Hp 3d printer stock

Top 3D Printing Stocks

Table of Contents

Table of Contents

-

Best Value 3D Printing Stocks

-

Fastest Growing 3D Printing Stocks

-

3D Printing Stocks With the Best Performance

-

Trends in 3D Printing Sector

-

Advantages of 3D Printing Stocks

SSYS is top for value and performance and NNDM is top for growth

By

Noah Bolton

Full Bio

Noah has about a year of freelance writing experience. He's worked on his investing website dealing with topics such as the stock market and financial advice for beginners.

Learn about our editorial policies

Updated October 06, 2022

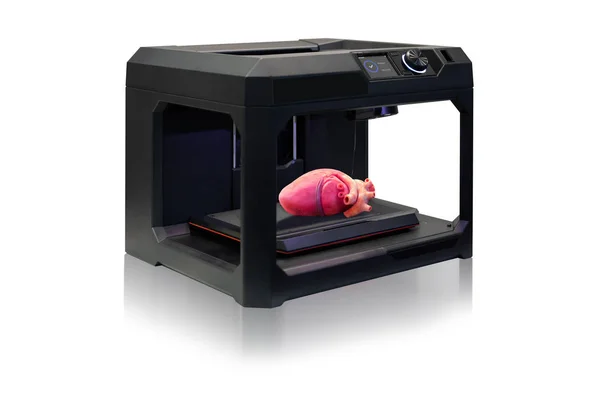

The 3D printing industry is made up of companies that provide products and services capable of manufacturing a range of products. 3D printing, also known as additive manufacturing, creates physical objects from digital designs. The printing process works by laying down thin layers of material in the form of liquid or powdered plastic, metal, or cement, and then fusing the layers together. Though still too slow for mass production, it is a revolutionary technology that has the potential to disrupt the manufacturing logistics and inventory management industries. The 3D printing industry is comprised of only a handful of companies, including players such as Proto Labs Inc., Faro Technologies Inc., and Desktop Metal Inc.

The industry is so young that it has no meaningful benchmark index. But the performance of these stocks can be compared to the broader market as represented by the Russell 1000 Index. These stocks have not performed well. Stratasys Ltd. (SSYS), the best performing 3D printing stock, has dramatically underperformed the Russell 1000, which has provided a total return of -12.5% over the past 12 months. This market performance number and all statistics in the tables below are as of Sept. 20, 2022.

Here are the top three 3D printing stocks with the best value, fastest sales growth, and the best performance.

These are the 3D printing stocks with the lowest 12-month trailing price-to-sales (P/S) ratio. For companies in early stages of development or industries suffering from major shocks, this metric can be substituted as a rough measure of a business's value. A business with higher sales could eventually produce more profit when it achieves (or returns to) profitability. The price-to-sales ratio shows how much you're paying for the stock for each dollar of sales generated.

| Best Value 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing P/S Ratio | |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | 1.6 |

| 3D Systems Corp. (DDD) | 9. 00 00 | 1.2 | 2.0 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | 2.1 |

Source: YCharts

- Stratasys Ltd.: Stratasys offers 3D printing solutions, such as 3D printers, polymer materials, a software ecosystem, and related parts. It serves a variety of industries, including aerospace, automotive, consumer products, and healthcare. On Sept. 13, Stratasys completed the merger of its MakerBot subsidiary with Ultimaker, which offers platforms used to make 3-D printers. Ultimaker is backed by NPM Capital. The merged company will keep the Ultimaker name and focus on providing solutions, hardware, software and materials to the industry. NPM Capital will have majority ownership of the new company at 53.5%, and Stratasys will own 46.5%.

- 3D Systems Corp.: 3D Systems provides 3D printing solutions. The company offers a range of hardware, software, and materials designed for additive manufacturing.

Its products and services are used in a variety of industries and sectors, including aerospace, automotive, semiconductor, healthcare, and more.

Its products and services are used in a variety of industries and sectors, including aerospace, automotive, semiconductor, healthcare, and more. - Proto Labs Inc.: Proto Labs is an e-commerce-based company that provides digital manufacturing services. It offers 3D printing, injection molding, CNC machining, and sheet metal fabrication. On Aug. 5, Proto Labs announced financial results for Q2 2022, the three-month period ending on June 30, 2022. Net income fell more than 80% to $2.6 million from the prior-year quarter while revenue rose 3.1%.

These are the 3D printing stocks with the highest YOY sales growth for the most recent quarter. Rising sales can help investors identify companies that are able to grow revenue organically or through other means and find growing companies that have not yet reached profitability. In addition, accounting factors that may not reflect the overall strength of the business can significantly influence earnings per share. However, sales growth can also be potentially misleading about the strength of a business, because growing sales on money-losing businesses can be harmful if the company has no plan to reach profitability.

However, sales growth can also be potentially misleading about the strength of a business, because growing sales on money-losing businesses can be harmful if the company has no plan to reach profitability.

| Fastest Growing 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | Revenue Growth (%) | |

| Nano Dimension Ltd. (NNDM) | 2.45 | 0.6 | 1,270 |

| Desktop Metal Inc. (DM) | 3.07 | 1.0 | 203.9 |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | 13.3 |

Source: YCharts

- Nano Dimension Ltd.: Nano Dimension is an Israel-based 3D printing company focused on developing equipment and software for 3D-printed electronics. It develops printers for multilayer printed circuit boards and nanotechnology-based inks.

The company serves a range of industries, including consumer electronics, healthcare, aerospace, and automotive. On Sept. 1, Nano Dimension released Q2 2022 results. The company's net loss widened sharply to $40.0 million from a loss of $13.6 million in the same quarter a year earlier even as revenue soared more than 13-fold. The larger second-quarter loss was fueled partly by $10.9 million in non-cash adjustments for depreciation and amortization expenses, and share-based payments.

The company serves a range of industries, including consumer electronics, healthcare, aerospace, and automotive. On Sept. 1, Nano Dimension released Q2 2022 results. The company's net loss widened sharply to $40.0 million from a loss of $13.6 million in the same quarter a year earlier even as revenue soared more than 13-fold. The larger second-quarter loss was fueled partly by $10.9 million in non-cash adjustments for depreciation and amortization expenses, and share-based payments. - Desktop Metal Inc.: Desktop Metal manufactures 3D printers and related equipment used to build complex parts from metal. It also offers 3D printing software. The company serves a range of industries, including automotive, consumer products, education, and heavy industry. On Aug. 08, the company reported Q2 2022 results. Desktop Metals' net loss increase nearly seven-fold to $297.3 million compared to the same quarter a year earlier even as revenue tripled.

- Stratasys Ltd.

: See above for company description.

: See above for company description.

These are the 3D printing stocks that had the smallest declines in total return over the past 12 months out of the companies we looked at.

| 3D Printing Stocks With the Best Performance | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing Total Return (%) | |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | -34.5 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | -50.6 |

| Materialise NV (MTLS) | 10.95 | 0.6 | -53.9 |

| Russell 1000 | N/A | N/A | -12.5 |

Source: YCharts

- Stratasys Ltd.: See above for company description.

- Proto Labs Inc.: See above for company description.

- Materialise NV: Materialise is a Belgium-based provider of additive manufacturing software and 3D printing services. It serves a range of industries, including healthcare, aerospace, and automotive. On Sept. 7, Materialise completed its acquisition of Identity3D, which makes products that encrypt, distribute, and track digital parts as they move through supply-chains. The value of the deal was not specified in the announcement.

Trends in 3D Printing Sector

The 3D printing industry is a young one, and companies are still jockeying for market share or facing consolidation risks. Nonetheless, 3D printing has significant potential to impact a host of other industries. 3D printing businesses may be crucial in helping other companies maximize production efficiencies in an effort to reduce environmental impact out of a concern for climate change, for example. 3D printing can be used to create personalized products in the healthcare or therapeutics spaces. This technology can also be used to facilitate a faster turnaround for the creation of new models of existing products in industries such as the automotive space.

This technology can also be used to facilitate a faster turnaround for the creation of new models of existing products in industries such as the automotive space.

Advantages of 3D Printing Stocks

3D printing technology has the benefit of being a relatively new technology which has potential applications across a range of fields. This is one reason why the 3D printing market is expected to roughly triple in size to $44.5 billion by 2026. This versatility provides a significant benefit to 3D printing stocks within an investment portfolio. Another advantage of 3D printing technology is that it may have the potential to alleviate some of the impact of supply chain constraints. Given the ongoing supply chain crisis which has impacted a host of industries, there is an opportunity for 3D printing companies to provide a critical service.

The comments, opinions, and analyses expressed herein are for informational purposes only and should not be considered individual investment advice or recommendations to invest in any security or to adopt any investment strategy. Though we believe the information provided herein is reliable, we do not warrant its accuracy or completeness. The views and strategies described in our content may not be suitable for all investors. Because market and economic conditions are subject to rapid change, all comments, opinions, and analyses contained within our content are rendered as of the date of the posting and may change without notice. The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

Though we believe the information provided herein is reliable, we do not warrant its accuracy or completeness. The views and strategies described in our content may not be suitable for all investors. Because market and economic conditions are subject to rapid change, all comments, opinions, and analyses contained within our content are rendered as of the date of the posting and may change without notice. The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "Financial Data.

"

"Stratasys Ltd. "Stratasys Completes Merger of MakerBot with Ultimaker."

Proto Labs Inc. "Proto Labs Q2 2022 Earnings Release."

Nano Dimension Ltd. "Earnings Press Release for Q2 2022."

Desktop Metals Inc. " Desktop Metals Second Quarter 2022 Earnings."

Materialise NV. "Materialise Acquires Indenity3D."

3D Natives. "What Were the 3D Printing Trends in 2021?"

Fast Company. "Four 3D printing trends to look for in 2022."

Hubs. "3D printing trend report 2022."

5 3D Printing Stocks to Consider in 2022

An in-depth look at the leading 3D printing stocks in the U.S stock market this year. Here’s what you need to know.

By Nicholas Rossolillo – Updated Jul 11, 2022 at 2:42PM

Back in the early 2010s, stocks were booming for 3D printing -- also known as additive manufacturing, a computer-controlled process in which three-dimensional objects are made. But the boom was followed by a bust as many pure-play 3D printing companies didn't immediately deliver on lofty expectations.

But the boom was followed by a bust as many pure-play 3D printing companies didn't immediately deliver on lofty expectations.

Rumors of the manufacturing technology's demise are clearly premature. These days, 3D printing is a high-growth niche that is steadily reshaping the manufacturing and industrial sectors. Some estimates point to a doubling in annual revenue from additive manufacturing between 2022 and 2026. Even growth investor Cathie Wood has launched a fund focused on manufacturing tech, The 3D Printing ETF (NYSEMKT:PRNT), via her company ARK Invest.

Here's what you need to know about 3D printing and additive manufacturing stocks for 2022:

Image source: Getty Images.

Investing in 3D printing stocks

The manufacturing of products in all corners of the economy is being revolutionized by 3D printing, from healthcare equipment to metal fabrication to housing construction. It's invading so many sectors that tech giants such as Microsoft (NASDAQ:MSFT), Autodesk (NASDAQ:ADSK), and HP (NYSE:HPQ) have launched products aimed at 3D printing and additive manufacturing. Other engineering and software outfits such as Dassault Systemes (OTC:DASTY), ANSYS (NASDAQ:ANSS), and Trimble (NASDAQ:TRMB) have also gotten involved in 3D printing technology.

It's invading so many sectors that tech giants such as Microsoft (NASDAQ:MSFT), Autodesk (NASDAQ:ADSK), and HP (NYSE:HPQ) have launched products aimed at 3D printing and additive manufacturing. Other engineering and software outfits such as Dassault Systemes (OTC:DASTY), ANSYS (NASDAQ:ANSS), and Trimble (NASDAQ:TRMB) have also gotten involved in 3D printing technology.

Here are five key players to consider for 2022 that are a more focused bet on 3D printing:

| Company | Market Cap | Description |

|---|---|---|

| Desktop Metal (NYSE:DM) | $1.3 billion | Recent IPO that focuses on metal fabrication technology. |

| Stratasys (NASDAQ:SSYS) | $1.5 billion | One of the original 3D printing pioneers, with a wide array of printers and supporting design software. |

| Xometry (NASDAQ:XMTR) | $1.9 billion | A manufacturing marketplace, including access to on-demand 3D printing services. |

| 3D Systems (NYSE:DDD) | $1.9 billion | Another original 3D printing pioneer and the largest pure-play stock on 3D printing technology. |

| PTC (NASDAQ:PTC) | $11.7 billion | A manufacturing technology provider with a suite of software and related services for industrial businesses. |

1. Desktop Metal

This company is a recent entry into the 3D printing space after going public via a SPAC at the end of 2020. The stock has been a terrible market underperformer since then, losing three-quarters of its value as of spring 2022. However, Desktop Metal could still be a promising investment for the long term.

As its name implies, Desktop Metal develops 3D printing hardware and accompanying design software for metal and carbon fiber parts. The company's smaller systems can handle prototyping and one-off parts, and larger printers are production grade-designed for manufacturing facilities. Desktop Metal serves companies operating in automotive, consumer goods, and heavy industrial equipment businesses.

The company's smaller systems can handle prototyping and one-off parts, and larger printers are production grade-designed for manufacturing facilities. Desktop Metal serves companies operating in automotive, consumer goods, and heavy industrial equipment businesses.

Despite a tenuous start as a public company, Desktop Metal was actually increasing revenue at a torrid triple-digit pace in 2021. Gross profit margins are thin, and the company generated a steep net loss, but that should improve over time as the business scales its operation. Desktop Metal also has several hundred million dollars in cash and investments to fund its expansion. It used some of these funds to acquire additive manufacturing peer ExOne at the end of 2021.

2. Stratasys

Stratasys was part of the early 2010s 3D printing stock boom and bust, but its business has endured. Sales took a dip early in the COVID-19 pandemic but are rebounding as the Israel-based company picks up new manufacturing contracts.

Stratasys serves a diverse set of customers, including aerospace and automotive parts manufacturers, medical and dental companies, and makers of basic consumer products. In addition to a wide array of 3D printer models, Stratasys develops software to help users accelerate the time between design and final printing.

It isn't the highest-growth name on this list, but Stratasys is profitable (on a free cash flow basis) and has more than $500 million in cash and investments on its balance sheet, as well as no debt. Management thinks its payoff from years of research and development into additive manufacturing will accelerate in 2022.

3. Xometry

This is another newcomer to public markets. Xometry completed its initial public offering (IPO) over the summer of 2021, raising almost $350 million in cash in the process. As is often the case with new IPOs, the stock has underperformed since then. It has lost over half of its value from the time it started trading on public markets, but the business itself is rapidly growing.

It has lost over half of its value from the time it started trading on public markets, but the business itself is rapidly growing.

Xometry is a marketplace for on-demand manufacturing of prototyping and mass production. It has a network of more than 5,000 suppliers that companies can call on to meet their fabrication needs. Among the suppliers on the Xometry platform are 3D printing companies, injection molding, and automated machining. The company reported having more than 28,000 active buyers utilizing its platform at the end of 2021.

Although it isn't profitable yet, Xometry's unique approach to the 3D printing and additive manufacturing industry is growing fast. Like other names on this list, it has a sizable war chest of cash and short-term investments that it can spend on research and marketing as it tries to attract more suppliers and buyers to its marketplace.

4. 3D Systems

3D Systems was another early player in the 3D printing industry, and while it suffered through the boom-and-bust period of the early 2010s, its business has held steady for much of the past decade. After a brief dip during the early days of the pandemic, 3D Systems is back in growth mode.

After a brief dip during the early days of the pandemic, 3D Systems is back in growth mode.

The company develops printers and design software for all sorts of materials and industries (medical device makers, dental labs, semiconductor designers, aerospace, and automotive manufacturers). It claims leadership among independent 3D printing companies (as measured by sales). As the 3D printing industry expands in the coming years, 3D Systems thinks it will be able to attract lots of new business with its extensive experience and global reach.

As an established tech outfit in the manufacturing sector, 3D Systems offers investors the prospect of more stable growth, along with profitability. It also has a large net cash position from which it can consolidate its lead in 3D printers and software technology.

5. PTC

By far the largest company on this list, PTC is a longtime technology partner of manufacturing and industrial enterprises. Fast approaching $2 billion in annualized sales and highly profitable, PTC has all the tools needed to digitally transform industrial businesses.

Fast approaching $2 billion in annualized sales and highly profitable, PTC has all the tools needed to digitally transform industrial businesses.

Besides 3D printing computer-aided design software (ANSYS is a peer and software partner that also operates in this space), PTC specializes in augmented reality, industrial IoT (Internet of Things), and product life-cycle management software. Most of its revenue is subscription-based (including its Creo software that enables 3D printing), making for a stable and steadily growing business model that generates ample cash flow. PTC puts spare cash to work developing new products for its partners and makes bolt-on acquisitions of other software companies that enhance its overall portfolio.

As a larger company, PTC won't be the fastest-growing stock in the additive manufacturing and 3D printing space. However, the company has established itself as a leader in industrial technology and should be a primary beneficiary as the production of manufactured goods gets more efficient.

The future of 3D printing

Manufacturing technology is making inroads throughout the global economy by reducing the cost of production and localizing and speeding up the time it takes to deliver customer orders. This is far from mere hype. Nevertheless, as is the case with all technology investments, progress won't go straight up. Expect twists and turns in these stocks as they develop new methods to design and make products.

If you decide to invest, do so in a measured way. Maintain a diversified portfolio, be wary of stocks benefiting from investor over-optimism, and always leave spare cash to invest more when there are inevitable dips. Given enough time -- years and decades -- investing in 3D printing could eventually provide a big payoff.

Related communication stocks topics

Investing in 5G Stocks

As the 5G technology rollout continues, these companies look like winners.

Investing in Top Telecommunications Stocks

Our world is increasingly interconnected, and these companies make it happen.

Investing in Communication Stocks

Communications has a broad definition. These companies are the leaders in the space.

Investing in Top Consumer Discretionary Stocks

When people have a little extra cash, they indulge in offerings from these companies.

Nicholas Rossolillo has positions in Autodesk and PTC. The Motley Fool has positions in and recommends Autodesk, HP, and Microsoft. The Motley Fool recommends 3D Systems, ANSYS, Dassault Systemes, PTC, and Trimble Inc. The Motley Fool has a disclosure policy.

Motley Fool Investing Philosophy

- #1 Buy 25+ Companies

- #2 Hold Stocks for 5+ Years

- #3 Add New Savings Regularly

- #4 Hold Through Market Volatility

- #5 Let Winners Run

- #6 Target Long-Term Returns

Why do we invest this way? Learn More

Related Articles

If You Invested $1,000 in Microsoft Stock in 1986, Here's How Much You'd Have Now

Down 30% in 2022, Is Microsoft Stock a Buy for 2023?

2 Top Stocks to Buy Before 2023

Microsoft Strikes a Big Deal With the London Stock Exchange

Have $1,000? 2 All-Weather Dividend Stocks to Buy and Hold Forever

Better Buy: Microsoft Stock vs. Apple Stock

Apple Stock

Better Buy for 2023: Microsoft vs. Alphabet

Premium Investing Services

Invest better with The Motley Fool. Get stock recommendations, portfolio guidance, and more from The Motley Fool's premium services.

View Premium Services

HP Neverstop Laser Printers | HP Neverstop Laser - laser printer without cartridges | Official site HP

Cartridgeless printer with toner reservoir

An innovative solution that will take your business to the next level.

Without cartridges, easy to use. The HP Neverstop Laser Printer is equipped with a toner refill reservoir, making printing more affordable and affordable. Designed to meet your current and future printing needs at no extra cost

- nine0013

-

5,000 page starter toner 2

The included toner will last up to 5,000 pages - it won't take long to refill.

2

2 -

Print up to 2500 pages per refill 4

HP Neverstop Printer Toner is available at a fraction of the cost of traditional HP toner cartridges. nine0033 1

-

Self-priming in 15 seconds 4

With the innovative refill, you can refill your toner in seconds! Fast and clean!

Learn more about the HP Neverstop Laser 1200w printers.

nine0002 WATCH VIDEO

Refilling the HP Neverstop Laser Printer.

WATCH VIDEO

nine0002Setting up the HP Neverstop Laser Printer.

WATCH VIDEO

Download the HP Smart app for quick and easy access to printer features. 3

Choose the right laser printer for your business without the HP Neverstop Laser Cartridge. nine0008

HP Neverstop Laser 1000n

High Volume Laser Printer with Ethernet Connection

- Printing

- Print speed up to 20 ppm.

in b/w mode

in b/w mode - 150-sheet input tray

- Hi-Speed USB 2.0; Fast Ethernet 10/100 Base

Buy

nine0002 MoreHP Neverstop Laser 1000w

Wireless laser printer with high volume toner refill capability.

- Seal

- Print speed up to 20 ppm. in b/w mode

- 150-sheet input tray

- Hi-Speed USB 2.0; built-in Wi-Fi 802.11b/g/n

Buy

Read more

nine0003 HP Neverstop Laser 1200n Laser MFP with high volume toner refill capability and Ethernet connection.

- Print, copy, scan

- Speed printing up to 20 ppm in b/w mode

- Input 150-sheet tray

- High speed USB 2.0 port; Fast Ethernet 10/100 Base

Buy

nine0002 MoreHP Neverstop Laser 1200w

Wireless laser MFP with high capacity toner refills.

- Print, copy, scan

- Print speed up to 20 ppm. in b/w mode

- 150-sheet input tray

- High speed USB 2.

0 port; built-in Wi-Fi 802.11b/g/n

0 port; built-in Wi-Fi 802.11b/g/n

Buy

Read more

nine0002HP Neverstop Laser 1000n

HP Neverstop Laser 1200n

HP Neverstop Laser 1000a

HP Neverstop Laser 1000w

HP Neverstop Laser 1200a

HP Neverstop Laser Wireless 1200w

Fast and clean toner refilling in 15 seconds

Original HP toner. Low cost per print and high quality without worries.

Low cost per print and high quality without worries.

HP 103A Original HP Neverstop Laser Refueling Unit

HP 103A Original HP Neverstop Laser Toner Reloader, 2500 pages.

nine0002 Buy nowHP 103AD Original HP Neverstop Laser Refueling Unit (2 pcs)

HP 103AD Original HP Neverstop Laser Toner Reloader (pack of 2), 2 x 2,500 pages

nine0002 Buy nowHP 104A Original HP Neverstop Laser Printer

Ideal for sole proprietors and small businesses looking for affordable HP laser printing technology, 20,000 pages.

HP 103A Original HP Neverstop Laser Refueling Unit

HP 103AD Original HP Neverstop Laser Refueling Unit (2 pcs)

HP 104A Original HP Neverstop Laser 9 Print Engine0004

Notes

- Based on HP's internal comparison of MSRP / (MSRP for EMEA region) and cost per page by class of HP LaserJet Pro M15 and HP LaserJet Pro MFP M28 printers with HP 44A/48A Standard Original Black LaserJet Toner Cartridge data as of March 2019. More information can be found at: www.hp.com/go/learnaboutsupplies. nine0013 The actual number of pages may vary significantly depending on the content of the pages and other factors.

- HP Smart app download required. Information on local printing requirements can be found at hp.com/go/mobileprinting. Some options/software are only available in English and differ between desktop and mobile apps. Internet access required, sold separately. Full functionality requires an HP account. A list of supported operating systems is available in the app stores. nine0014

- The toner refill kit is not included with the printer and must be purchased separately.

Averages based on ISO/IEC 19752 and long term printing experience. More information can be found at: www.hp.com/go/learnaboutsupplies.

Averages based on ISO/IEC 19752 and long term printing experience. More information can be found at: www.hp.com/go/learnaboutsupplies. Which 3D printer to choose for business

3D printed business models

3D printing is making its way into more and more areas of life these days. At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request. nine0005

In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request. nine0005

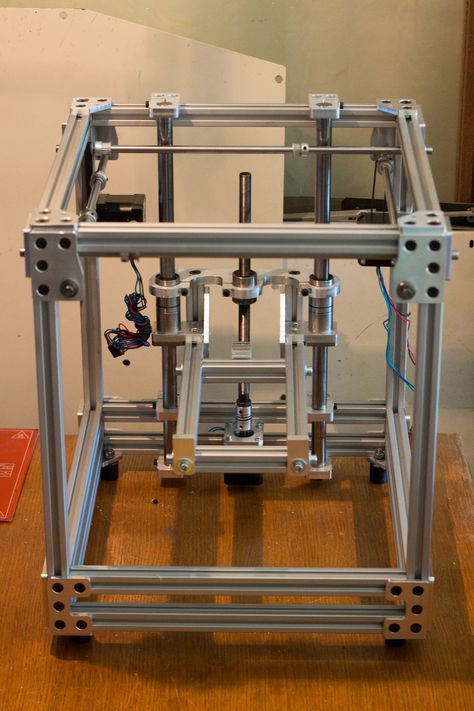

For new players in the 3D printing market, the choice of niche is closely related to the choice of technology, technique, and, sometimes, even specific models of 3D printers.

It is important that we are talking about business - a sphere of life in which everything can be found at a price expressed in the amount of money, which means that there are general requirements that apply to equipment. Maximum reliability allows you not to spend on repairs, which means it is worth the investment. The presence of all certificates for the equipment is required by the state from the business. The maximum level of after-sales service allows the entrepreneur not to learn 3D printing, but simply to do the business for which he created his business. The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous. nine0005

nine0005

In general, there are several models for using a 3D printer for profit.

-

The company is introducing 3D printing to help existing processes.

-

The company switches to the production of a product using additive technologies

-

And there are companies that deal exclusively with printing, and the very idea of their business and their product is tied to additive technologies. nine0005

Let's see what 3D printing technologies are used in different models of companies on the market, as well as how to choose the right 3D printer for the business in your chosen niche!

Business 3D Printer

Modernization of existing business and technical processes is the key to the success of any enterprise. Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed. nine0005

With the cost of additive technologies becoming cheaper, more and more enterprises are looking for ways to optimize their production using 3D printing. Sometimes, the optimization process leads to quite interesting results.

Sometimes, the optimization process leads to quite interesting results.

3D printing in production

Machine production is a method that allows you to get the most profit, and therefore the most interesting from a business point of view. Production line machines require constant maintenance and regular replacement of worn out parts. Usually, the process of replacing a part when it breaks down is as follows - a service employee localizes the malfunction, diagnoses the cause of the failure of a particular part, and orders a new part from the manufacturer according to the catalog. It’s good if the supplier has such spare parts in stock, but it happens that you have to wait until the spare part you need is produced. nine0005

From the moment of ordering to receipt, it can take from a week to months. All this time the machine is idle, and in our time of widespread use of conveyor chains, this can mean idleness of the whole chain of machines. Moreover, for some machine tools, spare parts cannot be obtained in principle - they can be discontinued, and sometimes it turns out that the company - the manufacturer of the machine has already gone bankrupt and there will be no new parts for the existing machine in principle.

Possible production losses in this case can reach amounts comparable to the value of the enterprise.

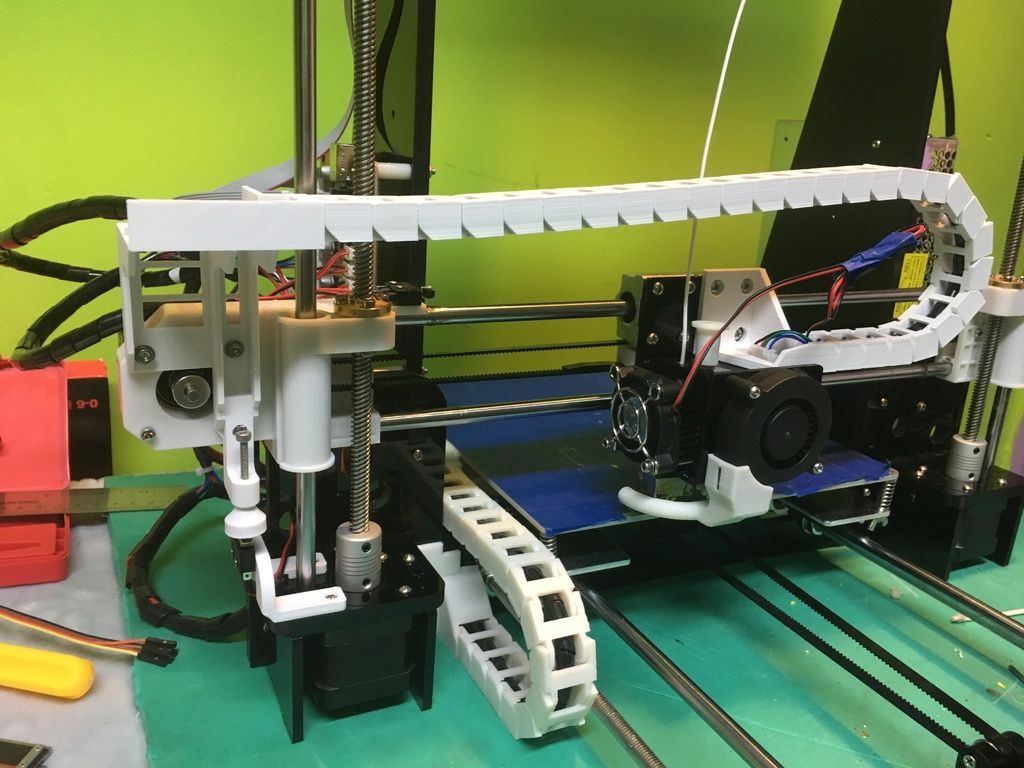

But what if the part you need can be obtained without ordering it from the machine manufacturer? The increase in the availability of 3D printing has led more manufacturers to create 3D printing departments based on their service departments. Such a department consists of several 3D modelers, several 3D printers and several 3D printers.

Such 3D printers must meet several requirements - machine parts must be strong enough, the cost of maintaining a 3D printer fleet must be reasonable, and the 3D printer must be able to produce both the spare part itself and models to obtain parts using more expensive methods. nine0005

Such requests are met by 3D printers using FDM and LCD technology.

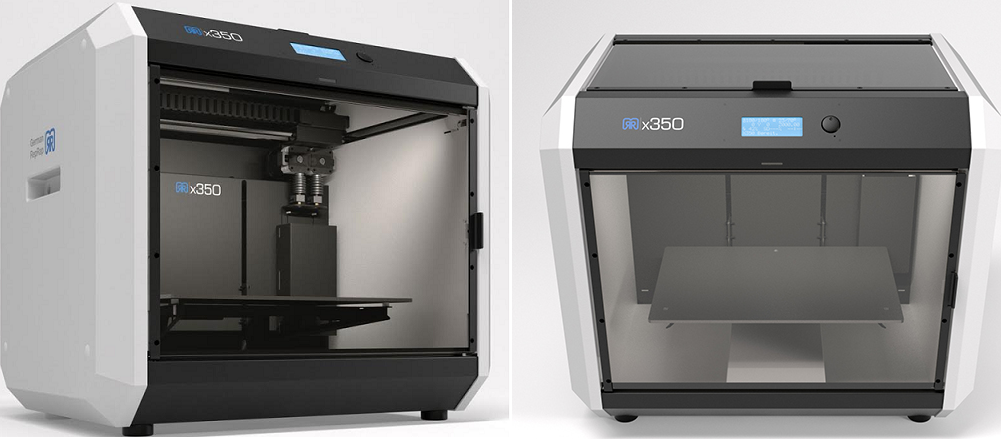

Picaso 3D Designer X Pro

One of the bestsellers in this category is the Picaso 3D Designer X Pro printer. The defining advantages here are the omnivorousness of this model - you can print both ABS, PLA, PETG, Flex, Nylon, as well as more specific and composite plastics - and the ability to print simultaneously with two materials. nine0005

nine0005

Phrozen Transform Standard

Phrozen Transform Standard is also a good choice. Huge build area - 292x165x400 mm, print speed up to 10mm/hour and high-intensity ParaLED system allow this printer to quickly and accurately print parts, including those from specific polymers.

Architectural 3D printing

In architecture, the ability to present a material model of the proposed project to the customer is of great importance. There is little to promote acceptance; a positive decision, such as the opportunity to inspect and feel live at least a model of a building or apartment. For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology; nine0005

Affordable 3D printing has taken the manufacturability of the production of architectural models to a whole new level! Moreover, it turned out to be extremely simple to integrate 3D printing technologies into the work of an architectural bureau - engineers in this direction have already specialized in working with one or another software product related to the creation of 3D models, it only remained to bring this work to its logical conclusion - a layout.

The requirements for 3D printers for architectural offices are primarily related to the ability to produce large layouts. Strength here is not as important as the ability to convey the characteristic features of the project as accurately as possible - after all, the layout is a reduced copy, which means all the details will be tiny. These requirements are met by FDM 3D printers. nine0005

Raise3D Pro2 Plus

A good choice for an architecture studio is the Raise3D Pro2 Plus 3D printer. A large construction area, coupled with precision, through the use of high-quality components and optimal kinematics, allow you to carry out large-scale projects. The ability to print with two materials at the same time makes the implementation of projects easier and allows you to simplify the post-processing of finished models.

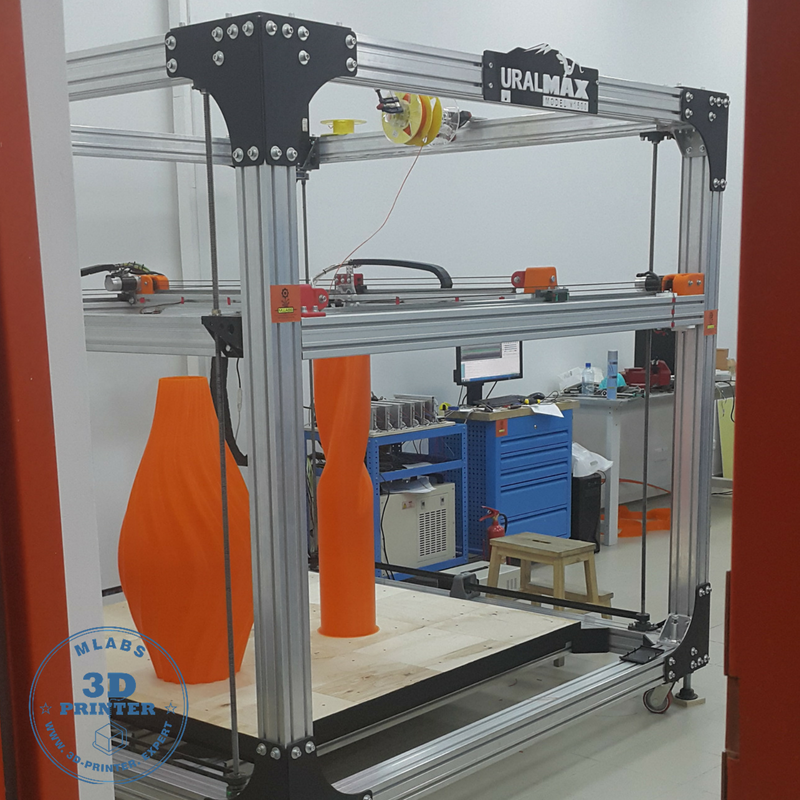

BigRep Studio

For particularly demanding architects, BigRep Studio will be a pleasure to work with. Resume printing from the same place after a power outage, remote control and print management make it possible to install this truly large machine in its dedicated room. Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Advertising and exhibitions

The advertising business is probably one of the most demanding of novelty. The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

A special area of this business is the organization of stands for exhibitions and similar events. It often happens that there is very little time to implement an idea, and success is achieved due to the possibility of implementing the maximum range of such ideas. nine0005

So in advertising, 3D printing is in demand in a huge number of its manifestations. Here the creation of handouts, and layouts of future projects, and noticeable signs of pylons and posters. Different 3D printing methods are suitable for different areas of the advertising business, FDM and LCD are very much in demand. One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from a distance. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics. nine0005

One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from a distance. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics. nine0005

Flashforge AD1 Channel Letter

The Flashforge AD1 Channel Letter 3D printer is perfect for solving such problems. Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production. nine0005

Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production. nine0005

Jewelry 3D Printer

Since ancient times, jewelry has been considered one of the most profitable. The history of jewelry creation dates back many centuries and goes back to the time of the birth of the Homo Sapiens species. Many techniques in this area of production have been preserved for decades, and are in many ways an art. But even in this area, we see that additive technologies help to realize more and more projects and ideas.

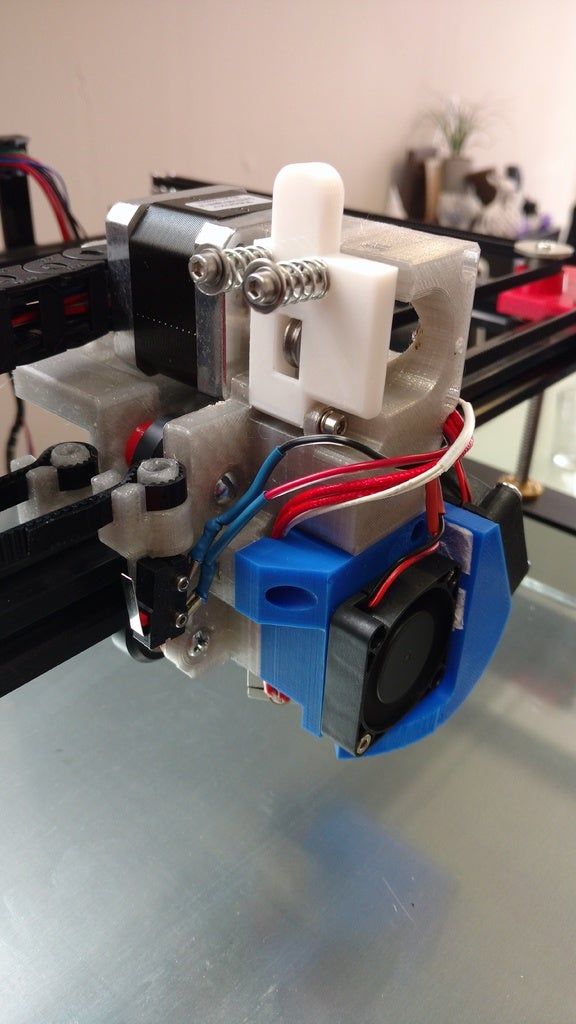

The meaning of the word “jewelry” itself is associated with miniature, precision and painstaking work. A lot of time and effort is spent on creating each piece of jewelry, which as a result can easily turn out to be a masterpiece of art. 3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting. nine0005

3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting. nine0005

Phrozen Sonic XL 4K

A good example of a suitable 3D printer for jewelry is the Phrozen Sonic XL 4K LCD technology. The maximum resolution of 4K allows you to create the most detailed models, and the ParaLED system significantly reduces the time of their production.

Phrozen Sonic Mighty 4K

For workshops dealing with more miniature production, the Phrozen Sonic Mighty 4K may be sufficient. Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop. nine0005

Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop. nine0005

Sculpture

A striking example of a paradigm shift in production in our time is sculpture. Many people remember the saying of the great Michelangelo Buonarroti “I take a stone and cut off all that is superfluous.” How exactly the master defines the fundamental principle of subtractive technologies! Modern developments help to make the process of creating masterpieces more connected with working with the head than with the hands.

In our time, the sculptor has the opportunity not only to work with material objects, but to almost completely rid himself of such work. A chisel and hammer can replace a computer and a 3D printer. The requirements for the machine in this bundle are mainly related to the area of \u200b\u200bconstruction - sculptures can often be large. There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA. nine0005

There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA. nine0005

CreatBot D600 Pro

The CreateBot D600 Pro 3D printer becomes a frequent inhabitant of the studios of successful architects. A huge build area, the ability to print with two materials at the same time make this machine ready for the implementation of projects of increased complexity. The presence of a special table cover, as well as a special compartment for drying plastics, makes the process as comfortable as possible and does not require extra space.

Peopoly Phenom XXL

For more detailed sculpting tasks, it will be useful to look at the Peopoly Phenom XXL 3D printer. The gigantic build area, coupled with the use of MSLA technology, makes this machine stand out from other printers in this price range.

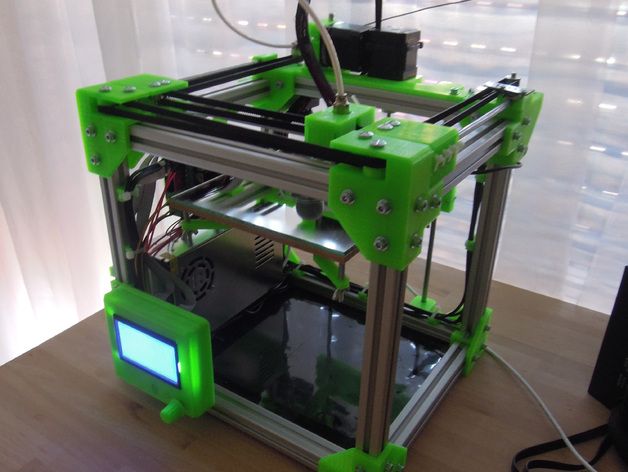

Business converted to use a 3D printer

There are several periods of the so-called “breakthrough development of production” in history. One of the last can be called the Great Industrial Revolution in England. This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors. nine0005

Today we see a huge number of companies that, while remaining fundamentally in the same area, are changing the entire production line of their product, based on the new opportunities that 3D printing provides.

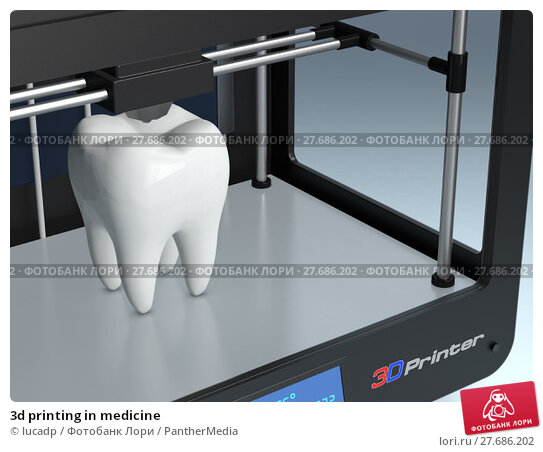

Dental 3D printers

For me personally, going to the dentist is always stressful. Despite the fact that in our time sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also likely that for this reason you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical. nine0005

Despite the fact that in our time sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also likely that for this reason you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical. nine0005

Modern technologies have made it possible to change the correction of such a frequent feature of dental clinic clients as malocclusion. In the days before 3D printing, overbite was corrected with braces or braces. This process was very pleasant, required a lot of attention from the client, and also forced to replace the usual tools, such as a toothbrush, with specific and inconvenient ones. For many, wearing braces was also unpleasant from an aesthetic point of view.

Why did people make such sacrifices? A metal brace attached to the teeth puts pressure on them in a certain direction, forcing them to shift towards the medically correct position. After a few months of wearing, the braces literally push the teeth where the dentist has determined. nine0005

After a few months of wearing, the braces literally push the teeth where the dentist has determined. nine0005

This is what the aligners look like

3D printing has changed the approach to the process itself so much that a patient undergoing a course of bite changes practically does not change his habits and lifestyle! This technology is called aligners (from the English allign, align). Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models. nine0005

The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models. nine0005

One of the leading printer manufacturers for this market segment is Formlabs.

Formlabs Form 3

The Formlabs Form 3 3D printer allows you to create high-quality models using a wide range of plastics. Particular attention to issues related to the possibility of using printers from this company in medical institutions allows you to be sure of their safety. Ergonomics and ease of use make it possible to concentrate even more on the really important things - helping the patient. nine0172

Formlabs Form 3L

For dental clinics that have already increased their production volumes and the need for even more advanced equipment is clearly overdue, the Formlabs Form 3L 3D printer will be a rational choice. The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

3D printing in modern orthotics

Will it be news to you that the left and right legs of each of us are of different lengths? And will it be news to you that this can affect your life much more than just complications with the choice of trousers? It turns out that the individual characteristics of a person associated with the length of the legs can be the cause of many diseases, including mental ones, such as depression. Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome. nine0005

And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome. nine0005

Raise3D E2

These requirements are met by the Raise3D E2 3D printer. Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Cosplay

Many of us love masquerades. Probably one of the most exaggerated ways to dress up is cosplay (from the English costume play - costume play). Changing clothes, applying make-up, using additional accessories, cosplayers sometimes become almost like a copy of the heroes of movies, cartoons or comics. And if a pipe and a bowler hat can be enough to become Commissioner Maigret, then in order to turn into Iron Man or Wonder Woman, you need to create many elements of the costume from scratch. 3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand. nine0005

3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand. nine0005

A cosplay 3D printer should be able to print large models as quickly as possible. Plastics used are different, but mostly inexpensive, accessible, and easy to process.

Anycubic Chiron

Cosplayers starting to print costume details often look at the Anycubic Chiron 3D printer. This is an inexpensive machine that allows you to print with affordable plastics and create models that fit into a large print area of 400x400x450mm. An additional advantage of the model is its high maintainability and unpretentiousness in maintenance. nine0005

nine0005

Anycubic Photon Mono

To create accessories and details requiring more detail, purchase the Anycubic Photon Mono. The main advantage of this machine, of course, is its price. At the same time, the print resolution, although it does not reach the height of professional models, is at a level more than sufficient for use in cosplay.

Pure 3D printing business

Speaking about the various niches in the market that have been created by new technological opportunities, one cannot fail to mention those companies whose business appeared as a result of the advent of 3D printing and cannot exist without it. It happens that such companies were initially engaged in something else, but then they saw the economic feasibility of switching to a new business model. There are many companies that were originally created and designed for entrepreneurship based on 3D printing. Due to the fact that additive technologies literally burst into all areas of our lives like an avalanche, it may seem that they are indistinguishable from the companies described in the previous parts of this article. Looking closely, you can see that they make a profit exclusively by doing 3D printing. nine0005

Looking closely, you can see that they make a profit exclusively by doing 3D printing. nine0005

Prototyping

Personally, 3D printing has always seemed to me to be a way to create some kind of device or device parts. Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain. nine0005

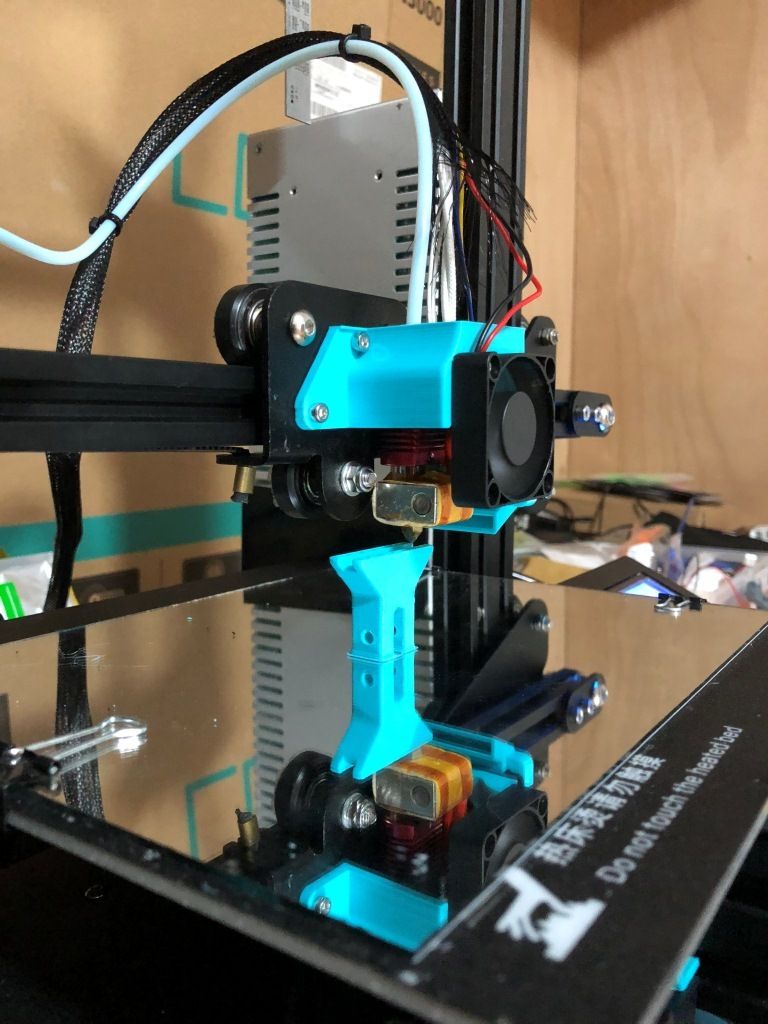

PICASO 3D Designer X

In our country, the PICASO 3D Designer X 3D printer is in great demand. The high printing accuracy of this printer is combined with a compact body with the ability to dry plastic in the process. Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer. nine0005

The high printing accuracy of this printer is combined with a compact body with the ability to dry plastic in the process. Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer. nine0005

Flash Forge Finder

The FlashForge Finder 3D printer is used to create low-level prototypes and to teach the 3D printing process. Also, the low cost and bright appearance make this printer an attractive purchase for studios and circles, where children get acquainted with additive technologies.

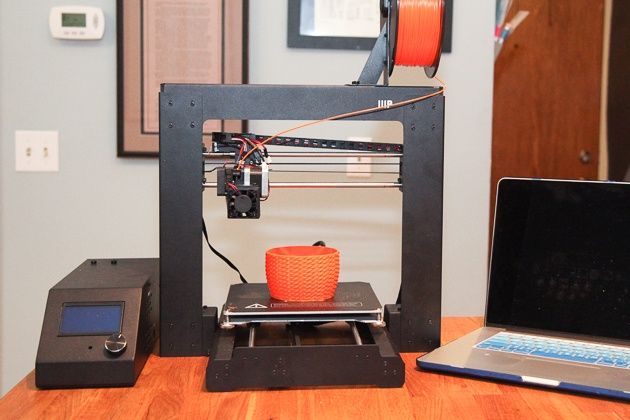

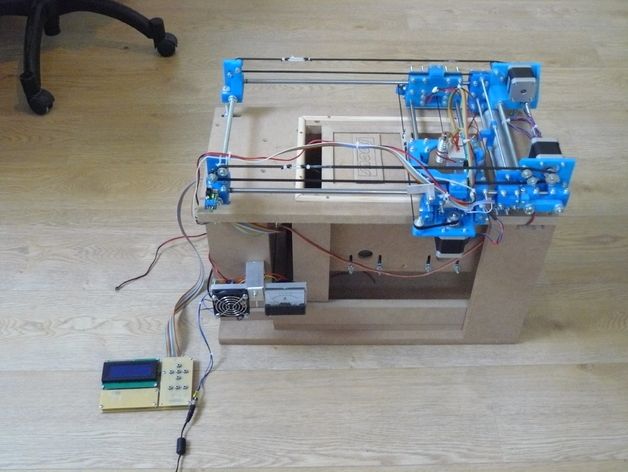

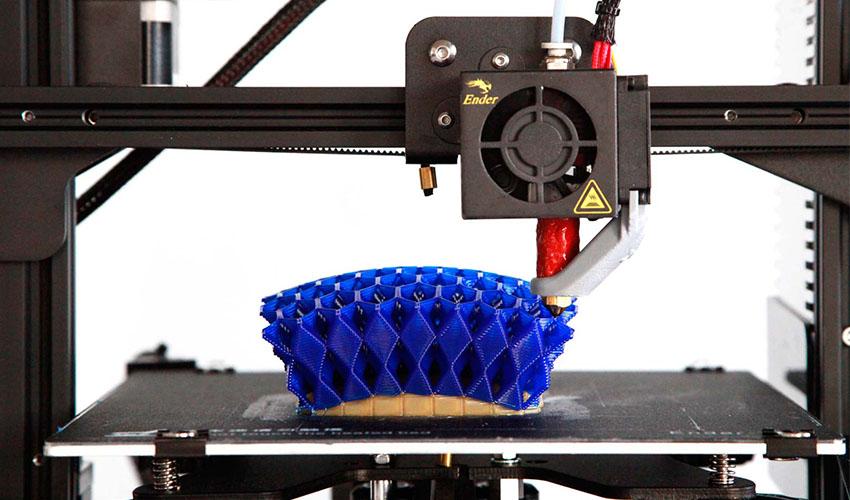

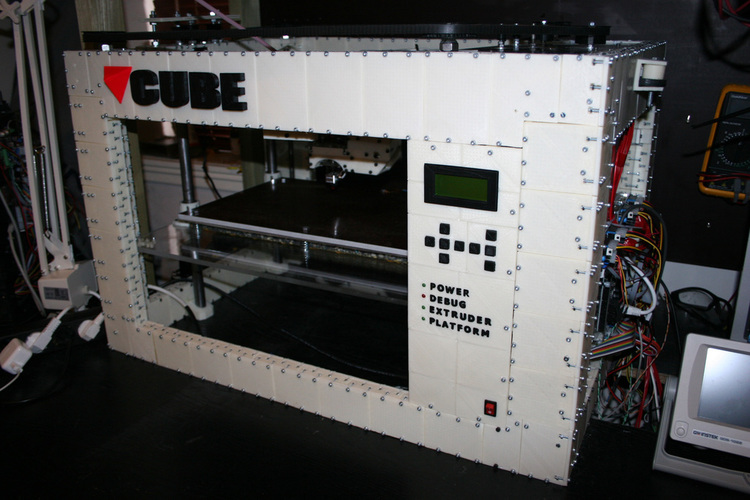

Custom 3D printing

You can print on a 3D printer a huge, almost infinite number of types of things. And some of them need to be printed in one copy and that's it. Someone needs 3D printing not constantly, but not often or even very rarely. Custom 3D printing companies are helping to meet the needs of these potential customers. Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work. nine0005

Someone needs 3D printing not constantly, but not often or even very rarely. Custom 3D printing companies are helping to meet the needs of these potential customers. Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work. nine0005

Creality3D Ender 3

The Creality3D Ender 3 3D printer holds the undisputed leader in terms of affordability/quality ratio in this market segment. Its cost, decent print quality, acceptable reliability and high maintainability make it possible to recoup investments in creating a farm based on such machines in the shortest possible time. Without a doubt, this is one of the best 3D printers for 3D printed farm!

Without a doubt, this is one of the best 3D printers for 3D printed farm!

Anycubic Photon Mono X

nine0005

It is not uncommon for 3D printed trusses to purchase multiple Anycubic Photon Mono X 3D printers to enable collaboration with customers who require a radically different level of detail. The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

Multiple cases

It's always interesting to hear success stories. Let me give you a few real cases as an example. nine0005

3D printer - creator of scarce spare parts

There is an AUCHAN plant in the Tambov region. On the production lines of this enterprise, most of the machines are foreign. The machines use a huge amount of plastic parts, some of which are considered consumables and are ordered from the manufacturer with a margin.

In particular, there is a line for the production and processing of plastic containers. For the washing machine on this line, the plant regularly ordered washer nozzles in Europe. nine0005

For the washing machine on this line, the plant regularly ordered washer nozzles in Europe. nine0005

One terrible day for the manufacturer, on another machine of this line, a plastic part failed, without which the line stood up. After contacting the supplier, it turned out that this particular part was out of stock. We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

The management decided to turn to a 3D printing studio to urgently create a scarce part based on a failed one. The part was created in the shortest possible time, production resumed its work, although there was a loss, it turned out to be completely incomparable with what it could have been. nine0005

Seems like a success story. But it was not all success!

In the process of negotiations with the contractor, it turned out that it is possible to quickly produce a large range of parts for this line, in particular, washer nozzles. At the same time, with the same quality of parts, the cost of these consumables turned out to be much lower. Such production made it possible to abandon logistics costs, free up storage space, and the cost of the part itself turned out to be corny lower. As a result, prototypes were presented, and then finished parts. The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner! nine0005

At the same time, with the same quality of parts, the cost of these consumables turned out to be much lower. Such production made it possible to abandon logistics costs, free up storage space, and the cost of the part itself turned out to be corny lower. As a result, prototypes were presented, and then finished parts. The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner! nine0005

Legs of different lengths and what does 3D printing have to do with it

I had a terrible boss at one of my previous jobs. He always found fault with no reason, voiced conflicting demands, in general, it was uncomfortable to work, and I thought about quitting.

But I didn't quit, and here's why.

It turned out that the boss was such a radish simply because he was haunted by constant headaches. He went to different doctors, to no avail. He made a visit to the next doctor when I was just starting work in the company. It was a turning point, he went to the orthopedist. In Germany. There, in a few days, they determined that he had headaches from the fact that the pelvis was displaced. And the pelvis is displaced because one leg is longer. Special insoles were prescribed and produced right in the clinic. nine0005

It was a turning point, he went to the orthopedist. In Germany. There, in a few days, they determined that he had headaches from the fact that the pelvis was displaced. And the pelvis is displaced because one leg is longer. Special insoles were prescribed and produced right in the clinic. nine0005

I remember that Thursday when he returned from his trip. I was shocked that he gave the bonus to our entire department, including me. Yes, and in person, it seemed that he had been replaced. Completely different, better person!

This story led him to invest in the creation of a laboratory for the production of such insoles in Russia based on the existing center of orthopedics. So to speak, I bought myself personal manufacturers of insoles. On this technological base, it was possible to produce, among other things, shoes designed taking into account the individual characteristics of the customer's foot. Subsequently, he sold this business, some of the specialists work in the Perseus Ortho center. nine0005

nine0005

How the desire to help his wife turned into a business

And finally, a description of the case in which I took a personal part.

Alexander is my neighbor. Worked in a company that was engaged in deliveries abroad. We crossed paths with him on the topic of 3D printing, he bought himself an Ender 3 and printed all sorts of toys, trinkets and useful details. His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram. nine0005

nine0005

I heard this story some time later, when Alexander asked me to help him complete an order for 3D printing. It turned out that Marina was literally inundated with questions about cookies, and subsequently, with orders for cutting molds. In just a couple of weeks, the number of orders for modeling and printing exceeded the capabilities of Sasha's printer, and he turned to me.

The ending of this story is good, Sasha has been creating and printing forms to order for some time. For this, a powerful computer and 6 printers were purchased. A year later, the business was sold and Alexander left for Canada for permanent residence. nine0005

Finalizing

3D printing helps companies of a completely different profile occupy a variety of niches in the market. At the same time, there are many free niches, and often the prospect of using 3D printing in a certain area is not so obvious.

The success stories associated with the use of additive technologies are numerous, from the aerospace industries to the creation of toys.