3D printer dentistry

How to Choose a Dental 3D Printer for Your Practice or Lab

Additive manufacturing is the latest piece of the workflow in digital dentistry that has become a logical business choice for dental practices and labs, combining high quality with low costs and streamlined workflows. The market has been expanding rapidly, bringing this technology within reach for more businesses.

In this guide, we’ll look at the different 3D printing technologies for dentistry and all of the attributes to evaluate before investing in a dental 3D printer.

New to digital dentistry? Check out our guide to find out more about the difference between analog and digital workflows, and learn what’s involved in integrating 3D printing into your business.

Sample Part

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 3B+ to evaluate.

Request a Free Sample Part

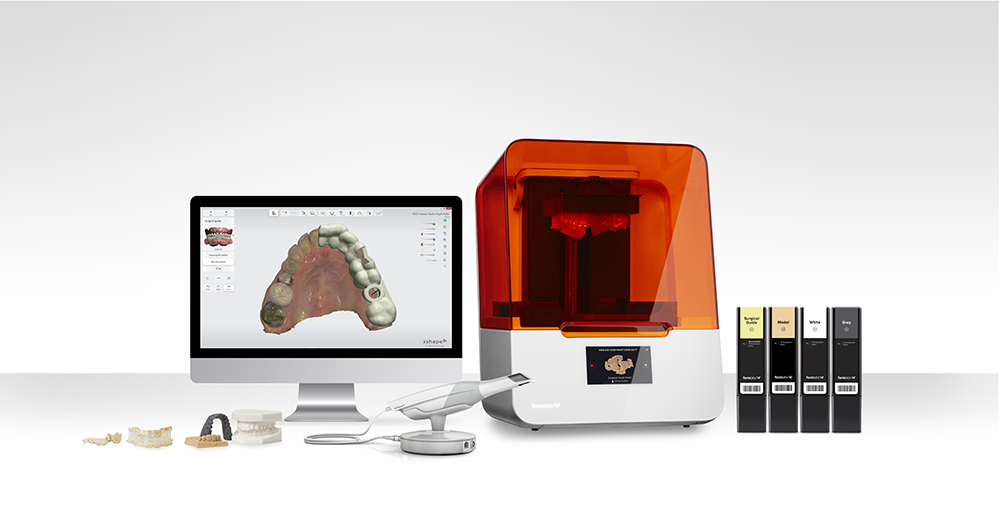

Today, two 3D printing technologies are common in dental and orthodontic practices and labs: stereolithography (SLA) and digital light processing (DLP).

In stereolithography, a vat of liquid resin is selectively exposed to a laser beam across the print area, solidifying resin in specific areas. Low Force Stereolithography (LFS) technology, used by Formlabs’ Form 3B+ 3D printer, is the next phase in SLA 3D printing that reduces the strain created on a part when peeling it from the resin tank between layers, producing parts with unmatched surface finish, clarity, and accuracy.

Digital Light Processing operates with the same chemical process as SLA and LFS, but uses a digital projector as a light source to solidify the resin, rather than a laser.

The most common orthodontic and dental 3D printers work by selectively exposing liquid resin to a light source—SLA and LFS a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object.

The way SLA, LFS, and DLP 3D printers work is similar—the differences in print quality, workflow, available materials, costs, and other factors are bigger from machine to machine more than technology to technology.

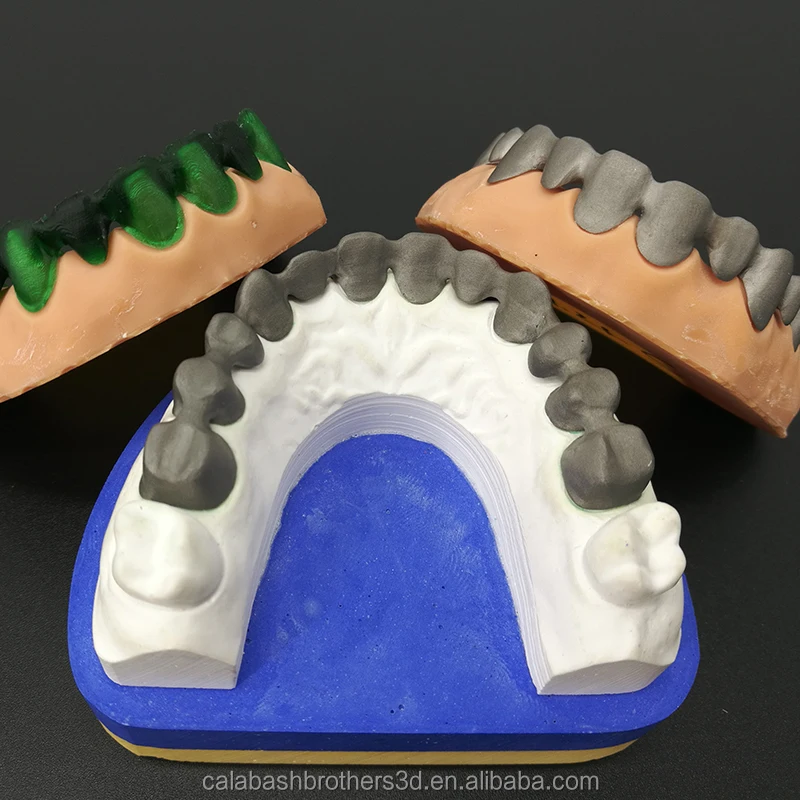

Clear aligner thermoformed over a 3D printed model produced on a Formlabs Form 3B+ dental 3D printer.

Webinar

Join Dr. Rick Ferguson, DMD, DABOI/ID, DICOI for a hands-on demo with the Form 3B+, the flagship 3D printer from industry leader Formlabs Dental.

Watch the Webinar Now

Guaranteeing high-quality, accurate, final parts is the most important concern for any dental practice and lab. Unfortunately, not all 3D printers marketed for dentistry or orthodontics can deliver the quality, precision, and accuracy needed for orthodontic applications. Additionally, comparing different dental 3D printers goes beyond looking at technical spec sheets.

Some manufacturers may try to confuse prospective customers with misleading statements and technical specifications. Most commonly, they masquerade layer height, laser spot size, or pixel size as “accuracy”, even though these specifications do not have a direct impact on the accuracy of final parts. While most companies refer to a single number for accuracy (i.e. 50 microns or 75 microns), these are typically marketing gimmicks, and most commonly represent the limit of resolution of the printer.

While most companies refer to a single number for accuracy (i.e. 50 microns or 75 microns), these are typically marketing gimmicks, and most commonly represent the limit of resolution of the printer.

The basic units of the SLA, LFS, and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

Fundamentally, accuracy and precision depend on many different factors: the quality of the 3D printer, the 3D printing technology, materials, software settings, post-processing, and how well-calibrated all of these systems are, so a 3D printer can only be judged on its final dental parts.

Always evaluate accuracy studies with real scan data of printed parts. Even better, ask for a sample part or a custom sample of your own design to check the fit or measure yourself against the original design.

Accuracy study of a full arch model with dies printed on the Form 3B LFS 3D printer. Dental 3D printers can produce high-quality custom products and appliances with superior fit and repeatable results.

Another important consideration is how easy it is to use a 3D printer. After all, you and your team are going to have to learn how to use the equipment and maintain it on a daily basis. Try to get a sense of the learning curve that will come with a new 3D printer by watching videos online, visiting a trade show, contacting sales teams, or asking colleagues about their experience.

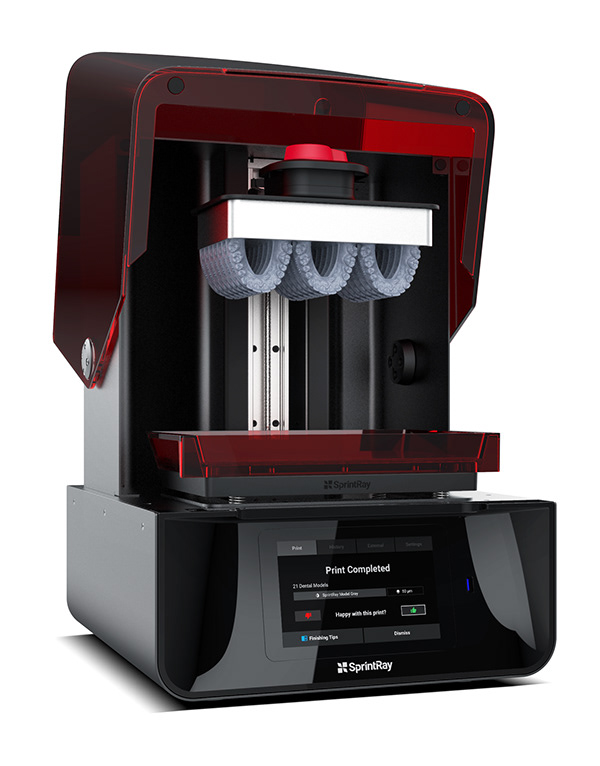

Modern 3D printers, like the Form 3B+, are designed intuitively so that any lab or practice can get familiar with the process easily.

Consider the types of everyday interactions and maintenance the printer will need once it is up and running. For example, automatic resin dispensing on Formlabs SLA and LFS 3D printers means that you never need to worry about running out of material.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers a one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time.

Curious to see how it works? Download PreFrom for free to test features.

Removing printed parts from the build platform can result in scratches, broken models, or part defects. Formlabs dental 3D printers also offer a build platform that instantly releases parts from the print surface with one simple movement of the stainless steel side handles.

Parts printed with SLA, LFS, and DLP technologies require post-processing after printing.

First, the parts need to be washed in a solvent to remove excess resin. Biocompatible dental parts also require post-curing. For SLA and LFS 3D printers, Formlabs offers solutions to automate these steps, saving time and effort, and making a big difference in keeping a clean, low-maintenance production environment.

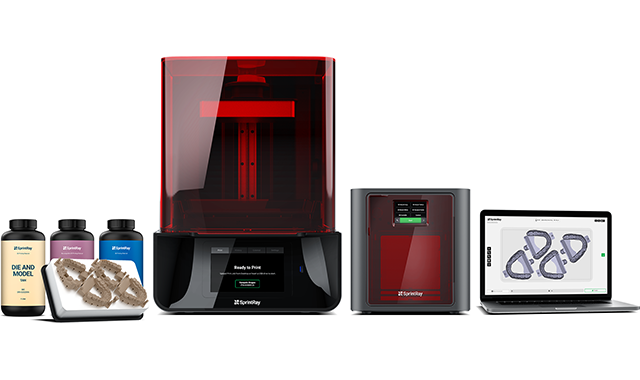

Form Wash and Form Cure automate post-processing, saving time and effort.

Lastly, depending on the design, some parts need to be cleared of support structures. To simplify this step, Formlabs’ Form 3B+ offers light touch supports that greatly reduce the need for finishing and costly labor.

Early 3D printers had an infamous reputation for spending half of their lives in service, with many failed prints even when they were online. Fortunately, the latest generation of printers delivers greatly improved reliability. For example, users of the Formlabs 3D printer reported a success rate of over 95% on millions of prints across tens of thousands of machines. Dig deep into published reliability information, and make sure that a manufacturer has appropriate warranties and service offerings to ensure you’ll be taken care of if service is needed.

When you consider adopting a new technology, it needs to make sense for your business. Dental 3D printer prices have dropped significantly since the early days and the systems on the market today offer the lowest costs for many applications.

For example, a practice or lab printing surgical guides or dental models to produce thermoformed aligners in-house can often reduce costs by 75-95% for each part compared to outsourcing to labs or service providers—enough to pay for a 3D printer in a few weeks and save many times its price tag over the years.

When you compare dental 3D printers, remember to consider:

-

Upfront costs, including not just the machine cost, but also training, setup, and potentially software.

-

Running costs, best estimated with per-unit material costs.

-

Servicing and maintenance costs. Beware of compulsory service contracts that can cost as much as 20% of the upfront cost of the printer annually.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Calculate Your Savings

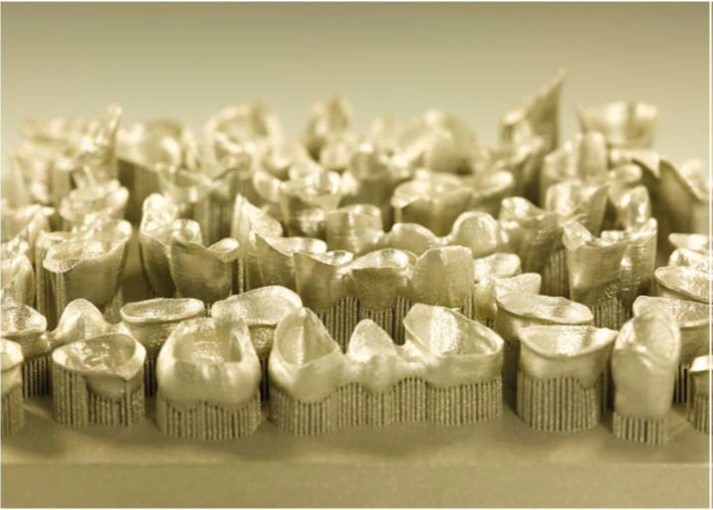

Professional 3D printers are some of the most versatile tools found today in dental and orthodontic practices and labs, and the key to their versatility is dedicated materials.

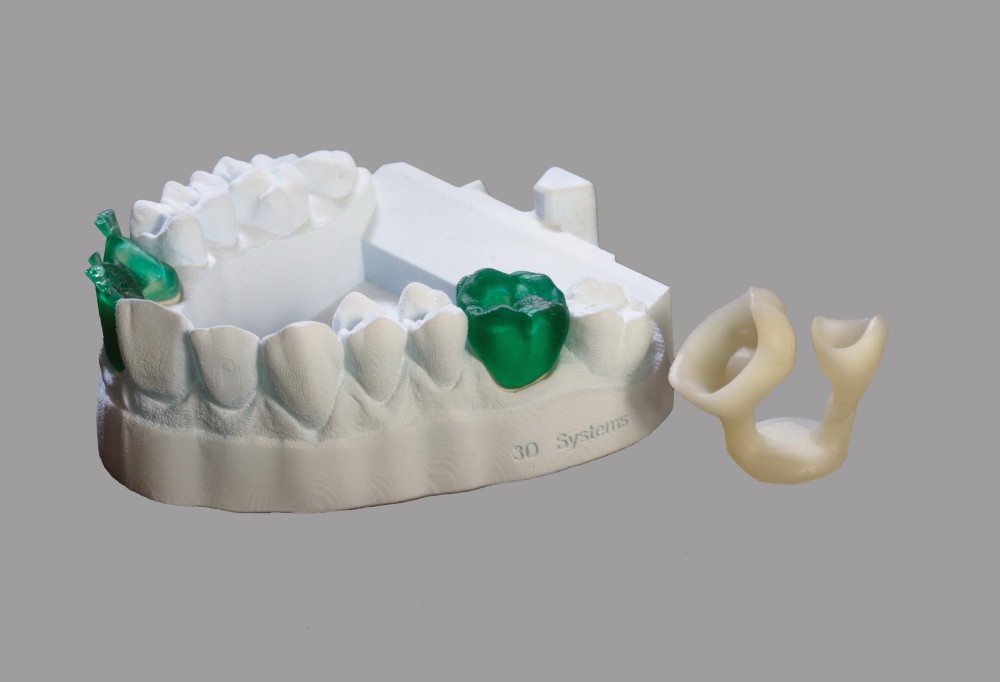

The material selection varies by printer model. Some basic 3D printers can only produce diagnostic models, while more advanced systems can manufacture highly accurate crown and bridge models, surgical guides, and castable/pressable restorations; long-term and biocompatible dental products like splints, retainers, or digital dentures, as well as orthodontic appliances such as clear aligners and Hawley retainers by thermoforming over 3D printed models.

Dental 3D printers enable cost-effective, mass-customized digital production of a wide range of dental products.

Some 3D printers work only with proprietary materials, which means your options are limited to the offerings of the printer manufacturer. Others have an open system, meaning that they can use materials made by third-party manufacturers.

However, when using third-party materials, it’s important to make sure that the results achieved clinically acceptable quality and accuracy. Furthermore, using biocompatible materials on non-validated 3D printers that claim to be “open” breaks the usage requirements and thus will produce non-biocompatible appliances. Be careful that you know what risks your business takes by using not validated 3D printers and materials.

Surgical guides 3D printed on a Formlabs Form 3B+ dental 3D printer.

Manufacturers release new materials on a regular basis, so there’s a good chance that the printer you buy today will become capable of creating an increasing variety of dental products in the near future.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA, LFS, and DLP 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the parts, whereas, SLA and LFS 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA and LFS 3D printers being comparable or faster when printing a single part or smaller parts, while DLP 3D printers are faster to print multiple parts that fill up much of the platform.

However, there’s a trade-off between resolution and build volume for DLP printers. A small DLP 3D printer might be able to print fast, but you can only fit a few models on the build platform. A different machine with a larger build volume might be able to print more parts, but only at a lower resolution, which means that it might not be accurate enough for printing restorative models or surgical guides that require higher accuracy.

SLA and LFS 3D printers can produce all of these options in one machine and offer practices and labs the freedom to decide whether they want to optimize for resolution, speed, or throughput, depending on the case.

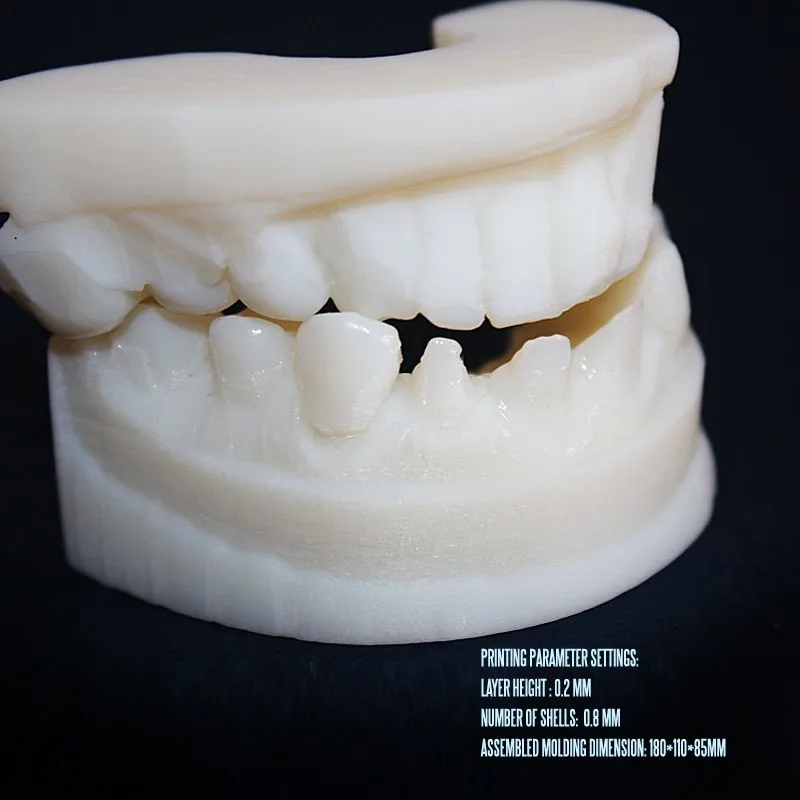

For example, the Form 3B+ LFS 3D printer can produce a single orthodontic model in about 20 minutes with Draft Resin and 8 models per print in ~1 hour, while the large build volume of the printer also allows you to produce up to 18 models at once for overnight “lights out” production. The Form 3BL, Formlabs’ large-format dental and orthodontic 3D printer can produce up to 52 models per print.

Total possible daily production = the number of possible prints in an eight-hour workday + one print overnight

A small build platform DLP 3D printer can quickly produce at most a handful of models at once. As you need to prepare the printer, set up the print in software, and post-process the parts for each print, which results in much higher labor costs per part to fully utilize its production capabilities.

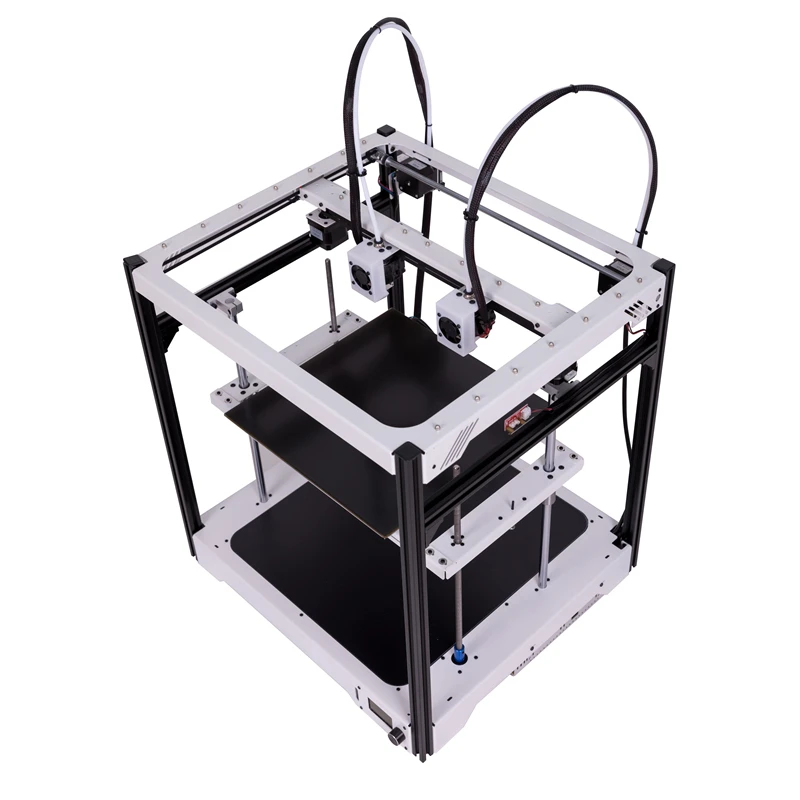

Another important consideration, especially for labs is whether to fulfill capacity with a single machine or multiple units. Production with multi-machine print cells often reduces upfront costs compared to larger-format machines. By buying one low-cost machine at first, labs can test out production methods before ultimately scaling up production with demand. This provides the opportunity to pay for production only when it is needed, rather than making large long-term investments in a rapidly evolving market. Print cells with multiple printers also empower you to create multiple different indications at once and reduce risk through redundancy. If one machine needs servicing, production can be balanced across the rest of the print cell.

Alternatively, large format dental 3D printers, like the Form 3BL, can maximize throughput for every print job and reduce labor needs by requiring minimal operator intervention.

Multi-machine print cells allow 3D printing for multiple different applications in parallel, balancing production needs and lowering risk through redundancy.

While a few years ago, 3D printers were only affordable to the largest dental labs and milling centers, now they are a common sight in many dental and orthodontic practices and labs.

Consider the factors discussed above and the needs of your business—different solutions might suit some dental businesses better than others. Make sure to do your research, evaluate actual parts, and avoid paying a hefty premium.

Explore the Formlabs Dental Academy for free guides, step-by-step tutorials, white papers, webinars to learn how you can integrate 3D printing into your lab or practice.

Curious to see the quality firsthand? Pick a material and we'll ship you a free sample part 3D printed on the Form 3B+ to evaluate.

Request a Free Sample Part

5 Ways 3D Printing has Redefined the Dental Industry

Additive manufacturing has affected many industries, but few stand to benefit as much as the medical fields, including dentistry.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

Read on to discover five ways in which the digital workflows are revolutionizing the dental industry.

While dentistry has always required high levels of customization, the industry has traditionally relied mostly on manual methods to create custom appliances. Today, digital workflows enable mass customization in a consistent, automated way, requiring less labor and incurring lower costs.

Everyone has a dentition—the pattern of development and arrangement of teeth—unique to them. Dental indications must, therefore, be made to match each individual patient’s anatomy. With traditional manual workflows, the quality of the finished products is highly dependent on the skills of a given technician. Achieving consistent and high-quality dental products with so many potential sources of error is incredibly difficult and expensive.

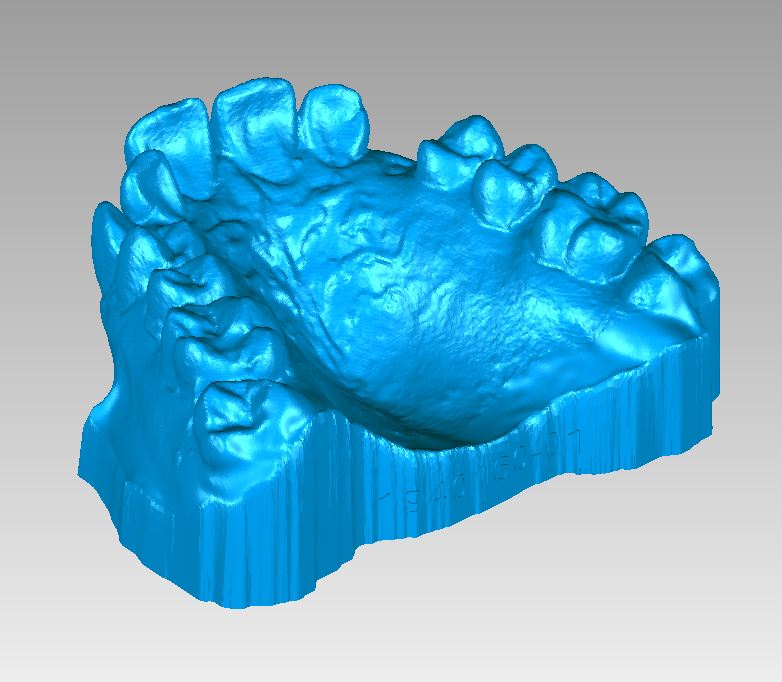

Intraoral scanners can capture scans directly from the patient, replacing manual impressions with fast and accurate digital impressions. Alternatively, desktop scanners in dental labs can be used to scan traditional alginate and PVS impressions.

With digital workflows, each dental product is precisely detailed to the specifications dictated by the patient's anatomy. 3D printers are like Swiss-army knives—no other tool can produce such a wide variety of dental products with consistently high quality. Using dedicated materials, labs and practices can use 3D printers to produce orthodontic models, highly accurate crown and bridge models, surgical guides, castable or pressable restorations, aligners, retainers, long-term biocompatible dental products like splints or dentures and more.

Digital technologies simplify workflows, reduce the room for error and the amount of labor required, resulting in time and cost savings on both the lab's and practice's side.

Orthodontics as a dental specialty has come a long way since traditional metal wired braces. While still necessary in some complex cases, removable clear aligners provide an appealing alternative today and have been used to treat millions of patients.

While still necessary in some complex cases, removable clear aligners provide an appealing alternative today and have been used to treat millions of patients.

Clear aligners, one of the most popular orthodontic treatments today, couldn't exist without digital technologies such as 3D printing.

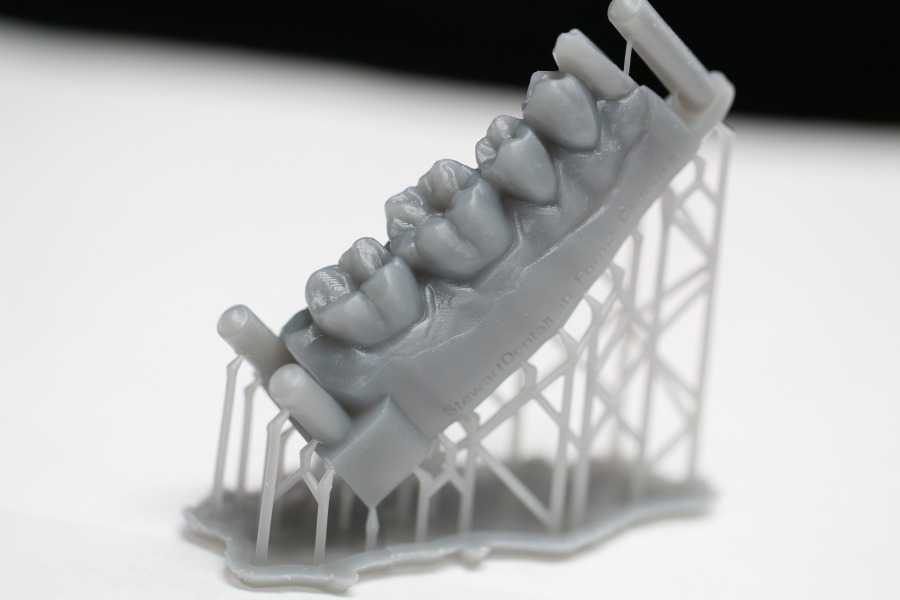

Clear aligners couldn't exist without digital technologies; their manufacturing process is a brilliant combination of multiple digital workflows. An orthodontist or dentist first captures an impression of a patient's dentition with a 3D intraoral scanner or takes a traditional impression for the lab to scan. The digital model provides a basis to plan the progressive stages between the current and desired teeth positions. Each stage is then 3D printed and the aligners are thermoformed over these 3D printed molds.

Traditionally, the 3D printers used in this process were large and complex to use and prohibitively expensive. Now, smaller format desktop 3D printers can create molds for thermoformed appliances, opening up the possibility for any lab or practice to produce aligners and retainers in-house and expand production without adding substantial overhead.

Ashford Orthodontics, the largest orthodontics laboratory in the UK produces thousands of clear retainers using 3D printed models.

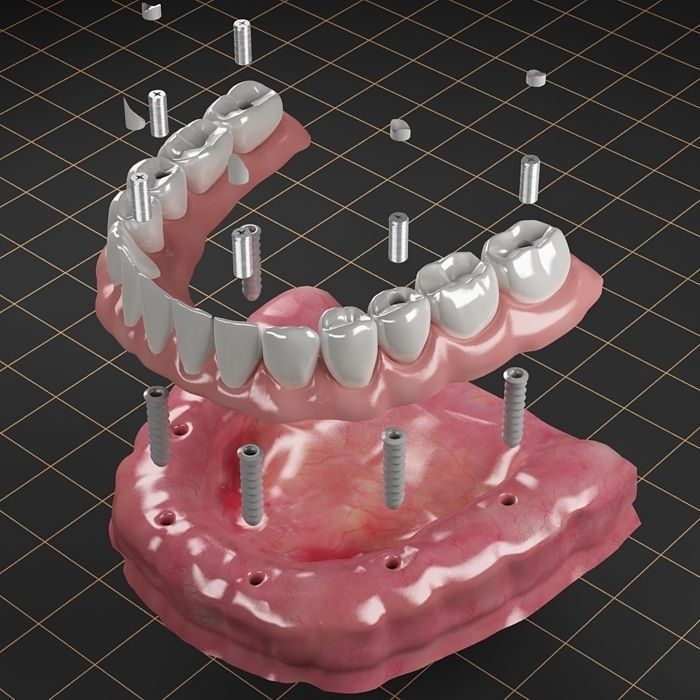

Digital technologies can augment complex surgical procedures. CBCT, virtual placement planning, and surgical guides are becoming the new standards of care in implantology. With them, the accuracy of implant placement during surgery is all but guaranteed, the risk of surgical complications fall, and clinical results are improved overall. Let's look at the workflow-enhanced production of a surgical guide as an example.

To create a guide, implantologists combine intraoral scan data of a patient's dentition and anatomy of the patient osteotomy from a CBCT or cone beam scanner. Based on the anatomical data, practitioners use CAD software to plan treatment with high accuracy and then use a 3D printer to produce a guide that is ready to be used in surgery.

A 3D printed surgical guide used in surgery.

Formerly, the only ways of producing surgical guides was through milling or 3D printing on industrial 3D printers. But due to the complex and expensive machinery involved, these guides could easily cost hundreds of dollars, which made them cost-prohibitive in most cases. Now with desktop 3D printing, the costs are down by a factor of 10-100X, paving the way for guided surgeries to become the standard.

But due to the complex and expensive machinery involved, these guides could easily cost hundreds of dollars, which made them cost-prohibitive in most cases. Now with desktop 3D printing, the costs are down by a factor of 10-100X, paving the way for guided surgeries to become the standard.

Traditional denture manufacturing is a time-consuming and labor-intensive analog workflow that involves multiple patient visits and production steps. It is a complex craft with a steep learning curve and dental labs increasingly struggle to find technicians with the advanced skills and expertise required to produce them.

Dentures are one of the latest innovations in digital dentistry. They offer an efficient and cost-effective manufacturing solution and a major step toward the overall simplification of the dental laboratory manufacturing process.

Digital dentures are cost-effective and offer a consistent workflow for a high-quality end product.

Denture production with the digital workflow includes fewer steps and less variability, resulting in a more consistent workflow for a high-quality end product every time. Digital denture designs are also reusable, shareable, modifiable, and easy to reproduce with 3D printing. The affordable hardware, lower material costs, and time savings (less labor) all contribute to a substantial cost advantage over their handcrafted counterparts.

Digital denture designs are also reusable, shareable, modifiable, and easy to reproduce with 3D printing. The affordable hardware, lower material costs, and time savings (less labor) all contribute to a substantial cost advantage over their handcrafted counterparts.

Scanning solutions, software tools, and materials are developing rapidly to take digital dentures to their full potential. As they do, digital dentures are bound to replace or supplement the traditional workflow for an increasing share of the 50 million dentures produced a year globally and pave the way for more inclusive denture solutions for everyone who needs treatment.

At the end of the day, it's the patients who stand to gain the most from the advances in digital dentistry.

Starting with the visit to the dentist or orthodontist, being able to visualize a dental procedure can be as reassuring for the patient as it is helpful for the practitioner. Virtual treatment planning, diagnostic wax-ups, and highly detailed replicas can help patients envision and understand the treatment they will be receiving in great detail, reducing anxiety and increasing patient acceptance.

Highly detailed replicas can help patients envision and understand their treatment.

Considering workflow and treatment improvements, taking an impression of a patient's dentition with intraoral scanning is quicker and more comfortable than traditional alginate and PVS impressions. The products themselves can be more aesthetically pleasing (clear aligners) and treatments more accurate and less invasive (digital implantology and surgical guides). Processes are generally faster as digital elements remove superfluous steps, making the patient's visit quicker and easier.

Precise and consistent treatments mean that patients are vastly less likely to need to return for repeat work on the same problem, saving their time and money. But a satisfied patient is more likely to become a return customer and refer others, contributing to the long-term success of all dental businesses.

These are just some examples of the wider scope of changes that digital dentistry and 3D printing processes are bringing to the dental industry.

Despite the narrative of “traditional vs. digital workflows” used frequently to promote the latter, contemporary dental workflows can combine the best of both. The support of digital workflows translates to a plethora of new possibilities for the industry and a raft of improvements for the customer.

Find out more about how Formlabs is driving this change, learn about the range of dental indications, and request a free sample part for yourself to see the quality firsthand.

Request a Sample 3D Printed Part

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar.

The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar.

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary.

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery.

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks.

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

Digital LED projection (DLP). Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay.

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D.

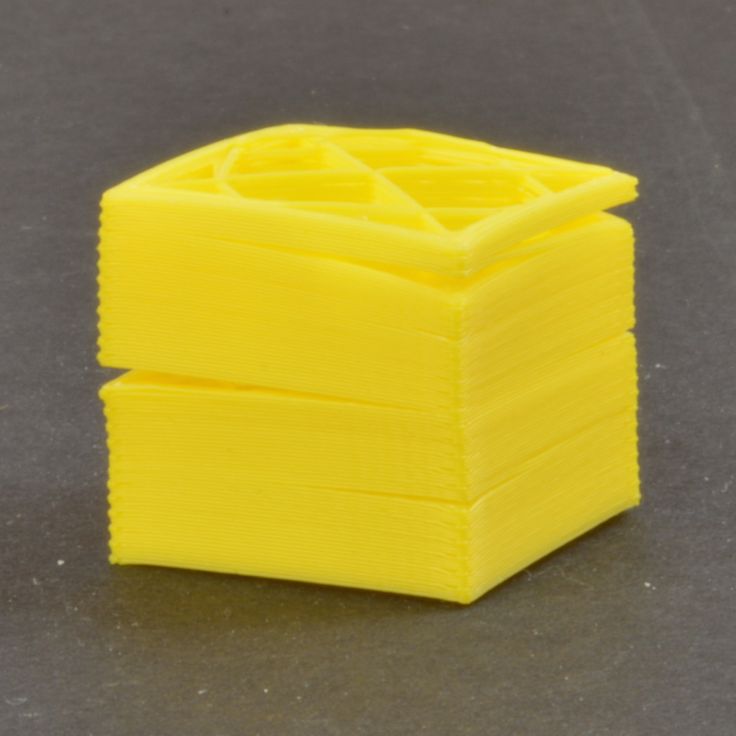

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic.

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet Technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

← General requirements for the placement of portable X-ray machines | TOP 5 Illuminated Physiodispensers →

How to choose a 3D printer for dental use

3D printing is making its way into more and more products around us. Sculptures, shoes, even food. Well, the happiest ones can already use the achievements of additive technologies for more comfortable treatment of their teeth.

The increasing popularization of new methods of treatment leads to the fact that new market niches appear, which are still very easy to occupy in our time. Accordingly, there is the prospect of a quick return on investment, obtaining a valuable asset, diversifying the sources of income for individual businesses.

In such a favorable situation, more and more investors decide to invest in this particular area - the production of dental products using 3D printing. And the question arises, how to spend these attracted investments? Or, to paraphrase, what kind of 3D printer to buy for use in a dental clinic?

Which 3D printers are in demand in dentistry

Printing multiple jaw impressions at the same time using the Phrozen Sonic 4K 9 printer0335

The situation on the market is so favorable that even those who previously were either very remotely or not at all connected with dentistry decide for themselves to enter this niche. Sometimes it is not even related to medicine at all. Therefore, I want to start with what actually needs to be made and how.

Variety of popular dental products

Only a small part of the range of 3D printed products

Most likely I will not be mistaken if I assume that absolutely anyone reading these lines has gone to the dentist. In recent years, dentists have ceased to scare children, visiting the dentist has become less stressful. And already without negative thoughts, we can choose dental products presented in catalogs, presentations or which experts talk about personally.

In recent years, dentists have ceased to scare children, visiting the dentist has become less stressful. And already without negative thoughts, we can choose dental products presented in catalogs, presentations or which experts talk about personally.

There are several groups of products that can be produced with a 3D printer. The most innovative can be called products for bite correction - aligners.

Less obvious is the use of additive technologies for the creation of surgical templates, the transfer of checks.

It may seem surprising, but a temporary crown, a temporary bridge can be printed on a 3D printer.

The ability to print a prototype of the jaw, in particular, to check the fit of implants, is of great help to dentists.

For those who are familiar with jewelry, it will be clear that products that are produced by casting using a burnt model created on a 3D printer will work well. It can be crowns and bridges and liners and many other metal products.

You can also print a matrix for later use in the thermoforming process.

3D printing technologies used in dentistry

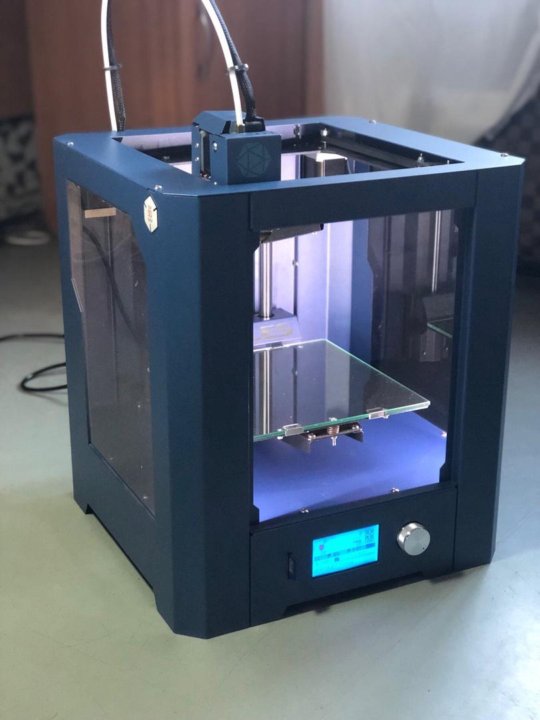

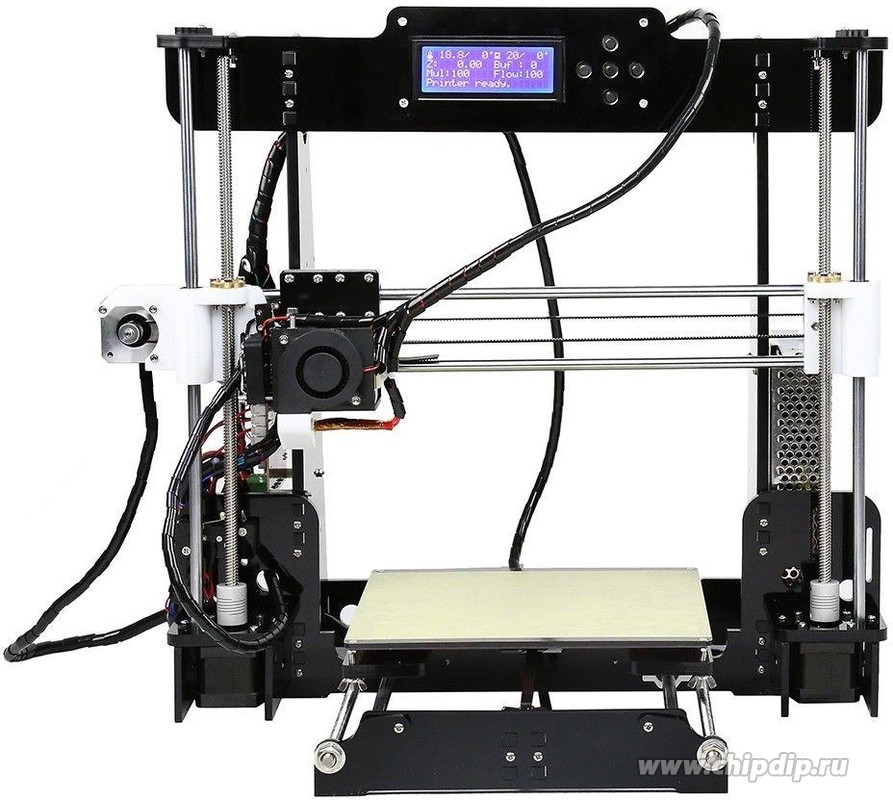

In FDM dentistry, 3D printers are used less often, but it happens. FDM 3D printer Stratasys

To a large extent, it is precisely such a wide range of products that are profitable to manufacture using a 3D printer that leads to a high demand for 3D printing in dentistry. Just by looking at this incomplete list, it becomes approximately clear which technology is used most often in dentistry.

SLA and LCD 3D printers can print with enough precision, suitable materials and are easy to use, so dentists are more likely to use them.

FDM 3D printers are less commonly used. Basically, enlarged models of jaws, presentation models are printed on them. Occasional auxiliary tools.

Let's take a closer look at the use of SLA and LCD 3D printers. The main difference between these technologies, from the point of view of application in dentistry, is that the LCD printer is designed to print small models with high resolution, while the SLA 3D printer can print a relatively large model without quality loss. Products required by dentists are not often large. The demand for SLA 3D printers, although it exists, cannot be compared with the demand for LCD models. LCD 3D printers have a printable area large enough to produce both aligners and jaw models. In terms of size, most dental products are not large. At the same time, the accuracy of such printers is sufficient - it is important to mention here that this is the case if we are talking about 4K or higher resolution print screens of such printers. LCD printers are more compact, easier to maintain, and cheaper.

Products required by dentists are not often large. The demand for SLA 3D printers, although it exists, cannot be compared with the demand for LCD models. LCD 3D printers have a printable area large enough to produce both aligners and jaw models. In terms of size, most dental products are not large. At the same time, the accuracy of such printers is sufficient - it is important to mention here that this is the case if we are talking about 4K or higher resolution print screens of such printers. LCD printers are more compact, easier to maintain, and cheaper.

In general, the choice of a printer for dentistry in 95 percent of cases will result in the purchase of an LCD 3D printer, so we will concentrate on machines using this technology.

Denote the initial conditions

Having familiarized ourselves a little with the niche that we will occupy, it is necessary to pay attention to who will use these 3D printers.

First of all, equipping a dental clinic with 3D printers should be profitable - we will pay considerable attention to issues related to the rate of return on investment and the optimal use of equipment.

Newcomers to dentistry, although they have the potential to gain a foothold in the 3D printing niche for dentists, will pick up all the bumps along the way, they are more likely to need advice about dentistry in general than advice on how to use 3D printing. Therefore, we will cover, for example, an already existing dental clinic or dental office.

At the same time, those who already use 3D printing most likely know what they lack and what is not very necessary. I suggest that such a reader go straight to the description of the advantages of individual models - most likely you will be able to find offers that are interesting to you.

Equipment of the new 3D printing laboratory

A 3D printed lab might look like this

So, it turns out that we are discussing the choice of a 3D printer for a new 3D printed laboratory in an existing dental clinic or dental office.

The level of investment should be relatively low - for an individual dentist who runs his own practice, the investment should be minimal.

A large dental clinic will be able to afford not only to allocate a separate, well-equipped room for a 3D printed laboratory, but also to hire specialists who will serve the laboratory without combining this activity with anything else.

In addition to an LCD 3D printer, a 3D scanner, a washing and backlighting station will be useful. When creating a 3D printed laboratory in a large clinic, you can immediately plan the purchase of machines for creating products by casting according to a burnout model and by thermoforming.

Both LCD and SLA 3D printers require a separate, well-ventilated area with a desktop. If for a small office it can be a separate closet-sized room, then in a large clinic it is worth thinking about allocating an appropriate area not only for the printers themselves, but also for post-processing tables, for storage racks for materials, for service jobs.

Who is an expert in dental 3D printing

Only a doctor can be an expert in 3D printing in dentistry

A separate question is who will work directly with 3D printers.

It would be more profitable for a large clinic to immediately hire specialists with experience in using 3D printing in dentistry. At the same time, in a small clinic or in the case of a private dental practice, the dentist or dental technician himself can relatively quickly learn how to use and maintain a 3D printer.

The dentist must still evaluate and accept the products. It is quite common to hold joint seminars for dental technicians and dentists at the same clinic.

It is very important to understand that only a dentist can be an expert in dental 3D printing, evaluate the quality of printouts, and set criteria! Even the most experienced 3D printer can't do this alone.

Key criteria for choosing a 3D printer for a dental lab

When selecting any machine for commercial use, the selection criteria must be clearly defined. Often it is the clarity of such criteria that determines the payback period and the overall value of the machine.

Earlier, we touched on issues related to what exactly dentists require from the 3D printers they use. Let's cover these requirements more fully and arrange them in order of priority.

Imprint accuracy is the main criterion

Rough model of the jaw. The color shows the deviation in dimensions from the original (mm)

The main criterion for choosing a modern 3D printer for use in a dental clinic is accuracy, or rather resolution. The tasks of modern dentistry, which specialists are ready to delegate to machines, require the ability to manufacture high-precision products. For LCD 3D printers, a resolution of 2K nominally may be suitable - the accuracy of aligners, for example, is allowed up to 50 microns - but the actual quality of the resulting printouts may be lower than declared by the manufacturer of the 3D printer, both due to the characteristics of the materials used, and in connection with the presence of the human factor. Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

Therefore, dentists use LCD printers with a print screen resolution of at least 4K.

The accuracy of the prints will be higher, with a shorter illumination time of the photopolymer. The Mono LCD screen will help reduce the time needed to expose one layer. The presence of such a screen will not only increase accuracy, but also speed up the printing process.

Print area - rate of return on investment

Even the largest laboratories use groups of identical 3D printers

A very important criterion that can be assessed by the passport of a 3D printer is the printable area. The larger the printable area, the faster you can produce a series of printouts - this is the peculiarity of using an LCD 3D printer. Due to the fact that a client of a dental clinic quite often needs to receive a series of products on hand during a visit - again, aligners, or immediately need to print a complex model with small details, the total print area will help to carry out the service faster.

At the same time, the print area of one printer may not be so large - remember that products for dentistry are rarely large. To speed up the production process, most often they buy several identical or very similar printers. Most often the same manufacturer.

Such a 3D printing farm will not only be cheaper than a single printer of a comparable printing area, but will also allow you to accept multiple clients at the same time. Maintenance and repair of printers is also simplified - one or a pair can be taken out of operation without stopping all production.

The choice in favor of several printers with a smaller print area is also justified in terms of the fact that it is recommended to invest in 3D printing gradually. Buying a dozen 3D printers at once is justified only when you know for sure that you have a large flow of customers and the total workload of the 3D printing laboratory will be about 60 percent.

In general, buying multiple 3D printers will reduce your initial costs and risks, while the overall larger printable area will allow you to make more profit.

Usability, reliability, ease of maintenance

Unfortunately, most of the mistakes when choosing a 3D printer for a dental clinic are associated with underestimating the importance of the usability of a 3D printer. These machines will be serviced by a person, which means there is a human factor. You know from experience that work is more productive when you work comfortably. Research confirms the validity of this personal experience. The more convenient it is to work on a 3D printer, the fewer mistakes the operator will make, which means less money will be spent - both material and time.

The reliability of a 3D printer - design, electronics, individual elements - will be economically justified. Less breakdowns - less downtime - less costs.

Ease of maintenance reduces costs in the same way

Post-processing

The process of removing supports is not easy

It must be borne in mind that after printing, absolutely all printed models require post-processing. At a minimum, this is flushing and backlighting. As a maximum, a printed, washed, illuminated part, from which the supports were removed, can be a semi-finished product that has yet to be worked on. A 3D printer should provide the ability to not be a stand-alone device, but to work in an ecosystem.

At a minimum, this is flushing and backlighting. As a maximum, a printed, washed, illuminated part, from which the supports were removed, can be a semi-finished product that has yet to be worked on. A 3D printer should provide the ability to not be a stand-alone device, but to work in an ecosystem.

What might be useful but not worth emphasizing

The standard marketing policy of any retailer is to try to convince you to buy a product based not so much on direct value as on features that sound and look good on paper, but do not greatly affect the quality of the product itself. A good example is the color of a delivery vehicle. If you do not take the possibility of applying advertising images and colors from the brand book, the delivery vehicle can be of any color. But the seller may try to convince you to buy this particular car by appealing to its color.

Similarly, when choosing a 3D printer for a dental clinic, some criteria are not as valuable as they sound.

Range of materials used

Most modern LCD 3D printers use ultraviolet wavelengths of 380nm-405nm to illuminate the photopolymer. The ability to use specific materials seems like a very useful feature, but in fact, you either know for sure that you will use such materials, or you will not use them. It is enough to understand what range of tasks the 3D printer will solve and choose accordingly. At the same time, it will be useful to be able to use the selected materials more conveniently, for example, a system of material profiles.

It is important to expand the range of materials used unnecessarily - it is not economically feasible.

Additional software - pros and cons

Software that helps you print. FormWare Phrozen Edition.

The whole process of creating printouts involves the use of several software products. And, if software that will allow you to facilitate or speed up printing without loss of quality is useful, then different programs for modeling or, for example, creating print time-lapses will never be used. The specialist models in the environment he is used to, and time-lapses are just a beautiful feature.

The specialist models in the environment he is used to, and time-lapses are just a beautiful feature.

Remote printing and control

When you think of 3D printing, there is often an assumption that I pressed a button, an hour later I came, and everything is ready. It's actually not that automated. In principle, it is better to keep the machine under supervision at least during the start of printing. This means that remote printing will not be so popular. At the same time, I note that after the operator of a 3D printer gets used to working with a particular machine, he will know most of its features, the ability to transfer files to the device remotely, or even remotely control printing will be useful.

Remote control will bring more benefit to an experienced operator, although a beginner in 3D printing will gain experience quickly if desired.

Top Best Dental 3D Printers

Based on what I have outlined, I will try to create a rating of the value of 3D printers for dentists.

Phrozen Sonic 4K

This 3D printer is specially designed for use in dental clinics. A good price/quality ratio makes this 3D printer an excellent choice for both a small clinic and as one of several printers in a large 3D printing laboratory. Mono LCD allows you to reduce the exposure time of the layer to 1 second, and the large area of \u200b\u200bthe 6.1” matrix allows you to print more models at the same time, making the production process even faster! With the FormWare Phrozen Edition software, post-processing can be facilitated by optimally positioning supports, and reduce printer control time by arranging more models in the same print volume. If you have a dedicated 3D printer operator, the function of remotely sending files to print will be useful.

Phrozen Sonic Mini 4K

Mini version of the popular printer. At a lower price, it has the same resolution and matrix size - 6.1” @ 4K. It will be a good choice for a private practice dentist's office. Also one of the options for entering 3D printing for a medium-sized clinic is that it performs well both as a single 3D printer and as an additional printer, if there are several more advanced ones. A fairly high print speed is achieved due to Mono LCD, which allows you to reduce the exposure time to 2 seconds.

Also one of the options for entering 3D printing for a medium-sized clinic is that it performs well both as a single 3D printer and as an additional printer, if there are several more advanced ones. A fairly high print speed is achieved due to Mono LCD, which allows you to reduce the exposure time to 2 seconds.

Peopoly Phenom

Large Format - 276 x 155 x 400mm build area - MSLA 3D printer (LCD+LED). The use of MSLA technology allows you to get high-precision prints on a 12.1” @ 4K matrix without distortion. Well suited for large clinics that want to increase their 3D printing capacity. At the same time, the extended life of the LCD panel will significantly reduce the overall cost of maintaining this machine.

FormLabs Form 3B

The LFS 3D printer is a higher priced printer. A special technology of low-intensity stereolithography and a specially designed light processing unit allows you to quickly obtain high-precision printouts up to 145x145x185 mm in size with a laser positioning accuracy of 25 microns.