Heroforge 3d printing

STL Downloads | Hero Forge®

Tell me about the downloadable 3D model files and home printing.

At the urging of many makers, tinkerers, inventors, and printers, we have begun offering digital print file distribution. This means, in addition to ordering 3D prints, users now have the option to buy the model file for their custom Hero Forge characters. These files can then be loaded into your 3D printing software for printing at home. Models are tessellated meshes with a polycount of up to 100,000 triangles. They are not rigged for animation.

Models are distributed via your Digital Downloads page in .stl file format. They are typically posted within 15-30 minutes of your purchase, but please allow for up to one business day. Digital models are only guaranteed to be available on your Digital Downloads page for six months from purchase.

Note that Hero Forge miniatures are finely detailed scale models. As a result, some home 3D printers do not have the ability to faithfully replicate the level of detail present in the source model or have issues printing thin, free-standing “wire” parts or the thin supports necessary to support a model during the build process. As a result, Hero Forge does not give any warranty about the models, and does not guarantee that the model will be fit for any particular purposes or be compatible with any specific make or model of printer.

We strongly recommend printing one of our free sample digital models before making a purchase. Sample models are available on your Digital Downloads page.

3D printers come in many shapes, sizes, and employ a wide range of technologies. Different technologies have different benefits and drawbacks. You are invited to submit photos of your prints, along with your printer’s make and model, materials used, and any pertinent settings used to create your print. The most common technologies are as follows:

SLA and DLP Printers

Some of the highest detail 3D printers are based on SLA (Stereolithography) and DLP (Digital Light Processing) technology. These printers use a pool of liquid resin which, by being exposed to a light source such as a projector or a laser, solidifies the liquid material into a solid layer by layer.

These printers most commonly function by submerging a “build platform” into a pool of liquid resin, allowing a light or laser on the underside to trace the layer’s shape, hardening it onto the build platform, which then serves as the foundation for the next layer. The platform then lifts from the resin, and is resubmerged again to print each successive layer.

SLA and DLP printers are known for producing some of the finest detail on the market, ideal for 30mm scale models for tabletop play. They also tend to be more expensive than other print technologies, both in terms of material costs and hardware.

Form2 by Formlabs

Material: “Gray Resin v3”

Settings: Printed at the maximum .025mm layer height. The models were oriented on their backs in order to allow high detail areas like the face and chest to remain free of support structures.

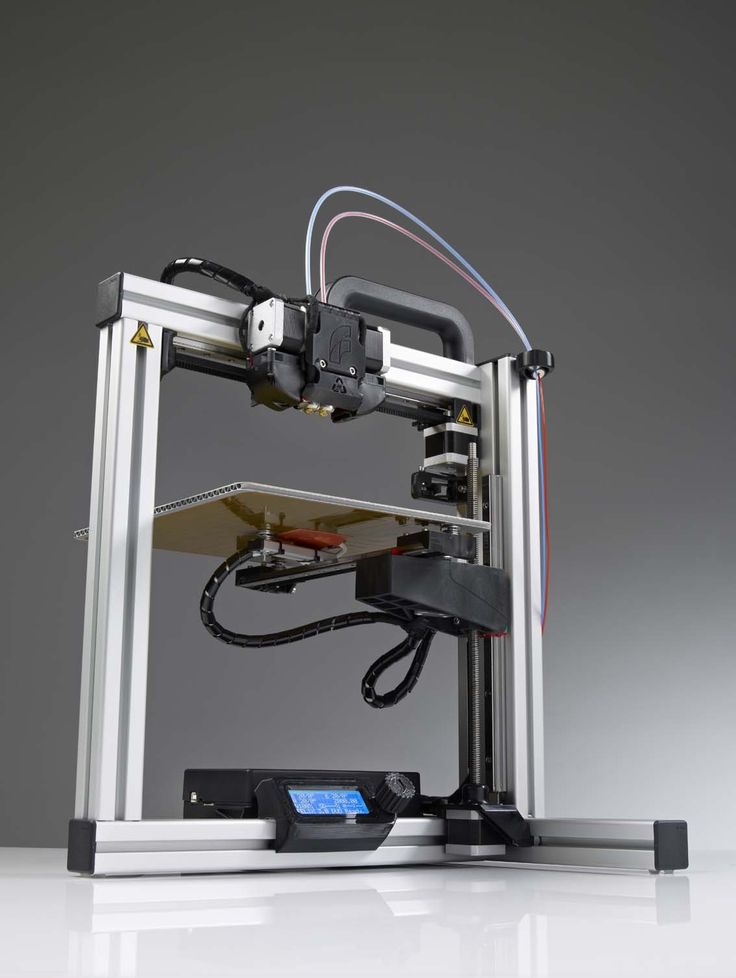

FDM Printers

The most common home 3D printers use FDM (fused deposition modeling) print technology. These machines start with a spool of ‘filament,’ typically a long wire of PLA or ABS plastic. The printer uses a heated nozzle to melt the filament, extruding onto a build tray similar to how a hot glue gun works. The material is extruded along a path predetermined by the controlling software. The melted material cools and solidifies, building the print layer by layer, with each new layer using the last as its foundation. This is one of the cheapest 3D printing technologies, and, while it does not match the detail levels of some other printing methods, is great for producing low-cost and large-scale models.

These machines start with a spool of ‘filament,’ typically a long wire of PLA or ABS plastic. The printer uses a heated nozzle to melt the filament, extruding onto a build tray similar to how a hot glue gun works. The material is extruded along a path predetermined by the controlling software. The melted material cools and solidifies, building the print layer by layer, with each new layer using the last as its foundation. This is one of the cheapest 3D printing technologies, and, while it does not match the detail levels of some other printing methods, is great for producing low-cost and large-scale models.

There are many, many companies producing a wide range of printers with a multitude of features, options, and settings. Common brands include Makerbot, LulzBot, XYZprinting, and many more. While we cannot test or provide recommended settings for every printer on the market, what follows are user-submitted images of their prints, along with any settings or material information they’ve provided. We encourage users to print and submit images of our sample models so we can add them to our directory!

We encourage users to print and submit images of our sample models so we can add them to our directory!

Da Vinci Jr. 1.0

Material: “PLA”

Settings: Vertical orientation, 200 micron resolution, raft with supports, slow print speed.

Dremel 3D Idea Builder 3D20

Material: PLA

Settings: Layer Height: 0.12mm, Speed: 2000mm/min, Had to rotate the models X:-90º to stand upright. Support structures were needed.

L3 MK2

Maker Select Plus

Material: PLA

Mono Price Select Mini

Material: Hatchbox Gold PLA, 1.75mm

Settings: For Model 1 (Paladin) - 0.04375mm layer height, on back rotated 45 degrees back, grid support. For Model 2 (Elf) - 0.04375mm layer height, laying flat on back, grid support.

MonoPrice IIIP

Material: PLA

Settings: Layer height: .1. Shell thickness: 1. 2. Bottom/top thickness: 1.2. Fill density 10%. Print speed: 40. Printing temp: 210c. Bed temp: 65c.

2. Bottom/top thickness: 1.2. Fill density 10%. Print speed: 40. Printing temp: 210c. Bed temp: 65c.

Robo3D R1+

Material: PLA

Settings: Printed at .1mm layer height.

Trinus

Material: PLA filament 1.75mm

Settings: Printed 45deg orientation, 1mm thickness, normal print speed, heated bed, base down, 0.1 layers.

Ultimaker 2+

Material: PLA

Up! Plus2

Material: PLA

Settings: Printed at 0.15mm layer resolution with a 0.4mm nozzle.

Do you have a question not covered by this guide? Please Contact Us!

About Our Products | Hero Forge®

Physical Minis Starting at $19.99 - Digital at $7.99

Hero Forge® offers a comprehensive range of materials and formats to meet any and all of your custom miniature needs. Our Custom Plastic and Premium Plastic are great options for players who love to paint their miniatures themselves. For table-ready minis right out of the box, try out unique Color-Printed Plastic miniatures. Hero Forge® also offers Digital STL files for 3D-printing enthusiasts who enjoy printing their own miniatures at home and full-color 3D Digital miniatures for use in your favorite virtual tabletop programs. Hero Forge® Pro and Pro Plus subscribers can also take advantage of unlimited tokens for character sheets, virtual tabletops, and more.

For table-ready minis right out of the box, try out unique Color-Printed Plastic miniatures. Hero Forge® also offers Digital STL files for 3D-printing enthusiasts who enjoy printing their own miniatures at home and full-color 3D Digital miniatures for use in your favorite virtual tabletop programs. Hero Forge® Pro and Pro Plus subscribers can also take advantage of unlimited tokens for character sheets, virtual tabletops, and more.

PHYSICAL PRODUCTS

3D Color-Printed Plastic

- ●●○○○Durability

- ●●●●○Detail

Our custom color miniatures are the apex of tabletop miniatures without you needing to lift a paintbrush. Color-printed miniatures are printed in an “inkjet” style 3D print with water soluble supports, meaning no sprues will mark up your beautiful gradients and fine decals.

Learn More

3D PRINTED BASE PLASTIC

- ●●●●○Durability

- ●●●●○Detail

Anything you design in Hero Forge®’s character creator can be printed in our durable yet detailed plastic. All plastic miniatures come in a smooth matte gray and pre-primed for easy painting.

All plastic miniatures come in a smooth matte gray and pre-primed for easy painting.

Learn More

3D Printed Premium Plastic

- ●●●○○Durability

- ●●●●●Detail

Premium plastic is the optimal material for all hobbyists looking for maximum detail. Take your tabletop RPG experience to another level with the perfect replica of your player character. All premium plastic miniatures are printed in SLA, coming in a glossy black finish.

Learn More

3D Printed Bronze

- ●●●●●Durability

- ●●●●●Detail

Our custom bronze miniatures are the epitome of tabletop epicness. Bronze miniatures are printed using the lost wax method and maintain the highest level of detail fidelity. Polished to a luminous shine and incredibly smooth to the touch, every detail of your custom character will gleam.

Learn More

Color Standees (Currently Unavailable)

- ●●●●●Durability

- ●●●●●Detail

Each color standee is precision cut to the unique outline of your character and rendered front, back, and base in full, high-resolution color. All color standees can be taken apart for flat storage, making them incredibly easy to use and portable enough to take on all of your adventures.

DIGITAL PRODUCTS

STL Download

STL Digital Downloads are for the 3D printing hobbyist looking to print their very own Hero Forge® design at home. Every Hero Forge® mini can be purchased as a downloadable STL file. Each miniature’s 3D model is distributed as a zipped .stl file with a file size around 5-10mb.

Learn More

3D Digital

Each custom digital miniature is a fully 3D model with all of your detailed color, effects, and posing. Use your Hero Forge® access key to connect your Hero Forge® account to supported virtual tabletops and all of your 3D digital minis will automatically sync to the tabletop.

Use your Hero Forge® access key to connect your Hero Forge® account to supported virtual tabletops and all of your 3D digital minis will automatically sync to the tabletop.

Learn More

Pre-Made Digital Packs

Each month, Hero Forge releases beautifully designed Pre-Made Digital Packs that include STL and 3D Digital files for five themed minis. Each pack is $7.99 and can also be purchased with 1 digital credit.

Learn More

SPECIALTY MATERIALS

Painted Plastic (Available exclusively to Kickstarter Backers)

- ●●●○○Durability

- ●●●●○Detail

For supporting us on Kickstarter, backers of the appropriate tier have access to hand-painted miniatures. Hand-painted miniatures are printed in our premium plastic and painted using traditional miniature painting techniques.

Learn More

2X Scale Nylon Plastic

- ●●●●●Durability

- ●●●○○Detail

When standard scale just won’t cut it, we offer custom nylon miniatures at two hundred percent the size of our standard 30mm scale miniatures. Our Nylon plastic is white and has a porous, slightly rough texture. These behemoth miniatures still maintain excellent detail even at the increased size.

Learn More

Gift Cards

Gift Cards

Give your adventuring party, friends, and loved ones the ability to bring their characters to life with a Hero Forge® gift card! Our user-friendly gift cards are delivered instantly via email and can be used on any Hero Forge® miniature, digital or physical!

Please note that gift cards cannot be applied to Hero Forge® Pro and Pro Plus Digital Download subscriptions.

Learn More

OTHER PRODUCTS

Polyhedral Dice

- Opaque: $9.99

- Translucent: $9.99

- Metal: $34.99

Roll our opaque, translucent, and metal dice in your next campaign! Each material comes in a variety of colors and features easy-to-read numbers.

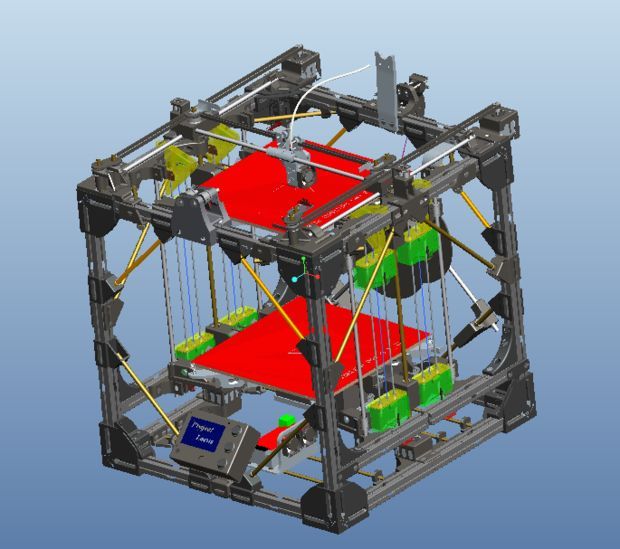

Zmorph is the most multi-head 3D printer. Investigation from REC.

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device.

1. External dimensions - 530 mm x 555 mm x 480 mm.

External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

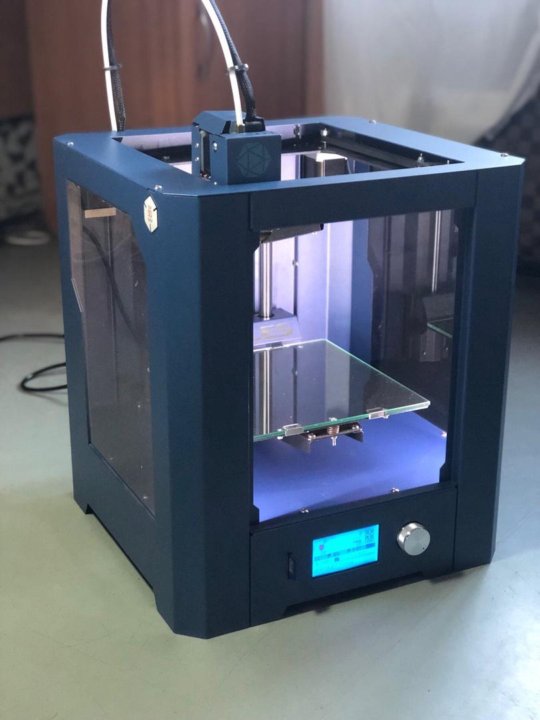

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets.

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer.

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

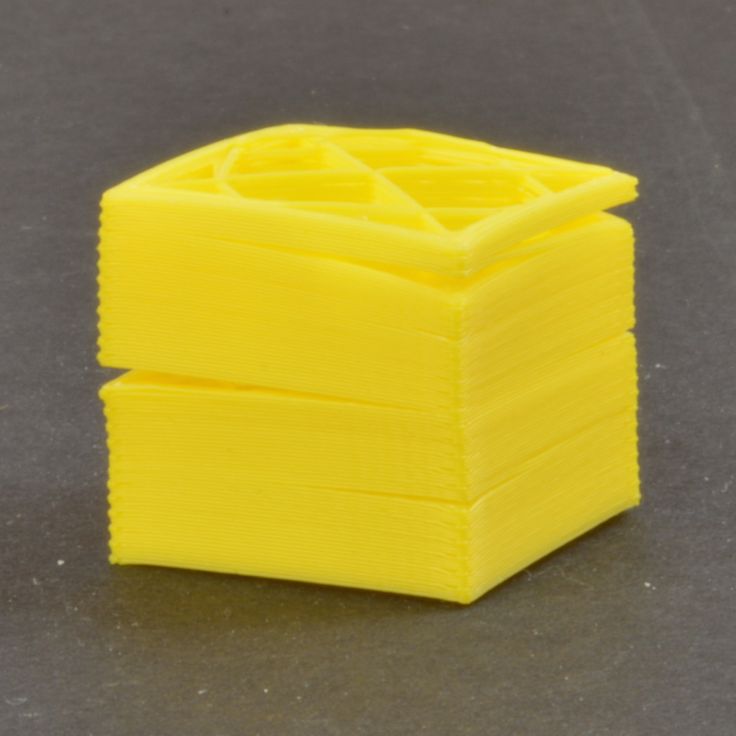

Print.

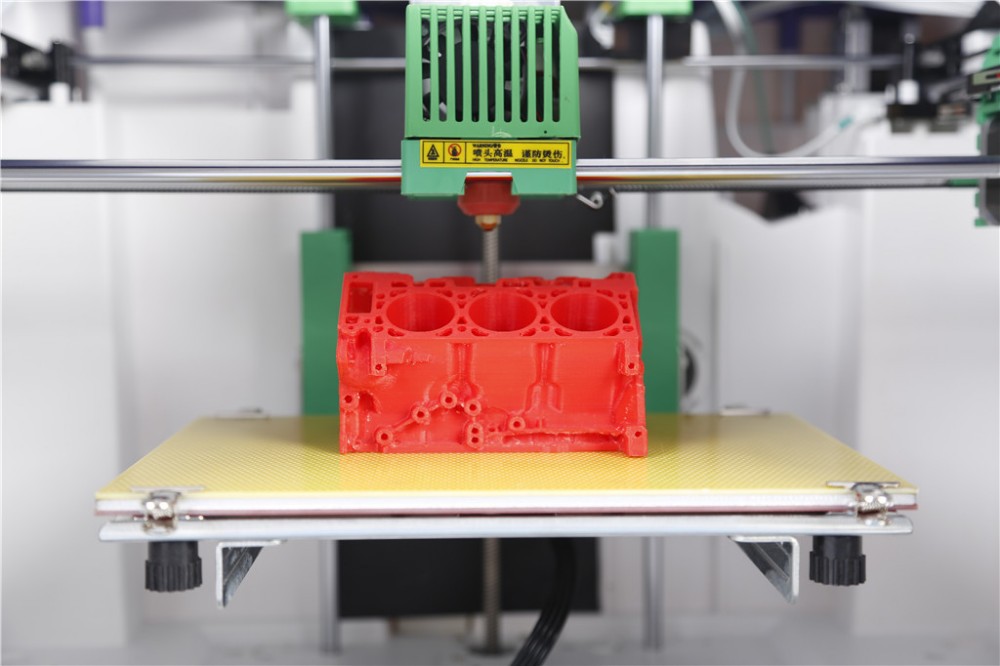

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

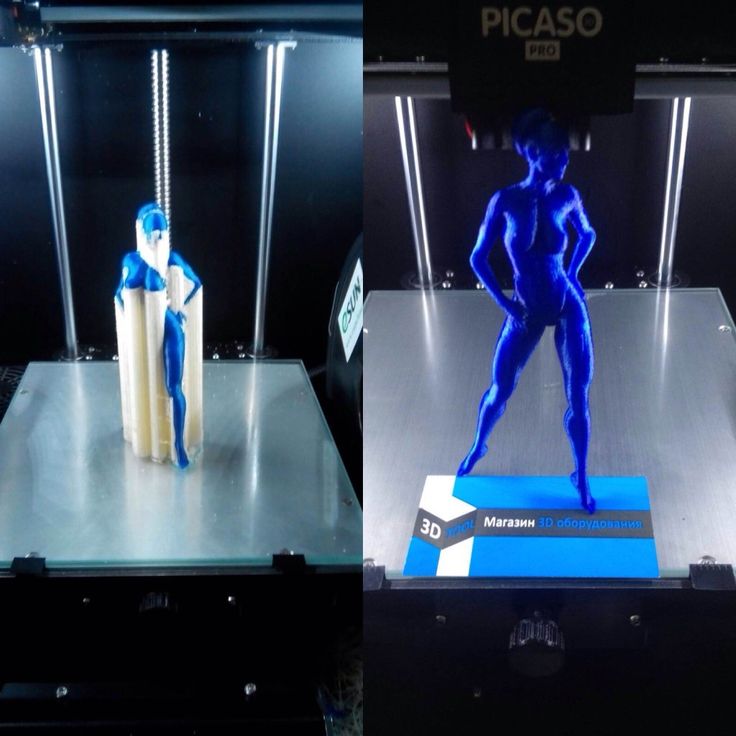

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head.

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them.

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program.

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts.

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic needed.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website.

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object.

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social. networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

Website: https://rec3d.ru/Phone: +7 (800) 775-7331 (free of charge from anywhere in Russia)

http://www.viber.com/rec3d https://telegram.me/Rec3d_bot https://vk.com/rec3dcompanyhttps://www.instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

Thank you for your attention and happy printing!

new advances in surgical simulation

Implementation stories

Medicine

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

High-precision models for training specialists in the field of surgery | Comments of hospital surgeons | Sharebot 3D printers are reliable tools for innovation

Undoubtedly, 3D printing is one of the most advanced technologies of our era and, probably, in a few decades, these years will be remembered as the period of its formation. This is one of the most promising and revolutionary technologies that is used in various fields, in particular, in healthcare. Therefore, it is worth clarifying a few questions. For example, how can 3D printers contribute to the development of medicine and healthcare in general?

This is one of the most promising and revolutionary technologies that is used in various fields, in particular, in healthcare. Therefore, it is worth clarifying a few questions. For example, how can 3D printers contribute to the development of medicine and healthcare in general?

A good example is the unique project of the General Surgery Department of the Sacra Famiglia Fatebenefratelli Hospital in Erba (Lombardy, Italy), where, using the Sharebot 3D printer, it was possible to recreate real anatomical organs and structures to simulate basic surgical interventions, such as video laparoscopic cholecystectomy.

Meet sharebot.ru : all about innovative 3D solutions to optimize your business. Catalog of 3D printers based on the most popular additive technologies, tasks and applications, success stories, promotions, videos and other useful materials!

Liver and gallbladder segment models printed on a Sharebot 43 FDM printer

In collaboration with Sharebot, an experimental model of a segment of the liver and gallbladder was created using a special material (LAY-FOMM) produced in the form of a plastic thread. After immersion in water, this material, thanks to its two-component composition (rubber and PVA-based soluble part), becomes similar to organic tissues, which also allows surgical sutures to be applied. It was found that the degree of extensibility in combination with residual moisture after immersion in water is similar to organic counterparts.

After immersion in water, this material, thanks to its two-component composition (rubber and PVA-based soluble part), becomes similar to organic tissues, which also allows surgical sutures to be applied. It was found that the degree of extensibility in combination with residual moisture after immersion in water is similar to organic counterparts.

iQB Technologies experts recommend the article: Additive technologies in medicine: how to reduce risks to patients' health

Is your healthcare facility interested in implementing 3D technologies? Order free test services 3D printing and 3D scanning!

Leave a request

High-precision surgical training models

Thus, the surgeons of the hospital were able to reproduce the video laparoscopic cholecystectomy directly on the printed models. In practice, this involves removing the gallbladder without damaging the liver tissue. Performing surgery on a model pelvis (laparoscopic simulator) allows surgeons to master the correct technique, as well as experiment with new non-invasive methods of removal.

Pelvic Surgery Simulator

By simulating important surgeries on high-precision 3D-printed anatomical models, it has been possible to make a big step in the field of medical technology, which undoubtedly increases the chances of patients recovering with similar interventions.

We are interested in 3D printing in terms of practical training of a new generation of surgeons based on more advanced and accurate models.

Specialists of the General Surgery Department of the Sacra Famiglia Fatebenefratelli Hospital

Comments from surgeons at hospital

The peculiarity of the model developed by us is that there are two holes between the liver and the gallbladder, which make it possible to completely empty the gallbladder in order to then fill it with a colored liquid to simulate bile. Due to its elasticity, the liver is also used to develop the technical possibilities of applying laparoscopic and traditional sutures.

In each model, the liver and gallbladder are directly connected by supporting structures. Using a raft (a horizontal mesh of plastic located at the base of the model) and supports, we developed a model of the gallbladder, in which they, simulating the liver bed, allow us to model the plane of the liver section. This model includes only the gallbladder and saves consumables, which speeds up the 3D printing process.

Anatomical base with liver made of PLA plastic

We also reduced the space between the support and the gallbladder to make the area between them more complex and realistic. For more efficient placement inside the pelvis model (laparoscopic simulator), we created an anatomical base with a liver made of PLA plastic. It contains a soft sponge that mimics a real liver, into which a component of a 3D model of the gallbladder made of LAY-FOMM, an easy-to-use filament, has been inserted through the valve. This rigid model allows quick and easy replacement of LAY-FOMM gallbladder models.

Finally, we created an ellipsoidal cylindrical model with a vertical hole, which makes it possible to simulate intestinal sutures and anastomoses. 3D printing of this model does not require much time and money.

Models for testing intestinal sutures

We believe that this technology opens up diverse and broad possibilities. We intend to create models of other organs for high-precision simulation of a number of important surgical interventions. To do this, we need to learn how to perform 3D printing based on DICOM files in particularly complex or atypical cases sometimes encountered in clinical practice. In general, 3D printing with LAY-FOMM interested us in terms of technical perspectives and, most importantly, the practical training of a new generation of surgeons based on more advanced and accurate models.

Specialists of the Department of General Surgery

iQB Technologies Experts Recommend Article: 3D Printed Prostheses Transform Patients' Lives

Sharebot 3D Printers - Reliable Tools for Innovation

Fatebfratelli hospital staff use a Sharebot 43 compact professional 3D printer equipped with two autonomous extruders. The device allows you to print products of the most complex geometry with soluble supports. In addition, a system of mirroring and duplication is available when printing. The flexible printer platform maintains a temperature of 120°C, and the maximum heating temperature of the extruders reaches 300°C, which allows the use of technical and professional materials that meet a wide variety of physical, chemical and mechanical conditions, including high or low temperature, the presence of oil and gasoline, as well as impact and friction.

The device allows you to print products of the most complex geometry with soluble supports. In addition, a system of mirroring and duplication is available when printing. The flexible printer platform maintains a temperature of 120°C, and the maximum heating temperature of the extruders reaches 300°C, which allows the use of technical and professional materials that meet a wide variety of physical, chemical and mechanical conditions, including high or low temperature, the presence of oil and gasoline, as well as impact and friction.

Printing process on Sharebot 43

The collaboration between Sharebot and the Department of General Surgery at the Fatebenefratelli Hospital in Erba has demonstrated the importance of introducing 3D printing, which opens up the possibility of creating new types of models and high-precision surgical simulators. This area is just one of the possible directions for the development of technology. Whether it's recreating organs for experimentation or printing implantable prostheses, 3D technology is becoming a key tool for medical innovation.