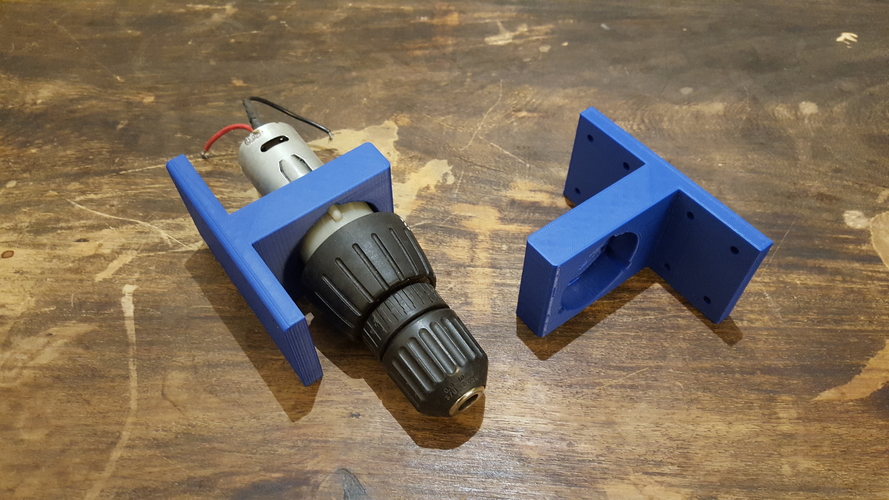

3D printed locking mechanism

STL file Educational key lock mechanism・3D printer design to download・Cults

Leprechaun's Hat Birdhouse

€3.21

Articulated Robot Scorpion

€3.60

CUTE CARAVAN BIRDHOUSE

€2.34

3D NEON LETTERS - 26 LETTERS FULL PACKAGE

€1.86

Articulated Long-Tailed Lizard - 114 cm (44in) Super long print-in-place

€3.11

Print in place Foldable mini House with wiggling Fir!

€1.85

Articulated dragon robot with moving jaws!

€3.37

TOONED BIRDHOUSE V1.0

€3.69

Best 3D printer files of the Gadget category

Print-in-Place Race Car

Free

Pocket shotgun / Christmas cracker. Print-in-place (no assembly), no support

€2. 45

shower for parrot

€3.88 -40% €2.33

Retrocade - Desktop Arcade Machine + RetroPie

Free

Elderberry Wand

€4.76

Gyrotourbillon - Jaeger-LeCoutre model

Free

HIPPO PENCIL UTENSIL

Free

Transformers Cyberverse Swoop Figure

€9.86

Best sellers of the category Gadget

DJI Avata Bumper

€3

Fidget Pumpkin Keychain - Halloween

€1.89

WALL KEY HOLDER - EYE (ENTIRE COLLECTION)

€1.88

Bone Finger Updated

€6.83

DJI AVATA GoPro Mount

€2.50

Tactical Repeating Bow (TRB)

€10

Fidget Cauldron Keychain - Halloween

€1. 89

89

Owl - Wall Key Holder

€1.84

App to create keychains

€3.67

Working steam engine, print-in-place, fully assembled, no supports

€3.34

PIXEL 7 PRO case (two designs)

€0.96

Gato fantasma / spooky cat

€3.32

Mini Adder || Alligator 2 || Repeating crossbow v3

€6.25

Giromate

€3.04

JEEP WRANGLER PEN HOLDER - 3-IN-1

€1.83

wall key holder (dragon ball)

€1.25

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ lock mechanism 3d models 【 STLFinder 】

Lock mechanism

grabcad

Lock mechanism

Lock Mechanism

grabcad

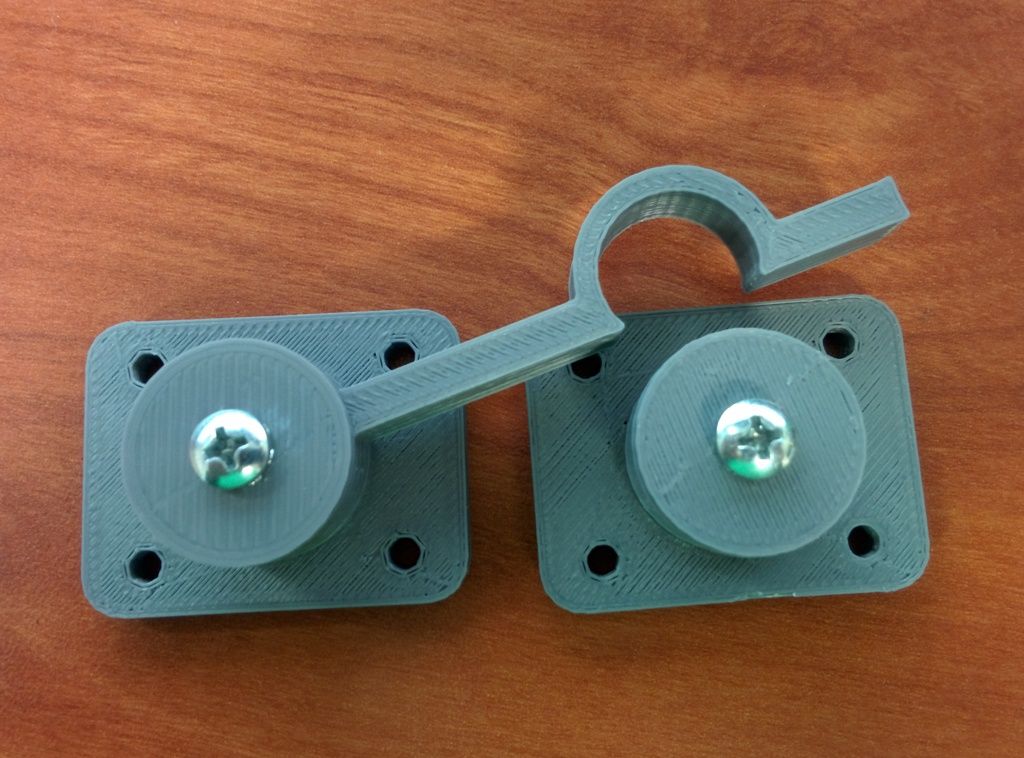

This is simple lock mechanism

Lock mechanism

grabcad

Lock mechanism - Push in keyed Lock cylinder to unlock . Works with 1mm cable

Works with 1mm cable

Snap Lock square mechanism for 3D prints

grabcad

Snap Lock square mechanism for 3D prints

Lock screw mechanism-long 3D model

cgtrader

Lock screw mechanism, the institution and ordinary simple electric motor lock screw mechanism is different, the agency for super, super long screw mechanism, through the bearing,universal coupling, universal shaft coupling and a series of...

3D print models for Compliant Mechanism

thingiverse

Robert Lang (https://langorigami. com) This thing has a half thickness of a standard Lego beam and the pocket span feature is built on one side only for the use of FDM type 3D printer. I have uploaded the files for 3D printing. If you would like to...

com) This thing has a half thickness of a standard Lego beam and the pocket span feature is built on one side only for the use of FDM type 3D printer. I have uploaded the files for 3D printing. If you would like to...

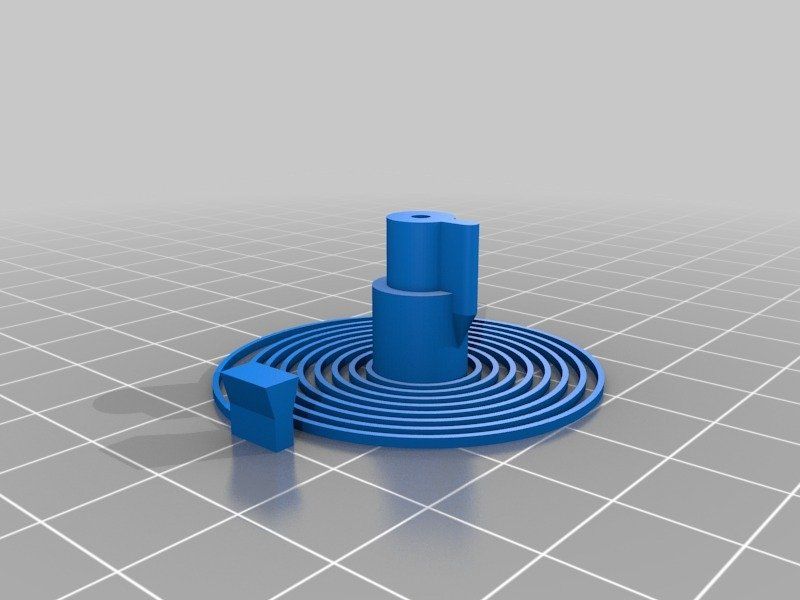

manual clutch mechanism for simple rotation lock Free 3D model

cgtrader

manual clutch mechanism for simple rotation lock

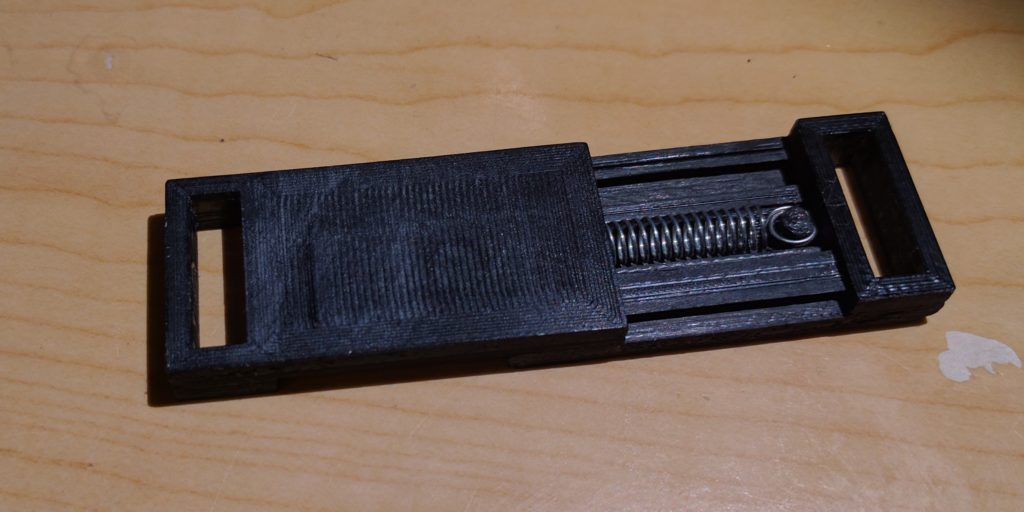

Sliding Lock Mechanism

grabcad

Used in door locks

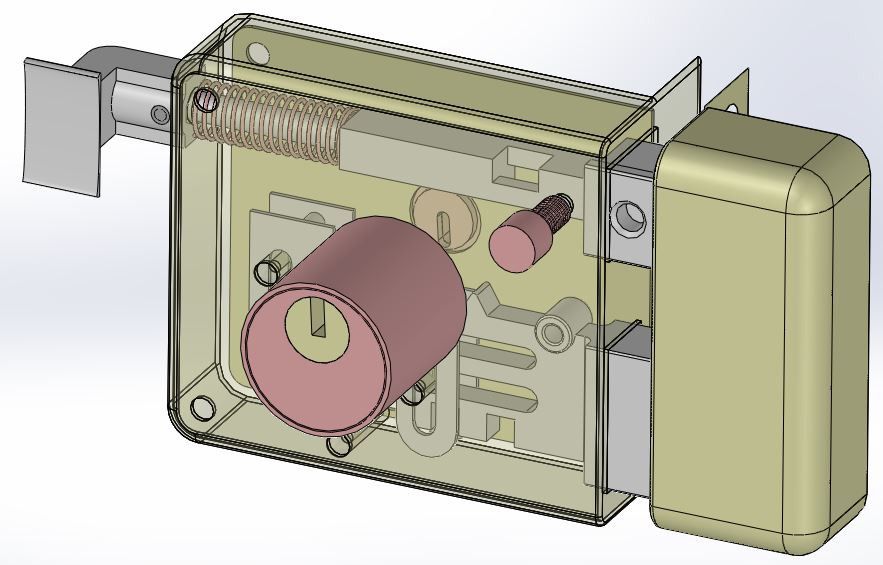

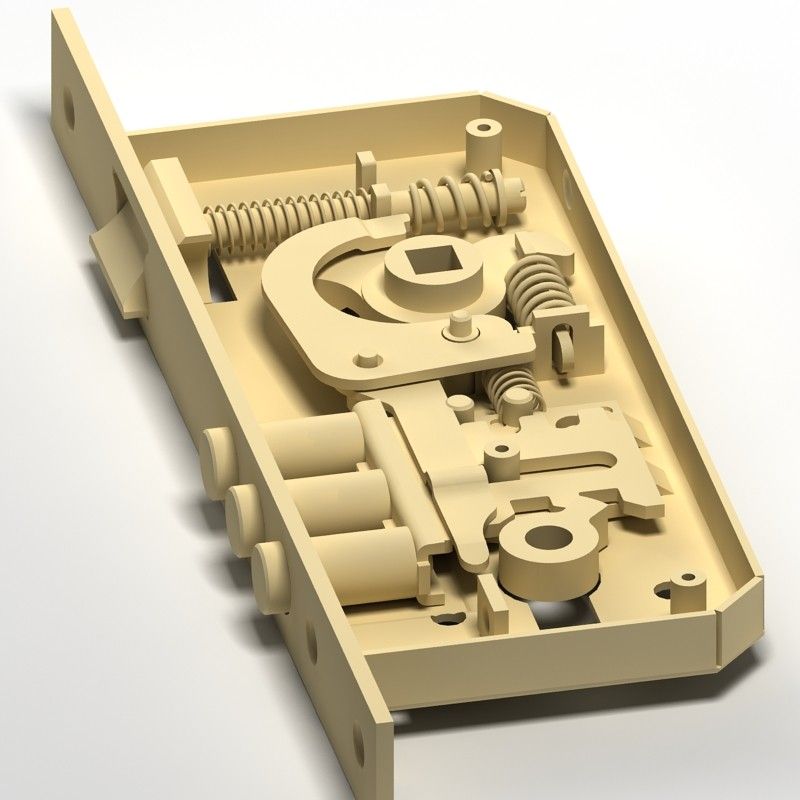

Cylinder Lock Mechanism

grabcad

practice cylinder locking mechanism.

DOOK LOCK MECHANISM

grabcad

Door Lock Mechanism

Electronic lock mechanism.

grabcad

Peugeot 307 trunk door electronic lock mechanism.

Door Lock Mechanism

grabcad

Door Lock Mechanism.Mortise Lock SetReverse Engineering.Catia Modeling.Keyshot Rendering.

Sliding lock mechanism Project

thingiverse

This is an undergoing project of a sliding lock mechanism automatism based on Arduino. Definitive parts are not beign loaded yet, so please don't print unless you want to waste your filament.

Objective is to build create a basic kinetic crank,rod,...

Definitive parts are not beign loaded yet, so please don't print unless you want to waste your filament.

Objective is to build create a basic kinetic crank,rod,...

simple automatic lock mechanism

grabcad

It is a very simple locking mechanism which works like a see-saw

Simple Lock Mechanism

grabcad

A common lock mechanism used in households, for less space applications like cupboards and drawers.

Recycling Bin Lock Mechanism

thingiverse

NEW DESIGN COMPLETE (recycling_bin_lock_v2_v3. stl) THE ORIGINAL DESIGN (recycling_bin_lockthumb_v6.stl) FAILED AFTER 4 WEEKS OF REAL WORLD USE The locking mechanism on my recycling bin broke, so I designed this replacement.

It will print without...

stl) THE ORIGINAL DESIGN (recycling_bin_lockthumb_v6.stl) FAILED AFTER 4 WEEKS OF REAL WORLD USE The locking mechanism on my recycling bin broke, so I designed this replacement.

It will print without...

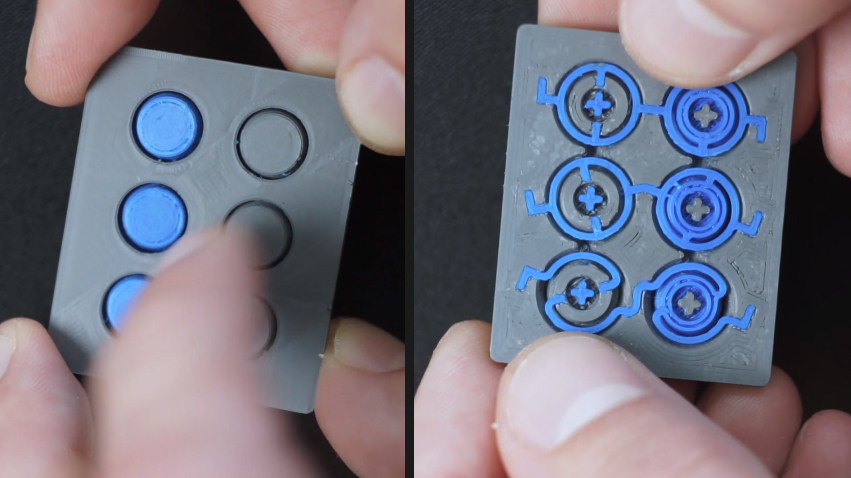

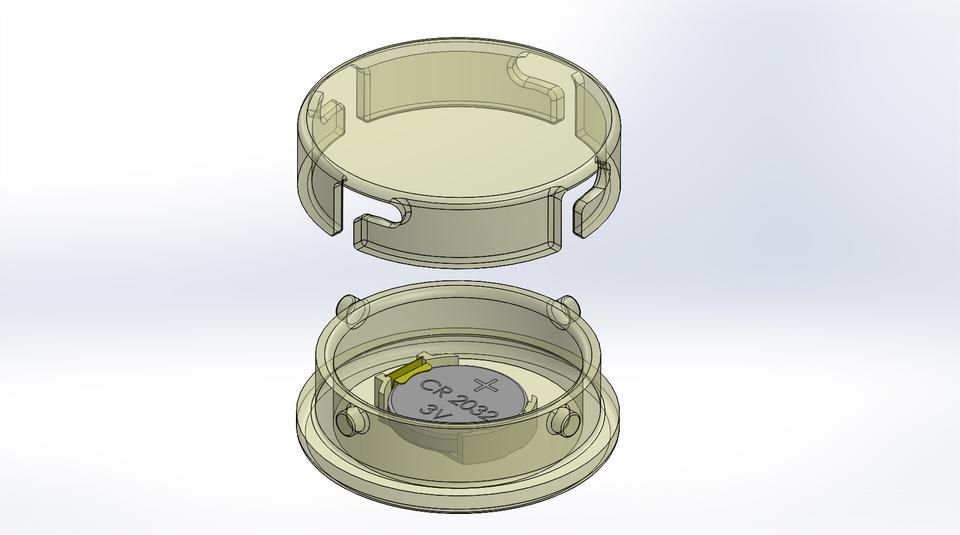

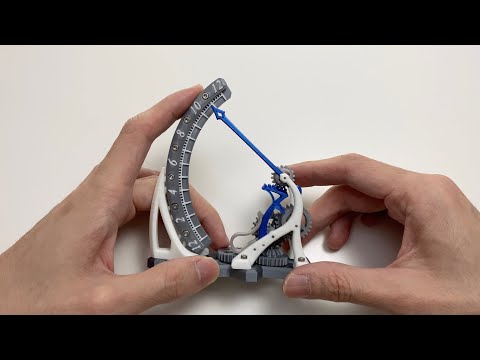

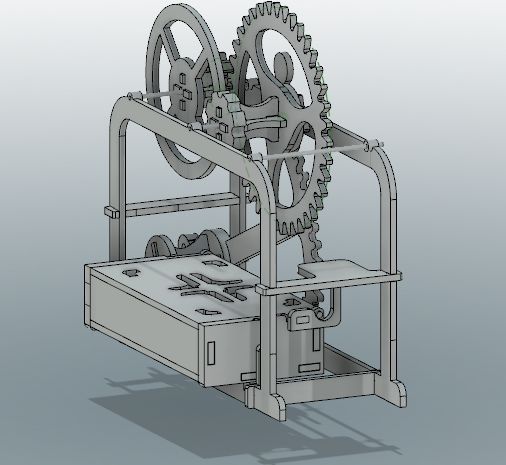

Educational key lock mechanism

cults3d

Educational kit that allows you to see clearly how works a key lock mechanism, without the need for plexiglass or any other transparent plastic. Everything is captive, and the mechanism works like a real one. The key remains captive when the lock is...

inverted pen lock mechanism

thingiverse

I wanted to understand the locking mechanism of a retractable pen for quite a while and what's better than modelling and printing one. The lock consists of 3 parts: two concentric cams and a follower. In an ordinary retractable pen one cam is hidden...

The lock consists of 3 parts: two concentric cams and a follower. In an ordinary retractable pen one cam is hidden...

Parametric snap lock mechanism

thingiverse

Snap lock mechanism that can be scaled and changed in a wide range of sizes. Works very reliably, and gives very positive locking. It works best when the arms has a reasonable length compared to their width. The version shown has a 32 mm c/c distance...

PEN LOCK MECHANISM

grabcad

This is a well engineered and calculated pen lock mechanism teeth developed during concept stage of home appliances. This have not been selected as final design for the project so it never been in production parts. ...Suitable for designers, engineers...

...Suitable for designers, engineers...

Open mechanism lock

thingiverse

https://youtu.be/r4T8rQFszQQ This is an open mechanism lock with its corresponding key, so you can see its moving parts and how does it work. It consists of four parts + the key. ... I designed it so all its tolerances are 0.3mm.

Mini Pump - Lock mechanism

prusaprinters

Simple lock to avoid a pump to spill everywhere. It clips on the main column (size here is 7mm)</p><p> </p><p>I would prefer a material that doesn't snap easily. PLA is not recommended. ...PETG, ABS, ASA, maybe TPU can be. ..

..

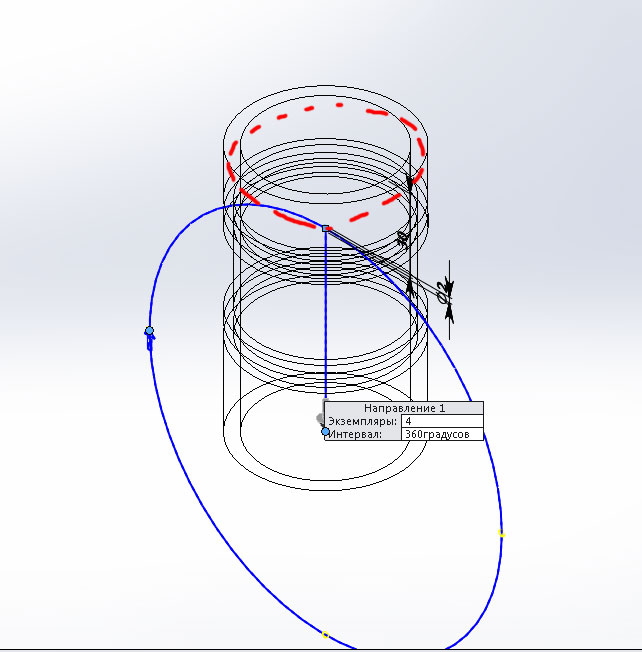

Twist Lock Mechanism

thingiverse

I decided to make use of a twist lock connection mechanism and split printing the shapes that had drastic changes in the cross-sections so as to allow their printing separately. This is the first cut of a parameterized freeCAD design that allows...

shutter lock mechanism

thingiverse

I ve been attempting here to duplicate an existing mechanism to lock my shutters. The skp sketchup file is a summary of the simple mechanism. To ckeck before printing : the thickness of the curtains on which it's to be installed. Parts to...

American Tourister lock mechanism

thingiverse

The locking mechanism on the handle of my American Toursiter Bon Air 55cm suitcase broke (the last level wouldn't retract). I contacted the company for a repair part but they never got back to me. So I decided to create a replacement part. The part...

I contacted the company for a repair part but they never got back to me. So I decided to create a replacement part. The part...

Twist Lock Mechanism in Solidworks

grabcad

Twist Lock Mechanism in Solidworks

Liquid One Way lock Mechanism

grabcad

Liquid One Way lock Mechanism.. ...enjoy

Matsui (MF654EWN) Dishwasher Lock Mechanism

thingiverse

A lock mechanism part for the Matsui MF654EWN dishwasher. It's better than the original part that breaks easily. Wrote a blog post about why and how I made this part http://hacklab.akan.fi/archives/868 OMG! ...got featured on...

It's better than the original part that breaks easily. Wrote a blog post about why and how I made this part http://hacklab.akan.fi/archives/868 OMG! ...got featured on...

Vacuum cleaner pipe lock mechanism

thingiverse

Vacuum cleaner pipe lock mechanism Including Fusion 360 CAD file

$1.30EDUCATIONAL KEY LOCK MECHANISM

myminifactory

Educational kit that allows you to see clearly how works a key lock mechanism, without the need for plexiglass or any other transparent plastic. Everything is captive, and the mechanism works like a real one. The key remains captive when the lock is. ..

..

⚙️ Best Mechanical STL Files for 3D Printing・Cults

⚙️ Best Mechanical STL Files for 3D Printing

Download 3D Mechanical Creations

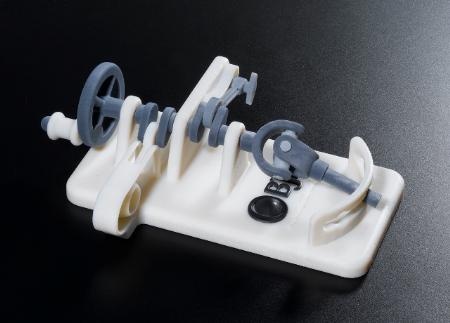

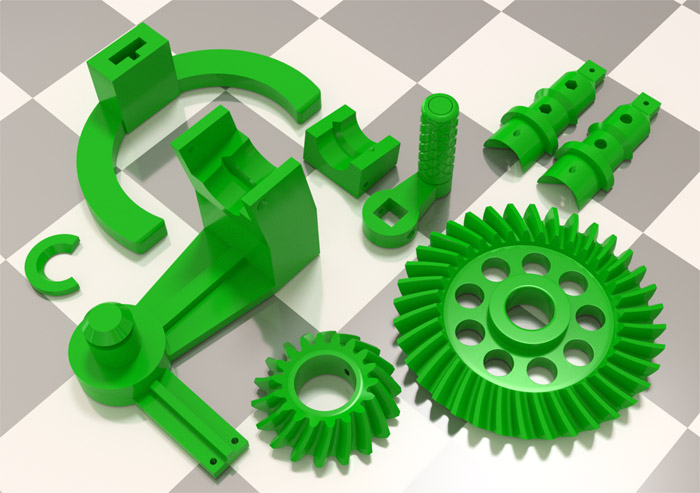

prints, but real projects. Each design consists of several mechanical parts that fit together to form a functional whole. These gears will let you bring toys, machines or even watches to life!

SPRING BOX FOR FIELD PRINTING

Free

Mechanical quick release phone stand

Free

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?!

Free

TT Furious

Free

Print-in-Site - Distance Measuring Roll Tool

Free

Predator Action Pliers

Free

Multicolored toy "Flying helicopter"

Free

Flying sea turtle

Free

Flying helicopter toy

Free

Triple Gear

Free

Cool Squeeze - fan grip

Free

Fidget Gears Revolving V2 (printed in place!)

Free

Smartphone Stabilizer

Free

Watch one

Free

Predator Action Pliers Mk2

Free

Differential Gears

Free

Mechanical Planetarium

Free

Triple Axis Tourbillon

Free

Platform Jack with some modifications

Free

planetary gear

Free

Save the Whales (Kinetic Whales)

Free

Keychain with fidget toy

0,59 €

Gyro Motor Factory / Clock Factory

€2. 50

50

Gyro Tourbillon - Jaeger-LeCoutre Model

Free

Turboprop Engine

Free

Gyrotourbillon

Free

Industrial Bevel Gearbox / Gear Reducer (Cutaway version)

Free

Elevated Print in Place Phone Holder!

Free

Bevel Gear Toy Set 17/51T or 3:1 Ratio

Free

Eolienne Wind Turbine

5 €

775 motor gear

Free

Planetary Gear Module Part 1

Free

Christian Huygens 3D printed clock

Free

Mechanical Gripper May 2019

Free

Industrial Spur Gearbox / Gear Reducer (Cutaway version)

Free

Jet Engine

Free

The Humble Velocipede

Free

Deadbolt Combination Lock

Free

SAKURA Gear ring

Free

Hummingbird

Free

Shredder V8 Gears

Free

Jet Engine, 2-Spool, Current

Free

Gear Keychain

Free

Crazy Cogs - Gear Play Set

Free

A Motorized Shark

Free

Jet Engine, Geared Turbofan (GTF)

Free

7 segments

€7. 84

84

Customizable Simple Pulley/Gear

Free

SPRING BOX FOR FIELD PRINTING

Mechanical quick release phone stand

7 Cylinder Radial Engine Model

Print-in-Place - Distance Measuring Roll Tool

Here is our selection of best mechanical STL files , all these beautiful creations are taken from Cults 3D file library and easily 3D printable . All you need to do is print out the various STL parts of these designs, assemble them and enjoy the super satisfying result of a perfectly working machine!

For a long time 3D printing was limited to very simple objects, but 3D designers are increasingly offering complex creations - which, of course, require some work after printing - but which allow very successful projects to be realized. Most often, these mechanisms are presented in the form of simple gears, but in some cases the addition of several gears and especially their special shape allow you to create real small dioramas.

Most often, these mechanisms are presented in the form of simple gears, but in some cases the addition of several gears and especially their special shape allow you to create real small dioramas.

3D printing is certainly 's incredible technical achievement, but gear projects add an extra layer: assembly. In this way, you will really have a hand in the project and experience a real sense of satisfaction when the assembly is completed. Then just turn on the engine and enjoy rendering!

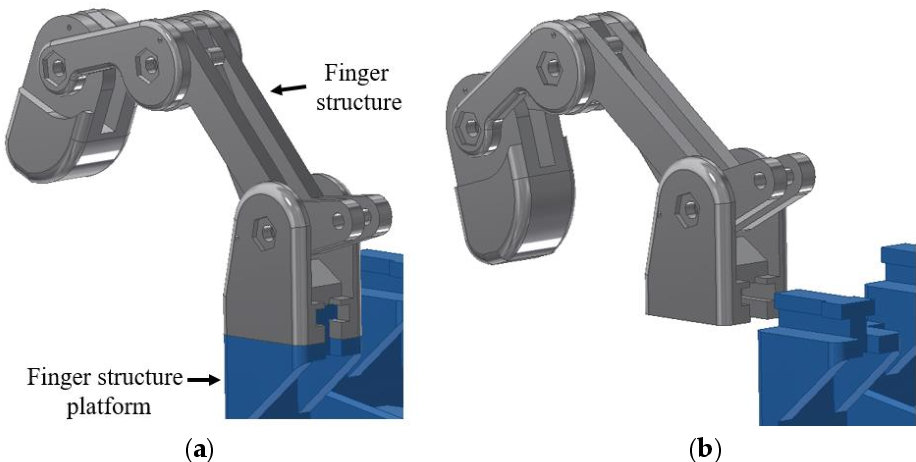

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale industries. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Warhammer 40k Chaplain 3D Model

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Weapon Seal

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0296

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production.