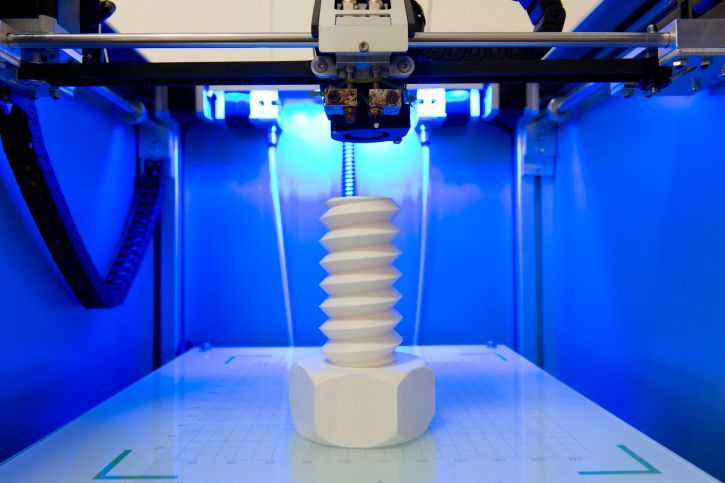

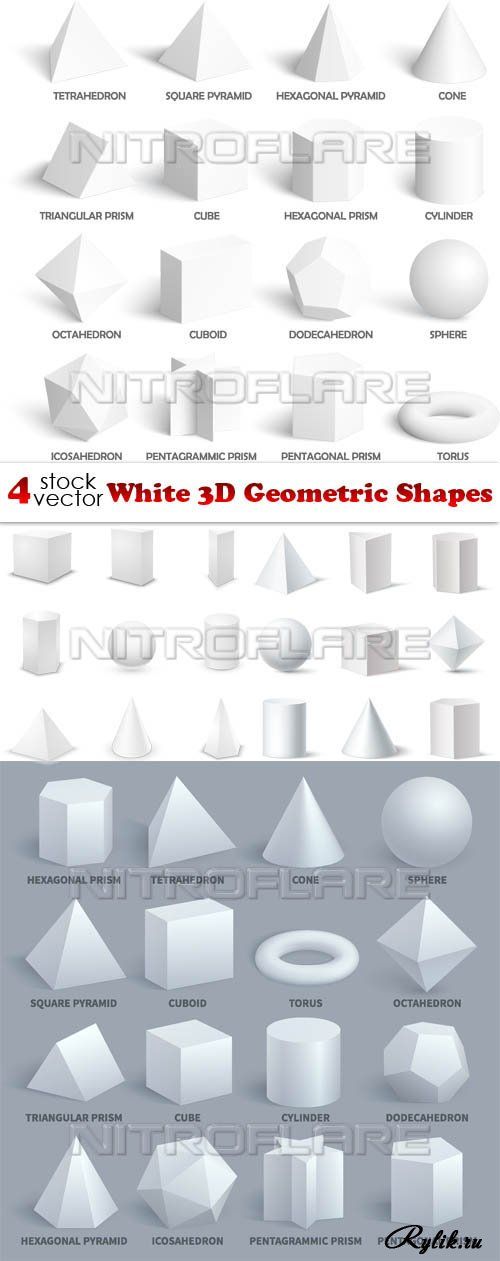

3D printing geometric shapes

Complex geometries are possible with 3D printing

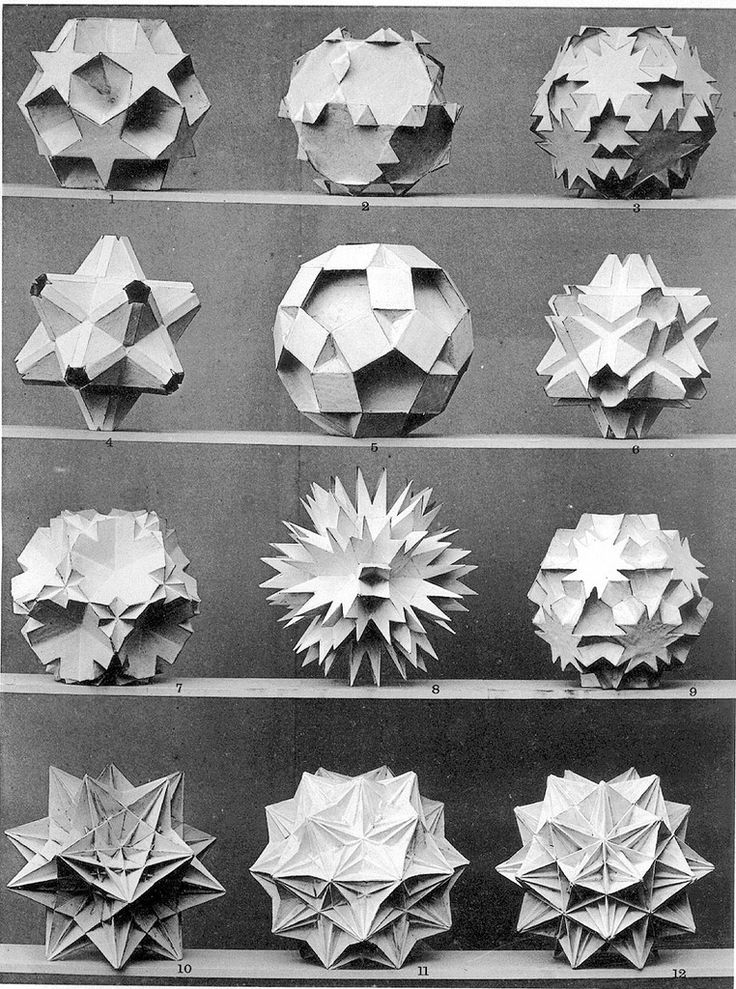

Industrial 3D printing means that the manufacturing process no longer determines the complexity of a component, but rather the product’s desired functionality and design. Complex geometries, such as three-dimensional structures with undercuts or cavities, are typically impossible to manufacture with conventional technologies like milling, turning or casting, or are only possible at disproportionately high costs.

Now, any shape that can be constructed in a 3D CAD program can be produced with additive manufacturing technology. There are almost no restrictions – even when manufacturing hollow structures. This works because the material is only added where it needs to go. Additive manufacturing gives developers maximum geometric design freedom, and complexity only plays a minor role in the production costs. The costs can often even be significantly reduced due to lower material consumption.

EOS technology was a logical choice for us because we manufacture small series productions with complex shapes. We acquired the high-temperature system EOS P 800 at an early stage and were able to rapidly make progress in the development cycle of OsteoFab™ technology. EOS accompanied us throughout the entire process.

Scott DeFelice | President and CEO | OPM

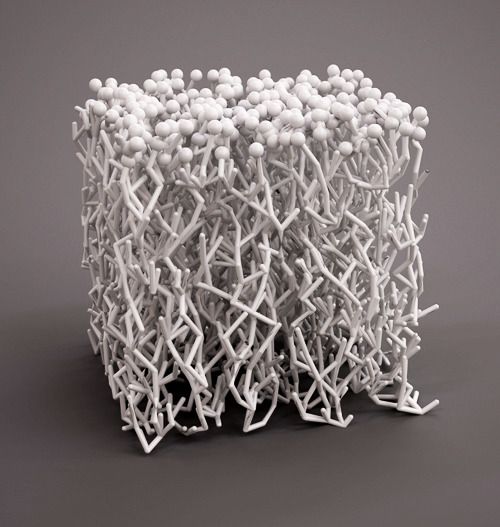

Multiple structures in the same part

Thanks to 3D printing, the hip cup implant was significantly optimized. The artificial hip cup consists of solid sections that provide stability and porous elements on the surface. The differently sized pores help to anchor the implant firmly: Large pores are helpful for pressure transmission - smaller pores support the initial fixation. In this way, the complex surface structure simplifies osseointegration, or the growth between the living bone tissue and the surface of the implant.

Flexible structural adjustment possible

The full implant is manufactured in a single production step by the 3D printer and would be extremely difficult to make with conventional manufacturing methods. At the same time, the high flexibility of additive manufacturing enables the structure, surface roughness and pore size to be determined individually for each patient. Together with the Additive Minds Team at EOS and the established 3D metal printing system EOS M 290, Permedica succeeded in realizing a completely new product.

At the same time, the high flexibility of additive manufacturing enables the structure, surface roughness and pore size to be determined individually for each patient. Together with the Additive Minds Team at EOS and the established 3D metal printing system EOS M 290, Permedica succeeded in realizing a completely new product.

Evolutionary processes have created biological structures in great abundance and diversity: today, we know of more than 1 million species of animals and around 500,000 species of plants. These systems often have shapes and structures that are optimally adapted to their environment and are created with minimal use of materials and energy. The interdisciplinary research field of bionics aims to exploit this massive potential by adapting natural blueprints to technical applications.

This is where conventional manufacturing processes encounter their limits. By contrast, additive manufacturing achieves maximum design freedom. With our technology, you have the opportunity to build, discard, re-engineer and continuously optimize your prototypes during development. The tool-free production saves time and money - while offering enormous opportunities. As a result, there have been disruptive innovations in medicine, ergonomics and aviation, for example, especially in connection with aerodynamics.

The tool-free production saves time and money - while offering enormous opportunities. As a result, there have been disruptive innovations in medicine, ergonomics and aviation, for example, especially in connection with aerodynamics.

Success Story Festo

Bionic Gripper

The additively manufactured Festo gripper DHDG is a bionic gripping device that can grip objects gently and flexibly but powerfully, and set them down safely. Its shape and function were inspired by nature. With the FORMIGA P 100 by EOS, the automation specialists Festo were able to produce the parts they needed quickly and cost-efficiently in small series production.

The results are impressive.

Thanks to the superior design freedom, the production can be flexibly guided by the design. By integration functionality into the part during production, Festo succeeded in significantly reducing the number of individual parts and the assembly cost. The resulting gripper is lightweight and durable. And even the price is right: Festo saved time and money with tool-free production.

And even the price is right: Festo saved time and money with tool-free production.

Thinking in new ways is worth it: you can’t drill around corners, but you can easily print holes. The geometric freedom of design granted by industrial 3D printing opens new possibilities for designers. This requires know-how and a new approach to design.

We're here to help you take full advantage of additive manufacturing.

There are many upsides to 3D printing. EOS technology allows highly complex parts featuring functional integration and maximum product customization to be developed and manufactured quickly.

3d Printed Shapes - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D printing of life figures and park sculptures.

Large sizes

Large sizes Modern technologies have opened up new possibilities in the implementation of ideas in the field of design. We are talking about growth figures and sculptures of various purposes. If earlier the figures were made of papier-mâché and left much to be desired or were created by artists, but cost simply fabulous sums, like those produced in factories by casting or stamping, now everything has become much simpler and much better in terms of quality. 3D printing allows you to quickly, efficiently and cheaply produce figures of any size and complexity.

So what options does 3D printing open up for us?

Life-size figures

Life-size figure is a figure of any real or fictional character made in full height and volume. These figures are very realistic.

Everyone has seen the figures and knows them well. You come across them at various promotions, they can be seen in amusement parks, theme parks, in cafes and restaurants, in shops and shopping centers, at exhibition sites. They allow you to create a mood, attract attention, which is extremely important from the point of view of advertising!

They allow you to create a mood, attract attention, which is extremely important from the point of view of advertising!

There is a place for a full-length figure in the interior, especially if it is a favorite hero or character. And both at home and in the office.

Life figures can be made by 3D printing, and this approach has many advantages:

- durability and practicality - the figures are printed from plastic, which is not affected by moisture and temperatures;

- the ability to print figures of any size;

- the ability to accurately implement an idea of any degree of complexity with the highest detail;

- high degree of realism;

- light weight - figures can be easily transported and moved;

- the shortest production time.

At 3D Service you can order 3D printing of life figures of any size. You can provide your file with a layout or entrust the creation of a 3D model to our specialists. All details must be agreed with the customer before printing. Our employees are also ready to paint the figure professionally. It can be monochrome painting, metallic or full color version. We guarantee high quality workmanship and affordable prices!

Our employees are also ready to paint the figure professionally. It can be monochrome painting, metallic or full color version. We guarantee high quality workmanship and affordable prices!

Park sculptures

Landscape design is not complete without various sculptures. They are made from different materials. Even in private gardens, small figurines appear to set the mood. As a rule, these are small ceramic products of standard production, that is, they do not carry a complex and extraordinary semantic load and are not unique.

Do you want to use unique park sculptures for your landscape? There is such an opportunity, and it will cost inexpensively, and the execution time will be very short.

3D printing allows you to create unique park sculptures. With this, you can create entire storylines, such as an Alice in Wonderland-themed theme park or a landscape in the style of a hobbit village. All this is possible thanks to 3D printing.

3D printed park sculptures have many advantages:

- the highest resistance to negative environmental influences;

- reasonable price;

- the shortest terms of execution;

- realistic and accurate implementation of tasks of any complexity;

- originality and exclusivity;

- low weight of products, which guarantees ease of transportation and mobility;

- no restrictions on size, detail, etc.

;

; - durability.

At 3Dservices you can order 3D printing of garden and park sculptures at a bargain price. You can provide us with a ready-made layout or we will create a unique 3D layout for you with mandatory approval before sending it to print. We can not only print park sculptures of fairy-tale characters, but also monuments, plaques, arches, any elements of small architectural forms (arches, columns, etc.) Products can be painted in colors according to your idea, made in monochrome or metal .

We are ready to help you to realize your ideas!

Let's make the world more beautiful together!

3D printing application how 3d printer works

Turch September 15th, 2014

No matter what anyone says, the future is still coming. And the point here is not only that the calendar changes year after year - we have in our hands such fruits of progress that our grandparents, moms and dads, and once we ourselves could not even dream of. Think about it - if you caught the days of Dial-up, then the very idea that you can sit on the Internet all day, download everything and not go broke, seemed incredible ...

Think about it - if you caught the days of Dial-up, then the very idea that you can sit on the Internet all day, download everything and not go broke, seemed incredible ...

However, there are much more striking and obvious examples. People over forty hardly thought in their childhood that a device would be hanging in their pocket that could provide them with communications, play computer games, watch movies, and there would be nothing unusual in this. Nevertheless, despite the fact that the whole world has been dreaming about smartphones since the first science fiction films, their appearance went quite smoothly and without cases of culture shock.

Think about this: things that are incredible from the point of view of people enter our life so smoothly and imperceptibly that we simply do not have time to be surprised when innovation becomes commonplace. Therefore, we invite you to take a short break and think about this: 3D printing. Today, this technology already exists, but has not yet become a part of every person's life, so let's not miss this moment - let's be surprised as we should.

What is a 3D printer?

While the regular printer has already become part of the everyday life of most computer users, 3D printers are still out of reach for the vast majority. Moreover, it is quite easy to meet a person who is completely unfamiliar with this type of device. So what is a 3D printer?

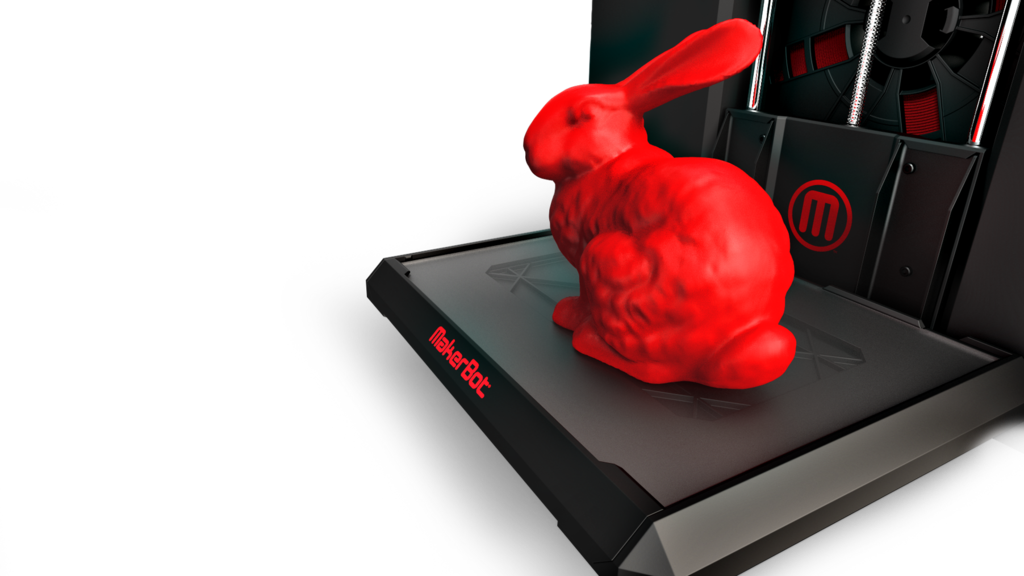

The 3D printer is a device that allows you to create tangible three-dimensional objects. For example, guests come to you and you are surprised to realize that you do not have enough mugs. No problem - open the desired file, send it to print and after a while you get a mug of the desired size and desired shape. Comfortable? More than.

However, while we are still far from having this magical device in every home, the price is too high. Yes, and the complexity of use, although incomparable with the management of a nuclear power plant, still has not reached the level of intuitiveness at which your grandmother, remembering the years of turbulent Komsomol youth, would have been churning out busts of Lenin for days on end.

In addition to cost, 3D printers have another significant drawback - they are unable to print complex objects. In most cases, you end up with a one-color item made of plastic or other similar material. As a result, no matter how fancy your 3D printer is, it still won’t be possible to print a brand new iPhone on it. Is that his toy plastic version.

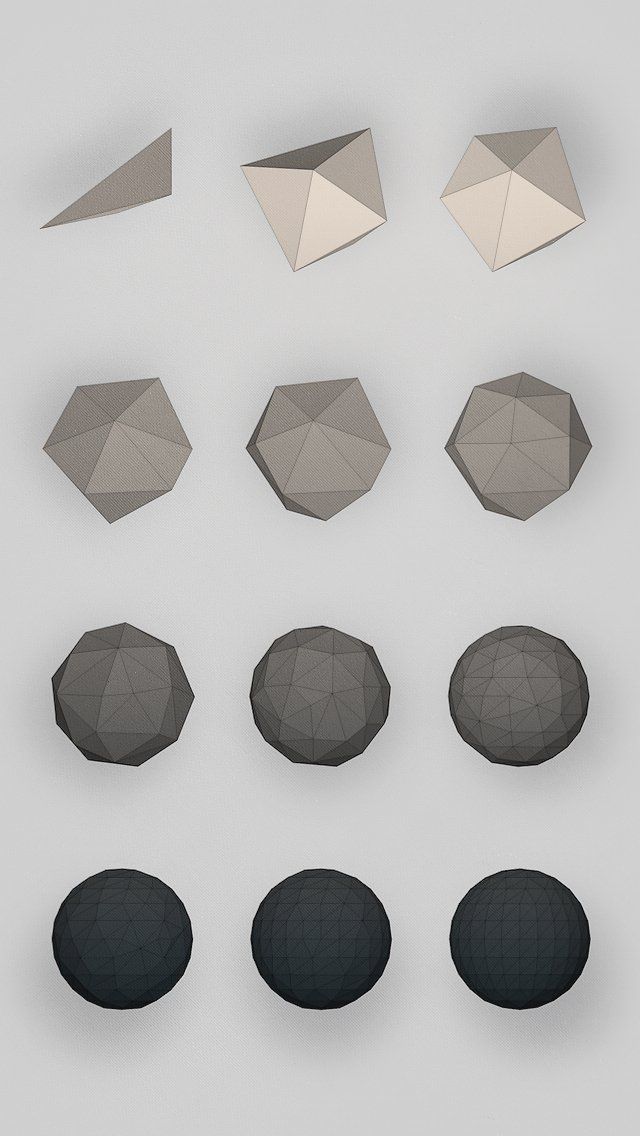

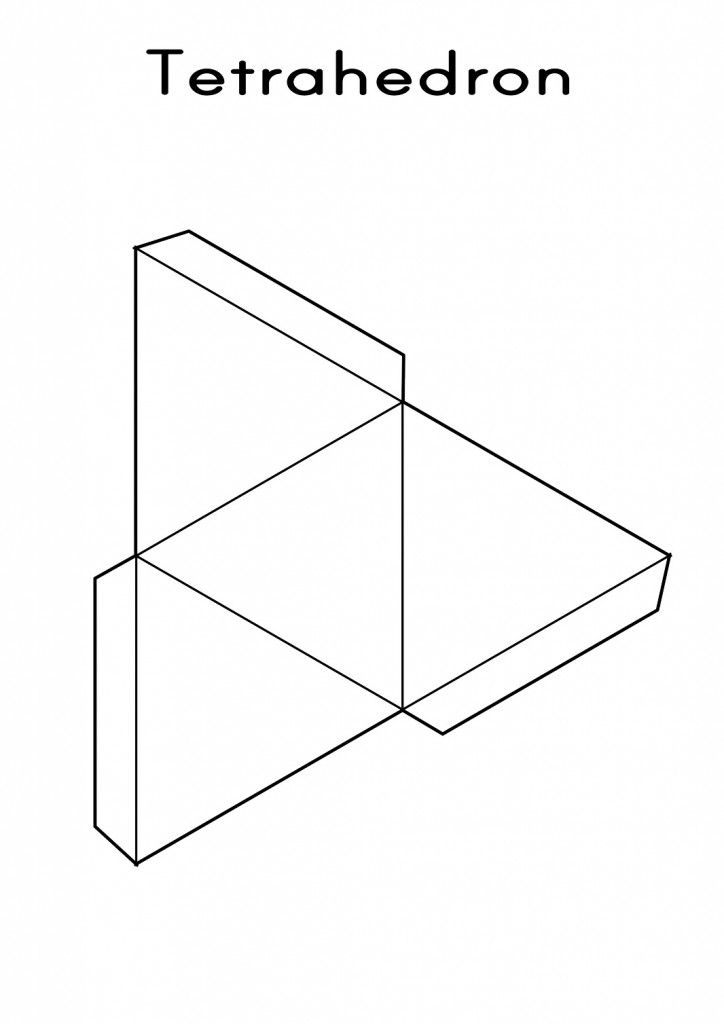

However, in fact, everything is not so sad - the complexity of reproducible items increases year after year. If the first 3D printers could only print not very neat geometric shapes, which had to be “brought to mind” with sandpaper, today we can create detailed models of buildings, and in the case of the latest advances in 3D printing, give these models a realistic look. , while some time ago even a two-tone item was something fantastic.

However, to better understand what can and cannot be 3D printed. You need to understand how it functions.

How does a 3D printer work?

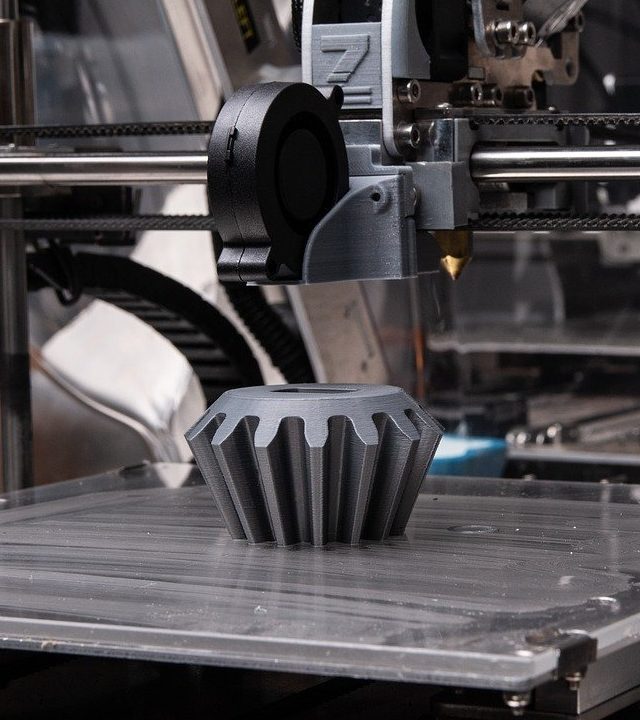

Although 3D printing technology has not yet reached the point where it can be said that it is on its feet, there are a whole bunch of different technologies that are used with equal success in modern 3D printers. Each of these technologies has its advantages, disadvantages and, of course, its purpose.

Each of these technologies has its advantages, disadvantages and, of course, its purpose.

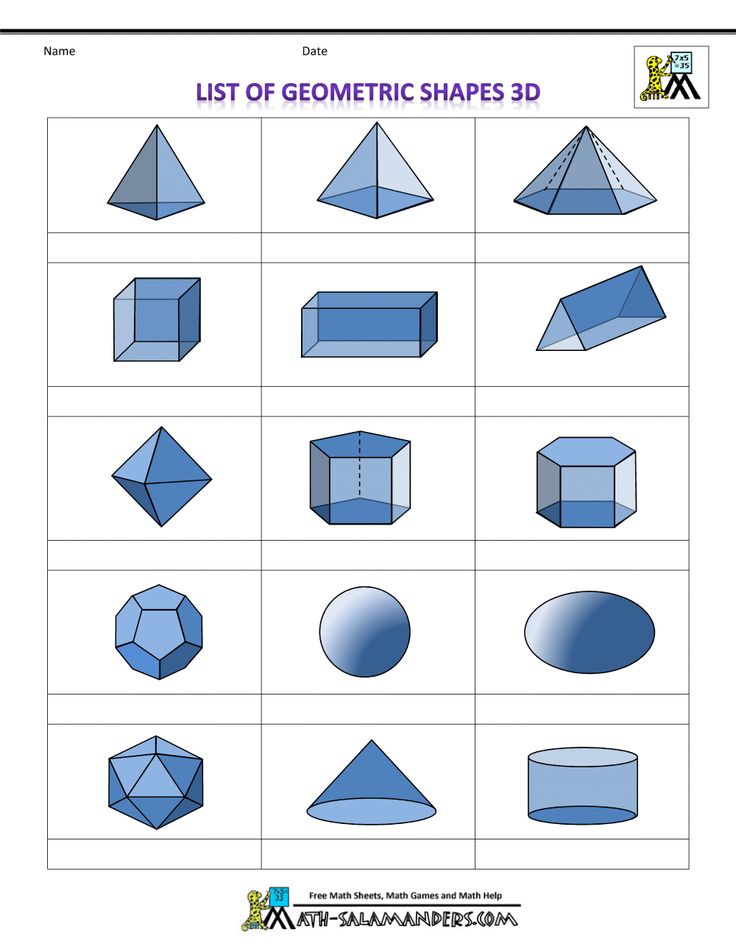

Today, all existing printing technologies can be divided into two main groups:

- Those that create objects by gluing their constituent particles;

- Those who create objects by spraying, squeezing or pouring the source material.

The first group can include stereolithographic printers, laser sintering systems, as well as the rather "ancient" 3DP technology. But let's take a closer look at them.

Stereolithography

Stereolithography is a process in which layers of material are obtained by exposing a laser to a special solution. After the beam reaches the required point, the solution in it hardens and turns into a solid material. Passing layer by layer, the printer literally "grows" the object you need.

It is also curious that the manufacture of such printers is relatively cheap, and they work at an enviable speed. However, why are they still not in our house? It's all about the solution - keeping a bath of a relatively toxic liquid polymer in an apartment is rather "burdensome", therefore this method is resorted to only in production conditions.

3DP

3DP is a very old technology that has been known for 30-35 years. Before printing, the model is divided into layers, after which the mechanism begins the production process. To begin with, the contours of the layer are filled with glue, after which the required amount of powder is fed into the chamber. The granules are glued together, after which the next layer is “drawn” on top. Technologically, such a printer is very simple to implement, however, the quality of the "print" leaves much to be desired - at the output we get a very fragile object that needs final processing. On the other hand, this approach is universal, for example, by replacing powder with powdered sugar, and glue with syrup, you can use this device in the confectionery industry.

Laser sintering

Laser sintering is a technology borrowed from laser printers. Each layer of the part is formed from a special powder, which is sintered with a laser beam. Roughly speaking, any laser printer can be called a 3D printer, it only prints from just 1 layer of a part . .. On the other hand, laser 3D printers can print from almost any material. Nobody prevents you from using bronze or titanium powder, getting strong metal objects as a result.

.. On the other hand, laser 3D printers can print from almost any material. Nobody prevents you from using bronze or titanium powder, getting strong metal objects as a result.

Laminated assembly

Laminated assembly. A principle that can be implemented with scissors and paper, however, with a large time investment. This technology involves cutting out layers from any material, and then gluing them into a single model.

The second group of 3D printers uses a slightly different principle - they do not glue anything, do not cut anything - objects are obtained using extrusion and spraying techniques.

Laser "sculpting"

The technology is quite interesting, since objects are created not even in layers, but point by point. This happens as follows: the laser is directed to the desired point, after which the powder of the desired material is sprayed onto it. The particles that flew past the beam are used in the next cycle, and those that got inside are sintered and become part of the created object. This technology has become a favorite among metal fabricators, as it allows the creation of alloys directly during the printing process.

This technology has become a favorite among metal fabricators, as it allows the creation of alloys directly during the printing process.

Polyjet

A more familiar technology for ordinary people - the material is loaded into the printer in liquid form. The printhead sprays it inside the contours of the layer, after which a flash of ultraviolet causes the liquid to solidify. This technology allows you to create objects with a high level of detail - the smallest detail can be as small as 16 microns, however, the polymer itself is very expensive, so this technology is not suitable for home use.

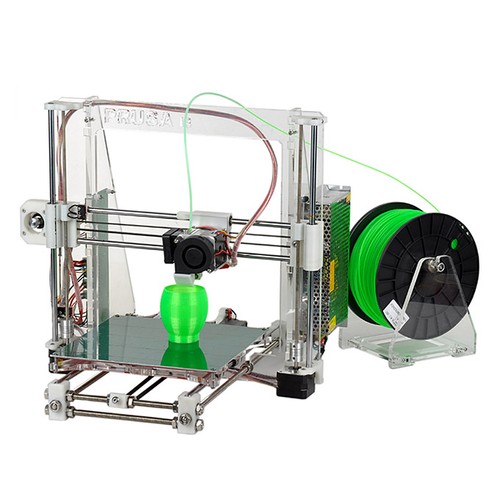

FDM printers

Finally, FDM printers. Today, they are the most common consumer 3D printers, as their technology is quite simple, economical and practical. The essence of this technology in a nutshell: the print head melts the plastic bundle and squeezes it out, forming the part in layers. It is pointless to talk about this technology, since more than enough has been said about it.

How much does a 3D printer cost? The simplest and cheapest copy will cost you $ 400-500, while you can only "print" small objects, the size of an average mug, and the printing itself will take a long time. In addition, cheap 3D printers are single-color, so you are unlikely to be able to draw something colorful.

However, while professional 3D printers cost tens of thousands of dollars with the ability to create color objects at high speed, there is a rather unusual alternative - RepRap. This printer should definitely become the topic of a separate article, however, talking about it in a nutshell, it is worth noting that this is one of the most ambitious projects created to design a 3D printer capable of printing ... a 3D printer. This project has already reached certain heights, significantly reducing the cost of the device (you only need to buy electronics), however, it still cannot create itself completely from scratch. It remains only to wait ...

Where is 3D printing used?

Actually, 3D printers have a lot to do.