Elfin resin 3d printer

Nova3D Elfin 3D printer review: A decent printer with software issues

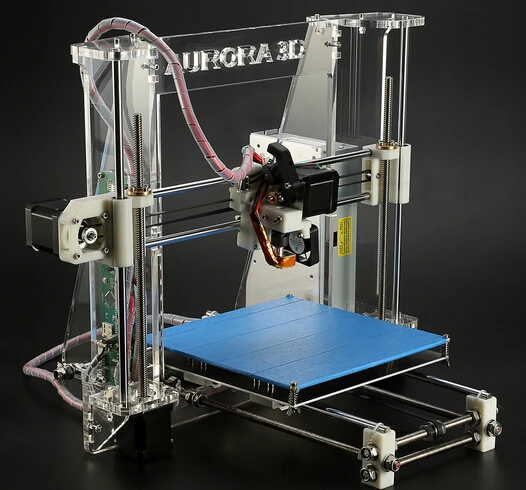

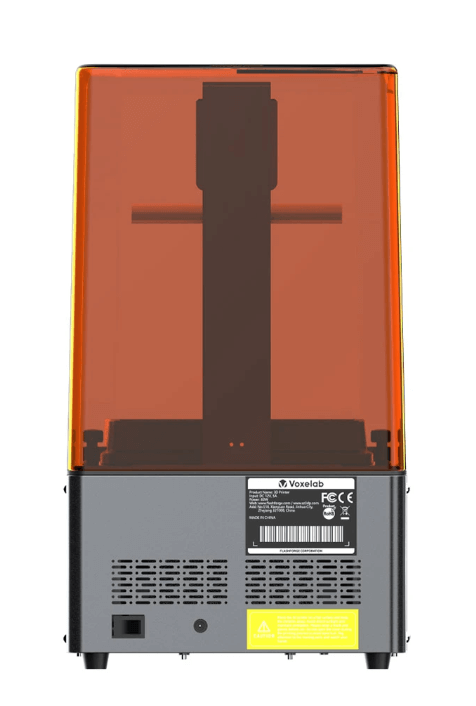

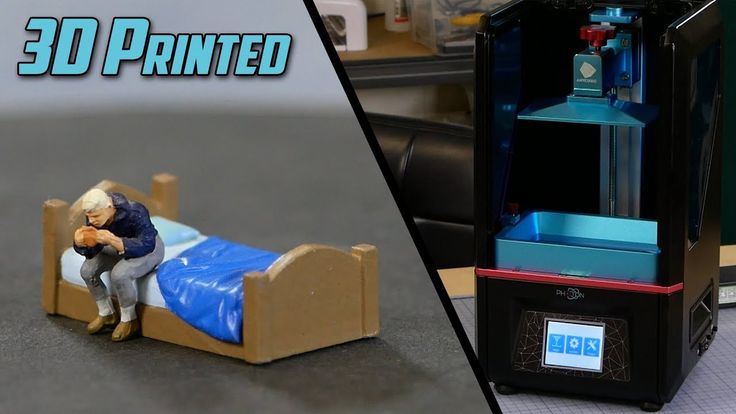

Source: Windows Central/James Bricknell (Image credit: Source: Windows Central/James Bricknell)Small, cheap resin printers have exploded onto the 3D printing scene in 2019. These printers have relatively small print areas but can print with incredibly accuracy and quality. The Elfin by Nova3d is one such printing trying to find its place in this exciting new market, and while it is similar to other resin printers in a lot of ways, it has some fun tricks to help it stand out from the crowd.

About this review

Nova3D sent me over one of its printers for me to have a look at and for me to give you my unbias review. I've been using it for several weeks now and I've printed several bottles of resin on it already.

Elfin resin printer

$360 Bottom line: The Nova3D Elfin is a decent resin printer in a market of decent resin printers. It does what's needed with a few nice touches, but the software lets it down in a big way.

For

- Connected every way you want

- Superb locking system for VAT

- Stable print bed. Level once and forget.

Against

- The software is the worst

What you'll love about the Elfin 3D printer

Source: Windows Central/James Bricknell (Image credit: Source: Windows Central/James Bricknell)Several of the features that the Elfin comes with are extremely helpful. The build area, for example, doesn't need aligning. The whole plate is incredibly sturdy, and after the initial calibration, the prints have no problem sticking to the bed. With even the most expensive printers, I have often have issues with the build plate becoming wonky over time. With the Elfin, that just isn't a thing you need to worry about unless you move it.

The locking mechanism for the vat is another helpful little edition. Instead of locking screws on either side, that can damage the LED screen if you are not careful, the Elfin has sliding locks that grip the VAT to the base. This makes removing the VAT with gloves on a breeze and reduces the uneven level that can happen with screws. It's a quick-release system that I much appreciate.

This makes removing the VAT with gloves on a breeze and reduces the uneven level that can happen with screws. It's a quick-release system that I much appreciate.

Source: Windows Central/James Bricknell

The print quality, when it works, is as good as you would expect from one of these printers. The Capricorn by Loubie3D was printed at 0.03mm layer height is flawless. Each scale is lovingly recreated in the Siraya Tech fast resin — a quick review of the resin; it's fantastic, and you should buy some today! — and the details along the horns are practically perfect. You can see from the Steampunk Octopus that comes as a test print that the details are spot on, and the Elfin had no trouble printing the articulated legs, something that can be tricky for resin printers.

The last thing that makes the elfin stand out is the range of connectivity options. The Elfin allows you to use a USB thumb drive like most resin printers, but it also has both LAN and Wi-Wi connections so you can monitor the progress of your print or send a file from the Novamaker software directly to your printer. Of course, the only issue there is how bad the Novamaker software is.

The Elfin allows you to use a USB thumb drive like most resin printers, but it also has both LAN and Wi-Wi connections so you can monitor the progress of your print or send a file from the Novamaker software directly to your printer. Of course, the only issue there is how bad the Novamaker software is.

What you'll dislike about the Elfin 3D printer

Source: Windows Central/James Bricknell (Image credit: Source: Windows Central/James Bricknell)Most modern resin printers have found a program that works for most of the population. Like Cura for FDM printing, Chitubox has become the gold standard for preparing 3d models for resin printing. Unfortunately, Nova3D uses a file extension that is only compatible with Chitubox with an extension, and that extension is not always successful in converting the files. Why not just use the Novamaker software supplied by Nova3D? Well, it's limited in what it can do and is less intuitive than Chitubox, and that slows everyone down.

Novamaker does allow you to send your sliced file directly to the printer over Wi-Fi, but it's missing the ability to hollow. Hollowing is one of the essential skills to learn for resin Printing as it saves you a lot of resin, as well as helping ensure a successful print. Without that function, I am forced to hollow in Chitubox, import the hollowed model into Novamaker, add the supports and slice. This adds a layer of complexity that allows errors to occur.

Hollowing is one of the essential skills to learn for resin Printing as it saves you a lot of resin, as well as helping ensure a successful print. Without that function, I am forced to hollow in Chitubox, import the hollowed model into Novamaker, add the supports and slice. This adds a layer of complexity that allows errors to occur.

The above Baby Yoda by Wekster is a fantastic print typically. Still, when I hollowed it out in Chitubox and sent it over to Novamaker, issues arose in the model that caused the holes you can see in the picture. Now, this may not be Novamaker's fault per se, but because the software doesn't have a way of hollowing — one of the staples of modern resin printing remember — it adds errors into the printing process that just shouldn't be there.

Nova3D either needs to work with Chitubox, like so many other manufacturers are right now, or it needs to up its game and make Novamaker a worthwhile competitor.

Should you buy the Elfin 3D printer?

Source: Windows Central/James Bricknell (Image credit: Source: Windows Central/James Bricknell)I'm torn. While the Elfin by Nova3D is a good printer, I'm not sure it's much better than anything else out there at the same price point. The Elfin is a little more expensive than other big brands, and while the cost isn't the only factor in making a buying decision, it is an important one.

While the Elfin by Nova3D is a good printer, I'm not sure it's much better than anything else out there at the same price point. The Elfin is a little more expensive than other big brands, and while the cost isn't the only factor in making a buying decision, it is an important one.

The additions that come with the Elfin — Wi-Fi connectivity, and the excellent build plate locking, for example — are just enough to tip the scales in favor of buying it from, what I feel, is some pretty shoddy work on the software department. Having spoken to the team at Nova3D, I know they are working on the software, and they are in talks with Chitubox, so we can hope that the software improves in time.

I like the Elfin 3D printer. The triangular form factor is fun and makes it stand out from the other resin printers I have, as do the features I've already mentioned. I think you should buy it, but find it on sale if you can, and be prepared to hollow your prints somewhere else for now.

Cool gadget

Elfin 3D printer

Fun extras hampered by bad software.

The Elfin creates beautiful prints at a reasonable price. Sure, the software is a mess, but the print quality and extras make up for it.

James built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.

eSUN High Precision PLA PRO Resin for LCD 3D Printers - Black (0.5kg)

- Home

- Store

- Sale

- 3D Printer Resins

- eSUN 3D Printer Resins

Sale

eSUN PLA Pro resin has been formulated to be a sustainable 3D printing resin. Synthesized from organic sources like corn and straw, just like PLA, eSUN PLA Pro provides a sustainable option for resin printer without sacrificing any of the printing quality you hope to achieve with this manufacturing technology.

Top eSUN eResin-PLA Pro Features:

• Sustainable origin

• High precision finish

• Several colors available

• Balance of hardness and toughness

15% off - use code BESTDEALS during checkout - offer ends 12/31/2022

Remove from wishlist Add to wishlist loading...

Product No. loading...

Notify me when this item becomes available Success You will be notified when ... becomes available. Request A QuoteTo get an instant quote, add everything you need to your cart, and click "Download as quote".

Or use the form below and a MatterHackers expert will contact you within one business day to discuss available discounts, training, and maintenance options.

Product(s)

Email *

Phone

Full Name

Company/Organization

Questions

Success Thank you for your request. We will be in touch shortly. Esun eResin-PLA Pro is the Most Sustainable 3D Printing Resin Available

We will be in touch shortly. Esun eResin-PLA Pro is the Most Sustainable 3D Printing Resin AvailableWhere other 3D printing resins are created from petroleum-based sources, eResin is synthesized from renewable products like corn and straw, just like the PLA you might already be familiar with. This is done without sacrificing the performance and quality you hope to achieve with resin 3D printed parts.

Here are the key features of eSUN PLA Pro Resin:

- Bio-based and low-odor

- High precision - print mechanical parts

- Incredible resolution

- Several color options

- Compatible with RGB and mono LCD resin printers

Rely On Plants, Not Oil

eSUN eResin-PLA Pro was devised as a biologically based resin from the start. Most other resins and plastics begin as oil pulled from deep within the Earth, but eResin-PLA Pro is corn and straw converted to the necessary polyols by eSUN for regular 3D printing use.

- Plant-based

- Low-odor

- Minimized skin-irritant

High Precision and High Quality 3D Prints

Sustainability isn't eResin-PLA Pro's only quality, its high precision and supreme surface finish makes is an excellent choice for any ornate and decorative products or functional mechanical parts.

- Easily capture small details

- Low shrinkage for precise features

- High toughness for post-processed 3D prints

Compatible with RGB and Mono LCD printers

With the advent of monochrome LCD 3D printers, it's become harder and harder to find resin compatible with RGB LCD screens. eResin-PLA Pro has been tested to work with many RGB MSLA 3D printers with some slight tweaks to print settings

- Exposure Time

- Mono LCD: Up to 4 seconds

- RGB LCD: Up to 14 seconds

- Printing Speed:

- Mono LCD: 10-15mm/h

- RGB LCD: 40-60mm/h

- Lower cost makes it easy to experiment

TECHNICAL SPECIFICATIONS

- Color: White

- First Layer Exposure Time: 30 - 60 seconds

- Normal Layer Exposure Time: 2 - 8 seconds

- Storage Temperature: Between 20°C - 30°C (68°F - 86°F)

- Type of Container: Black plastic bottle

- Container Dimensions (Approx.

):

): - Weight: 500g

- Size: confirm with inventory

- Compatible with most LCD/MSLA and DLP Resin 3D Printers

- Download the Safety Data Sheet

| SLA Resin 3D Printer | 0.05mm Layer Cure Time | Bottom Layer Cure Time |

|---|---|---|

| Elegoo Mars 2 Pro | 3.5 | 40 |

| Elegoo Mars 2 | 3.5 | 40 |

| AnyCubic Photon Mono X | 3.2 | 38 |

| AnyCubic Photon Mono 4K | 4.5 | 35 |

| Anycubic Photon Mono SE | 3.5 | 40 |

| Voxelab Proxima 6.0 | 3.8 | 30 |

| Voxelab Proxima 8.9 | 4 | 40 |

| Phrozen Sonic Mighty 4K | 4.3 | 40 |

| Nova3D whale2 | 3.5 | 40 |

| Nova Bene4 Mono | 2. 2 2 | 35 |

| Nova Elfin | 6 | 60 |

| Creality Halot One | 5.5 | 40 |

| Creality LD002R | 8 | 50 |

| Creality LD006 | 2 | 30 |

- Wear protective gear such as nitrile gloves, safety goggles, etc. before handling resin.

- Shake the container of resin well before using it.

- Avoid leaving the resin in a vat unused for more than one day.

- Do not store used resin in the same container as unused resin. Pour used resin from vat into a separate light-proof container.

- Handle resin in a well-ventilated room over protective surfaces like a silicone mat, aluminum trays, plastic sheets, etc. when possible.

- Cure resin under UV light before disposing with regular trash. NEVER dump wet, liquid resin in the trash unless it's being properly disposed of with hazardous waste.

Contact your local hazardous waste facility for further appropriate steps.

Contact your local hazardous waste facility for further appropriate steps.

Your success in 3D printing is our goal, so we have created some guides to help you create the highest quality 3D printed parts possible.

- Photopolymer Resin Safety

- Essential Accessories and Tools for SLA Resin 3D Printing

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

Photopolymer 3D printer: which one to choose | Equipment

Until recently, photopolymer printing was an expensive and inaccessible way to reproduce three-dimensional figures. Only professionals from narrow fields of activity could purchase powerful equipment. Today, with more offerings and lower printer costs, high-quality 3D printing has become more affordable. All equipment on the market can be classified according to the printing method and the raw materials used. Photopolymer 3D printers are especially popular. They are equipped with a high-quality matrix with the most smooth outer surface. Thanks to this, the final products, even the smallest ones, have the correct shape with a detailed drawing. nine0003

Photopolymer 3D printers are especially popular. They are equipped with a high-quality matrix with the most smooth outer surface. Thanks to this, the final products, even the smallest ones, have the correct shape with a detailed drawing. nine0003

Consumables at a glance

Photopolymer 3D printing will require special resins (liquid plastic) that harden when exposed to light. They are sensitive to ultraviolet radiation, which determines the design features of 3D printers. The physical properties of consumables vary widely. After polymerization, they can be hard or flexible, matte or transparent. Consistency, exposure time (curing), colors also vary. Both biologically safe resins and technical options can be selected based on the intended use of the end products. The cost of consumables is quite high, so when choosing equipment, it is worth considering the available range of compatible polymer raw materials. nine0003

SLA Technology (Laser Stereolithography)

Photopolymer 3D printing originated from this technology in 1984. The essence of the process lies in the fact that the curing of raw materials occurs under the influence of a high-precision laser.

The essence of the process lies in the fact that the curing of raw materials occurs under the influence of a high-precision laser.

Design features. The classic model of a photopolymer 3D printer consists of a resin tank, which is located under the platform. It is driven (raised, lowered and rotated) by a special mechanism. In some cases, the cuvette itself is driven. The laser emitter and mirror deflection system are located on the top of the equipment. nine0003

Printing method. During the operation of a laser stereolithographic 3D printer, the platform is immersed in a cuvette with consumable material to a depth of one layer. Due to the rather thick consistency of resins, a leveling mechanism can be used to speed up printing. This is followed by a progressive point process of illuminating the material with a laser irradiator. The direction of the beam in the horizontal and vertical planes is determined by the movement of the deflecting mirror system. Upon completion of drawing and polymerization, the platform is immersed in the cuvette for one more layer, and the process is repeated. This is how the entire digital model is formed step by step. nine0003

Upon completion of drawing and polymerization, the platform is immersed in the cuvette for one more layer, and the process is repeated. This is how the entire digital model is formed step by step. nine0003

Technology features. SLA-3D printers have very high precision and print quality. They are reliable and pretty straightforward to use. In addition, the equipment is compatible with many photopolymer resins on the market.

DLP Technology (LED Stereolithography)

This method of creating 3D models is very similar to SLA technology. The difference is that instead of a laser emitter with a mirror system, a digital LED projector is used. nine0003

Design features. The equipment consists of a glass platform with a vertical Z axis, a photopolymer resin cuvette, a glass substrate and a digital LED projector located below. An important difference between the equipment is the material from which the cuvette is made. It is completely transparent to ultraviolet radiation.

It is completely transparent to ultraviolet radiation.

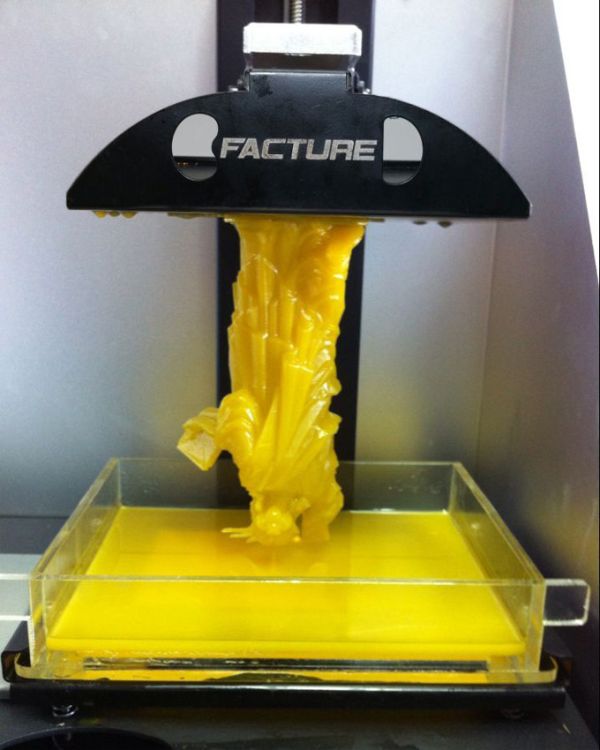

Printing method. With the help of a digital projector, the templates are polymerized at once as a whole layer, and not pointwise, as is the case with SLA equipment. A feature of a photopolymer 3D printer with DLP technology is the ability to invert, or reverse, print an image. In this case, the platform is not immersed in the consumable, but rises along the Z axis, gradually stretching the layers of exposed resin. nine0003

Technology features. Printing objects using LED stereolithography does not take much time. In addition, the absence of a delicate mirror system makes the equipment more resistant to physical impact and has a positive effect on printing accuracy, allowing you to get a higher resolution along the Z axis. The size of the projection and the models themselves can be quite significant in height, since it is not limited by the depth of the cuvette. This allows you to get a more voluminous build area without increasing the dimensions of the printer. During operation of the equipment, unwanted flare may occur, and as the print area increases, accuracy and speed decrease. Consumables are quite diverse and have an affordable cost. nine0003

During operation of the equipment, unwanted flare may occur, and as the print area increases, accuracy and speed decrease. Consumables are quite diverse and have an affordable cost. nine0003

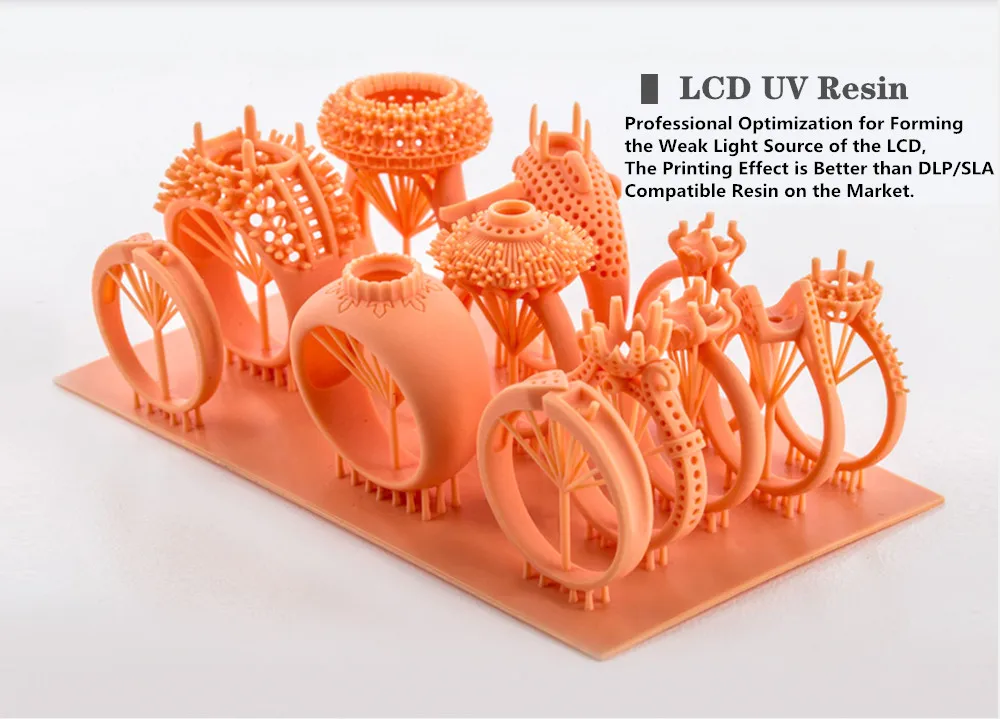

LCD technology (direct ultraviolet illumination)

This method of photopolymer 3D printing is based on the same principles as LED stereolithography. The difference lies in the fact that a special LCD panel is used as the illumination pattern (matrix).

Design features. A transparent resin cuvette is located under the Z-axis glass platform. Next, a matrix (LCD panel) and a Fresnel lens are layered. At the bottom of the equipment is an ultra-bright LED, which provides the resin polymerization process. nine0003

Printing method. Fresnel lens evens out the glow of a powerful LED. The LCD panel inside the equipment creates a white outline of the object and a rich black background. The black color does not transmit powerful radiation, while the white contour is freely illuminated. Due to this, each polymer layer quickly hardens.

Due to this, each polymer layer quickly hardens.

Technology features. The equipment does not contain complex and expensive components (laser sources, moving reflectors), so LCD printing technology is considered the least expensive. The cost of equipment is lower than the price of analogues. The working area of polymerization is limited only by the resolution of the matrix and the dimensions of the equipment. At the same time, a weak illumination force increases the polymerization rate compared to DLP technology. Flare may occur during printing. In addition, due to the features of the formation of the mask, the wall contour can be fuzzy. nine0003

What to look for when choosing

When choosing a photopolymer 3D printer, it must be taken into account that any equipment, regardless of the printing technology, tends to leave some of the original resins in the cuvette upon completion of work. If there is a need to use different raw materials at the same time, in order to reduce their consumption, additional tanks can be purchased. The larger the printable area of the equipment, the higher the resin consumption will be. nine0003

The larger the printable area of the equipment, the higher the resin consumption will be. nine0003

- First you need to decide on the purpose of buying equipment. If semi-professional and professional printing is required, you can consider the middle price segment. Industrial 3D printers are suitable for large-scale polymerization of complex products.

- Based on the printing tasks, the appropriate technology is selected. For smaller and more precise objects, classic high-precision laser stereolithography (SLA) models are suitable. Larger products, the surface of which can be additionally processed, are usually printed on LED stereolithographic photopolymer 3D printers (DLP). For medium-sized objects without complex embossed surfaces, direct ultraviolet illumination (LCD) models can be selected. An important nuance is that in models with SLA and DLP printing, the products are partially cured, which is necessary to maintain their physical shape. Since the complete polymerization process takes a long time, after manufacturing, the models must be subjected to additional irradiation.

To do this, you can use special cameras with ultraviolet lamps or transparent quartz glass boxes exposed to direct sunlight. nine0070

To do this, you can use special cameras with ultraviolet lamps or transparent quartz glass boxes exposed to direct sunlight. nine0070 - An important aspect is the ease of subsequent operation. Modern equipment does not provide a wide choice in print settings. As a rule, it is focused on the manufacture of specific samples. So, if the device is chosen for photopolymer 3D printing of narrow-profile small-sized products, then polymerization of other, larger workpieces can be difficult. The size of the chamber and the compatibility of the source materials come into play here. The degree of automation is also quite important. Features such as automatic resin feeding system, material level sensor, quick-release build platform can greatly speed up and simplify the process of setting up and tracking the print status. nine0070

Today, a wide range of photopolymer 3D printers from different manufacturers is presented on the market, which allows you to choose a model that is suitable for the price and most fully meets the requirements. Our store presents both new models of industrial 3D printers from leading manufacturers, as well as used equipment in good working condition.

Our store presents both new models of industrial 3D printers from leading manufacturers, as well as used equipment in good working condition.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing. nine0001

Contents:

- Introduction

- SLA Overview

- SLA standard resins

- Standard photopolymer resin - Standard

- Clear photopolymer resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility) nine0069 Dental Long Term Biocompatible Resin (Class IIa biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries: nine0003

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning. nine0003

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface. nine0003

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable. nine0003

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes. nine0003

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance. nine0003

nine0003

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips. nine0003

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber nine0003

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping. nine0003

nine0003

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

nine0003

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models. nine0003

nine0003

durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough ( tough ) resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness. nine0003

Heat Resistant Resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity. nine0003

nine0003

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs nine0003

Comparative chart of material properties of various technical resins. Image credit: Formlabs.

Dental and medical resins

Photopolymer resin for medical devices - Custom Medical Appliances 9000 (Bi -1 Bi -1,000) 9000 Class 1 biocompatible resins can be used to make medical equipment such as surgical guides. Parts printed on this resin can be steam sterilized in an autoclave for direct use in the operating room. nine0003

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible) 9017 7 018

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price nine0003

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin nine0003

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds nine0003

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.