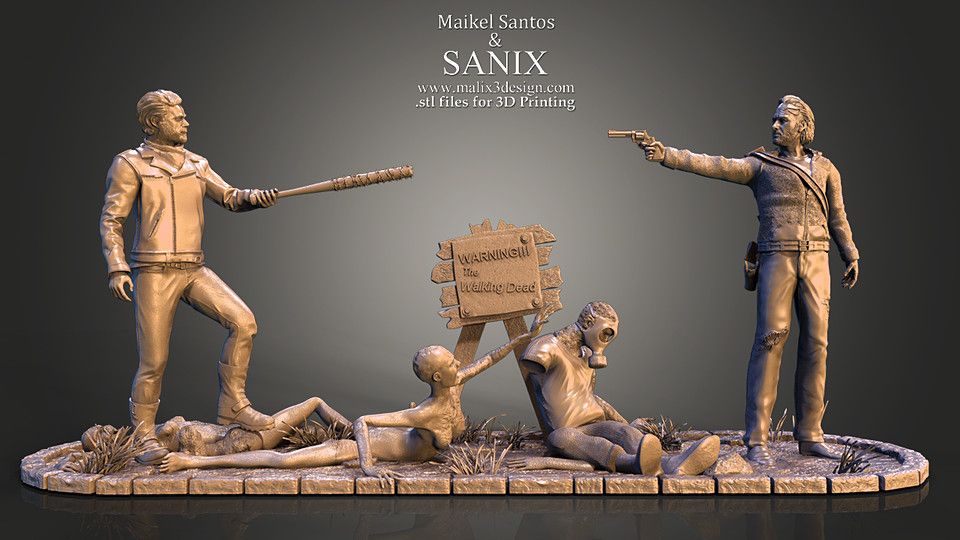

Diorama 3d print

Diorama best 3D printing files・Cults

Another Swamp Cooler for Scale Autos and Dioramas Firestone Style

€1.39 -15% €1.18

Another Swamp Cooler for Scale Autos and Dioramas

Free

Halloween diorama

Free

OZ Racing Superturismo LM 1:18 DIORAMA

€1.25

Mini Crawler Rock Faces Diorama

Free

Cult of the Lamb - Lamb ritual diorama with cultists

€8

Cult of the Lamb - Lamb ritual figure

€6

Star Wars Mos Eisley Junk Pile Piece 2 for 3.75" figures

€2.65

Jesus Statue with cross for dioramas

€2.99

Moonshine Jug

€3.61

Damajuana - Carboy - Demijohn

€2. 16

street lamp

€2.30 -30% €1.61

Plastic barrels

€1.99

Portable cooler

€1.25

Halloween Graveyard Diorama

€8

natasha v.2

€0.69

Trash bins for garage diorama in 1:24 scale

€2.06

Set of miniatures for Halloween dioramas and decorations (pumpkins, gravestones, candles, old bench, fence and lamp)

€3.50 -30% €2.45

mailbox blower hat

€2.06

Shiereker 3

€3.10

Shrieker 2

€3.10

Shrieker 1

€3. 10

10

Old damaged wooden fence

Free

Old gothic street lamp lantern

€0.50

Melted candles miniatures for dioramas etc.

€0.50

Old damaged bench

€0.50

Old tombstones, gravestones for halloween decoration, diorama

€1.50 -30% €1.05

Spooky pumpkin miniatures with scary faces (Halloween figures for decoration, diorama, desk buddy)

€1.50 -30% €1.05

Spooky cute ghost miniature figure (Halloween decoration, diorama)

Free

ww2 france street_Diorama 1_72

Free

Jack-o-lantern - Spooky Pumpkin for Halloween

€1

1/10 Scale SwizzTrax

€0. 98

98

gym girl

€0.99

girl beach v1

€1.19

161 MILITARY TELECOMMUNICATION SHELTER FOR WAR TABLETOP TERRAIN 1/24 1/35

€6.18

Scarecrow Pumpkin Base 25mm

Free

Ruined house 11 WW2 1/35

€6.63

surfer with board

€1.99

carregador

Free

man casual v.2

€1.59

Bucklebury ferry

€8.50

Firefighter Diorama

€10.36

woman police salute

€1.99

Star Wars New Republic Prison Ship Corridor Diorama

€3.27

Jaguar Image Steel Wheels

€5.70

Dymag Magnesium Wheels

€7.98

3M Motorsport Helmet

€8. 55

55

3m peltor rally headset

€5.70

3d Printed Diorama - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Create miniatures using 3D printing.

What 3D printer?

What 3D printer? 3D printing is used not only on an industrial scale and professional tasks, but also in a hobby. A prime example of this is the creation of thumbnails.

What is it?

Miniatures are small figurines that have an amazing appeal. The thumbnail size is from 6mm, and the most popular and demanded format is 28mm. The creation of miniatures is almost a jeweler's work. Each figurine has its own story. Based on the figurines, entire game locations, dioramas are created. Every smallest detail is worked out so carefully that it turns the product into a real work of art.

A diorama is a special kind of art, a piece of the universe frozen at a certain moment in time. The size can be very different, but the detail and elaboration is always amazing. The diorama consists of individual miniatures and objects that merge to give rise to a certain landscape.

The creation of miniatures is currently possible in several ways: modern technology and classics. It is on these options that we decided to dwell in more detail.

It is on these options that we decided to dwell in more detail.

Yesterday

Even at the dawn of this type of hobby, figurines were very, very expensive. But it was far from always possible to purchase the desired “hero”, and sometimes it simply was not on sale. In such cases, they resorted to modeling.

Self-hardening or bakeable plastics were used. To begin with, a wire frame was formed, which served as a reinforcing basis. This guaranteed the high strength of the future figurine. The frame is fixed on a stand, which guarantees the stability of the figurine and the convenience of working with it.

Layer by layer plastic is built up on the frame. In this case, each layer is dried (self-hardening plastic) or baked (baked plastic). Gradually, with each layer, they begin to work out the details. The process is very painstaking, complex, requiring perseverance. For work, special tools for sculpting are used. The result is a thumbnail.

This principle is used to create various figures, including large table figures, as well as dioramas.

Another option is to work with plasticine. The figurine is molded from plasticine, placed in a silicone mold, which is then used for casting. In this case, most often the figure is divided into several parts, which are subsequently connected. For ease of assembly, parts are made with a special “lock” that fixes individual parts into a figure. As a result, the miniature is assembled like a puzzle.

Miniatures are also made of fusible metals, in particular lead. Casting takes place using plaster molds. Sometimes silicone can also be used, but it is much more difficult to achieve good and high-quality pouring of a metal product in it.

Another option for creating thumbnails is conversion. This technology involves the alteration of an already finished figure. This method is used by many hobbyists, especially those who do not have good sculpting skills and do not know how to create miniatures from scratch.

With the help of conversion, you can achieve high detail, add missing elements to the figures. So you can create characters that are not on sale.

So you can create characters that are not on sale.

Modelers create colorful and interesting locations for complete immersion in their favorite world. This is a very difficult and painstaking work. In this case, various means, both special and improvised, can be used.

Today

Currently, 3D printing is actively used to create miniatures. The Internet offers users a huge range of different models, both paid and free. There are also options for elements of locations: houses, trees, fences, mechanisms ... 3D technologies allow you to change existing models, add or remove details. "Digital clay" is even more malleable than regular clay, and people with creativity and sculpting skills shouldn't have any problems.

The main advantage of 3D printing is high detail. Another advantage is repeatability. Printing a batch of miniatures is much easier than creating each individual model by hand. Casting is a complex process that requires not only skills, but also equipment. It is extremely difficult to achieve good repeatability with this approach.

It is extremely difficult to achieve good repeatability with this approach.

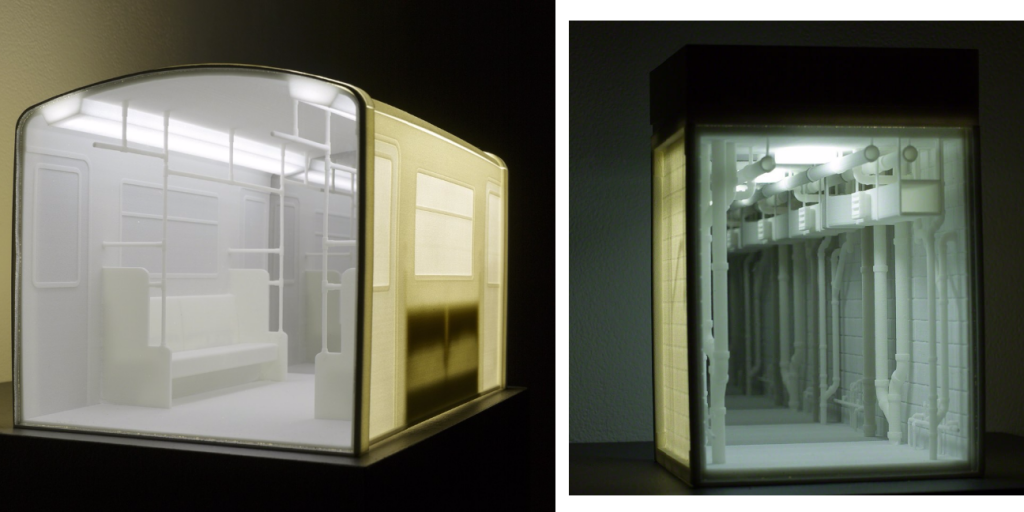

A 3D printer can replace many tools and materials. You can combine materials, getting different options. Manually, such models are almost impossible to achieve. A striking example is printing with transparent materials. Such materials can imitate glass.

3D printing technologies are different and options are possible here. FDM is a cheaper and easier 3D printing technology, but it takes time to post-process. In addition, such printers, as a rule, have a large print area. The materials are inexpensive and there are many options for taste and color. LCD and DLP are more complex and expensive printing technologies, but they allow for maximum precision and detail. The choice of materials is large, but they are not cheap. The surface of the finished figurines is always perfect. Photopolymer printers most often have a small print area.

Technology does not stand still. Every day they become more accessible and perfect, so the hobby is also improving. We are sure that tomorrow we are waiting for new discoveries!

We are sure that tomorrow we are waiting for new discoveries!

Making 28mm miniatures, dioramas, game locations with a 3D printer

miniatures

- The advantage of 3D printing for miniatures

- FDM

- LCD/DLP

- Examples of print

- Rating of the best printers

- FDM

- LCD

22 3D printing finds its application in various fields, not only as a production machine, but also as a reliable hobby assistant.

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history.

Warhammer 40k miniature soldier

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home.

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers.

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools.

Sculpting tool kit

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold.

Cast metal soldier

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully.

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting.

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

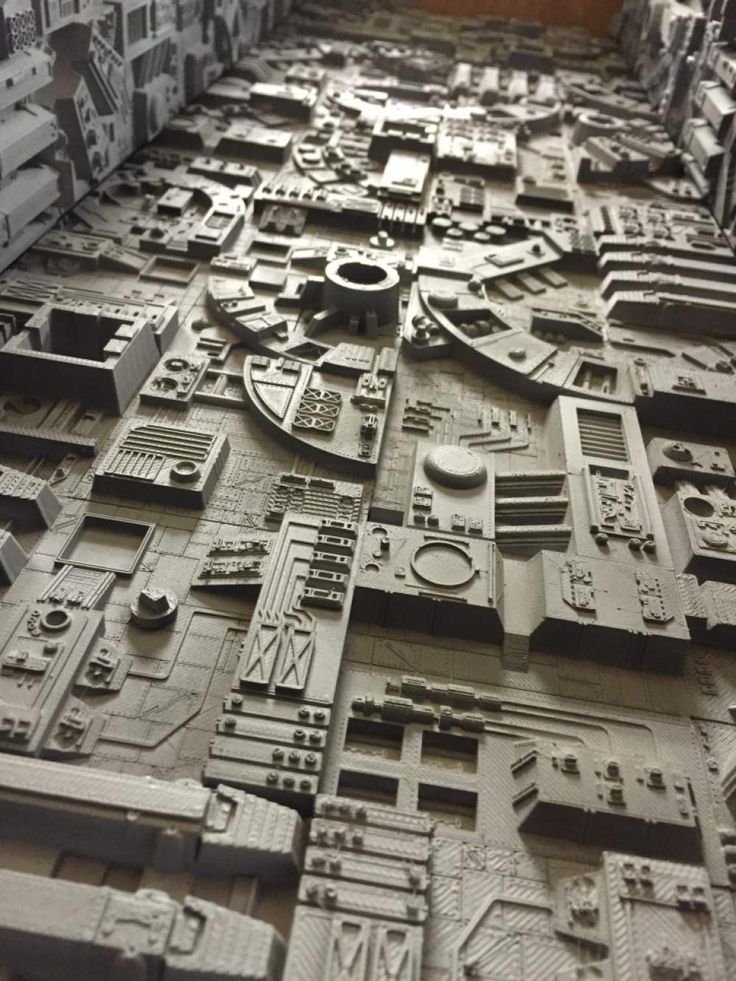

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”.

Warhammer40k universe 3D miniature model

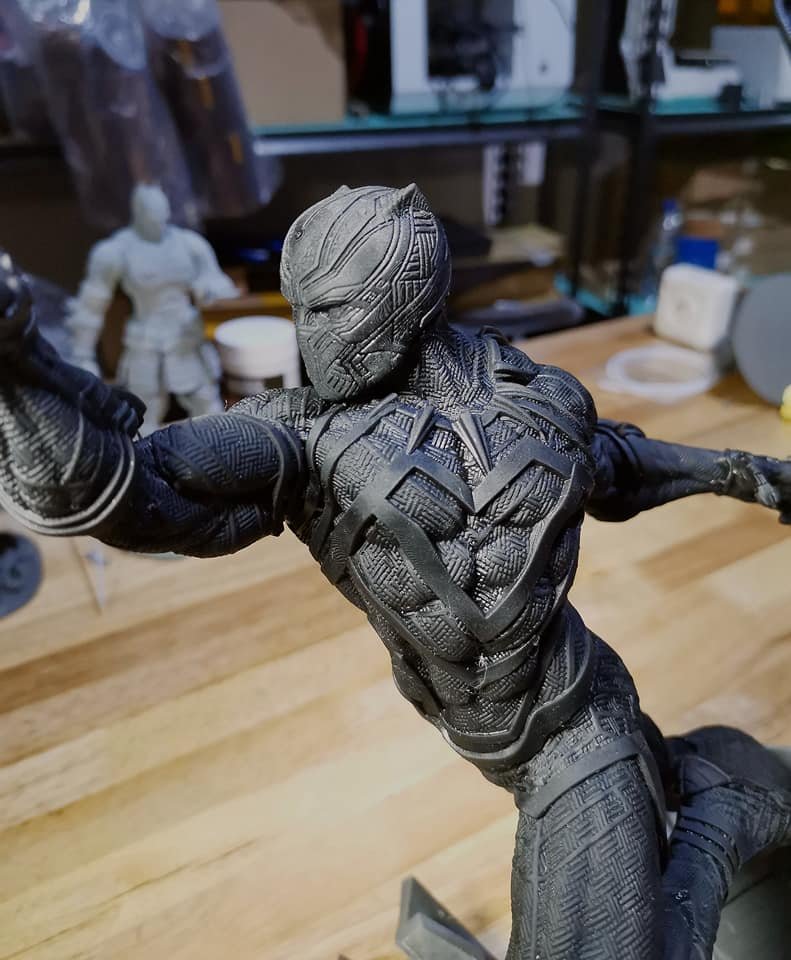

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time.

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass.

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular).

FDM

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

Working principle of FDM 3D printer

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow.

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

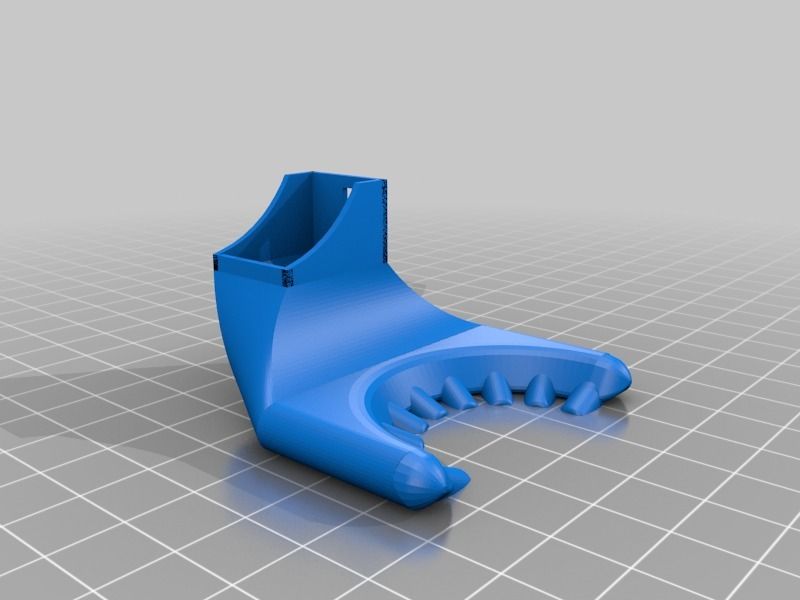

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas.

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

How a 3D photopolymer printer works

Pros:

-

The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc.

Print examples

Robot printed on Asiga Pro 4k

Figurine made with Phrozen Sonic Mini 4k

28mm 3D printed miniatures

3D Printed Halloween Miniature

3D printed play models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

Creality3D Ender 3 (Build Kit)

Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly.

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models.

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately.

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle.

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail. Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Totals

3D printers are gradually showing themselves to be great helpers in many areas, not only in medicine and industry, but also in home hobbies. Thanks to 3D printing, it is possible to produce small figurines or elements of dioramas much faster, paying more attention to the elaboration of details, rather than painstaking modeling or the search for exotic materials.

And digitalization makes it much easier to share your work and finished models in the community or adjust them to your needs, for example, change the scale or adjust the pose.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao

#Application

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.