How do 3d printers work with metal

What is metal 3D printing and how does it work?

What is metal 3D printing? How does this additive technology work? This article covers the basic principles of SLM (selective laser melting) and DMLS (direct metal laser sintering) and how these relate to the key benefits and limitations of 3D printing.

What is metal 3D printing? The differences between SLM and DMLS

Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) are two metal additive manufacturing processes that belong to the powder bed fusion 3D printing family. The two technologies have a lot of similarities: both use a laser to scan and selectively fuse (or melt) the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in both processes are metals that come in a granular form.

The differences between SLM and DMLS come down to the fundamentals of the particle bonding process (and also patents): SLM uses metal powders with a single melting temperature and fully melts the particles, while in DMLS the powder is composed of materials with variable melting points that fuse on a molecular level at elevated temperatures.

Essentially, SLM produces parts from a single metal, while DMLS produces parts from metal alloys.

The SLM and DMLS metal 3D printing processBoth SLM and DMLS are used in industrial applications to create end-use engineering products. In this article, we use the term metal 3D printing to refer to both processes in general and we describe the basic mechanisms of the fabrication process that are necessary for engineers and designers to understand the benefits and limitations of the technology.

There are other additive manufacturing processes that can be used to produce dense metal parts, such as Electron Beam Melting (EBM) and Ultrasonic Additive Manufacturing (UAM). Their availability and applications are limited though, so they won't be presented here.

Want to learn more about manufacturing metal parts?

Download our metal parts guide Our 3D printing services Our CNC machining services

How does metal 3D printing work?

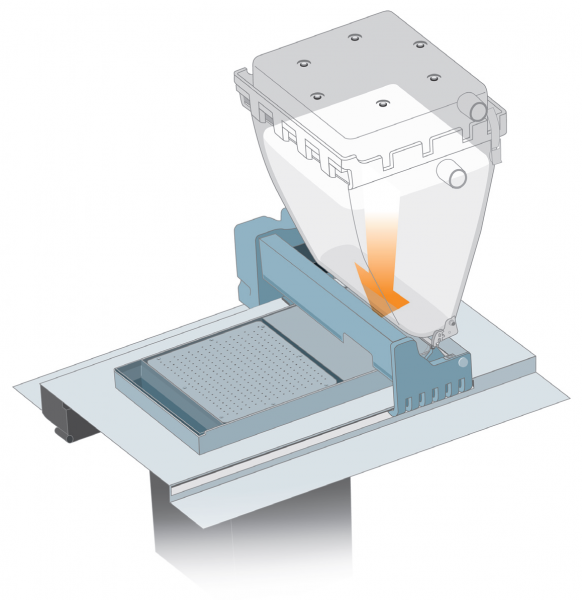

The basic fabrication process is similar for both SLM and DMLS. Here's how it works:

Here's how it works:

-

The build chamber is first filled with inert gas (for example argon) to minimize the oxidation of the metal powder and then it is heated to the optimal build temperature.

-

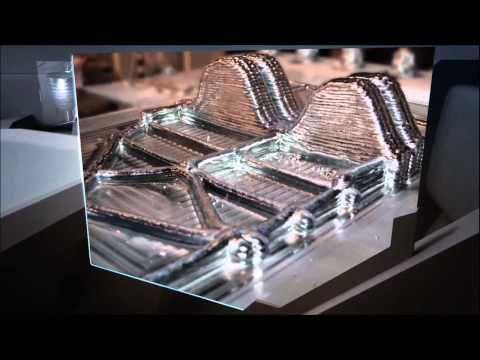

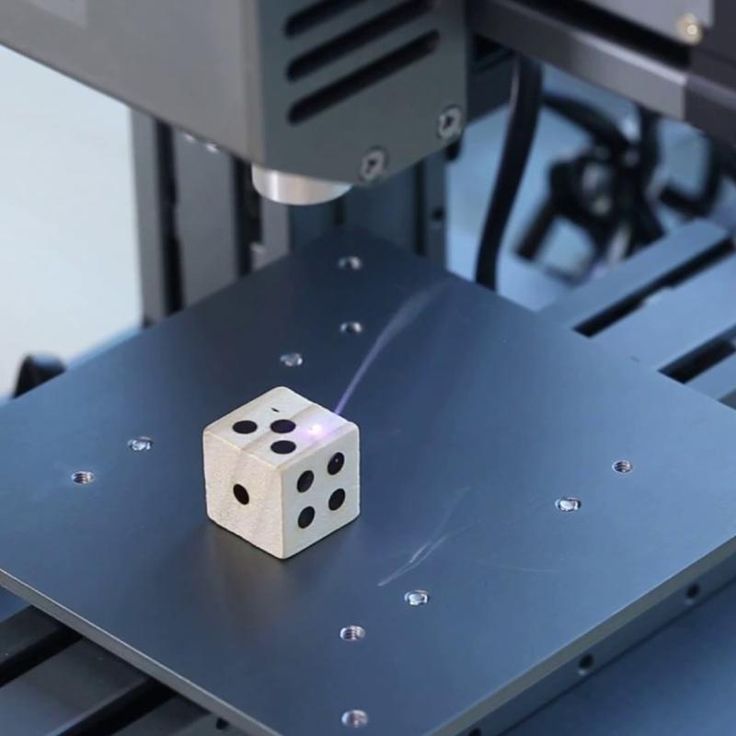

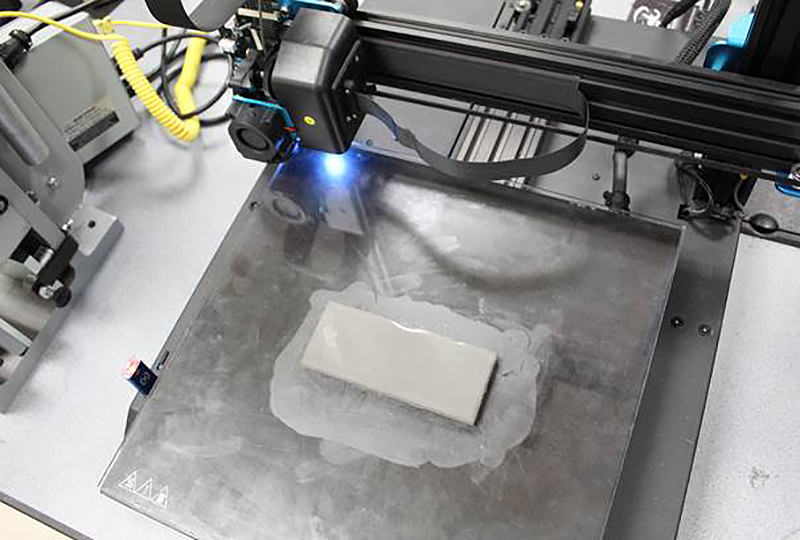

A thin layer of metal powder is spread over the build platform and a high-power laser scans the cross-section of the component, melting (or fusing) the metal particles together and creating the next layer. The entire area of the model is scanned, so the part is built fully solid.

-

When the scanning process is complete, the build platform moves downwards by one layer thickness and the recoater spreads another thin layer of metal powder. The process is repeated until the whole part is complete.

When the build process is finished, the parts are fully encapsulated in the metal powder. Unlike the polymer powder bed fusion process (such as SLS or MJF), the parts are attached to the build platform through support structures. Support in metal 3D printing is built using the same material as the part and is always required to mitigate the warping and distortion that may occur due to the high processing temperatures.

Support in metal 3D printing is built using the same material as the part and is always required to mitigate the warping and distortion that may occur due to the high processing temperatures.

When the bin cools to room temperature, the excess powder is manually removed and the parts are typically heat treated while still attached to the build platform to relieve any residual stresses. Then the components are detached from the build plate via cutting, machining or wire EDM and are ready for use or further post-processing.

Schematic of an SLM/DMLS printerWant to design better parts for 3D print manufacturing?

Download our 3D printing design rules poster

What are the characteristics of metal 3D printing? Get to know SLM & DMLS

SLM & DMLS printer parameters

In SLM and DMLS almost all process parameters are set by the machine manufacturer. The layer height used in metal 3D printing varies between 20 to 50 microns and depends on the properties of the metal powder (flowability, particle size distribution, shape and more).

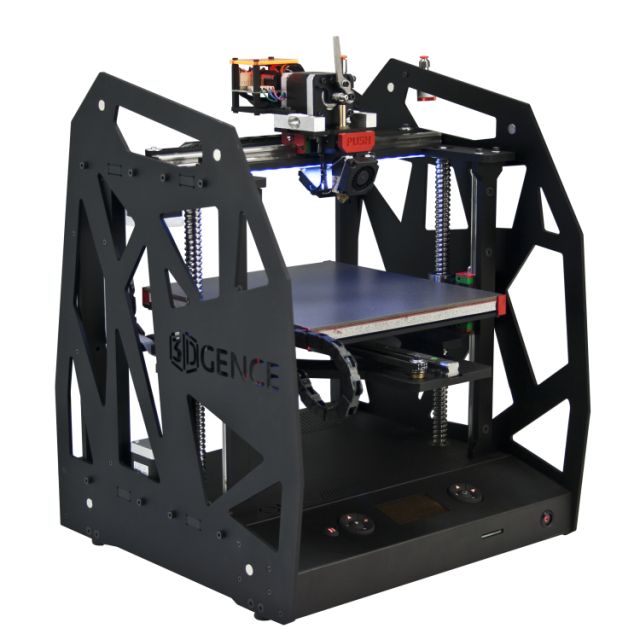

The typical build size of a metal 3D printing system is 250 x 150 x 150 mm, but larger machines are also available (up to 500 x 280 x 360 mm). The dimensional accuracy that a metal 3D printer can achieve is approximately ± 0.1 mm.

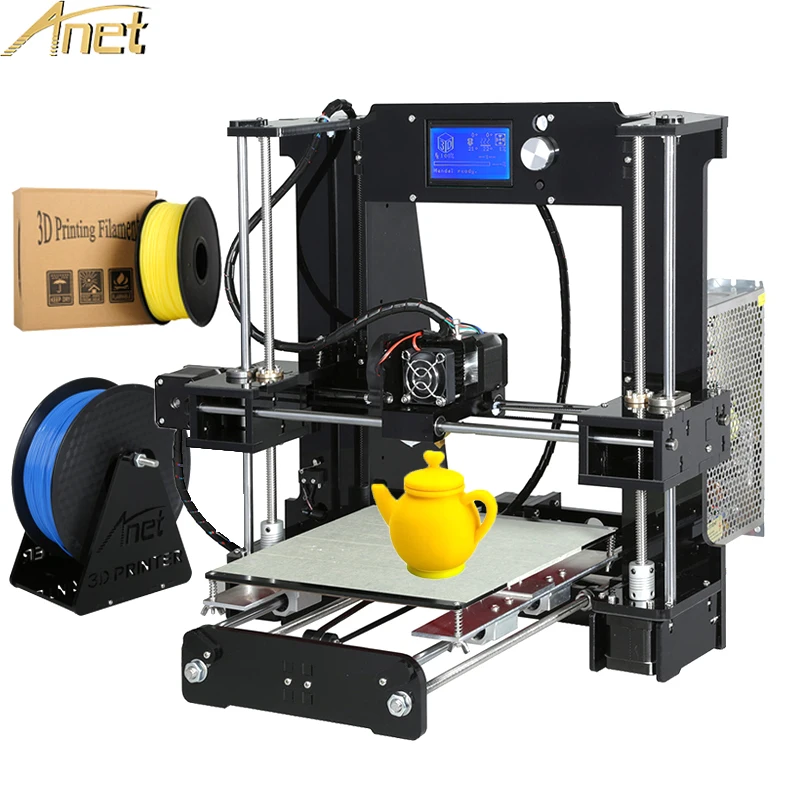

Metal printers can be used for small batch manufacturing, but the capabilities of metal 3D printing systems resemble more the batch manufacturing capabilities of FDM or SLA machines than that of SLS printers. They are restricted by the available print area (XY-direction), as the parts have to be attached to the build platform.

The metal powder in SLM and DMLS is highly recyclable. Typically, less than 5% is wasted. After each print, the unused powder is collected, sieved and then topped up with fresh material to the level required for the next build.

Waste in metal printing comes in the form of support structures, which are crucial for the successful completion of a build but can increase the amount of the required material (and the cost) drastically.

Layer adhesion

Metal SLM and DMLS parts have almost isotropic mechanical and thermal properties. They are solid with very little internal porosity (less than 0.2 - 0.5% in the as-printed state and close to none after thermal processing).

Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. However, they are more prone to fatigue.

For example, take a look at the mechanical properties of the AlSi10Mg EOS metal 3D printing alloy and the A360 die-cast alloy. These two materials have a very similar chemical composition, high in silicon and magnesium. The printed parts have superior mechanical properties and higher hardness compared to the wrought material.

Due to the granular form of the unprocessed material, the as-built surface roughness (Ra) of a metal 3D printed part is approximately 6 - 10 μm. This relatively high surface roughness can partially explain the lower fatigue strength.

This relatively high surface roughness can partially explain the lower fatigue strength.

| AlSi10Mg (3D printing alloy) | A360 (Die cast alloy) | |

|---|---|---|

| Yield Strength (0.2% strain) * | XY: 230 MPa Z: 230 MPa | 165 MPa |

| __Tensile Strength * __ | XY: 345 MPa Z: 350 MPa | 317 MPa |

| __Modulus * __ | XY: 70 GPa Z: 60 GPa | 71 GPa |

| __Elongation at break * __ | XY: 12% Z: 11% | 3.5% |

| __Hardness ** __ | 119 HBW | 75 HBW |

| __Fatigue Strength ± __ | 97 MPa | 124 MPa |

*Heat treated: annealed at 300 degrees Celsius for 2 hours

± Tested on as-built samples

Support structures & part orientation

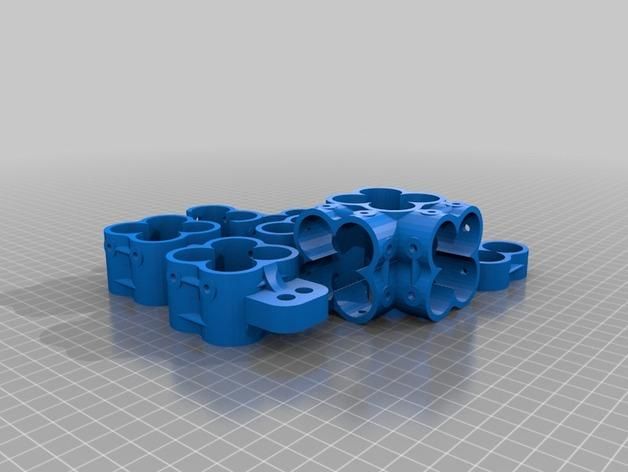

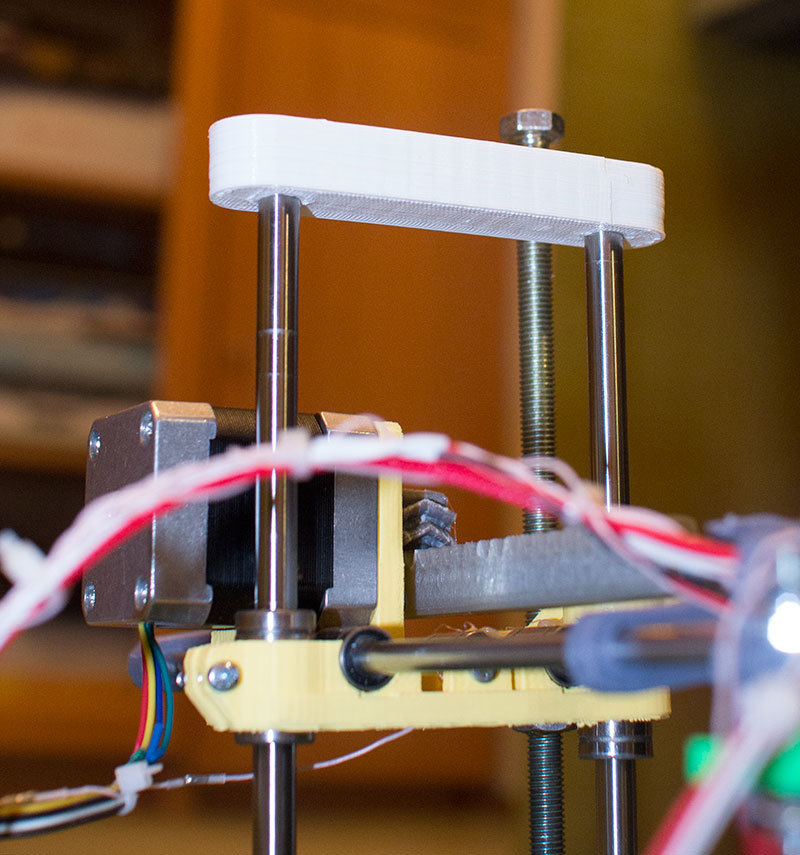

Support structures are always required in metal printing, due to the very high processing temperature and they are usually built using a lattice pattern.

Support structures in metal 3D printing serve three different functions:

-

They offer a suitable platform for the next layer to be built upon.

-

They anchor the part to the build plate and they prevent warping.

-

They act as heat sinks, drawing heat away from the part and allowing it to cool at a more controlled rate.

Parts are often oriented at an angle to minimize the likelihood of warping and maximize part strength in critical directions. However, this will increase the amount of required support, the build time, the material waste and (ultimately) the total cost.

Warping can also be minimized using randomized scan patterns. This scanning strategy prevents the buildup of residual stresses in any particular direction and will add a characteristic surface texture to the part.

Since the cost of metal printing is very high, simulations are often used to predict the behavior of the part during processing. Topology optimization algorithms are also used not only to maximize mechanical performance and create lightweight parts but also to minimize the need for support structure and the likelihood of warping.

Topology optimization algorithms are also used not only to maximize mechanical performance and create lightweight parts but also to minimize the need for support structure and the likelihood of warping.

Hollow sections & lightweight structures

Unlike polymer powder bed fusion processes like SLS, large hollow sections are not commonly used in metal printing as support structures cannot be easily removed.

For internal channels larger than Ø 8 mm, we recommend using diamond or tear-drop cross sections instead of circular ones, as they require no support structures. More design guidelines on SLM & DMLS can be found in this article .

As an alternative to hollow sections, parts can be designed with skin and cores. Skin and cores are processed using different laser power and scan speed, resulting in different material properties. Using skin and cores is very useful when manufacturing parts with large solid sections, as they significantly reduce the print time and the likelihood of warping and produce parts with high stability and excellent surface quality.

Using skin and cores is very useful when manufacturing parts with large solid sections, as they significantly reduce the print time and the likelihood of warping and produce parts with high stability and excellent surface quality.

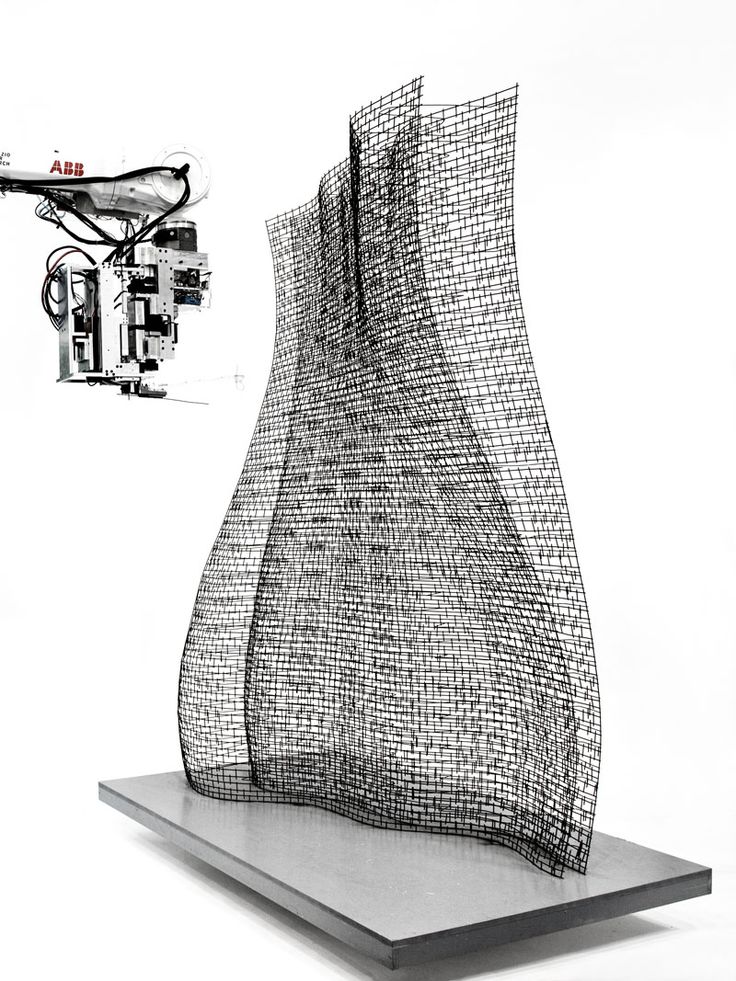

Using a lattice structure is also a common strategy in metal 3D printing for reducing the weight of a part. Topology optimization algorithms can also aid in the design of organic, lightweight forms.

What are the common materials for 3D metal printing?

SLM and DMLS can produce parts from a large range of metals and metal alloys including aluminum, stainless steel, titanium, cobalt chrome and Inconel. These materials cover the needs of most industrial applications, from aerospace to medical. Precious metals, such as gold, platinum, palladium and silver can also be processed, but their applications are mainly limited to jewelry making.

Powder for metal 3D printing is, as you’d imagine, very expensive. For example, a kilogram of stainless steel 316L powder cost approximately $350 - $450. For this reason, minimizing the part volume and the need for support is key to keeping the cost as low as possible.

For this reason, minimizing the part volume and the need for support is key to keeping the cost as low as possible.

A key strength of metal 3D printing is its compatibility with high-strength materials, such as nickel or cobalt-chrome superalloys, that are very difficult to process with traditional manufacturing methods. Significant cost and time savings can be made, by using metal 3D printing to create a near-net-shape part that can is later post-processed to a very high surface finish.

| Material | Material

|------------------------------|

| Aluminium alloys | Good mechanical & thermal properties; Low density; Good electrical conductivity; Low hardness |

| Stainless steel & tool steel | High wear resistance; Great hardness; Good ductility and weldability |

| Titanium alloys | Corrosion resistance; Excellent strength-to-weight ratio; Low thermal expansion; Biocompatible |

| Cobalt-Chrome superalloys | Excellent wear & corrosion resistance; Great properties at elevated temperatures; Very high hardness; Biocompatible |

| Nickel superalloys (Inconel) | Excellent mechanical properties; High corrosion resistance; Temperature resistant up to 1200 degrees Celcius; Used in extreme environments |

| Precious metals | Used in jewelry making; Not widely available

Post-processing methods for metal 3D printing

Various post-processing techniques are used to improve the mechanical properties, accuracy, and appearance of the metal printed parts.

Compulsory post-processing steps include the removal of the loose powder and the support structures, while heat treatment (thermal annealing) is commonly used to relieve the residual stresses and improve the mechanical properties of the part.

CNC machining can be employed for dimensionally crucial features (such as holes or threads). Media blasting, metal plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part.

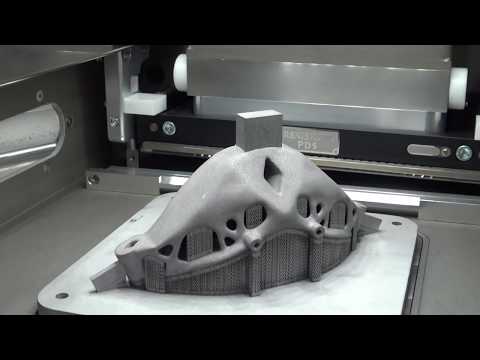

Satellite antenna manufactured using DMLS. Photo courtesy of Concept Laser and Optisys LLC.What are the benefits & limitations of metal 3D printing?

Here are the key advantages and disadvantages of metal 3D printing processes:

-

Metal 3D printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce.

-

Metal 3D printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total number of components in an assembly.

-

Metal 3D printed parts have excellent physical properties and the available material range includes difficult-to-process otherwise materials, such as metal superalloys.

-

The material and manufacturing costs connected with metal 3D printing are high, so these technologies are not suitable for parts that can be easily manufactured with traditional methods.

-

The build size of the metal 3D printing systems is limited, as precise manufacturing conditions and process control are required.

Already existing designs may not be suitable for metal 3D printing and may need to be altered.

The main characteristics of SLM and DMLS systems are summarized in the table below.

| Metal 3D printing (SLM / DMLS) | |

|---|---|

| __Materials __ | Metals & metal alloys (aluminum, steel, titanium) |

| Dimensional accuracy | ± 0. 1 mm 1 mm |

| Typical build size | 250 x 150 x 150 mm (up to up to 500 x 280 x 360 mm) |

| Common layer thickness | 20 – 50 μm |

| __Support structures __ | Always required |

Contact [email protected] or head to [Protolabs](https://www.protolabs.com/) to start 3D printing metal parts. For other 3D printing technoligies and CNC machining, you can upload a CAD file to our quote builder for a free, instant quote.

Our 3D printing service Our CNC machining service Get a free, instant quote

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteHow Metal 3D Printing works

When one considers additive manufacturing for industrial and business applications, 3D printing with metal is probably the first thing that comes to mind. Metal 3D printing is one of the most heavily invested and fastest-growing technologies in the manufacturing industry.

Metal 3D printing is one of the most heavily invested and fastest-growing technologies in the manufacturing industry.

- What is metal 3D printing?

- Main advantages of metal 3D printing

- Limitations of metal 3D printing

- What is DMLS and what is it used for?

- What is SLM and what is it used for?

- What is EBM and what is it used for?

- Other technologies for metal prints

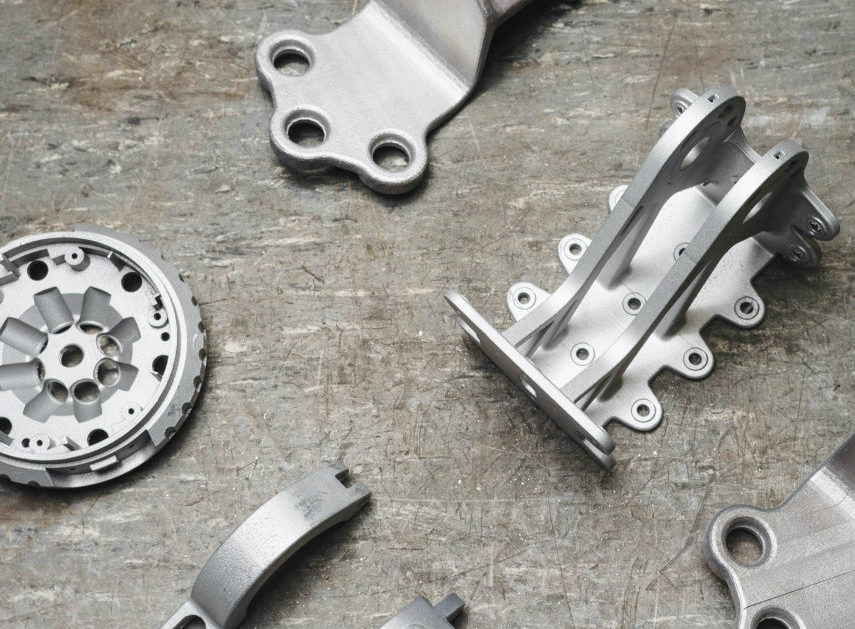

Metal 3D printing is sometimes introduced into existing supply chains to work alongside other manufacturing technologies. In other instances, printers are used as a prime way of manufacturing metal components. Certain geometries of 3D printed objects in metal come out just as good as machined parts.

Metal printing is mainly used in prototyping, aerospace, mechanical engineering, specific tools, and more. Here we’ll address the most common questions about all aspects of 3D printing with metal, including the main technologies, their advantages, limits, and more.

Metal 3D printing is an umbrella term for several families of AM technologies. Simply stated, any technology that creates metal objects layer by layer with sintering, melting, and welding could be called metal 3D printing.

For a long time machining was (and still is) one of the primary manufacturing methods for metal parts. And it is believed that CNC machining is capable of almost any kind of work. But the truth is that this “almost” sometimes isn’t enough. In some instances, there is a demand for components with new complex shapes, for example, for brand new tools and products.

And here comes the main advantage of metal 3D printing – it’s almost boundless when one considers manufacturing objects with a complicated shape. Other advantages of 3D printing with metal include:

- 3D printers can manufacture complicated details much quicker than traditional methods of manufacturing.

- The cost for short runs is cheaper in comparison with conventional methods of manufacturing.

- Depending on the chosen technology it’s possible to create precise objects with very small details.

- It’s possible to 3D print details in assembly, and as a result, save even more time and money.

- More complicated forms mean that the part can be lighter in weight without sacrificing strength. That’s why 3D printed parts are in such demand in the aerospace industry.

- 3D printing with metal almost doesn’t waste material.

To sum it up, 3D printing is highly recommended for intricate parts where other types of manufacturing are inefficient or difficult to use.

Order Metal 3D Printing

As great as it is, 3D printing is not without its faults, too. First of all, it’s not as fast and affordable for regular and simple parts in comparison with traditional methods of manufacturing. Your traditional U and V shapes, especially in large quantities, are better to be done through forming. Other limits of 3D printing metal include:

- Powdered metal is much more expensive than “regular” raw metal.

- Speed of production is comparatively slow for regular objects.

- Metal 3D printers are expensive and require special skills and training.

- Sometimes surface finishing is rough, so post-processing is needed for end-use components.

- Tolerance and precision are usually lower in comparison with CNC machining.

- Occasionally additional heat treatment is required to reduce the inner stress of a 3D printed object.

- Unused metal powder degrades after each run, so it requires adding fresh material every time.

- Designing for metal 3D printing can be more complicated in comparison to other manufacturing methods. So, it's better to work only with experienced specialists that know all the technological nuances.

- Metal 3D printers aren’t extremely large, so the dimensions of solid parts they can create are limited. The biggest build volumes on the market are around 1000 x 1000 x 700 mm, and most metal printers are much smaller.

As can be seen, the limits are self-evident that 3D printing isn’t an efficient source of regular metal parts. In other, less standard cases, additive manufacturing is the real deal.

In other, less standard cases, additive manufacturing is the real deal.

There are several different methods that can deliver printed metal parts. While they have a lot in common, there are some differences, which dictate what materials they can work with. Let’s compare the main 3D printing technologies for metal. These are DMLS (Direct Metal Laser Sintering), LMS (Laser Metal Sintering), and EBM (Electron Beam Melting).

What is DMLS and what is it used for?

DMLS or Direct Metal Laser Sintering is the most widespread method of 3D printing in metal. It uses a laser for sintering metal powder, layer by layer, and forming an object. During the process, stainless steel reaches a temperature of almost 3000 °F. However, the metal is not fully melted, which makes printed parts porous. Among the materials available are a wide variety of metal alloys, including maraging steel, aluminum AlSi10Mg, cobalt chromium, Inconel 625, and titanium Ti6Al4V.

DMLS applications

DMLS process is used in prototyping and manufacturing finished mechanical parts. It can also be used for making parts with cavities, undercuts, and draft angles. Among those are medical devices and instruments, functional prototypes, and tools.

It can also be used for making parts with cavities, undercuts, and draft angles. Among those are medical devices and instruments, functional prototypes, and tools.

What is SLM and what is it used for?

SLM or Selective Laser Melting, as the title suggests, melts the material. 3D printing happens in an inert gas environment. Thanks to that, a 3D print has parameters close to the one that was produced through metal casting. SLM is mainly used for manufacturing strong parts from titanium and aluminum.

SLM applications

Objects that were manufactured with SLM technology are quite durable and can be used for mechanical components such as gears and propellers. Medical, automotive, and aerospace industries often use SLM to manufacture their parts.

What is EBM and what is it used for?

EBM or Electron Beam Melting is similar to SLM but instead of a laser an electron beam is used. This technology is considered to be faster and more precise than laser-based printing, though the difference is not so significant. EBM 3D prints are usually stronger in comparison with other printed objects. This technology is used mainly for manufacturing objects from titanium and cobalt.

This technology is considered to be faster and more precise than laser-based printing, though the difference is not so significant. EBM 3D prints are usually stronger in comparison with other printed objects. This technology is used mainly for manufacturing objects from titanium and cobalt.

EBM applications

Aircraft, parts for space missiles, components of engines - these are some of the industries that actively use EBM 3D printing.

There are several extra types of 3D printing that could be used for manufacturing metal parts. They may not be as popular as DMLS, SLM, and EBM, but they have unique niches as well.

Selective laser sintering

Selective laser sintering (or SLS) is very similar to DMLS; it also uses a laser for sintering powder materials. It had been used for printing a wide range of materials, including metal, but nowadays this technology is mainly associated with polyamides (nylons). Thus, the sintering temperature that is used in SLS printers is usually less than 400 °F, which limits their capabilities with metal alloys.

Thus, the sintering temperature that is used in SLS printers is usually less than 400 °F, which limits their capabilities with metal alloys.

Binder Jetting

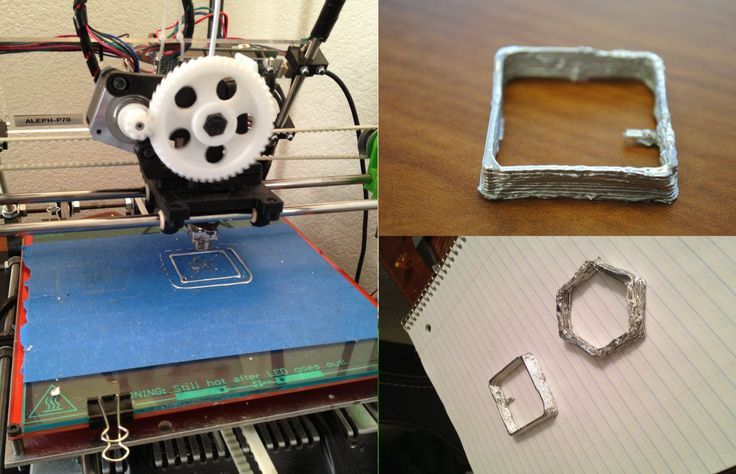

Binder Jetting, as the name implies, binds powder grains with a special agent. To make an object more solid, one can cure it with hot isostatic pressing. This way a 3D print becomes much stronger but at the same time, the production cost also goes up.

Binder Jetting is commonly used for manufacturing complex and large-scale prototypes. This technology is several times cheaper than DMLS/SLM/EBM and uses less power. Nevertheless, accuracy and strength are not perfect and for the best result, additional post-processing is required.

Laser Metal Deposition

LMD or Laser Metal Deposition is a technology that can be related to fused deposition modeling. Though instead of extruding melted plastic, heated metal is deposited layer by layer creating the object. In other words, a melt pool is formed on a metallic substrate.

In other words, a melt pool is formed on a metallic substrate.

The speed of LMD manufacturing is significantly higher in comparison to other methods, and different materials can be applied for producing the object, including steel alloys. LMD is used in aerospace, automotive, and medical industries.

Conclusion: Metal 3D printing is for special cases

Metal parts that were manufactured with 3D printing methods like DMLS, SLM, and EBM are considered to have almost the same strength as regular metal parts. However, there are many features that limit the usage of metal 3D printing, and that’s why it’s better to keep it for exceptional cases where other methods are not as effective. Keeping in mind the relatively high price for 3D printing machines and their powdered materials, the easiest and perhaps the most efficient way for rare productions is to order 3D prints on demand. We have personal managers on hand to offer free consultation and help answer any questions you may have.

We have personal managers on hand to offer free consultation and help answer any questions you may have.

How metal 3D printers work. Overview of SLM and DMLS technologies. additive manufacturing. 3D metal printing.

Metal 3D printing. Additive technologies.

SLM or DMLS: what's the difference?

Hello everyone, Friends! 3DTool is with you!

BLT metal 3D printer catalog

Selective laser melting ( SLM ) and direct metal laser sintering ( DMLS ) are two additive manufacturing processes that belong to the family of 3D printing using the powder layer method. The two technologies have much in common: they both use a laser to selectively melt (or melt) metal powder particles, bonding them together and creating a pattern layer by layer. In addition, the materials used in both processes are metals in granular form.

The differences between SLM and DMLS come down to the basics of the particle bonding process: SLM uses metal powders with a single melting point and completely melts the particles, while in DMLS the powder consists of materials with variable melting points.

Specifically:

SLM produces single metal parts while DMLS produces metal alloy parts.

Both SLM and DMLS technologies are used in industry to create final engineering products. In this article, we will use the term "metal 3D printing" to summarize the 2 technologies. We will also describe the main mechanisms of the manufacturing process that are necessary for engineers to understand the advantages and disadvantages of these technologies.

There are other manufacturing processes for producing dense metal parts, such as electron beam melting (EBM) and ultrasonic additive manufacturing (UAM). Their availability and distribution is rather limited, so they will not be presented in this article.

How 3D printing with SLM or DMLS metal works.

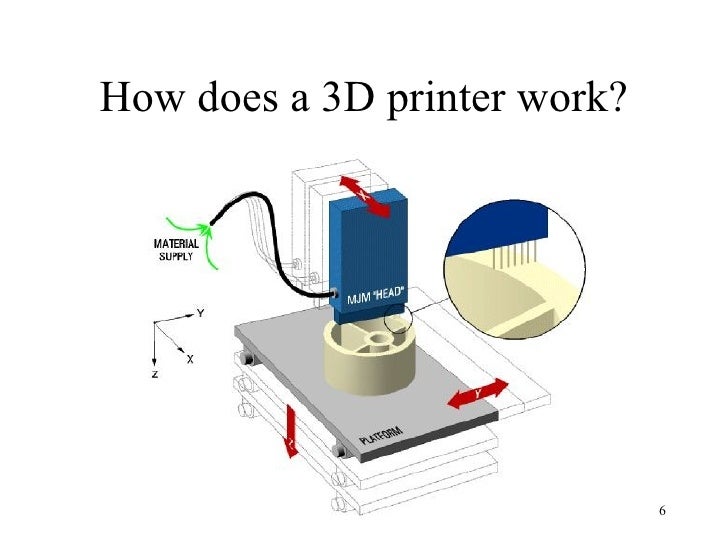

How does metal 3D printing work? The basic manufacturing process for SLM and DMLS is very similar.

1. The printing chamber is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder. It then heats up to the optimum operating temperature.

2. A layer of powder is spread over the platform, a powerful laser makes passes along a predetermined path in the program, fusing the metal particles together and creating the next layer.

3. When the sintering process is completed, the platform moves down 1 layer. Next, another thin layer of metal powder is applied. The process is repeated until the entire model is printed.

When the printing process is completed, the metal powder already has strong bonds in the structure. Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures.

Unlike the SLS process, parts are attached to the platform via support structures. The support in metal 3D printing is created from the same material as the base part. This condition is necessary to reduce deformations that may occur due to high processing temperatures.

When the 3D printer's chamber cools down to room temperature, excess powder is removed manually, such as with a brush. The parts are then typically heat treated while they are still attached to the platform. This is done to relieve any residual stresses. They can then be further processed. The removal of the part from the platform occurs by means of sawing.

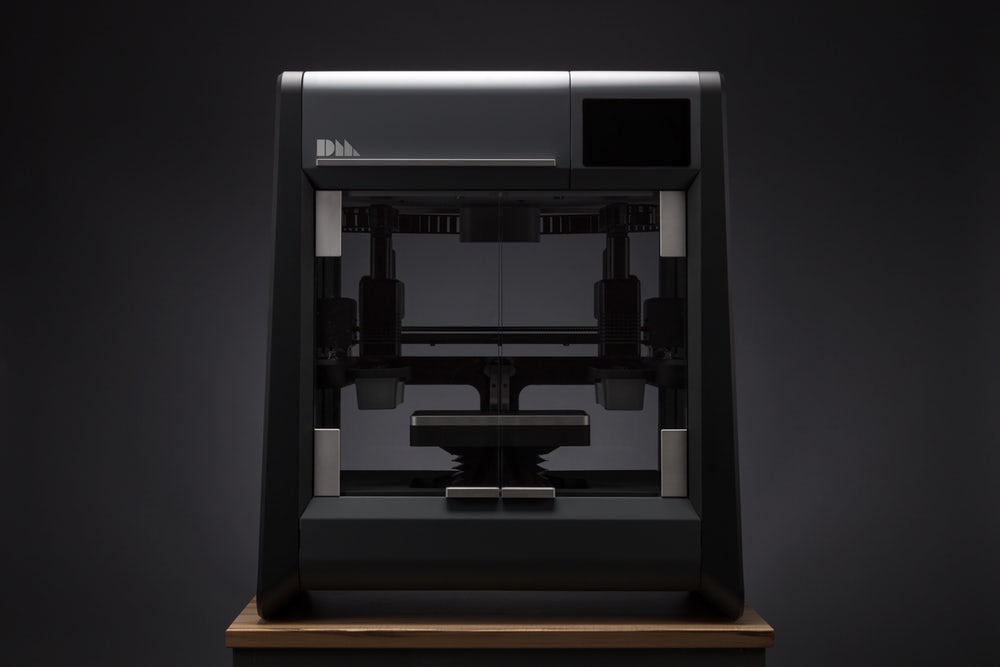

Scheme of operation of a 3D printer for metal.

In SLM and DMLS, almost all process parameters are set by the manufacturer. The layer height used in metal 3D printing varies from 20 to 50 microns and depends on the properties of the metal powder (fluidity, particle size distribution, shape, etc. ).

).

The basic size of the print area on metal 3D printers is 200 x 150 x 150 mm, but there are also larger sizes of the working area. Printing accuracy is from 50 - 100 microns. As of 2020, metal 3D printers start at $150,000. For example, our company offers 3D metal printers from BLT.

metal 3D printers can be used for small batch production, but the 3D printing capabilities of such systems are more like those of mass production on FDM or SLA machines.

The metal powder in SLM and DMLS is recyclable: typically less than 5% is consumed. After each impression, the unused powder is collected and sieved, and then topped up with fresh material to the level required for the next production.

Waste in metal printing, are supports (support structures, without which it will not be possible to achieve a successful result). With too much support on the manufactured parts, the cost of the entire production will increase accordingly.

Adhesion between coats.

3D metal printing on BLT 3D printers

SLM and DMLS metal parts have almost isotropic mechanical and thermal properties. They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

They are hard and have very little internal porosity (less than 0.2% in 3D printed condition and virtually non-existent after processing).

Metal printed parts have higher strength and hardness and are often more flexible than traditionally made parts. However, such metal becomes “tired” faster.

3D model support structure and part orientation on the work platform.

Support structures are always required when printing with metal, due to the very high processing temperatures. They are usually built using a lattice pattern.

Supports in metal 3D printing perform 3 functions:

• They form the basis for creating the first layer of the part.

• They secure the part to the platform and prevent it from deforming.

• They act as a heat sink, removing heat from the model.

Parts are often oriented at an angle. However, this will increase the amount of support required, the printing time, and ultimately the overall cost.

Deformation can also be minimized with laser sintering templates. This strategy prevents the accumulation of residual stresses in any particular direction and adds a characteristic surface texture to the part.

Since the cost of metal printing is very high, software simulations are often used to predict how a part will behave during processing. These topology optimization algorithms are otherwise used not only to increase mechanical performance and create lightweight parts, but also to minimize the need for supports and the likelihood of part distortion.

Hollow sections and lightweight structures.

An example of printing on a BLT 3D printer

Unlike polymer powder melt processes such as SLS, large hollow sections are not typically used in metal printing as the support would be very difficult to remove, if at all possible.

For internal channels larger than Ø 8 mm, it is recommended to use diamond or teardrop cross-sections instead of round ones, as they do not require support. More detailed recommendations on the design of SLM and DMLS can be found in other articles on this topic.

As an alternative to hollow sections, parts can be made with sheath and cores, which in turn are machined using different laser power and pass speeds, resulting in different material properties. The use of sheath and cores is very useful when making parts with a large solid section, as it greatly reduces printing time and reduces the chance of warping.

The use of a lattice structure is a common strategy in metal 3D printing to reduce part weight. Topology optimization algorithms can also help design organic lightweight shapes.

Consumables for 3D metal printing.

SLM and DMLS technologies can produce parts from a wide range of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt, chromium and inconel. These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making.

These materials meet the needs of most industrial applications, from aerospace to medical applications. Precious metals such as gold, platinum, palladium and silver can also be processed, but their use is of a minor nature and is mainly limited to jewelry making.

The cost of metal powder is very high. For example, a kilogram of 316 stainless steel powder costs approximately $350-$450. For this reason, minimizing part volume and the need for supports is key to maintaining optimal manufacturing cost.

The main advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium superalloys, which are very difficult to machine with traditional methods. Significant cost and time savings can be achieved by using metal 3D printing to create a near-clean shape part. Subsequently, such a part can be processed to a very high surface quality.

Metal post-processing.

Various post methods. treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

treatments are used to improve the mechanical properties, accuracy and appearance of metal printed products.

Mandatory post-processing steps include the removal of loose powder and support structures, while heat treatment (heat annealing) is typically used to relieve residual stresses and improve the mechanical properties of the part.

CNC machining can be used for critical features (such as holes or threads). Sandblasting, plating, polishing, and micro-machining can improve the surface quality and fatigue strength of a metal printed part.

Advantages and disadvantages of metal 3D printing.

Pros:

1. Metal 3D printing can be used to make complex custom parts, with geometries that traditional manufacturing methods cannot provide.

2. Metal 3D printed parts can be optimized to increase their performance with minimal weight.

3. Metal 3D printed parts have excellent physical properties, metal 3D printers can print a wide range of metals and alloys. Includes difficult-to-machine materials and metal superalloys.

Includes difficult-to-machine materials and metal superalloys.

Cons:

1. Manufacturing costs associated with metal 3D printing are high. The cost of consumables is from $ 500 per 1 kg.

2. The size of the working area in metal 3D printers is limited.

Conclusions.

• Metal 3D printing is most suitable for complex, one-piece parts that are difficult or very expensive to manufacture using traditional methods, such as CNC.

• Reducing the need for building supports, will significantly reduce the cost of printing with metal.

• 3D printed metal parts have excellent mechanical properties and can be made from a wide range of engineering materials, including superalloys.

And that's all we have! We hope the article was useful to you.

Catalog of 3D printers for metal BLT

You can purchase metal 3d printers, as well as any other 3d printers and CNC machines, by contacting us:

• By email: Sales@3dtool. ru

ru

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

how metal printing works on a 3D printer

Contents:

- Metal printing on a 3D printer

- How 3D technologies work

- Two main methods

- Video

Metal printing on a 3D printer (two main technologies)

The introduction of innovative technologies opens up new opportunities in various fields of human activity. A modern 3D printer for printing on metal allows you to print high-precision structural elements that are in demand in the space, engineering, and aviation industries.

How 3D technology works

3D parts are produced using different metal powder melting methods (using a laser). But the basic principle of operation remains unchanged, so any 3D printer prints with metal in several stages, these are:

- filling the build chamber with an inert gas to minimize the oxidation of the starting material;

- heating to the temperature required for the production process.

- distribution of powder over the surface of the build platform;

- 3D scanning of the cross section of the starting material with a laser beam;

- melting and sintering of particles, which makes it possible to obtain a hard layer;

- offset of the platform by the amount of the resulting layer for applying the next one (until the object is formed).

The moment the metal laser 3D printer completes the process, the product is completely covered in powder. Therefore, until the chamber cools down completely (to avoid deformations), the object on the platform is fixed by the support area.

Two main methods

A modern metal 3D printer can use one of the two most common technologies - selective laser beam melting (SLM) or direct laser sintering (DMLS). Among the main differences between the methods, the principle of gluing the component should be mentioned:

- SLM - occurs as a result of complete melting of the powder;

- DMLS - individual particles are sintered (at lower temperatures compared to SLM) without passing into a liquid substance.

Learn more