Filament extruder 3d printing

Felfil Filament Maker | Make your own 3D printing filament with Felfil Evo

Felfil Evo Extruder

The Perfect Match for your 3d printer

order now

Felfil Shredder

Crush your Plastic Wastes

order now

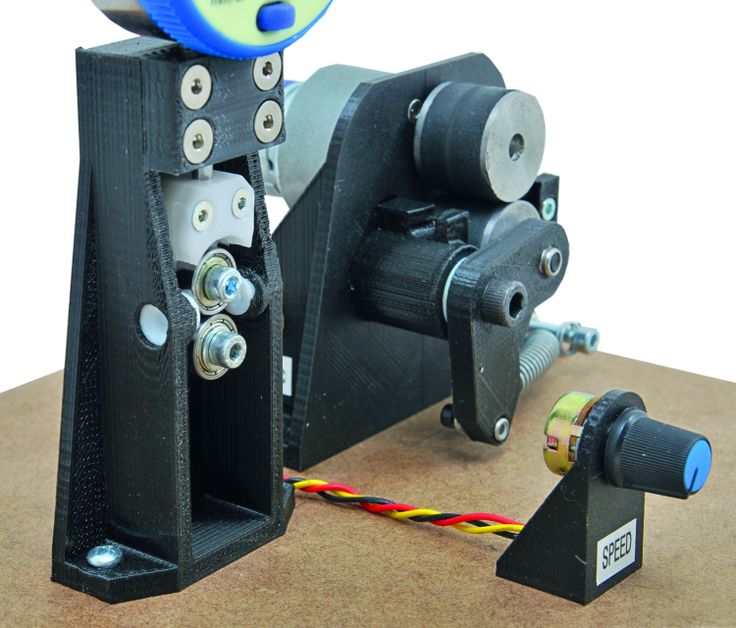

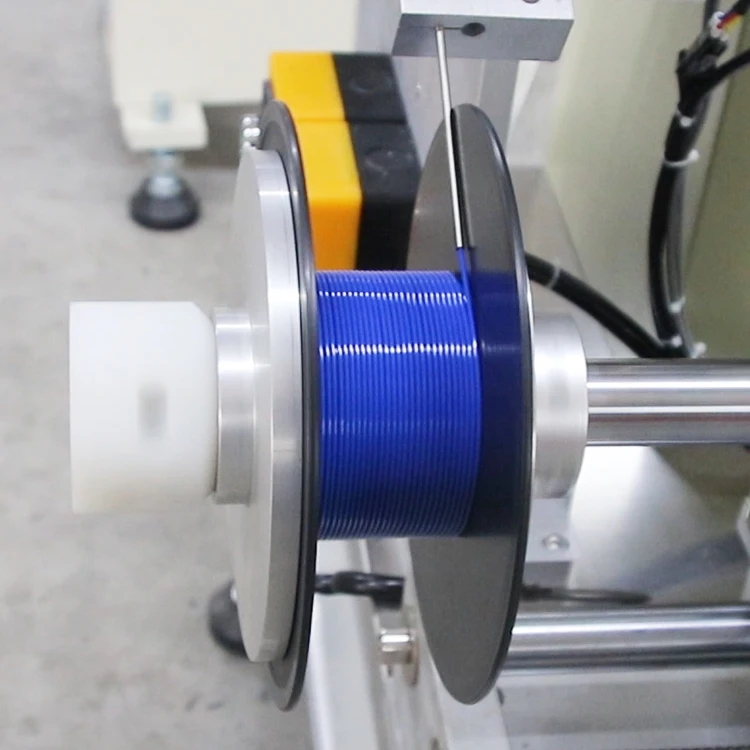

Felfil Spooler

Easier way to extrude

order now

Our filament maker system

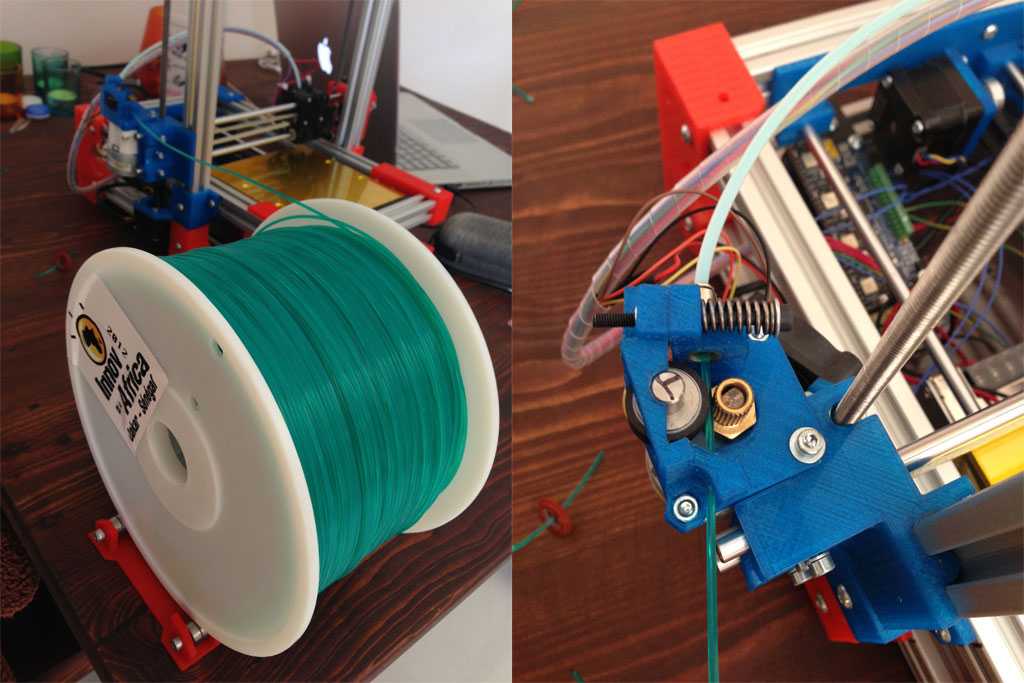

The Felfil filament extrusion line is composed by Felfil Evo, a 3d printer plastic extruder machine, Felfil Spooler which is a winding machine and Felfil Shredder that is a small plastic shredder. This extruding system allows anyone to make custom 3D printing filaments at home or in a lab, starting from industrial pellet or chopped wrong 3D prints, old models and plastic waste.

Using our desktop filament maker you will be able to choose your filament color, diameter and material, day by day, according to your creativity and your needs. In this way you will save over 80% of the price of filaments spools and help to protect the environment.

Recycle

Use failed 3D prints or plastic waste to create your filament

Save money

Save up to 80% of the spool costs starting from our pellets

Experiment

Make your custom 3D printing filament for any 3D printer

Get Your Desktop Filament Extruder

Choose between our different models and start to make your own filament

request a quote

-

Bundle Felfil Evo & Spooler

From: 1.169,00€ -

Bundle Felfil Evo, Spooler & Shredder

From: 2.184,00€ -

Felfil Evo Complete Kit

From: 616,00€

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

That’s the full recycling system by Felfil. It includes a plastic shredder, the extruder and the winder. All arrives already assembled and tested.

All three products can be placed on your desktop, and you can start immediately to recycle your old 3d prints or plastic wastes.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

ONE SYSTEM, SEVERAL APPLICATIONS

Our filament extruder system is easy to use and suitable for different applications, find out yours

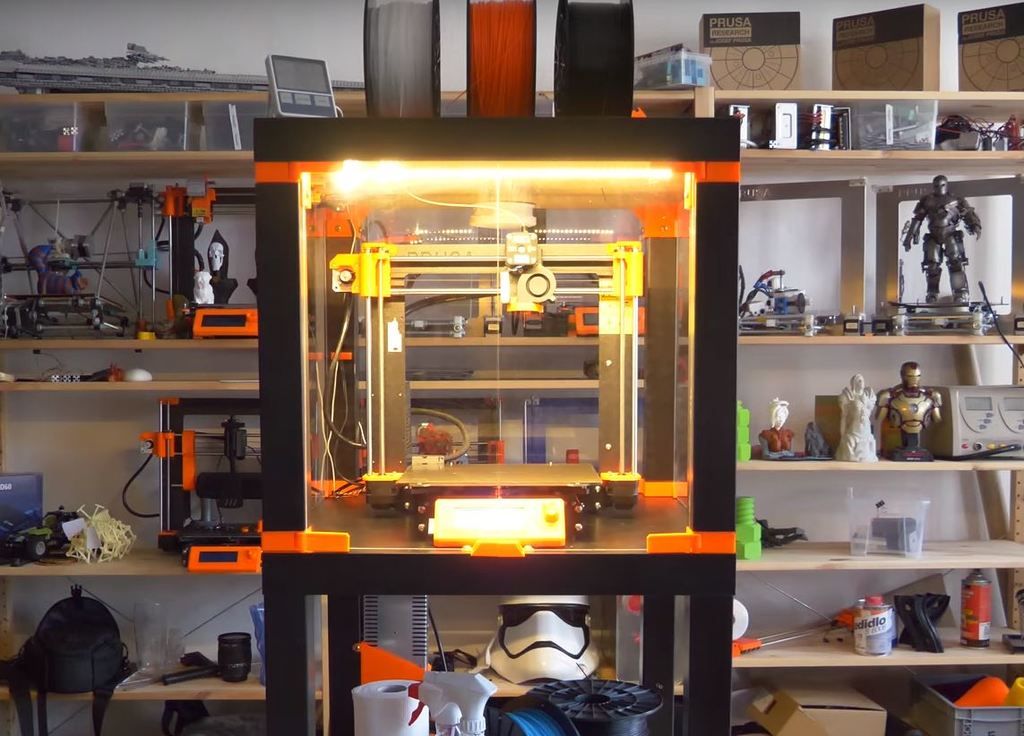

Fablab /Makers

Felfil Evo is an open source project and it is perfect for FabLabs and MakerSpace users: amatorial 3D printers and experts.

It is studied to help Makers recycle plastic waste from 3D printing activities, to save money and try different materials in order to stimulate creativity and innovative ideas.

You can create incredible and original objects from your old 3D prints.

Lean more

Laboratories

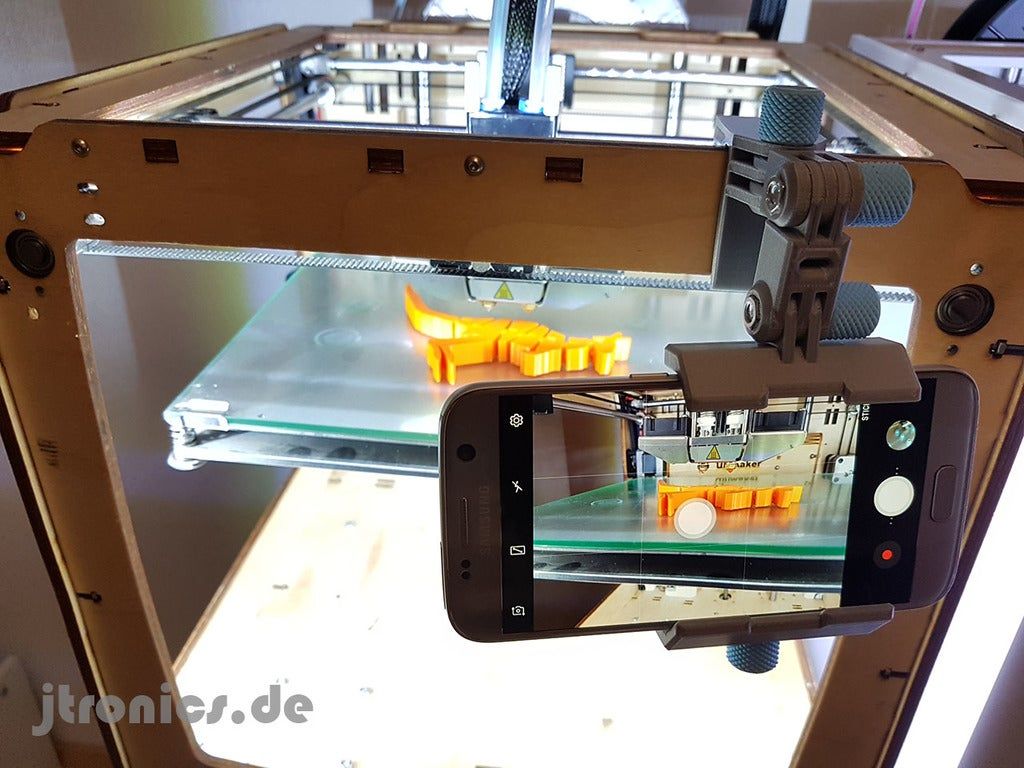

With our system it is possible to experiment new material, test their features and study their application. Felfil Evo and Felfil Spooler can be used in many sectors for prototyping activities.

With our desktop filament maker, research laboratories can be independent creating and testing small quantities of filament and have an immediate experience with the new materials.

Lean more

Education

Felfil helps students to learn about new technologies and additive manufacturing.

Thanks to our filament recycler system it is possible to learn about plastic materials for 3D printing and their potential for reuse culture.

The educational potentials of Felfil project concerns recycling and reuse, maker philosophy and application sectors of 3D printing.

Lean more

Our Clients

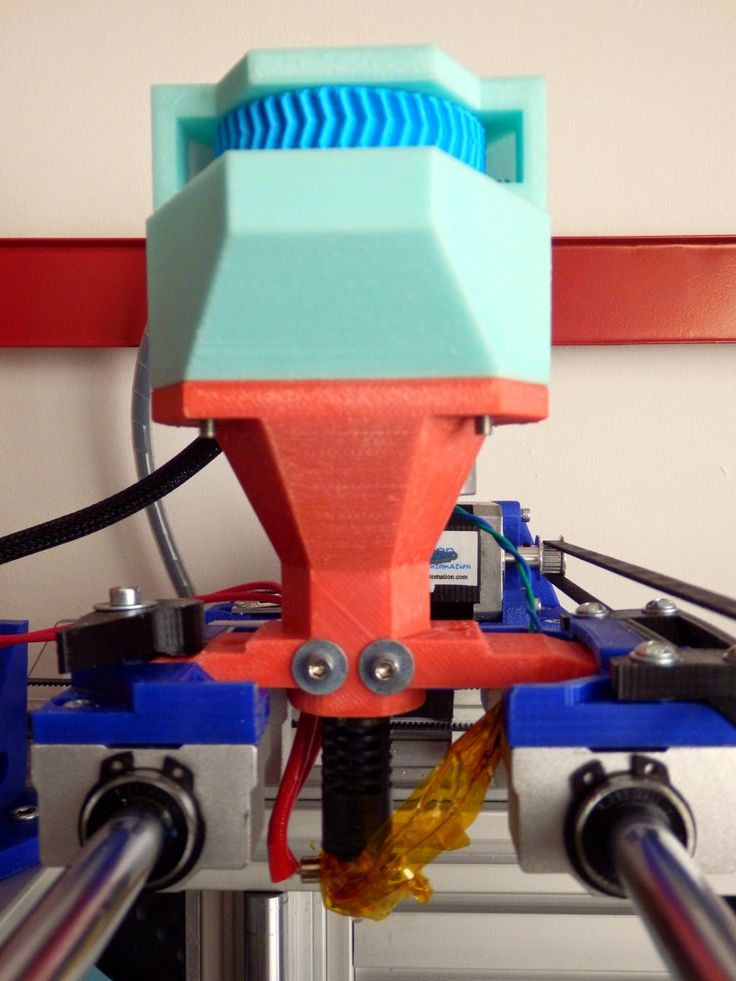

Born as open hardware but ready to make filament easily and safely at home. It’s a desktop 3d printer filament extruder able to produce custom filaments for your 3D printer.

Meet Felfil Evo

Meet

Make your choice

You can choose between three different version of Felfil Evo filament maker

DIY Project

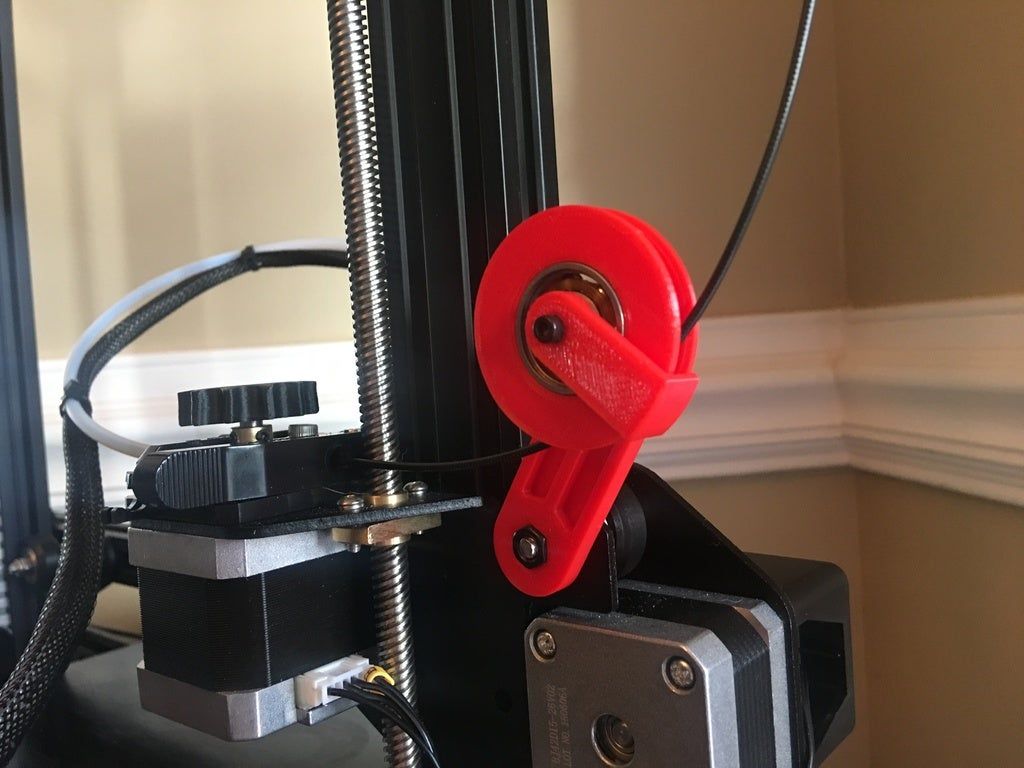

Discover how to customize Felfil Evo

More

Felfil Evo | Filament Extruder Kit or Assembled for 3D printers

Felfil Evo

Filament Extruder

The Perfect match

for your 3D printer

Make your filament and personalize

your prints with the Felfil Evo filament extruders

Order now

Tech Specs

Felfil Evo

Filament Extruder

The Perfect match

for your 3D printer

Make your filament and personalize

your prints with the Felfil Evo filament extruders

Order now

Despite a small delivery problem, which was fixed immediately, everything worked fine and quickly.

This is the service as you expect from some big company.

This is the service as you expect from some big company.Gerhard

Number 1 extruder on the market. High quality job, worth the money paid. I wish to see more innovative products in near future from Felfil Srl.

Anonymous

All the machines work perfectly. I already mixed up coffee beans, scissor powders but I see no problem so far. I'm really happy!

Shintaro

Goo customer service and transparency. I used the Felfil Evo for a Master Thesis in mechanical engineering and I got support to every question I asked them.

Theodor

"The assembling process is very easy"

Takawo (client) - takawo.hatenablog.com

"Your extruder kit works excellent!"

Glassy (Kickstarter Backer)

"An excellent and very cool looking design, that will be a great addition to any desktop: the Felfil Evo."

3ders.com - 3ders.com

Felfil Evo is a safe and easy to use plastic filament extruder, able to produce custom and recycled filament for 3D printers starting from pellet or wrong prints.

With Felfil Evo you can choose from many different plastic materials and make your 3D printing filament.

A desktop filament extruder

Felfil Evo is a small 3d printer filament maker and is designed to be used by every user, professional or amateur. Indeed, its compact design and small dimensions are suitable for every desktop.

With Felfil Evo you can make both filament diameter, 1.75mm and 2.85mm, just by changing the nozzle.

Felfil Evo interface is intuitive and make the extruder easy to use.

In particular, through it is possible to set manually the correct temperature and gearmotor speed, then start to make high quality custom filament for your 3D printer.

Moreover, Felfil Evo is available in four colors: yellow transparent, transparent, white or black.

THE FILAMENT EXTRUDER MADE FOR YOU

Felfil Evo is a safe and easy to use plastic filament extruder, able to produce custom and recycled filament for 3D printers starting from pellet or wrong prints.

With Felfil Evo you can choose from plastic materials and make your 3D printing filament.

A DESKTOP EXTRUSION SYSTEM

Felfil Evo is a domestic filament maker and is designed to be used by every user, whether 3D print expert or beginner. Indeed, its compact design and small dimensions are suitable for every desktop.

With Felfil Evo you can make two different filament diameter, 1.75mm and 2.85mm, just by changing the nozzle.

Felfil Evo interface is intuitive and make the extruder easy to use.

Through it is possible to set manually the correct temperature and gearmotor speed, then start to make high quality custom filament for your 3D printer.

Felfil Evo is available in four colors: yellow transparent, transparent, white or black.

Technical Specifications

Extrusion speed

100-150 gr/hour

Temperatures

250°C or 300°C

Extrusion screw

Specifically made screw

Licence

Open Hardware

Tolerance

up to +/- 0. 07mm

07mm

Multi Materials

PLA - ABS - HIPS - TPU and more

Open Source

Felfil Evo is an open source project, which means that you can see how it was designed.

For this reason Felfilino, our special PCB board, uses the same processor of Arduino.

Download the source files from here.

Industrial Solutions

We made specific components for specific objectives. The screw, nozzle and melting chamber design reports some industrial solutions. The screw is realized with durable materials and its precision guarantees a high-quality extrusion of plastic materials.

Awesome Design

The mechanical components are made in Italy with durable materials, ensuring the product quality.

Thanks to its design, Felfil Evo is easy to maintain and is suitable for different uses.

Three Faces of Felfil Evo Filament Maker

Choose your favourite filament extruder kit and let’s make at home your custom 3D filament with Felfil Evo.

shop now

-

Felfil Evo Assembled

From: 675,00€ -

Felfil Evo Basic Kit

From: 279,00€ -

Felfil Evo Complete Kit

From: 616,00€

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

This kit includes only the main components that are specifically made and are very expensive when handcrafted in single pieces.

All other parts, like heaters an electronics, are easily reachable on the market and are the same used in 3D printers. Complete the extruder following our guides.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

This is the complete filament maker system by Felfil, that includes Felfil Evo Assembled and Felfil Spooler.

You will receive all assembled, ready to make your custom and DIY 3d filament.

A complete solution to make your own filament directly on your desktop.

This solution is perfect for who want to try immediately our extruder! An ideal choice for those who want to begin to extrude easily.

You will receive the filament maker already assembled, ready to make your custom and DIY 3d filament. You have just to unbox it and connect the plug.

The Felfil Evo Complete Kit is the solution for who want to build their own extruder, step by step. Then, it is shortly to begin to extrude.

Buying this package you will get all the components of Felfil Evo, you just have to assemble them following the instruction manuals.

Powerfull Gearmotor

The Felfil Evo gearmotor has been selected for its reliability and power quality. It allows to Felfil Evo to work in a excellent way with many materials

23 9

Nm Rpm

Powerfull Gearmotor

The Felfil Evo gearmotor has been selected for its reliability and power quality. It allows to Felfil Evo to work in a excellent way with many materials

23 9

Nm Rpm

Special Extruding Screw

The screw has been designed to transform the plastic scraps into a brand new filament. Thanks to its design you can easily make colored filament. The extrusion screw is made by K100 steel machined from a solid base on a five-axis milling machine

12,7 1,47

L/D ratio Comp ratio

Special Extruding Screw

The screw has been designed to transform the plastic scraps into a brand new filament. Thanks to its design you can easily make colored filament. The extrusion screw is made by K100 steel machined from a solid base on a five-axis milling machine

Thanks to its design you can easily make colored filament. The extrusion screw is made by K100 steel machined from a solid base on a five-axis milling machine

12,7 1,47

L/D ratio Comp ratio

Interchangeable Nozzles

Felfil Evo nozzle allows to cool down the filament in output and to keep a constant filament diameter thanks to its internal processing. Easy to change, it’s available in two diameters.

1,75 2,85

Ø mm Ø mm

Dedicate Electronic Brain

Felfilino project is totally opensource and Arduino based.

Our PCB run the Felfil Evo interface and the filament extruder functioning. Moreover, the PCB manage also security system that allow to use Felfil Evo in the domestic environment.

12V 150W

Safe Powerfull

Interchangeable Nozzles

Felfil Evo nozzle allows to cool down the filament in output and to keep a constant filament diameter thanks to its internal processing. Easy to change, it’s available in two diameters.

Easy to change, it’s available in two diameters.

1,75 2,85

Ø mm Ø mm

Dedicate Electronic Brain

Felfilino project is totally opensource and Arduino based.

Our PCB run the Felfil Evo interface and the filament extruder functioning. In addiction, the PCB manage also security system that allow to use Felfil Evo in the domestic environment.

12V 150W

Safe Powerfull

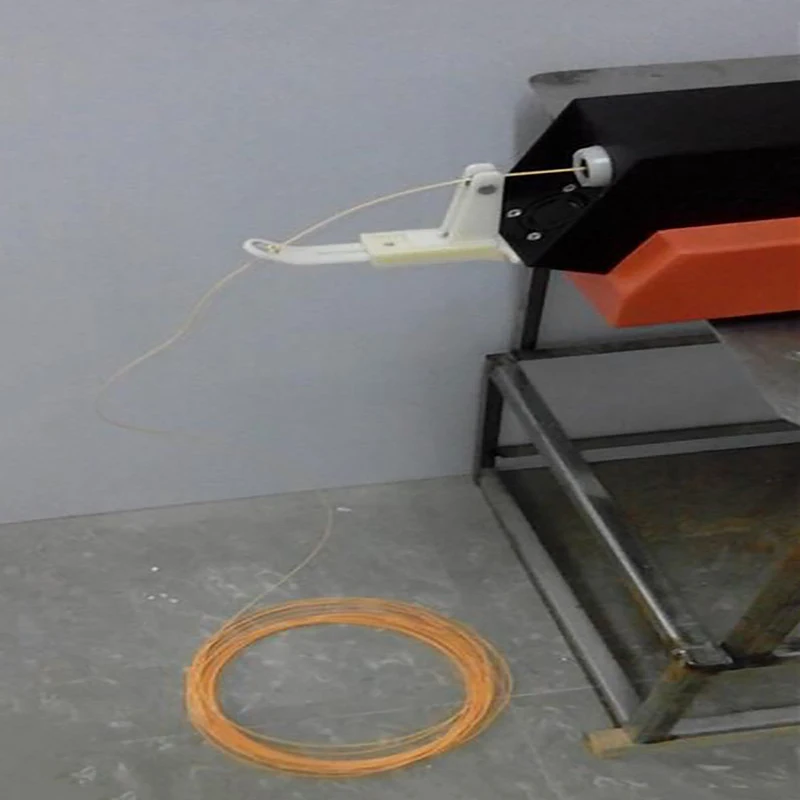

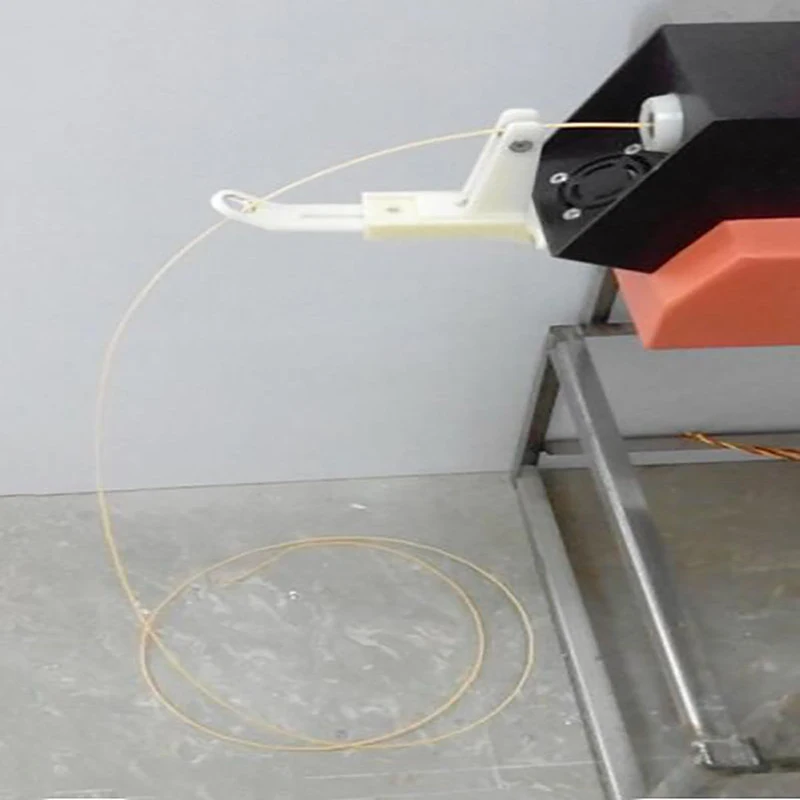

Make extrusion easier

Felfil Evo can work alone, but we developed Felfil spooler in order to make the extrusion process easier. See how Felfil Spooler works.

discover

Felfil Evo

Make your own 3D printing filament

order now

3D printer filament extruder

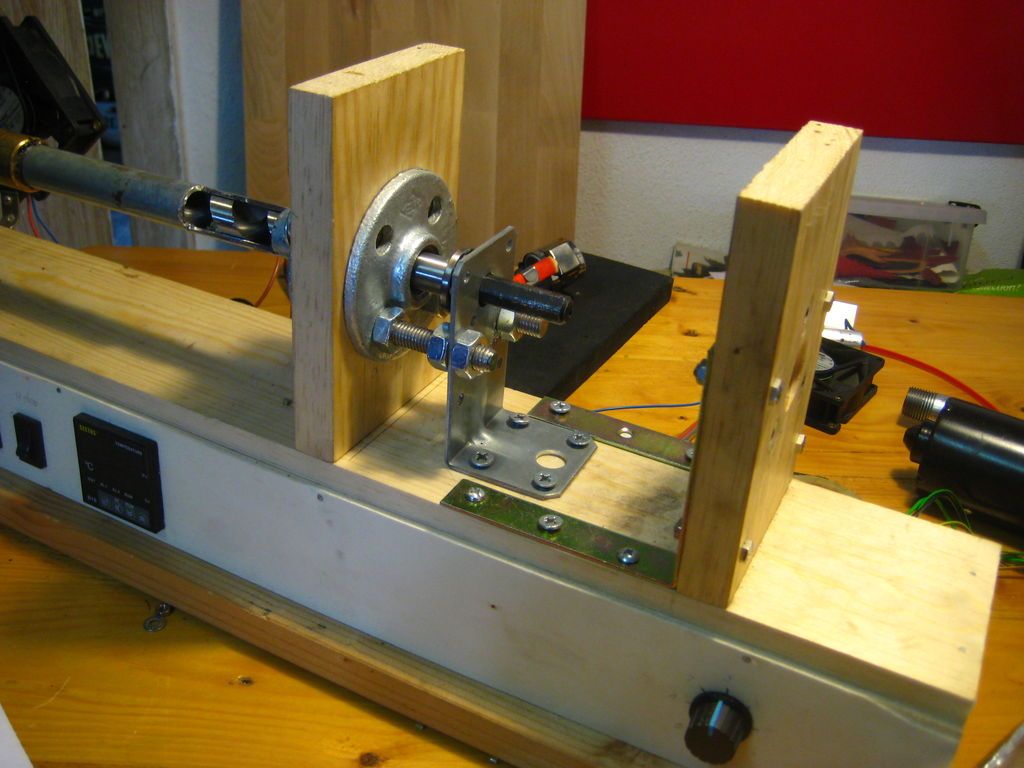

Technician

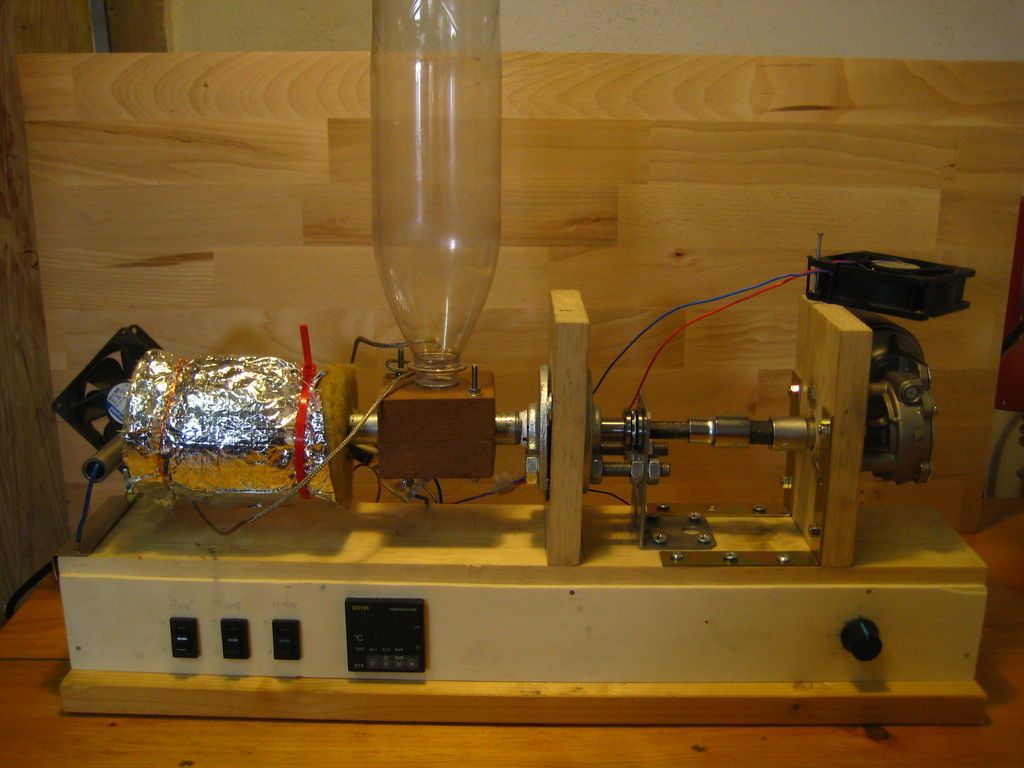

Good afternoon!

I want to share my experience in assembling a filament extruder for a 3D printer. I must admit that I collected slowly due to various circumstances. Just a colossal number of mistakes were made :)) As a rule, some mistakes cost both money and time. First of all, the mechanics turned out to be the most difficult for me. Due to the lack of centering of the auger, the grinding on the sleeve completely upset me and forced me to redo the mechanics every time. The most optimal for me was the installation of the auger directly into the gearbox without any additional bearings.

I must admit that I collected slowly due to various circumstances. Just a colossal number of mistakes were made :)) As a rule, some mistakes cost both money and time. First of all, the mechanics turned out to be the most difficult for me. Due to the lack of centering of the auger, the grinding on the sleeve completely upset me and forced me to redo the mechanics every time. The most optimal for me was the installation of the auger directly into the gearbox without any additional bearings.

And so let's see what happened:

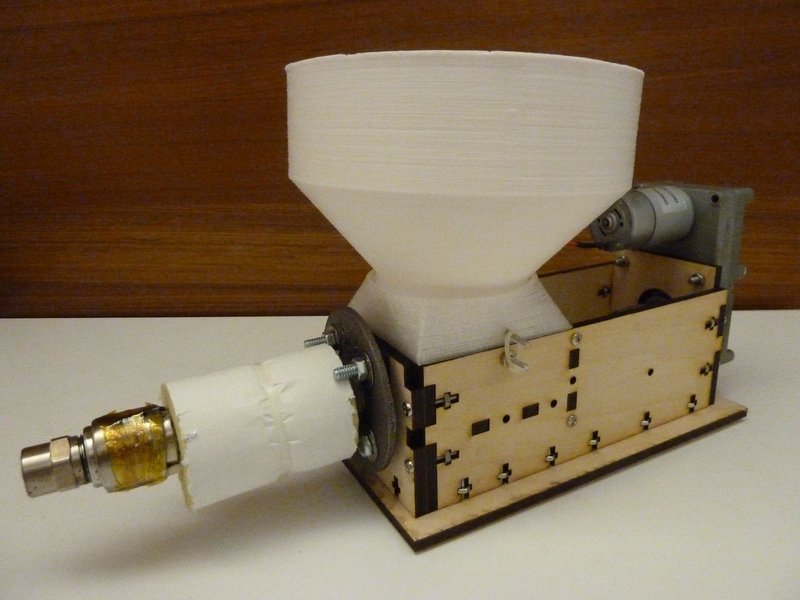

As you can see from the photo, I tried to make it as compact as possible. Placement of nodes carefully thought out.

A nema34 motor and gearbox was used. When working with such powers, you need to be careful and make such mistakes

Later, accidents and other stops were laid to prevent accidents

The first attempts to assemble the extruder were with many buttons, lights, switches and the like. I was especially annoyed by their installation, placement - this is another headache for me, since I had to redo the extruder so many times. As a result, I decided that there would not be a single button in my extruder! Many of my comrades did not like it, but still this is my extruder and I had just such a desire. Many guys who assembled the extruder used a Chinese PID controller for heating, but the presence of a display in the extruder did not fit into my concept, so the PID controller was programmed with my own.

I was especially annoyed by their installation, placement - this is another headache for me, since I had to redo the extruder so many times. As a result, I decided that there would not be a single button in my extruder! Many of my comrades did not like it, but still this is my extruder and I had just such a desire. Many guys who assembled the extruder used a Chinese PID controller for heating, but the presence of a display in the extruder did not fit into my concept, so the PID controller was programmed with my own.

On the bottom graph you can see the problems that I encountered - namely the pickup. max6675 let me down and had to convert it to a thermistor like on a 3d printer and as you can see the results are better.

Temperature control was carried out using the application again

I would like to pay special attention to the selection of coefficients for heating the extruder. The selection of good odds turned out to be not an easy task for me and it was spent sparingly for about one day.

The selection of good odds turned out to be not an easy task for me and it was spent sparingly for about one day.

I also attach a visual diagram of the extruder connection. On the diagram, you can see the main elements connected to the extruder control board, as well as a not tricky circuit.

A bit about management. As you can see from the diagram - I used esp8266-01. It uses the standard mqtt connection library. I did not plan to transfer important tasks under her control. Previously, I tried to use the hc-06, hc-12, 433mhz modules but nothing good came of it. It seemed to work, but in a couple of ways - the channel was not quite targeted and * clogged *. The mqtt protocol provides more targeted delivery and messaging, so I opted for it.

The Android application had implementations of the mqtt protocol, which made my life much easier.

The operation of the nodes can be seen on the video

fifteen

Subscribe to the author

Subscribe

Don't want to

Probably, many have already heard about the delights of the Klipper firmware, but after trying to install it, they broke the ambi...

Read more

7

Subscribe to the author

Subscribe

Don't want

Hi all!

My first post, so please save your slippers)

Zaden...

Read more

AKDZG

Loading

14.02.2015

845050

363

Subscribe to the author

Subscribe

Don't want to

Many 3D printers run the popular Marlin firmware. The firmware is initially configured...

The firmware is initially configured...

Read more

Portable bar extruders. Filament manufacturing. How to make your own 3D printing consumables

- 1 Description

- 2 Filabot Original

- 3 Filabot Wee

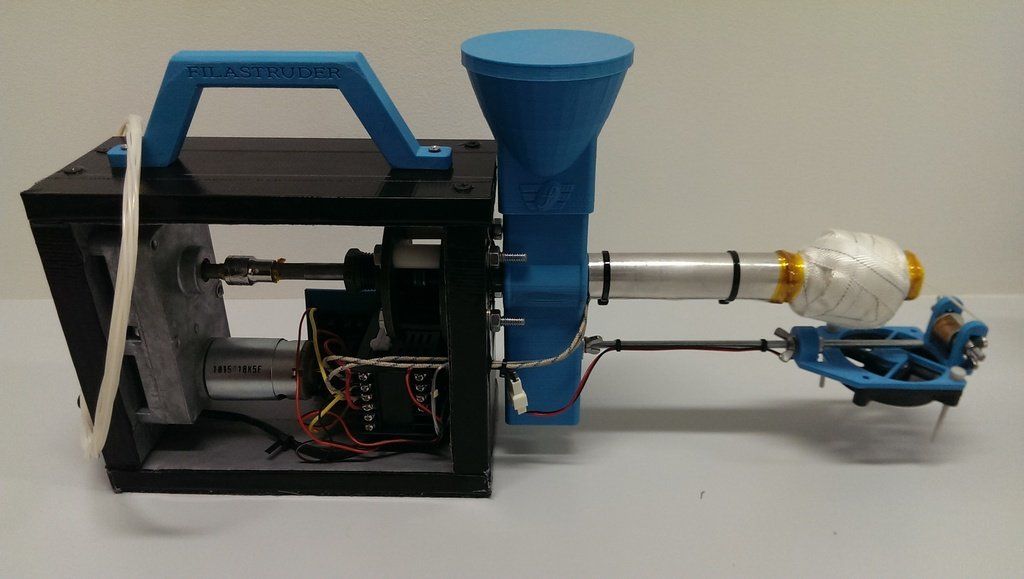

- 4 Filastruder

- 5 Lyman extruder

- 6 OmniDynamics Struder

- 7 STRUdittle

- 8 Filabot Reclaimer

- 9 FilaMaker

Description

One of the limiting factors in the development of FDM printing is the relatively high cost of consumables. Although most plastics are quite affordable for an ordinary user, the difference between raw materials and finished thread is very significant - often the cost of a rod exceeds the cost of granules of the same weight by dozens of times. Thus, it is not surprising that portable, desktop devices for home production of filament from granules and plastic waste have appeared.

Extruder device

Such installations can significantly reduce the cost of printing and, of course, improve the environment. In this section, we'll take a look at some of the most well-known home rod making practices, including filament extruders and plastic waste shredders.

Filabot Original

The most famous development with high performance. The device is designed to work with ABS, PLA and HIPS. Granulated plastic is used as a consumable, but plastic waste can also be used, provided that the particle size does not exceed 5 mm.

Filabot Original is the world's most famous home bar making machine.

The company offers a choice of seven colors of ABS granular dyes to give the finished material the desired shade. Dyes are supplied in packs of 25g. One or two packs are required to paint one kilogram of ABS. For best results, the use of colorants with white ABS granules is recommended.

In addition, ABS, PLA and HIPS can be blended with carbon fiber for stronger and more durable materials. To obtain such a composite, it is only necessary to mix plastic with carbon fiber granules and, if necessary, dye, and then load the finished mixture into a hopper.

Filabot Original has the highest performance of its kind. It takes about five hours to extrude one kilogram of bar. The temperature range during heating is 40°C-400°C, which allows you to experiment with a wide range of materials, including composites with wood filler, electrically conductive additives, etc.

The bar diameter can be 1.75mm or 3mm depending on the nozzle. The extrusion speed is 250-750mm per minute depending on the diameter of the bar to be produced.

The auger rotates at 35 rpm. The power consumption of the device reaches 300W depending on the extrusion temperature. The extruder is equipped with a filter to remove contaminants just before extrusion.

The device is equipped with a durable metal case and has fairly compact dimensions, comparable to a computer system unit: 431x178x203mm.

Factory selling price: $899.

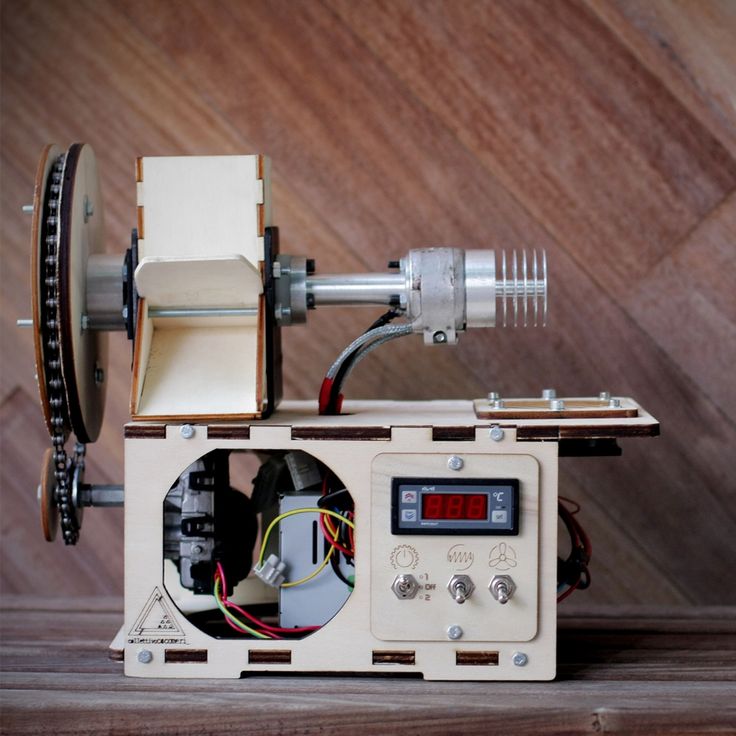

Filabot Wee

Filabot Wee is a more affordable option, not inferior to the Filabot Original

Version of the original Filabot extruder, equipped with a wooden body. This option is positioned as a budget version and is available both in assembled form and as a kit for self-assembly.

The budget version is slightly inferior to its more expensive counterpart in terms of performance: the extrusion speed varies from 125mm to 500mm per minute. The extrusion temperature varies from 40°C to 350°C.

The device is primarily intended for the production of HIPS, ABS and PLA rod, although other materials suitable for extrusion temperatures are also possible.

Due to the use of granulated dyes, a wide range of colors can be achieved - when using dyes, the use of white ABS plastic or a material with slight color shades is recommended.

The addition of granular carbon fiber results in a higher strength end product. Carbon fiber can be used in combination with any of the calculated plastics.

Carbon fiber can be used in combination with any of the calculated plastics.

The maximum power consumption is 300W. The device comes with interchangeable nozzles that allow the production of two of the most popular bar diameters: 1.75mm and 3mm.

Filabot Wee dimensions are similar to Filabot Original: 431x178x203mm.

Filabot has released the Filabot Wee drawings to the public. Those wishing to build an extruder with their own hands can download the necessary files here and here.

Factory selling price: $749for an assembled extruder, or $649 for a self-assembly kit.

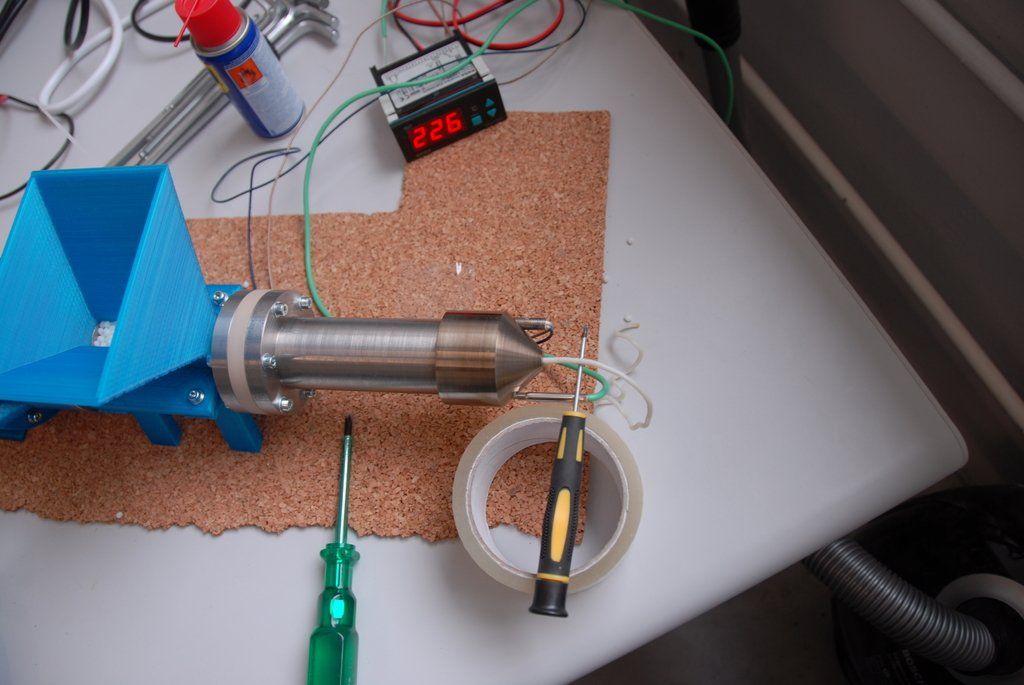

Filastruder

Relatively inexpensive extruder developed by two University of Florida students: Tim Elmore and Allen Haynes.

Filastruder is a relatively inexpensive but very efficient extruder

Filastruder can produce one kilogram of filament in 12 hours of operation of the device or from 150mm to 600mm per minute depending on the nozzle diameter, extrusion temperature and the material used. The developers tested the extruder with ABS plastic, but they allow the use of PLA, HIPS, nylon, polyethylene and other plastics. The maximum extrusion temperature reaches 225°C.

The developers tested the extruder with ABS plastic, but they allow the use of PLA, HIPS, nylon, polyethylene and other plastics. The maximum extrusion temperature reaches 225°C.

The extruder is quite economical - the maximum power consumption is 60W with an average of 50W.

Filastruder is available with 1.75 or 3mm nozzles.

Filastruder extruder sells for $300 without hopper or $310 with printed hopper.

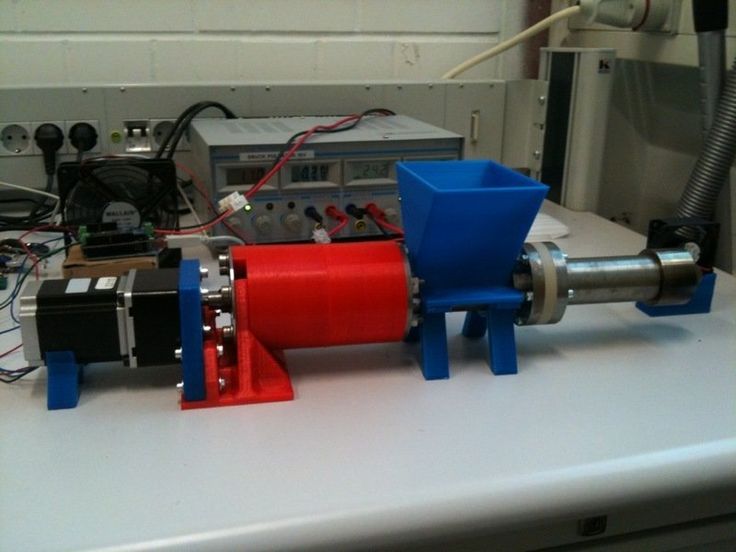

Lyman Extruder

Lyman Extruder - a pioneer of desktop filament mills

Named after the inventor, Hugh Lyman. The original development is probably the first homemade bar extruder. It was this design that won the top prize at the Desktop Factory Competition in 2013.

The design of the extruder was simplified as much as possible, which was the result of the main condition of the competition: the total cost of the components used in the design should not exceed $250.

The Lyman extruder is not commercially available and is not available at retail. The developer posted instructions for creating an extruder in the public domain. The required files can be downloaded here.

The developer posted instructions for creating an extruder in the public domain. The required files can be downloaded here.

OmniDynamics Struder

OmniDynamics Struder is designed for safety and ease of use

A compact device announced on Kickstarter in May 2014. The goal of the developers is to create a portable, convenient and safe device to use.

Delivery of the first batches of the extruder is scheduled for September 2014. The retail price of the device has yet to be announced, but the Kickstarter pre-order price is £149.

Extruder designed to work with any thermoplastic used in 3D printing, including ABS, PLA, PET, HDPE, HIPS, etc. The device is equipped with a full-fledged control module with a color LCD display.

STRUdittle

STRUdittle is a promising extruder with compact dimensions and high productivity

Another interesting development that received the necessary funding on Kickstarter.

The design of the device is aimed at high compactness and good affordability while maintaining high performance.

According to the developers, the device is capable of producing up to 600mm bars per minute. The extruder is designed to work with ABS plastic. Filament diameter deviations do not exceed 0.03 mm when using a winder or 0.05 mm if the bar is simply extruded onto the floor. Customers can specify the required nozzle diameter: 1.75mm or 3mm.

Kickstarter pre-order price is $385 for extruder with winder.

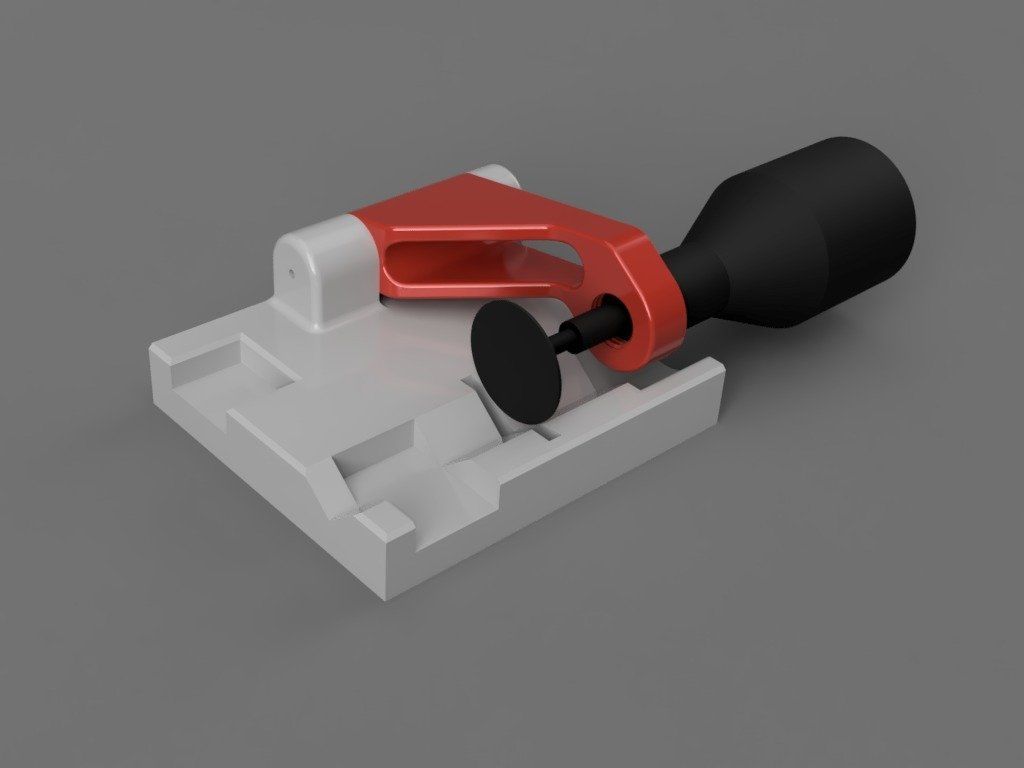

Filabot Reclaimer

The Filabot Reclaimer Hand Crusher handles all kinds of plastic waste. At the same time, FDM printers in combination with desktop extruders have great potential for recycling plastic waste into new products. Thus, to use plastic waste as consumables, a device is required that can crush plastic to obtain small particles - usually no more than 5 mm. Filabot has developed a simple yet effective shredder designed for just this purpose. The device was called the Filabot Reclaimer.

The device was called the Filabot Reclaimer.

The Filabot Reclaimer features a strong welded metal frame and hardened steel serrated rollers. The device is not equipped with an electric drive - the rollers are driven manually using a lever.

Almost any thermoplastic used in 3D printing can be used as raw material.

The Filabot Reclaimer lets you recycle bad models, 3D printed waste, and just plain old plastic items. The size of the neck and, accordingly, the processed pieces of plastic reach 50x90mm. Due to the robust metal construction of the fixture, the weight of the Filabot Reclaimer is an impressive 11kg. The installation dimensions are quite modest, reaching 255x255x380mm.

The Filabot Reclaimer retail price is $439. Despite the relatively high cost, the device quickly pays for itself, allowing, together with the extruder, to save up to 90% of the cost of the bar.

FilaMaker

FilaMaker combines crusher and extruder functionality

FilaMaker combines crusher and extruder functions in one device.