3D printing companies las vegas

3D Printing Service Las Vegas

High quality and large scale 3D printing service in Las Vegas. Get high quality parts without the headache.

No signup required.

Contact us

What makes PrintAWorld different from the other Las Vegas 3D printing companies out there

Get high quality parts

Our SLA 3d printer can print high resolution parts that other large format printers can only dream of.

Fast turnaround

We know how tough deadlines can be. Let us know and we'll do our best to get your project done in no time.

Get expert help

From ideation, design to production, we'll help you every step of the way.

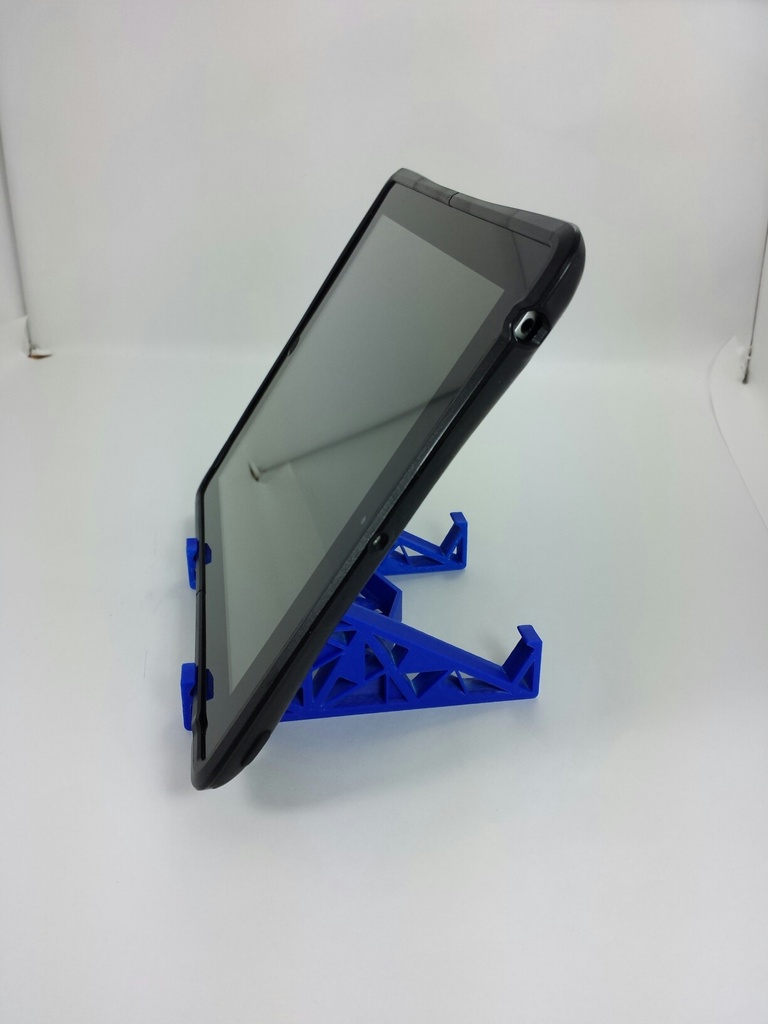

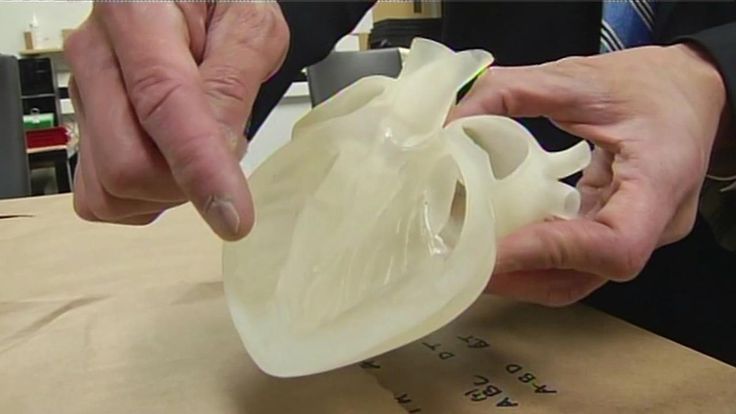

Some of the work that we did for our clients in Las Vegas

How our 3D printing service in Las Vegas works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project.

If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project. No minimum order quantities!

0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea. We'll keep you updated and we'll make sure the result is exactly what you want or even more.

No minimum orders.

No minimum orders.0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

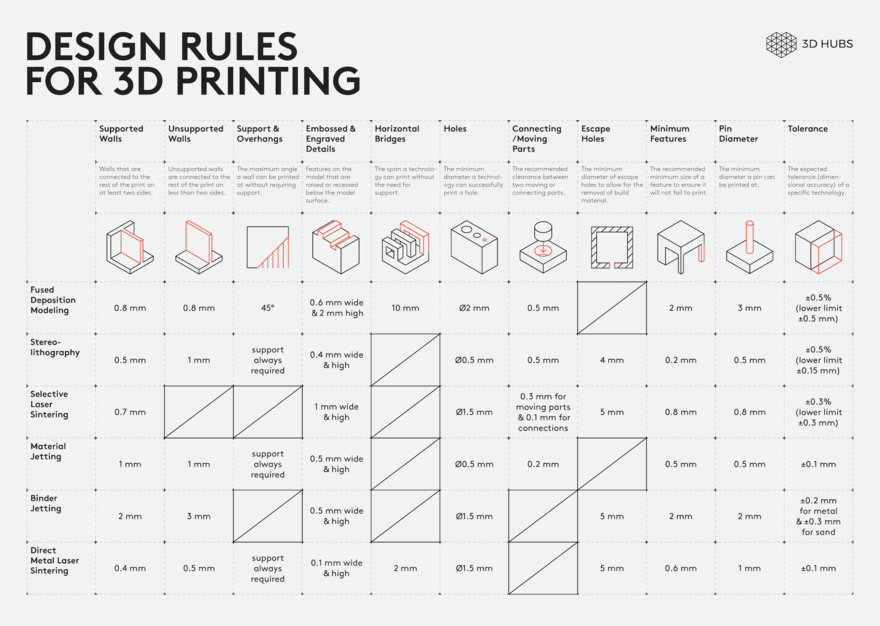

3D printing technologies that we use

These 3D printing technologies are what powers our 3D printing process

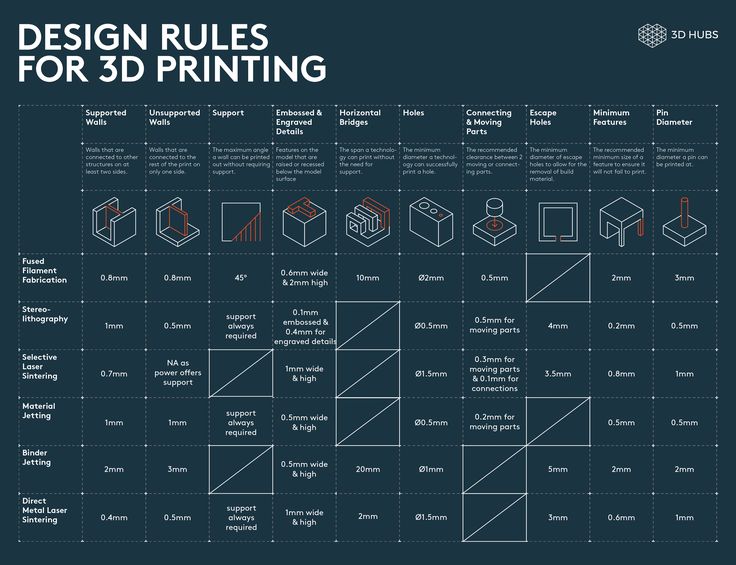

Fused Deposition Modeling (FDM)

We use Fused Deposition Modeling (FDM) for low-cost and simple 3d printed parts. We don't use this process as much because we find the quality lacking and the amount of post processing work involved negates the money you save from low material cost. This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

Selective Laser Sintering (SLS)

Selective laser sintering is another great additive manufacturing technology for rapid prototyping. SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

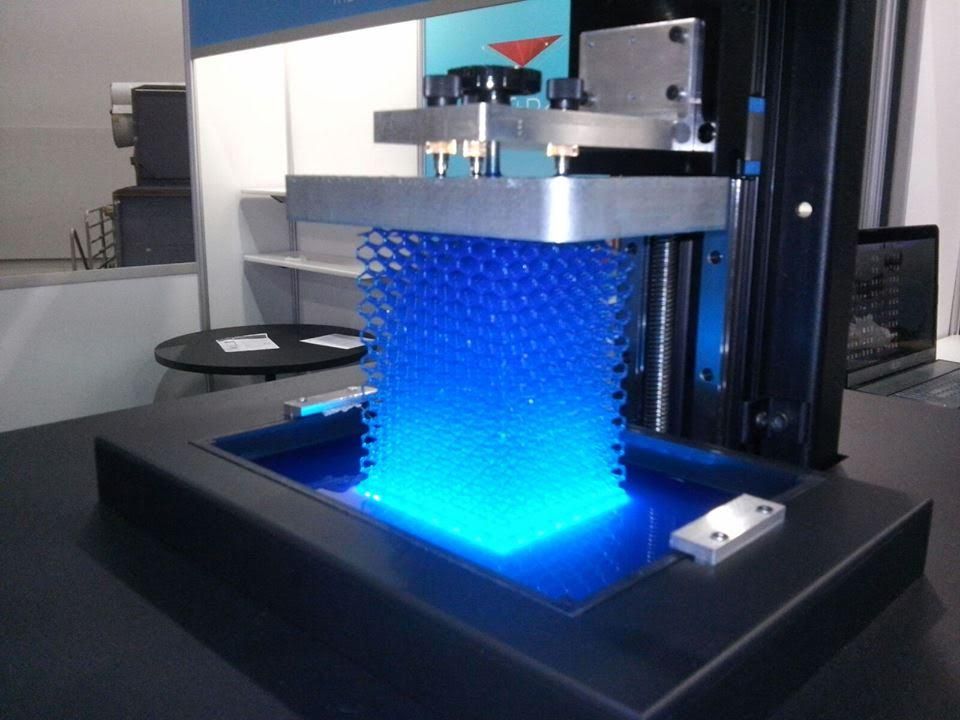

Stereolithography (SLA)

Stereolithography allows us to 3d print accurate and high resolution prototypes . We us this process to create functional prototypes that are highly detailed. We recommend SLA for almost any 3d printing projects because we believe it produces the highest quality prints.

Multi-Jet Fusion (MJF)

Multi Jet Fusion is what helps us 3d print end-use production in 24 hours.

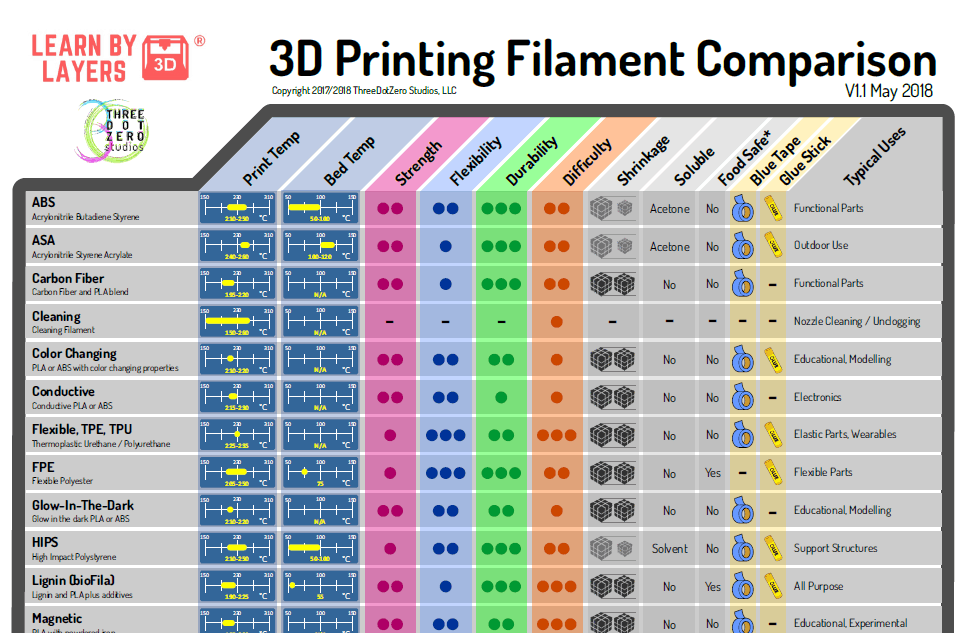

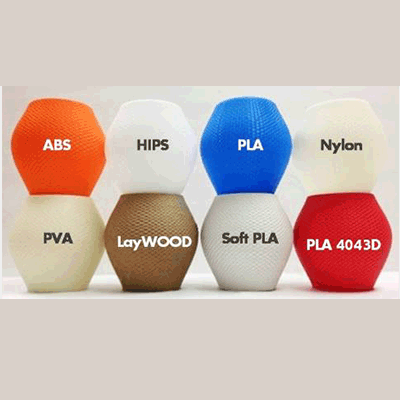

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin. It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

F.A.Q

How much does custom 3D printing cost?

Custom 3D printing can cost between $25 up to thousands of dollars depending on the size and volume of your 3D model. The 3D printing material used affects the price as well. At PrintAWorld, we use industrial SLA resin for our custom 3D printing as we believe it results in the best results for our clients. If you want to learn more, here's a breakdown of the cost of 3D printing.

The 3D printing material used affects the price as well. At PrintAWorld, we use industrial SLA resin for our custom 3D printing as we believe it results in the best results for our clients. If you want to learn more, here's a breakdown of the cost of 3D printing.

3D Printing Service for Las Vegas, Nevada

CapabilitiesCustom Online 3D Printing ServiceNevadaLas Vegas

High Quality Las Vegas, Nevada 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Las Vegas, Nevada 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4. 6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Las Vegas, Nevada

Henderson

NevadaSan Bernardino

CaliforniaFontana

CaliforniaMoreno Valley

CaliforniaRiverside

CaliforniaOntario

CaliforniaPasadena

CaliforniaBakersfield

CaliforniaGlendale

CaliforniaAnaheim

CaliforniaSanta Clarita

CaliforniaSanta Ana

CaliforniaIrvine

CaliforniaHuntington Beach

CaliforniaHawthorne

CaliforniaLong Beach

CaliforniaGlendale

ArizonaPhoenix

ArizonaScottsdale

ArizonaFresno

California

Ready to start making custom 3D printed parts?

CES 2016 in Las Vegas.

Overview of 3D industry novelties from Top 3D Shop

Overview of 3D industry novelties from Top 3D Shop In early January, a large-scale technological exhibition CES 2016 was held in Las Vegas, where the world's leading manufacturers of 3D equipment demonstrated their new products. Top 3D Shop has selected the most interesting novelties in the 3d industry and will talk about them in this review.

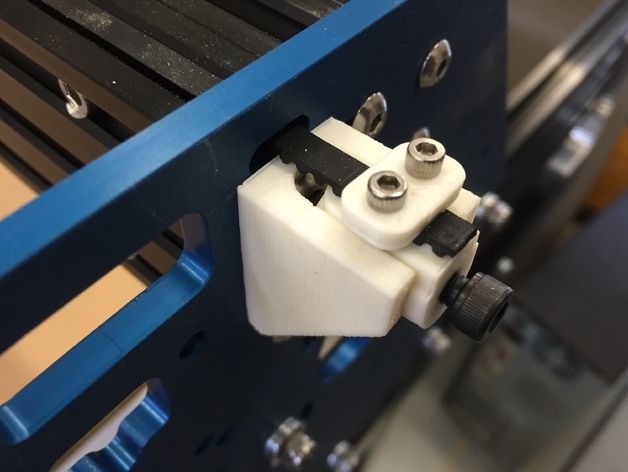

Makerbot Smart Extruder +

At CES, Makerbot introduced its new version of the Smart Extruder+, one of the most important parts of a 3D printer. The extruder is designed to be installed in Makerbot Replicator 5GEN, Makerbot Replicator, Makerbot Replicator Mini, and Makerbot Replicator Z18. Smart Extruder+ allows you to make your 3d printer easier to use and more reliable, while smart sensors inside the extruder make the printing process smoother. The new system tells the user when the thread ends by transmitting data using a mobile application or displaying it on the display. It can also be quickly replaced if worn or outdated. nine0003

nine0003

The new extruders are priced at $199 and are available for pre-order on the official Makerbot website.

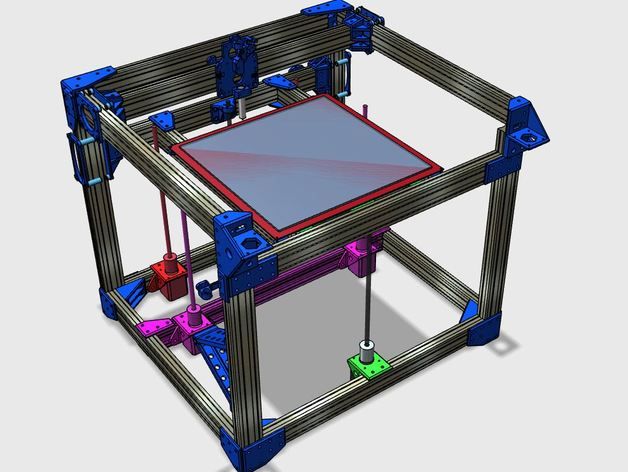

XYZPrinting Unveils Arsenal of 3D Printers

Taiwanese company XYZPrinting is showcasing a large number of new 3D printers, gadgets, robotics and more at this year's CES.

The new 3D printers were represented by the following models:

da Vinci Mini - ultra-small 3D printer priced at 269$, which has a wi-fi module and USB support. The new version has become more convenient, lighter and more portable.

da Vinci Junior 1.0 3-in-1 - $569 compact 3D printer with 3D scanning, laser engraving, auto-calibration and built-in wi-fi.

da Vinci Junior 2.0 Mix is able to mix 2 colors in one nozzle, getting a gradient. The cost of such a printer is $499

The cost of such a printer is $499

XYZprinting Nobel 1.0 Advanced (1.0 A) - This $1,699 3D printer offers 0.13mm XY and 0.025mm Z resolution, allowing you to print objects with complex geometries. This is a comfortable machine that is attractive to designers who are looking for high quality and affordability.

da Vinci 1.0 Pro 3-in-1 is a 3D printer designed for a wide range of professionals from designers to architects, available for $899. da Vinci 1.0 P[IMG]ro 3-in-1 has a large print area and a pre-installed wi-fi module. nine0003

XYZprinting Nobel DLP - XYZPrinting's fastest and most accurate 3D printer, perfect for jewelry making. The 3D printer prints in DLP technology with a quality of 50 microns on the XY axis and 25 microns on the Z axis. The price of such a printer reaches 1999 $

XYZprinting 3D JET - is the most competitive product for making small products. The dedicated printhead produces support materials that are great for printing moving parts. A personal-like 3D printer produces high quality models and is great for a wide range of people from toy makers to engineers. nine0003

A personal-like 3D printer produces high quality models and is great for a wide range of people from toy makers to engineers. nine0003

3D Systems ProX DMP 320

New from 3D Systems is the Prox DMP 320 3D printer that prints using DMLS technology. ProX DMP 320

is designed for the manufacture of high precision parts using materials such as titanium, steel, nickel and other alloys. The ProX DMP 320 has a large build area of 275 x 275 x 420 mm and 2 available configurations, one for stainless steel and one for nickel. The 3D printer provides centralized maintenance management, gas and argon reduction, and support for a consistent production process. nine0003

Voxel8

Daniel Oliver and his team showcased the Voxel 8, the first electronic ink 3D printer, at CES 2016. Samples included a wireless hard drive, a quadcopter and a futuristic clock, all of which were 3D printed.

Samples included a wireless hard drive, a quadcopter and a futuristic clock, all of which were 3D printed.

Ultimaker

Ultimaker announced 2 new 3D printers at CES 2016: Ultimker 2+ and Ultimaker Extended+ based on previous versions of 3D printers. The new printers are equipped with interchangeable nozzles, allowing users to more easily work with different materials, as well as choose between high detail or print speed. In addition, the feed system has been improved in the printers, as well as the cooling system. The company's new products are the result of the company's tremendous work with the Ultimaker community, which helped make the new models better. nine0003

MCOR

Mcor Arke is a new model from Mcor presented at CES 2016. According to the creators, Arke prints 4 times faster, resolution is increased by 50%, and color reproduction by 150%. All this has been achieved with a new sheet feeding system using rolls.

The Arke print area is 240 x 210 x 125 mm, which is slightly smaller in height but wider than the previous model. Switching from paper sheets to rolls also has a number of advantages: the printer has the best color reproduction of any 3D printer on the market. Also, this model was awarded the best innovative model in the category of 3D printers. The model attracted widespread attention from industrial designers, engineers, and other members of the media. nine0003

Up mini 2

Beijing Tiertime Technology Co, like many other companies, presented its new Up Mini 2 model at the exhibition - the first Up series 3D printer with a touch-screen screen and wi-fi connection, and also carry out 3D printing from mobile applications. The Up Mini 2 has improved print quality to 150 microns, which is a good result for this segment. The dimensions of the printer are 255 x 365 x 385 mm and the weight of 8 kg make the printer portable and easy to use. nine0003

nine0003

Fuel 3D

As one of the pioneers in the consumer segment, Fuel 3D, with their Scanify 3D scanner, has been acclaimed by the public for its fast scanning, portability and affordability, bringing 3D scanning technology within the reach of every family.

One of the devices on display is the 360-degree head scanning system. This scanner can be used to create hats, virtual reality devices and much more. The device uses a proprietary system from Fuel 3D for fast and detailed capture of the object. nine0003

Another interesting device is the 3D scanner, which is used to scan a person's whole hand in high resolution. This device can be used in the field of prosthetics, cosmetics and jewelry production.

In addition to all this, the company introduced its cloud technology, which allows you to process the received images through a web application installed on the scanner.

M3D

M3D has already become popular in the consumer segment for its compact 3D printer. Now the company has decided to start developing new materials. At CES, the company unveiled Tough 3D Ink and ABS-R materials, set to become the new standard in 3D printing. nine0003

Now the company has decided to start developing new materials. At CES, the company unveiled Tough 3D Ink and ABS-R materials, set to become the new standard in 3D printing. nine0003

Tough 3D Ink™ was developed to create durable and flexible products. This material is environmentally friendly and odorless. In addition, according to the company, it does not overheat when printing and can withstand high pressure. Tough 3D Ink allows for printing of varying hardness and flexibility depending on the product.

ABS-R is a material developed as a replacement for ABS material with higher grip and wear resistance. It is also said that the material is odorless and does not require heating. At the same time, it can print durable products that are slightly softer than those printed with PLA. nine0003

Polaroid

Arguably the world's most famous camera company, Polaroid decided to try its hand at 3D printing and announced the ModelSmart 250S at CES. The print resolution of this printer is in the range of 50 to 350 microns at a print speed of 100 to 200 mm. The device has a wi-fi camera that allows you to monitor the printing process remotely, as well as a self-calibrating extruder.

The device has a wi-fi camera that allows you to monitor the printing process remotely, as well as a self-calibrating extruder.

This device uses PLA filament developed by Polaroid, available in 9flowers. Thread spools are equipped with smart sensors that tell you when the material is low. The software runs on Windows and Mac OS and allows you to 3D print in just 3 clicks. There is support for stl-files, as well as loading models from repositories.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

Vk

Youtube

Top 3D Shop - Your expert in the 3D technology market

3D-printed electric car shown in Las Vegas / Video / 9(83) / Auto Bild Belarus

- 9(83)

- Video

- 3D printed electric car shown in Las Vegas

Local Motors, premiere, concept, electric car, LM3D Swim, video, 3D printing, 09 November 2015 1467

nine0002 Local Motors has unveiled its first 3D printed electric car, the LM3D Swim, according to Gizmag. The official debut took place at the 2015 SEMA Auto Show in Las Vegas.

The official debut took place at the 2015 SEMA Auto Show in Las Vegas.

At the moment the car is a concept model. LM3D Swim certification and safety testing is scheduled for 2016.

According to the developers from Local Motors, in total, about 75 percent of all parts in an electric car are created through 3D printing. This greatly accelerated the production process. nine0003

Also, thanks to the model structure of the novelty, the assembly of "printed" parts takes a record low amount of time. The pilot prototype was digitally assembled in just a few months. The second advantage of modular assembly is its relative cheapness.

As for the technical stuffing of the new LM3D Swim, here the manufacturer does not yet give accurate information.

Local Motors' modular electric car can be pre-ordered in spring 2016 for $53,000. The start of mass production is scheduled for early 2017. nine0003

The start of mass production is scheduled for early 2017. nine0003

korrespondent.net

Popular

23 December 2022 | car market, Chevrolet, Bolt, crossover

2023 Chevrolet Bolt EUV Cuts Prices

Lowering the price of EUV turns an already good car into an incredible value.

Kia EV6 loses 136kg

Single-engine EV6 reduces power but increases range…

Turn of the Russian car market to the East

Car sales in Russia began to grow with the help of…

Promotion

03 November 2022 |

KIA Rio X-Line at a price of 41 000 BYN! A large advantageous offer of cars with a guarantee, from a warehouse in Minsk

The popular compact crossovers KIA Rio X-Line and KIA Rio X 2019/2021, presented in a warehouse in Minsk at a very favorable price from 41,000 BYN.