3D printing with robot arm

The Top Robotic Arm 3D Printing Solutions

3D printing news News What Are the Robotic Arm 3D Printing Solutions on the Market?

Published on October 14, 2022 by Claire S.

One of the trends we have increasingly seen as additive manufacturing industrializes is an increased focus on large-format additive manufacturing. Though this can of course be achieved with large machines, notably those using FDM, robotic arms offer a number of advantages for users. Robotic arms allow not just for large-scale printing thanks to the long reach of the arms, but also more freedom thanks their multiple axes as well as the fact that the resulting parts often do not require support structures. Though there are only a handful of manufacturers who create the robotic arms, they have been adapted by 3D printing manufacturers for both polymer and metal AM solutions. In the following list, in no particular order, we take a closer look at what is currently on the market, both for original arms and adapted solutions.

Original Robotic Arms Manufacturers

KUKA

The German company KUKA is undoubtedly one of the leaders in the automation market, offering robots that enable the electronics, automotive and healthcare industries to simplify their manufacturing processes. KUKA develops solutions that can be adapted for additive manufacturing. It is therefore not surprising to find the KUKA brand on many robotic 3D printers, whether for designing metal, plastic or even concrete parts. One example is the KR QUANTEC line of robotic arms, which offers machines with a reach of 2,671 to 3,904 mm and a load capacity of 120 to 300 kilos.

The KR QUANTEC arm was equipped with a nozzle to extrude concrete for the Besix3D company (photo credits: KUKA)

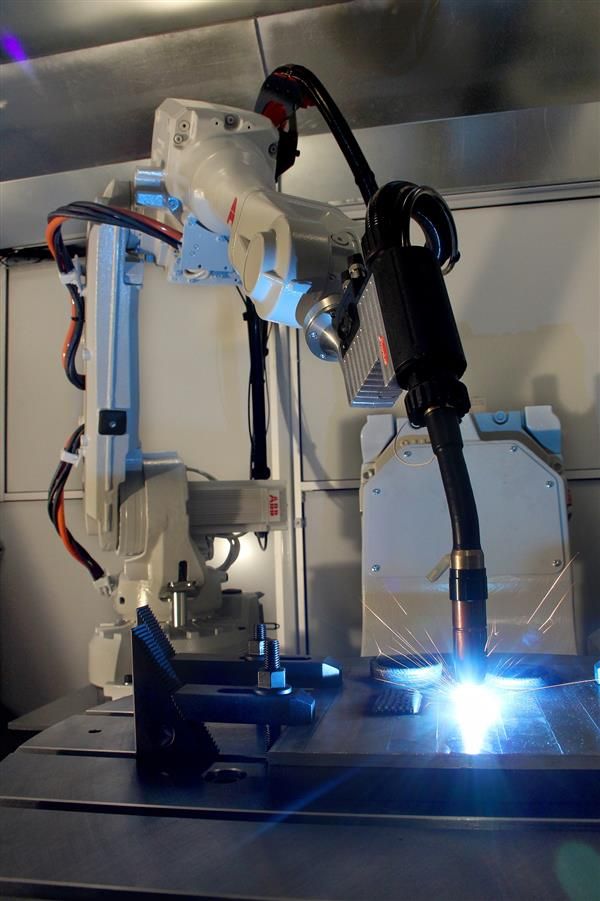

ABB

ABB group is a multinational company which produces robotic arms, including those used for 3D printing. Their robotics portfolio is diverse with different types of industrial robots to fulfil consumer needs.Their RobotStudio® programme is the world’s most popular offline programming and simulation tool for robotic applications. According to the company, with its solution, users can unlock flexibility and upgrade their business productivity to the next level. They are even able to design robots to suit their own unique needs, notably in additive manufacturing. As you will see further down the list, ABB six axis industrial robot is used by Massive Dimension, a company which works on sustainable development in the 3D printing industry.

According to the company, with its solution, users can unlock flexibility and upgrade their business productivity to the next level. They are even able to design robots to suit their own unique needs, notably in additive manufacturing. As you will see further down the list, ABB six axis industrial robot is used by Massive Dimension, a company which works on sustainable development in the 3D printing industry.

Massive Dimension and ABB Additive Manufacturing Demonstration at IMTS 2022. (Photo credit: Massive Dimension)

Comau

Comau is an Italian industrial automation and robotics company. The company develops systems, products and services compatible with Industry 4.0. In particular, its portfolio includes a complete family of robots, including robotic arm solutions. Since 1978, Comau has been manufacturing these machines with the aim of integrating and improving innovative applications in all industrial sectors. There are several robotic arms, and they differ in their payload capacities. Still, they leverage IoT and AI technology to operate autonomously.

Still, they leverage IoT and AI technology to operate autonomously.

Third Party 3D Printing Companies Using These Solutions

CEAD

CEAD is a Dutch company based in Delf that develops large-scale 3D printers. This company stands out as it offers robot-based solutions that combine printing and CNC milling processes in one process. Another solution is the AM Flexbot, a robot-based solution for large-scale 3D printing. Siemens Sinumerik controllers are responsible for controlling the Comau robot arm, thus not requiring any robot controller. This controller can control 31 axes at the same time as it moves along its path. Your AM Flexbot can be expanded with additional functions such as a rotary table, additional robots, or other production processes such as CNC milling. It is the perfect choice for a customized solution with a specific application.

DXR Series from Weber Additive

German company Weber Additive, dedicated to the development of different manufacturing technologies, also has robotic arm solutions for 3D printing. Weber’s DXR robotic system features a high-quality extruder capable of 3D printing. The extruder is powered by a 6-axis industrial robot that allows it to move precisely. Its robotic arm based on the manufacturer Kuka and its AE series extruders are adapted to the needs of its customers to provide the most optimal results. These systems offer great advantages, such as 3D printing with 6-axis kinematics, a variable angle of the manufacturing head or overprinting on existing parts, among others. You can take a look at the solution in the video below:

Weber’s DXR robotic system features a high-quality extruder capable of 3D printing. The extruder is powered by a 6-axis industrial robot that allows it to move precisely. Its robotic arm based on the manufacturer Kuka and its AE series extruders are adapted to the needs of its customers to provide the most optimal results. These systems offer great advantages, such as 3D printing with 6-axis kinematics, a variable angle of the manufacturing head or overprinting on existing parts, among others. You can take a look at the solution in the video below:

The robotic arm from Hyperion Robotics

Founded in 2019 in Helsinki, Hyperion Robotics is a company specializing in the construction industry. It uses additive manufacturing to design more affordable structures, wanting to make the market more sustainable and most importantly, more automated. To do this, it relies on KUKA robots on which it mounts an extruder capable of depositing Hyperion Robotics’ material. This is a special concrete mix that uses a reduced amount of cement thanks to recycled waste components. It also designed its own software that allows it to work with any robot. In terms of applications, the Finnish company has already built decorative elements, structures imitating coral reefs and energy infrastructures.

To do this, it relies on KUKA robots on which it mounts an extruder capable of depositing Hyperion Robotics’ material. This is a special concrete mix that uses a reduced amount of cement thanks to recycled waste components. It also designed its own software that allows it to work with any robot. In terms of applications, the Finnish company has already built decorative elements, structures imitating coral reefs and energy infrastructures.

Photo credits: Hyperion Robotics

Massive Dimension

Massive Dimension, as their name undoubtedly suggests, is a manufacturer of large format 3D extruders and full solutions, including turnkey robotic printing cells. Specifically, the company was founded with the goal of contributing to sustainable solutions in order to reduce waste on the planet. Currently, Massive Dimension’s solutions are centered around polymer pellet 3D printing. For their robotic cells, they include six-axis industrial robotic arms from ABB. When combined with the ABB 3D Printing Powerpac software, users have access to a comprehensible workflow for pellet 3D printing. The company notes that their robotic arms have been custom-tailored for robotic printing, including large format printing thanks to a build volume of 3ft x 5ft x 5ft. Moreover, these cells can also be further customized to fit each user’s individual needs.

The company notes that their robotic arms have been custom-tailored for robotic printing, including large format printing thanks to a build volume of 3ft x 5ft x 5ft. Moreover, these cells can also be further customized to fit each user’s individual needs.

Massive Dimension

Orbital CompositesOrbital Composites aims to disrupt the 3D printing industry. They believe that robotics is the answer to the limitations faced by the industry, such as scale, speed, strength and design. Their Orbital S, the first robotic 3D printer built for industrial scale, was released to tackle these problems. The impressive robot has a maximum speed of 2m/s, has a maximum payload of 10kg and a maximum reach of 1.1m. The build platform is 1m x 1m x 1m, giving the ability to create relatively large end use parts. Furthermore, the user has a choice of materials. It uses the Kuka KR10 R1100 robot arm; Kuka is an official partner of the company.

Orbital Composites’ Orbital S robotic 3D printer. Photo Credit: Orbital Composites

Photo Credit: Orbital Composites

Dyze Design et Pulsar

Pulsar is a state-of-the-art, large-scale, high-speed plastic pellet extruder. It was designed with one goal in mind: to 3D print large parts as quickly and inexpensively as possible. Pulsar is compatible with robotic arms for 3D printing and is capable of producing up to 500 mm3/s (2.5 kg/h) of material. It can also be used with large nozzles from 1.00 mm to 5.00 mm. Finally, Pulsar is ready for all environmental conditions. The water cooling loop ensures that the entire system is at a constant temperature. With an additional heat shield, Pulsar can withstand a 200°C environment. This makes the machine compatible with plastic materials such as PEEK, Ultem and PSU.

Branch Technology

This company combines additive manufacturing, prefabrication and digital technology on a large scale. Thanks to their patented technology, it allows the team of designers and architects to imagine, compose and finally build those structures that were previously impossible with traditional construction methods. One example of a project they have carried out is in the construction of a 3D printed pavilion in which they have used KUKA robotic technology. The combination of robots with 3D printing has enabled the architects and designers from Gould Turnes Group with whom they have collaborated to not only tackle the construction of the final structure but the design process from start to finish. The 3D printing process applied to the KUKA robots is a great combination as it allows the production of precise, lightweight and cost-effective components from a variety of materials.

One example of a project they have carried out is in the construction of a 3D printed pavilion in which they have used KUKA robotic technology. The combination of robots with 3D printing has enabled the architects and designers from Gould Turnes Group with whom they have collaborated to not only tackle the construction of the final structure but the design process from start to finish. The 3D printing process applied to the KUKA robots is a great combination as it allows the production of precise, lightweight and cost-effective components from a variety of materials.

At this point, if you are interested in WAAM technology, you have almost certainly heard of MX3D. The Dutch company made waves for its creation of an entirely 3D printed, metal bridge which is currently located in the center of Amsterdam. This among other large-scale metal 3D printing feats has made them a popular choice in many sectors. And the company uses robotic arms for its solutions. More specifically, MX3D uses an 8-axis ABB industrial robotics system in its M1 metal AM system, allowing for the creation of medium to large-scale metal parts. To ease the process, the company also offers MetalXL, a software that controls their WAAM-based systems, ensuring that the part is manufactured as intended, controlling everything from design through monitoring during the actual printing.

This among other large-scale metal 3D printing feats has made them a popular choice in many sectors. And the company uses robotic arms for its solutions. More specifically, MX3D uses an 8-axis ABB industrial robotics system in its M1 metal AM system, allowing for the creation of medium to large-scale metal parts. To ease the process, the company also offers MetalXL, a software that controls their WAAM-based systems, ensuring that the part is manufactured as intended, controlling everything from design through monitoring during the actual printing.

mx3D printer

Continuous CompositesContinuous Composites was recently selected by NASA to produce low coefficient of thermal expansion (CTE) open isogrid composite structures for space applications, using its patented Continuous Fiber 3D Printing (CF3D) technology. This printer combines high performing composite materials with rapid curing thermoset resins. They say that this will demonstrate the printer’s capability to produce high quality and consistent printing, with excellent accuracy and precision. The printer is configurable and scalable and therefore can be applied to projects of various dimensions. They turned to Comau for their robotic arm needs.

The printer is configurable and scalable and therefore can be applied to projects of various dimensions. They turned to Comau for their robotic arm needs.

A robotic 3D printer with Comau arm capable of producing thermoset objects with continuous carbon fiber (Photo credit: Continuous Composites)

What do you think of this listing? Have we missed any? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Guide to Robotic Arm 3D Printing

What is robotic 3D printing?

Robotic 3D printing can mean different things in different contexts. In most cases, the term refers to robotic arm 3D printing– or robotic additive manufacturing (sometimes abbreviated “RAM”)–, a technology-agnostic form of 3D printing in which a printhead is mounted to a robotic arm, providing extra degrees of freedom.

But while this article will focus on robotic arm 3D printing, robotics are also used in other areas of 3D printing. With additive manufacturing now a common production process, industry 4.0 factories can use robots to automate industrial 3D printing, programming them to pick parts from a print bed and deliver them to a post-processing station.

Whether for multi-axis 3D printing or smart manufacturing, robotic 3D printing is on the rise and becoming an important part of additive manufacturing (AM).

A transportable robotic arm 3D printer from Orbital Composites. Source: Orbital CompositesHow does robotic arm 3D printing work?

A typical Cartesian-style FDM 3D printer has a printhead that can move along the X, Y, and Z axes. Movement along the X and Y axes determines the shape of each horizontal layer, while movement along the Z-axis shifts the printhead upwards to the next layer.

Confusingly, a Cartesian-style 3D printer is in fact a perfect example of a cartesian coordinate robot (or linear robot), but we do not usually describe such 3D printers as robots.

A robotic 3D printer — that is, a 3D printer with a robotic arm — is different from an ordinary FDM printer. Robotic arms, which have articulated joints like a human arm, can move along and around multiple axes, so putting a printhead on the end of a robotic arm results in more degrees of freedom (often five or six; occasionally dozens). A robotic print bed that can rotate and/or tilt introduces further degrees of freedom.

But this range of movement can also make things complicated in a bad way. With so many moving parts, a robotic arm 3D printer requires more detailed and complex computer instructions in order to work. An FDM printer always has its printhead positioned above the printed part, while a robotic arm can reach around the part from many angles. Its multi-axis toolpaths must therefore account for different types of movement — often moving along or around multiple axes simultaneously — and must avoid collision with the part being built.

The actual printing technologies used on robotic 3D printers can vary. Extrusion technologies are common (polymers, concrete, continuous carbon fiber, etc.), as are directed energy deposition (DED) processes like wire arc additive manufacturing.

The MX3D Robot Arm, which uses Wire Arc Additive Manufacturing (WAAM) technology, in action. Source: MX3DThe robotic additive manufacturing market

Complete robotic 3D printers are limited in number, and those on the market typically use third-party robotic arms developed by industry specialists. Robotic 3D printers on the market include the CEAD AM Flexbot, which is fitted with a Comau robotic arm, and the MX3D M1, which has an ABB arm.

Many general-purpose robotic arms are suitable for robotic arm 3D printing (and some are explicitly designed for it). Leading industrial robotics companies like KUKA, ABB, and Stäubli build such systems.

And several AM companies develop end-of-arm printheads and extruders that can be mounted to these robotic arms to make a robotic-mounted 3D printer. The Weber Additive DXR direct extruder, for instance, is designed to work with a third-party 6-axis robotic arm. Spanish company Meltio offers a similar product, as does the aforementioned CEAD with its E25 and E50 printheads.

The Weber Additive DXR direct extruder, for instance, is designed to work with a third-party 6-axis robotic arm. Spanish company Meltio offers a similar product, as does the aforementioned CEAD with its E25 and E50 printheads.

Some companies have also developed robotic 3D printing software. Ordinary slicing software cannot unlock the full potential of a robotic arm 3D printer, since it only accommodates layer-by-layer printing. The AdaOne cross-platform software service from ADAXIS calibrates, simulates, and executes robotic 3D printing operations, while ABB’s own RobotStudio offers powerful tools for AM users.

The Meltio Engine system on an ABB robotic arm. Source: MeltioSome companies do not sell robotic 3D printers or software, but offer robotic 3D printing services using their own robotic 3D printing arm equipment. Robotics companies using 3D printing, such as Midwest Engineered Systems (which developed its ADDere robotic additive manufacturing systems using KUKA robots), offer part production services.

Advantages of robotic arms for 3D printing

Size

The majority of robotic 3D printers support large-scale robotic 3D printing. This is because the reach of most robotic arms far exceeds the build area of a typical 3D printer. KUKA says its robots can 3D print parts up to 30 meters in size.

Design freedom

Multi-axis 3D printing provides geometrical freedom. A 3D printing robot arm can, for example, print a curve (non-planar 3D printing), while an ordinary 3-axis FDM 3D printer can only approximate one: layers are often visible, producing a stepped effect.

Support-free

Robotic 3D printing can remove dependence on support structures in several ways. One way involves a moving print bed: tilting the print bed can turn a horizontal protrusion into a vertical one that doesn’t need supporting.

One way involves a moving print bed: tilting the print bed can turn a horizontal protrusion into a vertical one that doesn’t need supporting.

A more advanced solution is to use complex freeform 3D printing techniques. The Mediated Matter Group at MIT has used robotic arm 3D printing to print support-free structures in a way that mimics a silkworm spinning its cocoon.

Composite printing

Robotic additive manufacturing can improve composite printing. In 2016, Stratasys unveiled its prototype Robotic Composite 3D Demonstrator with KUKA robotic arm. Stratasys said the 8-axis system could enable “precise, directional material placement”, leading to stronger composite parts.

US-based company Continuous Composites has also explored continuous fiber reinforcement with their impressive CF3D technology.

Limitations of robotic arm 3D printing

Cost

Robotic 3D printing is mostly used by industrial companies, because high-end robotic arms such as those from KUKA and ABB cost tens of thousands of dollars. Complete robotic arm 3D printers can cost upwards of $100,000.

Complete robotic arm 3D printers can cost upwards of $100,000.

Complexity

The complexity of robotic arm 3D printing can lead to complex, strong, and reinforced parts. But it can also result in lower accuracy than (high-end) gantry-style 3D printers, which have fewer moving parts. The likelihood of error and breakdown also increases with robotic printers.

Cross-platform issues

Robotic 3D printing systems often comprise arms and extruders made by different companies, which can lead to cross-platform issues. Users need reliable software to avoid these issues.

Robotic 3D printing applications

Robotic additive manufacturing has diverse applications. Large-scale robotic 3D printing is particularly suited to construction, infrastructure, shipbuilding, and industrial manufacturing, using materials as diverse as titanium and concrete.

With an ability to print on diverse substrates at virtually any angle, robotic arm 3D printing is also used for the repairs of large objects. And the rugged nature of industrial-grade robotic arms means these repairs can sometimes be carried out at remote locations like oil rigs. For the same reasons, robotic 3D printing lends itself well to hybrid manufacturing: printed sections can be added to cast, forged, or machined parts.

Other uses for robotic arm 3D printers include automotive manufacturing, aerospace manufacturing, and tooling: Viridis3D, a subsidiary of EnvisionTEC (itself part of Desktop Metal), built its RAM 123 printer specifically for foundry applications such as the fabrication of sand molds, cores, and patterns.

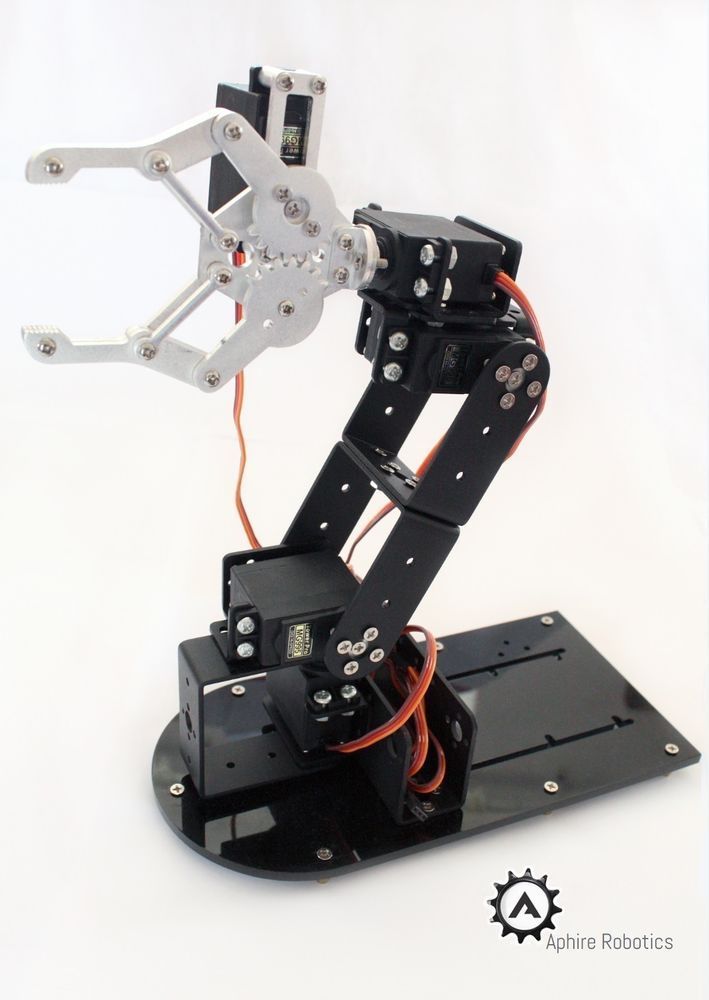

Top 10 DIY 3D Printing Manipulators

3DPrintStory Reviews 10 Best DIY 3D Printing Manipulators

There are many different configurations of robotic arms, but most of them work on the same general principles of movement. Unlike mechanisms that work in the Cartesian coordinate system, such as, for example, 3D printers, manipulators mostly use the polar coordinate system for movement and have an arc-shaped work area. Robotic arms are unique in that they are not limited by footprint and take up very little space compared to other machines with similar functions. nine0005

Unlike mechanisms that work in the Cartesian coordinate system, such as, for example, 3D printers, manipulators mostly use the polar coordinate system for movement and have an arc-shaped work area. Robotic arms are unique in that they are not limited by footprint and take up very little space compared to other machines with similar functions. nine0005

In robotics there is such a definition as degrees of freedom (DOF). The term is used to refer to the number of rotating joints or axles on a particular arm, for example a 4DOF arm can be rotated by four separate joints.

Robotic arms are used in a variety of ways, but most are capable of picking up and moving, while some are designed to work in tandem with CNC machines, laser engraving, and even 3D printing.

Because there are hundreds of great designs and designs to consider when choosing a good arm to buy or 3D print, we've narrowed it down to 10 of the best and most popular arms that you can find and reproduce designs using your 3D printer as well. . nine0005

. nine0005

UFactory uArm

UArm is probably one of the most versatile of all the robot arms on this list. At the moment, this design already has the third release version - uArm Swift and more functional Swift Pro.

This open source robot arm is fully compatible with Arduino, Raspberry Pi and Seeed Studio Grove kits. It's unique in that the Swift Pro can do laser engraving and 3D printing - provided it's equipped with the right heads - and can "learn" the movements without the need for a computer. nine0005

This is a 4DOF manipulator with an accuracy of 0.2 millimeters.

You can find more information and where to buy it on the UFactory product page.

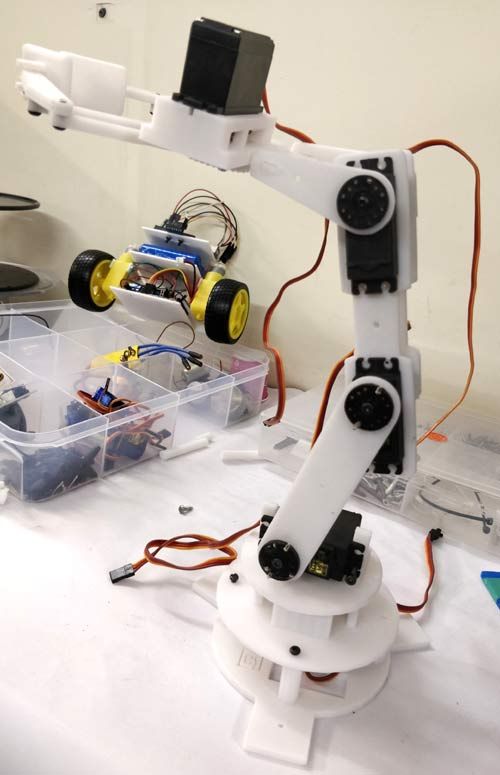

Thor

This arm, developed by Hackaday AngelLM, is completely open source and can be used for 3D printing. This is a 6DOF paddle with a maximum payload of 750 grams and a unique design for great flexibility.

You can find all the 3D printing files for this robot on the Thor project page.

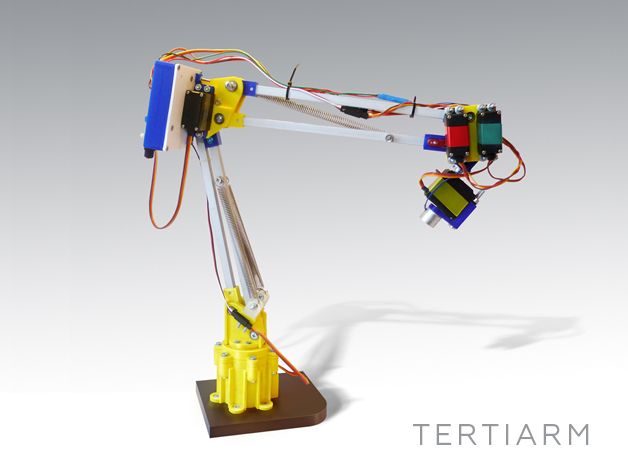

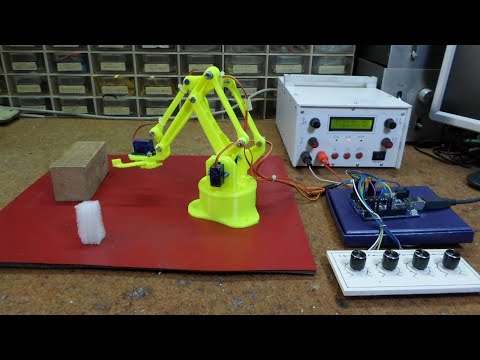

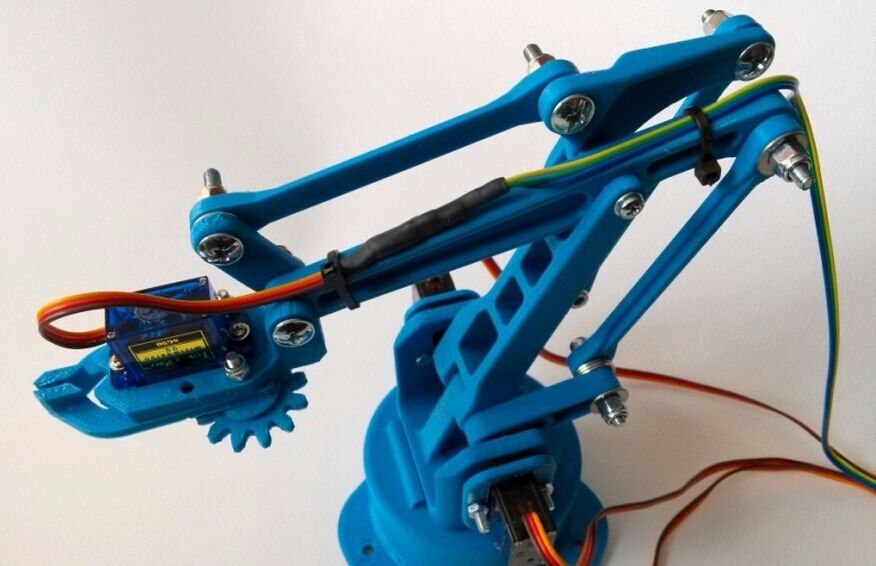

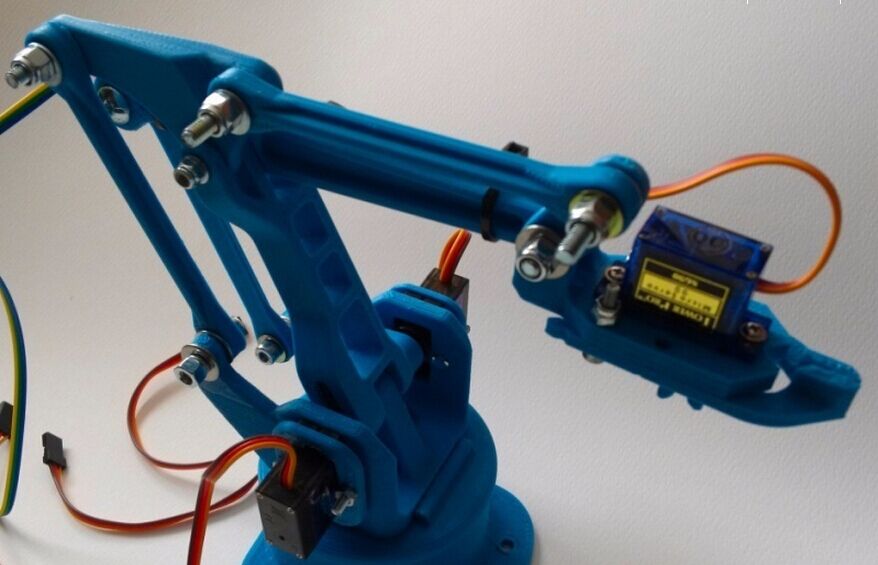

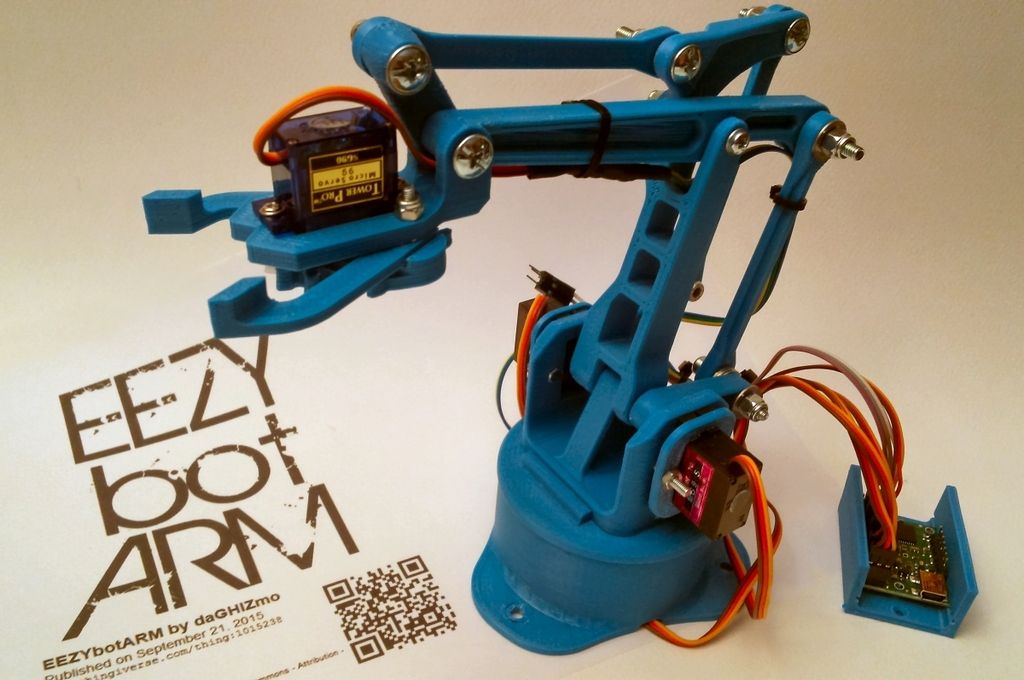

EEZYbotARM MK2

The EEZYbotARM MK2 is a 4DOF reference arm that is fully 3D printed with excellent building instructions. This robotic arm has won several competitions and is probably one of the easiest robotic arms to make. An MK3 version is also being developed.

You can find complete assembly instructions on the EEZYbotARM web page. nine0005

Roboteurs RBX1

This is another great fully 3D printed robot arm that has amazing flexibility and aesthetics. In addition to purchasing the components yourself, Roboteurs offers a complete parts kit with a proprietary stepper motor driver to run the RBX1. All you need is a Raspberry Pi and a 3D printer. This manipulator is a 6DOF type design and has a beautiful appearance.

You can find the complete specification and parts kit on the Roboteurs product page.

LittleArm

LittleArm, designed by Slant Concepts on Hackaday.io, is the simplest robotic arm on this list. With only 3DOF, this arm can be a great introduction to Arduino programming for students and opens exciting doors of new technologies for newcomers to the world of 3D printing and robotics.

With only 3DOF, this arm can be a great introduction to Arduino programming for students and opens exciting doors of new technologies for newcomers to the world of 3D printing and robotics.

This fully 3D printed arm is very easy to assemble. The creators even developed an application with a simple interface for computers that can be used with this robot. nine0005

You can find full documentation on the LittleArm project page.

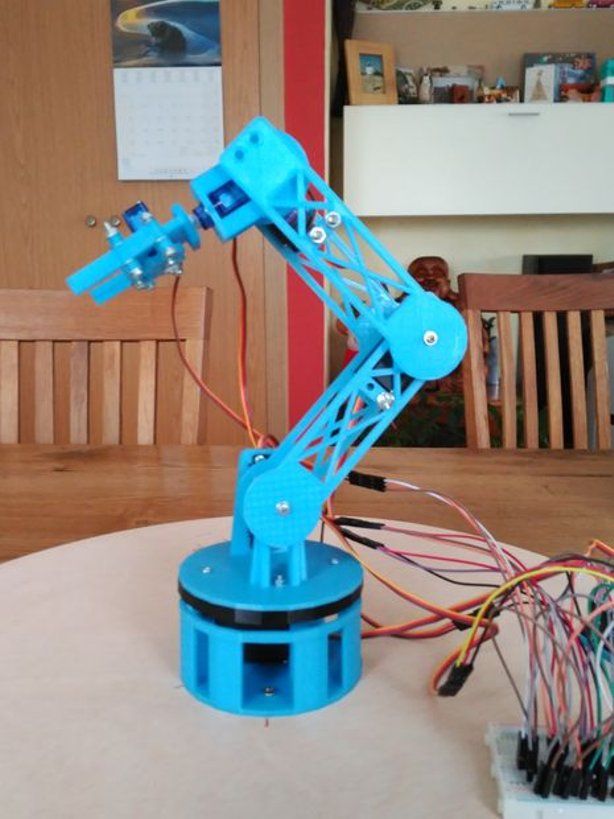

3D Printable Robot Arm

Created by Andreas Helldorfer on Hackaday.io. It's a large arm, fully 3D printed, with many uses. The creator developed it for 4 iterations before making a really worthy industrial design that is available to everyone. With a 6DOF design and a maximum payload of up to 2kg, this arm can really be used in many applications. nine0005

To find the 3D print files for this arm and the full specification, visit the project page.

MeArm

MeArm is one of the most popular manipulators and for good reason. It consists of simple parts that can be laser cut or 3D printed and features a simple yet robust 4DOF construction.

It consists of simple parts that can be laser cut or 3D printed and features a simple yet robust 4DOF construction.

This design is so popular that two others on this list copy it. This is a manipulator equipped with four servos and either an Arduino or a Raspberry Pi. It is available in several different colors as a kit, or you can make all the parts yourself. nine0005

For pre-assembled kits, check out the MeArm product page.

For 3D printing files, take a look at MeArm on Thingiverse.

Zortrax Robotic Arm

The 5DOF Zortrax Robotic Arm is not the strongest for its size, with a maximum payload of only 100 grams, but it has a very impressive design. And it's a fully 3D printed arm, making it worthy of a mention on the current list. Its uniqueness lies in the fact that only three axles are driven, while the rest are set manually. nine0005

This manipulator is primarily used for supplying a set of interchangeable tool heads.

For a complete list of part files, including those for 3D printing, visit the project page.

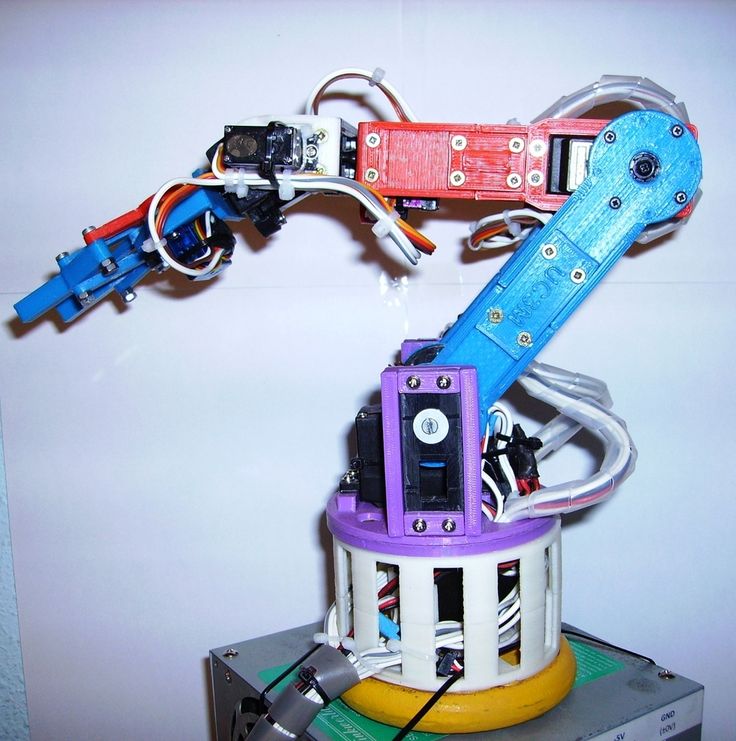

BCN3D Moveo

BCN3D Moveo is an impressive Arduino controlled 4DOF robot arm. It is fully 3D printed, open source, and has been well tested as a mockup for educational purposes and is already in active use in educational institutions. nine0005

Being open source, this manipulator is not limited to its intended use and, as such, can be modified to perform all kinds of tasks and can be used as a dedicated household apprentice or used on an industrial scale.

For more information, visit the BCN3D Moveo webpage.

OWI Robotic Arm Edge

Another 4DOF design, the OWI Robotic Arm Edge is a simple manipulator designed for educational purposes. It is only available as a kit. nine0005

When powered by DC motors without encoders, accuracy is limited, making this manipulator more suitable for use as a toy. We included it on this list because it's a fantastic kit for students interested in robotics and technology, and it can be a great "desk toy" during boring lunch breaks. It can also be extensively modified to serve as a base platform for Arduino projects and other DIY developments. nine0005

It can also be extensively modified to serve as a base platform for Arduino projects and other DIY developments. nine0005

You can buy it on the OWI website, well, or Amazon, Aliexpress is also at your service.

Manipulator 3d model

DOWNLOAD

-

Rating:

-

Difficulty:

Medium -

Weight:

9.72 MB -

Parts:

22 pcs.

Everyone knows the robotic arm that is used in factories and other enterprises. Perhaps the robotic arm is the most popular model for assembly and control experiments among robotics fans. In addition, she teaches children very well at RobotON robotics circles in Nizhny Novgorod, the guys study her with great pleasure, programming and forcing them to perform various manipulations. Of course, this robot has a lot of details, and printing them with high quality on a 3D printer is not an easy task for a beginner. But for this, we have prepared articles on 3D printing that will definitely help you cope with this task. nine0005

But for this, we have prepared articles on 3D printing that will definitely help you cope with this task. nine0005

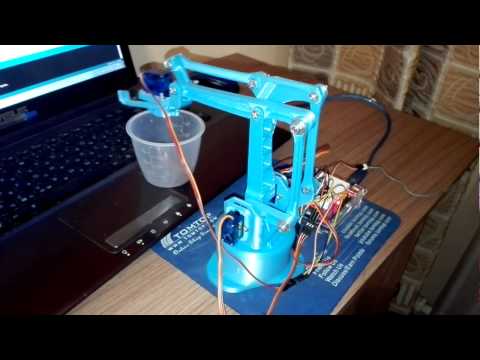

The instructions for assembling the robotic arm look very simple. It is worth collecting in 3 stages. First you need to assemble the base - the base on which the robot rotates around its axis in azimuth. Then you need to assemble the claw, and then the multi-lever mechanism of the crane itself. When assembling it, you need to make sure that each assembly rotates very easily. Otherwise, the servomotors will not have enough power to move the entire structure.

What causes poor mobility? Well, first of all, it can be caused by 3D printing defects. When you print a 3D model with a certain size of screw holes, you need to take into account the flow of plastic around the edges. That is, for example, if you have a round hole, then most often when printing, its diameter will decrease by 0.5 mm or even 1 mm. Because of this, the screw will hardly fit into this hole and cut the thread there. Therefore, there are 3 ways out here: pre-clear the hole with a screwdriver (or something else), develop a movement along the thread by assembling the knot, or simply put this error in the 3D model. This problem occurs depending on the printer, so it is quite individual. nine0005

Therefore, there are 3 ways out here: pre-clear the hole with a screwdriver (or something else), develop a movement along the thread by assembling the knot, or simply put this error in the 3D model. This problem occurs depending on the printer, so it is quite individual. nine0005

Another reason why a structure can be too stiff is overtightening the bolts or using the wrong sizes of connecting elements.

Features:

An important detail of the assembly is the pre-setting of the servos before attaching them to the crane or claw. The fact is that these places, due to the design and capabilities of servo motors, have dead zones. Therefore, before installing the servos on the crane, you need to program them at an angle of 90 degrees to be able to move the crane both to the right and to the left. We set the claw servomotor to 0, close its blades and fix it with a gear.