3D print solar cells

Researchers From Stanford University Introduce New 3D Printed Solar Panels

3D printing news News Researchers From Stanford University Introduce New 3D Printed Solar Panels

Published on August 4, 2022 by Clemens M.

Scientists from Stanford University in California recently developed a new, 3D-printed optical concentrator for solar panels. This pyramid-shaped lens device called Axially Graded Index Lens (AGILE) was designed by engineering researcher Nina Vaidya and is able to increase the capacity of power collected by a solar panel. All while reducing its production cost and making the process more practical.

As many people these days are becoming more and more aware of the problematic state of the planet, the demand for eco-friendly energy sources is higher than ever before. Those who are interested in switching to such alternatives are already presented with a variety of different options. Solar energy, for example, is probably one of the best-known eco-friendly new sources of energy that has been around for quite a while now. And although it is, without a doubt, a good option, its technologies still leave a lot of room for improvement and innovation. One new invention that could revolutionize the way solar energy is collected, was recently published in the July issue of Microsystems & Nanoengineering. In the paper, authored by Stanford alumni and researcher Nina Vaidya and her doctoral advisor, professor Olav Solgaard, the scientists introduce a brand-new 3D printed device that is able to collect more energy than any other solar panel before.

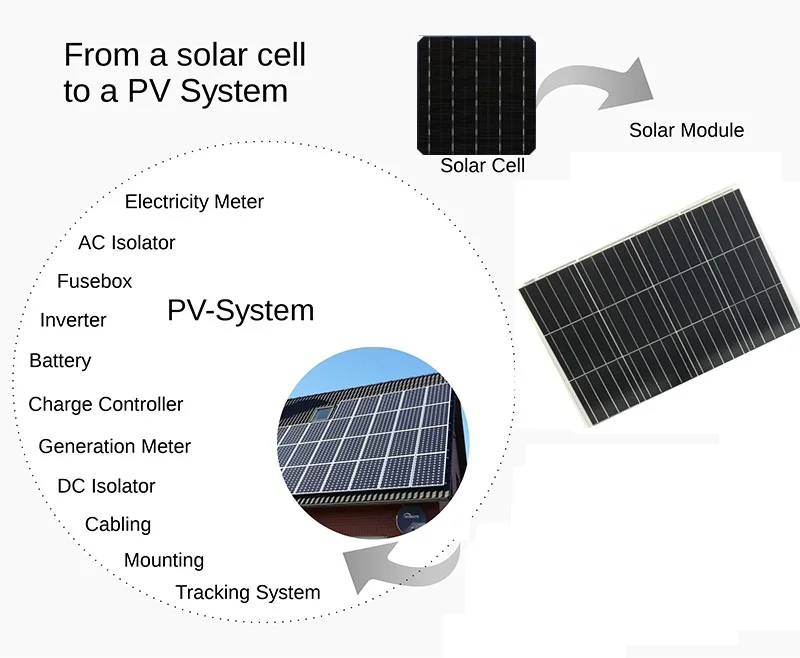

The panels are shaped like inverted pyramids (photo credits: Stanford)

The Way The Device WorksConventional solar panels only work best under the right circumstances. The sunlight, which, as you know, is this technology’s source of energy, has to be set in the exact direction where the light can hit the panel’s flat surface directly. Because the direction of the light changes during the day, many solar arrays actively rotate towards the sun in order to catch as much light as possible. With the newly introduced device, however, this lengthy and circumstantial procedure may soon be redundant. The new and innovative panel is able to capture and concentrate sunlight coming from any angle due to its special structure, which is shaped like a tipless inverted pyramid. The material, which is a combination of glass and polymers, enables the lens to concentrate the solar power from different angles in one spot, similar to when you burn grass with a magnifying glass.

With the newly introduced device, however, this lengthy and circumstantial procedure may soon be redundant. The new and innovative panel is able to capture and concentrate sunlight coming from any angle due to its special structure, which is shaped like a tipless inverted pyramid. The material, which is a combination of glass and polymers, enables the lens to concentrate the solar power from different angles in one spot, similar to when you burn grass with a magnifying glass.

Nina Vaidya explains, “We wanted to create something that takes in light and concentrates it at the same position, even as the source changes direction. We don’t want to have to keep moving our detector or solar cell or moving the system to face the source. It’s a completely passive system – it doesn’t need energy to track the source or have any moving parts. Without optical focus that moves positions or need for tracking systems, concentrating light becomes much simpler.”

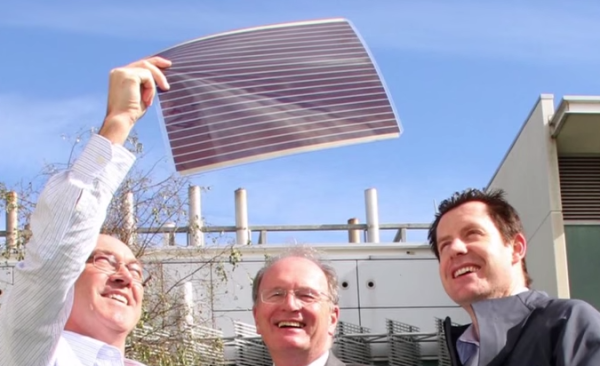

Nina Vaidya at work (photo credits: Nina Vaidya)

Not much is known about the exact 3D printing technology that is used to create the panels. The way the panels are manufactured, however, is by layering together different glasses and polymers that bend light to different degrees, that ultimately focus the light in one exact spot. After a long phase of trial and error and the production of many different prototypes, Nina Vaidya is now confident that her design will soon be successfully used in the solar industry and other areas. She concludes, “To be able to use these new materials, these new fabrication techniques, and this new AGILE concept to create better solar concentrators has been very rewarding. Abundant and affordable clean energy is a vital part of addressing the urgent climate and sustainability challenges, and we need to catalyze engineering solutions to make that a reality.” You can read more about it on Stanford University’s website HERE.

The way the panels are manufactured, however, is by layering together different glasses and polymers that bend light to different degrees, that ultimately focus the light in one exact spot. After a long phase of trial and error and the production of many different prototypes, Nina Vaidya is now confident that her design will soon be successfully used in the solar industry and other areas. She concludes, “To be able to use these new materials, these new fabrication techniques, and this new AGILE concept to create better solar concentrators has been very rewarding. Abundant and affordable clean energy is a vital part of addressing the urgent climate and sustainability challenges, and we need to catalyze engineering solutions to make that a reality.” You can read more about it on Stanford University’s website HERE.

What do you think of the 3D-printed solar panels? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Standford University

Powering the renewable energy transition with 3D printing: Solar

0Shares

The 3D Printing Industry interviews series looking at low carbon power generation together with 3D printing and renewable energy continues with deep dive into the application of additive manufacturing for solar energy.

“3D Printing has the potential to revolutionize the solar industry,” says Daniel Clark. The entrepreneur holds multiple patents in volumetric solar energy and 3D printing and is the founder of solar energy company T3DP

I spoke to Clark about the efficiency inroads additive manufacturing is making in the development of next-generation photovoltaics, and the potential for the technology to unlock a new era of solar energy.

According to BP’s most recent Statistical Review of World Energy, solar power recorded its largest-ever increase in 2020, and alongside wind accounted for more than 90 percent of the entire renewable energy sector’s growth across the year. This growth is also reflected in the rising market value of the sector, with the global solar energy market expected to be worth $422 billion in 2022, in comparison to $86 billion in 2015.

This growth is also reflected in the rising market value of the sector, with the global solar energy market expected to be worth $422 billion in 2022, in comparison to $86 billion in 2015.

The sun is rising on solar 3D printing

Solar remains the third-largest renewable electricity technology behind hydropower and onshore wind, with power generation increasing by a record 23 percent in 2020 compared to 2019.

While the technology’s plus points include helping people to save money on their bills and become energy independent, there are also several caveats, such as high upfront costs, large space requirements, and the environmental impact of manufacturing the photovoltaic panels. In fact, it takes 130 liters of oil to produce a single silicon solar panel and an estimated 78 million metric tons of toxic solar panel waste will end up in landfills by 2050.

Several years back, there was a flurry of activity within the additive manufacturing sector surrounding the 3D printing of more efficient, low-cost photovoltaics, spurred on by various solar power innovation contests launched by the likes of the US Department of Energy. However, there seems to have been somewhat of a tailing-off in this area since then.

However, there seems to have been somewhat of a tailing-off in this area since then.

Recently, though, there seems to have been a resurgence of activity in this field, with the Chemistry of Thin Film Materials (CTFM) laboratory at the University of Erlangen in Germany announcing a grant from the European Research Council (ERC) to rapidly prototype solar cells using its atomic-layer additive manufacturing technology. The lab hopes to bring the solar cells to market with the help of Formnext Start-up Challenge 2021 winner, atomic layer 3D printer developer ATLANT 3D Nanosystems.

One firm that has remained very active in this field is California-based start-up T3DP, founded by Clark, which has been applying its patented volumetric 3D printing technique to build perovskite-based solar panels since 2019.

Nature-inspired volumetric 3D printing

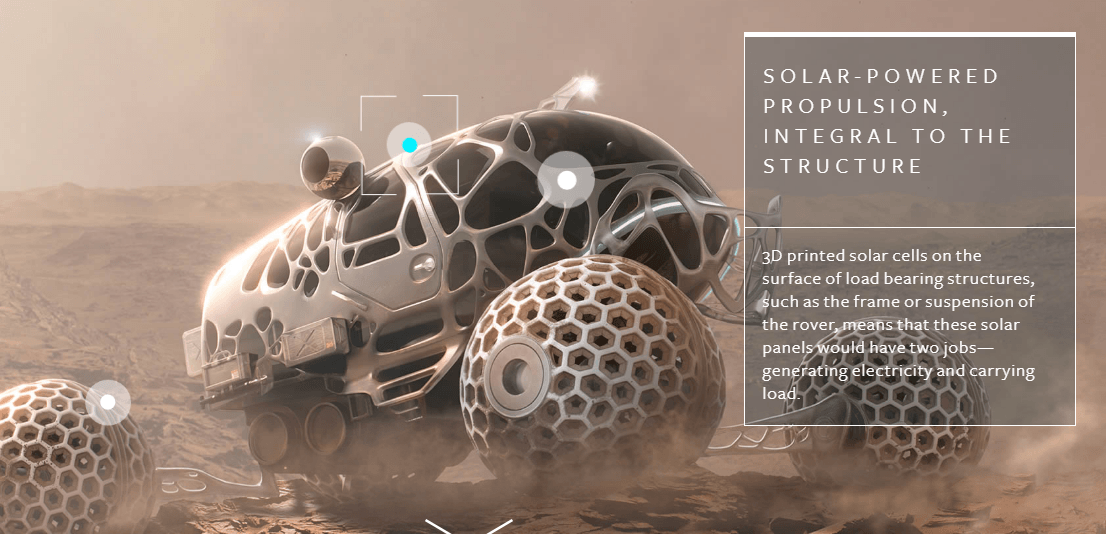

Taking inspiration from the honeycomb structure of insect eyes, T3DP has designed a novel solar cell able to capture three times more energy at half the cost of conventional, silicon-based cells. The process also allows micro-solar cells to be manufactured at close to carbon neutral by re-using glass from discarded solar panels.

The process also allows micro-solar cells to be manufactured at close to carbon neutral by re-using glass from discarded solar panels.

“Volumetric 3D printing has the potential to revolutionize the solar industry by increasing the power output two to three times that of flat silicon panels,” Clark says. “A typical flat solar panel produces 200 watts per meter squared, while our designs can reach 400-600 watts in the same area.”

Volumetric 3D printing is a process capable of overcoming the low throughput, geometric restrictions, structural defects, and scaling concerns commonly associated with additive manufacturing by curing objects in a single step, rather than layer by layer.

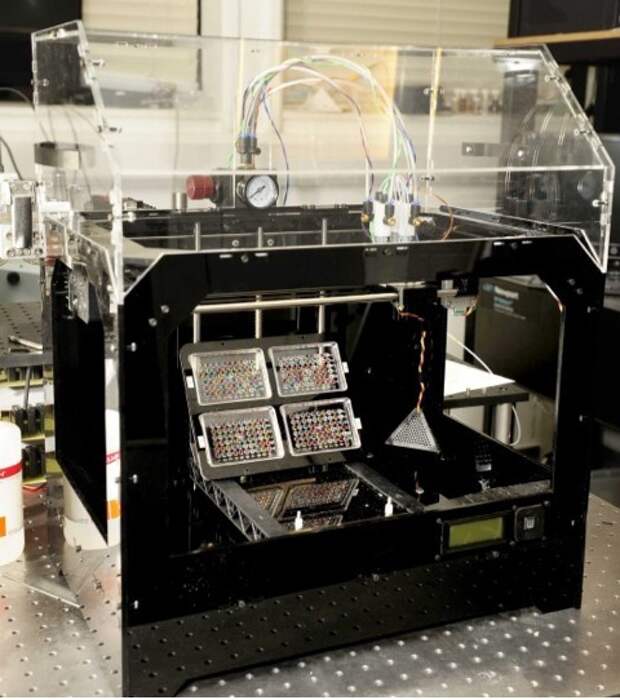

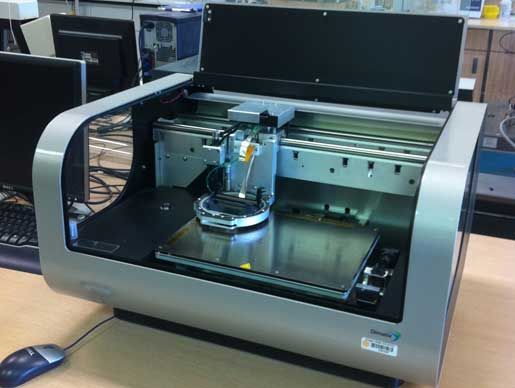

Clark worked with the team of Alexander Lippert, Associate Professor of Chemistry at Southern Methodist University (SMU), to develop and commercialize a unique volumetric 3D printer, dubbed the 3D Light PAD, designed specifically for the 3D printing of a wide range of complex components for solar cell manufacturing.

The printer operates by using a photoswitchable photoinitiator to direct polymerization to points only at the intersection of two different wavelengths of light, creating high-resolution 3D components. T3DP formed a strategic partnership with AsterTech, a company that alongside the Air Force Research Laboratory (AFRL) has developed an aerosol-jet-assisted perovskite deposition method for fabricating high-quality solar cells on the complex surfaces SMU and Clark produced using their 3D Light PAD printer.

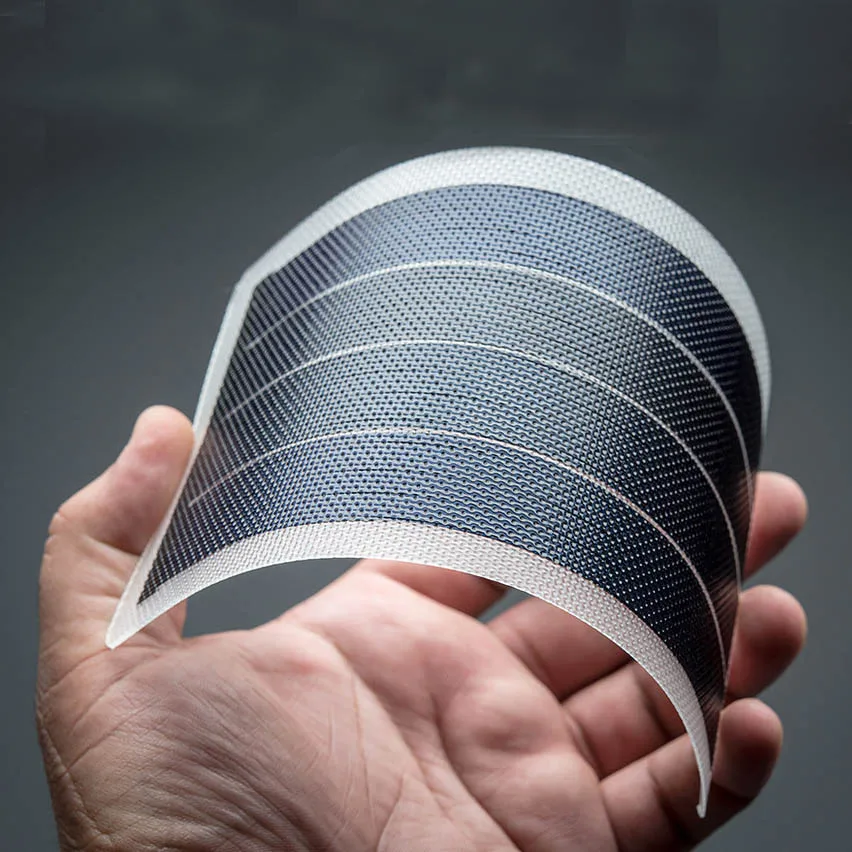

A part made from recycled solar panel glass with flexible 50um thick walls. Image via Daniel Clark.Clark’s volumetric 3D printing patent was granted last year after a four-year application process, with the IP now being utilized by volumetric 3D printing start-up xolo.

While there are no real-world application scenarios that Clark can publicly talk about right now due to a non-disclosure agreement (NDA) with xolo, he says: “While the volumetric 3D printing technology is awesome, it’s still two to three years away before we will see any major mainstream applications. However, the printer is the beachhead to my new Subzero Molding and Embossing technology that can scale the manufacturing of our micro 3D solar cell substrates from recycled solar panel glass.

However, the printer is the beachhead to my new Subzero Molding and Embossing technology that can scale the manufacturing of our micro 3D solar cell substrates from recycled solar panel glass.

“We have some continuation of patents that include a new True Volumetric Display from Lightfield Labs’ Solid Light.”

Lightfield Labs is developing next-generation holographic display technologies and has backing from the likes of multinational technology firm Bosch which, Clark says, will have an interest in the LightPAD 3D printer and its pending patents going forwards.

Clark’s plan is to make the 3D solar glass substrates, turn them into 3D solar cells and then wire them up and encapsulate them within a 3D solar module, similar to the beer cap table pictured. Image via Clark.Scaling solar with next-gen advanced manufacturing

Clark’s Sub Zero Manufacturing technology is designed for the mass production of flexible optically smooth solar cell substrates from recycled solar panel glass which do not require post-processing or polishing. The process involves mixing the crushed recycled glass with Glassomer UV Curable Resin and Tethon 3D Genesis Development Resin and “punching” the material into a 3D spiked pyramid shape imprinted with ultra-small micro LEDs.

The process involves mixing the crushed recycled glass with Glassomer UV Curable Resin and Tethon 3D Genesis Development Resin and “punching” the material into a 3D spiked pyramid shape imprinted with ultra-small micro LEDs.

The technique is reportedly “thousands of times faster” than 3D printing alone, and Clark believes the technology could also be effectively applied to the semiconductor industry to improve its green footprint.

Regarding the current state of the solar energy generation field, Clark offers: “The current silicon solar sector is dominated and controlled by China. The price of Silicon was up 300 percent in 7-8 weeks last October. As this trend continues upwards I see an opportunity for the Western world to reignite an extinguished flame through advanced manufacturing of aesthetically appealing solar that will be difficult to counterfeit.

The imprinting bit of Clark’s sub zero manufacturing technology. Photo via Daniel Clark.“I foresee our advanced one-step Volumetric 3D Printing and unique Subzero Forming processes to create a synergistic dichotomy to balance the solar manufacturing power back to the EU, USA, and the Western world.

”

Clark also works for Villara Energy Systems, developer of the VillaGrid energy storage system which claims to deliver more power, more safety, and more useful life than traditional home batteries. While the firm isn’t using Clark’s volumetric 3D printing technology yet, he says it is plausible that someday the process could help the mass manufacturing of batteries and solar cells at the firm’s battery and solar manufacturing facility in Sacramento County, California.

Make sure to subscribe to our newsletter and don’t miss the next installment of the series, where we will be looking at how 3D printing is helping to bring the hydrogen economy closer to reality.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry. You can also stay connected by following us on Twitter and liking us on Facebook.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a hexagonal part of a larger solar panel by T3DP. Image via T3DP.

Tags 3D Light PAD 3D printing and renewable energy Air Force Research Laboratory Alexander Lippert Atlant 3D Nanosystems Bosch BP Daniel Clark European Research Council Formnext Start-up Challenge 2021 Glassomer Lightfield Labs Southern Methodist University T3DP Tethon 3D University of Erlangen US Department of Energy Villara Energy Systems xolo

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Production of solar panels on a 3D printer

Implementation stories

Experts recommend

Energy

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

Why 3D printing is an effective solution for energy | Solar panels: 3D printing in renewable energy | Are such systems really profitable to print on a 3D printer? | Additive Manufacturing of Solar Cells: 5 Successful Projects | The Future of Solar 3D Printing

3D printing is increasingly used in the energy industry. The place of additive manufacturing in the renewable energy industry is of great interest. Take a look at the situation with climate change: today, obtaining energy from environmentally friendly sources is one of the most important tasks.

The place of additive manufacturing in the renewable energy industry is of great interest. Take a look at the situation with climate change: today, obtaining energy from environmentally friendly sources is one of the most important tasks.

Fossil fuels are rapidly declining, and so we see more and more electric vehicles, wind turbines and solar panels. However, most of them are far from perfect, and production is still costly. Fortunately, researchers are already working on 3D-printable solar cells to make the most of the sun, an inexhaustible source of energy.

Did you know that 3D printing is an excellent method for making solar cells? The researchers claim that additive manufacturing will help reduce the cost of manufacturing solar panels by 50%, and 3D-printed batteries are more efficient than solar panels made by traditional methods. This article talks about the effective use of 3D printing in the field of renewable energy, and more precisely, in solar energy. In addition, methods for 3D printing of photovoltaic cells for solar cells, as well as research on these methods, are considered here.

In addition, methods for 3D printing of photovoltaic cells for solar cells, as well as research on these methods, are considered here.

Why 3D printing is an efficient energy solution

Additive manufacturing is used in a variety of industries and can be extremely effective for making energy sources. Digital manufacturing is an excellent way to implement projects in the energy industry: the quality of products increases and production costs are reduced. Renewable energy producers face the challenge of reducing production costs. Let's find out why manufacturers of solar-powered systems or other green sources should look into 3D printing.

3D printing streamlines product development

A 3D printer is a great tool for prototyping, increasing productivity and cutting costs. Using 3D modeling software, models can be modified until the ideal design is obtained. You can perform as many iterations as needed before fabricating systems and parts. With the speed and precision of 3D printing, rapid prototyping is also simplified.

With the speed and precision of 3D printing, rapid prototyping is also simplified.

Significant cost reduction

Trying to cut down on prototyping and manufacturing costs? Take a look at 3D printing. It uses only the required amount of material and is cheaper to iterate on a 3D printer than injection molding because you don't have to make a new mold and repeat the whole process.

3D printers improve production efficiency

Digital technologies are suitable not only for prototyping, but also for production. These methods have many advantages: for example, 3D printers can produce small batches of parts very quickly. In addition, using additive manufacturing, you can fully control the process and order only the required number of parts. These features make additive technologies the best solution for the implementation of the entire project or the manufacture of individual parts.

Photo: www. csiro.au

csiro.au

Additive technologies - an excellent tool for scientific research

Later in the article, we will talk about why 3D printing is suitable for testing your ideas and working with new materials. Researchers continue to find new uses for 3D printing, such as the production of clean energy devices such as solar panels.

Solar Panels: 3D Printing for Renewable Energy

What are solar panels?

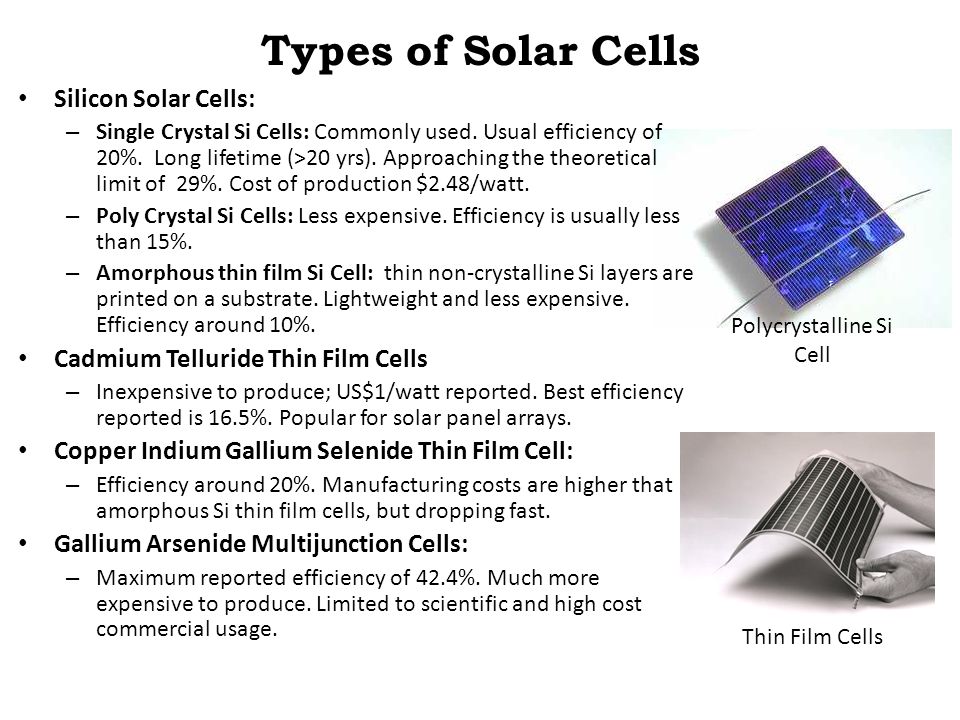

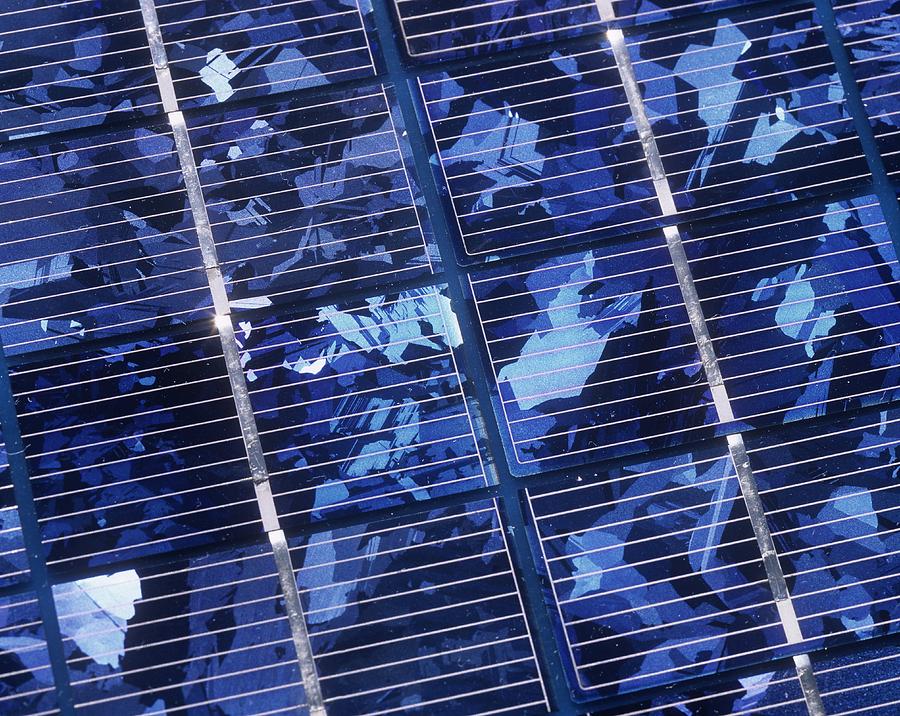

These are blocks that convert solar energy into heat or electricity. They are made of photovoltaic cells in which a number of physical and chemical phenomena take place. Typically, photovoltaic cells are made from crystalline silicon, but new materials are being actively developed (a recent example is thin-film solar cell technology). The quality and efficiency of solar panels manufactured by traditional methods leave much to be desired. That is why additive technology scientists are experimenting with the goal of creating high-quality solar panels on 3D printers.

Additive manufacturing could help cut solar panel production costs by 50%

3D printing is the best solution for making solar cells

One of the main challenges in the development and production of renewable energy sources is high costs. For this reason, such sources are not available to everyone. We have seen how 3D printing is suitable for new projects, and the production of solar panels is a great example.

First of all, a lot of research and development is required to produce high quality efficient solar panels. Previously, photovoltaic cells were made from expensive materials. When developing new solar cells and using materials with new technical properties, it is necessary to conduct many tests and make many prototypes. Projects like this need to be carefully thought out and showcased to the team, investors, and prospective clients require high quality models. This is where 3D printing comes in, as it will allow you to create high-quality prototypes. In addition, you can carry out as many iterations as you need. Additive technologies are also suitable for manufacturing, but you will need to find 3D printers that can print from these materials. For example, solar panels are made from a material that absorbs sunlight.

In addition, you can carry out as many iterations as you need. Additive technologies are also suitable for manufacturing, but you will need to find 3D printers that can print from these materials. For example, solar panels are made from a material that absorbs sunlight.

In theory, 3D printing is suitable for making greener energy sources at a lower cost. But is it so in practice?

Is it really profitable to print such systems on a 3D printer?

Using printed solar cells reduces costs by 50%

MIT researchers claim that additive manufacturing of solar panels can help cut costs by 50%. Such facilities do not require expensive materials (for example, glass, polycrystalline silicon, and indium). Obviously, the implementation of such projects is possible thanks to the printing of new materials on a 3D printer. For example, not so long ago it became known that the production of photovoltaic cells from synthetic perovskite is cheaper.

Project model ASTRI and CSIRO (Australia) / Photo: blog.csiro.au

Such systems can be implemented in developing countries

Solar panels can be 3D printed and are cheaper than glass panels made with traditional methods. Printed solar panels are lighter because they are made from ultra-thin strips. The transportation of such batteries is less of a problem. This technology is becoming more accessible, which means that renewable energy sources can be introduced almost everywhere and transported even to developing countries where there are problems with electricity supply.

3D printed solar cells are 20% more efficient

Solar panels made on a 3D printer are 20% more efficient than batteries created using traditional methods. This is due to the emergence of new methods, materials and design possibilities that have become possible thanks to 3D printing. Solar energy needed innovation, and most importantly, cost reduction. It looks like 3D printing will revolutionize the industry.

It looks like 3D printing will revolutionize the industry.

Solar Additive Manufacturing: 5 Successful Projects

A new technology for 3D printing of photovoltaic cells already exists, and it can fundamentally change the renewable energy industry. Below are examples of how companies are using 3D printing to produce solar cells and how researchers are developing the best options for producing high-quality photovoltaic cells.

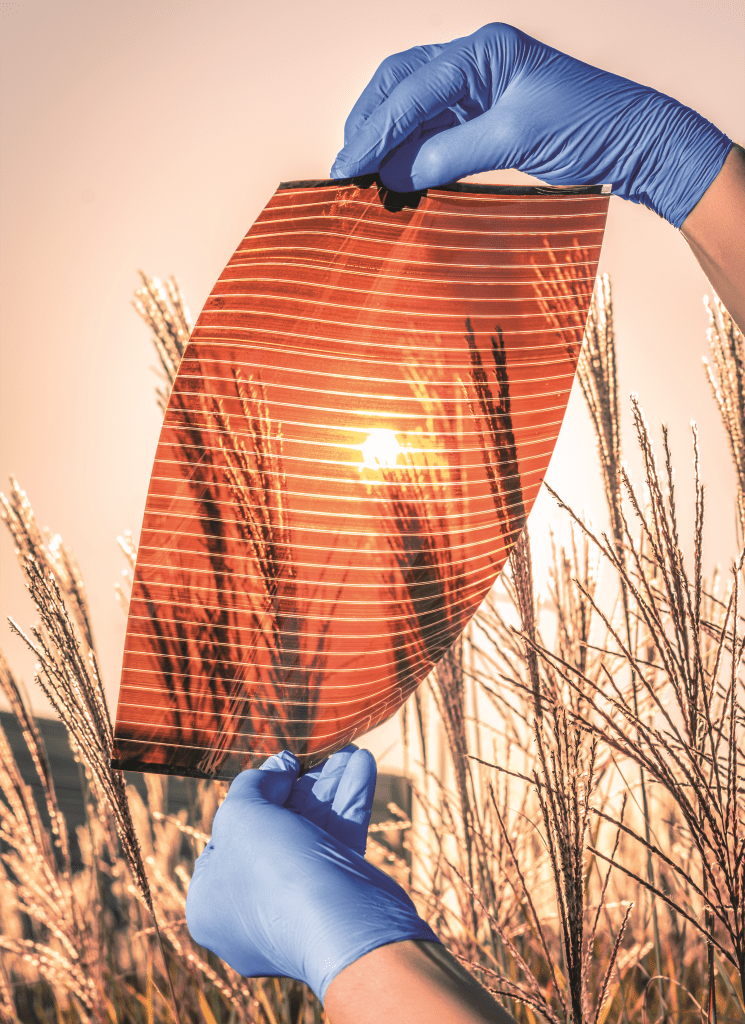

In the Australian organization CSIRO (Commonwealth Scientific and Industrial Research Organization), rolls of photovoltaic cells are made on industrial 3D printers. The researchers produce sheets of A3 photovoltaic cells that are suitable for all surfaces (such as windows and buildings). Batteries made from such elements are functional and efficient.

To date, these are the largest photovoltaic cells. They are made of flexible lightweight plastic. Researchers have developed an ink with photoelectric properties that is applied to a strip of flexible plastic. The production process includes coating the strips with an engraved cylinder, applying the material using a slotted die, as well as squeegee printing. The use of additive technology helped to produce a high-precision system.

The production process includes coating the strips with an engraved cylinder, applying the material using a slotted die, as well as squeegee printing. The use of additive technology helped to produce a high-precision system.

Solar panel field: ASTRI and CSIRO project (Australia) / Photo: www.csiro.au

Australian specialists use solar energy as efficiently as possible, but they print not only photovoltaic cells. For example, they can print an entire field of solar panels, because Australia has the highest solar radiation density in the world.

This project is implemented by the Australian Solar Energy Research Program (ASTRI) and its lead partner, CSIRO. The device collects concentrated solar radiation in the form of thermal energy. Heliostats literally fill the whole field, concentrating the radiation of the Sun 50-1000 times its normal power. The converted solar energy is stored in the receiver tower.

Some customers of the French company Sculpteo work with solar energy and use 3D printing. For example, Simusolar, founded in 2014, is building solar power plants in rural Tanzania, designing and implementing compact, sustainable solutions that help people in their daily lives. The company's customers are farmers, fishermen and villagers who need equipment powered by solar electricity. Simusolar uses 3D printing because there is a need for many custom parts.

For example, Simusolar, founded in 2014, is building solar power plants in rural Tanzania, designing and implementing compact, sustainable solutions that help people in their daily lives. The company's customers are farmers, fishermen and villagers who need equipment powered by solar electricity. Simusolar uses 3D printing because there is a need for many custom parts.

Kyung-In Synthetic's goal is to bring solar power to remote areas. To do this, it was decided to print solar panels. As part of the project, renewable energy sources have become available to more than one million people. The 3D-printed solar panels are made from perovskite, a mineral that contains calcium titanate. The properties of photovoltaic cells made from perovskite are improving every year, which means that systems made of such cells can work without reducing efficiency for several years. This technology has a great future.

3D printed solar panels at Sandia National Laboratories / Photo: 3dprint. com

com

Engineers at Sandia National Laboratories (New Mexico, USA) have been working on solar receivers and have proven that they are 20% more efficient than solar panels made by traditional methods. The batteries have been reconfigured to absorb more sunlight. Thanks to their special design, they can absorb light at different scales.

Additive manufacturing allows engineers to create solar installations with complex geometries and greatly simplifies the design process. Researchers have created louver-type panels that absorb more light. This system works without energy loss. The light first hits the receiver and then is absorbed.

Of course, for the manufacture of such systems it is necessary to develop new materials and technologies. And if you think manufacturing solar cells is a complicated process, these examples show how 3D printing makes it easy.

The Future of Solar 3D Printing

3D printing in this area can quickly become one of the key technologies. For example, it makes mass customization of parts and systems possible. People will be able to order solar panels of the desired shapes and sizes, made on a 3D printer according to individual requirements.

For example, it makes mass customization of parts and systems possible. People will be able to order solar panels of the desired shapes and sizes, made on a 3D printer according to individual requirements.

The development of a new material for 3D printing could greatly change the solar energy industry. What's more, low-cost, high-efficiency cells will be suitable for solar-powered devices, and perhaps electricity will become available all over the world, even in the most remote areas.

Energy and 3D printing are becoming excellent partners. It is likely that in the future they will help develop many environmentally friendly systems, the use of which will help fight climate change.

Author: Lucy Gage. Translation from English. Original material on the site Sculpteo

Screensaver photo: Littlegate Publishing

Article published on 11/05/2019, updated on 04/18/2022

3D printed solar cells are cheaper and easier to manufacture

Do you remember the solar panels that Professor Paul Dastor of New Castle University and his team made with a 3D printer?

3D printing is an important asset for the energy industry. Four years ago, Dastur and his team invented light, ultra-flexible, recyclable and low-cost solar panels.

Four years ago, Dastur and his team invented light, ultra-flexible, recyclable and low-cost solar panels.

Newcastle University was one of only three places in the world to test printed solar cells that use electronic ink to conduct electricity.

Solar panels on the street

Firstly, some of these solar panels were installed in the city to increase their visibility and public awareness.

“There were so few such installations around the world that we know very little about how they work in public places. This setup is an important next step in accelerating the development and commercialization of this technology,” Professor Dastuor said in a 2018 edition.

Scientists planned to make significant progress in the commercial availability of material for 3D printed solar panels.

What were the benefits?

As 2019 rolled around, the project began to take on a “real” shape.

With industrial equipment capable of producing miles of material every day, printing solar power was fast and inexpensive, and the production cost was less than $10 per square meter.

“No other renewable energy technology can be produced so quickly,” said Professor Dastoor.

Since more than 99 percent of the panels are made from PET, a recyclable material that gives it a distinct advantage over traditional silicone panels.

"This is the first commercial use of printed solar cells in Australia, and most likely the world," said Dastuor. “This is a historic step in the development of this technology and yet another example of private enterprise and the community leading the way in renewable energy adoption.”

What does the future hold for us?

Professor Paul Dastur stated that it will soon be possible to develop a printable solar technology that will fit on almost any surface to power city lights, roadside water pumps, emergency shelters, caravans and camping equipment, and be mounted on anything from smart blinds for residential buildings to floating roofs.