Glowforge 3d printers

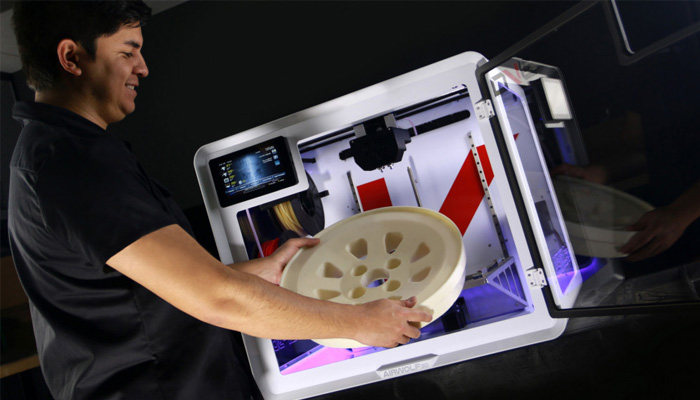

Meet Glowforge | Glowforge

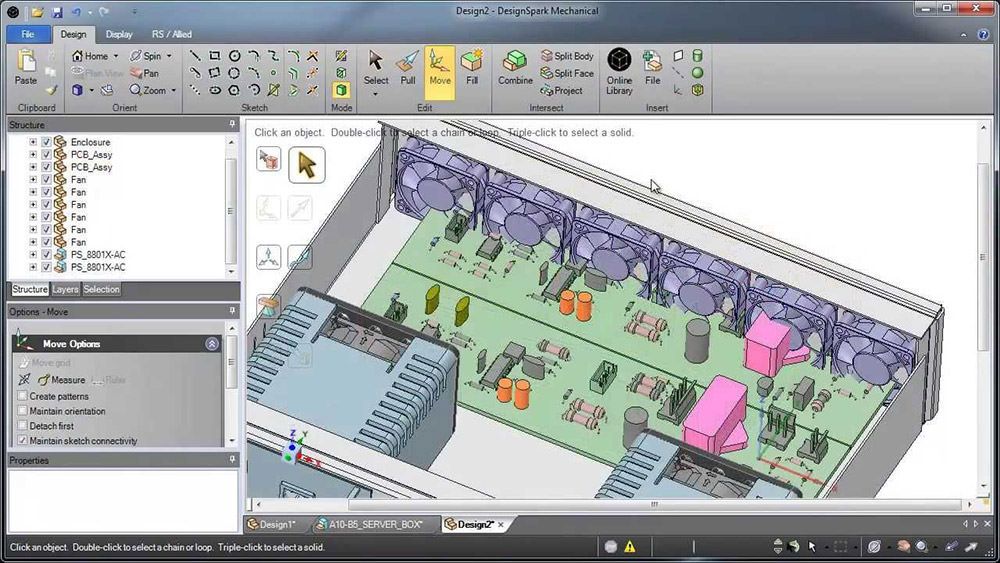

Great news! You can use your Glowforge from a Mac, PC, tablet, and smartphone, using our simple, powerful, and free web interface. To prepare your project, you can choose to use any software that saves a PDF (Adobe Illustrator, Inkscape, CorelDraw, Adobe Photoshop, GIMP, Autodesk 360, and Sketchup and more) Glowforge can print JPG, PNG, SVG, PDF, and other file formats. To print a file, just drag-and-drop it directly on our app, and then adjust the preview to your liking.

Your Glowforge is yours to use, free of charge! The Glowforge cloud service gives you unlimited monthly prints, including all the features you see in our video. And don’t worry, there’s no paid subscription required.

Believe it or not - most of our customers tell us it takes them less than 30 minutes to get their printer out of the box, plug it in, set it up, and finish their first print!

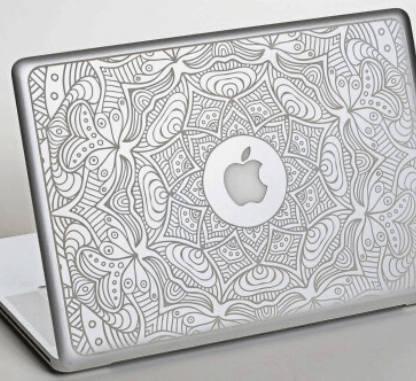

Glowforge uses a beam of light the width of a human hair to cut and engrave with incredible accuracy within a thousandth of an inch. Further, your Glowforge can engrave images in stunning high-resolution - comparable to what you see on your phone or computer screen now. You can learn more, here.

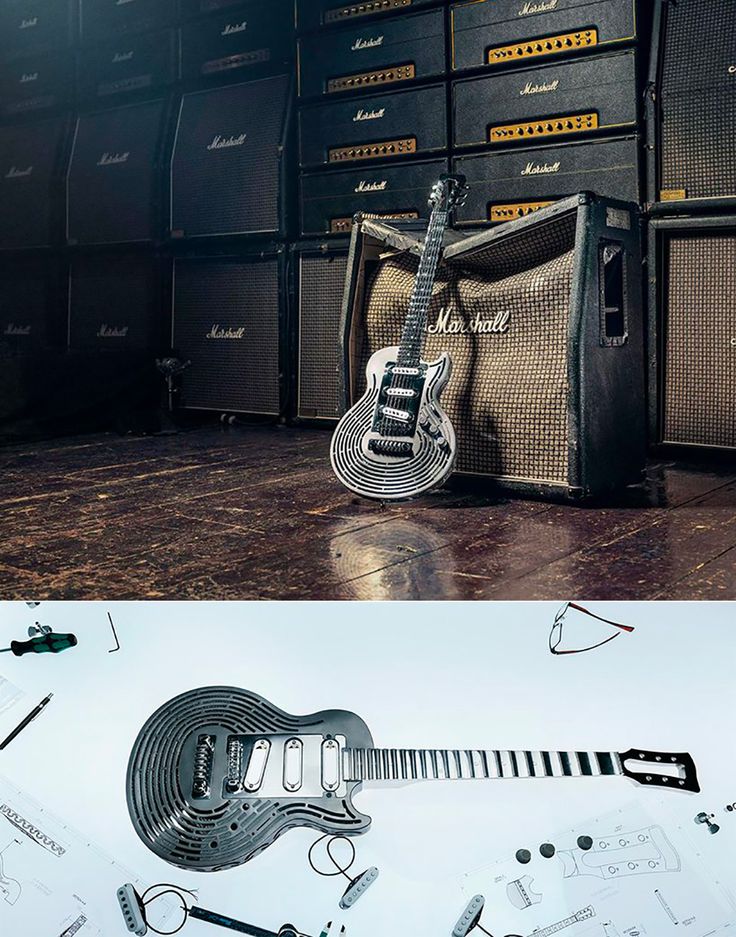

Glowforge opens up a world of materials. While traditional 3D printers are confined to layers of plastic, Glowforge is completely different. Delve into hundreds of beautiful materials like leather, acrylic, hardwood, fabric - even chocolate! Glowforge can cut wood, fabric, leather, paper, Plexiglas (acrylic), Delrin (acetal), mylar, rubber, Corian, foods, and more. Glowforge can also engrave all of the above plus glass, coated metal, marble, anodized aluminum, titanium, some phones, tablets, and laptops, and more laser safe materials. For a by-the-minute update on what folks are printing: check out #glowforge on Instagram.

No matter which Glowforge you choose, you’ll be able to use materials measuring 12 x 20. 4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

4” The Glowforge Pro has a Passthrough slot which accommodates material up to 20.4” wide, 1/4" thick, and as long as you want. Want to work with a thicker material? Simply remove the stainless steel crumb tray in the bottom of your Glowforge and print with materials up to 2” thick.

The Glowforge has a compact 3’ x 2’ footprint and fits well in any craft space, workshop, or family area.

Whichever Glowforge model you choose, you can be sure your Glowforge will be easy to set up and use, and will allow you to work with hundreds of materials. It comes will free printing software, everything you need to get started, and a free supply of premium materials to get you started. But there are some differences between our three models.

Not sure which model is right for you?

- The Glowforge Basic is our introductory model, perfect for moderate home use.

- The Glowforge Plus is a great solution for people who want to print frequently and quickly.

- The Glowforge Pro is our most powerful and capable model, ideal for a small business, or when more than one person will be using it.

Here are a few more details to help you decide:

Speed (Pro is fastest): The Glowforge Pro top engraving speed is 3x as fast as the Glowforge Basic, and cutting is 1.2x as fast. The Glowforge Plus top engraving speed is 2x as fast as the Glowforge Basic.

Warranty (Plus and Pro have 12 months): The Glowforge Basic has 6 months of warranty coverage, while the Plus and Pro offer a double warranty of a full 12 months warranty.

Material Size (Pro has Passthrough): All Glowforge printers can accommodate materials measuring up to 18” deep, 20.4” wide, and 2” tall. The maximum printable area is about 11 x 19.5”. The Glowforge Pro allows you to make enormous oversized prints.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.

The Pro Passthrough slot in the front and back allows for materials that are 20” wide, up to ¼” thick, and as long as you want. That means you can create huge, dramatic products like furniture. To use the passthrough, you print the first 10 inches (25.4 cm), then slide the material through the slot, and repeat.Laser Class: The Plus and Basic models are a Class 1 laser (like a DVD player). The Passthrough slot makes the Pro model a Class 4 laser which requires the person using it to have laser safety training (included with your purchase). You should not use the Pro in public or around kids without installing Pro Shields, which are included with your purchase.

Temperatures (Pro prints up to 81°F (27°C)): The Pro is designed for printing all day in temperatures up to 81°F (27°C). The Basic and Plus will pause periodically to cool if used continually in warm temperatures; they’re designed for environments up to 75°F (24°C).

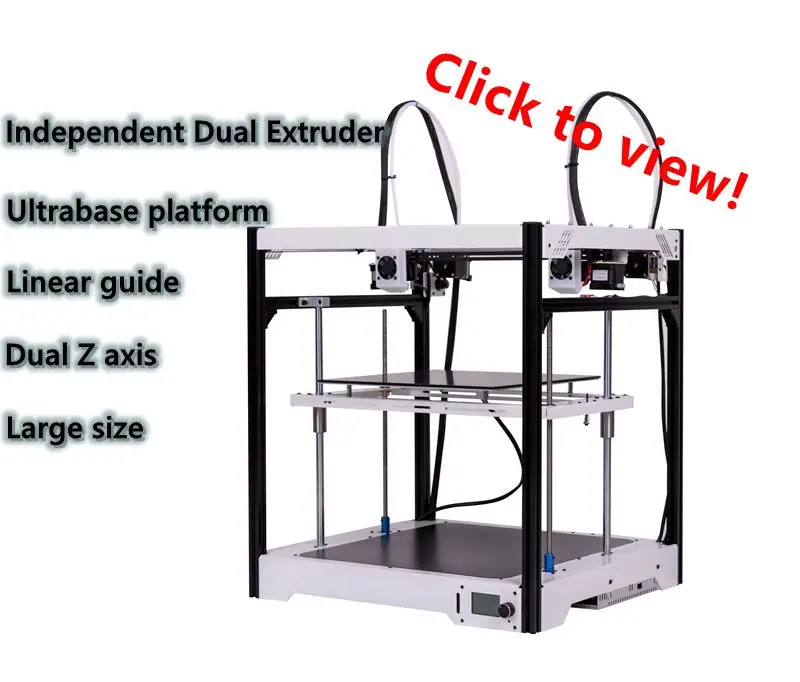

Technology. The Glowforge Plus has an upgraded linear system to support faster motor speeds. The Glowforge Pro adds a solid state cooling unit and an upgraded 45 watt laser for the fastest possible prints.

Glowforge - the 3D laser printer

The Glowforge Pro is the ultimate option for home, business, or school. It prints truly enormous objects like furniture with the exclusive Pro Passthrough, allowing you to use infinitely long materials. Upgraded solid-state cooling allows nonstop printing all day long. The powerful 45 watt laser cuts up to 20% faster, and the top engraving speed is up to three times as fast as the Glowforge Basic. Class 4 laser product; place near a window for ventilation.

$6,995

Buy Now

The Glowforge Pro is quick to set up, easy to use, and work with dozens of different materials.

Simple setup in under 30 minutes

Works with hundreds of materials

Live camera preview of your work

Free web-based software

Autofocus and 3D engraving

Compatible with your Mac, PC, tablet, or phone

Safe for home and school

Plus, you'll receive everything you need to make your first print in minutes.

What's in the Box

- Your Glowforge Pro, Plus, or Basic 3D Laser Printer

- The Glowforge laser head with macro camera and autofocus

- Power cord

- Magnetic lens replacement tool

- Steel crumb tray

- Exhaust hose

- Ring clamps for hose connection

- Pro Shields (Pro only)

Proofgrade Starter Pack

To ensure you can start printing immediately with your Glowforge, we'll include a starter pack of our coveted Proofgrade™ materials. It will include $150 worth of products such as:

- Draftboard

- Plywood

- Hardwood

- Acrylic

- Leather

These materials are sourced, encoded, and lab-tested for perfect printing every time and are specially formulated for the Glowforge 3D laser printer.

| Pro | Plus | Basic | |

|---|---|---|---|

| Comprehensive warranty | 12 mo | 12 mo | 6 mo |

| Laser tube power | 45W | 40W | 40W |

| Upgraded hardware for improved speed | |||

| Cut speed | 120% | ||

| Enhanced cooling for all-day use | |||

| Giant-size prints with Passthrough Slot | |||

| Price | $6,995 | $4,995 | $3,995 |

Material Capability

- 19.

5” by ∞

5” by ∞

Software

- Drag-and-drop with live camera preview

- Works with Mac, PC, iPhone, Android, and more

- JPG, PNG, SVG, PDF, and more

Hardware

- Dual cameras: wide angle & macro

- Custom 45W (Pro) laser

- Precise to 1/1000th of an inch

- Full autofocus

See Detailed Specs

Lasers like your Glowforge require ventilation. All Glowforge printers come with a 4" (10 cm) diameter hose which allows you to use your Glowforge near a window.

Our Air Filter upgrade lets you put your Glowforge anywhere. It sits on the ground near your Glowforge printer and cleans the air, allowing you to operate it anywhere in your home, school, or office!

$1,295

Buy Now

3D Printers - All About 3D Printers and 3D Printing Technology / Sudo Null IT News Articles Authors Companies

Show first

Rating threshold

3D graphics work *Cyberpunk 3D printers Wearable electronics Processing *

Tutorial

Hello everyone! We develop "smart sequins" - electromechanical color-reproducing devices for designer clothes.

Today I will tell you how we printed our first dress on a 3D printer!

Read more

Total votes 18: ↑18 and ↓0 +18

Views3.7K

Comments 4

smart_alex

Timeweb Cloud Blog0003

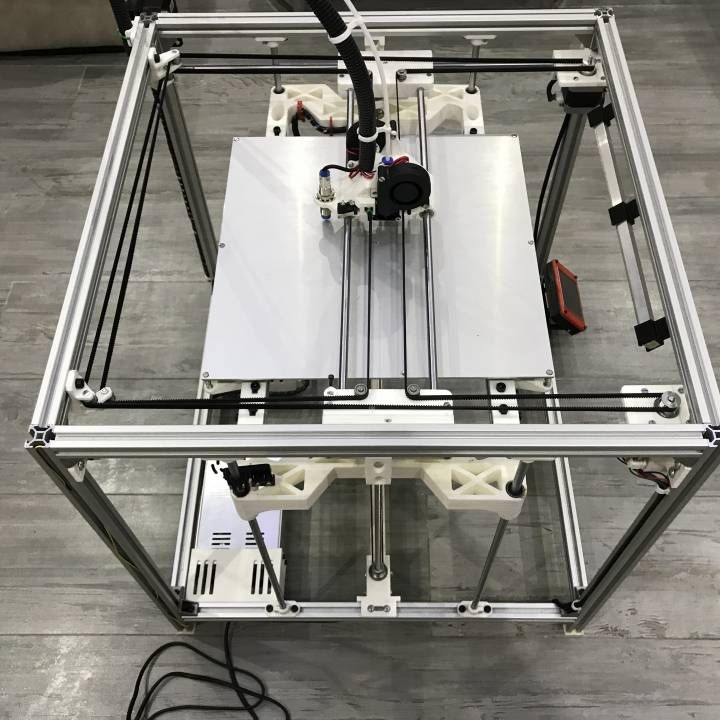

There is one extremely useful tool in my household - a 3D printer. For me, as a hobbyist to make something, from time to time he provides invaluable services in prototyping and creating various parts (bushings, holders, cases for equipment, etc., etc.).

But there is one problem: the printer is quite voluminous (40x60x60 cm), plus consumables and a repair kit - all this takes up a lot of space and turns any room into a kind of production workshop. If you have, for example, a free garage or other similar premises, then there are no problems, but in other cases you have to put up with this foreign element for any residential interior. nine0003

If you have, for example, a free garage or other similar premises, then there are no problems, but in other cases you have to put up with this foreign element for any residential interior. nine0003

For a long time I tried to somehow solve this problem and finally I managed to find, as it seems to me, a rather harmonious solution, which I want to share with you, maybe it will help someone “to pass between Scylla and Charybdis” - to have in their a valuable tool and at the same time not disfigure your living space.

So…

Read more →

Total votes 20: ↑18 and ↓2 +16

Views7.9K

Comments 37

sand77777 nine00223D graphics work *Old hardware DIY or DIY 3D printers

✏️ Technotext 2022

Did you dream of turning a real ship's wheel as a child? Just imagine: the sea, salt spray, wind-filled sails buzzing in the wind above your head, you have a steering wheel in your hands, and your fast clipper rushes towards the horizon . ..

..

This steering wheel is a watch. It is silky and coppery (the exposed copper of the printed circuit board, the unique and peculiar texture of this master’s favorite material), twist and imagine how time ran in the opposite direction, to the past, where the salt spray and the sails of your childhood dreams. Or maybe this is the entrance to a parallel reality? nine0003

Joke. But still, turn the steering wheel, and suddenly ...)

We turn further)

Total votes 15: ↑13 and ↓2 +11

Views4.2K

Comments fifteen

compas_3d

ASCON CAD/CAM company blog *Design 3D printers

We came to self-propelled machines through aviation. Graduates of Samara State Aerospace University became the backbone of the future enterprise . We also sprayed fertilizers, but we pollinated the fields from the air on hang-gliders and airplanes. It was difficult and at times risky. Therefore, we decided to design a "ground" machine, which, nevertheless, would be comparable to aviation technology in terms of speed and quality of processing, or even surpass it. Development was carried out according to aviation standards, since we were all pilots.

Graduates of Samara State Aerospace University became the backbone of the future enterprise . We also sprayed fertilizers, but we pollinated the fields from the air on hang-gliders and airplanes. It was difficult and at times risky. Therefore, we decided to design a "ground" machine, which, nevertheless, would be comparable to aviation technology in terms of speed and quality of processing, or even surpass it. Development was carried out according to aviation standards, since we were all pilots.

As a result of these studies, in 2001 we made our first car. Even then, it worked the fields at high speed and was very light. nine0003

Learn more

Total votes 35: ↑34 and ↓1 +33

Views5.5K

Comments eighteen

compas_3d

ASCON Blog Work with 3D graphics *CAD/CAM *3D printers DIY or DIY

In early September we released a new version of the KOMPAS-3D Home system for amateur 3D modeling and home use. Makers, 3D printers, DIYers and bloggers have access to all the features of professional CAD. nine0116

What's new in KOMPAS-3D v21 Home?

Large detailed article

Total votes 10: ↑10 and ↓0 +10

Views8.3K

Comments 23

Erwinmal

RUVDS.com company blog Reading room Popular science 3D printers The future is here

Even in the unexpectedly turbulent 2020s, already challenging the 1920s for the Roaring Twenties, progress is not going to stand still. Technologies are moving further and further, and not all of them are as well-known as conversational and graphical neural networks, neural interfaces, or self-guided combat drones. However, many of them can affect our lives. In particular, these three. nine0003

Technologies are moving further and further, and not all of them are as well-known as conversational and graphical neural networks, neural interfaces, or self-guided combat drones. However, many of them can affect our lives. In particular, these three. nine0003

Read more →

Total votes 47: ↑39 and ↓8 +31

Views12K

Comments 54

Sergiv

Company Blog Special Technology Center Popular Science 3D printers Multicopters DIY or Do it yourself for "zero" speed (hovering). Your quad will now fly slower, climb slower, more likely to be "dumb" in response to controls, and less able to hold the wind. Vibrations may also appear (the controller is configured for exactly that thrust-rev ratio, but it has become different for you)

In this article I will try to figure out if this is really so, what pluses and minuses will arise, how these propellers will behave in flight.

We flew again

Total votes 19: ↑18 and ↓1 +17

Views5.6K

Comments 25

compas_3d

ASCON Blog CAD/CAM *Cosmonautics 3D printers

In July, the third stage of the international project SIRIUS (Scientific International Research In Unique Terrestrial Station), simulating long-term manned space flights, was completed. For 240 days, the crew of 5 people, representing three countries - Russia, the USA and the UAE, was in complete isolation in conditions that simulate the work of a real expedition on a circumlunar orbital station and the surface of the Moon. The experiment took place in the test complex of the Institute of Biomedical Problems of the Russian Academy of Sciences (IMBP RAS) and assumed full immersion in all stages of the space mission: from entering the Earth's orbit and flying to the Moon to staying in orbit and returning to Earth. nine0003

nine0003

We spoke with the SIRIUS-21 crew commander, head of the department for the creation of integrated simulators for promising transport ships of the Cosmonaut Training Center. Yu. A. Gagarin Oleg Blinov about participation in the experiment, solving various problems using available 3D technologies and, of course, about the everyday life of a future interplanetary flight.

Learn more

Total votes 3: ↑3 and ↓0 +3

Views904

Comments 0 nine0003 TilekSamiev

Sales Management *IT Legislation Business Models *Popular Science 3D Printers

This article is written to introduce the reader to such a phenomenon as the Ghost Gun. The author does not call for anything. Remember, the illegal acquisition, possession and use of weapons is a crime and must be prosecuted to the fullest extent of the Law!

Ghost Gun (ghost gun), a general term for non-serial and homemade firearms, which first appeared in America as a creation of amateur gunsmiths in the late 1980s. But in recent years, thanks to the booming gun industry, they have become more accessible and popular with criminals and intruders. They are inexpensive, easy to obtain, and have long been out of the government's radar. Ghost gun assembly kits are the basis of the vast majority of weapons sold to the public and used in crime in the United States. Many components such as the barrel, bolt and magazine can be legally purchased online in convenient kits without a firearms license

But in recent years, thanks to the booming gun industry, they have become more accessible and popular with criminals and intruders. They are inexpensive, easy to obtain, and have long been out of the government's radar. Ghost gun assembly kits are the basis of the vast majority of weapons sold to the public and used in crime in the United States. Many components such as the barrel, bolt and magazine can be legally purchased online in convenient kits without a firearms license

But once the firearm is assembled, the legal threshold is passed because the manufacturer then becomes the manufacturer and owner of the firearm, and this already requires a license and registration certificate.

On August 24, 2022, new federal regulations came into effect to reduce the proliferation of untraceable, privately assembled firearms. But the Biden administration's requirement for serialization of the gost gun and mandatory background checks on sale cannot apply to the millions of weapons already in circulation. nine0203

nine0203

Read more →

Total votes 14: ↑10 and ↓4 +6

Views6K

Comments 32

TimurYanovskiy

Belaya Raduga Company Blog Scientific 3D printers Health

3D printed jaw model with future restorations

We, dentists, constantly need additive manufacturing. Either the patient will meet a tree, then grab the curb with his teeth, or even jump from the third floor onto his face, and some of these patients do not want to wait four months for permanent implantation, but need temporary structures to come out after 40 minutes and smile at a business meeting. We also use 3D printers to print a fragment of you for training before surgery. Plus, today a good dental laboratory has its own 3D printer for printing models, artificial crowns, veneers and caps. nine0003

nine0003

Today we will tell you what features of 3D printing we have. First and foremost, everything that is certified for medicine costs three to ten times more. But there are other features as well.

- What are 3D technologies in dental practice, what methods are used.

- How they are used in orthodontics, orthopedics and surgery.

- How we scan you.

- About materials.

- Why we often prefer more traditional milling. nine0229

- How much do modern dental printers cost.

- How we choose a dental laboratory for model printing and prosthetics.

Read more →

Total votes 44: ↑41 and ↓3 +38

Views6.8K

Comments 10

vandiemen

3D printers

✏️ Technotext 2022

Hello everyone! Filament prices have not been encouraging at all lately. Also a feature of 3D printing is the fact that some parts have to be reprinted several times to achieve the desired results. The process of developing and printing a part is sometimes quite iterative and meditative)). What if you had unlimited plastic? A kind of "super ability" - a human filament? Would it help you in your 3D craft? nine0003

Also a feature of 3D printing is the fact that some parts have to be reprinted several times to achieve the desired results. The process of developing and printing a part is sometimes quite iterative and meditative)). What if you had unlimited plastic? A kind of "super ability" - a human filament? Would it help you in your 3D craft? nine0003

I present to your attention a compact filament extruder from PET bottles!

Read more

Total votes 87: ↑84 and ↓3 +81

Views21K

Comments 33

Bright_Translate

RUVDS.com company blog Development for Arduino *3D printers DIY or DIY

Translation

Tutorial

Rocket modellers often want their creations to perform at their best in a certain category of competition, whether it's egg lifting (when you need to design a rocket that can lift a raw chicken egg to its maximum height and return it intact), duration flights (when the rocket must stay in the air as long as possible) or to the maximum height. nine0003

nine0003

Thinking about what kind of new project to pursue, and having a craving for 3D printing, CAD modeling and physics, I decided to design a rocket to reach the maximum height due to the capabilities of the D-class engine. The aim of this project was to evaluate the practical effectiveness of 3D printing in rocket modeling compared to existing model making techniques.

Read more →

Total votes 44: ↑42 and ↓2 +40

Views9.2K

Comments 17 nine0003 Bright_Translate

RUVDS.com Blog The goal of this project was to turn the head massager into an automated device that would massage me by itself. The original idea was to simply use a linear actuator or a single stepper motor with a threaded stud to implement the up/down movement. However, I got carried away, and I decided to make the device move in all directions, for which the Hugh-Stewart platform was chosen, providing 6 degrees of freedom. nine0003

nine0003

- Isn't that too tricky? Yes!

- Was it expensive? Yes!

- Am I crazy? Yes!

All software and hardware files are available on GitHub

Read more →

Total votes 53: ↑53 and ↓0 +53

Views5.6K

Comments 12

DAN_SEA

RUVDS.com company blog Reading room 3D printers DIY or DIY Electronics for beginners

macrovector, freepik

Every hunter wants to know where the pheasant sits. This is what the story will be about below.

Read more →

Total votes 47: ↑44 and ↓3 +41

Views6.5K

Comments 35

additive_rocket_science

Robotics Space science 3D printers Chemistry The future is here

And again, video first.

This video shows the Rocket Factory In-a-Box (RFIB) concept from the Air Force Research Laboratory (AFRL) in the USA. A small-sized mobile plant for the production of customized solid rockets in the form factor of a cargo container will allow rockets to be launched anytime and anywhere (Fig. 1). A network of hidden autonomous missile plants (ARZ) will ensure the continuity of high-precision fire impact on demand (an on-demand service for the military), allowing you to get away from dependence on two or three industrial centers for the production of missile weapons that are vulnerable and transparent for intelligence with inflexible logistics of bulky cargo to rapid prototyping and production of missile weapons directly on the front line with flexible logistics, bulk raw materials for which are transported by small-sized highly mobile hidden vehicles. nine0003

nine0003

Straight "Supreme Commander" at maximum speed - this is how the Americans are going to fight in

, the twenty-first century.

Read more

Total votes 15: ↑12 and ↓3 +9

Views6.1K

Comments 84

5-55

.NET *C# *Soft 3D printers manufacturers and is useful for people using/testing a large number of filaments. nine0003

Ask

Total votes 6: ↑5 and ↓1 +4

Views1.8K

Comments 12

additive_rocket_science

Robotics Astronautics 3D printers Chemistry The future is here

Out of the sandbox

3D printing mixed propellant - we did it. After a hundred experiments, several waves of despair and stages of acceptance of the inevitable. Made and patented. nine0003

After a hundred experiments, several waves of despair and stages of acceptance of the inevitable. Made and patented. nine0003

The developed technology for the additive production of solid propellant charges (SFC) from mixed propellant fuel (SRT) for a solid propellant rocket engine (SRM) using the FDM printing method includes: a special SPT composition with the required energy and operational parameters, the layer-by-layer synthesis 3D printer itself for printing rocket fuel; and several related technologies.

Read more

Total votes 87: ↑85 and ↓2 +83

Views13K

Comments 169

Bright_Translate

Company Blog RUVDS.com Arduino Development *3D Printers DIY or DIY Electronics for Beginners

Translation

Tutorial

This is the second part of a series dedicated to the assembly of tools based on the Hall sensor. If you haven't read the first part, it's best to start with this: Tim's Electronic Compass. In this project, I will use not one, but two sensors 49E, each with a pair of magnets, following the same principle as when assembling a compass.

If you haven't read the first part, it's best to start with this: Tim's Electronic Compass. In this project, I will use not one, but two sensors 49E, each with a pair of magnets, following the same principle as when assembling a compass.

Read more →

Total votes 45: ↑45 and ↓0 +45

Views8K

Comments 13

Bright_Translate

Company Blog RUVDS.com The first of two articles devoted to the assembly of electronic instruments based on the Hall sensor. In this part, the simplest modification of the compass, which includes one sensor and two magnets, is disassembled. The second part will be devoted to a more complex instrument - pantograph (approx. Per.). nine0003

I recently had the idea to assemble a small instrument - an electronic compass - to show the basic principles of the Hall effect sensor. And in the process of shooting a video demonstrating the compass in action, I also decided to explain how I find the poles of the magnets used in this compass.

And in the process of shooting a video demonstrating the compass in action, I also decided to explain how I find the poles of the magnets used in this compass.

Read more →

Total votes 50: ↑49 and ↓1 +48

Views11K

Comments eleven

DAN_SEA

RUVDS.com company blog 3D printers DIY or DIY Lasers Engineering systems *

I really like to make various homemade devices, and it didn’t start yesterday, I have always been fascinated by people who can combine various technologies, approaches, device elements and create something new.

Not so long ago, I realized that the lack of an affordable metal 3D printer is very slowing me down in development, and I began to figure out how difficult it is to create such a printer myself? nine0003

Read more →

Total votes 59: ↑57 and ↓2 +55

Views20K

Comments 56

How it works.

Industrial 3D printer

Industrial 3D printer

Photo: Alexander Utkin

Additive technologies are gradually changing the industrial way. Products that can be made using 3D printing are becoming more functional and larger. The number of such parts in the composition of complex equipment is growing. More and more enterprises supplement their production with additive equipment. 3D printers save money and time on the production of parts, they are more environmentally friendly than traditional machines. Using the example of metal 3D printing, which is actively used at Rostec enterprises, we talk about the advantages of industrial printers and the principle of their operation. nine0203

Layer by layer

Metal-based additive manufacturing (from Latin addere "to add") is one of the fastest growing technologies in the manufacturing industry. This is a method of creating parts by adding material to a substrate in stages, also called industrial 3D printing. Unlike traditional production (for example, turning or milling), where everything superfluous is cut off from the workpiece, in additive production, on the contrary, the object is gradually created from the desired material, as if grown. The main areas of application for 3D metal printing are prototyping, aerospace, mechanical engineering, instrument manufacturing, medical implants, etc. nine0003

Unlike traditional production (for example, turning or milling), where everything superfluous is cut off from the workpiece, in additive production, on the contrary, the object is gradually created from the desired material, as if grown. The main areas of application for 3D metal printing are prototyping, aerospace, mechanical engineering, instrument manufacturing, medical implants, etc. nine0003

The main advantages of metal 3D printing are the ability to create objects of complex shapes, reducing the weight of parts without compromising strength, shorter production time, cost-effectiveness and environmental friendliness of the method. Indeed, 3D printers work with a minimum of waste, and special cleaning technologies make it possible to reuse the remnants of raw materials.

3D metal printing allows you to create complex one-piece designs. This makes it possible to exclude many technological operations, such as welding, assembly. 3D printing allows you to combine 30-40 elements in one node without losing functionality and create parts that are simply impossible to obtain on conventional machines. nine0203

nine0203

How a 3D printer works

Metal 3D printing is a general definition for a number of technologies. In general, any technology can be called this when a metal object is created layer by layer using sintering, melting or welding processes. A common type of metal 3D printing is selective laser melting (SLM, Selective laser melting), when a metal powder is fused using a powerful laser. Consider the operation of an industrial printer using this technology as an example. nine0003

When using any type of printing, before working with a metal 3D printer, we need a three-dimensional model of the part to be manufactured. It is created using CAD programs - computer-aided design systems. Then the digital model is converted into the STL stereolithographic format and loaded into special software, which divides the model into very thin, 20 to 100 micron thick, horizontal layers, determines the necessary supports, and performs other preparatory work. nine0003

nine0003

Next, we go directly to the printer itself. The chamber of the device is first filled with an inert gas (such as argon) to minimize the oxidation of the metal powder, and then heated to the optimum temperature.

A thin layer of metal powder is spread over the build platform and a high power laser travels at a predetermined speed across the component's cross section, fusing the metal particles together and creating the layer. When the fusion process is completed, the platform moves down one layer thickness and the device spreads another thin layer of metal powder. The process is repeated until the part is completely built. nine0003

Parts are usually attached to the assembly platform through supporting structures - supports. The support is necessary to reduce the deformation that can occur due to high processing temperatures, and also removes excess heat. In metal 3D printing, the support is made from the same material as the part and is usually an openwork structure that is removed after the part is created.

After printing is completed, the chamber is cooled to room temperature, excess powder is removed manually. Then the part, together with the platform, is removed from the chamber, subjected to heat treatment and mechanically separated from the platform. After that, all the necessary actions for finishing the part are carried out. nine0203

About the Rostec Center for Additive Technologies

Metal 3D printing and other types of additive manufacturing are actively developing at the enterprises of the State Corporation. The integration of these processes within Rostec is carried out by the Center for Additive Technologies (TsAT), created on the basis of holding corporations of the aviation complex. The shareholders of the organization are the holdings UEC, Technodinamika, KRET and Russian Helicopters. nine0003

The center has been operating for more than three years and today is the largest enterprise in Russia specializing in full-cycle industrial 3D printing. Parts for the largest domestic aviation projects are created here, such as the PD-14, PD-35, VK-650V, VK-1600V engines, the Ansat helicopter, etc.

Parts for the largest domestic aviation projects are created here, such as the PD-14, PD-35, VK-650V, VK-1600V engines, the Ansat helicopter, etc.

Demonstrator engine VK-1600V at MAKS-2021. Photo: Viktor Molodtsov

At the recently held in the Zhukovsky International Aviation and Space Salon MAKS-2021 near Moscow, several developments using parts created at the Center were presented at once. One of the premieres of the salon was the VK-1600V demonstrator engine for the Ka-62 helicopter, about 10% of whose parts were printed on a 3D printer. And in the VK-650V demonstrator engine for the Ka-226T helicopter, the share of parts printed in the TsAT will already be about 15%. Also at MAKS, Mi-8/17 and Mi-171A3 helicopters were demonstrated, the blanks for the parts of which were created by the Center. As a result of optimization, it was possible to achieve a reduction of up to 30% in the mass of parts and a 50% reduction in the estimated time for finishing machining in comparison with traditional methods.