3D printing color changing filament

Color Changing PLA Filament Color Changes if Looking from Different Angles

Christmas Sale: Up to 60% off !

-

Day

- :

-

Hrs

- :

-

Min

- :

-

Sec

Flashforge Christmas Sale: Up to 60% off! Get an extra Christmas gift when order US$200+.

loading

Share the product to

Worry-free warranty

Dedicated support

Fast shipping.Free shipping for items available at USA/UK/AU/EU warehouses.

- Overview

- Parameter

- In the Box

Flashforge color changing filament is made of a reinforced and toughened modified material. A color toner is added in it during production this is the reason why this PLA filament presents different colors if looking it at different angles. Think how cool it would be when the color change effects taking on your 3D printed models!

Think how cool it would be when the color change effects taking on your 3D printed models!

Flashforge color changing PLA filament features:

- This filament feeds and extrudes smoothly and constantly, with good finish texture and stably performing well until the end of using.

- Compatible with most types of FDM 3D printers.

- Flashforge color changing PLA filament diameter: 1.75mm.

- Recommended printing temperature:190~220℃.

- Platform heating temperature:Room temperature~60℃ (40℃ is recommended).

Warm tips:

1. To keep a good printing effect, please ensure this color changing 3D printer filament be stored in dry and cool environment. Moist air and long-time sunlight exposure is bad for the filament.

2. Please use up the filament as soon as possible after unsealing it. The leftover color changing PLA filament should be sealed well.

PLA Multicolor

Color Changing

Filament

Color change effects if looking at different angles!

Burnt Titanium

The 3D model changes gray blue, gray green or gray purple if looking at different angles.

Amazing indoor decorations and outdoor supplies

For Flashforge PLA Multicolor Filament spec, please refer to this page.

Your questions will be answered by the users who have purchased this product

May not be greater than 255 characters.

Read All Reviews

FAQ

No questions.

Colour Change 3D Print PLA Filaments

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

Filters:

- Special

-

3DJAKE magicPLA Metallic Emerald 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Deep Space 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Parrot 4 Model types- Shimmering colours

- ecoPLA basis

- Made in EU

-

3DJAKE magicPLA Frozen Gold 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Juicy Peach 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Sunset Sky 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Watermelon 4 Model types- Shimmering colours

- ecoPLA basis

- Made in EU

-

3DJAKE magicPLA Frozen Lavender 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

R3D PLA Colour Change Blue to Pink- High toughness/strength

- Colour changing effect

- Versatile in use

-

Spectrum PLA Special Thermoactive Red 2 Model types- Colour-changing

- Easy to print

- High-quality

-

R3D PLA UV Colour Change Yellow to Green- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change White to Sky Blue- Changes colour under sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change Pink to Purple- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change White to Peach Red- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA Colour Change Purple to Red- High toughness/strength

- Colour changing effect

- Versatile in use

All prices incl. VAT.

VAT.

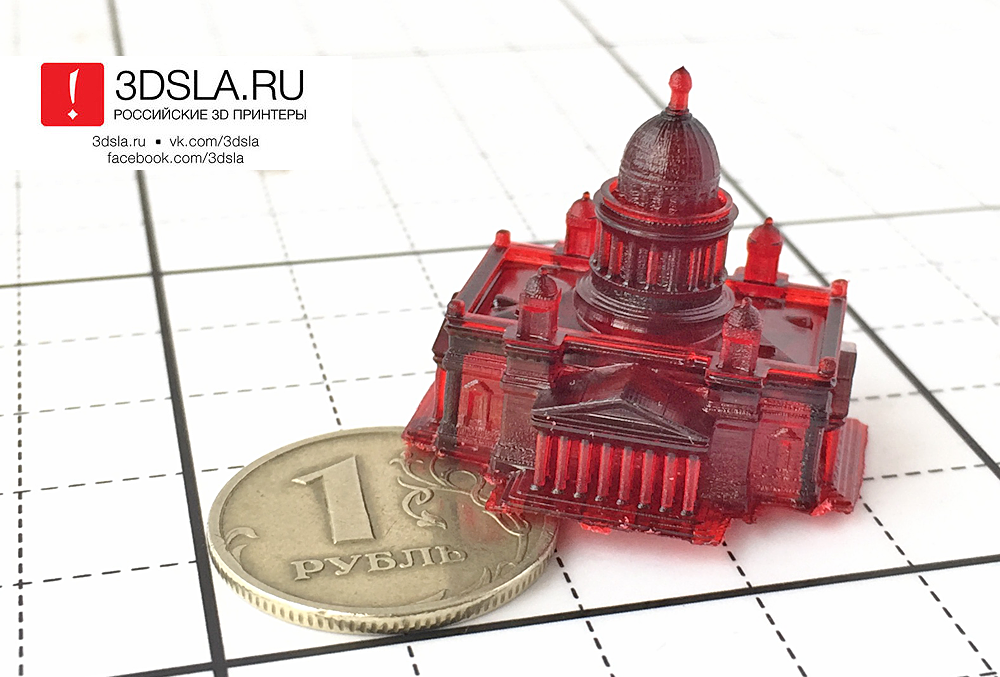

3D printer prints multi-colored filament from different materials

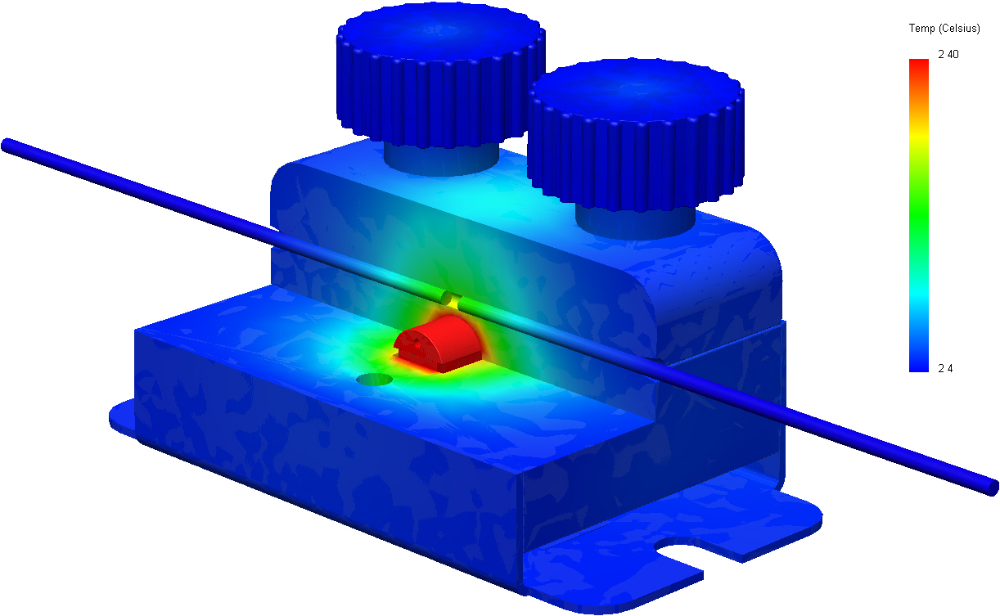

Engineers have introduced a new technique for printing colored plastic objects on a simple 3D printer with a single nozzle without the use of additional tools. To do this, it is necessary to print a thread consisting of colored segments in the right places in several steps, and then you can use this filament for conventional printing by layer-by-layer deposition. In addition to color, the method also allows you to create a thread from different materials. Article published at ACM Digital Library .

The most common and affordable 3D printing method is Fused Deposition Modeling (FDM). FDM printers have one (sometimes more) extruder that supplies filament to the substrate, and to print multi-colored objects, you either need to change the filament spool manually, stopping the printing process, or print on a printer with several extruders, or use additional devices to thread several threads at once. Printing with two extruders increases the chance of shearing, welding and other defects, and these defects are also difficult to avoid when manually changing the filament. In addition, manual replacement may be required several times during the printing process, which can greatly increase the time spent and increase the likelihood of printing defects. Accessories, on the other hand, need to be bought separately, and they often require certain skills and training, complicate and increase the cost of printing. There are also multi-color threads and materials that can change their color and properties, but these are not universal solutions that are usually not available to the average user. nine0007 Haruki Takahashi of Meiji University and colleagues have come up with a low-cost method for printing filaments of different colors and even materials on a printer with only one extruder. The method involves the creation of a programmable thread for each individual project using a 3D printer, which is then fed into the 3D printer as a regular filament.

Printing with two extruders increases the chance of shearing, welding and other defects, and these defects are also difficult to avoid when manually changing the filament. In addition, manual replacement may be required several times during the printing process, which can greatly increase the time spent and increase the likelihood of printing defects. Accessories, on the other hand, need to be bought separately, and they often require certain skills and training, complicate and increase the cost of printing. There are also multi-color threads and materials that can change their color and properties, but these are not universal solutions that are usually not available to the average user. nine0007 Haruki Takahashi of Meiji University and colleagues have come up with a low-cost method for printing filaments of different colors and even materials on a printer with only one extruder. The method involves the creation of a programmable thread for each individual project using a 3D printer, which is then fed into the 3D printer as a regular filament. The length and number of required segments is generated in G-code format from a 3D model or 2D image using printer software. nine0005

The length and number of required segments is generated in G-code format from a 3D model or 2D image using printer software. nine0005

A program developed by scientists uses this G-code to design a future filament and offers optimal printing options. The printer sequentially prints the filament in the form of a spiral, starting from the edge towards the center. First, all segments of one color are printed, and only then another, which significantly reduces the number of manual filament changes. The ends of the segments are cut diagonally during the printing process to increase the contact area between the segments, and are additionally fused with stitches - additional layers of filament. Fusing the stitch and simultaneously passing a hot nozzle at the point of contact increases the strength of the connection. nine0005

The scientists tested their technique on four different printers using filaments of different colors and different materials: polylactide, thermoplastic polyurethane, acrylonitrile butadiene styrene, polyvinyl acetate, nylon. One of the samples printed with the programmable filament consisted of five colors, which is difficult to achieve using even multi-extrusion machines. In addition, the engineers printed a mock-up of a watch that combines a solid base and a flexible strap, proving the possibility of using dissimilar materials in their technique. nine0005

One of the samples printed with the programmable filament consisted of five colors, which is difficult to achieve using even multi-extrusion machines. In addition, the engineers printed a mock-up of a watch that combines a solid base and a flexible strap, proving the possibility of using dissimilar materials in their technique. nine0005

The researchers plan to refine their method in further studies and study the mechanical behavior of composite structures in more detail, as well as increase the strength of connections between heterogeneous materials. Already at this stage, the filament stitching technique provides good joint strength, reduces the cost and simplifies the printing process.

Recently, we wrote about another way to simplify the post-processing of 3D printed materials - this is the addition of a catalyst to the plastic to facilitate subsequent metallization. nine0005

Roman Kolesov

Found a typo? Select the fragment and press Ctrl+Enter.

Laywood 1.

75 mm: Materials for 3D printers Kai P.

75 mm: Materials for 3D printers Kai P. from Kai P.

Starting price 3 000 ₽

Starting price 3 000 ₽ - starting price 3 000 ₽

Starting price 3 000 ₽

Current price 2 500 ₽

2 500 ₽ - 2 500 ₽

Current price 2 500 ₽

| /

Saving 500 ₽ Saving 500 ₽

In stock

LAYWOOD is a composite of recycled wood (40%) and safe binding polymer. The thermal resistance of the material is similar to PLA.

Polymer properties | |

| Material type | FDM |

| Plastic diameter | 1. 75 mm 75 mm |

| Material | Laywood |

LAYWOOD

The unique blend of natural, recycled wood and resin binder (40:60) has the same thermal and tactile characteristics as PLA. Printing temperature 175 - 250 C. Laywood filament even changes color depending on the chosen printing temperature (175 C lighter, 250 C darker). You can even draw rings in a tree trunk. You can handle printed objects like real wood, even saw and sand and much more! nine0005Recommended products

- Saving 1 000 ₽ Savings 0 ₽

Plastic PETG monofilament for 3D printing with LPD deposition filament, made of ethylene polymers (ethylene terephthal polymer.

..

.. Ultimaker

Starting price 5 500 ₽

Starting price 5 500 ₽ - starting price 5 500 ₽

Starting price 5 500 ₽

Current price 4 500 ₽

4 500 ₽ - 4 500 ₽

Current price 4 500 ₽

nine0103 - Savings 0 ₽ Savings 0 ₽

- Saving 1 600 ₽ Savings 0 ₽ nine0002 Plastic PVA monofilament for fusing 3D printing, from hydrolysis products (vinyl acetate polymer), filament diameter 2.

Learn more