may shift or fall off after a few hours if the first layer was not well extruded. nine0003

Solution .

- Make a few test prints ahead of time and see how well the material adheres.

- Use an adhesive such as 3D Printer Varnish or at least a glue stick.

- Increase the flow rate (extrusion multiplier) for the first layer so that the material has a better chance of sticking to the printer bed.

2. Do not seek help from the 3D printing communities.

Every user of a 3D printer has encountered some kind of problem that required some effort to fix. Some people took on entire projects just to solve a 3D printer problem, when the solution was easy to find. nine0003

3D printing communities are known for helping people solve their problems, so be sure to check out these free resources. From 3D printing forums to Facebook groups and YouTube surveys of other 3D printer users, the options are endless.

When we first started exploring 3D printing, we noticed that many people mention how helpful other 3D printer users are, so we immediately registered on all kinds of Russian and English resources, Facebook and Reddit communities and joined this space . nine0003

In most cases, people will offer the right solution and will be happy to help you try various troubleshooting options.

Not only can they help you with troubleshooting, but they can point you to some fun projects to try, as well as some of the latest innovations in the world of 3D printing.

Solution .

- Join active Facebook groups on 3D printing and your specific 3D printer. nine0020

- Subscribe to news feeds of authoritative 3D printing resources.

- Be sure to check out YouTube 3D printing bloggers who post new and interesting content on a regular basis.

- Find groups in Viber and Telegram. This is the fastest way to get an answer to your question.

3. Random entanglement of the filament.

We have read many reviews about 3D printer materials including PLA, ABS, PETG, etc. and some of the negative reviews mention tangled filament. nine0003

Unfortunately, in most cases, the thread becomes tangled due to the fault of users.

As a general rule, when the thread is wound onto the spool, there is very little chance of tangling, much more often after you take the spool out of the package.

If you loosen the windings in the winding and then wind the deflated windings back on the spool, you could accidentally wind them unevenly and create an overlap that will ruin your prints.

Solution .

When storing the filament, make sure that the end is securely fastened and cannot be easily loosened.

If there are already tangles on the spool, unwind enough thread and wind it tightly again so that it does not cross over.

If you are still unlucky, and you have purchased plastic of inadequate quality, during the production of which all technological cards were violated, then here is our advice: buy plastic for a 3D printer from trusted brands. The $100 price difference is infinitesimal compared to all sorts of other 3D printing costs. nine0003

However, this 100 UAH will save you not only from problems with overlaps, but also provide a stable diameter and color along the entire length, the absence of ovalities and smooth feeding.

4. Quickly assemble your 3D printer.

We were all very excited when we got our first 3D printer and it came to building it, but being overly excited can cause your 3D printer to build too quickly, resulting in poor print results.

This may not be immediately noticeable and you will get good quality prints within a few months. nine0003

What can happen gradually is wear due to incorrect assembly.

Ask yourself these questions before starting your first print.

Was your belt tight? Did you properly and securely fasten each wire? Is the Bowden tube installed correctly?

When it comes to a 3D printer, every little detail counts, so don't fall prey to 3D printing problems because of a quick and careless build.

Solution .

Find an authoritative YouTube video tutorial from an experienced 3D printer operator and follow assembly. nine0115 There are always a few little tricks they advise you to do for durability and high quality prints.

Even if you've already built your 3D printer, you can fix some things you may have missed.

The correct and high-quality assembly of a 3D printer actually leads to higher quality prints.

See also: How to set up your new 3D printer.

5. Wrong table and nozzle height calibration.

Of all the layers in your 3D print, the first layer is the most important and it depends a lot on how well you leveled your platform and set your nozzle height. nine0003

It's not as easy as uploading a 3D model, sending it to an SD card and starting printing.

The software side of things is important, but the hardware side is just as important.

Many 3D printers come with manual platform calibration, so you have to raise or lower each corner yourself.

Your 3D printer doesn't have a perfect feedback system, which means it can't always check where the print head is.

The best he can do is use the X, Y and Z limit switches to make sure the printhead is 0.00mm in each axis. nine0003

What your 3D printer is very good at is extremely precise movements in the X, Y and Z axes, but if the nozzle height is not set properly at the beginning, everything falls apart.

The Z axis is height, so the nozzle must be properly adjusted so that it smoothly extrudes the filament along the surface of the build, neither too high nor too low.

Solution .

- Learn how to manually calibrate the table.

- Once your table is properly calibrated and the nozzle height adjusted, you can expect good prints. nine0020

- It might be a good idea for you to invest in an auto leveling system like BLTouch. We at our 3D printing studio in Odessa prefer manual calibration.

6. Using incorrect slicer settings.

The slicer settings you use to print are some of the most important things when it comes to successful 3D printing.

Of the hundreds of setting changes you can make, one wrong setting is enough to ruin your print. nine0003

Fortunately, there are printer profiles and default settings that give people a basic starting point for printing.

After a few prints, you will start experimenting with different settings such as temperature, line width, flow rate, and so on.

Some of the misapplied misconfigurations are related to changing materials.

Whether PLA or ABS or PLA of different brands and/or colors, temperature recommendations will vary. nine0003

Make sure you set them correctly.

Slicer settings can either help you or break your 3D printing, so use them wisely, preferably with some kind of guide.

In most cases, when you load a model from Thingiverse, for example, designers create a list of settings that generally work well, but don't blindly follow them and be careful.

For example, if you replaced a brass nozzle with a hardened steel nozzle, you would need to slightly increase the nozzle temperature because hardened steel does not conduct heat as well as brass. nine0003

Another example is your work surface.

If you have added a glass substrate to your 3D printer, you should increase the table temperature to allow for the extra layer of heat transfer material.

Solution .

- Use calibration models such as speed and temperature towers for each new material.

- Spend a little more time looking at the slicer options to make sure you know what changing a particular setting will do. nine0020

- Repetition is the mother of learning. The more often you type, the faster you will become a pro.

Read also: The best models for 3D printing testing.

7. Using high % infill to reinforce details instead of walls/shells.

For years, most people have tried to reinforce their 3D printed parts with infill. This method definitely does the job, but there is a much more efficient method that has been proven to work much better. nine0003

Instead of wasting a lot of material and extra time printing the infill, you should use shells/walls to make the 3D printed part stronger.

In some cases, increasing the percentage of filling does not provide the necessary margin of safety, while increasing the wall thickness makes it possible to produce truly reliable and impact-resistant products.

Solution.

- Instead of adding more infill, add more shells/walls to your prints to make them stronger. nine0020

- For a functional 3D printed part requiring strength, about 4-6 walls are recommended.

8. Do not use supports when necessary.

Most people try to avoid the use of auxiliary supports to save time and material, but there are times when their use is necessary.

You can try tilting the prints in a certain way and moving them around the print bed, but sooner or later there will come a point when this approach doesn't work. nine0003

Many models are specially designed not to use support for successful printing, which is very convenient.

On the other hand, some designs are too complex to print without support.

3D printers cannot print in the air and large ridges definitely need support structures to extrude the material onto.

Most often you can do without supports on 45° or lower overhangs, but for anything higher it is recommended to use supports. nine0003

nine0003

This is more of a visual skill that, with time and experience, allows you to understand when models need supports and when you can do without them.

Some slicers may not show support in preview, so you'll have to judge for yourself.

Solution.

- Make sure you don't avoid supports when they're needed, because in that case you'll just lose overall. nine0020

- Use proper part orientation to ensure your prints use as little support material as possible.

9. Never replace worn parts.

Although your 3D printer profile, power supply and stepper motors are designed to last for several years, other parts are consumables.

These are parts such as belts, nozzles and bearings. Make sure you replace these parts as they wear out.

You may notice a decrease in print quality over time, and wear and tear on certain parts can definitely be the cause, so check these consumables and replace them as needed. nine0003

nine0003

If you are printing with materials such as ABS, PA12, PC or glow-in-the-dark plastics, the brass nozzles wear out much faster than when printing with traditional materials.

Switching to a hardened steel nozzle is a good idea if you want to print with abrasive materials.

The disadvantage is that it does not have the same level of thermal conductivity as brass nozzles.

Here is a short list of 3D printer parts that wear out over time:

- Thermal barrier;

- PTFE tube;

- Fans;

- Wires/connectors;

- Thermistors;

- Belts;

- Glass platforms;

- Bearings;

- Heating block;

- Motherboard.

You can buy accessories for 3D printers in the corresponding section of our catalog.

Solution.

- Be aware that some parts will not last forever, so check these parts from time to time and replace them as needed. nine0020

- Make sure these components are installed in a way that reduces wear.

- Keep a set of replacement parts on hand in case they fail (nozzles, belts, wiring, PTFE tubing).

- Purchase high quality parts designed for a long service life.

10. No 3D printing monitoring.

Whether you have a premium or budget 3D printer, any of them can fail. They can fail within the first few minutes when the first layer is not printing well, or a few hours after printing starts. nine0003

In our practice, there have been a few cases when checking our printers after a night shift, we found a mess on the work surface and the printer continued to extrude spaghetti plastic.

Monitoring is not a panacea for all problems, but with its help you can stop the process in time and avoid waste of plastic and electricity.

It is recommended to constantly monitor your 3D printers throughout the printing process to make sure everything is in order. nine0003

What we make sure to do is monitor the first coat and then come back 15 minutes later to make sure everything is going according to plan.

After that, checking the printers every hour or so is a good idea to control your prints.

Solution.

- Check the 3D print from time to time to make sure everything goes smoothly.

- Use the camera for remote fingerprint verification with remote power control. nine0020

- Be sure to teach others how to stop your 3D printer if necessary.

11. Neglect of safety rules in 3D printing.

Basic precautions are based on burn and fire hazards, mechanical hazards, and injury from tools or melted plastic.

The risk of fire is very rare these days because 3D printers are usually equipped with overheating protection.

Pay attention to burns from hot nozzle or print bed. nine0003

We've also heard stories of injuries from the sharp edges of the printer's scraper.

This can be easily avoided if you are careful in your actions.

Removing supports is not the most pleasant and interesting thing to do, but getting cuts or scratches when cleaning parts is even worse.

It is recommended to check the wiring, bolts, belts and all moving parts from time to time so that a potential malfunction can be detected in the future. nine0003

Connectors can sometimes fail, so be sure to check these aspects to ensure the 3D printing process runs smoothly and safely.

Solution.

- Be aware of your surroundings and be safe.

- Do not put your hand too close to the nozzle.

- Do not keep your hand on the platen when taking the print.

- Provide good ventilation.

12. Buying a bad 3D printer out of over-enthusiasm. nine0111

We are regularly contacted by clients who, on a wave of enthusiasm, bought a cheap 3D printer on Aliexpress or another market place, and this printer does not work.

Spontaneous cheap purchases do not give you time to analyze and compare 3D printer models. In other words, you are making your choice unconsciously.

People have experienced a number of problems, such as the SD card slot not working along with serious difficulties in transferring files over Wi-Fi.

Other options included poorly insulated wires, crooked frames and platforms. nine0003

Deformed threaded screws, cheap hot ends, broken parts, poor shipping packaging, poor assembly at the factory are also common when buying cheap "NoName" printers.

You may end up spending most of your time repairing, fixing poor print quality issues, and just getting frustrated with 3D printing.

If you've been one of those unlucky ones, you've probably learned to take your time buying a 3D printer. nine0003

One of the most popular manufacturers of inexpensive 3D printers around the world is Creality, and their top product Ender-3 v2.

This 3D printer has been tested many times by users around the world, and its popularity proves to be the perfect combination of price and quality.

Every 3D company is a team that buys parts and builds a printer, but some do it much better than others and more consistently.

Some people who buy a bad printer either give up 3D printing, do a complete costly rebuild, or buy a better 3D printer much later.