Home sls 3d printer

hardware selection and technology guide

What desktop SLS 3D printers are available on the market?

SLS (Selective Laser Sintering) is a 3D printing technology that uses a laser beam to sinter powdered material. This technique enables the 3D printing of detailed functional parts and prototypes.

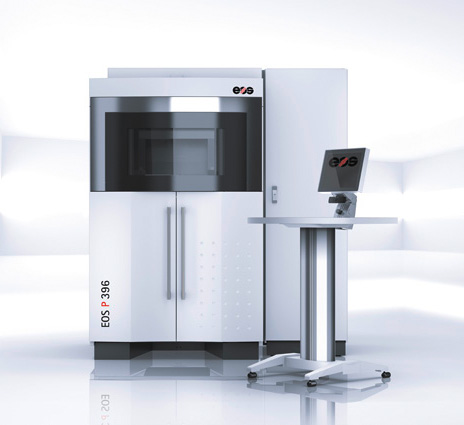

Five to ten years ago, SLS technology was exclusive to large, industrial additive manufacturing systems. In recent years, a more compact SLS 3D printer niche has been slowly emerging, with lower prices and office-friendly formats.

Starting at around $6,000, these benchtop or desktop SLS 3D printers enable SMEs to access accurate and advanced in-house prototyping without having to rely on external 3D printing services. They are able to print with powder materials such as Nylon, TPE, and other thermoplastics.

In this guide, we take a closer look at which desktop SLS printers are available on the market from brands like Sintratec, Sinterit, and Formlabs.

The best desktop SLS printers for professionals

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €5,321 £894,187 ¥ | Quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9.84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €11,443 £1,922,822 ¥ | Quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €11,527 £1,936,983 ¥ | Quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5. 91 × 7.87 × 10.24 in 91 × 7.87 × 10.24 in | – | $ 17,99011 990 €15,958 £2,681,517 ¥ | Quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | – | $ 18,49918 499 €16,409 £2,757,387 ¥ | Quote |

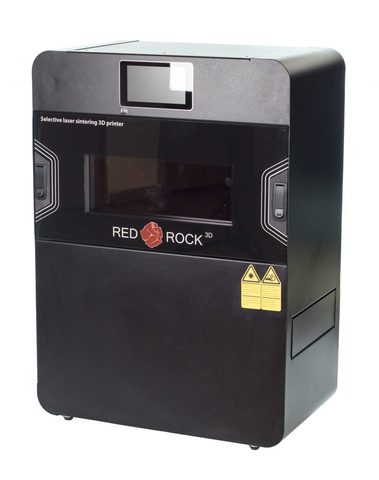

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Sintratec | Sintratec Kit | 110 × 110 × 110 mm4.33 × 4.33 × 4.33 in | – | $ 5,9994 990 €5,321 £894,187 ¥ | Get a quote |

| Natural Robotics | VIT SLS | 250 × 250 × 300 mm9. 84 × 9.84 × 11.81 in 84 × 9.84 × 11.81 in | Spain | $ 12,90011 000 €11,443 £1,922,822 ¥ | Get a quote |

| Sinterit | Lisa | 150 × 200 × 150 mm5.91 × 7.87 × 5.91 in | – | $ 12,9957 990 €11,527 £1,936,983 ¥ | Get a quote |

| Sinterit | Lisa Pro This product has been reviewed by our team. | 150 × 200 × 260 mm5.91 × 7.87 × 10.24 in | – | $ 17,99011 990 €15,958 £2,681,517 ¥ | Get a quote |

| Formlabs | Fuse 1 | 165 × 165 × 320 mm6.5 × 6.5 × 12.6 in | – | $ 18,49918 499 €16,409 £2,757,387 ¥ | Get a quote |

| RED ROCK 3D | RED ROCK | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | upon request | Get a quote |

What is SLS (Selective Laser Sintering) technology?

Up until early 2014, Carl Deckard from Structured Polymers held a patent on Selective Laser Sintering 3D printing technology. Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

Selective Laser Sintering (SLS) is part of the Powder Bed Fusion family of 3D printing technologies.

How does Selective Laser Sintering work?

This technology uses a laser to sinter powdered material. In other words, a powerful laser beam selectively melts and fuses tiny powder particles together.

SLS 3D printing technology. Source: SculpteoOnce a layer is finished, more powder is rolled and spread onto the print bed. The process repeats itself layer after layer. The excess powder stays in the powder bed, thus automatically providing support for the object and its intricacies (though supports are still needed when it comes to metal 3D printing).

When the 3D printing process is finished and the powder bed has cooled down, the objects can be removed. The excess powder material is then to be brushed off to reveal the final part. Aside from powder removal, the parts require little to no post-processing for basic applications.

Overview of the best desktop SLS printers

The Sinterit Lisa is a plug-and-play desktop SLS 3D printer made by Polish manufacturer Sinterit. It is one of the most affordable SLS 3D printers actually available on the market.

It is one of the most affordable SLS 3D printers actually available on the market.

This 3D printer offers a relatively large build volume for a desktop 3D printer, and even more so for an SLS 3D printer in this price range. With the Lisa it is possible to 3D print flexible material (Flexa Black/Grey) or rigid, strong material (PA12).

Contact manufacturer Get a quote Add to comparison

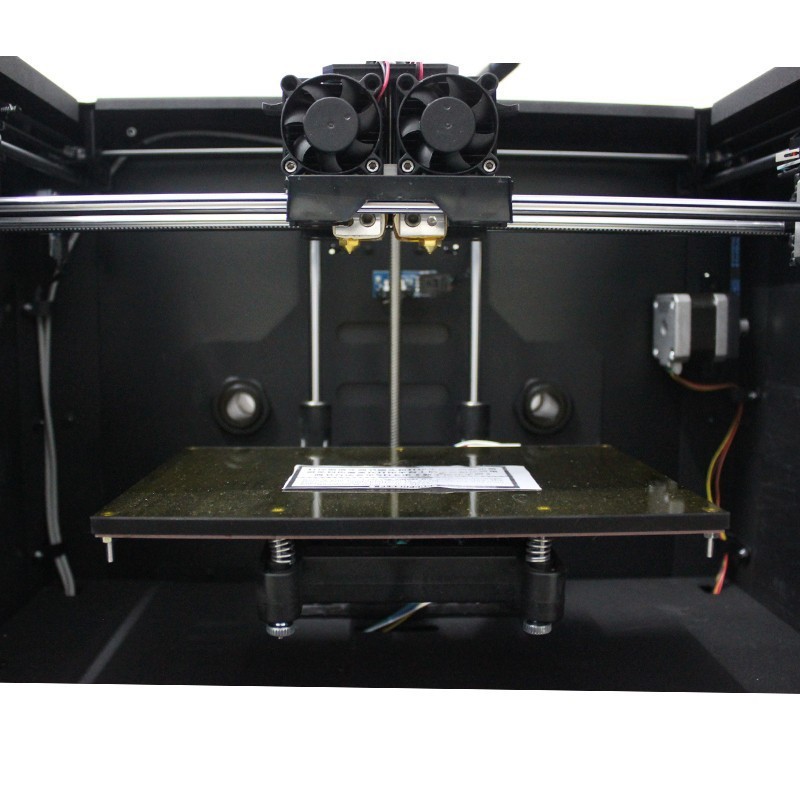

In comparison with the regular Lisa, the Lisa Pro boasts various upgrades and features. For starters, the Pro version is equipped with a Nitrogen chamber, for wider material compatibility.

The Lisa Pro SLS printer also provides a bigger print volume as well as a larger touchscreen than the Lisa.

Our review at Sinterit headquarters: Sinterit Lisa Pro review

Contact manufacturer Get a quote Add to comparison

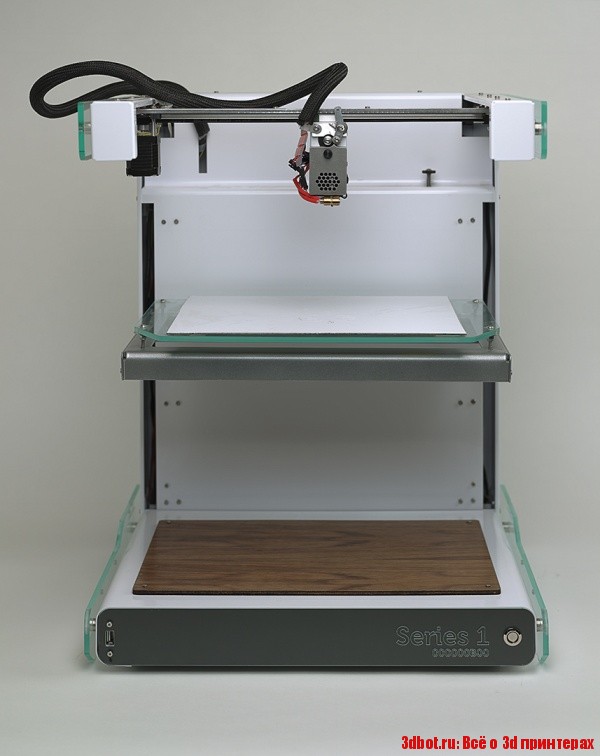

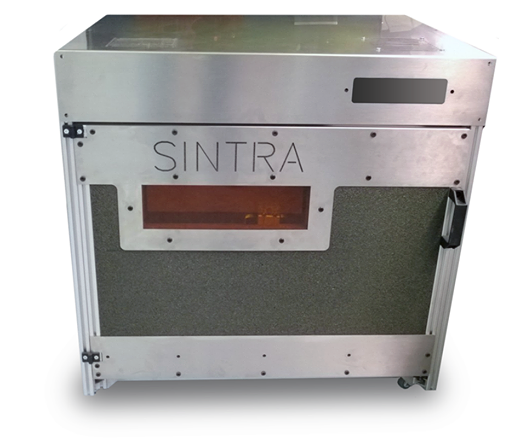

The Sintratec Kit started out as an Indiegogo crowdfunding campaign in 2014. It is one of the most affordable SLS 3D printers available today.

The Kit requires around four days of assembly. Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Users can freely adjust the laser’s height, speed, and temperature in order to try out different materials.

Contact manufacturer Get a quote Add to comparison

Formlabs, originally an SLA 3D printer manufacturer, introduced their first SLS 3D printer – the Fuse 1 – mid 2017. It is officially available since January 2021.

The printer works with Formlab’s PreForm software, and features two separate build chambers. This enables users to immediately launch a second build once the first job is complete.

After the printing process, the chamber can be directly placed as-is in the Fuse Sift, an all-in-one sieving machine that collects unused powder and prepares it for future builds by mixing it with fresh powder. The Fuse 1 can work with up to 70% of recycled powder, so each new build only requires 30% of fresh material (which costs around $100/kg).

Contact manufacturer Get a quote Add to comparison

Note: Natural Robotics launched the VIT SLS via Kickstarter in 2017. As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

As of January 2021, some backers are stating that they still haven’t received their printers, although the company claims to be shipping products.

The VIT SLS offers a relatively large build volume compared to the other 3D printers in this range.

Contact manufacturer Get a quote Add to comparison

Note: This 3D printer is only available in a limited geographical region.

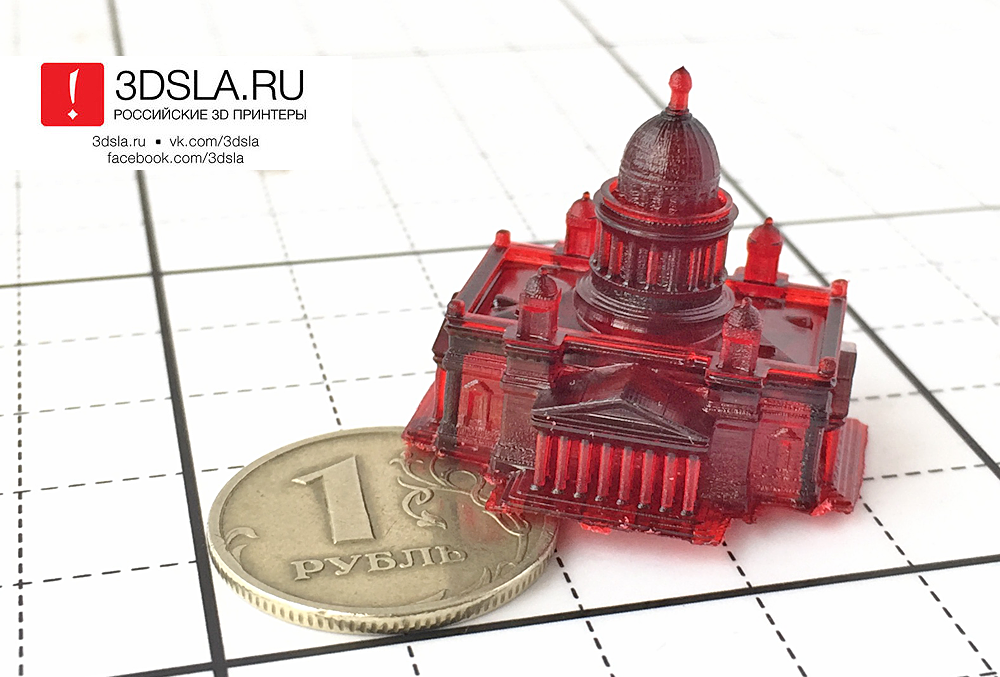

RED ROCK 3D is a new 3D printer manufacturer from Russia. Its RED ROCK SLS 3D printer offers a relatively large build volume compared to most of the other desktop SLS 3D printers in this selection.

Little information about this SLS 3D printer is available on the RED ROCK 3D website, which hasn’t been updated in a while (as of January 2021).

Contact manufacturer Get a quote Add to comparison

Compact industrial-grade SLS 3D printers: our picks

The following printers are larger than the benchtop SLS printers from our main selection but are still relatively compact considering the usual size of industrial SLS systems.

The Sintratec S2 is an all-in-one modular and scalable SLS 3D printing system with an onboard camera and large, intuitive touchscreen. It integrates a material preparation module as well as a depowdering station for semi-automatic workflows.

Optional stations include a blasting station, vortex unit, and a polishing station, enabling easier part post-processing.

Contact manufacturer Get a quote Add to comparison

The SnowWhite 2 features a powerful CO₂ laser that is able to sinter a range of materials including PA 12, PA 11, and TPU, as well as powder loaded with carbon or glass fiber or even aluminum.

All unused powder can be recycled. The printer can be powered up in ten minutes and the minimum amount of powder required to start a print is 300g.

Contact manufacturer Get a quote Add to comparison

XYZprinting’s range of products is one of the industry’s most diverse in terms of technology, suiting both consumers and businesses.

The MfgPro230 xS is an open-source system, meaning that its powerful 30W CO2 can print with any powder that’s available on the market. Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Hence, users can experiment with different types of Nylons and TPU materials, and even light-colored ones, which is not the case with entry-level SLS printers.

Contact manufacturer Get a quote Add to comparison

Released in 2020, the Gravity SLS 3D printer by Swedish manufacturer Wematter is the most recent printer in our selection. The printer features integrated powder recycling and easy material handling with user-friendly packaging.

Wematter’s cloud-based slicing software automatically optimizes the build area, packing parts efficiently and as close together as possible thanks to advanced algorithms.

Contact manufacturer Get a quote Add to comparison

Benefits and limits of SLS 3D printing

Main benefits of SLS 3D printing

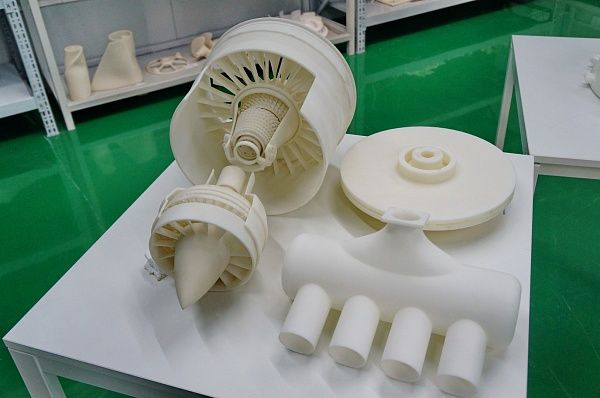

No need for support: 3D printing complex and functional parts

Since unused powder remains in the powder bed, it naturally acts as support for the following sintered layers. This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

This support, which is present all over, allows the 3D printing of very complex and/or functional parts and prototypes.

It’s also possible to 3D print objects within objects, also known as nesting. This is not possible with other 3D printing technologies such as FFF and FDM (extrusion) or SLA and DLP (resins).

Multiple layers of parts to be 3D printed with SLS technology. Source: SinteritWaste reduction

It is possible to re-use powder that has not been sintered. This significantly reduces material waste and costs compared to other 3D printing techniques. Also, no material is wasted on support structures.

Main limitations of powder SLS 3D printing

Just like any technology, SLS 3D printing has its downsides.

Porosity/rough surface

SLS 3D printed objects are porous, though it is possible to apply sealant to alter their sandy, granular-like surfaces.

Expensive material

The price for one kilogram of PA12 powder can range from around $55 to about $180.

Logistics and post-processing

Due to the volatile nature of powder, extra caution is required when handling the material and taking the final 3D print out of the powder bed. The prints must be depowdered; either manually, which is time-consuming, or with a dedicated powder removal solution.

SLS vs FDM vs SLA

SLS vs FDM (FFF)

Compared to Fused Filament Fabrication, SLS can:

- achieve higher quality prints

- provide thinner layers and wall thicknesses

- generate complex 3D prints without the need for support

However, Selective Laser Sintering 3D printers offer much less material choice (and colors).

SLS vs SLA

Compared to stereolithography 3D printing technology, Selective Laser sintering offers:

- thinner wall thicknesses

- complex 3D prints without support structures

That being said, SLS 3D prints have rougher surfaces than SLA 3D prints.

SLS 3D printing: what materials are available?

Main desktop SLS 3D printing powders

Most desktop SLS 3D printers use Polyamide (PA) powdered material, also known as Nylon. The main PA powders available on the market are:

- Nylon PA12

- Nylon PA11

Then, there are composite or “charged” powders, meaning that different materials are mixed with PA. The most common are the following:

- Alumide: PA mixed with aluminum (shiny, metallic appearance)

- Carbonamide: PA reinforced with carbon fiber (stiff and lightweight)

- Nylon 3200: PA filled with glass (more chemical and heat resistant than PA12)

There is also PEBA 2031, a flexible, rubbery, and resistant plastic powder. Some manufacturers produce elastic 3D printing powders (such as Sinterit’s Flexa Black and Flexa Grey) to 3D print shock absorbers, clothing parts, bellows, etc.

Nylon SLS 3D printing material

Nylon, or Polyamide (PA), is the most common powdered material used by SLS 3D printers. It boasts many interesting characteristics:

- Lightweight: Polyamide is a lightweight 3D printing material.

- Robust: this material can bear loads or be used for mechanical parts.

- Flexible: Nylon can bend and come back to its original form.

- Resistance: PA offers good heat and chemical resistance.

Manufacturers generally sell their own, branded powder material.

SLS 3D printing in general

Desktop SLS printers are limited to plastics when it comes to material choice. However, when using larger, more expensive powder industrial 3D printers, it is possible to 3D print metal powder. Some industrial SLS 3D printers are also able to 3D print ceramics.

Manufacturer of compact and industrial SLS 3D printers

These industries leaders trust us

Sinterit’s compact series

Print batches of top quality SLS parts faster. Larger print volume and revolutionary fast rapid prototyping.

Larger print volume and revolutionary fast rapid prototyping.

LEARN MORE

The SLS 3D printer for top-quality functional prototypes, research work, and to speed up the product engineering process.

The most compact SLS 3D printer to start your additive manufacturing journey.

Sinterit’s industrial series

A new industrial SLS 3D printer with the best ROI on the SLS technology market.

Priced individually

LEARN MORE

Any shape you want. Without supports.

Nine different materials + the ability to use third-party powders

Standard prototyping

Performance & Special Applications

Flexible

ALL MATERIALS

Build your custom solution

based on modules

Solutions

Industrial Set

Industrial performance & build volume with the best ROI on the market. An open & multi-material printer offering industrial-size build volume.

Priced individually

MORE

Performance Set

Top performance & build volume in an open, multi-material printer. Offering large build volume and industrial speed & quality.

Offering large build volume and industrial speed & quality.

Starts from 33.490 €

MORE

Open Set

Professional SLS quality in an open, multi-material printer. Compatible with 9 different Sinterit materials. Easily modify 32 printing parameters thanks to the open system.

Starts from 22.490 €

MORE

Entry Set

The most compact SLS 3D printer. It offers professional SLS print quality, it’s cost effective, and very easy to use.

Starts from 11.990 €

MORE

Thanks to the nitrogen chamber built in to the LISA PRO, LISA X and NILS 480, you can experiment with third-party powders outside of our offer, opening up a world of flexibility.

SLS 3D printing is one of the most cost-effective means of additive manufacturing. You can reuse the unsintered powder, which acts as a supporting structure during the printing process. Some powders need to be refreshed, while others are good to go.

PRINTING COSTS

Rigo Herold

Professor Dr.

It was the best choice for me to fulfill all requirements: possibility to print complex structures, price, speed, reliability.

Maurice Briggs

Director at Lazerthrust

Sinterit LISA is the most accessible means to produce precise constraint-free solutions to modern problems. The technology does what it says on the tin and the team at Sinterit is dedicated to working with their customers to achieve their objectives.

Joshua Rosen

ECA Medical

One of the main benefits of SLS is the ability to print complex geometry in quick succession to do rapid prototyping.

SEE CASE STUDY

Peter Benthues

H. Gautzsch Firmengruppe

For a company at the beginning of an investigation, support from, and discussion with the technology experts is extremely beneficial. The LISA is one of the few economically feasible solutions in the first stages of any AM Strategy. At lower volumes, it is a perfect solution.

SEE CASE STUDY

Lluís Llenas

Regner

The FFF and SLA parts are a good choice to get a physical impression of the designs and to assemble rough prototypes. But when it comes to producing reliable prototypes to be verified in our fatigue tests or to send functional samples to our customers for validation, SLS is the only acceptable choice.

SEE CASE STUDY

Walter Pucheanu

R&D Technician

Department of Chemical and Biological Engineering (CBI) / University of Erlangen–Nuremberg

The print quality of the Lisa PRO is impressive.

SEE CASE STUDY

Sean Higgins

Nabson Inc.

In order to keep up with our production demand, we have been operating the Lisa PRO almost 7 days a week for the past couple of months, without incident, and produced over 1500 sleeves.

SEE CASE STUDY

Case Studies

ALL CASES

We empower innovation with new possibilities based on SLS – the most powerful additive manufacturing technology.

Sinterit’s goal is to support the creativity of engineers, researchers, developers, academics, and visionaries wherever it’s needed. Our focus, every day, is on making the world more innovative and sustainable.

MORE ABOUT SINTERIT

Sinterit printers are available worldwide thanks to our distribution network. Choose the one closest to you and check out Sinterit printers in person.

DISTRIBUTORS LIST

Get SLS knowledge straight to your inbox. Keep up to date with new applications, products, and powders, while being among the first to know about new webinars, ebooks, and case studies.

Access the prestigious SLS 3D printing owners and experts club. We don’t get in touch often, but when we do you’ll know it’s worth your time.

We understand that choosing the right 3D printing technology can be a daunting task, even for professionals. That’s why we invite you to consult our advisors and ask as many questions as you need to. Our experts will help you choose the best technology for your applications, suggest the powders you will need, provide more information for specifications or tenders, or send you sample printouts demonstrating the features you’re looking for. Send a form and try to describe all your needs so we can be prepared when contacting you. Once we receive your message, we will contact you soon.

Send a form and try to describe all your needs so we can be prepared when contacting you. Once we receive your message, we will contact you soon.

Select topic

---Price quotationTechnical questionMore product/offer detailsSample print request

First name*

Last name

E-mail

Phone number

Company name

Job title (optional)

Country

---AfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia (Plurinational State of)Bonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIran (Islamic Republic of)IraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea (Democratic People's Republic of)Korea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia (Federated States of)Moldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussiaRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUAEUKUSAUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela (Bolivarian Republic of)Viet NamVirgin Islands (British)Virgin Islands (U. S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

State

---AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyomingDistrict of Columbia

Requested Products

Upload o file

How can we help you?

* Information about the processing of your personal data provided to Sinterit by the contact form is here. To read all our Privacy Policy please click here.

(Optional) By provision of your email address (and other data, if you wish) you agree to receive newsletter from Sinterit sp. z o.o. that may include commercial information e. g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

Click to make an appointment and learn more about our printers

First name*

E-mail

Phone number

Company name

Country

---AfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia (Plurinational State of)Bonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIran (Islamic Republic of)IraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea (Democratic People's Republic of)Korea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia (Federated States of)Moldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussiaRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUAEUKUSAUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela (Bolivarian Republic of)Viet NamVirgin Islands (British)Virgin Islands (U. S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.)Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

State

---AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyomingDistrict of Columbia

* Information about the processing of your personal data provided to Sinterit by the contact form is here. To read all our Privacy Policy please click here.

(Optional) By provision of your email address (and other data, if you wish) you agree to receive newsletter from Sinterit sp. z o.o. that may include commercial information e.g. Sinterit Lisa Pro updates, products and services offers, information about exhibitions and use-cases, as well as, from time to time, we may send you inquiries or surveys to ask you about Sinterit and our products. You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

You can find more information about processing your personal data here. To read all our Privacy Policy please click here.

Pricing

Below there are approximate costs for some example models.

Be aware that the quotation assumes that there is only one piece printed. In SLS technology, the cost per part will be much lower with a higher number of elements printed at once.

Flexible

Standard

[contact-form-7 404 "Not Found"]

Get a free sample box

The free samplebox contains two printouts made from PA12 Smooth. They are both movable designs, and each one is printed in one piece.

These are examples showing high precision and freedom of design ensured by SLS technology.

order free sample box

This product includes GeoLite2 data created by MaxMind, available from https://www.maxmind.com.

Skip to content

What is SLS 3D printing.

How does an SLS 3D printer work? Overview of additive technologies.

How does an SLS 3D printer work? Overview of additive technologies.

What is SLS?

Hello everyone, Friends! 3DTool is with you!

In this article, we will talk in detail about one of the most promising technologies 3D printing . Selective laser sintering.

Selective Laser Sintering (SLS) is an additive manufacturing process belonging to a broad family of wafer synthesis methods. In SLS, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer. Granular thermoplastic polymers are used as construction material. Options for such devices can be considered in our catalog. For example, the Sintratec 3D printer. nine0004

This technology is used both for prototyping functional polymer products and for integration into small production runs, as it offers complete design freedom, high precision and produces parts with good and stable mechanical properties, unlike FDM or SLA .

Naturally, as in any other case, the possibilities of technology can be used to the full only if its key advantages and disadvantages are taken into account, so let's take a closer look at its features and principle of operation. nine0004

SLS printing process

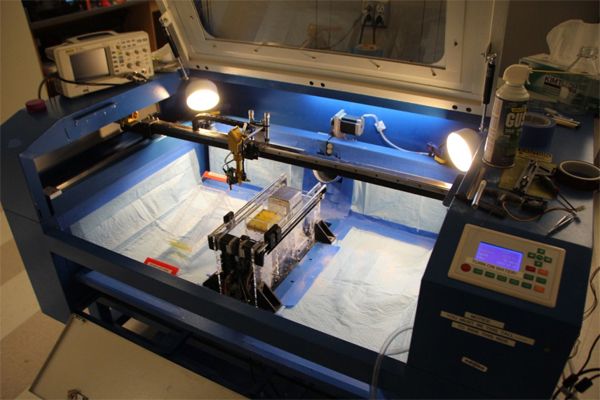

How does SLS work?

The SLS fabrication process works as follows:

I. The powder chamber, as well as the entire printable area, is heated just below the melting temperature of the resin, after which the leveling blade distributes a thin layer of powder over the build platform.

II. The CO2 laser scans the contour of the next layer and selectively sinters (melts) the polymer powder particles. The cross section of the component is scanned ( is sintered ) completely, so the part is monolithic.

III. When the layer is completed, the work platform moves down and the blade re-coats the surface with powder.

The process is repeated until the entire part is completed.

After printing, the part is completely sealed in the non-sintered powder, so the chamber and powder must cool before being removed. Cooling down can take a significant amount of time, up to 12 hours. Then the resulting part is cleaned of powder residues with compressed air. The unsintered powder is collected for further reuse. nine0004

Schematic diagram of an SLS 3D printer.

SLS printing specifications In SLS, almost all print options are set by the printer manufacturer. The default layer height for is 100-120 µm . For example, the Sintratec 3D printer we mentioned above allows you to print a much thinner layer, the layer thickness declared by the manufacturer varies from 50 to 150 micron.

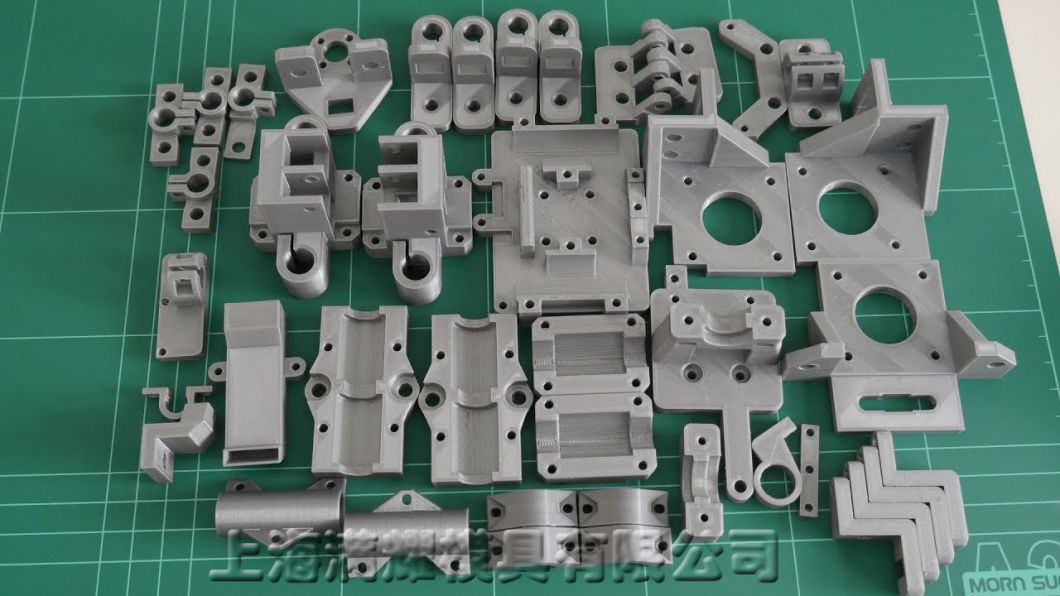

The main advantage of method SLS is that the part does not need supports . In this case, the non-sintered powder plays the role of the necessary support. For this reason, the SLS method can print geometries of any shape that are impossible to print with any other additive or subtractive manufacturing method.

When printing with this method, it is very important to use as much of the printable area as possible, especially in small-scale production. Regardless of the amount of detail in the printable area, if the overall height is the same, printing will take the same amount of time. This is because it is the recoating step that determines the total print time ( the laser scanning and sintering itself is very fast ), and the printer has to cycle through the same number of layers. Also, you need to take into account the time for refilling the hopper with powder, because the same amount is poured into the chamber, regardless of the size of the printed part.

Layer sintering

When using method SLS , the sintering strength of the layers to each other is excellent. This means that printed on SLS printer parts have almost isotropic mechanical properties.

As an example, the mechanical properties of samples printed on SLS using standard polyamide powder ( PA12 or Nylon12 ), the most commonly used material in SLS printing , are shown in the table in comparison with the properties of solid nylon:

Parts printed on SLS have superior tensile strength and modulus comparable to solid material, but are more brittle ( their elongation at break is much lower than ). This is due to the internal porosity of the resulting part.

!A typical SLS part has a porosity of about 30%!

Porosity gives parts printed on SLS a characteristic grainy surface. This porosity also means that the parts can easily absorb water and are easy to paint. At the same time, such parts require special post-processing if they are to be used in a humid environment. nine0004

At the same time, such parts require special post-processing if they are to be used in a humid environment. nine0004

Shrinkage and deformation

SLS parts are subject to shrinkage and deformation: when the newly sintered layer cools, its dimensions decrease and internal stress accumulates in it, due to which the underlying layer is pulled upwards.

Shrinkage of 3 to 3.5% is typical for SLS printing of and printer operators must take this into account during model preparation.

Large flat surfaces are most prone to deformation. This problem can be mitigated slightly by orienting the part vertically on the build platform. But still, the best way to reduce deformation is to minimize the thickness of the flat areas of the part, and add cutouts to the model where the design allows. These actions will also reduce the overall cost of the part, as less material will be used. nine0004

Finished sls-part with embedded embedded elements.

Excessive caking

Over-sintering occurs when excess heat around the contour of the part melts the unsintered powder around. This is fraught with loss of detail on small objects such as slots and holes.

Excessive sintering depends on both element size and wall thickness. For example, a slot with a width of 0.5mm or hole diameter 1mm will print successfully on a wall thickness of 2mm but will not print if the wall thickness is 4mm or more. As a general rule, slits from to 0.8mm and holes from to 2mm can be safely printed in SLS without fear of excessive caking.

Powder removal

Since printing method SLS no support required, parts with hollow sections print quickly and accurately.

Hollow sections in this case reduce the weight and cost of the part, as less material is ultimately used. But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

If high rigidity is required, the parts must be printed solid. An alternative here would be to make the structure hollow, with no outlets. In this way, the powder will be compacted tightly into the part, increasing its mass and providing some additional support when mechanical loads increase, without affecting print time. Also, instead of one solid internal cavity, you can add a honeycomb structure ( similar to the infill patterns used in FDM ) to further increase the rigidity of the model. Laying out the part in this way will also help reduce warping.

Removing powder from an SLS part

General materials SLS

The most commonly used material for SLS is Polyamide 12 (PA 12) , also known as Nylon 12 . At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

As an example, you can see the list of materials used in our catalog: Sintratec Powder Sls.

Polyamide powder can be supplemented with various additives ( such as carbon fibers, glass fibers or aluminum ) to improve the mechanical and thermal properties of the printed part. Materials supplemented with additives are usually more brittle and have higher anisotropy. nine0004

Post-processing

SLS produces parts with a powdery, grainy finish that is easy to paint. The appearance of SLS printed parts can be improved to a very high standard using a variety of post-processing methods such as polishing, classic painting, spray painting and varnishing. Their functionality can also be improved by applying a waterproof coating or metal coating. nine0004

Their functionality can also be improved by applying a waterproof coating or metal coating. nine0004

Advantages and limitations of SLS

Summarizing the above, the key advantages and disadvantages of the technology are given below:

- SLS parts have good, isotropic mechanical properties, making them ideal for functional parts and prototypes.

- SLS does not require support, so parts with complex geometries can be easily printed.

- SLS manufacturing capabilities are excellent for small to medium series production. nine0288

- Only industrial SLS systems are currently widely available, so lead times are longer than other 3D printing technologies such as FDM and SLA.

- SLS parts have a grainy surface and internal porosity that may require post-treatment if a smooth surface or water resistance is required.

- SLS cannot accurately print large flat surfaces and small holes as they are prone to warping and warping.

nine0288

nine0288

The main characteristics of SLS technology are shown in the table below:

And that's all we have! We hope the article was useful to you.

You can purchase SLS 3d printers, consumables for them, as well as any other 3d printers and CNC machines, by contacting us:

• By email: [email protected]

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

YOU-SLS Personal 3D Printer: Quality 3D printing at home

11/13/2017

Selective laser sintering (SLS) is one of the fundamental 3D printing technologies based on step-by-step sintering of layers of powder material by high power lasers. nine0348

Due to the high quality of SLS 3D printing, it has been popular in the market for several decades.

By the way, this technology was developed back in the mid-80s of the last century by Carl Deckard and Joseph Beeman from the University of Texas at Austin. It was from this moment that the development of additive technologies in industry began.

By the way, this technology was developed back in the mid-80s of the last century by Carl Deckard and Joseph Beeman from the University of Texas at Austin. It was from this moment that the development of additive technologies in industry began. SLS-technology is successfully used in enterprises of various industries, such as:

- automotive and aerospace industry;

- instrumentation;

- medicine;

- art and architecture.

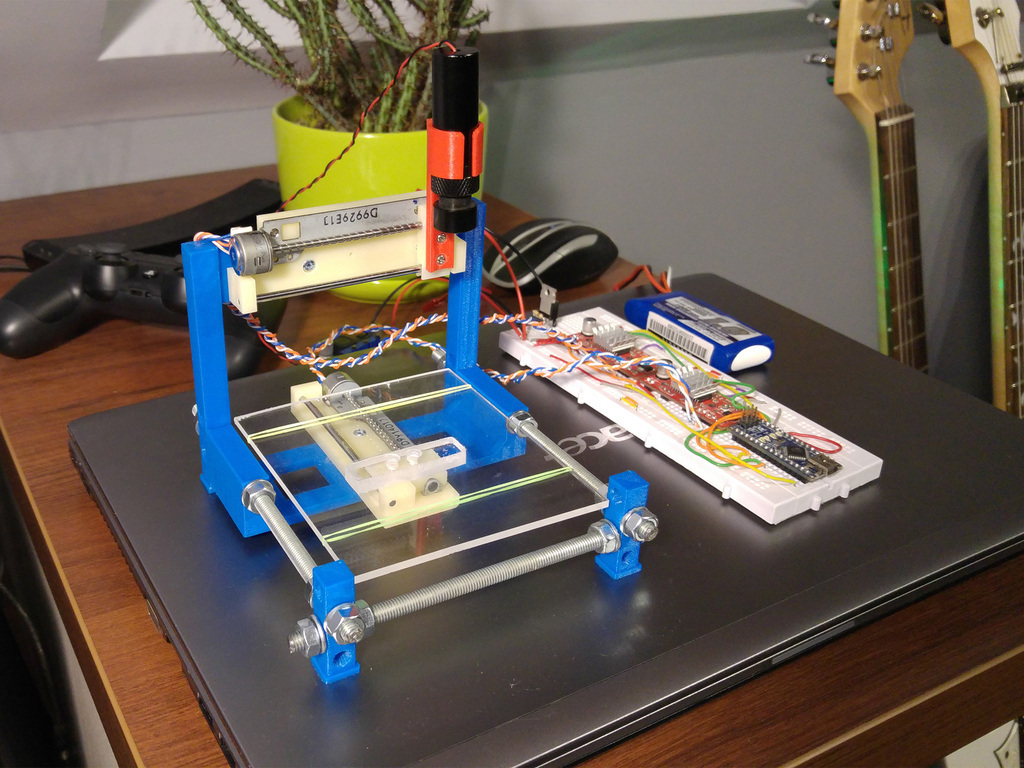

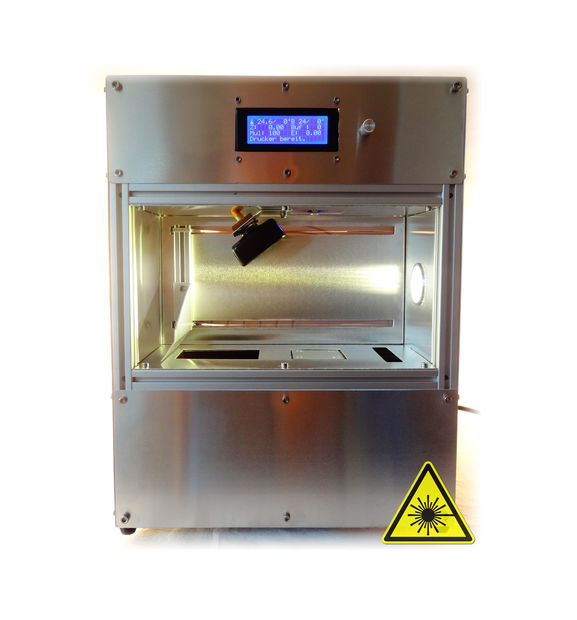

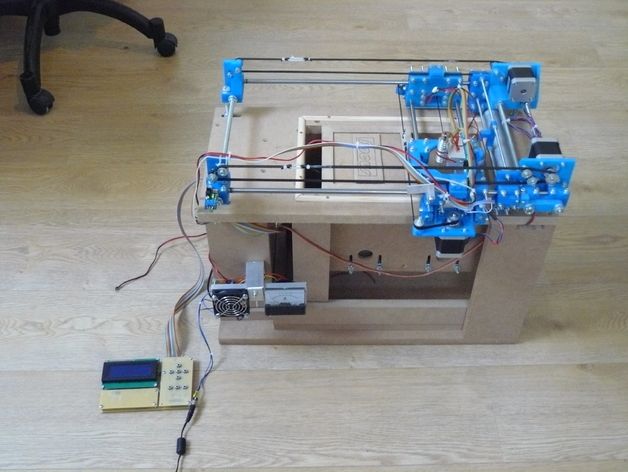

The YOU-SLS 3D printer from the American company InDemand belongs to the category of personal 3D printing devices. Therefore, it is an excellent option for private use at home.

Technical data

| Technology | SLS |

| Working chamber, mm | 130 x 130 x 130 |

| Dimensions, mm | 500 x 500 x 300 |

| Country of origin | USA |

| Supported Consumables | nine0400

How the YOU-SLS 3D printer works

- The UV source has a power of 2 W and operates at a wavelength of 445 nm.

- A diode laser is used for sintering, which can be replaced with a similar two-watt laser.

- The hardware camera of the 3D printer operates on its own heating system.

- Lasers only need 10°C to reach their melting point. nine0288

- Finished product dimensions can be 200 x 150 x 100 mm.

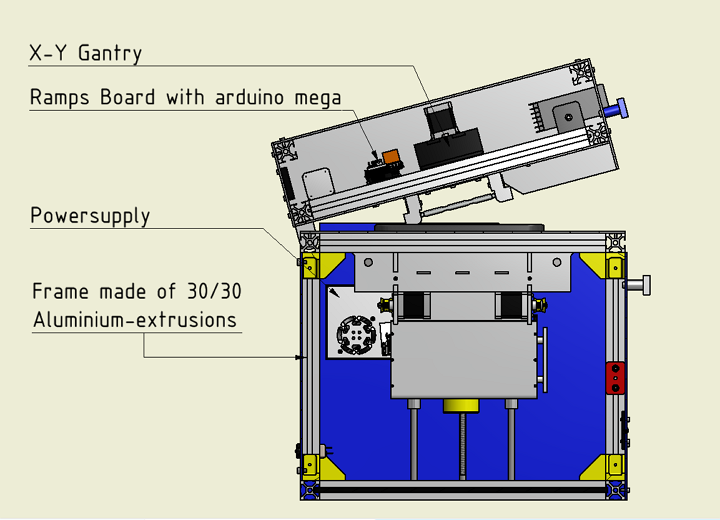

- The device works on a RAMPS board and a regular Arduino Mega.

Advantages of

- Due to its rectangular shape, the printer can print longer parts diagonally without using too much consumable to fill the layer.

- The presence of a three-way heating system allows you to control the temperature, which should be below the melting temperature of the material. The same system eliminates another problem - it does not allow deformation of the product during printing. nine0288

- The "hot" and "cold" zones of the printer are located in separate sectors, fixed one on top of the other. Therefore, high temperatures do not create any obstacle for the effective functioning of the laser and electronic filling.

Learn more