3D laser scanner instructables

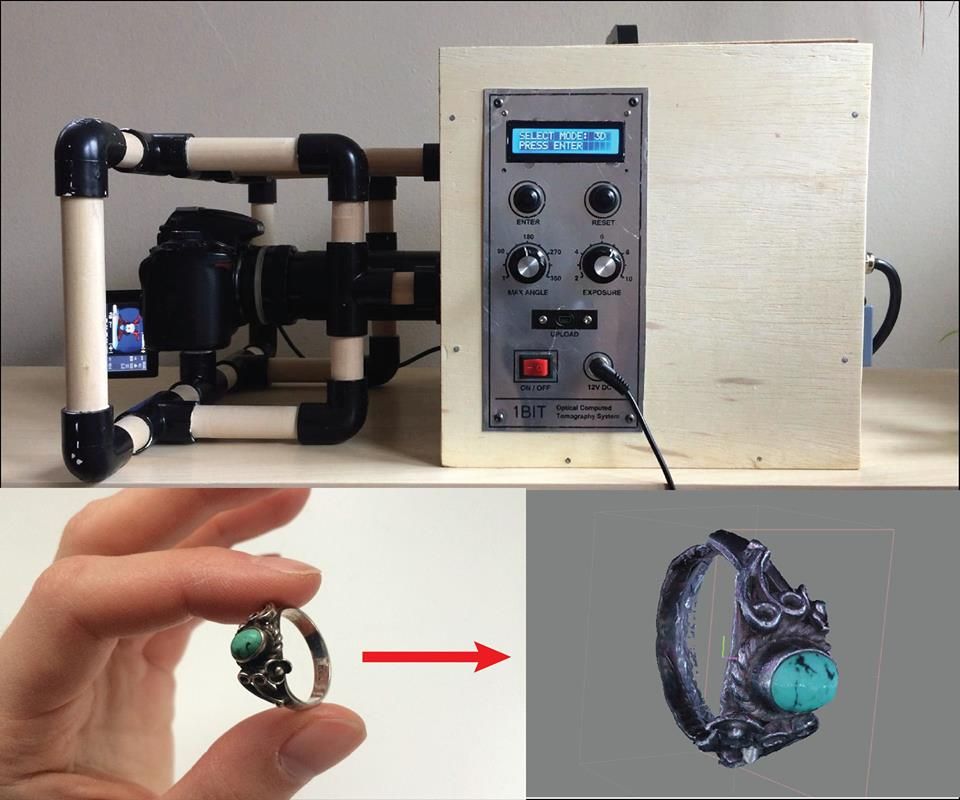

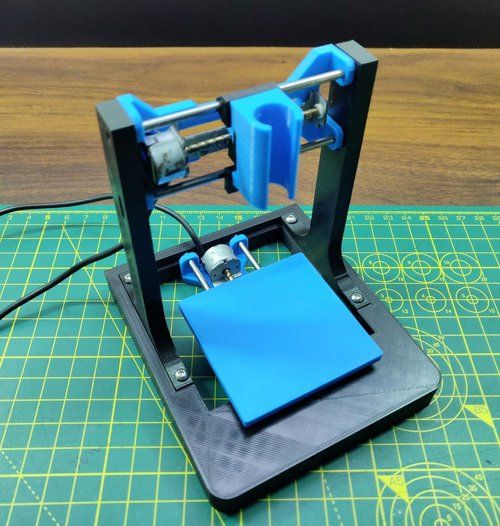

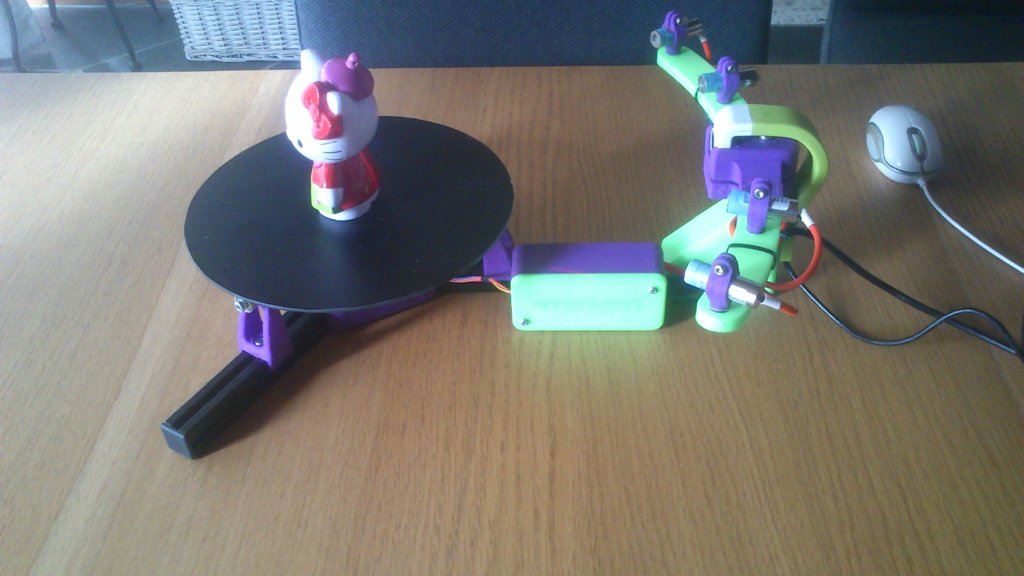

John Price - Stereoscopic 3D Scanner Design Project

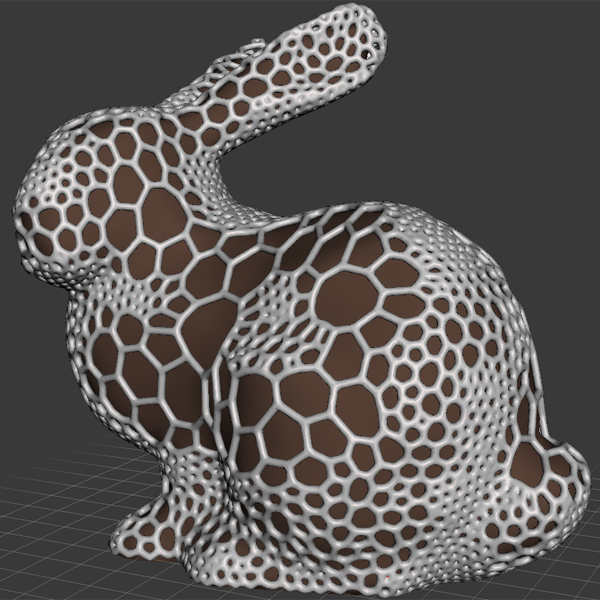

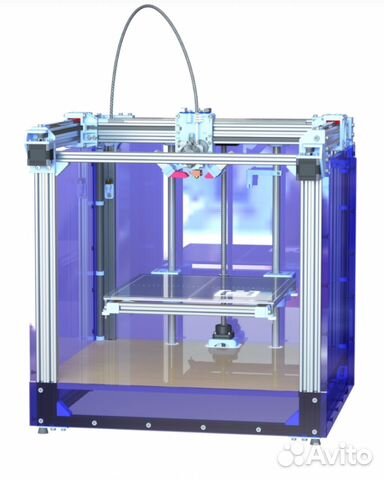

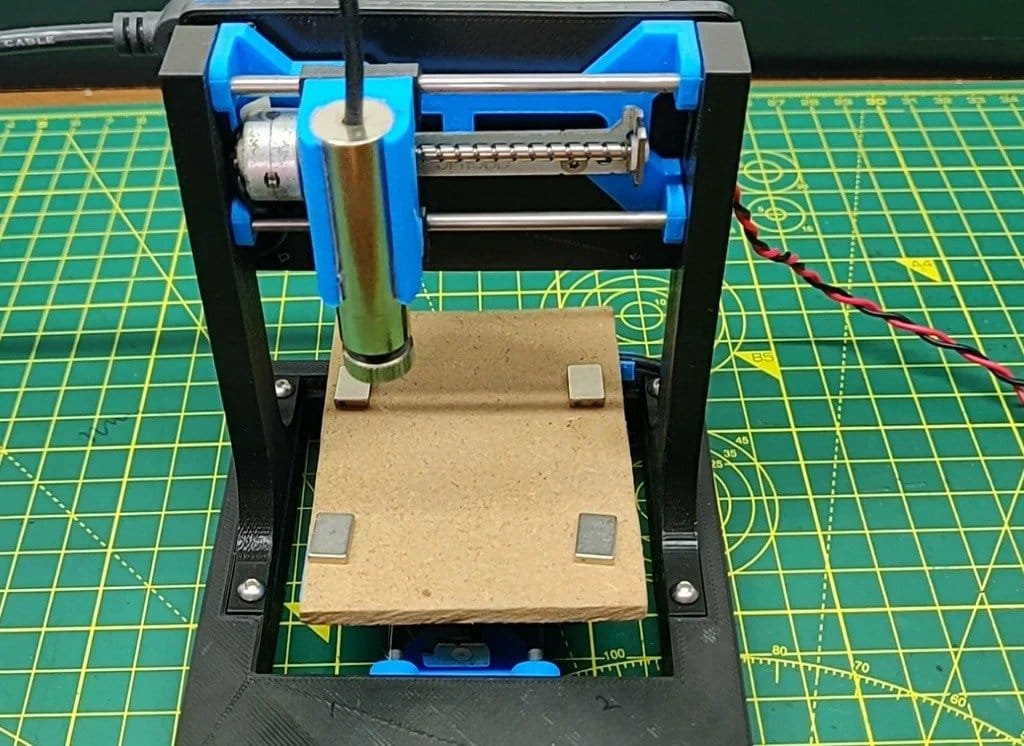

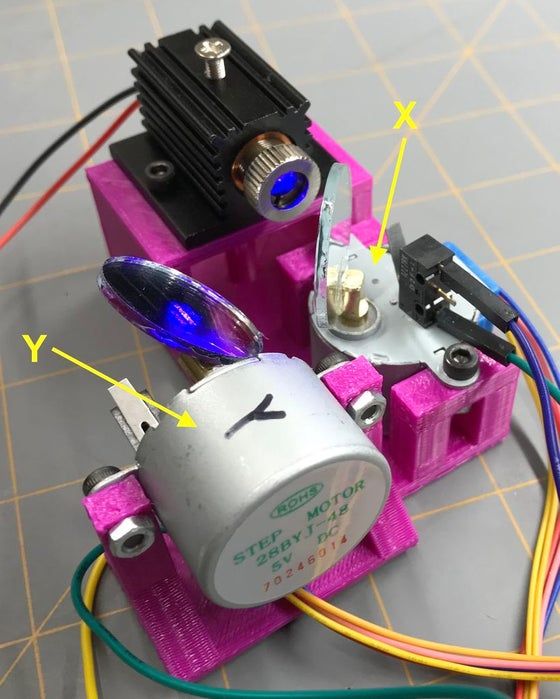

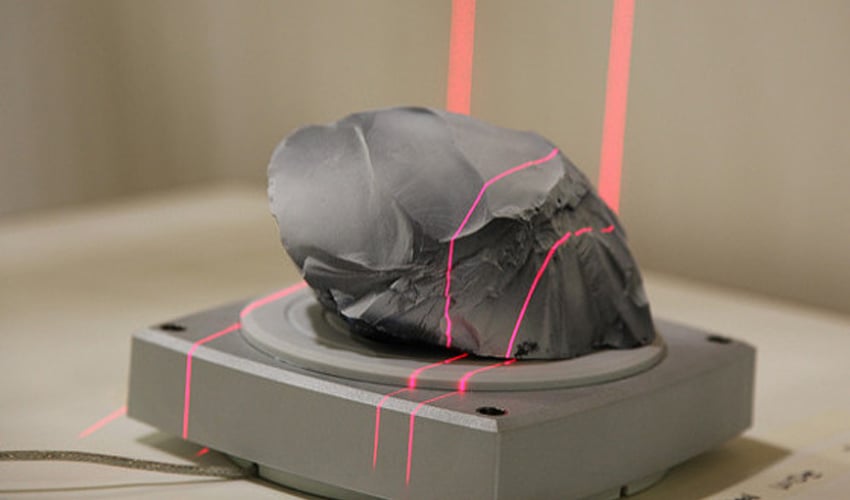

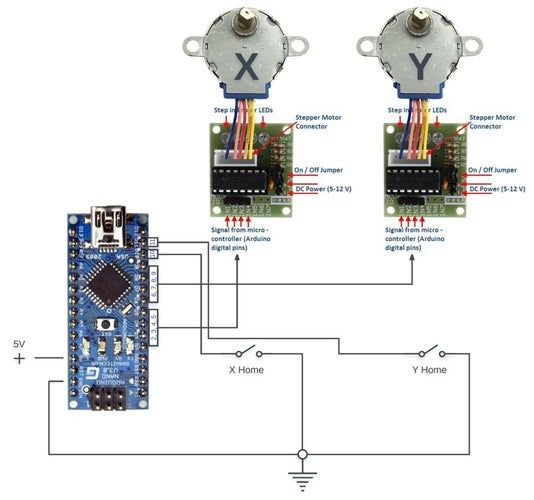

University of Kentucky Major: Computer Science Minor: Math Graduating May 2016 Individual Activity for John Price II _________________________________________________________________________________________________________________________________________________________________________________________________________ 2/7/2016 – 2/14/2016 I researched the internet for instructables and other information regarding building a 3D scanner, per Dr. Dietz’s suggestion. Many of the do-it-yourself scanners out there use the single camera with a laser line approach. In addition, a stepper motor and central platter are used to rotate the object being scanned, in view of the camera, while the line laser projects onto the object of interest. I am having trouble finding good DIY information for this approach but have found a couple of academic papers that look promising. I found a paper that describes a structured light approach that uses a projector to project a greyscale light pattern on the object of interest and utilizes two cameras. Although, in our project, we would like to use a laser line instead of a greyscale projection, the pinhole cameral model and triangulation methods give some insight into the math behind using two cameras to scan an object. This paper can be found at http://mesh.brown.edu/byo3d/notes/byo3D.pdf. From my online research, I also discovered a powerful open source software library called OpenCV that we have decided to use for our scanner. This library has many powerful image processing functions. I also found a good textbook for learning OpenCV. It has a chapter devote4d to reconstructing 3D images from a stereo camera. Last, I found an instructable that has files for making 3D printed parts for mounting the cameras and laser to extendable tracks that radiate from a central printed platter. We can attach the stepper motor to the platter and rotate the platter in steps to get stereo images for each position of the motor. The website for the instructable is found here: http://www.thingiverse.com/thing:159981. Dr. Dietz said we are welcome to use his 3D printer to print any parts we need. _________________________________________________________________________________________________________________________________________________________________________________________________________ 2/15/2016 - 2/21/2016 I conducted more research regarding the stereo camera approach for 3D scanning. I read an article by Zhihua Lv and Zhiyi Zhang from Northwest A &F University in Yangling CHina entitled Build 3D Scanner System based on Binocular Stereo Vision printed in JOURNAL OF COMPUTERS, VOL. I also read through chapter 10 from Practical OpenCV (Technology in Action) by Samarth Brahmbhatt. This chapter discusses 3D reconstruction from a stereo camera setup. The technique is mathematically intensive and several pieces sections of code are given to illustrate how one might handle 3D reconstruciton using OpenCV. However, it is far from a DIY guide. Dr. Dietz had mentioned that he would be fine with our team using a DIY guide or online Instructable if we wrote part of the code ourselves and tried to improve upon it. Due to the complexity of the image processing code that our team would need to write, I have reservations about pursuing the stereo camera approach. I found an Instructable that uses an Arduino nano, a stepper motor, laser lines and a camera to make an inexpensive 3D scanner. The team could use the parts provided by Dr. Dietz, a laser line, a stepper motor and an Arduino nano, to build the scanner. The parts would not be the exact parts used by the Instructable I found here: http://www.instructables.com/id/Build-a-30-laser/ but the open source software was written to accept plugins. The team would write the plugins for the webcam provided by Dr. Dietz. I will present the possibility of using this Instructable for our project when me meet n Tuesday, 2/23/2016. _________________________________________________________________________________________________________________________________________________________________________________________________________ 2/22/2016 - 2/28/2016 I worked on the design overview describing our 3D scanner project. What I wrote follows. With the advent of 3D printing, it is possible to print precision parts, or even toys and artwork at your desk. CAD tools can be used to design these items from scratch but in some cases a replica of an existing part is needed. In order to make a precise replica a 3D scanner is necessary. 3D scanners incorporate one or two cameras and a laser for the single camera option. Our scanner will use a single web camera, a laser, a stepper motor an Arduino Nano, a laptop and printed parts. We also use the source code from the Sardauscan Instructable (found here: http://www.instructables.com/id/Sardauscan-sub-30-Opensource-3d-laser-scanner/) to create our scanner. Our goal is to have a scanner that requires minimal human interaction and is capable of making scans for the purpose of making parts usable by our client, Dr. Dietz. Dr. Dietz explained that his 3D printer is accurate to 100 microns. Therefore, we strive for a scanner that is as close to 100 microns of accuracy as possible. Last, the scanner will scan objects as large as Dr. Dietz’s printer is able to print; that is, about 1 cubic foot. In addition, I worked on the pseudocode for the plugins specific to the hardware we will be using for our project. The team met Sunday 2/28/2016 to work on the design phase and will be ready to discuss the design with Dr. Piwowarski on Wednesday, 3/2/2016. ___________________________________________________________________________________________________________________________________________________________________________________________________________ 2/29/2016 - 3/8/2016 I wrote the pseudocode for the three hardware plugins. __________________________________________________________________________________________________________________________________________________________________________________________________________ 3/21/2016 - 3/27/2016 I downloaded Cura to look at the STL files needed to print parts for our scanner apparatus per Dr. Dietz's suggestion. I alo signed up for Tinkercad so I can design a camera mount for the Webcam. The team met with Dr. Dietz to discuss printing parts and will meet on Tuesday to print them at Dr. Dietz's lab. _________________________________________________________________________________________________________________________________________________________________________________________________________ 3/28/2016 - 4/5/2016 I spent several hours in Dr. Dietz's lab printing parts and discussing the project. _________________________________________________________________________________________________________________________________________________________________________________________________________ |

How to Build a 3D Environment Scanner from Scratch

0Shares

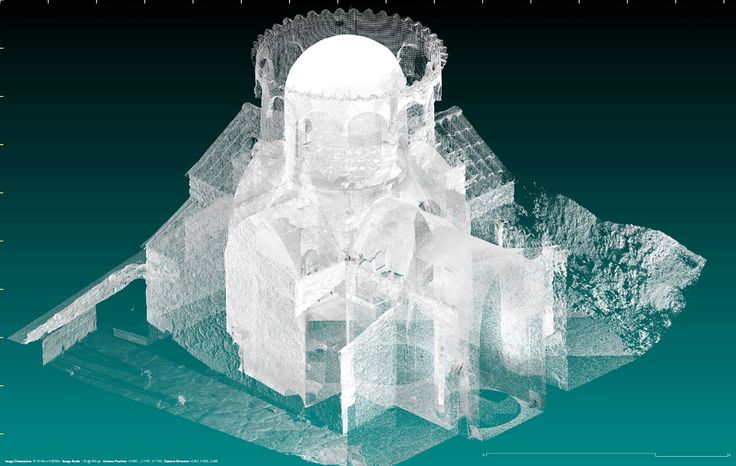

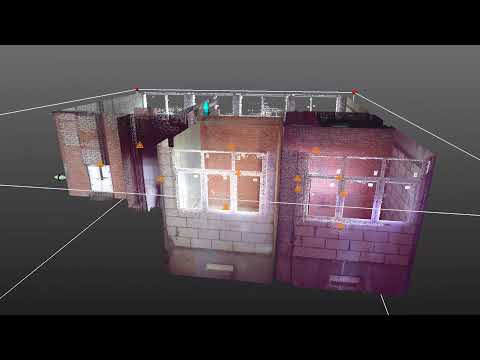

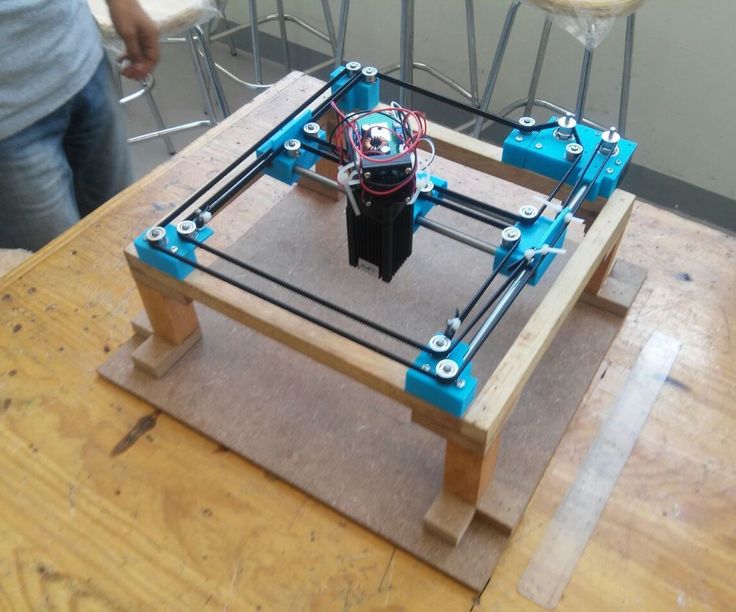

While some 3D scanner companies are working to scale down the cost and size of 3D laser scanners, mechanical engineer Callan Mackay has decided to take matters into his own hands. Mackay, a graduate from Scotland’s Heriot Watt University, has taken onto Instrutables.com to show how to build an affordable and functional 3D Laser Scanner. Mackay’s DIY scanner is capable of scanning both indoor and outdoor environments, and seems to offer some big capabilities for a fraction of the usual cost.

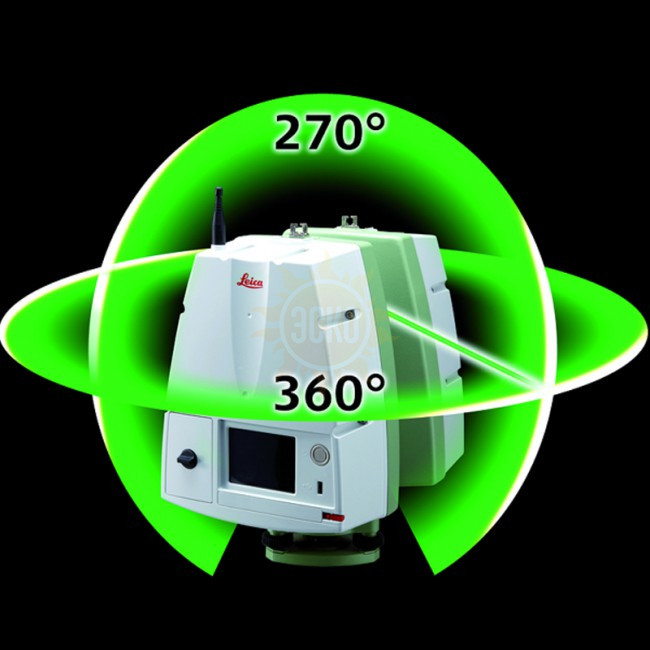

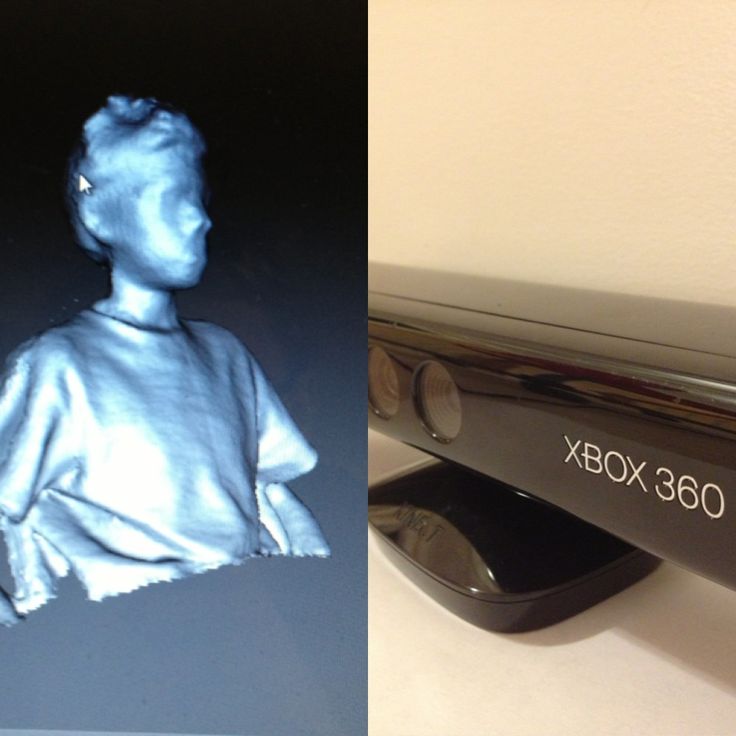

This isn’t the first laser scanner on Instructables; there have been quite a few different iterations ranging in price and quality. But, according to Mackay, there are two major factors that set his scanner apart from the rest. First, his does not utilize any 3D scanning software whatsoever and, instead, uses Arduino and Processing. Secondly, as opposed to other scanners that generally use a turntable mechanism to scan relatively small objects, Mackay’s 3D scanner turns both the camera and the laser, allowing for a 360 degree capture. Mackay claims that this feature makes his the ideal advice for video game setting design or even full-body and facial scanning.

Depending on what source you go through to buy the necessary parts, Mackay estimates that, in order to fully build the 3D Laser Scanner, it will cost you just around £20 to £30 for the parts that Makers may not already own. Here is the full list of materials, electronics, tools, and programs needed to complete the project yourself.

Materials required:

- External webcam

- Line laser module

- NEMA 16 Stepper motor and pulley

- Timing belt (~10cm)

- L-shaped bracket

- Terry tool clip (9mm)

- 3 x AA battery pack

- Tripod

- Some strips of wood

- Nuts and Bolts

- Screws

- Zip ties

Electronics Required:

- Arduino Uno

- 16×2 LCD screen (optional)

- 2 x Potentiometers (optional)

- Stepper motor Driver (A4988)

- 12v Power supply

- 100uF Capacitor

- Jumper wires

- Breadboard

- 4 x Screw terminal block connector

Tools Required:

- Drill

- Wood saw

- Screw driver

- Wire clippers

Software Required:

- Arduino

- Processing 3.05b

Aside from the lengthy, yet moderately affordable component checklist, there is a lot of drilling, fastening, and cutting involved with the build, so the project definitely seems to require a certain level of handy experience. But for those feeling capable or ambitious enough, Mackay is satisfying both the visual and textbook learners by providing full step-by-step instructions in both on YouTube and in text via Instructables. Mackay’s 3D Laser Scanner project has been submitted into the 2016 Full Spectrum Laser contest, so if you think his project is worthy of recognition, you can throw his entry a vote here!

But for those feeling capable or ambitious enough, Mackay is satisfying both the visual and textbook learners by providing full step-by-step instructions in both on YouTube and in text via Instructables. Mackay’s 3D Laser Scanner project has been submitted into the 2016 Full Spectrum Laser contest, so if you think his project is worthy of recognition, you can throw his entry a vote here!

Tyler Koslow

Tyler Koslow is a Brooklyn-based writer for 3D Printing Industry, and has also produced content for publications and companies such as Dell, Brooklyn Magazine, and Equity Arcade. His content is focused on a wide range of topics including tech, gaming, and music . Tyler is also a habitual instrument player, a writer of fiction, and generally all around fun haver. Tyler received a Bachelor’s degree studying English-Creative Writing at the University of Central Florida in 2008.

04/16/2021

Content

-

- What is 3D scan and why it is used by

- How 3D scanner

- 3D scan technologies

- Methods 3D

- Contact 3D scanners

- Non-contact 3D scanners

- Types of 3D scanners according to the principle of use

- Advantages and disadvantages of 3D scanners

- Things to consider when choosing a 3D scanner

- Applications

Currently, few people are not familiar with such a concept as 3D printing. Many companies are using modern 3D printers with might and main, recreating layouts of various shapes and sizes with their help. There are also those that recreate whole objects - not only small ones (for example, phone cases, souvenirs, sneakers), but also large ones (houses, engine parts, etc.). But all this would not be possible without 3D scanners. It is they who allow you to accurately copy almost anything - from huge buildings and structures to humans, animals, small objects and much more. nine0003

nine0003

What is 3D scanning and what is it used for

Three-dimensional scanning is a technology that appeared in the 60s of the 20th century. It was created in order to transfer the physical parameters of the object into a digital format in the form of a three-dimensional model. The need for this naturally arose when people around the world increasingly began to use computers both in everyday life and in production.

The first samples of 3D scanners were quite simple and did not have wide functionality. Gradually, they became more complex and improved, making it possible to achieve an ever clearer image of the object. This has become especially relevant with the advent of lasers. nine0003

3D scanners allow you to transfer object data into digital format

3D scanning has opened up new opportunities in various areas of human activity - from the automotive industry and the military industry to design, medicine and cinema.

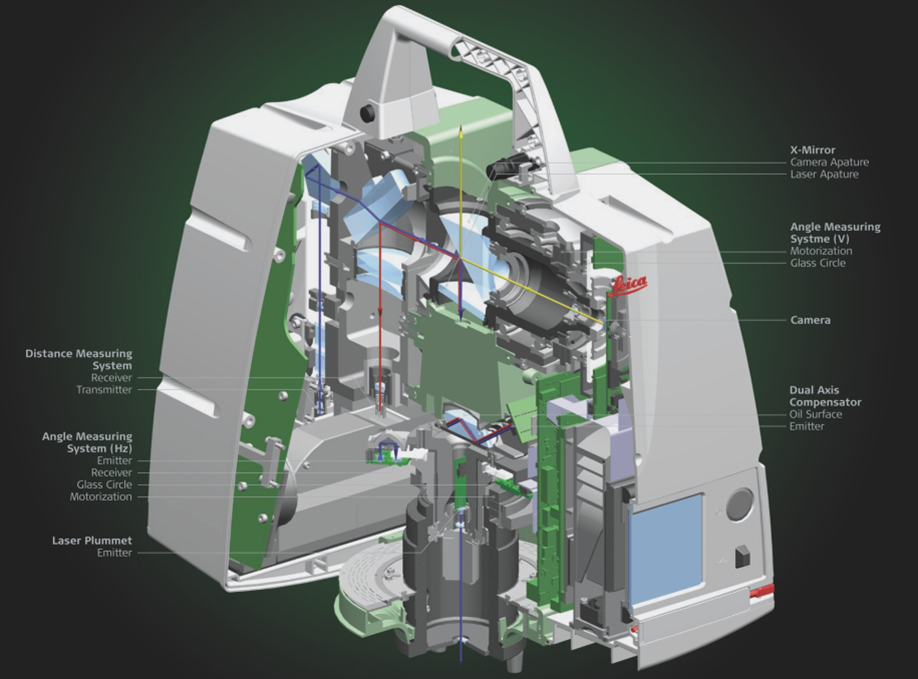

How a 3D scanner works

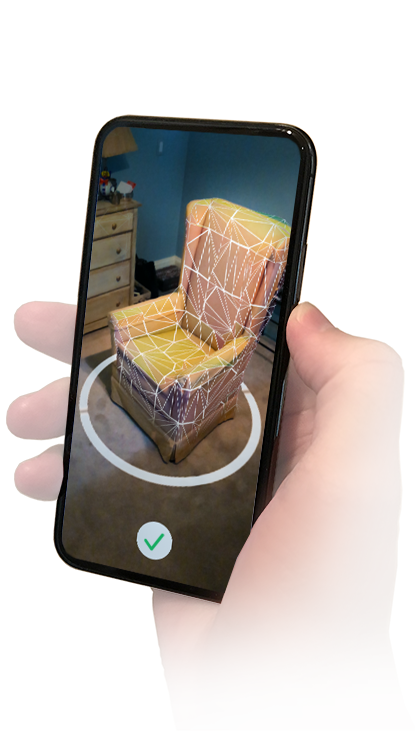

A 3D scanner is a device that examines an object by digitizing it using sensors and using the information received to create a three-dimensional model. In fact, a 3D scanner creates a digital copy of a physical object of any configuration and complexity. In this, it fundamentally differs from its predecessors - conventional scanners that can only read information from documents and photos. nine0003

The scanning process itself can take place in different ways - depending on the type of 3D device and the technology used, as well as on what object you want to process with it - moving or static.

3D Scanning Technologies

There are 2 main types of 3D scanners - laser and optical. Their fundamental difference lies in how and with the help of what the “removal” of data takes place. Let's take a closer look at both.

Laser 3D scanning, as the name implies, uses a laser and can be carried out both at short and long distances from the object. nine0003

nine0003

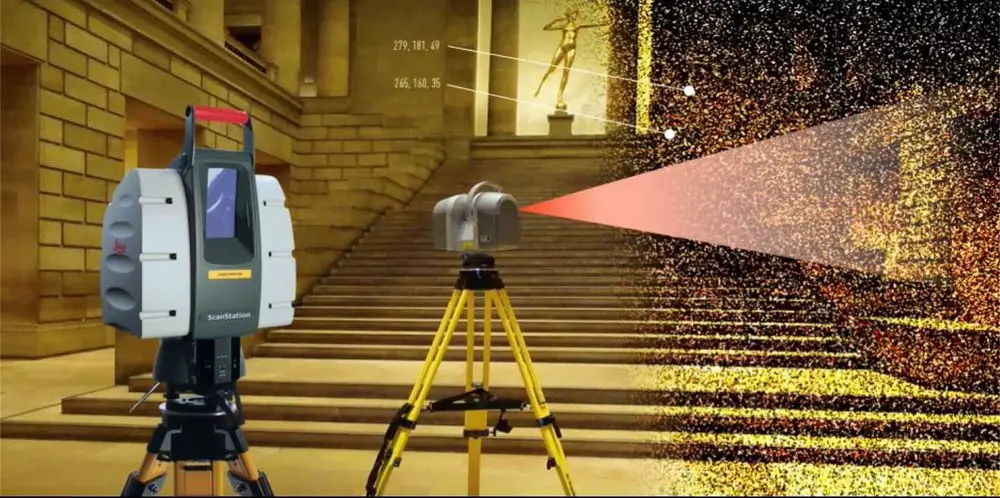

Laser Scanner

For the most part, 3D laser scanners work on the principle of triangulation, when the camera finds a beam on the surface of an object and measures the distance to it, after which a cloud of points is created, each of which has its own coordinates in space, and a 3D model is built. Their "advantages" are affordable price and ease of use combined with high scanning accuracy. Of the "minuses" - there are restrictions on the remoteness and size of the object. nine0003

Another type of laser scanner works by measuring the response time of a beam from the surface of an object - the so-called laser range finder. They are widely used where it is necessary to create 3D models of various buildings and structures. It is not advisable to use them at short distances, since in such cases the response time is very short and the accuracy of the data is reduced. Otherwise, this type of scanner is characterized by high scanning speed and the ability to read all the details. nine0003

nine0003

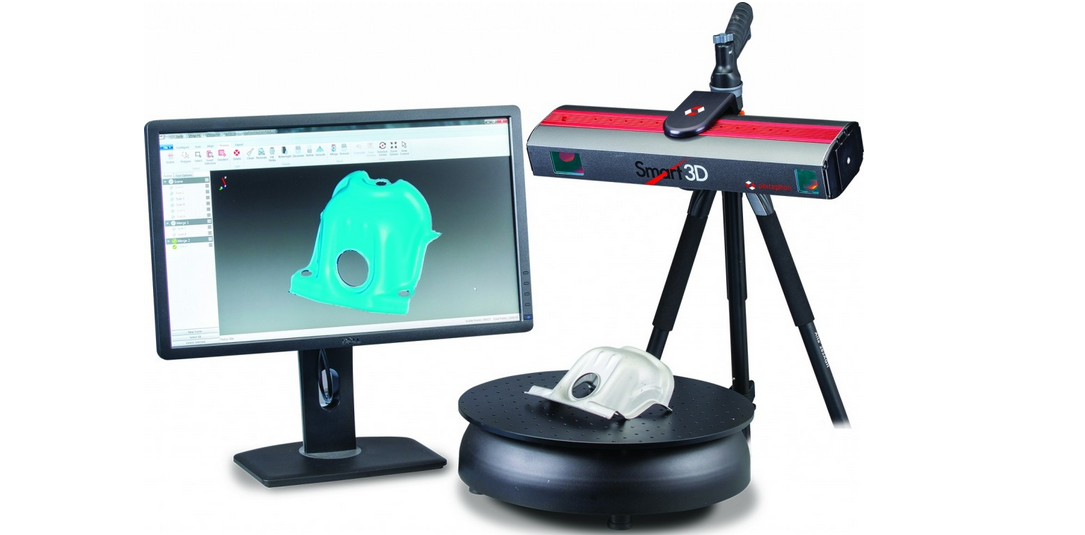

The disadvantage of laser scanners is the impossibility of their use on moving objects. Then optical 3D scanners come to the rescue, which shoot with one or more cameras from different angles an object illuminated by a special projector. Based on the received image, a three-dimensional image is built.

Optical scanner

A "contraindication" for the use of this technology are reflective and translucent surfaces - shiny, mirror or transparent. But when scanning a person, they are simply irreplaceable. nine0003

3D scanning methods

Any object can be digitized both by contact and non-contact methods. In the first case, active interaction with the subject is necessary, in the second, accordingly, no. Both of these methods have their advantages and disadvantages.

Contact 3D scanners

They have a mechanical probe with a special sensor that measures parameters and transmits the collected information to the device. To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

To do this, the object under study is placed on a special surface and fixed (if necessary). Such tight physical contact makes it possible to determine and then build a 3D image as accurately as possible, however, there is a small risk of damage to the prototype. nine0003

Non-contact 3D scanners

This category includes all devices capable of scanning at a distance. This is especially true for objects located in hard-to-reach places.

Non-contact 3D scanner

A stream of radiation (it can be ultrasound, light, X-rays or a laser) is directed to the object and reflected from it, it is recognized by the 3D scanner. They are similar in principle to a video camera and may require the use of additional devices for better lighting. nine0003

Non-contact 3D scanners come in 2 types:

-

Active - work with the help of a laser beam or structured light directed at an object, which, when reflected, give information about the location of the object in the form of coordinates.

-

Passive - use time-of-flight rangefinders that read the time and distance that the laser beam travels to the object, and so - for each point in space, which ultimately allows you to accurately recreate its three-dimensional image. nine0003

Desktop 3D scanners are very popular and widespread, since they are mostly simple and safe to use, do not require any special technical skills and are quite cheap. The EinScan-SE 3D scanner is one such example. It can be used both at home and in the office. It has access to the API of many popular 3D printers, which makes it possible to immediately print the created three-dimensional model.

Add to compare

Product added to compare Go

| Manufacturer | Thor3D |

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Types of 3D scanners according to the principle of use

There is also a variety of species here. Let's highlight the main ones:

Let's highlight the main ones:

- nine0002 Manual: The are handy and simple models that are easy to use as they are quite compact and do not require special skills. True, their technical capabilities may be somewhat limited.

-

Portable: are mainly used for field work, they are convenient to take with you.

-

Desktop: have extended functionality and are used to create high-quality 3D models. Most often used in offices. nine0003

-

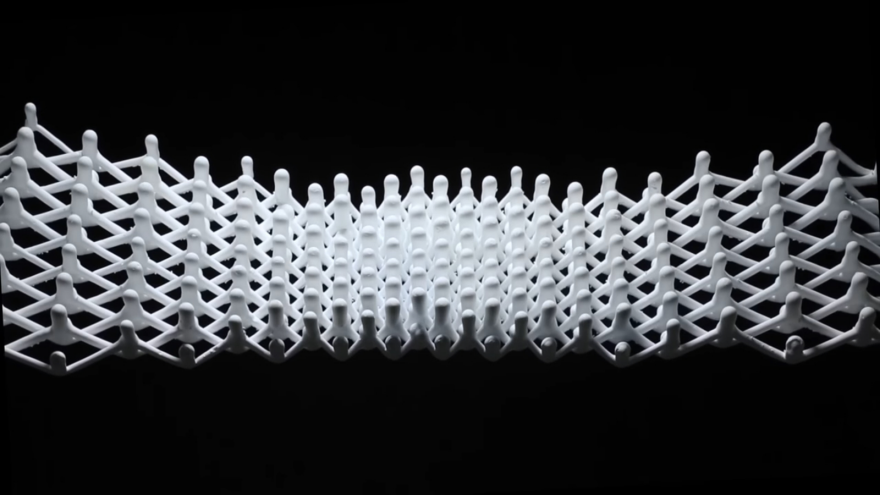

Stationary: are used, as a rule, in production, various enterprises, as they can scan a large number of objects of the same type at once. Mounted on special turntables.

Handheld 3D Scanner Calibry

Such a choice of products allows you to select the right model for a specific task. In some cases, scanners independently measure objects, in others - with the help of a person who sequentially moves the device until all the necessary information is collected. nine0003

nine0003

Such options for hand-held 3D scanners as Calibry are in high demand among buyers. Despite the apparent simplicity of execution, it has a high resolution and scanning accuracy, due to which it is able to digitize objects with a length of 0.2 to 10 meters. Objects that have a non-standard surface - dark or shiny, with a large number of corners and small details will not become a problem either. Among other things, its undoubted advantage is its low weight, only 900 grams. nine0003

Advantages and disadvantages of 3D scanners

Surely, many of the potential buyers are wondering: do you really need a 3D scanner to invest a lot of money in it? What can this acquisition give and will such an investment be justified?

3D scanning has become an integral part of any modern manufacturing process

In order to understand how much you need this equipment, we will list its advantages and disadvantages. nine0003

Benefits:

-

They make it possible to scan objects located at a remote distance and in places inaccessible to the presence.

-

They have the ability to "read" not only colors and images, but also to convey the texture of the surface.

-

Significantly speed up the process of "taking" data from any object, even a very complex one with a large number of planes. nine0003

-

A variety of models allows you to choose the most convenient version of the scanner, including manual or portable, which can be easily taken with you.

Weaknesses:

-

Some scanners are unable to recognize transparent or black and white objects. In this case, their preliminary preparation (treatment with a special composition) is required. nine0003

-

I do not always display complex objects correctly, with a large number of inserts and partitions.

-

To obtain a high-quality result, they require skills and abilities to work with certain computer programs for creating 3D models.

-

If the rules of operation are constantly violated, it may become necessary for expensive repairs to the equipment. nine0003

If you need high-precision and high-quality three-dimensional copies of objects, then you cannot do without a 3D scanner. It makes it possible to work in almost any conditions - indoors and outdoors, and with any objects by type and size. It is not surprising that now these devices are in great demand, which gives rise to the annual release of a large number of models, from which you can always choose the one that suits you in terms of quality and price.

What to consider when choosing a 3D scanner

The computer equipment market offers a huge amount of all kinds of equipment, including devices for three-dimensional scanning. Navigating that variety is sometimes not at all easy: some buyers are only concerned about the cost, others are interested in the number of options (sometimes completely useless), but the most far-sighted look at the ratio of the first and second.

Choosing the right 3D scanner is a big deal

It is not always easy to take into account all the technical points that can significantly affect what result will be ultimately achieved. We will tell you what you should pay attention to if you are thinking about buying a 3D scanner.

Focus on the following parameters:

-

How high is the accuracy of the 3D scanner. This is one of the most important features. It needs to be targeted first. nine0003

-

Resolution also plays an important role. It follows from the first, since the accuracy of measurements and the quality of copying depend on the resolution.

-

In what range the device operates, how close / far it can be from the scanned object.

-

The scanning field is the parameters of that object, thing that it is able to process in 1 session. nine0003

-

Does the scanner capture various atypical types of surfaces with complex terrain - channels, partitions, holes, etc.

).

). -

Portability, mobility of the device - how easy it can be moved if desired, taken with you, its size.

-

The time it takes to prepare for work, as well as the duration of the digitization process itself. nine0003

-

The range of possibilities in terms of copying: are there any restrictions on shapes, textures, material, as well as operating conditions - temperature, light, etc.

Of course, the better the quality of the 3D scanner, the more expensive it is. However, you should focus primarily on the tasks that you face, and only then take into account everything else.

Applications

Three-dimensional scanners are in demand in many areas of human life. They are irreplaceable both in the industry, and for household needs. The range of their application is so wide that it is possible to list for a very long time. It's easier to say where they are not needed.

The most common areas of use are, of course, medicine, industry, architecture, construction, film industry and design.

For example, in dentistry, these devices allow you to create ultra-precise three-dimensional models of dentures. One type of such a scanner is Shining 3D's AutoScan DS-EX PRO, which does a great job with a variety of tasks while being quite affordable and reliable. nine0003

Medical 3D Scanner

In engineering, such technologies are also indispensable. Digital building prototypes are now much easier and faster to obtain than in the past, when it required multiple manual measurements and then entered into a database. Any physical object can now be recreated in three-dimensional form, moreover, in the shortest possible time and with a minimum error.

In cinemas, we can see with our own eyes "revived" fantastic characters, which were created using motion capture technology, which made them as realistic and impressive as possible. This would not have been possible without 3D scanners.

A few decades ago, it was even difficult to imagine all the things that we use all the time today. And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning. nine0003

And in many ways this has become achievable thanks to three-dimensional digitization. This approach provides huge advantages in work (especially for technical specialists - engineers, designers, designers), however, in order to use them to the maximum, it is also necessary to understand computer programs for 3D scanning. nine0003

We will talk more about this topic in one of our next articles. And if you want to know more about it, stay tuned.

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data. nine0003

Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data. nine0003

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

In comparison with traditional methods of measurement, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas. nine0003

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building project, it is necessary to assess the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies. nine0003

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships. nine0003

The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships. nine0003

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents. nine0003

The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents. nine0003

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry. nine0021

Overview of Models and Manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is part of the pool of popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects. nine0003

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0. 35 km. The device is designed for outdoor use.

35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features. nine0003

Main parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz. com

com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects. nine0003

Main Features:

Composite Series

Source: twitter.com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduced financial and time costs in construction with the help of FARO Focus

Source: autodesk. com

com

US construction company Gilbane invested $60,000 in the purchase of a FARO Focus-S 350 laser scanner, software and employee training. At first glance, the amount seems too large for a small-scale firm. But, after the calculations, the company's management came to the conclusion that the investment will pay off in the shortest possible time. nine0003

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar. com

com

At the time of the start of work, the architects had at their disposal drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning. nine0003

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production. nine0003

nine0003

Having understood the problems of the manufacturer, ScanTech experts proposed to check the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode. nine0003

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech. com

com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort. nine0003

Using FARO 3D Scanners on Justin Timberlake's World Tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air. nine0003

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www. esa.int

esa.int

Considering the limited preparation time, the large surface areas for displaying the image, and the corresponding need for high image resolution, it was not possible to create visual effects in a short time without using the chosen technology. nine0003

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+). nine0043 ScanTech: KSCAN20 PRINCE 775 PRINCE 335 The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production.

The book is entitled Practical OpenCV (Technology in Action) by Samarth Brahmbhatt. I rented the Kindle version of this book from amazon.com for the rest of the semester.

The book is entitled Practical OpenCV (Technology in Action) by Samarth Brahmbhatt. I rented the Kindle version of this book from amazon.com for the rest of the semester. 7, NO. 2, FEBRUARY 2012. The article is found here: http://www.jcomputers.us/vol7/jcp0702-13.pdf. This article explores the technique of 3D scanning using a stereo camera setup with a single laser. The mathematical methods used to calibrate the camera and match points from the two separate cameras are discussed here.

7, NO. 2, FEBRUARY 2012. The article is found here: http://www.jcomputers.us/vol7/jcp0702-13.pdf. This article explores the technique of 3D scanning using a stereo camera setup with a single laser. The mathematical methods used to calibrate the camera and match points from the two separate cameras are discussed here.  In fact, in the teams conversations with Dr. Dietz, he made it quite clear that this approach might prove too challenging. However, he also said he didn't want to tell us not to pursue this design. Given the amount of time the team has to produce a working scanner and the learning curve for OpenCV, I think using following and improving upon an instructable would be more realistic.

In fact, in the teams conversations with Dr. Dietz, he made it quite clear that this approach might prove too challenging. However, he also said he didn't want to tell us not to pursue this design. Given the amount of time the team has to produce a working scanner and the learning curve for OpenCV, I think using following and improving upon an instructable would be more realistic.

We will write the plugins for the specific hardware we use (stepper motor, lasers and webcam) to interface with the Sardauscan source code.

We will write the plugins for the specific hardware we use (stepper motor, lasers and webcam) to interface with the Sardauscan source code.  The plugins are for the specific camera, laser and stepper motor we will use. In addition, I met with Ryan and Layne to wrap up the high level design.

The plugins are for the specific camera, laser and stepper motor we will use. In addition, I met with Ryan and Layne to wrap up the high level design. In addition, the team met to discuss and create a testing plan. We will use stub programs to simulate the hardware output to the core program. That way we can do some testing before our plugins are actually coded. Once that is complete, we will finish coding our plugins.

In addition, the team met to discuss and create a testing plan. We will use stub programs to simulate the hardware output to the core program. That way we can do some testing before our plugins are actually coded. Once that is complete, we will finish coding our plugins.