Eleven 3d printer

The 3D Printing Eleven - 3DPrinting.Lighting

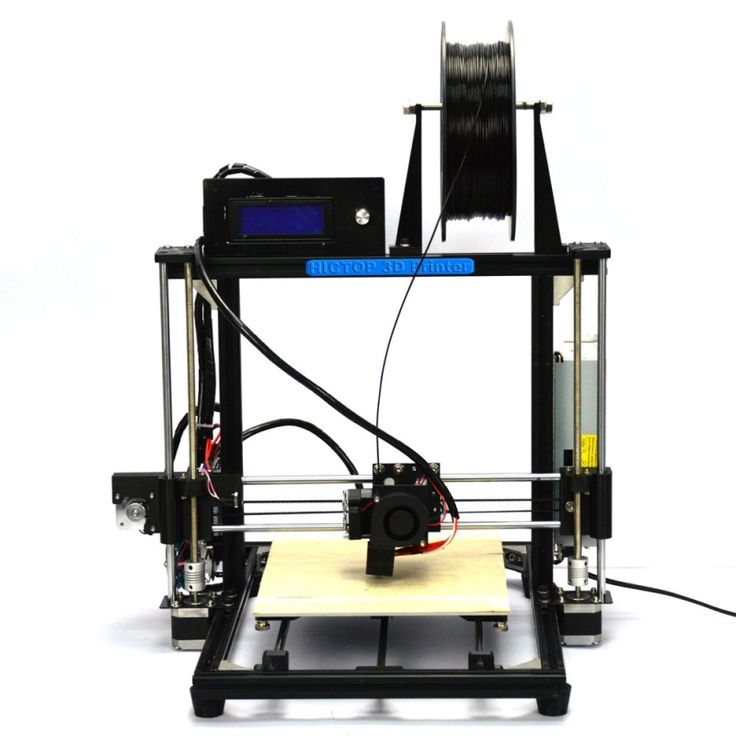

In today’s lighting industry, there’s a shift in focus from purely improving the efficacy of lighting installations towards more intelligent lighting systems. It is however not just the system that’s getting more intelligent and diverse, also the manufacturing process and the overall supply chain in the lighting landscape are rapidly evolving. Huge volumes of identical light modules that foresee in a “generous” lighting need – without bringing a real lighting experience – are no longer accepted. Project customization is key: good lighting for all places. Exactly, this is where 3D printing comes in as an extremely powerful and disruptive tool for anyone working with light.

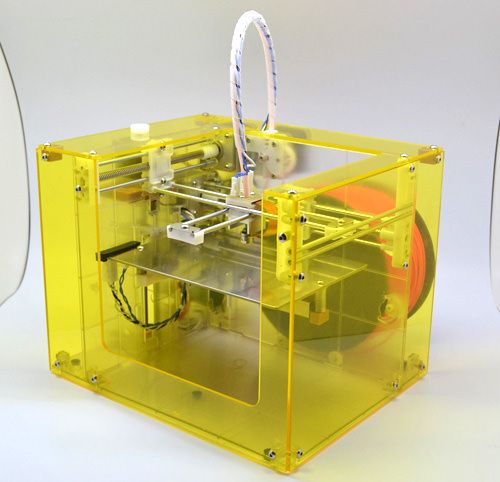

3D Printing: fixed staying & evolving3D printing: you must have heard about it meanwhile. A 21st century digital technology that rapidly evolves, thanks to the on-going digitization. More than 30 years ago, the first 3D printing equipment was already developed and the first print materials became available on the market. The use of this technology however was subject to some early adopters, and the average light professional did have no or very limited access to this groundbreaking technology. Finally, even after the digital revolution took place in the past decade, the technology become more famous, attractive and useful.

The process is quite simple. 3D printing is based on the idea of adding material: building up a product “layer wise”, or for precision manufacturing, even with “droplets-on-demand”, rather than starting with a solid block or sheet of material and then removing the material that you don’t want, such as machining. Using 3D printing equipment today, you can choose from a great variety of materials, such as plastics and metals to create your objects. With having a digital CAD file that specifies the exact shape contours and complexity of the product to be printed, it’s only one step from the digital design process towards the real end-product.

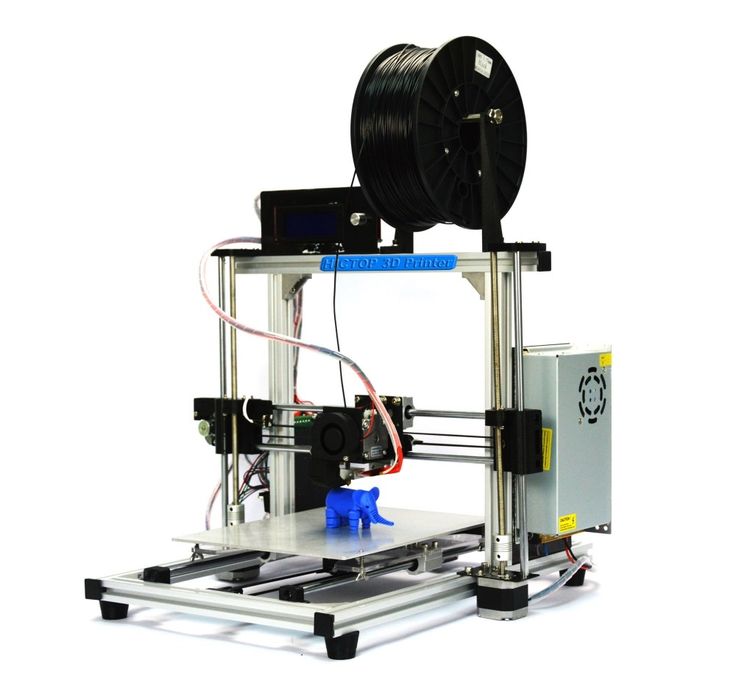

Some high-end, decorative fixture manufacturers are using 3D printing for the past 10 to 15 years already, most for rapid prototyping purposes or to create replacement parts in a fast and affordable way. Especially when speed is crucial in the product development, 3D printing is a wise solution. These initial applications of 3D printing however aren’t the real ‘game-changers’ the lighting industry has been looking for. What has recently changed is that the cost of 3D printers has dropped to a level that individual users and small businesses that are not associated with wealthy traditional lighting manufacturers can now access the technology.

“The 3D Printing Eleven”The 3D Printing Benefits for Lighting Professionals

Hereafter, you’ll find a couple of unique process benefits listed. The individual bullets are worked out in more detail at the underlying pages. Just to understand the unique advantages of 3D printing technology and what it makes it so adorable above conventional ways of manufacturing.

• No Upfront Investments, no MOQ:

With 3D printing, no extraordinary upfront investments in tooling and inventory are required. Ordering only one part is as easy as ordering hundreds or even thousands.

• Greater Product Variety:

Apart from the printer itself, 3D printing only requires a digital CAD file and some raw materials to create an infinite variety of shapes.

• Complexity is Free:

Printing a complex lighting design is no more expensive than printing a simple one.

• Easy Iterations:

Creating and manufacturing multiple product variations is one, making sure they perfectly fit the needs is two. The digital flexibility and the printing speed enable the fabrication of multiple product variations in a short time frame for functional “trial-and-error” testing or “form-and-fit” purposes.

• No Assembly Required:

Traditional manufacturing requires assembling many parts, 3D printing however can print fully assembled end products and significantly reduce labor, handling, supply and shipping cost.

• Short Lead Times:

Products can be readily available: printed “on demand”. With just one step from CAD-file to product, printing a finished product has become as easy as printing just a piece of paper, resulting in shorter cycle times and faster product marketing.

• Unparalleled Design Freedom:

3D printers can print shapes that were never possible before when using traditional manufacturing methods.

• Zero Manufacturing Skills:

Operating a 3D printer requires less skilled operators than traditional manufacturing methods does.

• Reduced Material Waste:

Depending on the materials involved, 3D printing significantly reduce when compared to traditional machining methods.

• Multi-material Applications:

Blending and mixing-up different kinds of raw materials in one run into a single product is now possible in new ways with 3D printing.

• Exact Part Replication:

Digital 3D modeling allows unlimited copying of designs without loss of quality. Similarly, the 3D model/file will not degrade, regardless of how many times the object is being printed.

Similarly, the 3D model/file will not degrade, regardless of how many times the object is being printed.

The most disruptive scenario for 3D printing includes bypassing the traditional luminaire designer, wholesaler or even manufacturer by the end-user. This will occur when end-users start to design and print their own customized luminaires for their projects. Both software and printing solutions arrived at a level that is available for not only high-end professionals, but even small to mid-sized firms as well as home professionals can now permit doing an affordable and effective job.

3D printing: Winning ApproachesFrom now on, our editorial team will intensify posting content and blogging on 3D printing topics that impact the lighting industry and guide you step-by-step through the various printing principles as listed above: “The 3D Printing Eleven for Lighting Professionals”. We’d be glad to explain how 3D printing opens doors to applications you never thought of before, how it eases the manufacturing and optimizes the speed of product development.

We’d be glad to explain how 3D printing opens doors to applications you never thought of before, how it eases the manufacturing and optimizes the speed of product development.

Please stay connected and make sure you won’t miss our upcoming in-depth articles and frequent blog posts!

Eleven best STL files for 3D printing・Cults

VECNA STRANGER THINGS BUST

€3 -50% €1.50

Eleven stranger things

€15

ELEVEN 11 ELECTRO STRANGER THINGS FUNKO POP TOYART

€4.78

ELEVEN 11 HOSPITAL SUIT STRANGER THINGS FUNKO POP TOYART

€4.60

ELEVEN 11 HAND STRANGER THINGS FUNKO POP TOYART

€4.43

ELEVEN 11 WAFFLE STRANGER THINGS FUNKO POP TOYART

€4. 96

96

ELEVEN 11 T-SHIRT BURGUER STRANGER THINGS FUNKO POP TOYART

€4.43

Hellfire Cake Base

€1.09

Round Waffle

Free

stranger things cookie cutters pack

€3.75

Stranger Things Pop Art Demogorgon Wall Art

€1.38

Stranger Things Eleven Halloween coffin tealight

€1.50

Max - Stranger T - Fanart

Free

Steve Harrington Stranger Things

€2.73

Stranger Things Door from the Vecna Creel House

€4.70

Mate - Eleven

€1.64

Eleven Stranger Things

€2. 73

73

Chibi SD x-mas elf christmas cute girl figure

€3.50

BIKE GADGET universal adapter underseat, for all lights

€7

Keychain - Stranger Things - Will

€0.55

Keychain - Stranger Things - Lucas

€0.55

Keychain - Stranger Things - Steve

€0.55

Keychain - Stranger Things - Once

€0.55

Keychain - Stranger Things - Dustin

€0.55

Keychain - Stranger Things - Mike

€0.55

Stranger Things 6-Pack

€1.64

Jonathan Byers Strangers Things

€2. 73

73

Stranger Things panel

Free

Stranger Things Cookie and Fondant Cutter Set with Marker

€4.61

Steve Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Mike Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Max Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Lucas Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Eleven Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Dustin Stranger Things Cookie and Fondant Cutter with Marker

€0.95

Eleven Eleven Stranger Things Silhouette Frame

€3. 55

55

Vecna vs Eleven - Stranger Things

€9.41

Mike - Stranger Things

€4.23

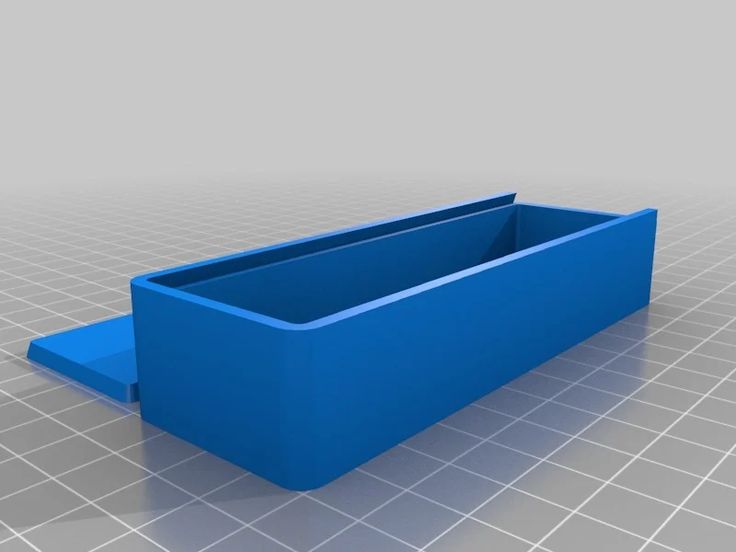

Box 011 Once Stranger Things

€3.55

stranger things cake topper

€0.55

Luminária Stranger Things ( Stranger Things Lamp)

€6.20

Metallica Black Album 3D

€1

Stranger Things Vecna Creel House

€18.69

Cutter/Cookie cutter set stranger things 6 units

€2.82

Funko Pop Eddie Munson Replica Stranger Things Netflix

€15.37

Stranger Things Eleven & Vecna

€6. 30

30

Funko Pop Steve Stranger Things Netflix

€15.43 -50% €7.72

Funko Lucas - Stranger Things

€4.23

Zmorph is the most multi-head 3D printer. Investigation from REC.

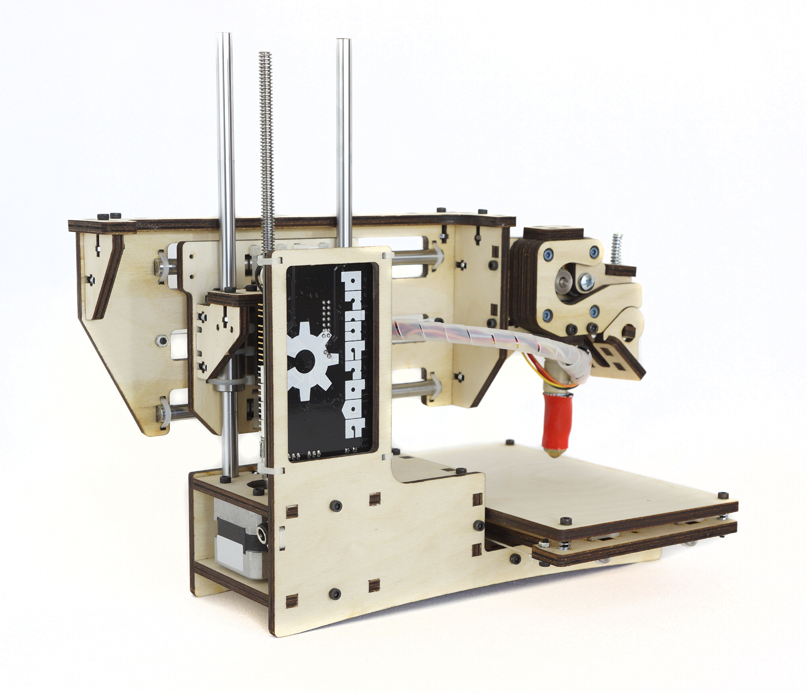

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device. nine0006

1. External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

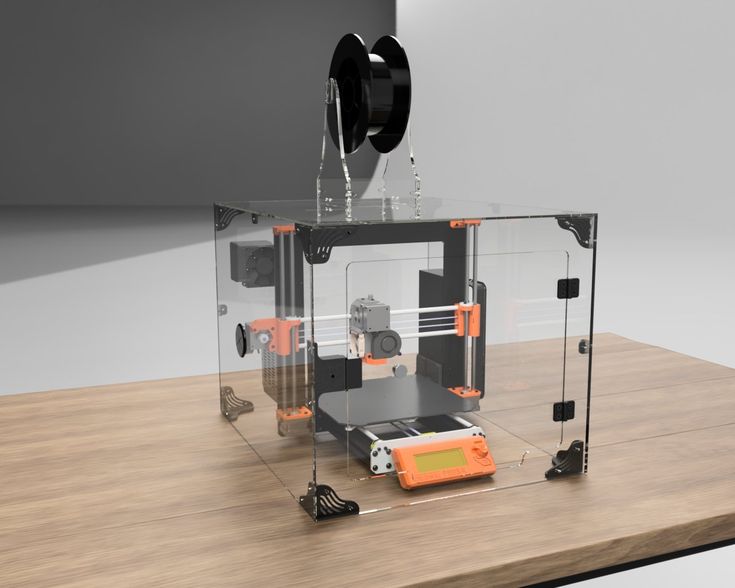

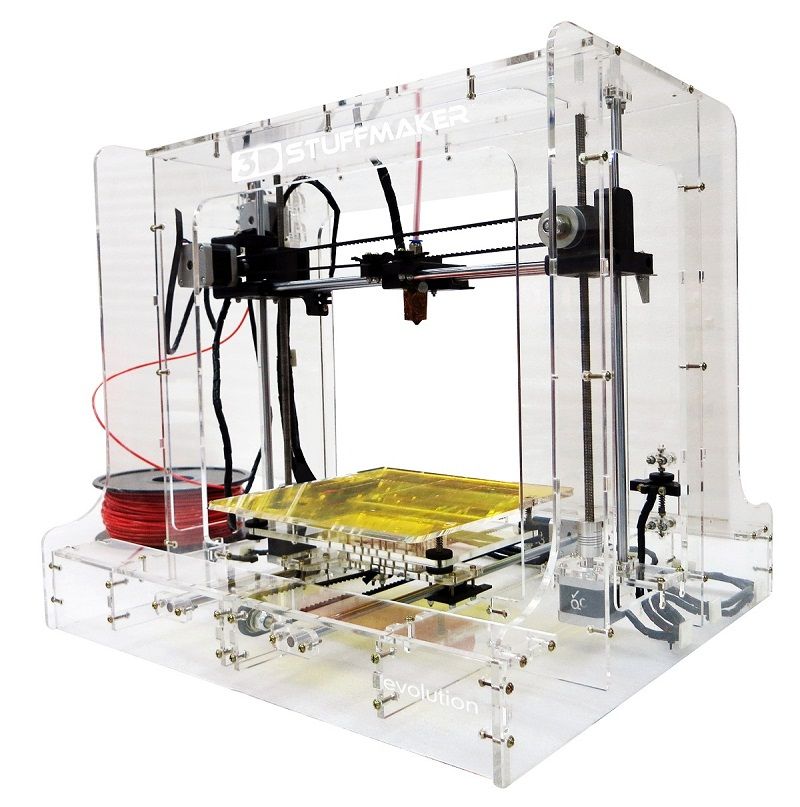

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

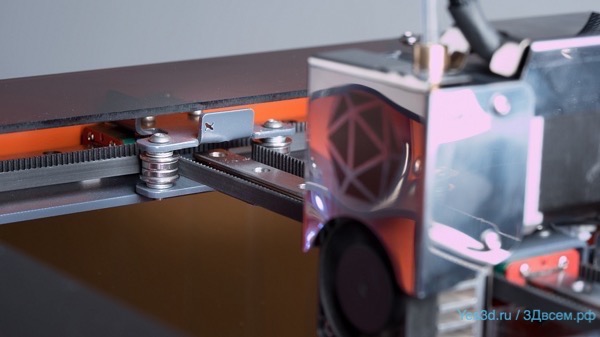

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets. nine0003

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer. nine0003

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

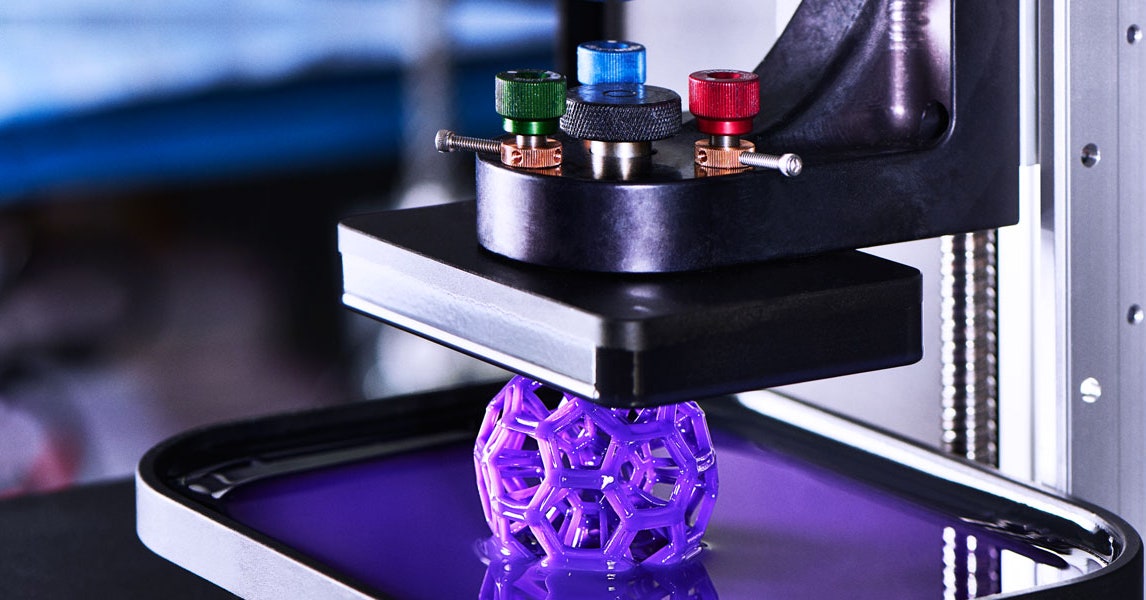

Print.

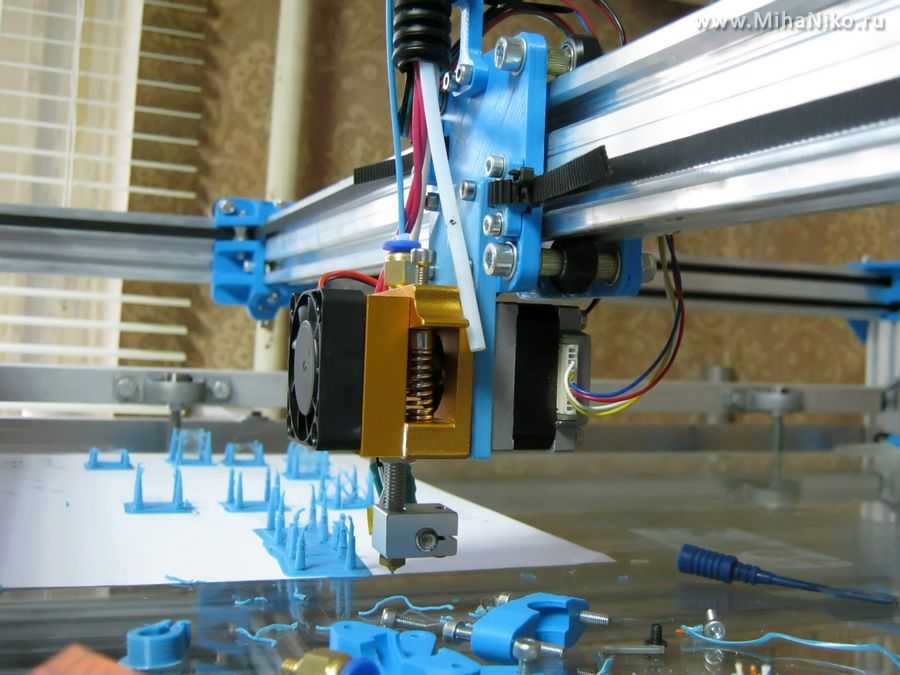

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head. nine0003

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them. nine0003

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program. nine0003

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts. nine0129

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic needed.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website. nine0003

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects. nine0003

Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects. nine0003

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object. nine0003

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social. networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

networks or by mail, we are always ready to answer. And don't forget that we welcome guests in our office.

Website: https://rec3d.ru/Phone: +7 (800) 775-7331 (free of charge from anywhere in Russia)

http://www.viber.com/rec3d https://telegram.me/Rec3d_bot https://vk.com/rec3dcompanyhttps://www.instagram.com/rec3dcompany/Office: Moscow, st. Godovikova d. 9, building 1, entrance 1.19, office 2.3. Technopark "Caliber".

Thank you for your attention and happy printing!

How do 3D printing standards improve the performance of Olympic athletes?

You are here

Home

Some of the Olympic cycling teams competing in Tokyo made extensive use of 3D scanners and 3D printers to customize equipment and fit bike parts exactly to the requirements of the athletes. The teams used 3D printers to make new bike handlebars and chains, avoiding the use of expensive tooling/moulds. nine0003

Application of 3D printing to assist athletes outside of the Tokyo Olympics

To be fair, 3D printing advances are being applied to other sports disciplines as well. For athletes competing in the upcoming Paralympic Games, for example, 3D printing offers an effective way to create lighter and more aerodynamic prostheses, as well as wheelchairs.

For athletes competing in the upcoming Paralympic Games, for example, 3D printing offers an effective way to create lighter and more aerodynamic prostheses, as well as wheelchairs.

Automaker Chevrolet is now actively outfitting its INDYCAR and NASCAR race cars with 3D printed parts including oil tanks, intake manifolds and fuel tank caps. The company uses this technology both at the stage of prototyping and at the stage of final production. London-based Cavendish Imaging is using the technology to produce protective masks that allow athletes with facial injuries (such as a broken nose/cheekbone) to continue playing. Using special software, the company 3D-scans the athlete's face and creates a model, on the basis of which the individual protective mask is printed. nine0003

This innovation reduces the athlete's downtime associated with injury and prevents further injury while healing. The company's masks have already been worn by several professional football and rugby players, including former Chelsea Football Club captain John Terry and footballer Sergio Ramos. Most bicycle helmets are made of foam, which is not completely safe when dropped. HEXR has created a new type of helmet in polyamide 11 (PA 11). The product is made by 3D printing to provide maximum personalization through 3D scanning of the shape of the head and thus increase protection. nine0003

Most bicycle helmets are made of foam, which is not completely safe when dropped. HEXR has created a new type of helmet in polyamide 11 (PA 11). The product is made by 3D printing to provide maximum personalization through 3D scanning of the shape of the head and thus increase protection. nine0003

Another sport supported by the 3D printing industry is surfing. The French startup Wyve is already developing surfboards using this technology, which allows you to create personalized products with an original translucent design. The company produces boards from recycled plastic waste, offering the end user a reliable solution with optimal performance. An original way to combine sustainability and innovation in one project. 3D printing of sports shoes may soon be on the stream. More and more sporting goods manufacturers including Adidas, Nike and Reebok are using the technology in question. A prime example is the Adidas 4D Fusion sneakers. The reason for the growth in the use of 3D printing in this area is again the possibility of personalization. 3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool. nine0003

3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool. nine0003

The value of 3D printing standards

In short, in the world of sports today, 3D printers are being used to produce a variety of objects that improve the performance of athletes: from sneakers and ski boots to surfboards and parts for racing cars. This technology additionally comes to the rescue in case of accidents and injuries.

This technology additionally comes to the rescue in case of accidents and injuries.

International standards have played a decisive role in ensuring the reliability, efficiency and safety of 3D printers and related device components, as well as consumables used in advanced equipment in this category. A number of technical committees and subcommittees make a significant contribution to standardization work. For example, ISO / IEC STK 1, a joint technical committee of the International Electrical Commission (IEC; IEC) and the International Organization for Standardization (ISO; ISO), develops standards on the topic of 3D printing and 3D scanning , including the fundamental standards that form the basis of new documents. nine0003

In addition, a number of IEC technical committees and subcommittees are working to determine the feasibility of preparation, development and harmonization of international standards on electrical and electronic components installed inside 3D printers.