Glowforge 3d laser printer review

Glowforge Pro review: Laser cutting and engraving for serious hobbyists and makers

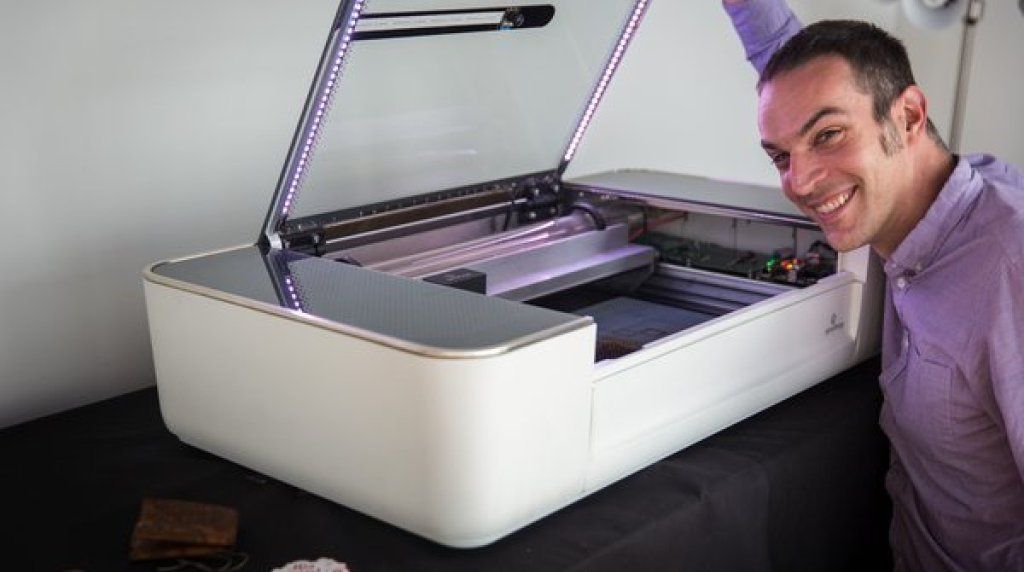

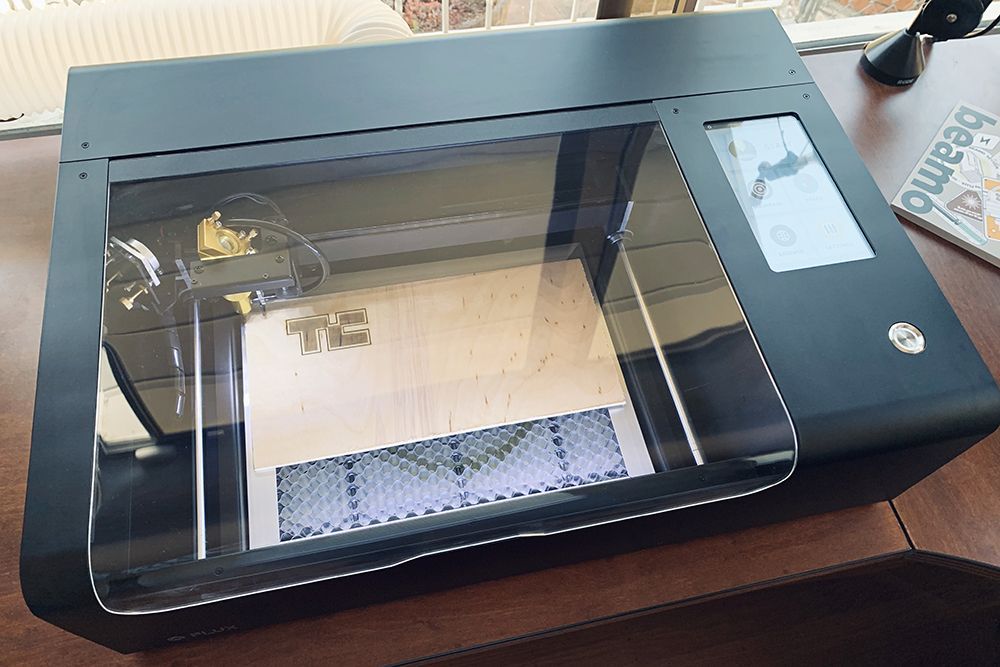

The Glowforge Pro looks like a bulky large-format conventional printer, but rather than depositing ink on paper this 25kg (55lbs) device engraves and cuts a variety of materials.

Image: Charles McLellan / ZDNet3D printing, and its industrial counterpart additive manufacturing, is widely covered on ZDNet and in the media generally. Prices range from a few hundred dollars to seven-figure sums, with materials including various kinds of plastic, resins, metals and even concrete.

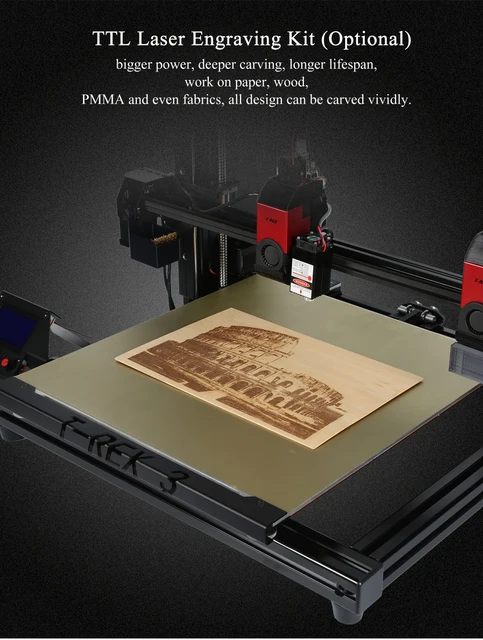

Another kind of device, which also spans the range from hobbyist to industrial applications, is the CNC laser cutter/engraver, which can etch designs into a variety of materials, including plastic, leather, wood, metal and glass, and also cut out shapes from some of them, which you can then assemble into 3D objects. That's why Glowforge calls its device a '3D laser printer'.

Founded in 2014, Glowforge raised a record $27. 9 million for a 30-day crowdfunding campaign in October of the following year, and launched its finalised product range in April 2018. There are three models, with different combinations of laser power, performance and maximum 'print' size. Glowforge Basic costs $2,995, while the Plus model costs $3,995 and the Pro version costs $5,995. The company recently announced the availability of its product line in the UK (prices are a direct dollar-to-pound translation) -- hence the presence of the Pro model on the reviews bench (OK, my home office) here at ZDNet UK.

Design

The Glowforge Pro arrives in a bulky and well-protected box measuring 116.8cm by 71.1cm by 35.5cm (46in. x 28in. x 14in.) and weighing 32kg (70lbs). The device inside is 96.5cm wide by 52.7cm deep by 21cm tall (38in. x 20.75in. x 8.25in.) and weighs 25kg (55lbs) -- a definite two-person lift. You'll need a sturdy desk or table with at least 2.5cm (1in.) of clearance around all sides, and considerably more to the front and back if you intend to use the Pro's passthrough slot to accommodate larger materials.

All three models can take materials measuring up to 20.4 inches wide by 18 inches deep by 2 inches thick, with a maximum printable area of around 11in. by 19.5in. The Pro's passthrough slot allows for materials measuring 20 inches wide by a quarter of an inch thick, with no limit on length – you print 10 inches at a time and then slide the material through the slot to process the next section.

The Glowforge comes with an accessory pack that includes the black metal crumb tray, which sits in the bed of the printer to collect any debris, an exhaust hose that clamps over the outlet on the back of the device, and a starter pack of Proofgrade materials. We had a selection of woods and MDF, a couple of pieces of acrylic and some leather. Official Proofgrade materials come with peel-off protective coating on both sides and a QR code from which the Glowforge's built-in camera reads the correct laser settings. If you buy third-party materials, you'll need to check their CO2 laser compatibility, and ascertain the correct settings. The Glowforge Community is helpful with this issue, among numerous others.

The Glowforge Community is helpful with this issue, among numerous others.

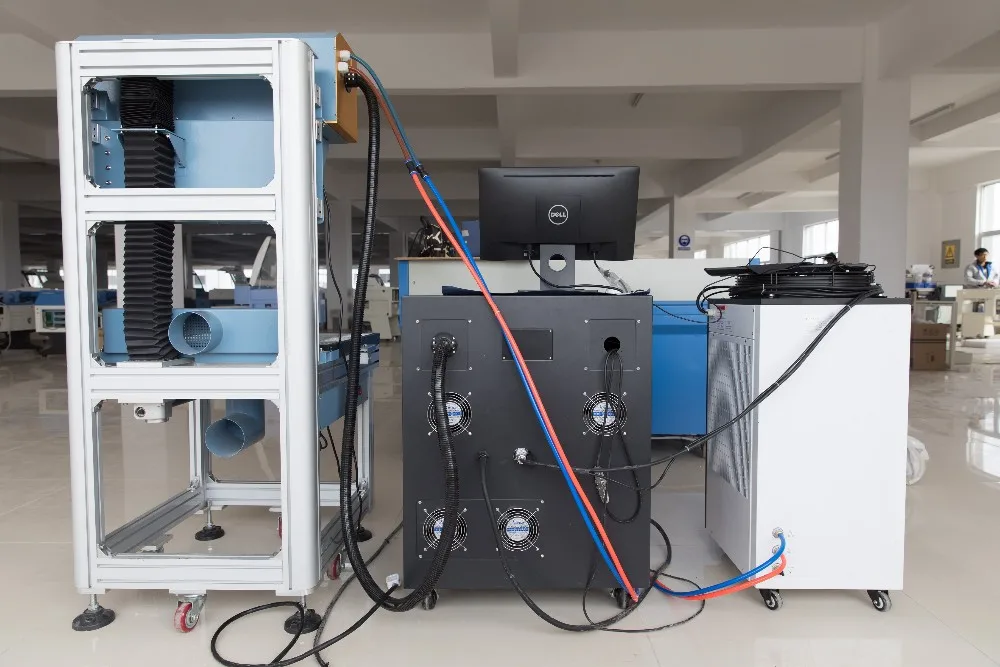

There are two options for disposing of the dust and odour that emerge from the exhaust hose: you can route the hose to the outside through a window or a window vent, or you can attach it to the optional air filter unit. The latter is hefty both in terms of weight (22kg/48lbs) and expense ($995/£901.62), with replacement filter cartridges costing $250 or £187.96. The estimated cartridge lifetime depends on what you print, and for how long.

The Glowforge Pro looks like a big printer with a white moulded plastic case, a glass top and lid (with a camera on its underside), which opens to reveal the rail-mounted laser tube/arm/printer head mechanism, and the crumb tray on the floor of the device. There's a front door that pulls down for easy access to the insides, with passthrough slots front and back for large materials (Pro model only). At the back you'll find the power input, on/off switch and exhaust connection. There's a large circular button on the top, on the right side towards the front, which flashes white to show that the Glowforge is ready to print, which it does when you press the button.

There's a large circular button on the top, on the right side towards the front, which flashes white to show that the Glowforge is ready to print, which it does when you press the button.

Setup & features

Once you've unboxed the Glowforge and put the various elements in place (printer head, crumb tray, exhaust hose) you power it up and wait for the button to glow a teal colour, which signifies that the printer's temporary Wi-Fi access point is ready to connect to your computer (or phone) to complete the setup. You do this via setup.glowforge.com, signing in using the email and password used during the ordering process. Once the printer head has completed its calibration, you can reconnect to your usual Wi-Fi network. Wi-Fi is the only connection method between your computer and the Glowforge: there's no cable involved, and an internet connection is required for print processing.

Projects are prepared for printing in the Glowforge web app, https://app.glowforge. com, which can import bitmap (JPG, PNG) and vector files (SVG, PDF). The app also provides access, via a Glowforge Premium subscription, to a catalogue of free and paid-for designs, and allows you to create your own projects from scratch using a variety of clip-art-style graphics, shapes and text in a range of fonts.

com, which can import bitmap (JPG, PNG) and vector files (SVG, PDF). The app also provides access, via a Glowforge Premium subscription, to a catalogue of free and paid-for designs, and allows you to create your own projects from scratch using a variety of clip-art-style graphics, shapes and text in a range of fonts.

Glowforge Premium is, as the name suggests, not cheap: the full price is $/£50 a month, although it's currently on offer at £349 in the UK when billed every 18 months (£19.39 a month). If you're a confident user of vector graphics software like Inkscape or Adobe Illustrator, you may not need Glowforge Premium. But the tools (especially the auto-outline feature), artwork and fonts are useful, and the discount might well swing the decision for some users. Other Premium benefits include processing of print designs on faster cloud-based servers, unlimited cloud storage for your designs and early access to experimental features.

SEE: CES 2022 preview: Crowds set to return to Las Vegas, but digital element remains

You can also create a print by drawing or writing on paper, placing it in the bed of the device and having the camera in the lid turn it into a digital file, which you can then manipulate in various ways in the web app.

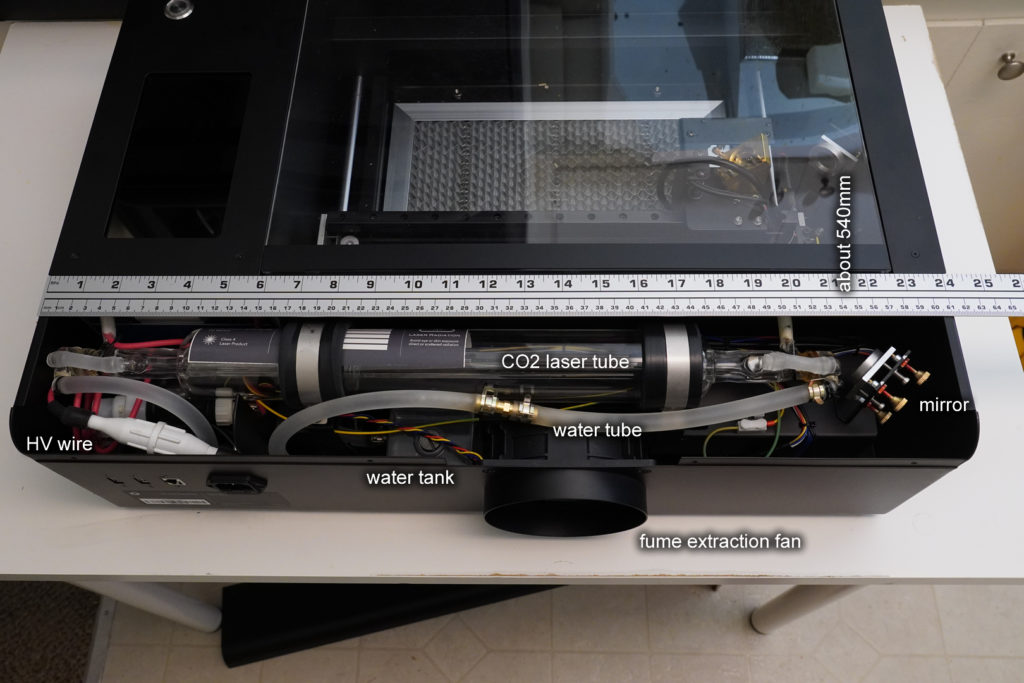

The Glowforge Pro uses a CO2 laser tube operating at 10,600nm and averaging 45W (the Plus and Basic models use less powerful 40W lasers), with the X/Y axis motors allowing the laser to engrave with 1,000dpi resolution. It can score (drawing a line, at low power) and engrave in multiple passes, varying the laser power between pixels to achieve different levels of darkness. The laser can also cut material up to half an inch (1.2cm) thick, at speeds depending on the material and its thickness.

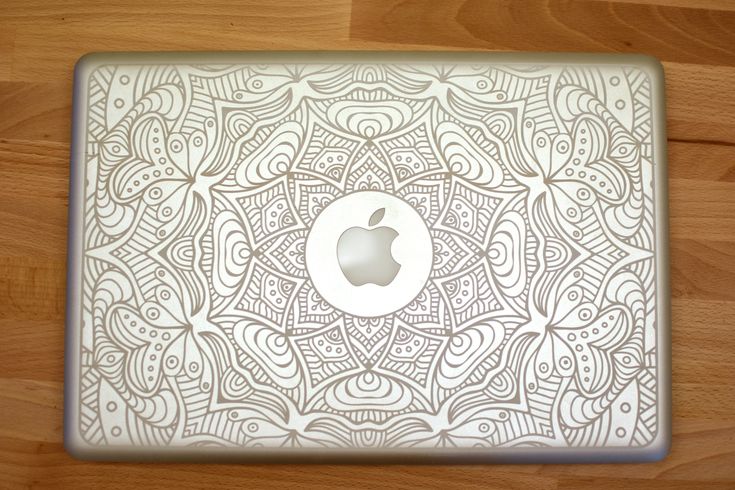

You can't cut metal, as this would require laser power levels beyond those feasible on a desktop device. However, you can cut wood, fabric, leather, paper, acrylic, mylar, rubber, and more. All of these materials can also be engraved, along with glass, coated metal, marble, anodised aluminium and titanium. So you can, if you wish, etch your name or a design onto your phone, tablet or laptop, among other things that aren't more than two inches thick.

Usability & performance

I tested the Glowforge Pro by engraving photos and scans onto a variety of Proofgrade materials. I also created a headphone stand in MDF and etched the ZDNet logo into the back of an iPad.

I also created a headphone stand in MDF and etched the ZDNet logo into the back of an iPad.

A scan of a wood engraving by Thomas Bewick (1753-1828), engraved onto Proofgrade maple plywood, which costs £20.26 in the UK per standard-size (12in. x 20in.) medium-thickness (1/8in.) sheet. Print time was around 40 minutes.

Image: Charles McLellan / ZDNet. Original artwork: Thomas BewickA headphone stand, cut and assembled from Proofgrade draftboard, which costs £8.28 in the UK per standard-size (12in. x 20in.) medium-thickness (1/8in.) sheet. The design was downloaded from the Glowforge Catalog, and print time was around 11 minutes.

Images: Charles McLellan / ZDNetA photo (above left) engraved on Proofgrade clear acrylic at draft resolution and photographed against a window pane (above right). A standard-size (12in. x 20in.) medium-thickness (1/8in.) sheet of Proofgrade clear acrylic costs £16.96 in the UK.

Images: Charles McLellan / ZDNetA logo etched onto the back of an iPad. I found the correct laser settings for this anodised aluminium material on the Glowforge forum. This etching took about 10 minutes.

I found the correct laser settings for this anodised aluminium material on the Glowforge forum. This etching took about 10 minutes.

I had no major issues with any of these projects. The web app interface is straightforward, with good feedback about which stage of the process is underway. Print times will vary depending on the size and detail level of the content, whether it's being engraved or cut, and the output resolution: photos can be Draft or HD; graphics can be Draft, SD or HD, and there's a 3D Engrave option (for certain materials) that engraves with extra depth (you'll need a heightmap image file for this). Removing the protective layer after printing can be fiddly for complex engravings, but it's worth the effort: removing it prior to printing runs the risk of unsightly burn marks.

SEE: The secret to being more creative at work? Why timing could be the key

There's a fair amount of noise when the Glowforge is operating, especially if you use the air filter as there will be two fans whirring away. The amount of noise and residual odour will depend on the content being printed and the material it's being printed on. We tested the Glowforge in a home office in a small terraced house, but its preferred habitat is probably a spacious workshop where family/neighbour-annoyance won't be an issue.

The amount of noise and residual odour will depend on the content being printed and the material it's being printed on. We tested the Glowforge in a home office in a small terraced house, but its preferred habitat is probably a spacious workshop where family/neighbour-annoyance won't be an issue.

Conclusions

The top-end Glowforge Pro setup we tested, with the air filter unit, is by no means cheap at $6,990 or £6,897 all told ($/£5,995 + $995 or £902). Official Proofgrade materials carry premium prices, too, and certain types are currently in short supply in the UK. "Since launching Glowforge in the UK we have had a much higher demand than expected for Proofgrade materials. We are however doing our best to meet this demand and to ensure every UK customer receives their Proofgrade materials," Glowforge told ZDNet.

More affordable third-party materials are available online and in retail outlets, but it's up to you to determine their laser compatibility and apply the correct settings in the web app. Then there's the Glowforge Premium subscription, if you need it, which is currently on offer at £19.39 a month.

Then there's the Glowforge Premium subscription, if you need it, which is currently on offer at £19.39 a month.

If you're prepared to vent the exhaust out of a window rather than use the air filter, drop down to a 40W laser with slower engraving and cutting speeds, and forego enhanced cooling and the passthrough slot, you can reduce the outlay to $/£3,995 for the Plus model -- substantial savings of $2,995 and £2,902 over the Pro+air filter price tag. And if you don't mind even slower engraving speed, and half the warranty period, $/£2,995 for the Basic model looks pretty attractive.

Glowforge model | Pro | Plus | Basic |

CDRH classification | Class 4 | Class 1 | Class 1 |

Laser power | 45W | 40W | 40W |

Warranty | 12 months | 12 months | 6 months |

Upgraded hardware (faster speed) | yes | yes | no |

Engraving speed | 3x | 2x | 1x |

Cut speed | 1. | 1x | 1x |

Enhanced cooling | yes | no | no |

Passthrough slot | yes | no | no |

Price | $5,995 | $3,995 | $2,995 |

I found the Glowforge Pro a rewarding device to use. It's straightforward to set up, engraves and cuts a good range of materials, and use cases are limited more by the user's creative capabilities than any deficiencies of the machine itself.

You'll need to be aware of safety, especially if experimenting with third-party materials, and will have to cope with noise and some odour issues when printing – even if you have the exhaust hose properly set up. You'll also need plenty of room to house this large device, especially if you intend to use the Pro's passthrough slot.

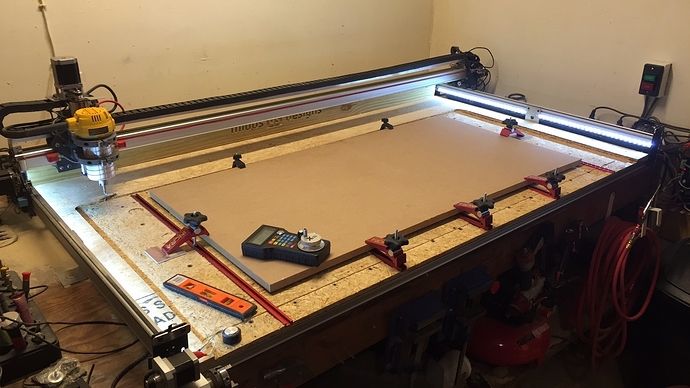

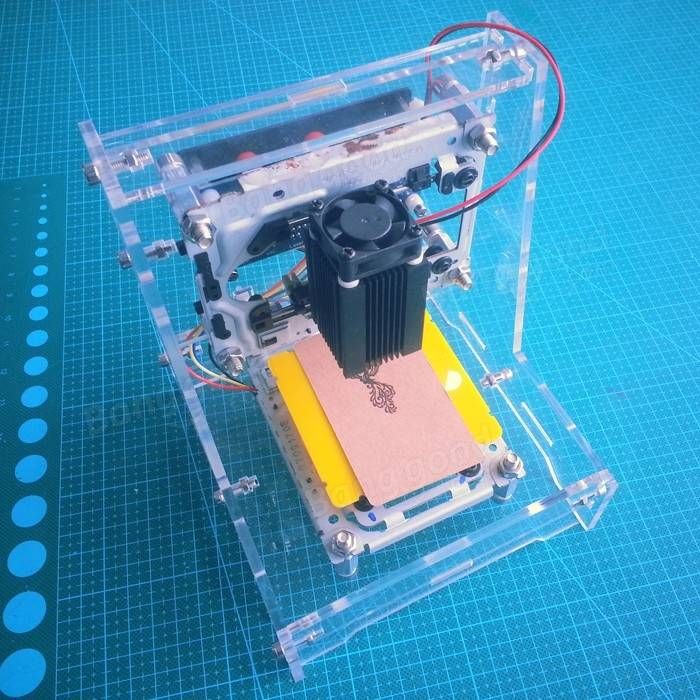

You don't have to spend $3-6,000 on a laser cutter/engraver, as (less capable) products are available for as little as $500, or even less. We're looking here at the mid-range, while above Glowforge's offerings are industrial-level devices that cost considerably more.

The Glowforge Pro is an excellent choice for well-heeled hobbyists and makers, while the Plus and Basic models offer more affordable routes into the world of laser cutting and engraving. Glowforge is not just for hobbyists, either: many users run profitable small businesses selling the projects they create on these versatile machines.

RECENT AND RELATED CONTENT

Desktop Fabrication 2022: Looking forward to a year of fun in the Fab Lab

Desktop Metal Q3 revenue light, aims to scale its 3D printing systems

3D printing vendors poised to benefit long term from supply chain disruptions

3D printing suppliers Ultimaker and Formlabs launch post-processing solutions

Stratasys expands 3D printed anatomical modeling efforts

Read more reviews

- Biqu B1 3D printer: An inexpensive direct-drive FDM printer

- Biqu B1 3D printer review: Less than $300, some helpful features, but not perfect

- Anycubic Vyper: An under $500 filament printer with all the best features

Glowforge Pro laser cutter review

Skip to main contentTechRadar is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

The only laser printer you'll ever need

Editor's Choice

(Image: © Future)

TechRadar Verdict

It's rare to find a machine with such wide appeal, but Glowforge manages to tick almost every box for businesses, education and, of course, crafters. There's little to fault with the ease of use and quality, the only gripes are that you need a good Wi-Fi signal, and the Premium service subscription can be expensive.

TODAY'S BEST DEALS

Pros

- +

Class-leading laser cutting

- +

Wide material support

- +

Incredibly easy to use

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Glowforge is a powerhouse in the laser cutting world and offers a safe, commercially minded machine at an affordable price. There are at present three versions, the Glowforge Basic, Glowforge Plus and the Glowforge Pro that we'll be looking at in this review.

There are at present three versions, the Glowforge Basic, Glowforge Plus and the Glowforge Pro that we'll be looking at in this review.

When I say affordable, I mean compared with the large commercial machines common in businesses and educational facilities, not the compact build it yourself models that cost less than $100/£100.

Glowforge Pro is for those wanting a largescale laser cutter that anyone can use, and it's suitable for keen crafters, small businesses, and educational facilities. It also looks great, like a futuristic oversized printer rather than a large piece of workshop equipment.

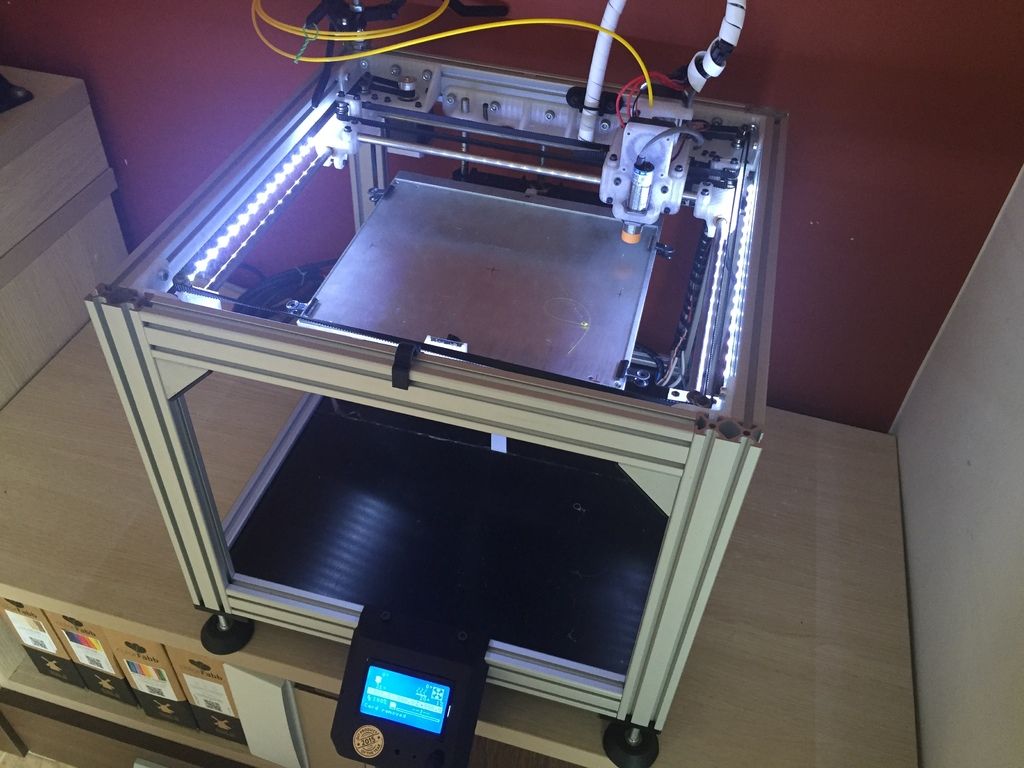

(Image credit: Future)Glowforge Pro looks akin to a standard desktop printer, just far larger. It's a well designed, solid piece of equipment with usability at its heart. Lift the lid, place it in your material, align your design in the browser-based software, and hit the large button on top of the Glowforge to start.

(Image credit: Future)The design of the hardware and software is outwardly simple, with files transferred to the machine through Wi-Fi. This Wi-Fi approach is your only option as there's no USB or other type of direct connection option. When it comes to buttons and ports, there is just the power cord socket, on/off switch and extractor vent on the back, then on top; there's the action button.

This Wi-Fi approach is your only option as there's no USB or other type of direct connection option. When it comes to buttons and ports, there is just the power cord socket, on/off switch and extractor vent on the back, then on top; there's the action button.

The Glowforge Pro arrives with a selection of proof grade materials, these are essentially laser ready. Each features a QR code on top that tells the Glowforge Pro what the material is and automatically sets the laser power options for that material.

(Image credit: Future)A small camera on the lid of the Glowforge Pro scans the print bed and then that scan is shown on the browser software. You can then move your design accurately into position. Glowforge has been designed to make cutting, scoring and engraving incredibly easy and removes all guesswork that you have with other printers.

The camera and its integration is one of the features that make the Glowforge Pro stand out. It enables the machine to read Proofgrade material QR codes, preview the contents of the print bed, and exactly match designs with materials.

You can even scan drawings so they can be traced and used as cutting paths.

The material size for the Glowforge Pro is a little odd at 518mm x 304mm, whereas most materials in the UK are either smaller than this or 600x300mm, so a little chopping is required if not using official Glowforge Proofgrade materials.

(Image credit: Future)All materials sit on the laser bed, which can be removed for cleaning. The Glowforge Pro has a few differences compared to the Basic and Standard; firstly, it features a more powerful laser that enables faster print times. Then there's the pass-through slot that enables longer materials to be passed through the machine.

The Glowforge is large, and while it will sit on a desktop, at 96.5 cm x 52.7 x 20cm, it does mean that it will be the only thing on it. In the workshop, the Glowforge Pro was positioned to accommodate itself, materials and the Air Filter.

(Image credit: Future)While the Glowforge is large, you also need to consider the Air Filter. This is essentially a self-contained extractor unit that enables you to use the laser cutter inside without fixed workshop ventilation. This air filter attaches directly to the back of the Glowforge and makes a huge difference to where you can position and use the machine.

This is essentially a self-contained extractor unit that enables you to use the laser cutter inside without fixed workshop ventilation. This air filter attaches directly to the back of the Glowforge and makes a huge difference to where you can position and use the machine.

Again, this extractor unit is not small, and while it can sit on the floor neatly under the Glowforge, this is again a space consideration. The other consideration is that the Glowforge weighs 32kg, that's a little bit more than your average adult labrador.

Glowforge is a very elegantly designed machine that looks like any consumer printer, just larger. In reality, the Glowforge is a large laser cutter aimed at keen enthusiasts and professionals; its sleek style is a world apart from your standard workshop equipment. Still, there's no doubt once you get started with cutting the Glowforge Pro is a very serious piece of kit.

Features

All three models of the Glowforge, from the basic to Pro, look very similar, and it's only the logo on the lid that identifies each model. On the inside, the technology is also very similar, although it leaps in specification with each model. In the Basic and model, you have a class 1 40W laser, while in the Pro, you have a Class 4 45W laser.

On the inside, the technology is also very similar, although it leaps in specification with each model. In the Basic and model, you have a class 1 40W laser, while in the Pro, you have a Class 4 45W laser.

The custom CO2 laser tube operates at 10,600 nm 45W, and for this reason, unlike the other two models, the Pro does require a little additional training and safety precautions. The Pro model also benefits from upgraded motors that make it 120% faster than the other Glowforge models, which are by no means slow to start with.

(Image credit: Future)Another feature of the Pro model that anyone using the laser cutter professionally will require is enhanced cooling. This means that the Glowforge Pro can be happily used all day without overheating.

(Image credit: Future)There's a huge selection of materials to choose from plastics to woods and leather. Glowforge produces their own, and these are high quality but expensive. You can get materials from elsewhere, but you need to ensure that they are laser ready. Non-laser ply, for instance, uses laminate glue that can be inappropriate for cutting in this way.

Non-laser ply, for instance, uses laminate glue that can be inappropriate for cutting in this way.

However, there's a huge selection of options out there; you will need to cut the material to size as they are non-standard.

(Image credit: Future)Glowforge's materials make full use of the bed are at 30.4 cm x 51.8 cm with a printable size: 27.9 cm x 49.5 cm. The laser can also cut 1.2cm and 2cm materials with the tray removed.

When it comes to getting your designs or those downloaded from elsewhere into the browser software, Glowforge will read; JPG, PNG, SVG, PDF and if you have a subscription to Glowforge Premium, you also get support DXF files.

(Image credit: Future)The big feature of the Glowforge Pro is the pass-through slot, aside from the upgraded components. This in itself is pretty simple; it's a slot in the front and back of the printer that enables larger materials to be fed through.

The width of the materials is limited to 51.8cm and depth 0. 9cm, but the length can be as long as you like.

9cm, but the length can be as long as you like.

Setup

As you unpack the Glowforge you can't fail to notice the large label on the top that prompts you to log in to the Glowforge setup website and follow the instructions to get started.

Spec Sheet

Laser tube: custom CO2 laser tube operating at 10,600 nm, 45W

Laser Class: Class 4

Air Filter: Optional

Material size: 30.4 cm x 51.8 cm

Pass through slot material size: infinity x 51.8 cm x 0.9cm

Material max thickness with tray: 1.2cm

Material max thickness without tray: 5cm

Power: 100-240 VAC, 50/60hz

All-day printing: Yes (Pro prints up to 81°F (27°C))

Power requirements: 800W peak, average 300W

Laser tube warranty: 2 years

Laser tube replacement cost: $499

Dimensions: 96. 5 cm x 52.7 cm x 20 cm

5 cm x 52.7 cm x 20 cm

Weight: 25 kg

Those instructions are clear and easy to follow, and it only takes a short time to connect and get started. I did find that some older Wi-Fi connections with the Mac Pro (Late 2013) that I usually have set up in the workshop failed to connect, although the printer was recognised. The connection was made smoothly on newer machines, and the trial period for Glowforge Premium appears after finishing the connection.

After the initial setup, you can access the print dashboard by signing into the Glowforge website and clicking create.

Unlike other solutions, Glowforge hosts the laser cutting application. While you can design and develop your creations in almost any design application, you need to use their software to print.

When you first purchase the Glowforge, you get a trial of Premium; this gives you access to a huge selection of templates that you can download and print, support for DXF files, faster printing as your prints are handled by high powered servers, household logins, creative tools, community and a host of other features.

The Premium subscription does give you a lot on the community side, and the free designs and increase in print speed are probably worth it if you're using the Glowforge professionally. If you're a hobbyist, then $50 a month is quite a lot, however, Glowforge does offer an 18-month subscription, which brings the price right down.

Once you have everything set with the web interface and the machine is switched on, the small lid-mounted camera gives you a preview of the cutting bed with the material. You can then import your design and lay it over the material in the exact position you want.

(Image credit: Future)Here things get interesting as Glowforge materials feature a QR code that enables the machine to recognise the material and adjust the settings automatically. If you're using third party materials, you can select from a series of options to get the correct settings. Often choosing a Glowforge material and tweaking the settings gets an excellent result.

When choosing a setting, you can choose Engrave, Cut, Score, or Ignore. With each, you select the outline of the path or paths from the file you have imported and then click to assign; it's all straightforward even for the non-tech savvy.

With each, you select the outline of the path or paths from the file you have imported and then click to assign; it's all straightforward even for the non-tech savvy.

Importing a pre-designed file is just one option; when you click the Create button to start the process, you can select; New blank design, Upload from file or Capture from Image.

The New blank design requires you to have the Premium subscription and offers many tools to create your shapes and designs. It also gives you access to a huge selection of pre-designed-designed templates that you can use and customise.

The upload file enables you to import a good variety of files. The different file types enable different levels of adjustment, cutting and engraving options.

For example, load in a JPG, and you have the bitmap options that enable you to adjust the speed and power. This means that you can essentially engrave the design into the material. Using an SVG, DXF or pathed PDF lets, you take full control of how Glowforge works with the file. Take a simple design created in an application such as Adobe Illustrator and export it out as an SVG that file can then be imported into Glowforge software.

Take a simple design created in an application such as Adobe Illustrator and export it out as an SVG that file can then be imported into Glowforge software.

The path or paths from the file will initially be grouped as one object and you can apply the laser settings you want to the group.

However, if the file contains more than one path, you can separate this into multiple different steps that can have different settings applied.

For example; right-click and select ungroup and then Cut and Paste a Path as a New Step, then each Path can then be dealt with separately as a Cut, Score, Engrave or ignore. Once the laser starts, it recognises the differences in power and speed required for each path for that selected material.

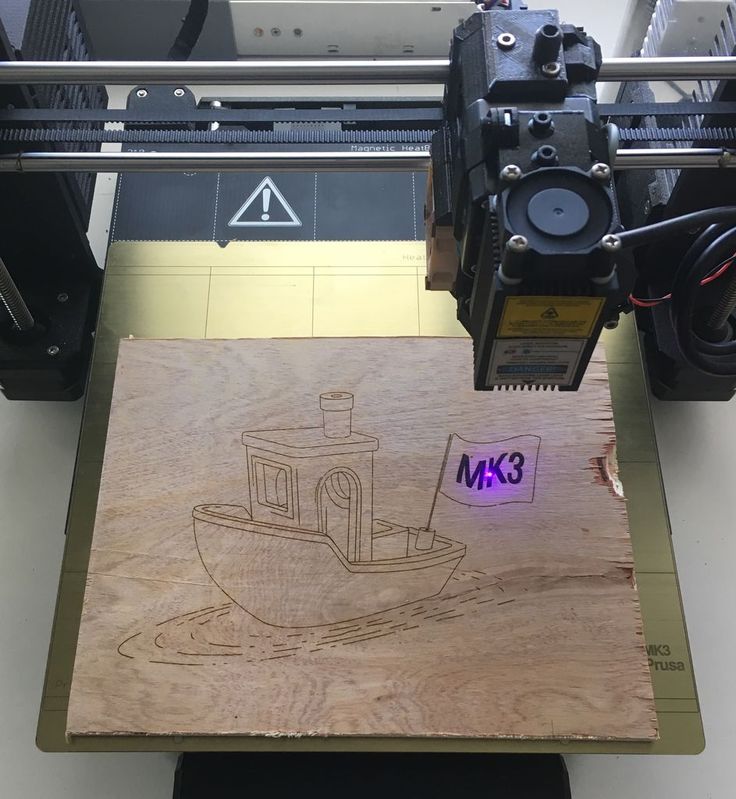

The final option is the Trace feature; this is the most impressive option and enables the non-tech savvy to access this advanced creative technology.

Here, all you need to do is draw on paper the design you want and then pop it into the Glowforge. Once done the software scans the path and then you can assign the cutting paths you want.

Once done the software scans the path and then you can assign the cutting paths you want.

It takes a while to navigate the settings and options of the Glowforge interface and does require a good network connection. That wireless connection is required on two levels. The first is to enable the computer to communicate with the Glowforge and the second is for the browser-based software to connect to the Glowforge server to process the file ready for printing.

(Image credit: Future)Performance

As you start to use Glowforge Pro, you realise just how elegant a solution it is. The web interface enables fast processing of files and gives you plenty of flexibility when cutting, scoring or engraving, depending on the files you're importing.

Loading in one of the pre-designed files and the camera shows you the material with the design overlayed. You can then click and move the design into position. With the proof grade materials supplied, this is easy enough. Still, this ability to drag the design to the exact point makes printing onto almost any material accurately really simple and easy.

Printing with the Glowforge files gets a good result, and running through the Glowforge start-up tasks helps outline what you can do with the machine.

While these starting tasks are good and show you how to customise the designs, it's only when you start experimenting with your content that the machine comes alive.

Loading in a design created in Illustrator and exported in the SVG format, I can ungroup and split each design path into a New Step. Once this process is done, I can assign Cut, Score or Engrave to each path.

When it comes to the materials and the laser power settings, this is sorted automatically if you use the Proof Grade materials. These materials feature that QR code that the machine recognises and automatically applies the correct settings.

However, the cost of these materials is considerably more than generic laser ready materials, so if you go down the cheaper route, then it is possible to select the material type and thickness manually.

Either way, once the laser settings are correct, you can click print on the browser interface, at which point the single large button on the machine starts to flash. A single push of the button starts the printing process and the laser fires up, and the printing begins.

Compared with other laser cutters, the process of getting your design from a software application to materials is fluid and simple. The camera material and design preview takes out all the guesswork and is by far the easiest and most accurate printer that I have used.

It's also incredibly reliable; there are no mistakes, no messing around with laser heights, no focusing, no guesswork it's just excellent.

Working with a RAW file that you have designed shows the machine's full capabilities, and that's fine for those of us who know how to use Illustrator or similar packages that can export files in the formats required.

However, a far more impressive feature is the Trace feature. This enables you to place a drawing under the camera, it's then scanned and traced ready for printing.

If you have the premium subscription, you go in and click each of the traced paths and assign them as Cut, Score, engrave or ignore. If you don't have the subscription, it's a little harder to separate the paths, but there are workarounds.

Likewise, if you create a line drawing in Illustrator and import the paths into Glowforge, you can click to ungroup, then separate the paths into steps. It can be a bit of a time-consuming process, depending on the complexity. Still, it does enable you to get stunning, accurate results with plenty of flexibility over the finish.

A note on materials

Through the test, I started by using the proof grade materials supplied by Glowforge. The quality and thickness accuracy of these is extremely high. However, after a surprisingly short time, I'd burnt through the complete stock of Proofgrade and had to invest in other laser proof materials.

As these don't have the quick recognition QR code, you are required to select the material type and thickness, and then there is a little experimentation when it comes to the correct power settings. After a while, you get the run of things with each new material, run a test, write down the settings, and off you go.

After a while, you get the run of things with each new material, run a test, write down the settings, and off you go.

The results from other manufacturer materials are just as good as those from the proof grade, but a few more steps are involved. Some materials need to be cut to size, but generally, the results are excellent.

Using the Pro version of the machine, I also had access to the pass-through slot. This massively increases the use of the machine as long materials can be fitted through the slot, ready for cutting and engraving.

The process of using the pass-through slot is simple, remove the plates, select the pass-through slot setting in the software and off you go. After each file has been cut, you manually push the material through to the next position, align the design and start the next section of printing, it's simple but highly effective.

Final verdict

In the last couple of years, I've looked at quite a few laser cutters; many have worried me greatly due to the simple open design and build it yourself approach. The Glowforge is at the other end of the spectrum; it's a workshop tool with a refined approach.

The Glowforge is at the other end of the spectrum; it's a workshop tool with a refined approach.

The design of the machine is visually striking and elegant. It is large, so you need to have enough space to ensure it is properly set up, especially with the Air Filter.

The Ait Filter is a little functional by design, and although it adds to the cost, in my opinion, it is essential if you're using the machine in an office or home workshop space.

Due to the size, most home users will think about placing the Glowforge in a garage, which is ideal. However, you do need to be careful about temperature. In my workshop, the temperatures dip below 10º before the frost protection kicks in, and that temperature is too low for the Glowforge to operate, so just something to be mindful of.

Materials are the other consideration. Proofgrade materials are superb, and if I were making a living from laser cutting and printing, I would probably stump up the additional cost for the premium material when needed. However, at £20 plus a sheet, I could ill afford the cost and went to my usual supplier for cheaper materials.

However, at £20 plus a sheet, I could ill afford the cost and went to my usual supplier for cheaper materials.

The other big cost aside from the machine and materials is the subscription to Glowforge Premium. While this supplies you with loads of designs, templates and many very useful advanced features, the cost for home users makes it inaccessible for most. The seven-day trial is also short and fleeting and not enough to get a good feel of what's on offer.

My only other niggle about the Glowforge is that there are no other connection options other than through Wi-Fi.

However, these are, in reality, small points as the Glowforge itself is by far the best laser printer out there for the price. Its stylish design and simple usability make it fully accessible from home to small business and education and for any user level.

Used in an education environment, the Glowforge cuts through sheet after sheet of 3mm ply without issue and puts the laser and its features to the test.

At home, in a rather more sedate setting, the Glowforge Pro acts as the only laser printer you'll ever need and cuts with exceptional quality. The cost may be high for the Glowforge Pro, but even the Glowforge Basic is a phenomenal machine and far outperforms anything else for the price presently available.

We've also highlighted the best 3D printers

Glowforge Pro: Price Comparison

No price information

Check Amazon

powered by

Imaging Lab Manager

Ali Jennings is the imaging lab manager for Future Publishing's Photography portfolio. Using Imatest Master and DxO Analyser he produces the image quality tests for all new cameras and lenses review in TechRadar's cameras channel. Ali has been shooting digital since the early nineties and joined Future's Photography portfolio back in 2003.

TechRadar is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

90,000 GlowForge: laser 3D printer, which was in history ...Technologies By Administor

GlowForge: laser 3D printer, which entered the history of financial training camp from the Krawedfanding Site.

All images courtesy of Glowforge™.

In today's world, technology is developing at a tremendous speed. The 3D printer industry is no exception. Not so long ago, the smallest Tiko 3D printer was introduced for $179. But in this article, we will not talk about a standard 3D printer that creates layers of models from special plastic. Before us is the world's first laser 3D printer, which was called Glowforge. This project has achieved incredible success on the crowdfunding site, raising $27,907,995 in 30 days. Yes, yes, we were not mistaken with the numbers! At the time of writing, Glowforge is the most successful crowdfunding project in history.

This project has achieved incredible success on the crowdfunding site, raising $27,907,995 in 30 days. Yes, yes, we were not mistaken with the numbers! At the time of writing, Glowforge is the most successful crowdfunding project in history.

What's so special about this printer? It's probably not quite right to say "3D printer". Glowforge cuts the desired shape from a thin plate. Wood, leather, cardboard, chocolate and even dried seaweed, which are used in the preparation of rolls, can be used as a material. To cut a shape from any material, no special knowledge is required. You have software for your computer, tablet and even smartphone at your disposal. You can also engrave surfaces with this laser printer. To create a design, it is not necessary to use graphic editors. It is enough to draw all the elements of the desired engraving on paper. Glowforge's onboard cameras will recognize the design and engrave over it, taking into account the contours. Engraving can be done on a wallet, a bag, a wooden decor element, and even on a MacBook. Here you are only limited by your imagination. The Glowforge printer comes with a 3D focus that allows you to cut and engrave curved surfaces. The printer is equipped with a laser that is classified as a Class 1 laser. This means that it is not capable of creating a level of radiation dangerous to the human eye.

Engraving can be done on a wallet, a bag, a wooden decor element, and even on a MacBook. Here you are only limited by your imagination. The Glowforge printer comes with a 3D focus that allows you to cut and engrave curved surfaces. The printer is equipped with a laser that is classified as a Class 1 laser. This means that it is not capable of creating a level of radiation dangerous to the human eye.

If you have no interest in design, and you do not want to understand anything, then you can use the catalog of ready-made models. Buy ready-made models designed by professionals and then print them on your printer. Choose from dozens of design categories such as personal electronics, jewelry, toys, furniture, leather goods, lighting and more.

Specifications: Glowforge has a working area of 50x30 centimeters, the maximum thickness of the material is 38 millimeters, the laser power is 40 watts. You can buy a Glowforce laser 3D printer on the official website of the company at a price of $ 2. 395.

395.

Glowforge Pro laser engraving machine in Moscow

Out of stock

Add to comparison

Item added to comparison Go

533 000 ₽

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When you buy a 3D printer from us,

you get a 10% discount on all consumables.

Glowforge Laser Engraver . Uses a beam of light the width of a hair to cut and engrave various materials. Can work with a wide variety of materials: wood, paper, leather, acrylic, food, fabric, cardboard, glass, cork, sandpaper, ceramic tiles, etc. Materials are automatically recognized by the device. Allows you to create jewelry, toys, architectural models, leather goods, containers, home decoration and much more.

Housing made of high modulus injection molded plastic. Equipped with dual Y-axis hybrid stepping motor and X-axis single hybrid stepping motor. Equipped with automatic focusing system, which can cut and engrave materials of different thickness.

Equipped with automatic focusing system, which can cut and engrave materials of different thickness.

Glowforge is highly accurate. It can control movement to within one thousandth of an inch, and the laser can be focused down to the size of a human hair.

The Glowforge catalog allows you to choose a print-ready design, personalize it or create your own. You can preview your work in real time. Compatible with Mac, iPad, iPhone, Android, Windows or Linux PC.

Glowforge is available in three versions. Pro have increased top speed. Pro Model Wattage: 45W. Maximum material depth for: no limit.

Specifications:

- Auto focus and 3D engraving

- Positioning accuracy: up to 0.025 mm

- Engraving: up to 1355 dpi

- Max. material width: 515 mm

- Cut area: 279mm depth and 495 mm width

- Max. material height: 50 mm

- Operating temperature: 16 -24 °C

- Compatibility: Mac, PC, iPhone, Android, etc.

- Dimensions: 965 x 527 x 210 mm

Layout work

- Drag and drop a layout with live preview to place designs on the media.

- Automatic drawing scanning and printing without design software.

- A catalog of high quality, customizable, print-ready designs.

One button printing

- When used with quality control materials, automatically detects settings for perfect cutting and engraving

Cameras

- Cover-mounted wide-angle camera provides a 0.25" (6 mm) view of the entire printable area

- Macro - head-mounted camera focuses automatically to within 0.004 inches (0.1 mm)

Auto focus

- Exceptional accuracy - low power laser measurement scans the surface of the material to determine the exact height

- Fully internal - lens moves up and down inside the head to print on media up to 0.

5" (13mm) thick

5" (13mm) thick - Multi-pass focus can be shifted between engraving passes, allowing engraving with detailed depth

- Manual focus option - The laser can be focused at a precise height to experiment with a range of techniques.

Laser System

- CO2 Laser - Custom CO2 glass laser tube capable of continuous operation at 10,600 nm; rated power 45 W for the Pro model and 40 W for the Plus and Basic models

- Fixed Alignment - Factory calibrated optical system does not require user alignment

- Sealed Optics - Enclosed optical path with cleanable and replaceable windows protects laser optics to avoid replacement or realignment

Lighting

- Dual high performance indoor LED strips give your work ample illumination for a wide angle view

- Lights under the cover provide spotlights for fine tuning

Mechanisms

- Housing - molded plastic with high modulus of elasticity

- Linear System - Custom Extruded Aluminum Belt Driven Linear Rails on V-Wheel

- Movement - Dual Hybrid Y-Step; one hybrid stepping axis X

- Cooling - closed circuit independent internal cooling.

- Air Assist - internal air assistant without external compressor connection

- Recommended operating temperature: 60F-75F (16C-24C) for Basic and Plus models; 60F-81F (16C-27C) for Pro

Requirements

- Requires Wi-Fi (2.4 GHz b/g/n and WPA2, WPA, WEP or open)

- Ventilate with Glowforge compact filter or open window within 8 feet.

- 110/220 V AC, 50 or 60 Hz output

- Glowforge Basic, Plus and Pro have a peak power consumption of 800 W

- Compact filter has an additional 350 W peak power consumption

Carves and engraves

- wood

- fabric

- leather

- paper

- cardboard

- plexiglass (acrylic)

- delrin (acetal)

- mylar

- rubber

- stopper

- sandpaper

- products

- and more

Only engraves

- glass

- marble

- rubber stamps

- stone

- ceramic tiles

- anodized aluminum

- titanium

- corian

- and more

2x

2x