Triangle 3d printer

Triangle best STL files for 3D printer・Cults

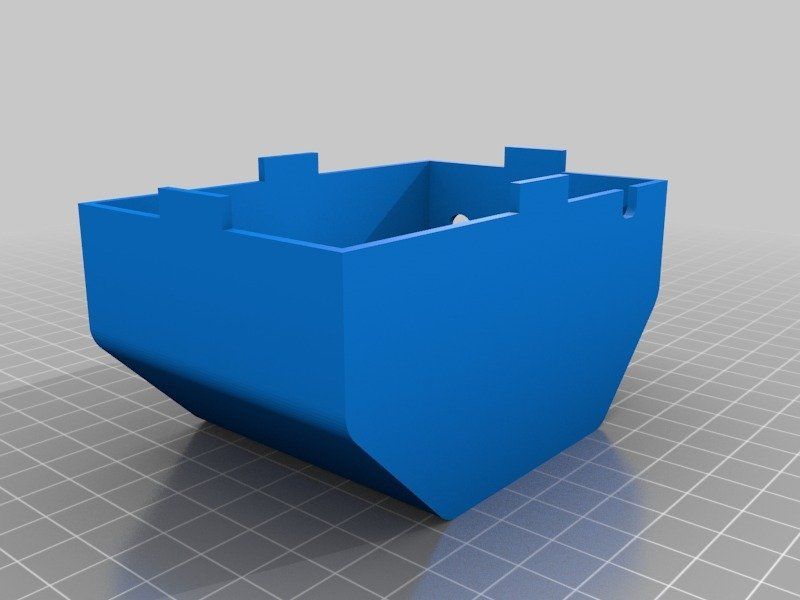

3D Geometry educational box

Free

Tradicional Triangle Plant Pot and planter - Vase mode

€1.13

Angel Vortex Crown Piece

€13.64

Vortex Golden Ring 5

€18.18

Triangular Design Ring

Free

Vortex ring 2

€13.64

Traffic signal caution cats crossing ( Traffic signal caution cats crossing )

€1.50

Cookie cutters

€1.24

Cactus Pot and Planter

€0.93

Basic shapes // STL File

€0.71

Cernit clay cutouts

€0. 51

Phone Stand Light & Classy

Free

Penrose Triangle

€0.65

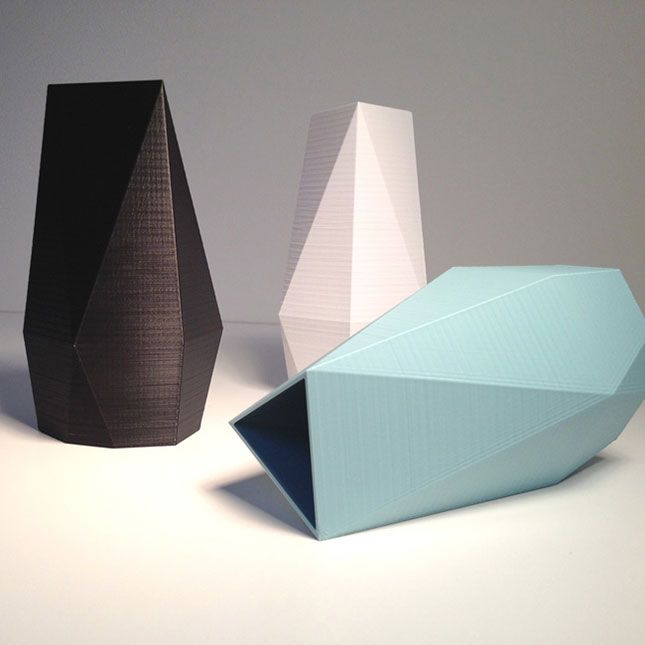

Tradicional Triangle Vase

€1.22 -46% €0.66

Square, Triangle, Circle

€0.87

5 Cookie Cutters / Moon, Square, Circle, Triangle and Heart

€0.50

Foldable Fidget

Free

Triangle Lock Switch Cabinet Locking

€1

Geometric Earring Cutter

€1.39

Clipper Lighter Display Stand Triangle Shape

€0.50

Triangular Cutter

€0. 54

54

Reuleaux Triangle

Free

Ring All seeing eye circle

€20

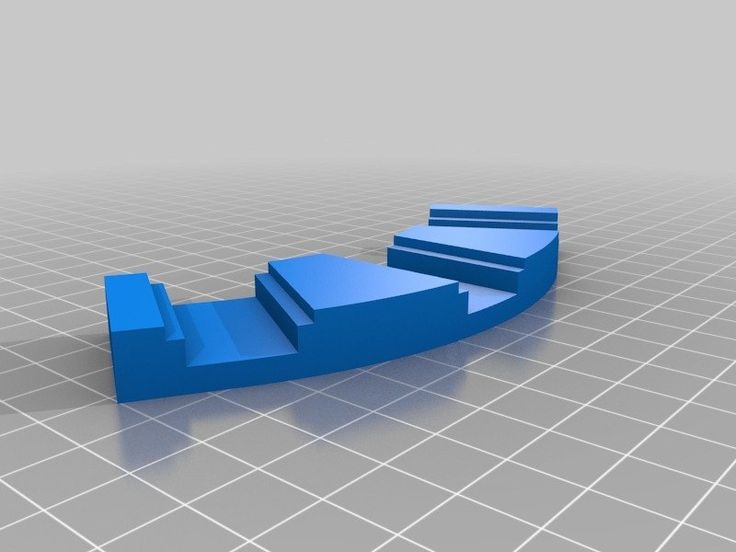

CG-Bonwill-Triangle 25° + Curve of Spee

€9.12

Rubik's Cube Puzzle Stand

Free

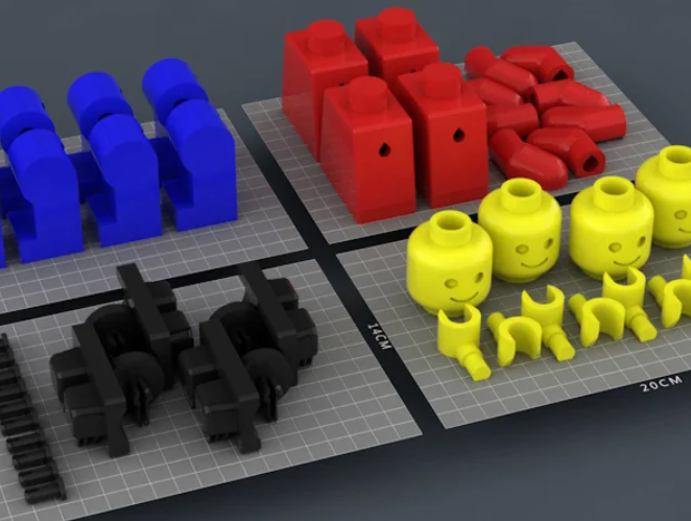

Rest Filament Recycling

Free

Trigon Slotted Lamp

Free

Playstation_coverfan

Free

SQUID GAME / SQUID GAME KEYCHAIN

€4

Text Flip - Triangle

Free

Shape Drawing Templates

Free

Montessori Geometry Cabinet

Free

Indian Billiard Pack - Carrom

€2

Camper Trailer Key

Free

Centreur Carrom - Indian Billiards

€0. 75

75

Coupat_CookieCutter_Triangle

€0.62

Generic Shape Cookie Cutters

€1.14

Triangle Cookie Cutter

€0.51

Zelda key ring

€1

Triangle key bollard according to DIN 3223

€0.50

Tetrahedron

Free

Paradox Illusions - Penrose triangle optimised

Free

Customizable spiral vase Sierpinski pyramid (subtractive model)

Free

Modular Planters or Shelves

Free

Lion head - LOW POLY

€2

TRIANGLE POT 3D

€0. 54

54

royal tease SPACE-FILLING COOKIE CUTTER collection👑

€18

Triangle Space-Filling Cookie Cutter 👑

€3

Triangles best STL files for 3D printing・Cults

Pangolin Strategic Armored Suit LF-13

€7.54

MR-04 VF-1 Gun Carrier cart

€4.71

Composition frames

Free

Stacking Lid Holders For Ball Mason Jars

€4.71

Many Triangles - Retro Big Earrings

€1.21

Triangles - Retro Fashion Earrings

€1.21

Diamond triangles bead and charm 3D print model

€4.71

Triforce

Free

VC-33 VTOL Aircraft MR-03

€7. 54

54

Triangle (v2) shaped earrings

Free

Triangle shaped earrings

Free

A.F.S. SpaceTrooper ST-05

€4.71

Triangle Ring

€2

Parametric Painters Triangles

Free

AEW aircraft MR-02

€7.54

Marvel Quicksilver Logo Keychain

Free

Painters Triangle

Free

LanRev Bust

Free

Comanchero

€7.54

A.F.S. - SpaceType 3 ST-03

€4.71

A.F.V. goliTank LF-07

€5. 65

65

Armored power suit <Film version> ZR-02 1/100

€7.54

Asymmetrical Low Poly Vase

€0.65

Pythagorean Theorem on Hinges with Equilateral Triangles

Free

Favoletti Studios filament ferris wheel

Free

AIRBRUSH/SPRAY TEMPLATES/STENCIL

€0.60

Circle Base Solids

Free

Cubic Base Solids

Free

Sinusoidal Base Solid

Free

Handy Dandy Triangle

Free

Triangles earring

Free

Pantograph, Print in One Piece

Free

Square Pen Holder

Free

Four triangles earrings

Free

Floral tissue holder

Free

Geometric tissue holder

Free

Set of triangles

€2

cookie cutter triangle set 1-7cm

€0. 99

99

Triangle and Cone Pots

€1.25

cookie cutter triangles x10

Free

cookie cutter triangles

Free

cookie cutter triangles

Free

iPhone XR Phone Cases

€2.59

The Prototype

€3.30

Geometric Stars Stencil

Free

Mazinger Z Bust

Free

Venus Vase

Free

Tangle

€10

Free STL file Triangular key・3D printing plan for download・Cults

"Candeeiro" FCP - Futebol Clube do Porto

2,50 €

"Candeeiro" SCP

2,50 €

M88 - Miguel Oliveira Logo

7. 68 €

68 €

M88 Led Lamp

4,80 €

nine0003 Spool HolderFree

DJI OM 4 SE Storage Box

Free

The best files for 3D printers in the Tools category

Hex key handle (metric)

€1.99

EEZYxyDRAW

Free

nine0003 Harbor Freight Hollow Punch Set Pegboard RackFree

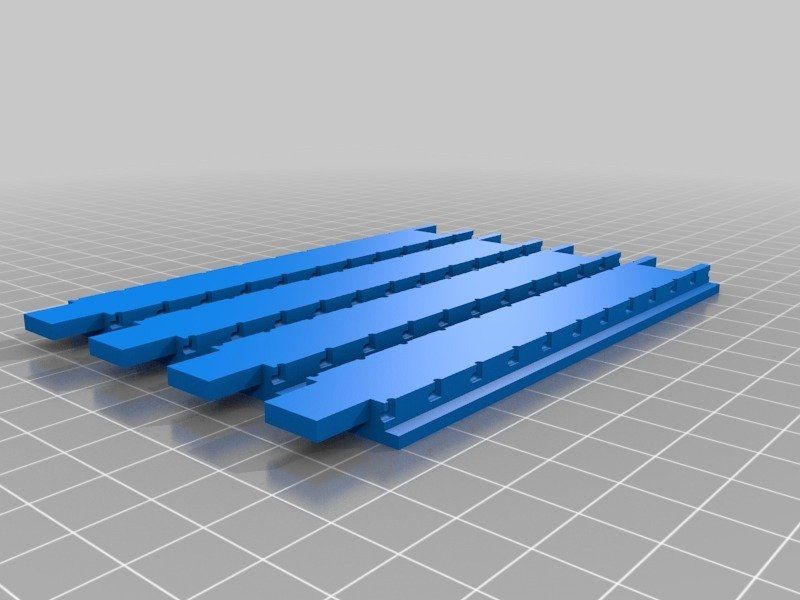

Tile crossbar 4mm

Free

Multi-Color Flexible Pliers

Free

Vernier - Pie de Rey - Rule

Free

HalloWing Mac M0

Free

nine0003 Mini Safe Cash Box with 3 Combination Lock and Hinge PrintFree

Bestsellers in the Tools category

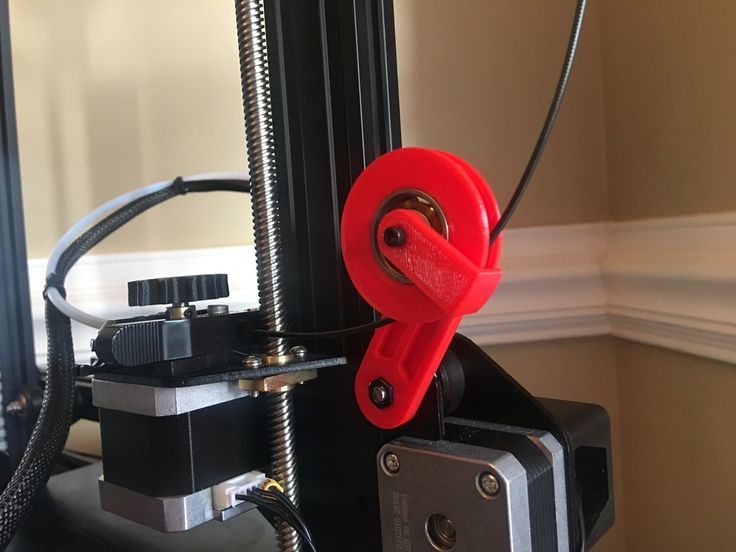

ENDER 3 S1/S1 PRO REEL HOLDER AND DEPORTED REEL

€2. -twenty% 1.70 €  12

12

Armadillo - flexible wire conduit

€1.68 -10% 1.51 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.82 €

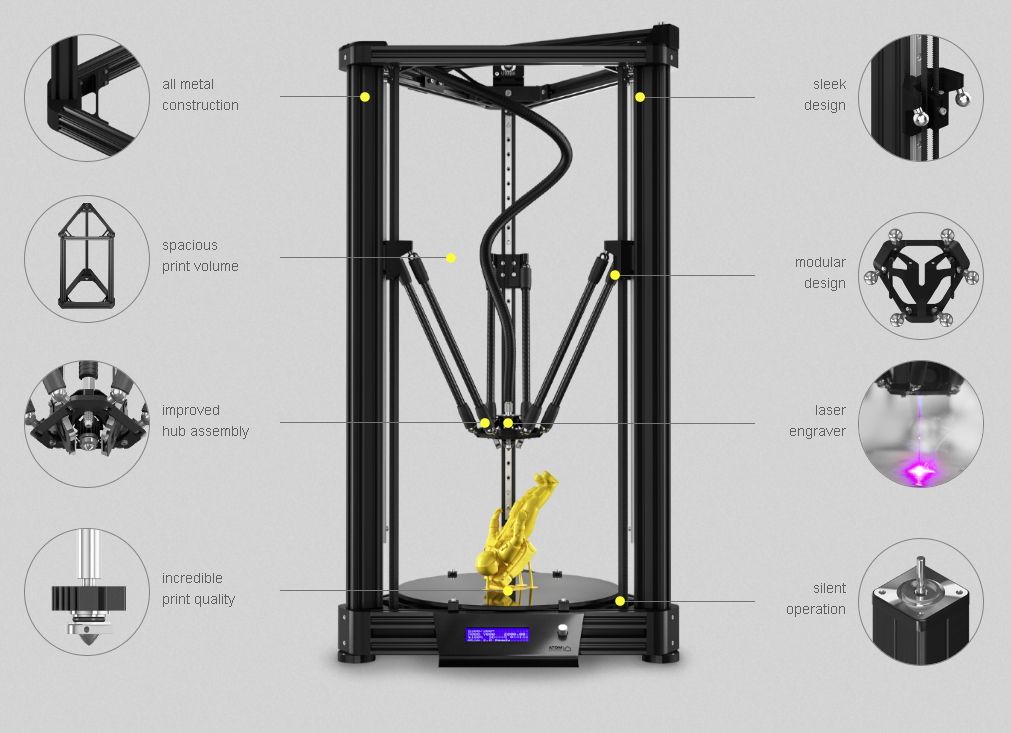

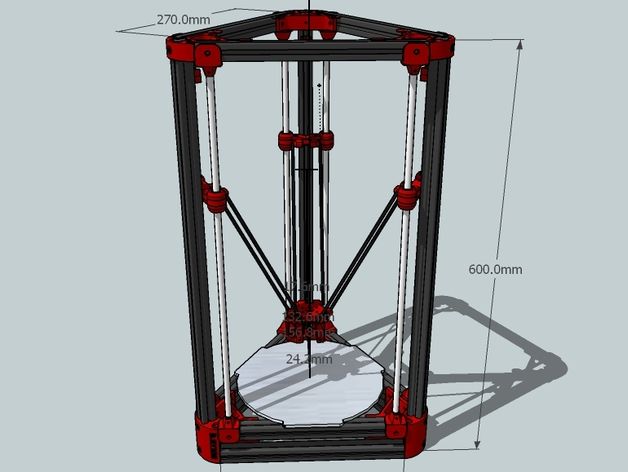

Display holder FLSUN v400

€9.99 -fifty% 4.99 €

Rapid print paint bottle rack (6 sizes)

2.84 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.73 €

Cooling system Minimus Hotend

€2. -10% 2.10€ 34

34

telephone ring holder

0,90 €

Ender 3 S1 pro fan duct 5015 4020

1,30 €

3D printed wave transmission (harmonic drive)

4.99 €

well designed: Hemera fan duct

2.50 €

nine0003 Case for Chill Buddy lighter0,93 €

Bit holder Spartan 4 mm Hex

1,80 €

SUPERBOX

1,50 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2. -twenty% 1.82 €  27

27

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

Stereolithography - what you need to know about the technology

Stereolithography - what you need to know about the technology

What is stereolithography? How it works? Where did this name come from? We cover all the basics of this impressive and outstanding technology, including pros and cons, comparisons and more!

What is stereolithography?

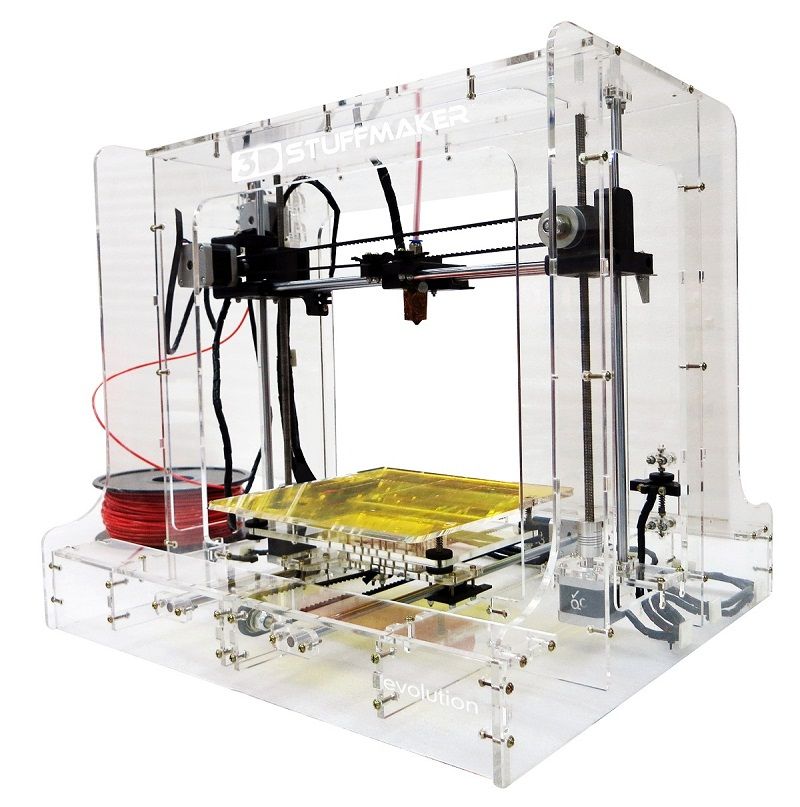

Stereolithography - more commonly referred to as SLA - is one of the most popular and widespread methods in the additive manufacturing world. The technology works by using a powerful laser to solidify a liquid resin that is contained in a tank to create the desired three-dimensional shape. In a nutshell, this process converts photosensitive liquid into three-dimensional solid plastics in stages using low laser power and photopolymerization. nine0006

The technology works by using a powerful laser to solidify a liquid resin that is contained in a tank to create the desired three-dimensional shape. In a nutshell, this process converts photosensitive liquid into three-dimensional solid plastics in stages using low laser power and photopolymerization. nine0006

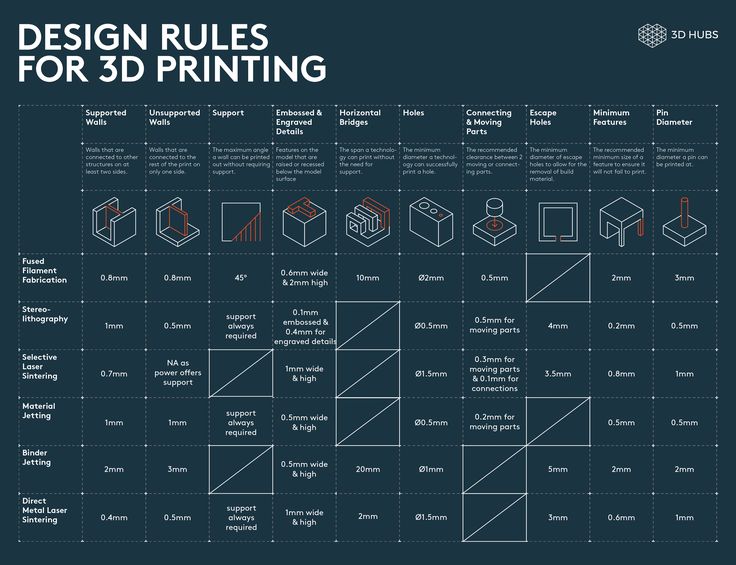

SLA is one of the three main technologies used in 3D printing, Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). It belongs to the category 3D printing resin. A similar technique, which is usually grouped with SLA, is called Digital Light Processing (DLP). It represents a kind of evolution of the SLA process, using a projector screen instead of a laser.

Stereolithography: history

Although SLA is less popular than FDM, SLA is actually the oldest additive manufacturing technology.

This method was developed by the American company 3D Systems, founded by Chuck Hull in 1986. In 1986, Hull coined the term "stereolithography". He defined this technology as a method of creating three-dimensional objects by successively printing thin layers cured with an ultraviolet laser.

He defined this technology as a method of creating three-dimensional objects by successively printing thin layers cured with an ultraviolet laser.

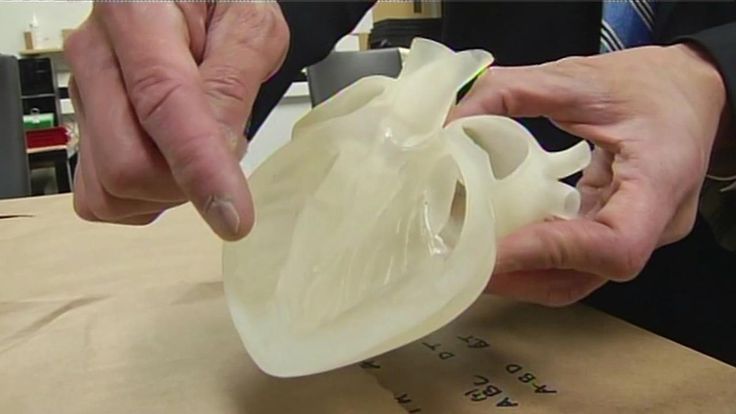

In 1992, 3D Systems created the world's first SLA machine, which made it possible to fabricate complex parts in seconds.

Stereolithography: Components

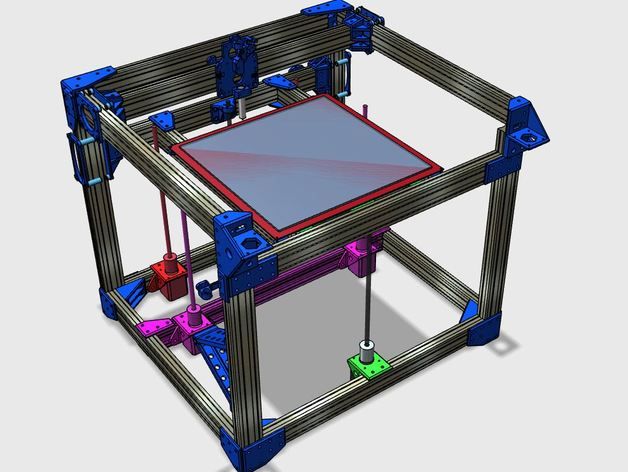

Each standard SLA 3D printer typically consists of four main components:

- Tank filled with liquid photopolymer. Liquid resin is usually a clear and liquid plastic.

- Perforated platform immersed in the tank: the platform is lowered into the tank and can move up and down according to the printing process. nine0161

- High Efficiency UV Laser

- Computer interface that controls both platform and laser movements

Stereolithography: how does it work?

Software

As with many additive manufacturing processes, the first step is to develop a 3D model through CAD software. The resulting CAD files are digitized representations of the desired object. nine0006

The resulting CAD files are digitized representations of the desired object. nine0006

If not automatically generated, CAD files must be converted to STL files. Standard Tessellation Language (STL) or "Standard Triangular Language" is a file format native to stereolithography software created by Abert Consulting Group specifically for 3D Systems back in 1987. STL files describe the surface geometry of a 3D object, ignoring other common CAD model attributes such as color and texture.

The preprinter step is for feeding the STL file to the 3D slicer software such as Cura. Such platforms are responsible for generating G-code, native language 3D printer .

SLA 3D printing

When the process starts, the laser "draws" the first layer of print into the photosensitive resin. Where the laser strikes, the liquid solidifies. The laser is directed to the appropriate coordinates using a computer mirror.

It's worth mentioning at this point that most desktop SLA printers work in reverse. That is, the laser points to the build platform, which starts low and gradually increases. nine0006

That is, the laser points to the build platform, which starts low and gradually increases. nine0006

After the first layer, the platform rises according to the thickness of the layer (usually about 0.1 mm) and additional resin can flow below the already printed part. The laser then solidifies with the next cross section and the process is repeated until the entire piece is complete. Resin that is not touched by the laser remains in the vat and can be reused.

Post-processing

After the material has cured, the platform is lifted out of the tank and excess resin is drained off. At the end of the process, the model is removed from the platform, rinsed with excess resin and then placed in a UV oven for final curing. Post-print curing allows objects to reach their highest possible strength and become more stable. nine0006

Alternative Process: Digital Light Processing

As we mentioned earlier, one of the descendants of SLA is Digital Light Processing (DLP). Unlike SLA, DLP uses a digital projector screen to flash one image of each layer across the entire platform. Since the projector is a digital screen, each layer will be made up of square pixels. Thus, the resolution of a DLP printer corresponds to the size of a pixel, while with SLA it is the size of a laser spot. nine0006

Unlike SLA, DLP uses a digital projector screen to flash one image of each layer across the entire platform. Since the projector is a digital screen, each layer will be made up of square pixels. Thus, the resolution of a DLP printer corresponds to the size of a pixel, while with SLA it is the size of a laser spot. nine0006

Stereolithography Pros and Cons

Pros

- SLA is probably the most accurate functional prototyping method on the market.

- Prototypes can be created to extremely high quality, with fine details (thin walls, sharp corners, etc.) and complex geometries. Layer thicknesses up to 25 µm can be achieved, with minimum dimensions ranging from 50 to 250 µm.

- SLA provides the most accurate dimensional tolerances of any rapid prototyping or additive technology: +/- 0.005" (0.127 mm) for the first inch and an additional 0.002" for each additional inch. nine0161

- Print surfaces are smooth.

- Build volumes can be up to 50 x 50 x 60 cm³ without sacrificing accuracy.

Cons

- The printing process is usually slow: depending on the size and number of objects created, the laser can take a minute or two for each layer. Large objects require long runs.

- Sharp corners and protrusions require structures to be supported during the printing process. Such parts can potentially break down during the printing or curing phase. nine0161

- Resins are relatively brittle and therefore not suitable for functional prototypes or mechanical testing.

- SLA offers a limited selection of materials and colors, typically offering black, white, gray and clear material.

- The cost of SLA printing is relatively high.

SLA vs. FDM

In FDM, fiber is fed through a hot extruder and deposited in stages. The materials used are usually thermoplastics, but they can be mixed with other elements including wood, metal and carbon fiber. This is one advantage over SLA, which has a limited selection of materials. nine0006

nine0006

The resolution of FDM depends on the size of the nozzle, as well as the accuracy of the motors in the X and Y axes. SLA usually creates objects with a higher resolution than FDM due to the small optical size of the laser.

Post-processing with 3D printed FDM includes removing supports (if necessary) and smoothing surfaces. In the case of SLA, an isopropyl alcohol bath removes excess sticky resin. In addition, the post-cure phase provides a higher strength of the photopolymerized object. (However, this still doesn't result in the object being mechanically strong or durable like FDM printing.)0006

Material cost for FDM is much lower because printers are more affordable and plastic spools are cheaper than resin.

In a nutshell, if high precision and a smooth finish are your priorities, SLA will be your best bet. If cost and (to a lesser extent) durability play a role, use an FDM printer.

SLA vs. SLS

Selective laser sintering (SLS) takes a completely different approach. Like SLA, it uses a laser but has higher power and is used to fuse fine powder. Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are similar methods but are optimized for metals and alloys instead of thermoplastics. SLS works primarily with nylon, polystyrene and other polymeric materials. nine0006

Like SLA, it uses a laser but has higher power and is used to fuse fine powder. Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) are similar methods but are optimized for metals and alloys instead of thermoplastics. SLS works primarily with nylon, polystyrene and other polymeric materials. nine0006

The main strength of SLS printing is their superior strength and durability. Also, they can be complex geometries that are not possible with SLA (or FDM). While SLS can produce prints with greater detail than FDM, they are not typically compared to the accuracy of SLA.

Thanks to their powerful lasers, SLS machines incorporate more advanced technologies, including special protection against harmful UV radiation. This results in printers costing more, with several desktop or desktop options available. nine0006

In addition, SLS powders are more expensive than liquid photopolymers.

In a nutshell, if your high mechanical strength and complex shapes are your priority and cost is of secondary importance, use the SLS printer.