Iro3D desktop metal 3d printer

Metal 3D printer

Metal 3D printerOverview

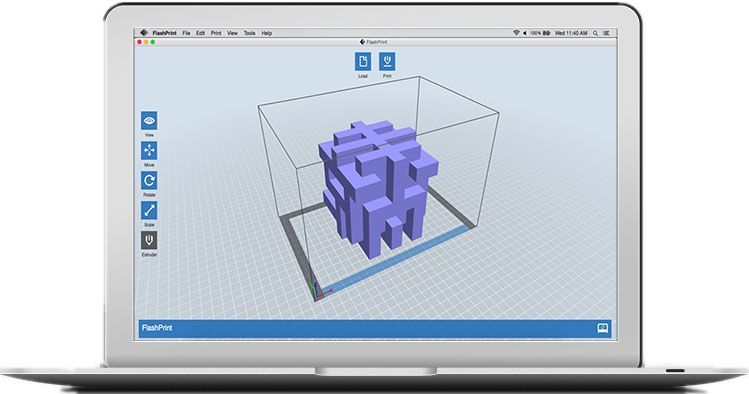

Selective Powder Deposition (SPD) is a new 3D printing process, which you can use to print metal, glass, ceramic, and composite materials. There are 2 main variants: infilling and sintering. With infilling you get a 100% solid object, and with sintering you usually get a porous object. The best metal 3D printer video helps visualizing it.

Variant 1 - SPD with infill

First, the 3D printer selectively deposits build and support powders into a crucible. When it finishes filling the whole crucible, you add some infill material, and bake it in a kiln. The temperature in the kiln should be above the melting temperature of the infill, but below the melting temperature of the powders. When the infill melts, it soaks the build powder, but it doesn't soak the support powder, because the support powder is chosen such that it's not wettable by the infill.

To prevent metal oxidation, the atmosphere in the crucible should be reducing. The easiest way to create a reducing atmosphere is to place some carbon (metallurgical coke) or hydro-carbon (plastic) in the crucible. But some metals require a controlled atmosphere furnace with hydrogen and argon.

After the infilling, if you cool down the crucible quickly - you'll get a composite material, because the atoms of the build powder and the infill didn't have enough time to mix. But if you hold it at high temperature for a while - the atoms of the build powder and the infill will diffuse and mix with each other, so you'll get a uniform alloy. The time required for diffusion depends on the metals and temperature. For example, at 790°C, copper+tin can mix uniformly in 2 hours and you'll get bronze. But copper and tungsten, even at 1090°C, won't alloy much even in a day, so you'll get a composite.

When it cools down, remove it from the kiln, and clean it with a wire brush or sand blaster.

Variant 2 - SPD with sintering

The 2nd variant, sintering - is even simpler - you just don't add any infill, and bake it at the temperature sufficient to sinter the build powder. Note that sintering causes shrinkage and warping. By changing the baking temperature, you can influence the amount of shrinkage, warping and porosity. With sintering it's hard to achieve 100% density with pure metals (those that have a single melting point), but it's easy with glass, and some metal alloys, though it requires a vacuum furnace.

Note that sintering causes shrinkage and warping. By changing the baking temperature, you can influence the amount of shrinkage, warping and porosity. With sintering it's hard to achieve 100% density with pure metals (those that have a single melting point), but it's easy with glass, and some metal alloys, though it requires a vacuum furnace.

Materials

In theory, SPD can be used to 3D print almost any material. Actually, the printer itself is material agnostic, and can pour any powder that flows through a small hole. But when it comes to baking, some materials are easier than others. For the details see Which materials can be 3D printed with SPD

Advantages

Parts are 100% solid.

AFAIK, Selective Powder Deposition is the only method that can produce 100% solid metal 3D prints.

Laser printers can't do that, because they melt metal one pixel at a time, and it solidifies one pixel at a time. During the solidification metal shrinks and breaks away from the neighboring pixels, causing voids and warping.

During the solidification metal shrinks and breaks away from the neighboring pixels, causing voids and warping.

No warping or internal stress

AFAIK, SPD with infill is the only metal 3D printing method that doesn't cause any warping or internal stress. This is because the printed object is warmed up and cooled down all together at the same time.

In contrast, laser printers use localized melting, which causes localized shrinkage, and thus warping. And the processes that rely on sintering always have some warping due to uneven shrinkage.

Versatile - can 3D print many different materials, even glass

SPD can be used to 3D print many different materials. AFAIK, SPD with sintering is the only way to 3D print glass.

Comparison of metal 3D printing methods (2022)

| Cost | Internal stress | Shrinkage | Porosity | Strength | Resolution | Shape limitation | Max size | |

|---|---|---|---|---|---|---|---|---|

| Laser, SLS, SLM, EBM, DMLS | high | high1 | none | low-med | med-high | high | med | med |

| MIG welding | med | high1 | none | low-med | med-high | low | med | huge |

| FDM or Binder Jet + sintering in air | low | none | high2,3 | low-med2,3 | low-med2,3 | med | med | small |

| FDM or Binder Jet + sintering in argon | high | none | high2,3 | low-med2,3 | med-high2,3 | med | med | small |

| iro3d SPD with infill | low | none | none | none | high | med | low | large |

| iro3d SPD with sintering for ceramics and pure metals | low | none | low2,4 | high2,4 | low2,4 | med | low | large |

| iro3d SPD with sintering for glass and some alloys | low | none | med-high2,5 | none-high2,5 | low-high2,5 | med | low | large |

1Localized heating and cooling cause internal stress, which can cause warping, so additional support structures are needed for most shapes.

2With sintering, shrinkage and porosity can be traded for one another - reducing the particle size or increasing the temperature or time - results in lower porosity and higher strength, but higher shrinkage. And vice versa.

3With FDM and Binder Jet sintering, the powder particle size must be relatively small, so the shrinkage is usually high, but porosity can be low and strength medium-high. Sintering in argon rather than air - increases the strength, but also increases the price.

4With SPD, the powder particle size must be relatively large, so when the powder is non-viscous the shrinkage is usually low, but porosity is high and strength is low.

5Glass (and some alloys) become viscous at high temperatures, so sintering them naturally results in low porosity. And when using a vacuum furnace - 0% porosity and full strength can be achieved. This is very useful for glass - it makes it transparent.

Products and specifications

Model-C

| 3D Printing process: | Selective Powder Deposition (SPD) |

| Build volume: | 279 x 274 x 110 mm |

| Printer size: | 690 x 530 x 610 mm |

| Shipping box size: | 770 x 620 x 440 mm |

| Shipping weight: | 24 kg |

| Power: | 12V DC or 100-240V AC, 40W |

| Pourer diameters: | 0.9 mm and 1.9 mm |

| Min layer height: | 0.1 mm |

| Min width of a detail: | one pourer diameter |

| Min height of a detail: | one layer height |

Buy

Model-G

| 3D Printing process: | Selective Powder Deposition (SPD) |

| Build volume: | 610 x 610 x 310 mm |

| Printer size: | 1320 x 1010 x 1230 mm |

| Shipping box size: | TBD |

| Shipping weight: | TBD |

| Power: | 24V DC or 100-240V AC, 60W |

| Pourer diameters: | 0. 9 mm, 1.9 mm and 3.9 mm 9 mm, 1.9 mm and 3.9 mm |

| Min layer height: | 0.1 mm |

| Min width of a detail: | one pourer diameter |

| Min height of a detail: | one layer height |

Buy

iro3d starts shipment of $5,000 metal 3D printer

0Shares

iro3d, a metal 3D printer startup based in Seattle, Washington, has started shipment of its $5,000 desktop systems.

Available for U.S. pre-oders from May 2018, the company reported in June that production was “on schedule.” Now, iro3d has reportedly completed 4 orders within the past few months, delivering to a potential reseller in Hong Kong, one Canadian company, and two independent customers in the U.S.

Selective Powder Deposition

The iro3d metal 3D printer is a compact desktop system that uses a process termed Selective Powder Deposition (SPD).

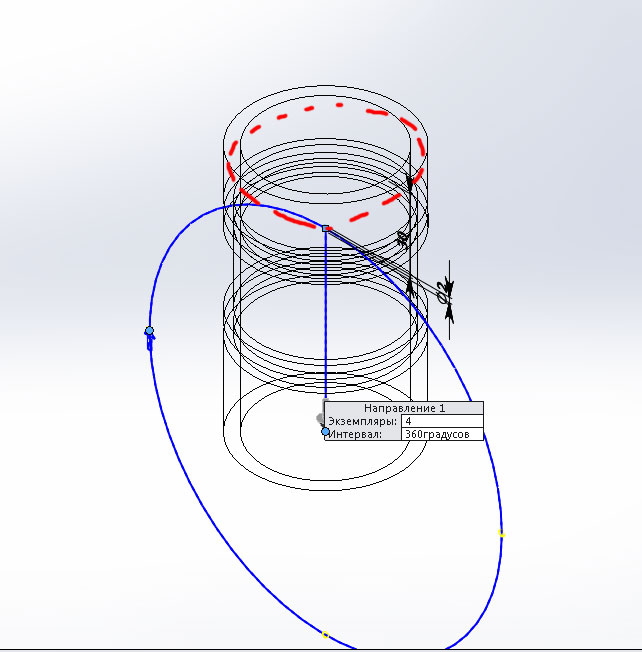

In SPD, metal powders are deposited alongside various layers of sand support through a tubular “pourer” head. Completed inside a crucible, the 3D printing process is relatively slow. As an estimate, iro3d recommends that users allow about 24 hours for completion dependent on part complexity.

In the last step of 3D printing, the crucible gets filled to the top with sand, and a tether that appears in the center as a small square of metal powder.

A finished crucible filled with sand and metal powder exposed in a small square on the top. Image via iro3dAt this point, the sand/powder crucible is transferred to a kiln. Before heating, “pancakes” of filler metal are placed directly over the metal powder window on top of the sand. A lid is added, followed by coke, and more sand to compact all the contents below.

Metal via capillary action

In the kiln, the crucible is baked at different temperatures dependent on the melting point of the filler metal, and the 3D printed metal powder. On iro3d’s recommendation: “For high-carbon steel the temperature is 1250°C, hold time is 3 hours. For copper-iron and copper-nickel the temperature is 1184°C, hold time is 2 hours.”

On iro3d’s recommendation: “For high-carbon steel the temperature is 1250°C, hold time is 3 hours. For copper-iron and copper-nickel the temperature is 1184°C, hold time is 2 hours.”

Here, we see how the SPD process is related to the metal brazing process, commonly used in joining to combine two or more different metals.

Inside the kiln, the filler metal melts and is soaked up by the metal powder due to capillary action. Capillary action occurs in molten metal when the adhesive force is stronger than the cohesive force – creating an attraction between the liquid metal particles and the related powdered metal. As such, the liquid metal fills all the gaps between the powdered particles and, presumably, brings those particles up to the same temperature to form a kind of eutectic alloy.

Capillary action does not occur between the molten metal and sand due to the absence of attraction between metal particles and the dissimilar sand grains.

After melting, the crucible is left to cool. Solidifying the 3D printed metal shape at its core. Post processing is completed by brushing away excess sand, sand blasting or machining. The metal “tether,” that acts as a channel between filler metal “pancakes” and the deposited powder, can be removed with a chisel and machined to finish.

Solidifying the 3D printed metal shape at its core. Post processing is completed by brushing away excess sand, sand blasting or machining. The metal “tether,” that acts as a channel between filler metal “pancakes” and the deposited powder, can be removed with a chisel and machined to finish.

iro3d printer technical specifications

At present, high-carbon steel, copper-iron and copper-nickel are the only material compositions thoroughly tested by for iro3d printing, though the company says “Mild steel, copper-silver, copper-gold, silver-gold, gold-nickel, and silver-nickel should be possible too.” Other metals, like titanium or aluminum, would require a controlled inert atmosphere.

Unlike other metal 3D printing process that use a kiln, (Desktop Metal, Markforged, and metal filaments like Filamet) there is no shrinkage in the SPD process. However, a 2% shape distortion occurs when parts are baked in a stainless steel crucible, rather than a ceramic crucible.

The volume of the iro3d printer is approximately 300 x 300 x 100 mm. It has a horizontal resolution of 0.05 mm, and 3D prints with a layer thickness of 0.3 mm. The “pourer” diameter, used for sand and metal powder deposition is 1mm. As a starting price, iron and support powders for the system are around $5 per pound. The starting price of the 3D printer is $5,000, plus shipping.

For the latest additive manufacturing developments subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows the iro3d printer. Photo via iro3d

Tags iro3D Selective Powder Deposition SPD

Beau Jackson

90,000 table 4MMU Metallic 3D printing, with high-carbon greetings from 3DPN-NerdPersonal diaries

Subscribe to

Subscribe

I do not want

7

Toropoli: 9000 Pre-assessment of the cost of the serial ~~5000 US$.

Metal 3d printing - can be prohibitively expensive

but Iro3d is trying to change that -

with their latest desktop 3D printer.

Metal powders are placed - in layers - in a crucible,

are then fired in a furnace,

creating an all-metal Product!

Unfortunately, there are no captions, so - only by ear and 'from the picture'.

[01:57] - List of selective extruder containers for a pre-prepared rectangular crucible.

Hopper components that do not require translation and without reference to plasticizers, which are probably already added in advance, and with the apparent absence of heaters:

3. METAL RAF (=rough? , coarse grinding)

2. METAL FINE

1. SAND RAF

0. SAND FINE

machines, and some coffee machines.

One auger = one container, drive - crankshaft from steering machine,

converted to endless rotation.

Usually set to 100% Infill / Filling,

however, two fractions from each material are used.

Read more about the pre-production version of this desktop printer:

http://iro3d.com https://www.facebook.com/iro3d https://twitter.com/iro3d_com It's time to remember where in our household with you - the induction stove has fallen... ;)

And - by the way, it seems that our compatriots are also in 3D Washington ... heard? 8)

Regards,

Ski.

P.S.

3D Printing Metal with the Iro3D Desktop Metal 3D Printer - Solid High Carbon Steel Parts!

Author: 3D Printing Nerd , Published: 13 Jan. 2018

Video:

https://youtu.be/4FkzLs7cLes

[]

Follow author

Follow

Don't want

7

More interesting articles

onvoid

Loading

21. 10.2022

10.2022

563

2

Follow author

Subscribe

Don't want

Many letters ! ! !

I wrote the instruction at work during my vacation, so that other m...

Read more

one

Subscribe to the author

Subscribe

Don't want

so, as usual on Saturday evening, out of vulgar sobriety, I wanted a strange

a...

Read more

103

Subscribe to the author

Subscribe

Don't want

So I had the opportunity to try to implement everything based on MMU2 (1h, 2h, 3h, 4h, 5h,). I have. ..

..

Read more

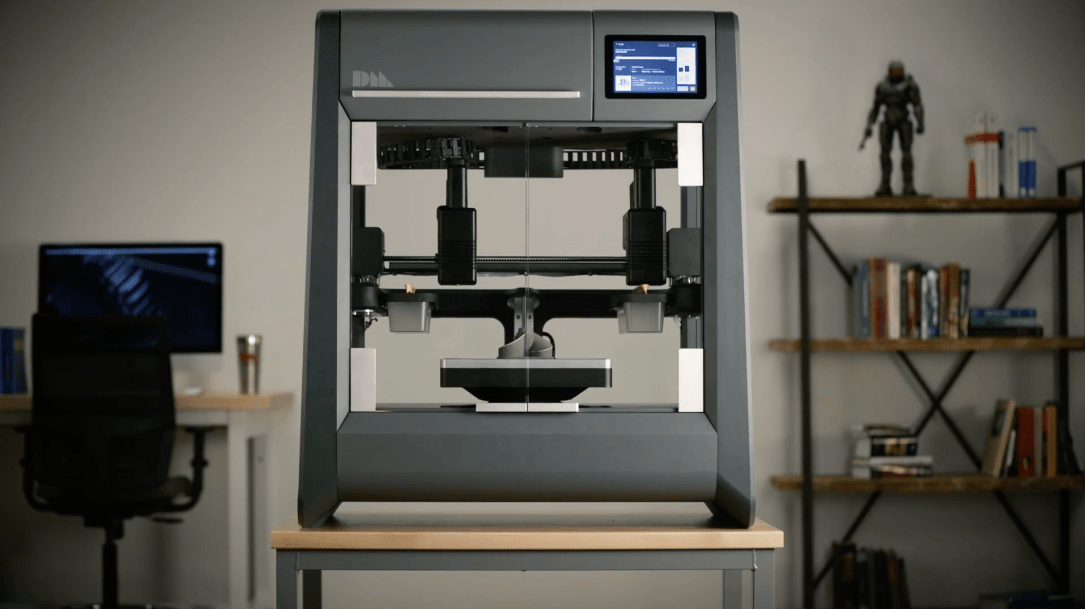

Burn metal: how a desktop 3D printer will print alloys In autumn, it begins the first deliveries of metal 3D printing systems. Devices must fit on an office desk

Photo: Desktop Metal

Desktop Metal was founded in 2015 by four MIT professors. Among them is Emanuel Sachs, who in 1989 was the first to patent the 3D printer device. The 3D printing industry is looking forward to another very important innovation from Sachs and his colleagues: already this fall, Desktop Metal is launching Studio metal 3D printing systems, and in 2018 - Production.

The first system is designed for industrial designers and engineers, the second one for production workers. Both devices claim to be "disruptive" technology, meaning they could change the economic structure of an entire industry. For the first time in the history of 3D printing, printers that print metal objects will fit on an office desk. The Studio ($120,000) and Production ($420,000, corporate clients will be able to pay $3,200 per month in installments) include the 3D printer itself and a miniature microwave-powered melting furnace (heated up to 1,400 degrees), for heat treatment of metal. The systems use additive technologies, i.e. can “grow” an object in layers from the material loaded into the printer, and are capable of processing about 200 alloys, including steel, aluminum and titanium. The more powerful Production is capable of printing 8.2 thousand cubic meters per hour. see metal products. This figure is at least 100 times higher than existing solutions on the market, say the founders of Desktop Metal.

The systems use additive technologies, i.e. can “grow” an object in layers from the material loaded into the printer, and are capable of processing about 200 alloys, including steel, aluminum and titanium. The more powerful Production is capable of printing 8.2 thousand cubic meters per hour. see metal products. This figure is at least 100 times higher than existing solutions on the market, say the founders of Desktop Metal.

The Markforged Metal X printer is similar in technology to the Desktop Metal device: objects are printed from a metal-plastic mixture, but the plastic is removed from the composition during the heat treatment (Photo: Markforged)

Studio's work is based on the process described in a 26-year-old Sacks patent: a thin layer of a mixture of metal powder and a binder of molten polymer material is applied to the surface. A thread from this mixture is used to print products. During firing, the polymer disappears, leaving an all-metal product at the output. Innovative printing methods invented in recent years helped bring the technology to market viability, the inventor explained. In Production, the printing process looks different. First, a layer of metal powder as thick as a human hair is applied to the object construction area with an area of up to 300x200x200 mm, then the printer “sprays” the binder polymer, after which the surface becomes very hot under the influence of high temperature. This process is repeated up to 1500 times, after which the system places the billet into the furnace.

During firing, the polymer disappears, leaving an all-metal product at the output. Innovative printing methods invented in recent years helped bring the technology to market viability, the inventor explained. In Production, the printing process looks different. First, a layer of metal powder as thick as a human hair is applied to the object construction area with an area of up to 300x200x200 mm, then the printer “sprays” the binder polymer, after which the surface becomes very hot under the influence of high temperature. This process is repeated up to 1500 times, after which the system places the billet into the furnace.

own business

The real future: how 3D printers are changing medicine

Massachusetts company raised about $100 million in venture capital investments. Industrial giants have also invested in the technology: General Electric (GE), BMW, the main IT holding of the planet Alphabet and the leading player in the 3D printer market Stratasys. Eminent investors are another evidence of the high hopes placed on Desktop Metal. 3D printing still doesn't live up to the expectations of big players: the materials that printers work with on an industrial scale are short-lived and unreliable, CEO Rick Fulop said in a June interview with MIT Technology Review magazine. Rare exceptions, such as the successful introduction of 3D printing for the production of dental implants, only confirm the general failure of the technology, he stressed.

Industrial giants have also invested in the technology: General Electric (GE), BMW, the main IT holding of the planet Alphabet and the leading player in the 3D printer market Stratasys. Eminent investors are another evidence of the high hopes placed on Desktop Metal. 3D printing still doesn't live up to the expectations of big players: the materials that printers work with on an industrial scale are short-lived and unreliable, CEO Rick Fulop said in a June interview with MIT Technology Review magazine. Rare exceptions, such as the successful introduction of 3D printing for the production of dental implants, only confirm the general failure of the technology, he stressed.

Delivery of systems from Desktop Metal to first customers should begin in a few months. However, there is not a single full-fledged commercial copy of the device yet. (Photo: Desktop Metal)

The reduction in cost and simplification of the process of "metal" printing can change the market. Industrialists are actively experimenting in this direction, but the market has not yet seen devices similar in characteristics to Studio and Production. The same GE concern in June at the Le Bourget air show presented a prototype of the world's largest Atlas laser 3D printer for printing jet engine parts and other components. According to GE, the device will save an average of $2-3 million on the production of one aircraft. But when Atlas can be introduced into the production chain, it is still unknown: billions of investments will be needed in changing logistics, re-equipping factories and retraining personnel.

Industrialists are actively experimenting in this direction, but the market has not yet seen devices similar in characteristics to Studio and Production. The same GE concern in June at the Le Bourget air show presented a prototype of the world's largest Atlas laser 3D printer for printing jet engine parts and other components. According to GE, the device will save an average of $2-3 million on the production of one aircraft. But when Atlas can be introduced into the production chain, it is still unknown: billions of investments will be needed in changing logistics, re-equipping factories and retraining personnel.

The MIT company also has non-industrial competitors - other 3D printer manufacturers are also preparing "revolutionary" devices that work with metal. This autumn, the Metal X printer, worth about $100,000, will be presented by Markforged. It is based on the additive atomic diffusion technology developed by the company. Whether Metal X will become a competitor for Studio and Production will become known after the disclosure of production details.

own business

Who and how makes money on 3D printing in Russia

With the help of Studio and Production, it will be possible to quickly create industrial design objects, print prototypes, and then use the modified version file to produce a commercial product. Theoretically, devices claim a share not even in the 3D printing market, but in the manufacturing industry. “Metal manufacturing is a trillion-dollar industry,” Fulop says. “Conquering even a small sector of it means making billions.”

Photo: GE

The mass adoption of Desktop Metal's technology will allow large manufacturers to become more flexible in their logistics and production strategies and make product adjustments faster. “Production will be distributed - instead of large factories, from where goods are delivered all over the world, there will be a network of local sites that quickly respond to demand with the help of 3D printing. It is still difficult to talk more specifically about the application of technology. More than a decade will have to pass before we ourselves answer the question of whether we really need such an invention, ”said another co-founder of Desktop Metal, John Hart. The company's first client is expected to be California-based industrial design studio Fathom.

It is still difficult to talk more specifically about the application of technology. More than a decade will have to pass before we ourselves answer the question of whether we really need such an invention, ”said another co-founder of Desktop Metal, John Hart. The company's first client is expected to be California-based industrial design studio Fathom.

“The main challenge for the 3D printing industry today is scaling, increasing efficiency. Industrial companies must certify and standardize all manufacturing processes related to 3D printing. It will take at least a few more years, ”Gil Perez, senior vice president of SAP, confirmed in an interview with RBC magazine. In the company, he oversees a program of cooperation with companies that introduce 3D printing into production chains. According to Perez, the engine of change for technology will be the aerospace industry. For example, Boeing in April, in alliance with the Norwegian Norsk Titanium, printed titanium alloy elements for the B787 Dreamliner on a 3D printer.