How to make 3d printed shirts

3D Print A Custom T-Shirt Design, Step-by-Step

- by: Donald Papp

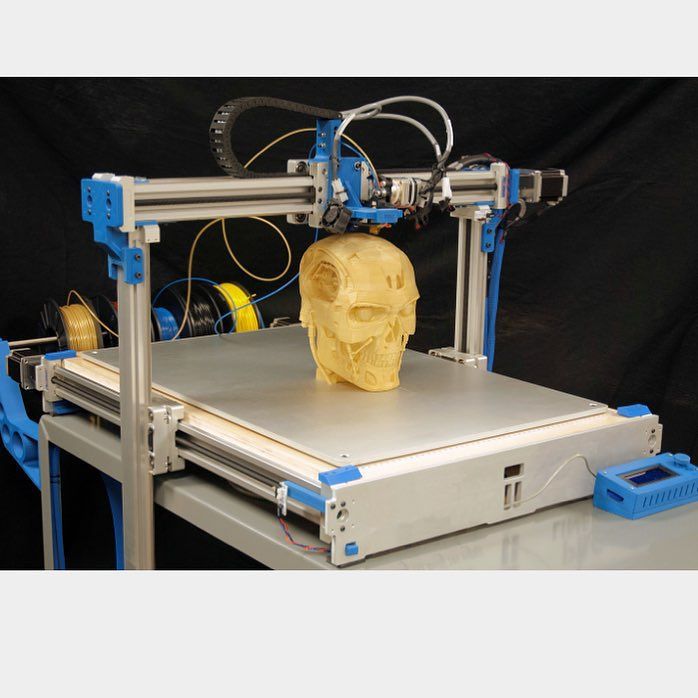

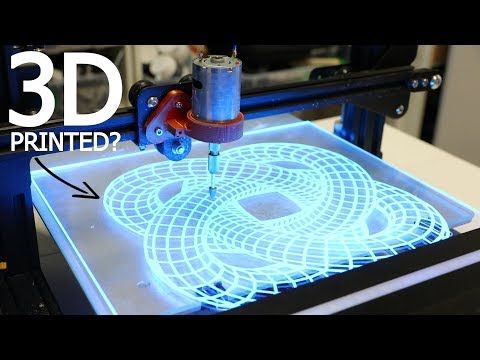

Want to make a t-shirt with a custom design printed on it? It’s possible to use a 3D printer, and Prusa Research have a well-documented blog post and video detailing two different ways to use 3D printing to create colorful t-shirt designs. One method uses a thin 3D print as an iron-on, the other prints directly onto the fabric. It turns out that a very thin PLA print makes a dandy iron-on that can survive a few washes before peeling, but printing flexible filament directly onto the fabric — while more complicated — yields a much more permanent result. Not sure how to turn a graphic into a 3D printable model in the first place? No problem, they cover that as well.

Making an iron-on is fairly straightforward, and the method can be adapted to just about any printer type. One simply secures a sheet of baking paper (better known as parchment paper in North America) to the print bed with some binder clips, then applies glue stick so that the print can adhere. A one- or two-layer thick 3D print will stick to the sheet, which can then be laid print-side down onto a t-shirt and transferred to the fabric by ironing it at maximum temperature. PLA seems to work best for iron-ons, as it preserves details better. The results look good, and the method is fairly simple.

Direct printing to the fabric with flexible filament can yield much better (and more permanent) results, but the process is more involved and requires 3D printing a raised bed adapter for a Prusa printer, and fiddling quite a few print settings. But the results speak for themselves: printed designs look sharp and won’t come loose even after multiple washings. So be certain to have a few old shirts around for practice, because mistakes can’t be undone.

A very thin 3D print makes a decent iron-on that survives a few washes. A 3D-printed bed adapter enables direct printing onto fabric for better results.That 3D printers can be used to embed designs directly onto fabric is something many have known for years, but it’s always nice to see a process not just demonstrated as a concept, but documented as a step-by-step workflow. A video demonstration of everything, from turning a graphic into a 3D model to printing on a t-shirt with both methods is all in the short video embedded below, so give it a watch.

A video demonstration of everything, from turning a graphic into a 3D model to printing on a t-shirt with both methods is all in the short video embedded below, so give it a watch.

With Halloween coming up, here’s a reminder that 3D printing onto fabric can go interesting places with costume design, and this 2020 Remoticon presentation goes into all the nitty-gritty details of how to make that kind of approach work.

t-shirt, art, custom design, fabric, iron-on

t-shirt, art, custom design, fabric, iron-on How to 3D Print Directly onto T-Shirts

Print a 3D logo on your t-shirt! You can 3D print directly onto a t-shirt with your home printer using standard PLA, ABS or other regular filament.

What do you need?

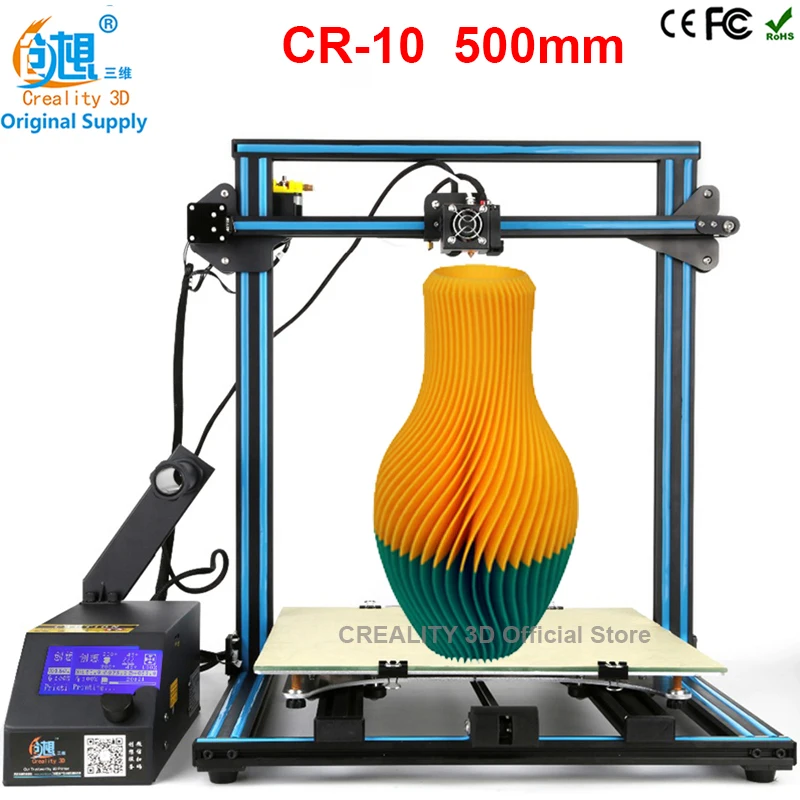

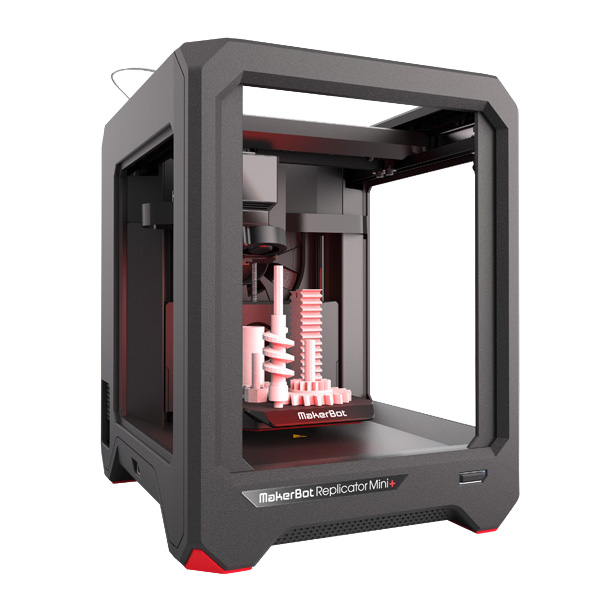

Standard 3D printer using regular PLA or ABS filament. We used an Ultimaker 2 with a heated bed and a Zeepro Zim, without a heated bed.

T-shirt. Cotton, polyester, or blends. Large surface decorations will interfere with the extruder.

Small clips. We recommend you use plastic clips or small clothespins. You don’t want anything that will scratch your build plate and you also want small clips so they won’t hit the sides of the printer when the build plates moves.

3D model. We used Tinkercad and prints downloaded from the Thingiverse.

Software for slicing. We used Cura.

Fabric glue (optional). Flexible fabric glue such as Fabri-tac or Jewel-it

Step 1:

Select your model. The size of your design will depend on your printer capacity. Individual designs up to about 4 inches square and arrays of geometric shapes are good choices. Large designs with no spaces between the elements will not be flexible.

Step 2:

Slice your model and convert to gCode. We’ve found that between 15-30% infill is adequate for most models.

Step 3:

Place one side of your shirt on the build plate. Smooth the fabric on the build plate and use numerous clips to hold the fabric taut at the middle and corners. Wrinkles in the fabric will interfere with the print. Watch out for cables and other moving parts and check that the clips won’t hit the extruder. Be sure you are only printing on one side of your shirt, not both the front and back.

Step 4:

Start your print. Watch the printer for the next couple of layers to be sure the extruder head isn’t pulling the fabric too much. Be careful when adjusting anything on the build plate, the extruder head is hot!

Be careful when adjusting anything on the build plate, the extruder head is hot!

Step 6:

Wait.

Step 7:

Hooray your print is done! Wait for the build plate and nozzle to cool and carefully remove your shirt.

Step 8:

Optional reinforcement with fabric glue. Your design is not permanently affixed to the t shirt and with enough effort you can peel it off the fabric. To be sure your print sticks you can reinforce it with fabric glue in two ways. On the inside of your shirt cover the backside of the print with enough fabric glue to permeate your fabric and stick to the print of the front. On the outside of your shirt you can also use a fine tip to spread a thin layer of glue along the edges of the print where it meets your t shirt fabric.

Want to see projects that use 3D printing on fabric?

Come to Hal Rodriguez’s Show and Tell at the Bay Area Maker Faire – Saturday in the Show and Tell Area

Want to find out about Electronics for Clothing and Costumes?

Come to Sahrye Cohen’s talk at the Bay Area Maker Faire on Sunday, 5/22/16, 2:30 PM-2:55 PM, Location Zone 2: Make Electronics

3D T-shirt technology

A feature of T-shirts with a 3D pattern is the high realism of the image. Thanks to three-dimensionality, any pattern on a T-shirt looks bright, extravagant, unusual and stylish. There are a huge number of 3D printed t-shirts on sale on a wide variety of topics - animals, landscapes and nature, fantasy, space theme, heroes of popular cartoons, movies and computer games, famous football players and much more.

Thanks to three-dimensionality, any pattern on a T-shirt looks bright, extravagant, unusual and stylish. There are a huge number of 3D printed t-shirts on sale on a wide variety of topics - animals, landscapes and nature, fantasy, space theme, heroes of popular cartoons, movies and computer games, famous football players and much more.

However, few people think about how T-shirts with a 3D pattern are created, what technologies and equipment are used for this.

At its core, three-dimensional images on T-shirts are pre-prepared drawings that have been transferred to the fabric in one way or another. For example, using the well-known thermal application method. Now the technology of creating T-shirts with a three-dimensional pattern using special holographic polymer materials is actively developing. This technology involves the use of ready-made holographic patterns that are transferred to the fabric by means of a relief press.

However, two methods of 3D printing on fabrics are still much more common:

- Textile printer.

The three-dimensional image is transferred to the T-shirt directly, in finished form;

The three-dimensional image is transferred to the T-shirt directly, in finished form; - Thermal application. A pre-prepared three-dimensional pattern is transferred to the fabric using a special heat press, under high temperature.

The use of a textile press is justified and convenient if you need to apply images to a small batch of T-shirts, up to several pieces. Since the application of one drawing takes quite a long time. The thermal transfer method (thermal application) is suitable for the production of large batches. In addition, thermal transfer allows images to settle very tightly on fabrics and remain in their original form for a long time.

The thermal transfer of three-dimensional images is very similar to the method of applying an image to T-shirts familiar to many people using special patterns and an iron. In Soviet times, you could find ready-made drawings in stores that were applied to a T-shirt or any other fabric, and the reverse side was intensively heated with a hot iron.

The modern method of printing 3D images using thermal application uses a special thermal transfer film, on which a previously prepared three-dimensional image is already located. This film is placed on a T-shirt with a pattern down, and then all together is placed under a heat press, where it is heated for 10-20 minutes at a temperature of about 160-180 degrees.

Equipment for creating 3D printed T-shirts

To transfer 3D images onto fabric, the following equipment is required:

- a special computer program for creating 3D images;

- high-quality home or industrial heat press;

- printer for printing images.

To create a T-shirt with a three-dimensional pattern, you must first create a suitable image in the computer, and then transfer it using an inkjet printer to a special thermal transfer film. And the film can, in turn, be applied to a T-shirt and then placed under a heat press.

To create a high-quality and washable pattern, you should approach the thermal transfer of the image as carefully as possible. If all procedures are followed with accuracy, then the output will be a T-shirt with an interesting original pattern. In this way, you can create an almost unlimited number of T-shirts with unique three-dimensional patterns.

logo printing on 3d t-shirts

-

Online editor

from 1 390 RUB

- Synthetics -360 RUB

- Cotton +360 RUB

- Available sizes

- Lookbook

Available materials

4 easy steps to place an order

Easy and fun process - won't take long

-

Choose from a full print T-shirt or other product

-

Add an image and / or text in a convenient graphic editor

-

Click "Buy" to place an order

-

In the comments, indicate the number of goods and other wishes

Full print t-shirt reviews

See also

Popular full print men's t-shirts in our store

-

Scandinavia.

One.

One. -

WE LOVEROV 2.0 by Design Ministry

-

Joker

-

Fidel Castro

-

Friends

-

Batman Print

-

Online editor

from 1 390 RUB

- Synthetics -360 RUB

- Cotton +360 RUB

- Available sizes

Available materials

4 easy steps to place an order

Easy and fun process - won't take long

-

Choose from a full print T-shirt or other product

-

Add an image and / or text in a convenient graphic editor

-

Click "Buy" to place an order

-

In the comments, indicate the number of goods and other wishes

Full print t-shirt reviews

-

Good afternoon everyone! I have already received two orders from Printio.

Very satisfied with the quality, service and speed of order fulfillment. I like the assortment: my eyes run wide, I want to choose a lot more. You can order a ready-made design or make your own adjustments. I will recommend to my friends. Thanks a lot!

Very satisfied with the quality, service and speed of order fulfillment. I like the assortment: my eyes run wide, I want to choose a lot more. You can order a ready-made design or make your own adjustments. I will recommend to my friends. Thanks a lot! Ekaterina

-

It was frustrating that one of the ordered T-shirts did not have the inscription ("Denis") printed on it, which was present on the layout. Service: the girl who issued the order on 21.02 (on Derbenevskaya) gave very high quality and full advice on various goods (both earlier and on the day of issue). Special thanks to!

Anastasia

-

Picked up my first order today from this amazing site. The t-shirt was pleased with both the quality and the pattern.

Everything looked and the village is amazing, the size approached perfectly. I hope that over time the thing will not deteriorate from washing and will please for a long time)) Thank you! I will recommend you to my friends!

Everything looked and the village is amazing, the size approached perfectly. I hope that over time the thing will not deteriorate from washing and will please for a long time)) Thank you! I will recommend you to my friends! Christina

See also

Popular women's full print T-shirts in our store

-

Bangtan Boys

-

Little Pony Princess Luna

-

Sally Face

-

Parrots

-

Rock

-

drawing dandelion

-

Online editor

from 3 650 RUB

- Available sizes

- Lookbook

4 easy steps to place an order

Easy and fun process - won't take long

-

Choose a men's sweatshirt with a full seal or another product

-

Add an image and / or text in a convenient graphic editor

-

Click "Buy" to place an order

-

In the comments, indicate the number of goods and other wishes

Reviews of men's sweatshirts with full print

See also

Popular sweatshirts for men with full print in our store

-

Harry Potter

-

Limited Edition 1975

-

Severe Santa Claus

-

Joker

-

Pixel Banana

-

Welsh Corgi

-

WITHOUT BAB

-

Evening Urgant

-

Gorillaz

-

Shrek

-

NASA Sweatshirt

-

BRAWL STARS LEON

Other items in the section Clothing

See all products in the section Clothing in the store →

Why choose us

3 reasons to become a regular customer

We sew our clothes and select only the best suppliers

Direct printing - from 2 hours.