Ge metal 3d printing

What is Additive Manufacturing | GE Additive

What is additive manufacturing?

Download our playbook "Building the Business Case: Identifying Criteria to Measure ROI for Additive Manufacturing" and learn why developing a business case can help ensure your investment in additive yields a higher return on investment.

DOWNLOAD THE ROI PLAYBOOK

Additive 101

It is yet, another technological advancement made possible by the transition from analog to digital processes. In recent decades, communications, imaging, architecture and engineering have all undergone their own digital revolutions. Now, AM can bring digital flexibility and efficiency to manufacturing operations.

Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. As its name implies, additive manufacturing adds material to create an object. By contrast, when you create an object by traditional means, it is often necessary to remove material through milling, machining, carving, shaping or other means.

Although the terms "3D printing" and "rapid prototyping" are casually used to discuss additive manufacturing, each process is actually a subset of additive manufacturing.

While additive manufacturing seems new to many, it has actually been around for several decades. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries and simplified fabrication. As a result, opportunities abound for those who actively embrace additive manufacturing.

Additive Manufacturing Processes | Additive Manufacturing Materials | A Guide to Metals used in Additive Manufacturing I Additive Manufacturing vs. 3D Printing

explore ge additive machines

How does additive manufacturing work?

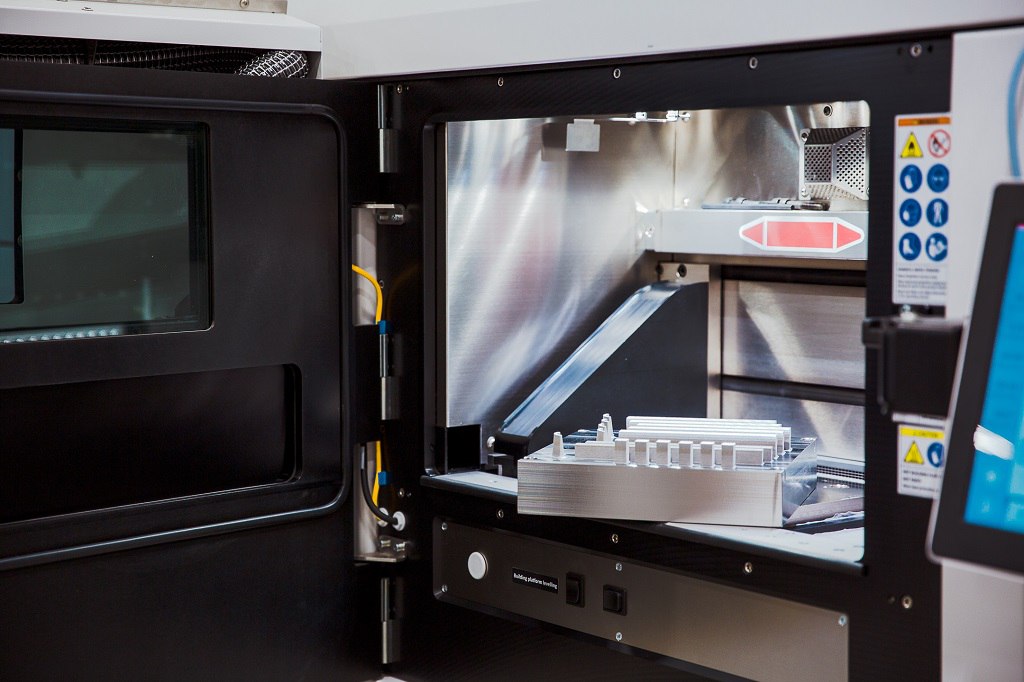

The term “additive manufacturing” references technologies that grow three-dimensional objects one superfine layer at a time. Each successive layer bonds to the preceding layer of melted or partially melted material. Objects are digitally defined by computer-aided-design (CAD) software that is used to create .stl files that essentially "slice" the object into ultra-thin layers. This information guides the path of a nozzle or print head as it precisely deposits material upon the preceding layer. Or, a laser or electron beam selectively melts or partially melts in a bed of powdered material. As materials cool or are cured, they fuse together to form a three-dimensional object.

Objects are digitally defined by computer-aided-design (CAD) software that is used to create .stl files that essentially "slice" the object into ultra-thin layers. This information guides the path of a nozzle or print head as it precisely deposits material upon the preceding layer. Or, a laser or electron beam selectively melts or partially melts in a bed of powdered material. As materials cool or are cured, they fuse together to form a three-dimensional object.

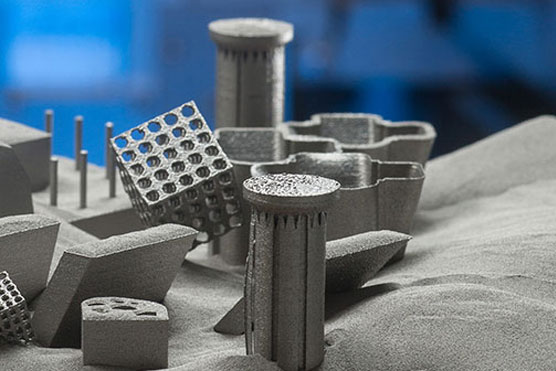

GE Additive specializes in developing Powder Bed Fusion (PBF) machines for the additive manufacturing of metal parts. The three processes GE offers with in the PBF category, recognized by the American Society for Testing and Materials (ASTM), include: Direct Metal Laser Melting (DMLM), Electron Beam Melting (EBM), Binder Jetting.

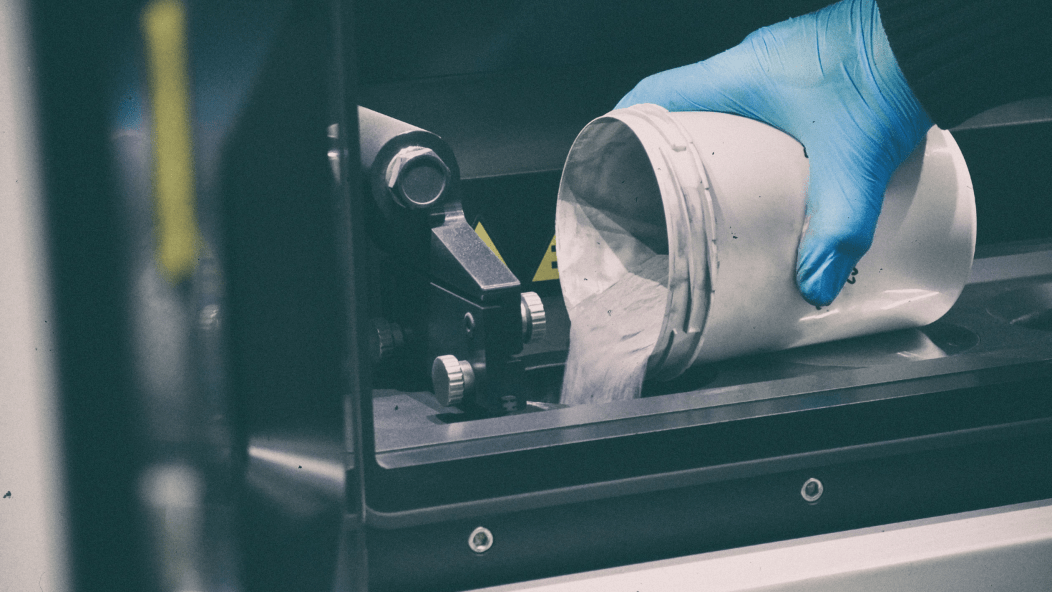

In all of GE Additive’s machines the process involve the spreading of the metal powder layer by layer and uses either a laser or electron beam to melt and fuse powder together to create a part. The process repeats until the entire part is created. Loose or unfused powder is removed during post processing and is recycled for the next build.

The process repeats until the entire part is created. Loose or unfused powder is removed during post processing and is recycled for the next build.

watch video

Powder bed fusion

Powder Bed Fusion (PBF) technology is used in a variety of AM processes, including direct metal laser sintering (DMLS), selective laser sintering (SLS), selective heat sintering (SHS), electron beam melting (EBM) and direct metal laser melting (DMLM). These systems use lasers, electron beams or thermal print heads to melt or partially melt ultra-fine layers of material in a three-dimensional space. As the process concludes, excess powder is blasted away from the object.

binder jetting

Binder Jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of powder particles — either metal, sand, ceramics or composites — to build high-value and one-of-a-kind parts and tooling. The process is repeated layer by layer, using a map from a digital design file, until the object is complete.

The process is repeated layer by layer, using a map from a digital design file, until the object is complete.

Direct energy deposition

The process of directed energy deposition (DED) is similar to material extrusion, although it can be used with a wider variety of materials, including polymers, ceramics and metals. An electron beam gun or laser mounted on a four- or five-axis arm melts either wire or filament feedstock or powder.

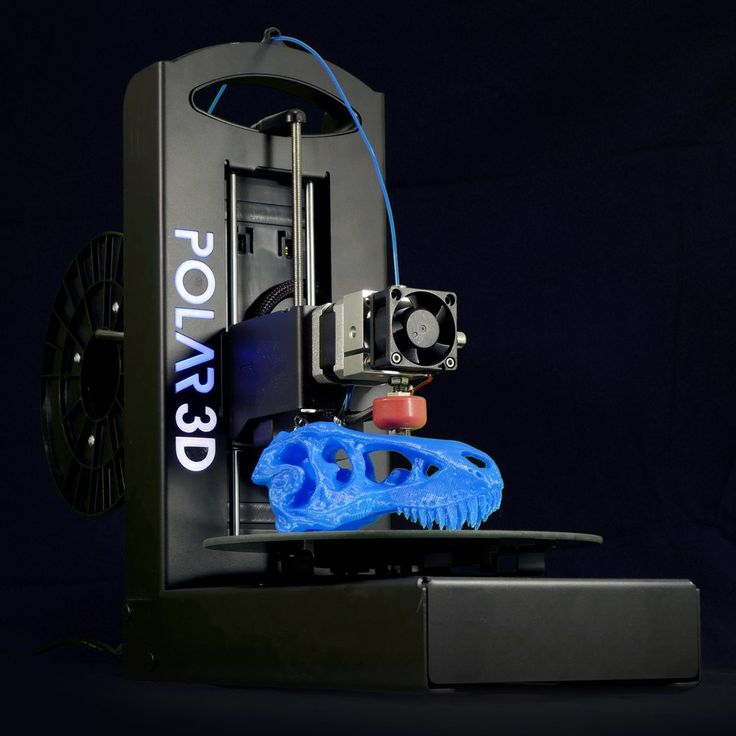

material extrusion

Material extrusion is one of the most well-known additive manufacturing processes. Spooled polymers are extruded, or drawn through a heated nozzle mounted on a movable arm. The nozzle moves horizontally while the bed moves vertically, allowing the melted material to be built layer after layer. Proper adhesion between layers occurs through precise temperature control or the use of chemical bonding agents.

material jetting

With material jetting, a print head moves back and forth, much like the head on a 2D inkjet printer. However, it typically moves on x-, y- and z-axes to create 3D objects. Layers harden as they cool or are cured by ultraviolet light.

However, it typically moves on x-, y- and z-axes to create 3D objects. Layers harden as they cool or are cured by ultraviolet light.

sheet lamination

Laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM) are two sheet lamination methods. LOM uses alternate layers of paper and adhesive, while UAM employs thin metal sheets conjoined through ultrasonic welding. LOM excels at creating objects ideal for visual or aesthetic modeling. UAM is a relatively low-temperature, low-energy process used with various metals, including titanium, stainless steel and aluminum.

vat polymerization

With vat photopolymerization, an object is created in a vat of a liquid resin photopolymer. A process called photopolymerization cures each microfine resin layer using ultraviolet (UV) light precisely directed by mirrors.

aerospace

Lighter parts

AM excels at producing parts with weight-saving, complex geometric designs.

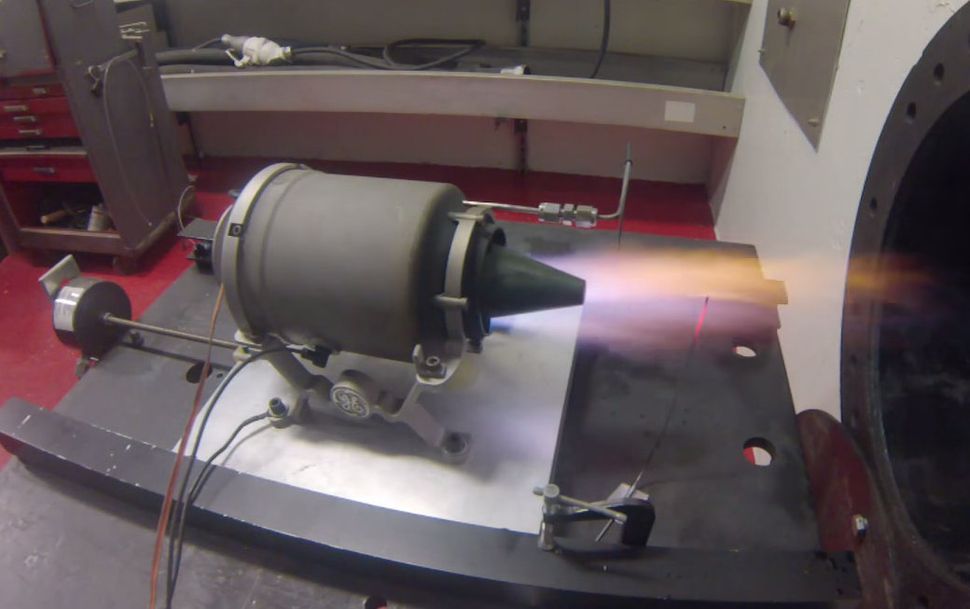

In August 2013, NASA successfully tested a SLM-printed rocket injector during a hot fire test that generated 20,000 pounds of thrust. In 2015, the FAA cleared the first 3D-printed part for use in a commercial jet engine. During the 2017 Paris Air Show, FAA-certified, Boeing 787 structural parts fabricated from titanium wire were displayed, according to Aviation Week.

automotive

Rapid prototyping

In the auto industry, AM's rapid prototyping potential garners serious interest as production parts are appearing. For example, aluminum alloys are used to produce exhaust pipes and pump parts.

CNN reported the McLaren racing team is using 3D-printed parts in its Formula 1 race cars. A rear wing replacement took about 10 days to produce instead of five weeks. The team has already produced more than 50 different parts using AM.

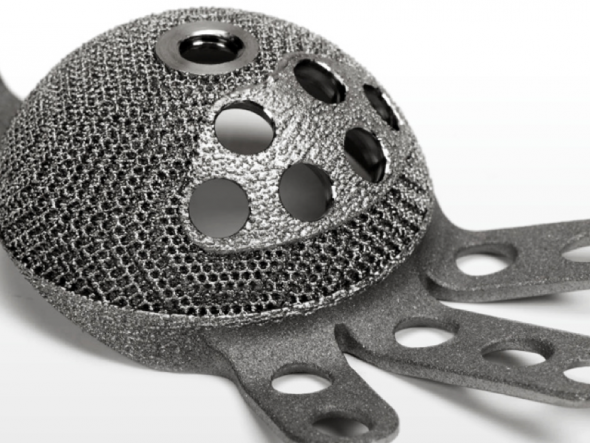

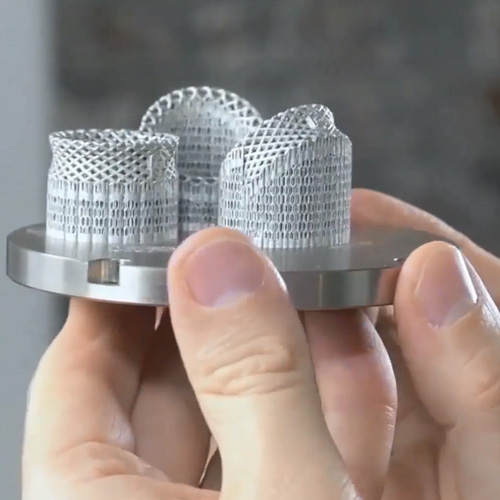

medical

Patient specific

Medical and orthopedic applications for AM are expanding, particularly as the safety and efficacy of AM-built medical devices are established.

Medical device manufacturing company Stryker are funding a research project in Australia that will use additive manufacturing technology to create custom, on-demand 3D printed surgical implants for patients suffering from bone cancer.

Industrial manufacturing

Product development

As the potential for AM's design flexibility is realized, once impossible design concepts are now being successfully re-imagined. Additive manufacturing unleashes the creative potential of designers who can now operate free of the constraints under which they once labored.

DMLM & EBM

By contrast, materials are fully melted in the Direct Metal Laser Melting (DMLM) and Electron Beam Melting (EBM) processes. With DMLM, a laser completely melts each layer of metal powder while EBM uses high-power electron beams to melt the metal powder. Both technologies are ideal for manufacturing dense, non-porous objects.

BINDER JET

In Binder Jetting, a liquid binding agent is selectively deposited onto a thin layer of powder particles - either metal, sand, ceramics, or composites - to create high-value and one-of-a-kind parts and tools. Layers are applied using a map from a digital design file, until the object is complete.

Layers are applied using a map from a digital design file, until the object is complete.

sintering

Sintering is the process of creating a solid mass using heat without liquefying it. Sintering is similar to traditional 2D photocopying, where toner is selectively melted to form an image on paper.

laser sintering

Within Direct Metal Laser Sintering (DMLS), a laser sinters each layer of metal powder so that the metal particles adhere to one another. DMLS machines produce high-resolution objects with desirable surface features and required mechanical properties. With SLS, a laser sinters thermoplastic powders to cause particles to adhere to one another.

stereolithography

Stereolithography (SLA) uses photopolymerization to print ceramic objects. The process employs a UV laser selectively fired into a vat of photopolymer resin. The UV-curable resins produce torque-resistant parts that can withstand extreme temperatures.

metals

Many different metals and metal alloys are used in additive manufacturing, from precious metals like gold and silver to strategic metals like stainless steel and titanium.

ceramics

A variety of ceramics have also been used in additive manufacturing, including zirconia, alumina and tricalcium phosphate. Also, alternate layers of powdered glass and adhesive are baked together to create entirely new classes of glass products.

THERMOPLASTICS

Thermoplastic polymers remain the most popular class of additive manufacturing materials. Acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC) each offer distinct advantages in different applications. Water-soluble polyvinyl alcohol (PVA) is typically used to create temporary support structures, which are later dissolved away.

biochemicals

Biochemical healthcare applications include the use of hardened material from silicon, calcium phosphate and zinc to support bone structures as new bone growth occurs. Researchers are also exploring the use of bio-inks fabricated from stem cells to form everything from blood vessels to bladders and beyond.

Researchers are also exploring the use of bio-inks fabricated from stem cells to form everything from blood vessels to bladders and beyond.

AM advantages

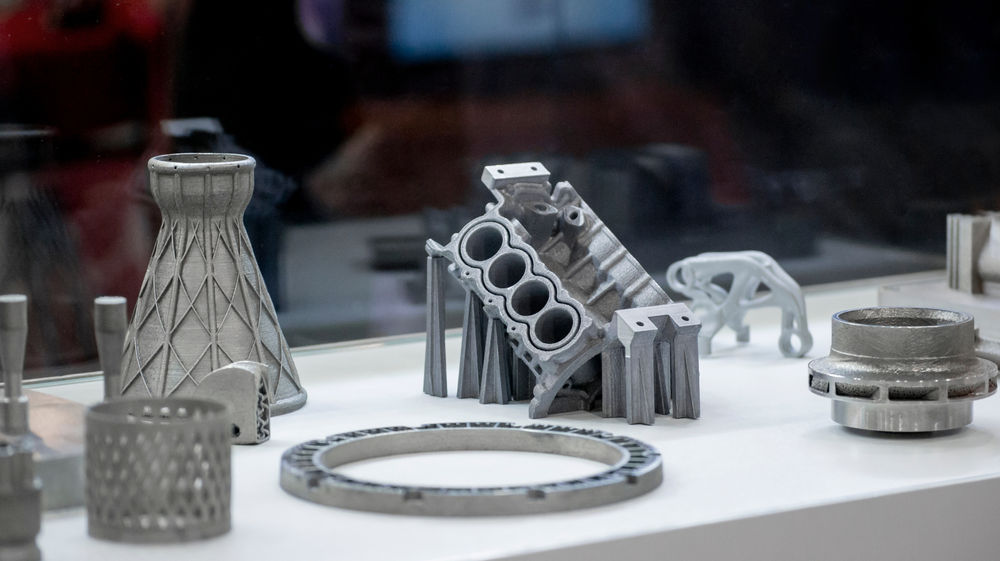

COMPLEX GEOMETRIES

The technology enables engineers to design parts that incorporate complexity that is not possible using other methods. Intricate features, such as conformal cooling passages, can be incorporated directly into a design. Parts that previously required assembly and welding or brazing of multiple pieces can now be grown as a single part, which makes for greater strength and durability. Designers are no longer restricted to the limitations of traditional machines and can create parts with greater design freedom.

TIME SAVINGS

Additive manufacturing is ideal for getting prototypes made quickly. Parts are manufactured directly from a 3D CAD file, which eliminates the cost and lengthy process of having fixtures or dies created. Plus, changes can be made mid-stream with virtually no interruption in the process.

WEIGHT SAVINGS

By incorporating organic structures into designs, designers can eliminate substantial weight while maintaining the part’s strength and integrity. An illustration of this advantage can be seen in a GrabCAD® Bracket Challenge conducted by GE. An existing bracket was redesigned for additive manufacturing, with the winning entry maintaining strength of the original while reducing the weight by 84%.

Ready to fast track your path to production?

Talk to an expert

Tomas Kellner

19 September 2019

About GE Additive | GE Additive

For the Ready

GE Additive – part of GE (NYSE: GE) – is a world leader in metal additive design and manufacturing, a pioneering process that has the power and potential to transform businesses. Through our integrated offering of additive experts, advanced machines, software and quality powders, we empower our customers to build innovative new products. Products that solve manufacturing challenges, improve business outcomes and help change the world for the better. GE Additive includes additive machine brands Concept Laser and Arcam EBM, along with additive powder supplier AP&C.

GE Additive includes additive machine brands Concept Laser and Arcam EBM, along with additive powder supplier AP&C.

WATCH VIDEO

Arcam EBM

Arcam History

Arcam EBM joined GE Additive in 2017 to further strengthen the additive offering with the unique Electron Beam Melting (EBM) technology, which is ideal for volume production of metal components. Arcam AB was founded in 1997 and delivered the first EBM system in 2003. Today, more than 300 systems are installed worldwide.

EBM Machines

Arcam EBM machines are ideally suited for producing dimensionally accurate parts that need to be created quickly and efficiently. Working in a vacuum using a high-power electron beam for high melting capacity and productivity, the EBM process delivers stress-relieved components with better material properties than casting.

explore our ebm machines

Concept Laser

Concept Laser History

Concept Laser was founded in 2000 and quickly became one of the world’s leading providers of machine and plant technology for 3D printing of metal parts. In December of 2016, Concept Laser joined GE Additive, adding a wide range of DMLM machine sizes to GE’s areas of additive expertise.

DMLM Machines

To create components with complex geometries requiring exceptional precision, Direct Metal Laser Melting (DMLM) is the ideal approach. Our DMLM machines use lasers to melt layers of fine metal powder and create complex geometries with incredible precision directly from a CAD file. Several different machine envelope sizes — including one of the largest powder-bed metal additive systems in the world — are available to meet the needs of any industry.

explore our DMLM machines

AP&C

a GE Additive company

AP&C has 10+ years of experience working with major biomedical and aerospace OEMs. AP&C is the only company able to supply the highest-quality AM powder at competitive prices.

AP&C is the only company able to supply the highest-quality AM powder at competitive prices.

AP&C’s mission is to enable the production of high-quality parts made from titanium and other high-melting-point alloys in additive manufacturing and powder metallurgy processes. AP&C continuously invests in R&D to optimize the proprietary Advanced Plasma Atomization (APA) process to provide superior quality products at competitive prices.

Learn more about AP&C

AddWorks™

We understand first-hand how this technology can help transform businesses by improving products and manufacturing operations. Furthermore, we know what it takes to implement this change in your organization.

Incorporating additive manufacturing into your production process is a journey. Wherever you are in that process, GE Additive’s AddWorks consultants can guide you. Comprised of designers, engineers and material scientists, our team of experts has developed assessments and best practices to identify the most effective way for additive technology to support your business.

Learn more about addworks

GE Global Research

GE Research is developing technologies to make metal additive manufacturing faster, more reliable and more pervasive in manufacturing. Developing faster and bigger machines, algorithms that enable perfection on the first build, rapid development and characterization of materials, and security technology that ensures a chain of digital trust from design to manufacture. GE Research is tackling the most critical challenges in additive manufacturing.

Learn more

We'll get to know your needs and priorities to help determine the machines and materials that can accelerate innovation in your business.

Tomas Kellner

19 September 2019

General Electric 3D printing for valve production

Share on Facebook Share on Twitter Share on Vkontakte

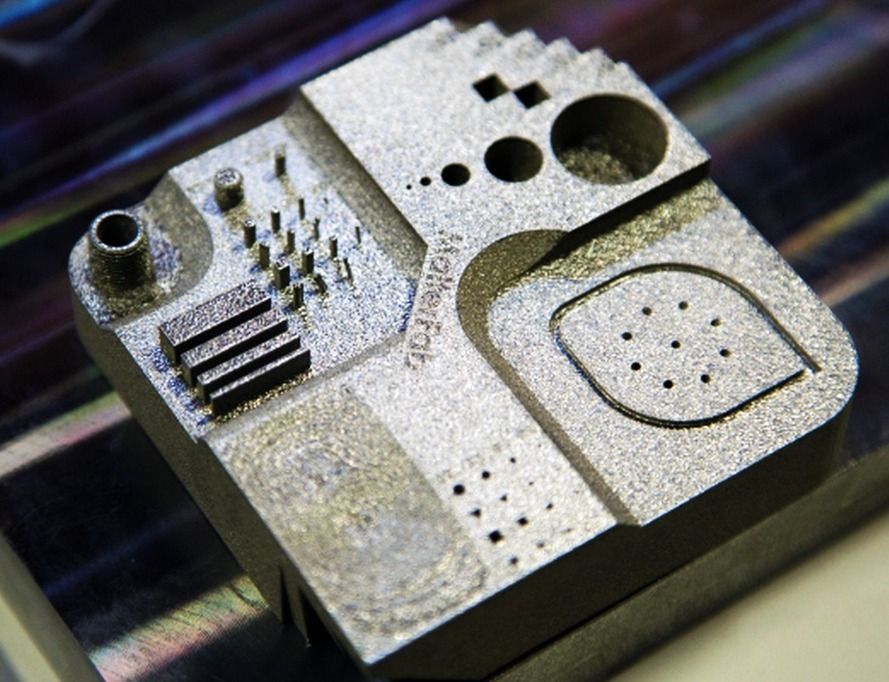

General Electric Gas & Oil uses one of the latest 3D printing technologies at its Kariwa factory, Niigata Prefecture, a hybrid technology of 3D printing metal laser sintering and high speed milling to produce various configuration control valve parts, which is used in various fields of the energy industry. nine0006

nine0006

GE acquired the Kariwa factory in 2011, and a couple of years later began testing 's 3D printing techniques for to create various kinds of control valves. The valves have rows of tiny holes and passages, which caused some difficulty in manufacturing these parts, so they had to be prefabricated from many parts. The use of additive technologies allowed GE to create valves of complex design and shapes, for example, hollow, curved, cellular, etc., these forms had only one thing in common - the high complexity of creating by traditional methods. nine0006

In the 3D printing process, on this printer also adopts high-speed milling, which shortens the mold processing process, speeds up the production process, and, importantly, reduces costs.

Benefits of additive manufacturing

“Existing traditional methods require processes such as soldering or assembling parts of complex shapes from individual parts,” says Yohji Mitsuhashi, an industrial designer who leads the test project additive technologies , – Metal 3D printing allows us to create a part in the right quantity, simplifies the production process and significantly speeds it up. ”

”

Accelerating the production of complex parts with 3D printing technologies is a great contribution to production, what was previously created in three months can now be achieved in 2 weeks.

Kariwa factory uses printer Lumex Avance-25 metal 3D printer , created by Matsuura Machinery Corporation , is the world's first printer that combines additive technology ( 3D printing uses fiber laser) and high-speed milling in one machine .

While existing 3D printers are accurate to 0.1mm, this one can be up to 100 times more accurate. This allows you to create products of optimal design that require minimal post-processing. One of the technicians working at the factory said: “Thanks to many years of experience, I can feel the smallest deviation of no more than a millimeter, just by holding the part in my hands. nine0006

Mitsuhashi remarked that his worker skills will allow him to take 3D printing of to the next level: “They show designers where there are weak points, help us understand how we can make products even better. ”

Specifications of the 3D printer LUMEX AVANCE-25 METAL 3D Printer

Lazer Type: Fiber-optical laser (laser on a fiber doped)

Laser output: Output power: 400W

The maximum size of the part: 250mm x 250mm x 150mm

Dimensional dimensions: 1800mm x 2050mm x 2500mm

Weight: 4500KG

Until the moment 9000 GE used 3D-sprout in the United State for the production of aircraft engine parts. This was a first for them to use the additive technology in their production outside the US.

See what else you can create with 3D printing:

How to complete a bust collection with 3D printing

Using 3D printing to create a dental model

3d printeradditive technologynews

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0006

This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts? nine0006

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

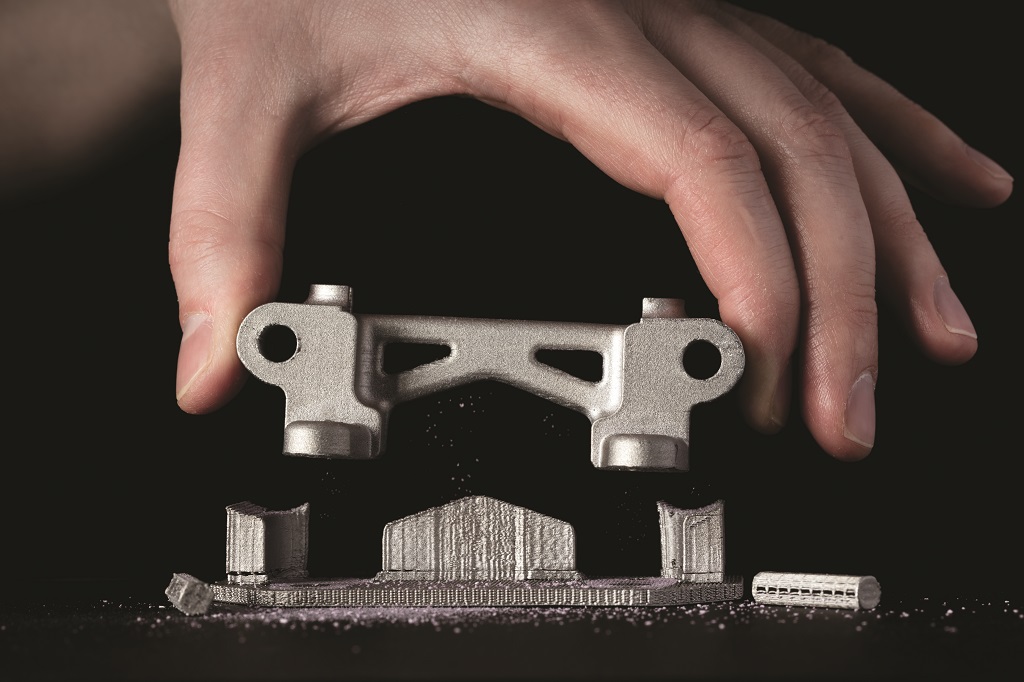

Strength of steel printed parts. nine0136 Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal)

The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than traditionally made ones. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0006

Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc. nine0006

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D)A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts. nine0006

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture. nine0006

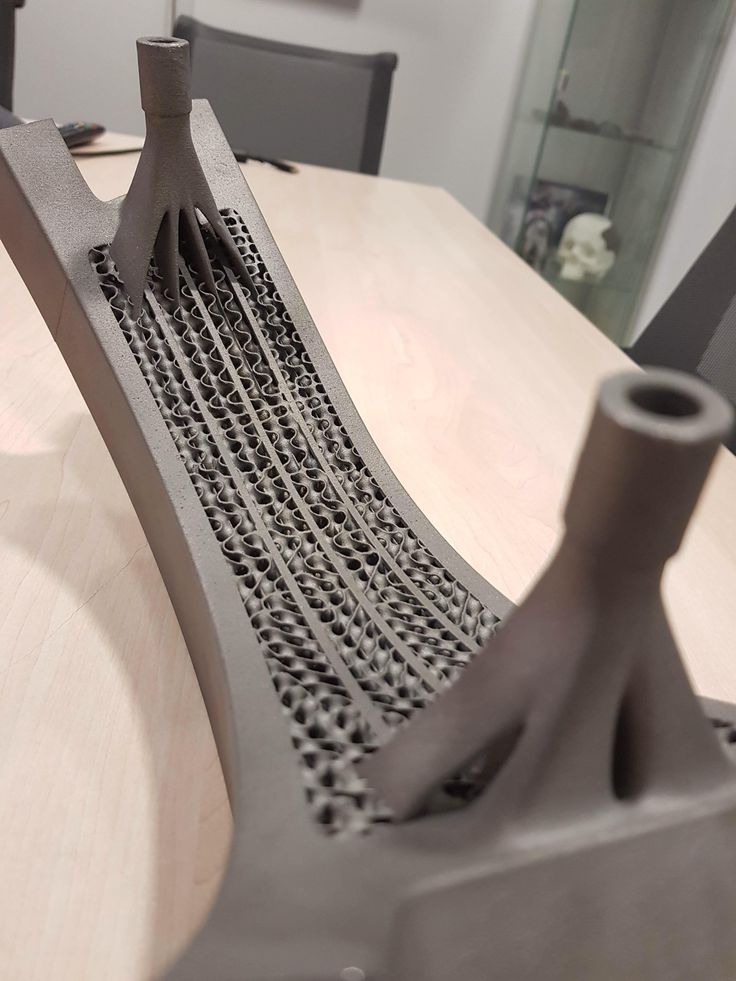

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength. nine0006 MX3D Wire Arc Additive Manufacturing (WAAM) printed steel architectural support (Source: MX3D)

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0006

When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product. nine0006

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants. nine0006

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc. ), then all these parameters can be incorporated into the product at the production stage.

), then all these parameters can be incorporated into the product at the production stage.

Kinds of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of kinds of different steel grades and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods. nine0006

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish. nine0006

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties, and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast. nine0006

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

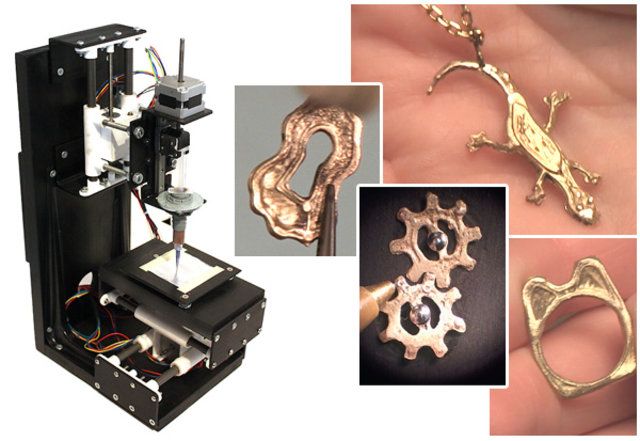

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced. nine0006FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts. nine0006

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's Ultrafuse 316L stainless steel filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts. nine0006 (Source: BCN3D)

While 3D printing with metallic materials may not be suitable for applications with high strength requirements (such as aerospace), the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology. nine0006

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal) Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0006

This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required. nine0006

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel. nine0006

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments. nine0006

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer. nine0006

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments. nine0006

Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments. nine0006

Binder Jetting

Binder Jetting 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or conventional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding. nine0006

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels. nine0006

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer. nine0006

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0006

Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries. nine0006

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation. nine0006

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding. nine0006

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining. nine0006

DED can get such parts much closer to finished than traditional CNC machining. nine0006

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field. nine0006

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less).