How will 3d printing change our future

6 Ways 3D Printing will Change the World

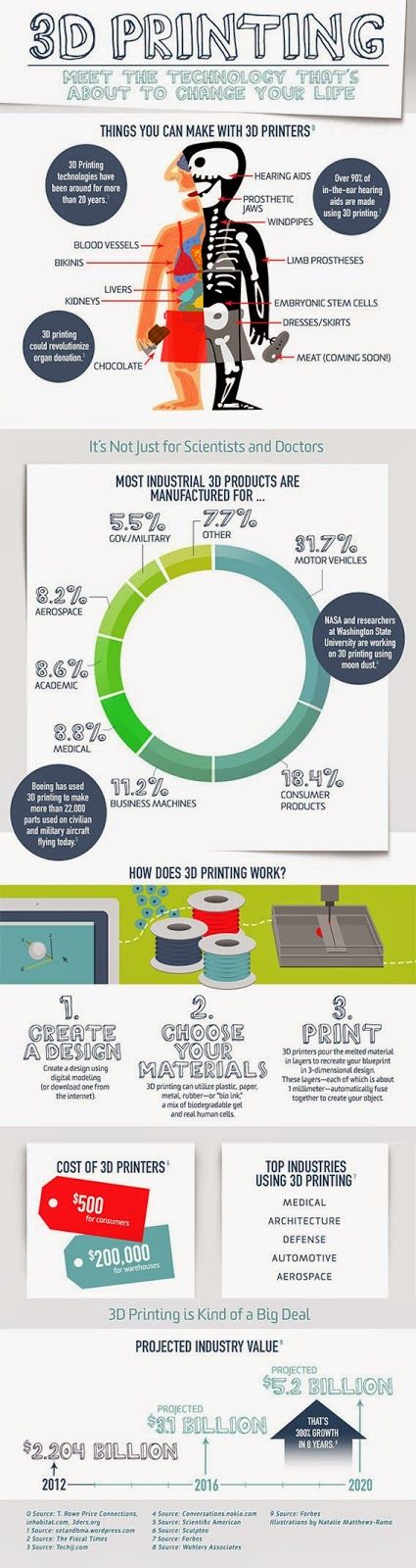

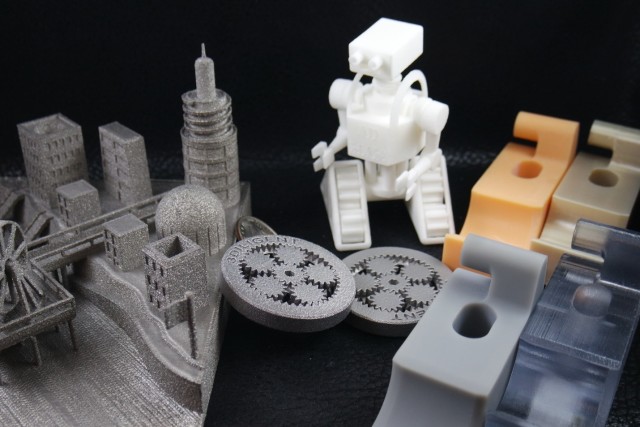

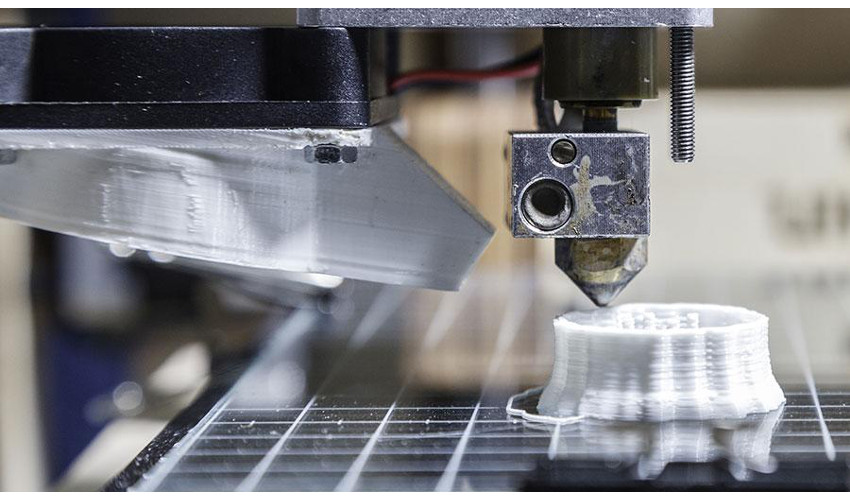

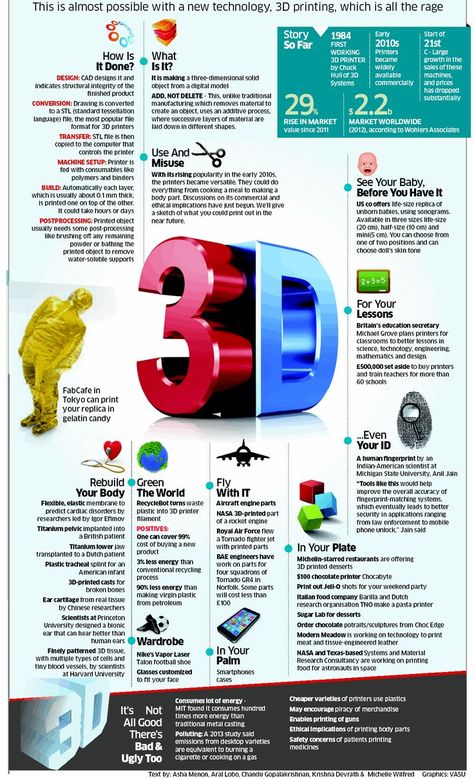

3D printing, or additive manufacturing, may not be making headlines like it was in 2013, but rest assured, the technology’s only been spreading and advancing over the past four years. The implications of 3D printing design are vast, and the technology has the potential to revolutionize our society.

Here are a few of the ways that 3D printing will change the industry, the economy, and the culture in the years to come.

1. Production will Take a Turn Towards the Local

Since the 1980s, corporate outsourcing has been a significant force driving change in the manufacturing industry. Large corporations often reduce costs by setting up factories in multiple companies to manufacture each sub-component of their end product.

With 3D printing, a company could manufacture a whole car in one place. 3D printing only requires a few employees, so labor laws will be less of a game-changer than they are with traditional manufacturing and its large labor forces. As the technology improves, it’ll become cheaper and more accessible for companies to manufacture their product close to home.

This would mean significant economic restructuring for China and other countries whose economies depend on being able to provide a cheap labor pool for manufacturing. They’ll have to find new forms of economic value-production to maintain their GDP.

If you’re looking to manufacture your invention locally with 3D printing, you’ll need to start with a CAD model and prototype. We can help with that. Contact us, and we’ll connect you with the best designers and 3D printers on the web to get your product out there.

2. The Medical World Will be Turned Upside-Down

From surgery to prosthetics to medications, 3D printing has the power to revolutionize the world of medicine.

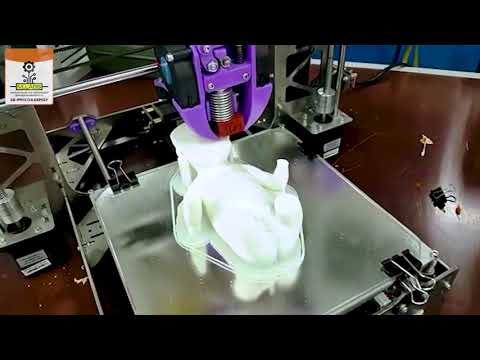

3D printing is already being used for prosthetics. Research firm Not Impossible Labs is already using the technology to print prosthetics for amputees in war-torn regions at a total cost of under $100. 3D printing could make prosthetics cheaper for everyone, changing the lives of amputees worldwide. 3D printing is also being used for surgery, with replicas of hearts and organs being used to help surgeons prep.

3D printing could make prosthetics cheaper for everyone, changing the lives of amputees worldwide. 3D printing is also being used for surgery, with replicas of hearts and organs being used to help surgeons prep.

Bioprinting, 3D printing that uses “ink” made of human cells and tissue, is making massive strides. Many tech and medical experts believe that 3D-printed internal organs will be in use for surgery by the year 2025. 3D printing has already been used to repair damaged bone and cartilage, with surgeons using the technology in 2014 to repair a man’s face after a road accident.

3D printed pills are already a reality, with Spiritam, a 3D printed anti-seizure medication, patented in 2015. 3D printed pills could be a cheap and practical way to make lifesaving drugs available worldwide.

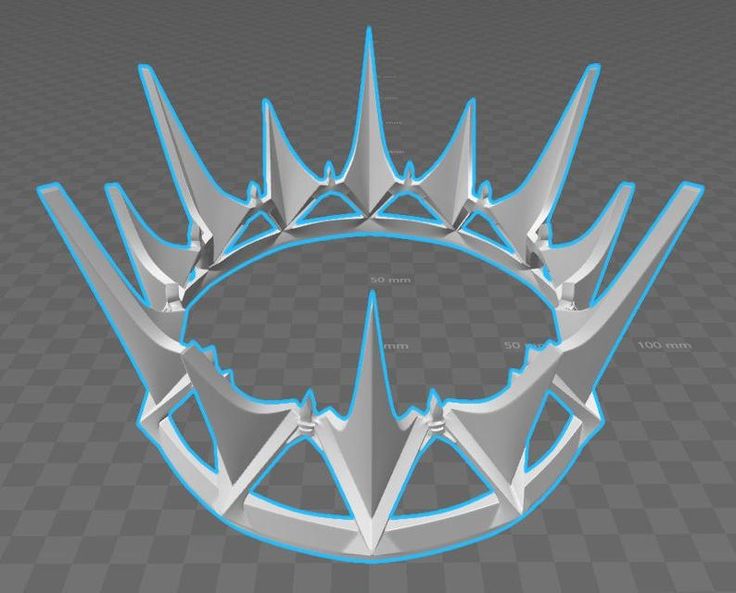

3. 3D Printing will Spark a Creative Renaissance

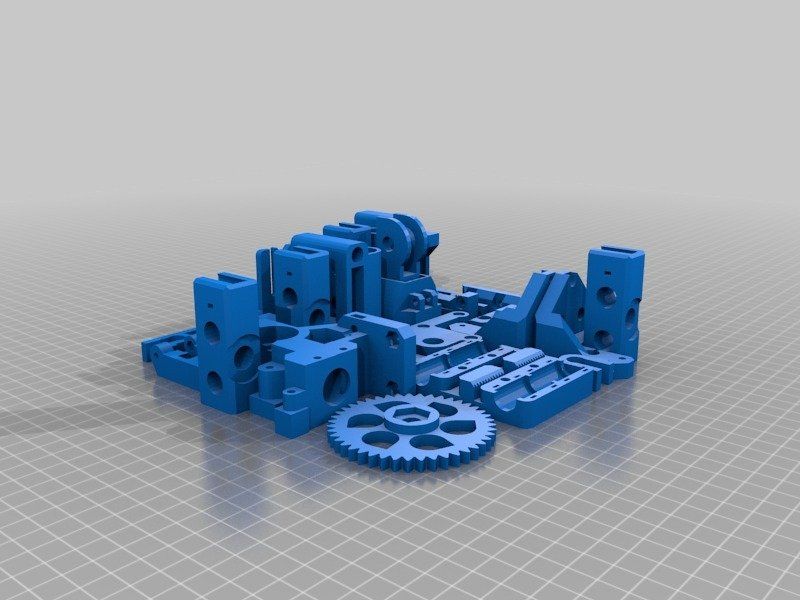

As 3D printing becomes more and more common, it’ll become more accessible and easier for inventors and creatives to turn their ideas into realities. 3D printing already makes it far easier for inventors to produce prototypes. In the future, the manufacturing process could be carried out by 3D printing as well. In a few decades, we might see the store shelves packed with a variety of 3D printed products that today would be unimaginable.

3D printing already makes it far easier for inventors to produce prototypes. In the future, the manufacturing process could be carried out by 3D printing as well. In a few decades, we might see the store shelves packed with a variety of 3D printed products that today would be unimaginable.

Are you an inventor trying to bring your product to the market? Contact Cad Crowd, and we’ll set you up with a 3D printing expert to help you produce your prototype.

4. 3D Printing Could Help Solve the Housing Crisis

Housing prices are skyrocketing across the West. Far fewer young people can afford to buy homes than their parents, and many people have difficulty even affording rent. 3D printing could help address that. A Chinese company called Winsun offers 3D houses built entirely out of recycled materials, which cost less than $5000 to produce. Their process uses “ink” made from fiberglass, steel, cement, binder, and recycled rubble. They’ve already built housing in China, have recently expanded to Saudi Arabia, and plan on expanding to twenty other countries over the next few years. 3D printing allows home builders to save on transportation costs, building materials, and labor costs. The cities of the future may be built through 3D printing!

3D printing allows home builders to save on transportation costs, building materials, and labor costs. The cities of the future may be built through 3D printing!

5. New Kinds of Crime Will Emerge

When 3D printers become a household item, digital piracy may spread from the media world to the general marketplace. Why buy an iPhone when you can buy some metal, plastic, and silicone “ink” for far less and print one yourself? This level of precision is well beyond the capability of the average 3D printer today, but that may no longer be the case in ten or twenty years. The digital pirates of the future may be sharing CAD files rather than media torrents.

3D printing will complicate gun registration. 3D-printed firearms are already a reality and will only improve in performance and practicality as time goes on. How will state governments regulate the sale and traffic of firearms when anybody with a modem and printer can make their own?

This could be a problem across the black market. If 3D printing medications become a reality, expect 3D printed illegal drugs to follow on their heels.

If 3D printing medications become a reality, expect 3D printed illegal drugs to follow on their heels.

This may sound bleak, but luckily, there’s a major upside to 3D printing that could help offset the dangers…

6. 3D Printing Could Save the Environment

3D printing will make it easier to produce goods locally, which dramatically reduces fuel costs. Faster production of goods may help curb the use of fossil fuels, perhaps even preventing the worst excesses of climate change.

With 3D printing, we’ll be able to step up our recycling game. Plastics, metals, and paper will become the “ink” used by printers, a process that uses less energy than conventional recycling.

Additionally, by its very nature, 3D printing produces less waste than conventional manufacturing. 3D printing is known as additive manufacturing, where an object is created by adding layer after layer of material to a previously empty space. Traditional manufacturing is a subtractive process, where the manufacturer starts with a block of material and carves away at it to produce the product. The latter produces far more waste, which will be eliminated by switching to 3D printing.

The latter produces far more waste, which will be eliminated by switching to 3D printing.

Finally, 3D printing can help study the process of environmental degradation. Researchers at the University of Sydney have produced a 3D model of the Great Barrier Reefs to help model how these natural structures are being impacted by climate change. This could be used to support the reefs recover from bleaching and storms.

Want to be part of the 3D printing revolution? Get in touch for your free consultation and we’ll connect you with the best modelers and 3D printing freelancers on the web!

How 3D Printing Could Revolutionize the Future of Development | by +SocialGood

By Annie Rosenthal as part of the 2018 +SocialGood series on emerging technologies

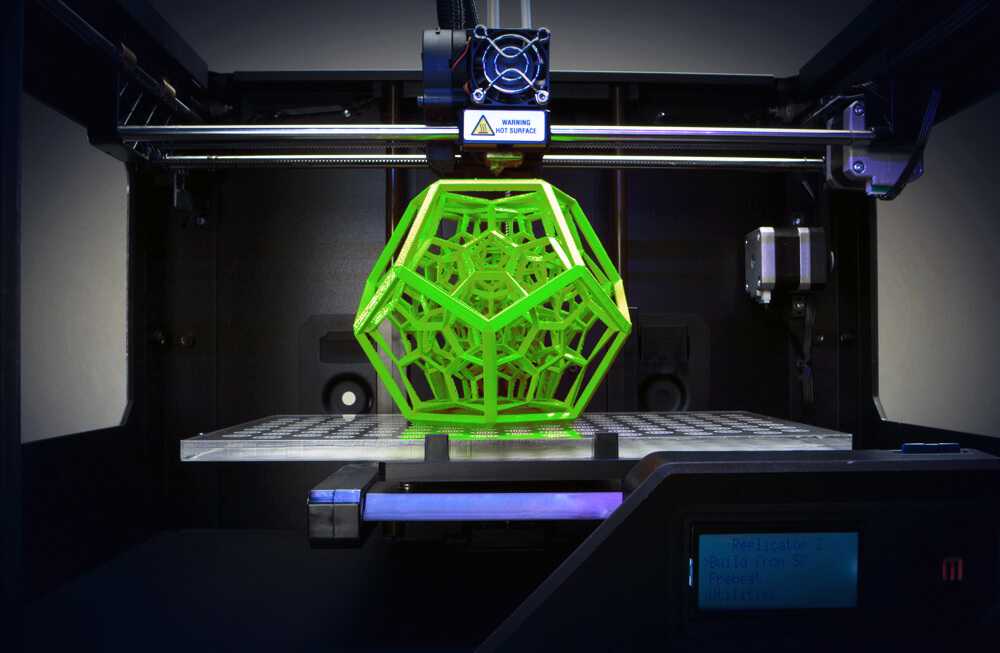

3D printing, or additive manufacturing, has the potential to democratize the production of goods, from food to medical supplies, to great coral reefs. In the future, 3D printing machines could make their way into homes, businesses, disaster sites, and even outer space. Get 3D printing basics from this 2 minute Mashable video.

Get 3D printing basics from this 2 minute Mashable video.

As this technology spreads, it could help connect marginalized and difficult-to-reach populations with essential products. All in all, this emerging technology has the potential to revolutionize our societies, and transform the development sector. In order for this to happen, we need to ensure that this emerging technology gets into the hands of development practitioners and stakeholders around the world. Here is one way that people are working to make 3D printing more accessible.

Like content on the top technologies and how they can be used for social good? Get updates about 3D printing and more with the +SocialGood newsletter.

The Sustainable Development Goals carry a big promise for the future of our people and planet. Goals this big will need big changes in order to succeed. 3D printing is being used to progress many of the Global Goals, and has the potential to make a further impact.

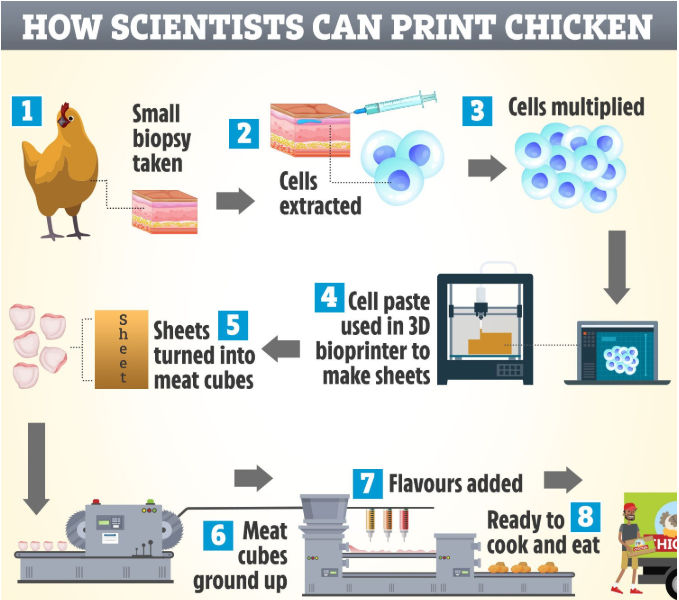

Supporting the fight against hunger and homelessness

3D printing is being explored as a major solution for current and future levels of hunger and homelessness. For example, Anjan Contractor hopes that one day, his 3D food printer will be able to empower the earth’s population to feed themselves “customized, nutritionally-appropriate meals synthesized one layer at a time, from cartridges of powder and oils they buy at the corner grocery store.” These cartridges would be easy to transport, long-lasting, and could be made of sustainable materials like insect protein. 3D printing is also revolutionizing home construction, making it cheaper and more efficient.

For example, Anjan Contractor hopes that one day, his 3D food printer will be able to empower the earth’s population to feed themselves “customized, nutritionally-appropriate meals synthesized one layer at a time, from cartridges of powder and oils they buy at the corner grocery store.” These cartridges would be easy to transport, long-lasting, and could be made of sustainable materials like insect protein. 3D printing is also revolutionizing home construction, making it cheaper and more efficient.

- This 3D printing technology uses industrial solid waste to replace cement in the production of a low-carbon building (Sustainia)

- How 3D printing could end food waste and tackle hunger (Quartz)

- This 3D printer can print a house in less than 24 hours

Transforming humanitarian response and modern medicine

3D printing also is being used to get essential goods and services to disaster areas and refugee camps, allowing workers and stakeholders to have access to the tools they need to recover. For example, in Nepal, the United Nations is implementing 3D printing as part of their plan for earthquake response, including printing customized pipe parts necessary for sanitation infrastructure. 3D printing is also enabling new and essential medical tools to get into the hands of people who need them, from medical possibilities like an 3D printed artificial heart to basic tools like umbilical cord clips.

For example, in Nepal, the United Nations is implementing 3D printing as part of their plan for earthquake response, including printing customized pipe parts necessary for sanitation infrastructure. 3D printing is also enabling new and essential medical tools to get into the hands of people who need them, from medical possibilities like an 3D printed artificial heart to basic tools like umbilical cord clips.

- The future of medicine is 3D printing (Futurism)

- How 3D printing is being used to transform aid (World Economic Forum)

- Tech eases Syrians’ trauma in Jordanian refugee camp (BBC)

Protecting our planet

3D printing is also allowing us to use old materials in new ways that are more sustainable. For example, researchers have figured out how to convert carbon dioxide into concrete using 3D printing. Utilizing former waste to create future products makes our society have more efficient consumption. 3D printing innovators are even exploring how to make the process itself more sustainable, including using algae based filaments to reduce the energy necessitated for the printing process. The creative use of materials and production methods opens up new possibilities as we approach climate action and sustainable living.

The creative use of materials and production methods opens up new possibilities as we approach climate action and sustainable living.

- Fred the tortoise had his damaged shell replaced by a 3D printed shell made of corn plastic (Futurism)

- These 3D printed shoes are made from plastic ocean waste (Sustainia)

- Engineers are 3D printing coral reefs to help save our oceans (Futurism)

Ensuring access

The United Nations is working with innovators and programmatic implementers to make this transformative technology more accessible to people worldwide. Currently, they are mostly confined to technical university and specialized labs, especially in developing countries. However, in order for the true possibilities of the technology to be realized, it must be brought outside those spaces and into the hands of stakeholders and local changemakers. United Nations agencies, like UNICEF, are using their reach and resources to help make this a reality. Check out UNICEF’s Innovation Fund here.

Check out UNICEF’s Innovation Fund here.

- UNDP Egypt hosted a ‘how to build a 3-D printer’ workshop to make the technology more affordable and accessible locally (UNDP)

- Why it’s important to bring 3D biofabrication and other health technologies to the most disadvantaged (UNICEF Innovate)

- UNDP Uzbekistan named a 3D printing startup the number 1 project during their ‘Startup Initiatives — 2017" programme (UNDP)

Join +SocialGood throughout May as we explore the opportunities 3D printing presents to help progress the Global Goals. Share your thoughts, solutions, and ideas with #SocialGoodTech!

Stay-tuned for our #SocialGoodTech Twitter chat on 3D printing for the Global Goals! Join the conversation at 10am ET on May 31st.

what lies ahead for 3D printing

The prospects for 3D printing

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful. nine0005

Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful. nine0005

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

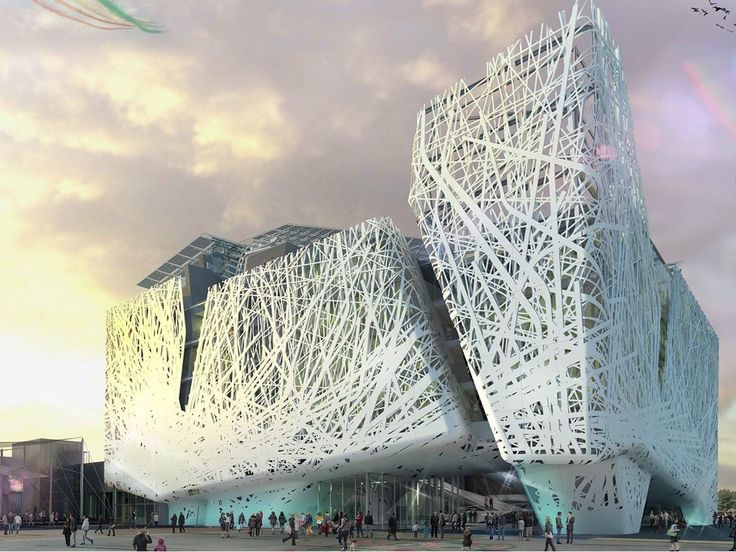

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer; nine0014

- Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason. Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry.

The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0014

The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars. nine0014 - Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

- Food industry. 3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent.

This is confirmed by the amazing 3D-printed desserts of our compatriot. nine0014

This is confirmed by the amazing 3D-printed desserts of our compatriot. nine0014

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

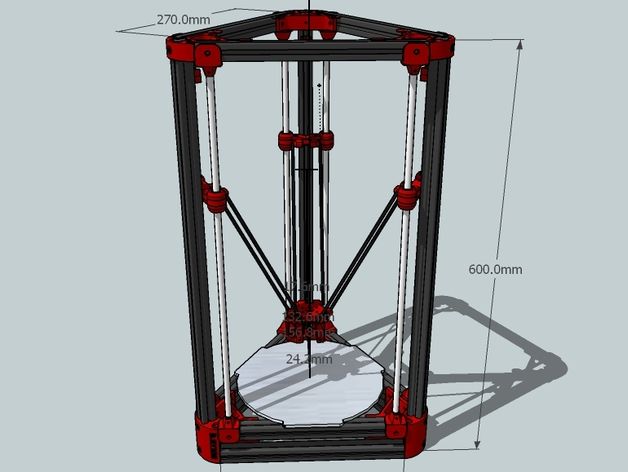

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of devices. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors; nine0014

- Large-scale distribution. It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more and more users learn about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability.

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0014

In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices; nine0014 - Enlargement of the construction area. 3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

- Expanding the range of available materials. The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing. nine0014

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0005

These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth. nine0005

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ). We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating! nine0005

We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating! nine0005

Back to main page

what industries will 3D printing change in the coming years

Progress, as you know, goes in a spiral, each of the turns of which is marked by a fundamental change in the approach to production, which immediately affects the volume of products, their quality and accessibility to the consumer.

Once upon a time, people began to use steam engines in factories, then they began to massively use electricity, and even later they invented conveyor production. At each of these stages, the production culture made a sharp leap in an effort to meet the growing needs of consumers. nine0005

Today, the factor that gave a new impetus to progress has been the spread of digital technologies - technologies of 3D modeling, 3D scanning, 3D printing and robotics. Digital technologies are changing the very concept of production, making it cheaper, more accurate, faster and more convenient.

Digital technologies are changing the very concept of production, making it cheaper, more accurate, faster and more convenient.

Medicine

There is nothing more important than health, and today digital technologies are becoming indispensable in this area. 3D modeling and 3D printing are successfully used in a field where an individual approach and strict compliance of the created object with the patient's anatomy is especially important. nine0005

Implants are already being produced this way to replace affected bones and joints

By scanning the area of intervention and combining data with computed tomography, doctors can design and print the desired implant with sub-millimeter accuracy. After that, the correctness of the geometry of the resulting implant is checked and preparations are made for the operation on a 3D model printed from the patient's tomography.

Such technologies have been used all over the world for several years, and now in Russia. nine0005

nine0005

Also, affordable bionic prostheses have been created for several years, giving new opportunities to people with amputated limbs.

And not only for people.

Doctors print individual splints, orthoses and splints that fix limbs in the treatment of fractures - they are much more convenient to use and comfortable for the patient than traditional gypsum. One of the domestic projects that manufacture such fixing limbs is Zdravprint. nine0005

New 3D technologies are also used in dentistry and maxillofacial surgery. They allow you to plan and carry out treatment, as well as design and create individual prostheses and temporary crowns of both individual teeth and entire jaw fragments.

How does this happen:

- Combines a 3D scan of the patient's jaw with CT scan data for highly accurate planning of implant placement based on the patient's bone quality, nerve and artery location.

nine0014

nine0014 - Determine the size and shape of the implant and the required angle of insertion.

- Based on these data, a surgical template is printed on a 3D printer, which does not allow medical error when installing an implant during surgery.

- A temporary crown is printed or milled for proper soft tissue healing for the postoperative period.

- A permanent metal-ceramic crown made of a biocompatible metal (titanium or cobalt-chromium) is printed or milled. nine0014

3D printing is also used in orthodontics. With its help, aligners are created - devices that correct the bite, which replaced uncomfortable and traumatic braces.

This method is gaining momentum around the world, and I decided to test one of them for myself. solutions. Aligners are almost invisible, but they do correct the position of the teeth.

But the most anticipated in medicine is, of course, the printing of living organs. Many people know about the 3D printed ear; work is underway with muscle, liver and skin cells. In the future, such technologies will make it possible to fully restore damaged or lost tissues and organs. nine0083

In the future, such technologies will make it possible to fully restore damaged or lost tissues and organs. nine0083

By the way, at Skolkovo there is a startup 3D Bioprinting Solutions, well-known in medical circles, which managed to print the mouse thyroid gland. This is the first step towards making living organs for human transplantation.

Jewelery

Digital technologies are used in the production of jewelry, bijouterie and accessories. Three-dimensional modeling allows you to create an accurate digital layout of the future product and print a prototype first, giving the master the opportunity to hold and refine the product in advance. nine0005

After that, a model is printed or milled from lost wax or photopolymer, which is poured with plaster to obtain an injection mold and burns out (melted) during the pouring process, allowing the metal to fill the mold and accurately repeat the slightest nuances of the future product.

The process itself looks like this:

There are already 3D printers that print directly with precious metals, but so far the price of powder for such machines is too high for permanent use. nine0005

nine0005

Engineering

Engineering has long used digital technologies such as CAD 3D modeling, 3D scanning and 3D printing. New the trend is the use of industrial robots and automatic machines.

For example, 3D scanning is used in quality control, and 3D printing is used, along with automated milling and turning machines in production shops.

There are already industrial printers capable of creating impressive 3D shapes. The 3D printer shown in the photo above can print objects several meters in diagonal. nine0083

The day is not far off when a project created by engineers, presented in digital form, will be fully implemented by industrial robots.

Automotive

First of all, this is the creation of CAD 3D models and prototyping. Now this symbiosis has reached a new level - from design bureaus to production. Global robotization begins just with the automotive industry, and the army of robots, not yet without the help of people, is already assembling cars in factories. This is what it looks like at the Tesla Factory:

This is what it looks like at the Tesla Factory:

There are already frames and bodies completely printed on a 3D printer.

This also applies to tuning - moldings, spoilers, decorative elements, wheel covers. What can we say about individual small elements - functional details and design details, many of which can be printed on a small household printer.

3D scanning is also used in repairs, it allows diagnosing deviations in body geometry with high accuracy and easily creating models for subsequent printing of replacement elements. nine0083

With the development of 3D printing technology, which allows complex functional parts to be printed from various materials, fully printed cars may appear, each part of which will be created by a 3D printer.

Construction

All over the world, experiments are underway on the use of 3D printing in construction. In this area, technology is used both in design, where industrial 3D scanners and special programs, and directly in the creation of objects. nine0005

In this area, technology is used both in design, where industrial 3D scanners and special programs, and directly in the creation of objects. nine0005

Special building 3D printers print modular blocks and entire buildings out of concrete. In Russia, one of the pioneers of construction 3D printing was the Spetsavia company, which has already built several objects using this method.

Construction 3D printing allows you to create objects of unusual and non-standard shapes that are inaccessible to conventional serial construction. At the same time, the production takes place from standard mixtures with the use of reinforcement.

Aggregates may soon appear that in a matter of hours will print, for example, a small cottage - from the foundation and communications to the weather vane on the roof. nine0005

Architecture and layout

Gone are the days when architects had to get their hands dirty with glue and breathe in the fumes of foam plastic cut with hot wire to create models of buildings. More and more space is occupied by software and technical devices that make it much more convenient and faster, and most importantly, more accurate to create layouts of future objects.

More and more space is occupied by software and technical devices that make it much more convenient and faster, and most importantly, more accurate to create layouts of future objects.

3D printers are able to print parts or whole layouts, depending on the size, with a precision that no one has dreamed of before. The slightest architectural elements are visible on them as clearly as on already built buildings. The cost of the layouts themselves becomes lower, and the speed of production is higher. nine0083

There are technologies that allow you to print immediately in color, not only from plaster or paper, but also from composite plastic, which makes it possible to print with gradients and with varying degrees of transparency.

These technologies are also used by amateurs whose hobby is the creation of miniatures. For example, scale models of various equipment, both bench and functional.

Soon mockups and models will be indistinguishable from real objects. Apart from the obvious difference in size, of course. nine0083

Apart from the obvious difference in size, of course. nine0083

Education

Not so long ago, a new subject appeared in schools - technology. As part of this discipline, students study digital production. Including 3D printing and scanning, creating 3D models.

Moscow has a FabLab at MISiS, created in collaboration with the Massachusetts Institute of Technology; there are two of them in St. Petersburg: FabLab Politech and FabLab Spb.

TsMITs (Centers for Youth Innovative Creativity) are similar formations that are not directly related to the FabLab network, there are even more of them. nine0005

All these educational institutions make full use of the latest advances in 3D technology - 3D printers and scanners, 3D pens and other equipment.

In the near future, the network of WACs will grow, and they will become an integral element of education. We can expect the emergence of such organizations in every locality and every district of a large city, which will ensure the growth of the technical education of the population and the speedy development of technologies and business segments related to this area. nine0083

nine0083

Household and service sector

3D printing is ideal for creating all sorts of useful little things for the home.

It is good for printing spare parts for broken household appliances, furniture fittings and much more.

You can create a toy for a child from scratch or download a 3D model from the Internet and make it unique in the editor program.

Such a toy at cost will be cheaper than purchased and much more interesting for the child, since he will be involved in the process of its creation. nine0083

Having bought a 3D printer, parents can print at least a few different toys a day: from simple to the most complex and educational - fortunately, thousands of models are already available for free downloads.

You can decorate your home with a figurine of a loved one or yourself - the service of scanning and printing a 3D portrait, both bust and full-length, is already available. Including full color.

New ones are constantly being developed 3D printing materials with all sorts of mechanical and aesthetic properties, and 3D printers and consumables are constantly getting cheaper. In a few years, such a device may become an integral part of almost every home, as TV is now. And no wonder - the usefulness of this device in everyday life is difficult to overestimate. nine0005

Food

There are several mass-produced and fairly popular 3D food printers. Some of them print candies of any given shape from a special consumable. Such devices are almost no different from conventional 3D printers. There are also more specialized tools.

For example, the English Choc Creator prints with chocolate both flat pictures (for example, for decorating cakes) and three-dimensional objects.

The design allows you to load several different ingredients into it and get a variety of dishes at the output. Fish 'n' chips, for example:

Or useful vegetable dinosaurs:

There is also a special pancake printer that allows you to print pancakes and pancakes of any shape. By the way, it is relatively inexpensive and easy to use. In the photo, Pancake Bot is preparing a pancake in the form of an astronaut and our logo. nine0005

The technology for creating 3D food printers is improving. It can be assumed that in the near future there will be inexpensive and widely available kitchen 3D printers, both specialized and universal, ideally combined with a food processor and oven.

Total

As we can see, digital production technologies have spread to all areas of human activity. This is not surprising given their usefulness and relative ease of working with them.