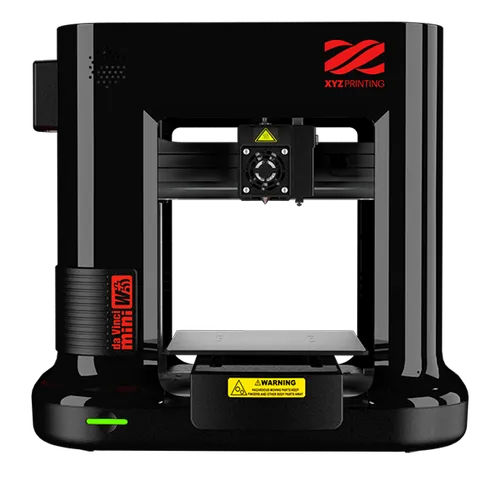

Davinci 3d printer scanner

XYZprinting da Vinci 1.0 Pro 3-in-1 3D Printer Review: Good Prints, Disappointing Scans

Skip to main contentTom's Guide is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

This 3-in-1 from XYZprinting handles two of its tasks (3D printing and laser etching) fairly well, but you'll be disappointed by the 3D-scanning features.

Tom's Guide Verdict

This 3-in-1 from XYZprinting handles two of its tasks (3D printing and laser etching) fairly well, but you'll be disappointed by the 3D-scanning features.

Pros

- +

Most 3D prints had excellent quality, with fine detail

- +

Can use third-party filament

- +

Laser etcher works well

Cons

- -

Prints at the smallest layer height often did not work

- -

Printing is slow

- -

3D scanner did not work well, often missing parts of objects and not capturing fine details

- -

Scanning works only over USB, not Wi-Fi

Today's best XYZprinting da Vinci 1. 0 Pro 3 in 1 deals

No price information

For more information visit their website

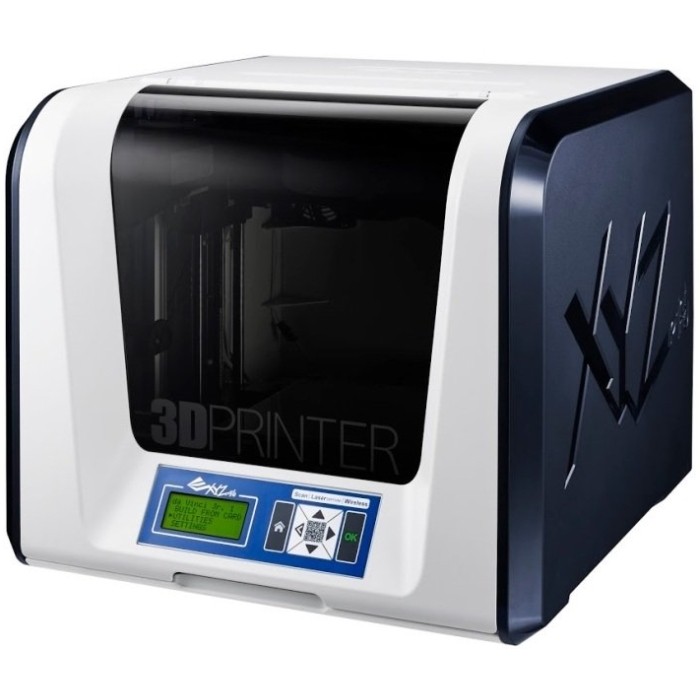

The XYZprinting da Vinci 1.0 Pro 3-in-1 has a lot of numbers in its name, because it does a lot of stuff. For $899, you get a 3D printer that can print with ABS and PLA filament, along with a 3D scanner. For an extra $99, you can add a laser engraver that can etch wood, plastic and other materials with 2D images.

The da Vinci Pro 3-in-1 does a decent job at two of its tasks: 3D printing and engraving. But the 3D scanner did not work well, making this device a jack of all trades, master of none.

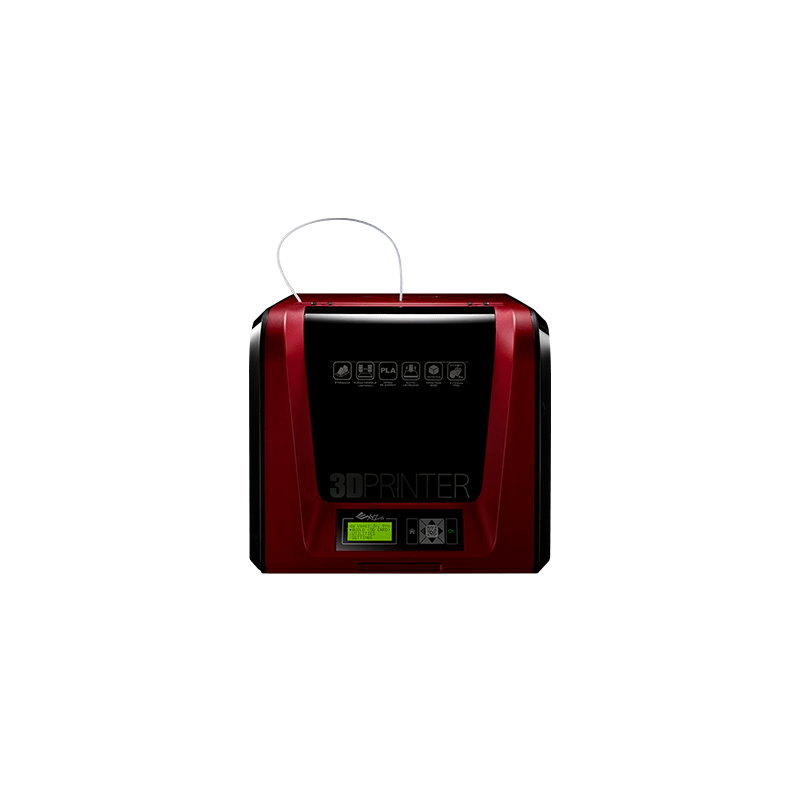

This large, imposing printer will take up a lot of desk space: At 22 x 20.5 x 18 inches, the da Vinci Pro 3-in-1 isn't going to fit into a tiny corner. A bulky, red-and-black plastic case encloses all of the features, with a door at the front that opens to reveal the 3D printing, scanning and etching area. Another door on the top provides access to the cavity where the filament cartridges fit.

Another door on the top provides access to the cavity where the filament cartridges fit.

The heated print bed can handle a print of up to 5.9 inches high, wide and deep, providing an impressive 205 cubic inches of print volume. XYZprinting recommends using painter's tape and white glue to help prints stick to the print bed, and the company includes three sheets of tape with the printer. Most of the prints we made stuck well to this combination of heat, tape and a bit of glue, though it's rather easy to damage the tape when removing the print, meaning you have to replace the entire sheet. The da Vinci Pro 3-in-1's print bed is definitely not as tough or resilient as the plastic bed on printers such as the LulzBot Mini.

The 3-in-1 includes USB and Wi-Fi, but the latter is a little limited. You can use the 3D-printing and laser-etching functions over a Wi-Fi network, but not the 3D scanner, which requires a USB connection.

Print Materials: Broad Support

Support for third-party materials distinguishes XYZprinting's Pro lineup from its amateur offerings. Whereas printers such as the da Vinci 1.0 AiO work only with filament in XYZprinting's own print cartridges, the Pro can handle these cartridges and 1.75-mm filament from other manufacturers. That said, XYZprinting does still try to nudge you toward using its own filament; when you start the companion software, a pop-up message warns you, "Print quality may vary with third-party filament."

Whereas printers such as the da Vinci 1.0 AiO work only with filament in XYZprinting's own print cartridges, the Pro can handle these cartridges and 1.75-mm filament from other manufacturers. That said, XYZprinting does still try to nudge you toward using its own filament; when you start the companion software, a pop-up message warns you, "Print quality may vary with third-party filament."

For print materials, XYZ includes 18 colors of ABS and seven colors of PLA. These range from the natural white to a particularly lurid neon magenta, and cost between $20 and $40 for a roll that contains 600 grams of filament. That's a decent value and comparable to most third-party filaments.

MORE: Best 3D Printers

Setup: Calibration Complications

It's fairly simple to get the da Vinci 1.0 Pro 3-in-1 up and running. With the exception of the etching laser, the printer comes fully assembled, so all you have to do is unbox it, remove the numerous bits of packing foam and tape, and plug it in.

It's also easy to load the filament. You just install the cartridge or reel, and then feed the filament into the tube that leads to the printhead. A motor pulls the filament into the printhead. Once you see the melted filament coming out of the printhead, you're ready to go.

The Pro 3-in-1 is not a particularly fast printer.

Our test unit didn't need any calibration before printing, but XYZprinting does recommend you calibrate every time the printer is moved, to make sure the print bed is level. Whereas printers such as the LulzBot Mini automate this process completely, the Pro 3-in-1 requires some manual intervention, which can be a little cumbersome.

The da Vinci printer uses a sensor on the print head to detect the print bed, and then asks you to adjust the print bed leveling dials. It might ask, for instance, that you "turn the right dial 0.5 steps forward." With each "step" representing a quarter turn of the dial, this gets a little confusing, as you have to figure out what something like 0. 1 steps backward actually represents. Once you have made the adjustments, the printer tests the level of the bed again.

1 steps backward actually represents. Once you have made the adjustments, the printer tests the level of the bed again.

Interface: Two Different Controls

You control the Pro 3-in-1 two ways — through the XYZware Pro software, available as a free download for Windows and Mac, or through a small LCD and buttons on the device itself. The XYZware Pro software is straightforward and simple to use, taking you through the process of loading a model, scaling and shifting it, and sending the file to the printer for building. When you load a model, the program shows a rotatable preview of it on the print bed, which you can scale, rotate, shift or delete.

The program hides most of the technical aspects of 3D printing from the casual user, but they are available if you dig. If you want to change the layer height or the infill (how much of the interior of the model is filled with material), you have to select Print and then go to the General tab of the Print Settings screen.

MORE: 8 Awesome 3D Printing Trends to Watch

Once you're ready to print, the program sends the file to the printer, and you can then exit XYZware Pro. From there, you can monitor the print, pause it or cancel it through a simple menu on the Pro 3-in-1's LCD screen. You can also do things such as change the filament or monitor the temperature of the various parts.

Print Process: Solid, with Some Failures

I found the process of printing on the Pro 3-in-1 to be mostly straightforward. For most materials, you place a sheet of bed tape (similar to painter's tape) on the print bed, and also apply white glue to the print area to help the print material stick to the bed. I found that this combination worked well, with most prints sticking to the bed properly.

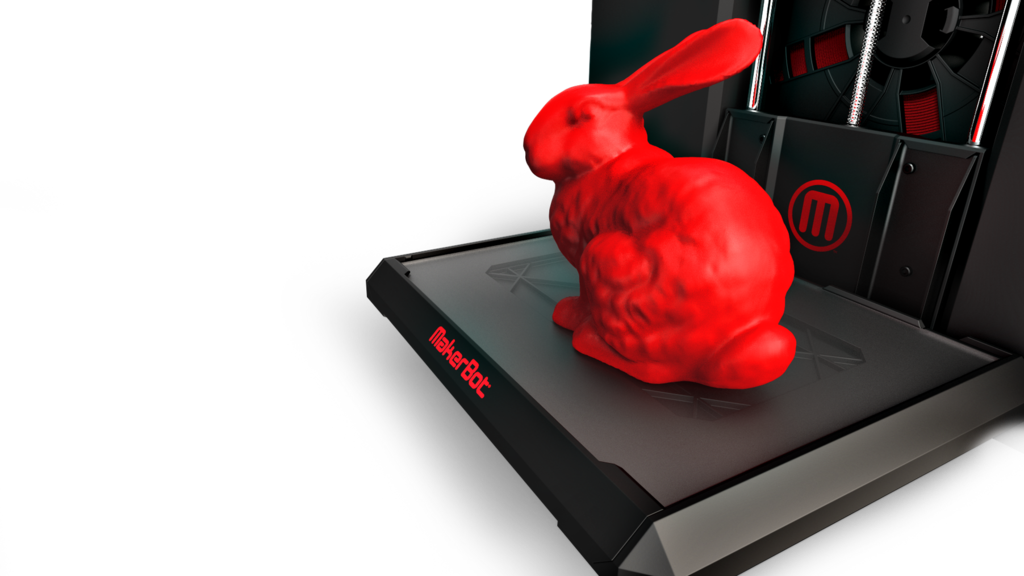

Most of the Pro 1.0 3-in-1's prints were very clean, with smooth surfaces and very few printing glitches.

I did have occasional failures where the print failed to stick, or a small bit of melted filament stuck to the print head and blocked the extruder. When this happened, I ended up with a large gunky mass of melted filament stuck to the print head that required cleaning. XYZprinting includes tools for this, such as a copper wire brush and a pin for unblocking the extruder head.

When this happened, I ended up with a large gunky mass of melted filament stuck to the print head that required cleaning. XYZprinting includes tools for this, such as a copper wire brush and a pin for unblocking the extruder head.

Print Speed: Slow Output

The Pro 3-in-1 is not a particularly fast printer; the print time ranged from 6 hours and 45 minutes (on the largest 0.3-mm layer height) and 11 hours and 23 minutes (on the 0.2-mm layer height) to produce a 4.5-inch-high print. That's significantly slower than the comparably priced LulzBot Mini, which managed to produce a similar print in about 2 hours, albeit with a slightly larger 0.38-mm layer height.

Print Quality: Some Issues with Small Layers

I was impressed with the quality of most of the prints produced by the Pro 3-in-1. Most of these were very clean, with smooth surfaces and very few printing glitches. However, I found that prints at the smallest, 0.1-mm layer height did not work very well, with some parts of these prints not sticking together, often causing the print to fail.

To test 3D printers, I use a series of test models: a geometric sculpture, a 3D scan of Rodin's "The Thinker" sculpture and a set of gears. The Pro 3-in-1 aced this test, producing a clean, well-formed 3D print of the sculpture that had smooth edges and nice sharp points at the end. I did, however, see some odd filaments hanging off the edges of the sculpture, caused by the melted filament stretching as the print head moved away to print another part of the sculpture. These were easily trimmed off the final model.

(Image credit: Richard Baguley)The Rodin sculpture test looks at the printer's ability to reproduce natural objects, such as the muscles in the sculpture's shoulder. Again, I saw few issues here, with the printer producing a clean, accurate print of the sculpture with the layer height set to 0.3 mm and 0.2 mm. However, the printer struggled to produce a print at a layer height of 0.1 mm; the supports for parts of the sculpture were formed incorrectly, and several parts came loose and stuck to other parts of the print.

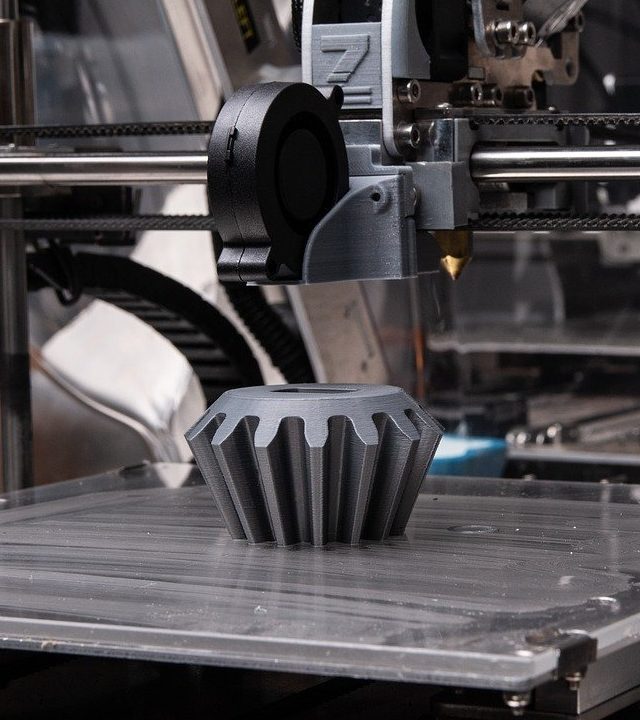

Finally, I printed a set of gears, and then assembled the final gear set to see how well the printer could create details such as the cogs of gears and the thread of screws. The 3-in-1 did well here, producing a clean set of gears that fit together well. Some of the gears did need a bit of cleaning with a sharp knife, as there were odd bits of loose filament stuck to some parts.

MORE: How to Buy a 3D Printer

3D Scanning: Disappointing Results

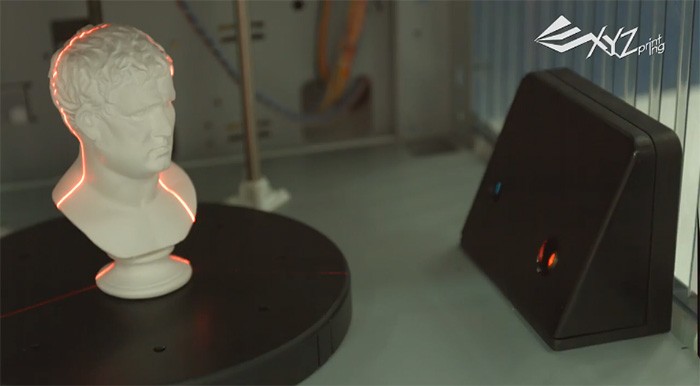

The da Vinci Pro 3-in-1 also acts as a 3D scanner; it can build a 3D model of an object by scanning and reconstructing it in software. The Pro 3-in-1 disappointed in this area, however, producing scans that lacked detail and often completely missed parts of the object. When it did work, the scanner did best with smooth, matte objects such as sculpture or pottery, but it couldn't scan dark, shiny or glass objects.

(Image credit: Richard Baguley)You can scan 6 x 6-inch objects — basically, anything the size of a hardback book. The 3D scanner shines two laser lines on the scanned object, which sits on a rotating platform in the bottom of the case. Then, two cameras detect this laser light, using the position of the detected laser line to calculate the shape of the object. One laser/camera combo looks up at the object from the left, while the second combo looks down from slightly above on the right side. The XYZscan software controls the process, which takes about 4 to 5 minutes.

The 3D scanner shines two laser lines on the scanned object, which sits on a rotating platform in the bottom of the case. Then, two cameras detect this laser light, using the position of the detected laser line to calculate the shape of the object. One laser/camera combo looks up at the object from the left, while the second combo looks down from slightly above on the right side. The XYZscan software controls the process, which takes about 4 to 5 minutes.

Your initial scan produces a rough version that you can edit using the software, smoothing parts of the scan. You can't do large-scale edits, such as filling in large holes.

The 3D scanning features disappoint, producing scans that lacked detail and often completely missed parts of the object.

If a scan misses parts of the object, the software's Multiscan feature lets you move the object, scan it again and mark similar points on the two scans. The software then tries to combine the two scans into one. This process had mixed results: On complex objects, it wasn't able to combine the results, but simpler objects could be combined for better scans.

This process had mixed results: On complex objects, it wasn't able to combine the results, but simpler objects could be combined for better scans.

The resolution of the scan isn't great: intricate details smaller than a quarter of an inch or so won't be captured very well. In one example below, I scanned a 4.5-inch print of "The Thinker." Though the general shape of his body is captured, his head is missing, and large areas of his body just aren't captured at all.

Laser Etching: Good with Some Tweaking

XYZprinting's 3-in-1 also offers laser etching if you opt for a $99 attachment. It can etch images into materials like wood, paper or cardboard. It does a pretty good job, but the process requires a lot of tweaking and experimentation to get good results. The quality also varies depending on the material you're etching.

The laser etcher contains a small (0.25 watt) blue laser, similar to the one in a Blu-ray player. The laser isn't powerful enough to do other tricks that bigger laser etchers can do. For example, it can't cut through things or etch materials harder than wood.

For example, it can't cut through things or etch materials harder than wood.

To use the etcher, you have to remove the 3D printhead. Just set the 3-in-1 to the Change Print Head option in the on-screen display, turn off the printer, remove a cable from the printhead, release a latch and lift the printhead out. To install the etcher, you simply reverse the process; the whole thing takes just a couple of minutes. It's unfortunate that you can't have both printheads installed side by side.

(Image credit: Richard Baguley)Once the etcher head is installed, you can start etching, using the same XYZware Pro software you use for 3D printing, but with a slightly different interface. Using a 2D representation of the print bed, you can load image files (JPEG, GIF, PNG, TIFF and BMP formats are supported) that you want to etch.

MORE: 3D Printing - News, Reviews and 3D Printer How-Tos

You can choose between two modes: Vector and Raster. Vector mode works best with simple, one-color logos; it processes the image by detecting the edges of the areas of colors. Raster mode is more complicated; it tries to turn different colors in the image into different shades, which will be etched by using the laser at different strengths. This creates a gray-scale version of the image. Either way, expect to spend some time experimenting with this for the best results, as the software offers a number of controls for tweaking the result.

Raster mode is more complicated; it tries to turn different colors in the image into different shades, which will be etched by using the laser at different strengths. This creates a gray-scale version of the image. Either way, expect to spend some time experimenting with this for the best results, as the software offers a number of controls for tweaking the result.

Once the file is processed, it is sent to the printer, and the etching starts. This is pretty quick for simple images; a Tom's Guide logo took less than 10 minutes. Etchings with larger areas to fill in or more complex images take longer; a 6.5 x 3-inch sample image took about 4 hours to etch into cardboard.

(Image credit: Richard Baguley)Etching can also be a little stinky, as you are burning the image onto the material being etched. It didn't set anything alight or trigger any smoke alarms in my tests of etching light wood and cardboard, but you should definitely make sure the area is well ventilated and keep a close eye on it.

The XYZprinting da Vinci 1.0 Pro 3-in-1 packs a lot into its large case, and the 3D-printing and laser-etching features of this do-it-all device work fairly well. Though it's slow, the 3D printer produced decent 3D prints at all but the smallest layer height, and the laser etcher produced nice, clean etchings on soft materials. However, we were disappointed by the lackluster performance of the 3D scanner, which produced scans that were missing parts and lacked detail and could not scan many common materials, such as glass, glossy metal and very dark objects.

Still, when you consider the low price tag, two out of three ain't bad. The da Vinci 1.0 Pro 3-in-1 represents a decent value compared to competitors such as the LulzBot Mini that may offer better performance, but at a higher price.

Today's best XYZprinting da Vinci 1.0 Pro 3 in 1 deals

No price information

For more information visit their website

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

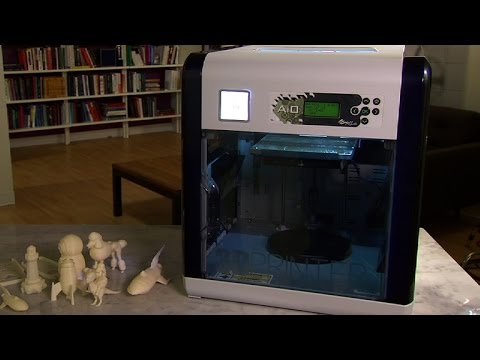

da Vinci AiO 3D Printer-Scanner Review: Very Interesting Machine

0Shares

XYZprinting is now the world’s largest maker/seller of desktop 3D printers in the world. According to Canalys, a market analysis firm, XYZprinting sold over 22% of all 3D printers in the first half of this year. That is a lot of machines, and when you examine their machines up close, it isn’t difficult to figure out why they can move so many.

Their machines run the gamut from the da Vinci Junior, da Vinci, da Vinci 2, Noble, the new da Vinci Pro, and soon they will be releasing a food printer. They are inexpensive, reliable, easy to use, and come in a range of models that are designed for different kinds of users. This is a company that is seeking to build the 3D printing consumer market like no other.

This is a company that is seeking to build the 3D printing consumer market like no other.

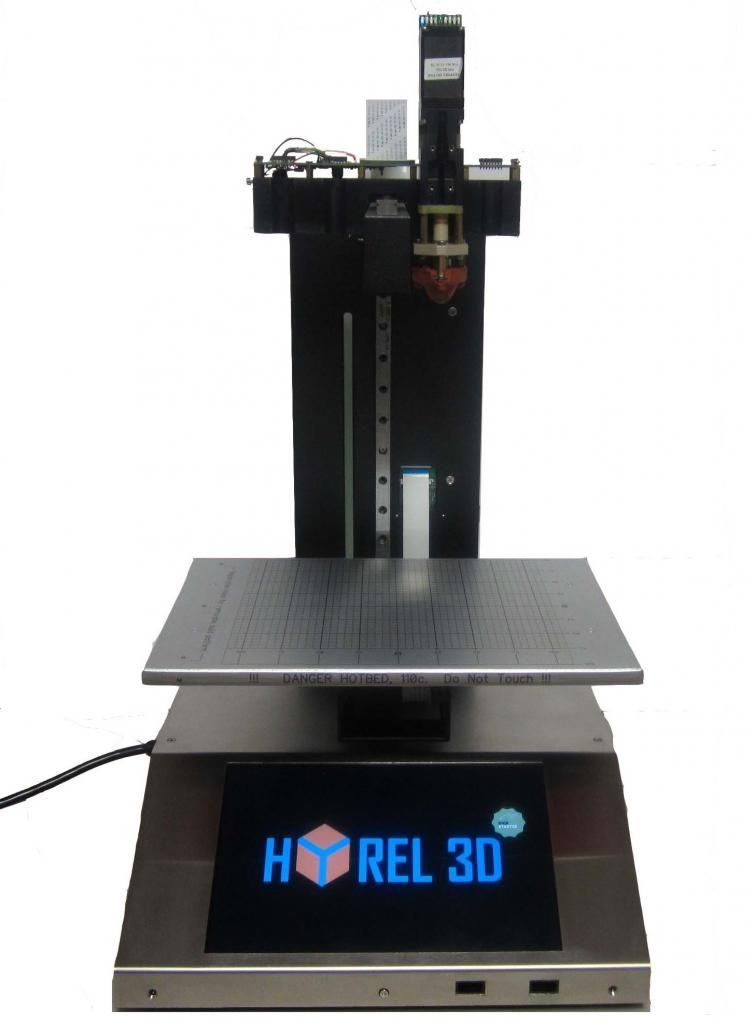

The AiO is a fairly standard FDM-style printer, with a slight twist. In addition to all its other features it also includes a built-in 3D laser scanner! Needless to say we were pretty excited to give it a go. While we have tested and played around with more printers than I can recall, we have had fairly limited experience with 3D scanners, so for us this was going to be a bit of a treat.

The machine arrived at out lab packed in what we now consider the usual XYZprinting style…which is to say, really well. While opening and unpacking the machine, nothing rattled or was out of place. Every component was padded or taped down for shipment, including all of the printer’s accessories. The AiO is a bit large compared to most desktop printers at 47cm wide, 57cm deep and 51cm high. Its fully enclosed, 20cm x 20cm x 19cm, single extruder build chamber has a heated build plate, allowing it to print in both PLA and ABS. And a cartridge of each type of filament was included with the package.

And a cartridge of each type of filament was included with the package.

We ran several prints in both materials, switching back and forth between cartridges to see if the extruder would jam up, which it (almost) did not. We had one minor jam…but unlike many other printers we have used, clearing the jam did not require us to disassemble the extruder. We simply ran the machine’s load/unload process again, and the problem resolved itself. As far as most machines go, ours was a bit noisy while printing but it didn’t seem to cause any printing troubles. The machine also had a clever nozzle cleaning device build onto the side of the buildplate that wipes the nozzle tip before it begins printing, helping to reduce plastic buildup on the hotend.

In our tests the machine printed very reliably and without any trouble. We used up the contents of both cartridges without a hitch, and while we would have liked to have seen a little better resolution, we had no real complaints. The PLA worked very nicely, but where this machine really stood out was its use of ABS. As anyone who has done any printing at all knows that ABS can be…difficult…to work with. Warping, peeling, delaminating…you name it, ABS can do it all! But the lion’s share of frustration comes from ABS’s tendency to warp. As incredible as this may sound, we experienced no warping of XYZprinting’s ABS at all! None. Every single print stuck to the printbed and printed flat and true, each and every time. We did absolutely nothing special to make this work, it just did.

As anyone who has done any printing at all knows that ABS can be…difficult…to work with. Warping, peeling, delaminating…you name it, ABS can do it all! But the lion’s share of frustration comes from ABS’s tendency to warp. As incredible as this may sound, we experienced no warping of XYZprinting’s ABS at all! None. Every single print stuck to the printbed and printed flat and true, each and every time. We did absolutely nothing special to make this work, it just did.

Truth be told, we do not know if the ABS’s superior performance was due to the AiO’s hardware abilities, the filament’s composition, or a combination of the two…but whatever it was, it worked! How often can you say that printing in ABS is as easy as printing with PLA? I would have loved to have tested the AiO with an off-brand ABS filament, but the machine will not allow that, as it (currently) only accepts XYZprinting’s filament cartridges. But in an interesting twist, XYZprinting has announced that their new da Vinci Pro will allow users to use whatever filament they please, and if hope be there, maybe all their future machines will follow suit.

The laser scanner, which we were excited to play with, was mounted on the bottom of the build chamber under the build plate. To use it, the build plate moves to the top of the build chamber out of the way leaving the black scanner turntable exposed and ready for use. Humorously, one of our students noted that it made the printer look a little like an oversized microwave oven.

Jokes notwithstanding, the scanner consisted of two red lasers mounted on either side of the chamber, at different heights so that as the item being scanned rotates, its contours are fully covered. The turntable is about 20cm across, but the chamber is big enough that substantially sized items can be scanned fairly easily. The manual states that the turntable’s maximum weight capability is 3kgs, and though we didn’t test that limit, the heaviest item we scanned weighed about 2.5kgs, and the turntable operated smoothly, and without any problems. All in all, the hardware seemed solid and reliable. But this is where the story changes a bit….

The scanner comes with its own special software called “XYZscan” which we believe is the machine’s weakest point. We followed the manual’s instructions to the letter, but could not get a clear scan of any item we tried, no matter what it was or how many times we repeated the scan. The items’ shape, color, and surface finish did make a big difference; with light-colored, smooth items that had a mat-finished surface working the best. In our case it was a white, plastic cylinder…but even that came out at only about 90% accurate.

It also did it seem to matter what kind of computer operating system we used. During our test we used a Windows 7 laptop, a Windows 8.1 desktop, and a Mac desktop running Yosemite. The Mac was able to get the best scans, but even those were far from ideal. Given all of the AiO’s great hardware features, the software was a big disappointment.

If XYZprinting’s engineers can get the troubles worked out of their programs, the AiO would be a truly amazing machine…especially for the price! While we cannot yet recommend it for its scanning abilities, it is STILL worth considering as a 3D printer in its own right. Whatever your feelings about its flaws, it is still the best ABS printer we have yet seen out of the box…to be able to “hit print and forget” while printing, especially with ABS, is something that you are not likely to see very often.

Whatever your feelings about its flaws, it is still the best ABS printer we have yet seen out of the box…to be able to “hit print and forget” while printing, especially with ABS, is something that you are not likely to see very often.

When I was younger I had been told that “perfection is the enemy of good enough”. Products need to get out into the hands of people who can play with them, learn on them, use them, and suggest improvements or complain about them…and then…and this is the tricky part for most companies…actually listen to those suggestions and complaints and make the products better. But that entire process cannot even begin if the machines don’t actually get out the factory doors.

While many people have complaints about XYZprinting’s machines, including myself, what cannot be denied is that by focusing on getting functional, entry-level, inexpensive, easy to use machines that are ready to go right out of the box out into the marketplace, warts and all, XYZprinting is doing more to expand the global 3D printing consumer market than just about any other company. Say what you will, but as a 3D enthusiasts, we are glad for it.

Say what you will, but as a 3D enthusiasts, we are glad for it.

Mark Lee

Mark teaches at a national university in Busan, South Korea and he conducts a variety of courses, including classes on transhumanism and additive manufacturing. He also supervises several student organizations and is currently organizing a student 3D design and printing users group to help further awareness about this exciting technology.

3D printer XYZPrinting da Vinci Color AiO

Out of stock

Add to compare

Item added to compare Go

Free shipping within Russia

564 200 ₽

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When buying a 3D printer from us,

you get a 10% discount on all consumables.

Model XYZprinting da Vinci Color AiO combines two devices at once - a 3D scanner and a 3D printer. At the same time, the function of full-color printing is also supported. Simply place the desired item to be scanned in a special camera, create a 3D model, cut into layers and start the printing procedure.

An important role is played by the integrated software XYZscan Color, which allows you to optimize the scanned models using a number of settings. Files are saved in .obj or .stl formats before further editing.

Files are saved in .obj or .stl formats before further editing.

The dimensions of the working platform are 200 x 200 x 150 mm, and the dimensions of the scanning area are 140 x 140 mm. Another additional option is the upgradeable laser engraving system. You can purchase a detachable laser engraver to carry out the corresponding creative process on various materials: leather, cardboard, plastic and others.

Note the high print speed of the da Vinci Color AiO printer - it is 180 mm / s. Remaining material control is provided by a second-generation NFC chip that transmits profile information to the device.

*An optional Open Smart Tag chip can be purchased to adapt the printer to third-party plastics.

Payment and delivery

Delivery scale

Delivery to all regions of Russia and countries of the Customs Union.

Free shipping

When you buy a 3D printer (except assembly kits) you get free shipping.

Cash

In our store you can pay for your order in cash.

Online payment on the website

You can pay for orders with a bank card on the website of our online store.

Similar Items

Free Shipping

Add to Compare

Item added to compare Go

Out of stock

3D printer Imprinta Hercules Strong Duo 3D Printers

Free Shipping

Add to Compare

Product added to compare Go

On request

3D printer PICASO Designer XL Pro 3D printers

Free shipping

Add to compare

Item added to compare Go

Available

3D printer CreatBot F430 Peek 3D Printers

Free Shipping

Add to Compare

Product added to comparison Go

Available

Raise3D Pro2 Plus 3D Printer 3D printers

Free shipping

Add to compare

Item added to compare Go

Available

Raise3D Pro2 3D printer 3D printers

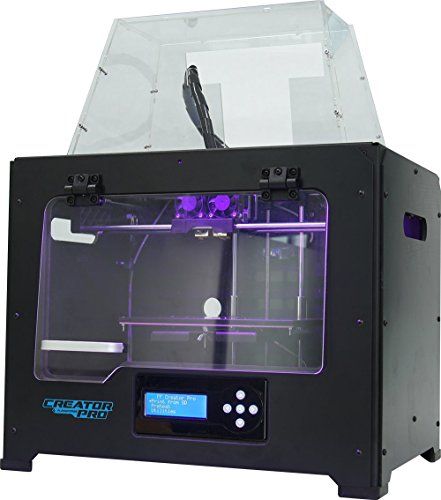

3D printer / 3D Scanner da Vinci 1.

0 Pro 3-in-1 - Tallinn

0 Pro 3-in-1 - Tallinn Listing is not active, product or service has been withdrawn from sale

690 €

€ 690.00

On request

Buy via deposit

- Delivery DPD, Omniva, SmartPOST, mail

- Return Within 14 days by money

- Added 25.02.2019 22:03

Tallinn

Täiesti töökorras vähe kasutatud 3D printer mis on ka 3D scanner.

https://www.xyzprinting.com/en-US/product/da-vinci-1-0-pro-3-in-1

https://www.youtube.com/watch?v=5x_iBKHU-o0

3D Printer

3D Scanner

Wifi

Soojendusega alus

Resolutsioon väga kõrge 0,1mm ja kuni 0,3mm

Toetab kõiki värve ja nii ABS kui PLA materjale

Võimalus lisana lasergraveeringu pea juurde osta.

https://www.youtube.com/watch?v=Yn6fm6x7w-Y

Helista ja küsi lisa: 5104024

Näha saab Kristiines

Return accepted

Within 14 days in cash.