Create 3d scanner

6 DIY 3D Scanners You Can Build at Home

Creating a 3D model of a real object can be done extremely fast if you have a 3D scanner at home. The problem is: 3D scanners are expensive to buy new.

If you're looking for a solution, why not try building your own affordable 3D scanner at home? It might not create perfect 3D models, but it's a cost-effective alternative to buying a 3D scanner.

Is It Cheaper to Build a DIY 3D Scanner?

The cost of buying a decent 3D scanner ranges from $700 to $10,000 at the highest end. On the other hand, building a DIY 3D scanner can cost less than $200—some even as little as $35.

Depending on the resolution of your homemade 3D scanner, you will still have to work to tidy up the 3D model so that it can be used for things like 3D printing, game development, or perhaps design prototyping. But overall, it will still speed up the design process when compared to building a model from scratch.

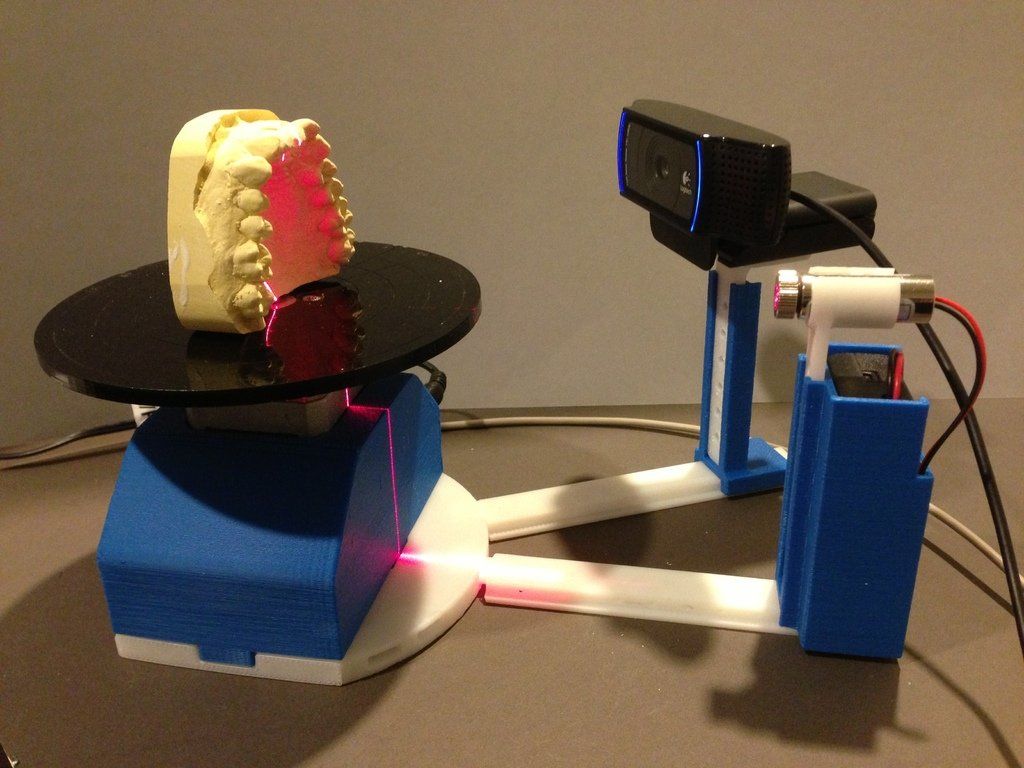

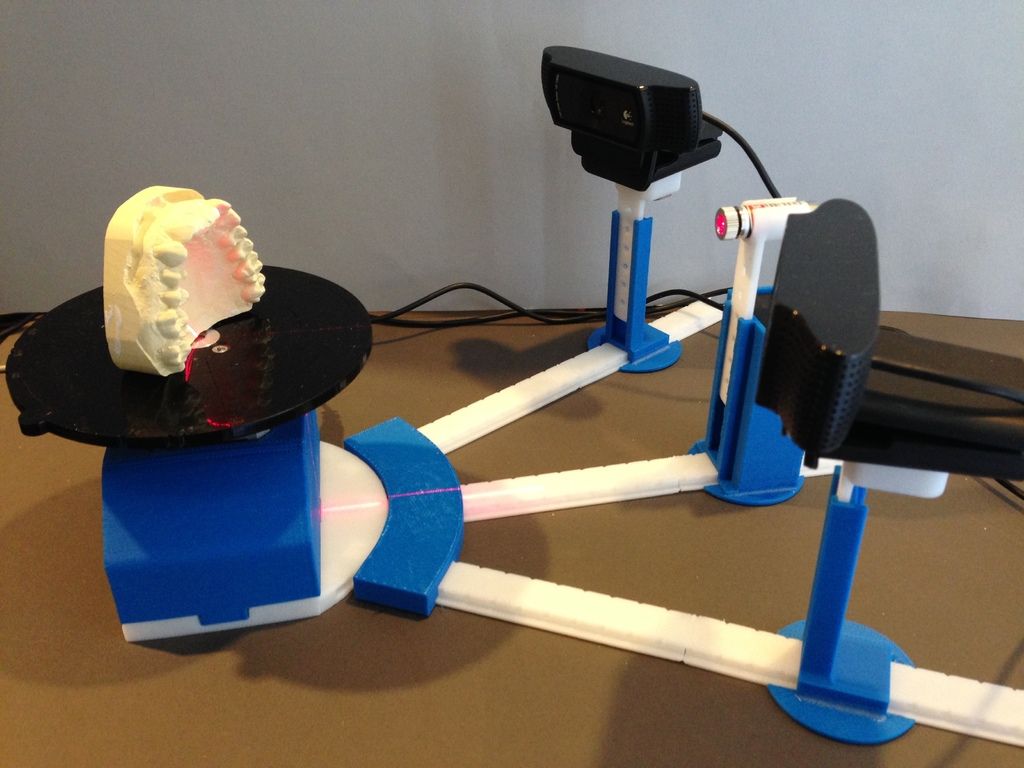

1. Cheap 3D Printed 3D Scanner

This 3D scanner is built using 3D printed parts, featuring both open source software and open source hardware files. If you choose to install the maximum of four lasers, then the cost of the project comes in at $35 to $50. Once it's built, handling the digital scan will require some legwork to smooth out. But considering its price tag, it's well worth giving it a go.

You can find the STL files and a full build guide on Instructables. Besides the 3D printed components, you will need one to four lasers, a stepper motor, a turntable, and an Arduino Nano to bring it all together. One benefit of this project is that it's been built many times by community makers, resulting in plenty of images and feedback surrounding the project to help fill in any gaps.

2. DIY 3D Scanner Using a DSLR Camera

Another option for building a 3D scanner is to use a DSLR camera and a method called photogrammetry. At its most basic, it involves taking a lot of images of an object from different angles and stitching those photos together in a software program to create a 3D model.

Alongside a DSLR camera, you will need an Arduino, a stepper motor and driver, an LCD screen, and an IR LED. The goal of the hardware is to build a rotating platform that moves by set amounts so that your camera can photograph the object in a very detailed and controlled way. You can find a great explanation of the project on Instructables.

The goal of the hardware is to build a rotating platform that moves by set amounts so that your camera can photograph the object in a very detailed and controlled way. You can find a great explanation of the project on Instructables.

The real difficulty of this project comes in processing the photos. A good photogrammetry program is essential, and that can cost over $150 to license. There is some free software available, but it may come with limitations.

If you're wondering if there is an alternative solution, you can read our guide to how to turn everyday objects into 3D models without a 3D scanner.

3. Optical CT/3D Scanner With Arduino

For something a little different, in this project you will build a 3D scanner that also doubles as an optical CT scanner. This type of scanner will do the trick if you have objects that are semi-transparent, like a gummy bear or a segment of orange. Otherwise, you can use this setup with the photogrammetry method for regular 3D scans.

Everything in this build is enclosed inside a box. This allows greater control over lighting the object to produce sharper images. While it involves some woodworking and construction, the hardware is still powered by a humble Arduino Nano, plus additional parts that you can find at any hardware store.

A great guide is available on Instructables for building the box, alongside details for creating a sleek control panel for changing photo parameters on the go.

4. FabScan: Raspberry Pi + Arduino 3D Scanner

This 3D scanner uses both a Raspberry Pi and an Arduino to build a 3D laser scanner. What sets this build apart is that it can be operated remotely via a web browser on a phone.

Much like other DIY 3D scanners, a stepper motor and driver are used to rotate a turntable holding the object you want to scan. Additionally, you will need a line laser and a Raspberry Pi camera. You can find the guide and a full components list on Instructables.

While the creators have gone with a laser-cut MDF box, you can just as easily use spare parts lying around the home to create the enclosure. Alternatively, cardboard can work too, and painting it black will aid in diffusing the laser light so that it doesn't interfere with the scan.

Alternatively, cardboard can work too, and painting it black will aid in diffusing the laser light so that it doesn't interfere with the scan.

Once you have a good scan of your object, you might be interested in 3D printing it. Haven't got a 3D printer? Here is our pick of the best 3D printers.

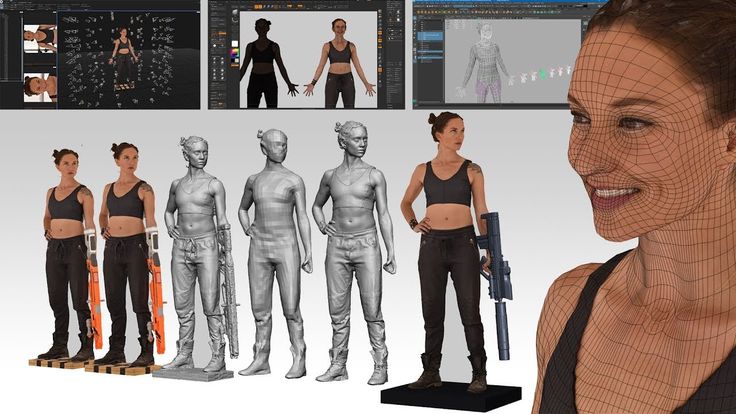

5. The Ultimate Human Sized 3D Scanner With Raspberry Pi

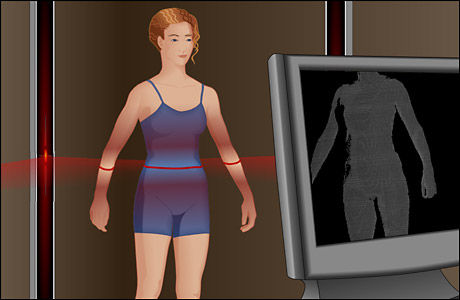

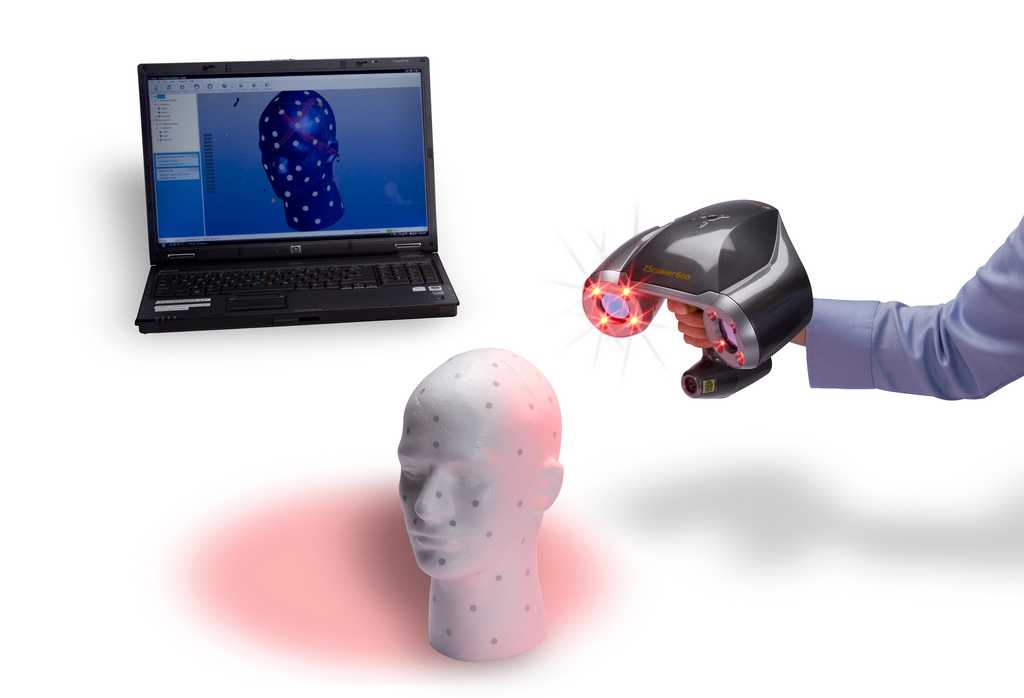

While most homemade 3D scanners are built to capture a small object, it's also possible to build a human-sized 3D scanner. The way to do this is with a lot of Raspberry Pis, as you can see over on Instructables.

The maker behind this project scaled up his 3D scanner using a whopping 47 Raspberry Pis plus a Raspberry Pi camera for each module. The goal was to use the photogrammetry method to take a photo of his subject from every possible angle. Because he wanted to capture a 3D model of his two-year-old son, this all had to happen instantly.

Incredibly, it works, and it works very well too. If you have the time and investment to buy a box full of Raspberry Pis, you won't be disappointed because the results are impressive. The maker says you can use fewer Pis and cameras and still get good results, especially if you only need to capture the front of a person’s face.

The maker says you can use fewer Pis and cameras and still get good results, especially if you only need to capture the front of a person’s face.

6. Standalone 3D Scanner

Maybe you're just after a simple and small 3D scanner that you can make over the weekend. If so, then this project will suit you. This 3D scanner on Instructables is designed to be all-in-one, meaning that the photos are compiled onboard and an STL file is saved directly to a memory card. Instead of compiling the photos in a separate photogrammetry program, this 3D scanner handles them for you.

While it doesn't produce incredibly detailed scans, it does make for a rapid way to take a 3D model straight to 3D printing. One thing to bear in mind, however, is that the dimensions of the 3D scanner structure need to be kept exactly as written in order to match the code.

Building a Homemade 3D Scanner

Putting together a 3D scanner at home isn't extremely difficult to achieve. When compared to the expensive price of commercial 3D scanners, it's well worth building a DIY 3D scanner yourself.

With a Raspberry Pi or Arduino and a few extra affordable parts, you'll be well on your way to creating a cheap and awesome 3D scanner.

9 Accurate DIY 3D Scanners You Can 3D Print At Home (2022)

3D scanners can get really expensive. We’d know – we’ve tested and researched them in creating our ranking of the best 3D scanners . However, if you’re willing to be a little more thrifty you can save a lot of money building your own DIY 3D scanner — and have a cheap 3D scanner you can feel proud of building yourself!

DIY projects, especially in an area where precision is key, have an unfairly slap-dash reputation. In fact, there are some very accurate DIY 3D scanners on our list, you just need to assemble them yourself.

The best part: they’re almost free if you 3D print the parts — your only costs are the camera/parts.

However, don’t be fooled – you won’t get $20,000-quality scans from these kits.

And, it takes focus and skill to build such a technical piece of kit – hence we’ve included a couple of easy-assemble kits which cost more, but let you get right down to scanning.

Best DIY 3D Scanner Kit Under $200

HE3D Open Source Ciclop DIY 3D Systems Scanner Kit for 3D Printer

$159.00

Amazon here

Best 3D Scanner Under $1000

$719.00

Amazon here

12/21/2022 06:35 pm GMT

Top Picks

Best DIY Scanners – Full Round-Up

- BQ Ciclop: Best 3D scanner kit overall

- Murobo Atlas: Good Ciclop DIY scanner alternative

- Cowtech Ciclop: Upgraded premium Ciclop scanner

- Openscan: Great open source 3D scanner

- AAScan: Great option for Android

- Revopoint POP 2: Best semi-assembled 3D scanner to save you time

For the DIY kits, we’ve included download links and links to documentation to get you started.

But first, let’s cover what to look for in a good homemade 3D scanner:

What Makes a Good DIY 3D Scanner?

- Price-performance ratio: for the price, how good are scans?

- Resolution: how crisp is scan quality

- Accessibility: you may be able to print most of the 3D scanner, but are the rest of the parts easy to buy?

- Ease of assembly and use: quick and easy builds are always better.

The best 3D scanner projects can be built by anyone, newbie or expert.

The best 3D scanner projects can be built by anyone, newbie or expert.

The Best 3D Printable 3D Scanner Kits

Ciclop DIY 3D scanners

Many of the best DIY scanner kits are based on the original Ciclop open-source files. Massive companies like BQ have created their version, as well as tweaked versions such as CowTech Engineering’s take.

We’ve included them all here, as each option are some of the most DIY accurate 3D scanner options for this price range. For a pre-assembled scanner with the same quality, you’d likely need to spend double this.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

BQ Ciclop

- Resolution: 0.3-0.5mm

- DIY 3D scanner technology: laser triangulation

- Price: around $150 — Available on Amazon worldwide here

BQ are a Spanish technology giant who are well-known across Europe for their smartphones, tablets, and 3D printers. They’ve also developed their Ciclop DIY 3D scanner, which scans a volume up to 250 x 205 mm, based on laser triangulation technology.

They’ve also developed their Ciclop DIY 3D scanner, which scans a volume up to 250 x 205 mm, based on laser triangulation technology.

An important feature of the BQ Ciclop is that it’s a completely open source 3D scanner. You’re free to modify it as you wish, following the RepRap philosophy. It’s easily accessible via USB or Bluetooth, and can 3D scan with a resolution of between 0.3-0.5mm.

- We also have a ranking of the best open source 3D printers.

Another great addition to this DIY 3D scanner is that it works with Horus open source 3D scanning suite which BQ also developed. This makes scanning much easier with the compatible program. You can buy just the electronics (includes an Arduino, webcam etc) and print the parts yourself for $115, or buy the whole kit for $240. Not bad.

However, it is worthy of note that the BQ Ciclop is difficult to assemble. Other DIY 3D scanners are quicker and simpler to build, though the Ciclop is still a fantastic DIY 3D digitizer.

Best DIY 3D Scanner Kit Under $200

HE3D Open Source Ciclop DIY 3D Systems Scanner Kit for 3D Printer

$159.00

Yes, you'll get better quality if you spend more on a scanner like the Revopoint POP range, but with this you get to build your own 3D scanner from the parts for several hundred dollars less.

Amazon here

We earn a commission if you make a purchase, at no additional cost to you.

12/21/2022 06:35 pm GMT

Murobo Atlas — Great Raspberry Pi 3D Scanner

- Resolution: 0.25mm

- DIY 3D scanner technology: laser triangulation technology

- Price: $200-250 — Available on Amazon worldwide here

Another homemade 3D scanner, the Atlas has the highest quality specs of any DIY 3D scanner we researched. It includes a 3D printed body made from PLA and ABS filaments, which can be purchased online. If you’re a serious DIY fanatic, you can print the parts yourself via the download link here.

It includes a 3D printed body made from PLA and ABS filaments, which can be purchased online. If you’re a serious DIY fanatic, you can print the parts yourself via the download link here.

Depending on if you already own a Raspberry Pi or not, you can save money on the build. This is because the Atlas DIY 3D scanner uses a Raspberry Pi camera to take detailed 3D scans with an accuracy of 0.25mm. Depending on your choice, the Atlas is likely to cost between $200 and $250, which is far less than most professional 3D scanners.

Moreover, Murobo has made considerable efforts to make sure that the Atlas DIY 3D scanner is convenient and simple to use. To achieve this, the Atlas comes with FreeLSS free 3D software which enables you to easily take 3D scans. In addition, you can access your Atlas via your computer’s browser through WiFi, as well as via SD card.

Overall, this DIY 3D scanner Raspberry Pi collaboration is a really interesting and creative way of combining several different innovative technologies to create a scanning device. If you’re an Arduino fan instead, you may be able to make it work for you too.

If you’re an Arduino fan instead, you may be able to make it work for you too.

CowTech Ciclop

- Price: $119 – $159 (depending on whether you’re 3D printing the parts or not) — Available on Amazon here

- Resolution: 0.5 mm

- Maximum scan volume: 200 x 200 x 205 mm

BQ formed the foundations of the DIY 3D scanner kit, and remains one of the best DIY 3D scanner on tight budget options. Then back in 2015, CowTech Engineering used the foundations led by BQ, putting their unique spin on an updated model.

True to the open source movement, Cowtech started a Kickstarter campaign to raise money to put their version of the original, the CowTech Ciclop, into production. The team set the lofty goal to raise $10,000, and were met with surprise when the community rallies to raise $183,000. The CowTech Ciclop DIY 3D scanner kit was born.

So what are the differences between CowTech’s version and BQ’s DIY 3D scanner?

The CowTech Ciclop still uses the Horus 3D software program as it does a fantastic shop for 3D scanning objects. Differences however include a slightly different design, which the team spent days designing so that the parts could be 3D printed on any FDM 3D printer. Some desktop 3D printers only have a small build volume, so CowTech designed parts that can be printed on any printer with a build volume of 115 x 110 x 65 mm, which almost all 3D printers have.

Additionally, CowTech’s Ciclop has adjustable laser holders, and whereas the BQ Ciclop uses threaded rods, CowTech’s DIY 3D scanner uses laser-cut acrylic. This isn’t anything drastic and the scanners still look fairly similar, but CowTech only intended to improve the existing design, not reform it. CowTech sell the Ciclop, ready-to-scan, for $159 on their website. Overall, this is a great cheap DIY 3D scanner, and very effective for laser triangulation 3D scanning.

OpenScan Classic and OpenScan Mini

- Max Scan Volume: 180 x 180 x 180 mm / 80 x 80 x 80 mm

- Accuracy: Up to 50 microns

- DIY 3D scanner technology: Photogrammetry

- Price: Starting at $100.00 up to $200.00 for a complete kit with 3D printed parts and electronic

The Mini and Classic are two low-cost but high-quality 3D printed DIY scanner projects designed by German company OpenScan. In action, the OpenScan uses a stepper motor mounted to a 3D printed frame to rotate an object to capture images from various angles. These are then compiled into a high-quality 3D model using open-source software or OpenScanCloud, ready for 3D printing.

Where the OpenScan Classic and Mini differ from one another is max scan volume and camera/SBC options. The Mini features an 80 x 80 x 80 mm scan volume, while the Classic more than doubles the scan volume to a roomy 180 x 180 x 180 mm, perfect for scanning larger objects.![]() The Openscan Mini – the cheaper and smaller 3D printable 3D scanner.

The Openscan Mini – the cheaper and smaller 3D printable 3D scanner.

The OpenScan Mini is tied to a Raspberry Pi and only works with either a Pi Camera or Arducam IMX 519 and includes one-click easy scanning. This allows the completed scanner to rotate not just the object but also the camera for a more detailed point cloud.

On the other hand, the OpenScan Classic is also compatible with Smartphones and DSLR cameras, which generally means better quality photos and, as a result, higher-quality models. It’s the tinkerer’s option and better suited for those that want to customize the scanner to their needs.

OpenScan offers a solution for all DIY skill levels and budgets, whichever model you decide on. You can customize kits based on your needs or order a complete kit that includes all the electronics and 3D printed parts.

The full assembly guide is here.

AAScan Open Source 3D Scanner Based on Arduino and Android

AAScan is a very recent (February 2020) DIY open source 3D scanner that’s fully automated in taking photos and moving the object around on the scan plate. All the files are on Thingiverse, which we’ve linked below. Interestingly, the creator stresses that the AAScan is intended to be a purposefully minimalist machine, able to scan but not filled with extra features beyond this primary capacity.

All the files are on Thingiverse, which we’ve linked below. Interestingly, the creator stresses that the AAScan is intended to be a purposefully minimalist machine, able to scan but not filled with extra features beyond this primary capacity.

All the instructions for how to build, print and assemble the AAScan are on the Thingiverse page, requiring an Arduino, some electronics, and either a 3D printer to print the plastic parts or someone else to print them for you — such as from a 3D printing service.

You can view the DIY scanner on Thingiverse here.

FabScan Pi

- DIY 3D scanner technology: laser triangulation

- Price: $100-200 depending on which version

The original FabScan was a DIY 3D scanner built by Francis Engelmann as part of his Bachelor’s thesis back in 2010. Since then, there have been numerous improvements made in new iterations up to the newest model, the FabScan Pi. This new model uses a Raspberry Pi camera along with the new design to offer higher quality 3D scans.

This new model uses a Raspberry Pi camera along with the new design to offer higher quality 3D scans.

Based on laser triangulation technology, the FabScan Pi is one of the best DIY 3D scanner options for those who are into doing it themselves. Depending on if you go for one of the older models or the latest, the price can vary between $100 and around $200 to completely create the 3D scanner. Overall, it’s a really cool kit and thesis which you can make at home.

If you want to create your own FabScan, you can follow the assembly guide here.

DIY Standalone 3D Scanner by Jun Takeda

- DIY 3D scanner technology: Photogrammetry

- Price: $200.00

The DIY Standalone 3D Scanner is an excellent option for those that want a hands-on project that results in a reasonably accurate and easy-to-use stationary 3D scanner.

By combining a Mbed board with a camera and OpenCV libraries, the scanning process is largely automated with just a single button push. The scanner captures multiple images of an object to create a 3D model that’s then output as an STL file written to an SD Card.

The scanner captures multiple images of an object to create a 3D model that’s then output as an STL file written to an SD Card.

To complete the project, you’ll need a GR-LYCHEE as a centerpiece sided by smaller electronic parts, plastic sheets to create the housing, and various nuts and wiring to piece it all together.

As the name implies, it’s very much a DIY project and, as such, would best suit those happy to troubleshoot any potential hurdles with little hand-holding. Though there are instructions, you’re responsible for designing the housing, wiring the board, and calibrating the camera.

Arduino-Controlled Photogrammetry 3D Scanner by Brian Brocken

- DIY 3D scanner technology: Photogrammetry

- Price: ~$100

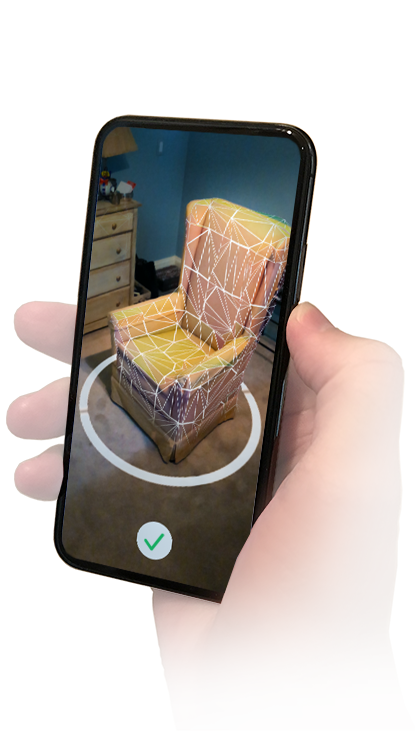

The Arduino-Controlled Photogrammetry 3D Scanner is a 3D printable 3D scanner DIY project that leverages the camera on any run-of-the-mill Smartphone and a cheap Arduino UNO SBC to keep costs low.

The core idea is to assemble a turntable consisting of 3D printed mechanical parts, including a print-in-place bearing. A Bluetooth-connected Smartphone does the actual scanning via the normal photogrammetry process. As for electronic components, you’ll need a servo motor, LCD screen, Arduino Uno, PCB, stepper motor, Bluetooth remote, regulator, and a small joystick module.

Once assembled, the Arduino-Controlled Photogrammetry 3D Scanner can capture anywhere from 2 to 200 photos in a single 360° rotation for reasonably detailed scans. The images are then sent to photogrammetry software such as AutoDesk Recap Photo to assemble a 3D model.

Aside from the cost of filament, expect to pay no more than $100 for all the parts and the STL files to 3D print the turntable.

Semi-assembled DIY scanners

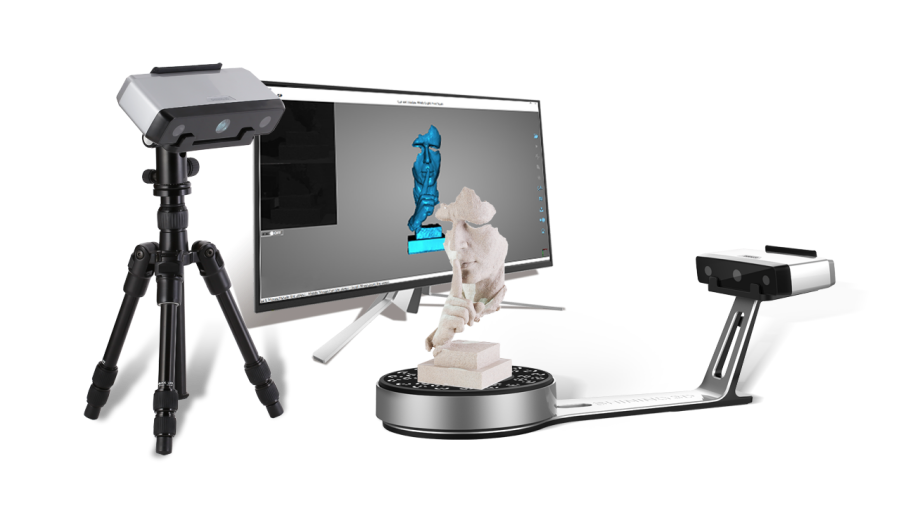

Revopoint POP / POP 2

- Price: $500-700 — Available at Revopoint store here

- Accuracy: 0.3 mm

- Max Scan Volume: 200 x 300 x 300 mm

- Scan Speed: Up to 8 FPS

- DIY 3D scanner technology: Structured light

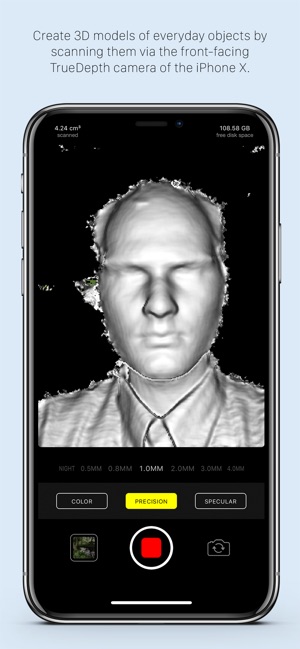

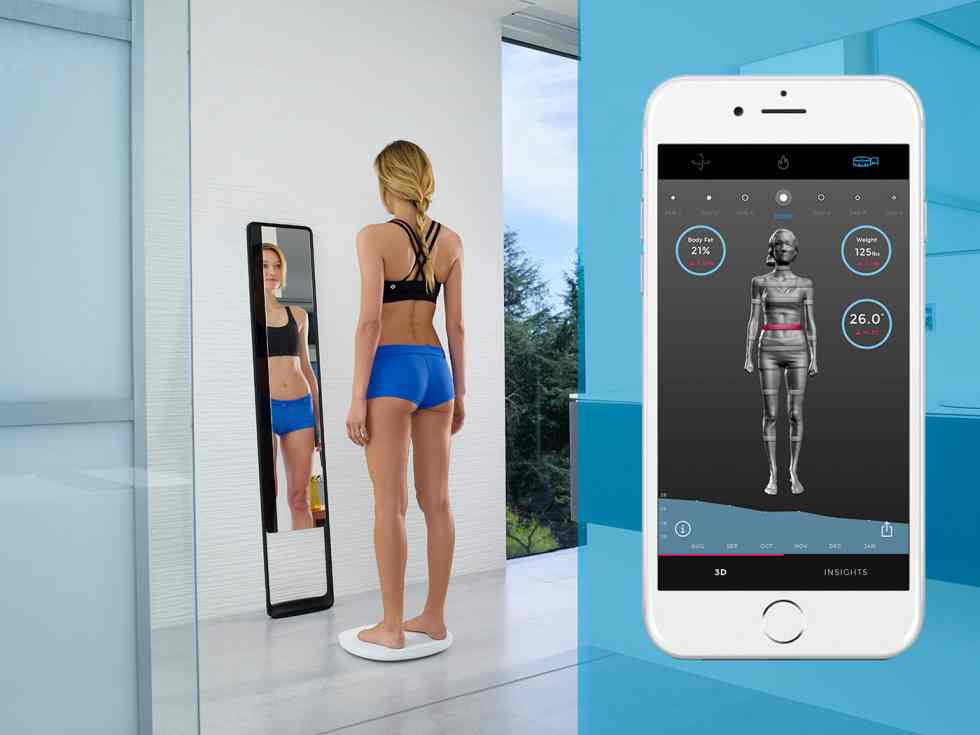

Though not technically a DIY scanner, we thought we’d slide in the Revopoint POP as a cheat option for those that want to save time and want largely better quality scans than you’d get with a homemade alternative.![]()

It comes semi-assembled – you just need to attach the tripod, connect the USB and the turntable, add the sticker markers for better scan tracking, and optionally build and attach the larger turntable – so you can get started in just 5 minutes!

A basic mug scan we did on our Revopoint POP 2.The catch? At around $500, the Revopoint POP is considerably pricier than a DIY scanner. Still, it may be worth paying the premium for the convenience and reliability.

The Revopoint POP offers 0.3 mm accuracy (the POP 2 offers within 0.1 mm!) and automatic alignment technology, making for more detailed and smooth full-color 3D models than DIY scanners. It can capture 360° scans of objects up to 200 x 300 x 300 mm, besting most DIY options.

The main benefit of all this is high accuracy scans that are just about ready for 3D printing with very little post-processing needed to iron out imperfections and poor surface details.

A statue scan we did with our Revopoint POP 2.Ease of use also extends to the intuitive software, which works with Smartphones for on-the-go scanning and features exports to STL and OBJ formats. Alongside, it bundles in best-of both-worlds handheld and stationary modes. Five different scanning profiles allow you to tune the POP to each scan with face, body, feature, mark, and dark mode.

Alongside, it bundles in best-of both-worlds handheld and stationary modes. Five different scanning profiles allow you to tune the POP to each scan with face, body, feature, mark, and dark mode.

Read more: we tested and reviewed the Revopoint POP 2

Best 3D Scanner Under $1000

Revopoint POP 2 3D High-Precision Scanner with 0.05mm Accuracy

$719.00

You'll see just how accurate this scanner is when you try it (I've tested it to confirm a 0.07mm accuracy in my hands-on review) - there's nothing better for under $1000.

Revopoint hereAmazon here

We earn a commission if you make a purchase, at no additional cost to you.

Can You Make a 3D Scanner?

- Choose a DIY 3D scanner design.

- Source the non-3D printable parts such as the camera, stepper motor, single board computer (such as an Arduino), wiring, and other electronic parts.

- 3D print the housing, brackets, turntable, mounts, and other parts required for the 3D scanner project.

- Wire and assemble all the parts.

- Configure and set up the single board computer.

- Test and scan.

FAQs

Which is the Best DIY 3D Scanner?

This depends on how much DIY you want to take on yourself, and how much you are ready to spend.

One of the most cost-effective options is scanners based on the Ciclop open-source 3D scanner design. You can purchase a low-cost Ciclop scanner like the BQ Ciclop or CowTech Ciclop 3D scanner, then 3D print the parts from home and modify and tune the scanner to your liking.

Alternatively, the Revopoint POP is an excellent semi-assembled 3D scanner with great specifications and software at an affordable price for those that want to save time.

What is a DIY 3D Scanner?

A DIY 3D scanner is a cost-effective, home-made device constructed from manufactured or 3D printed parts designed to capture the characteristics of a specific object – such as size, surface details, and shape – by scanning it from multiple angles to create an equivalent point cloud that can be processed into a 3D model via software.

Other articles you may be interested in:

- The best 3D scanners

- The best low-cost 3D scanners

- Top 3D scanner apps for iOS and Android

- The best photogrammetry software

- Structured light 3D scanning vs laser scanning

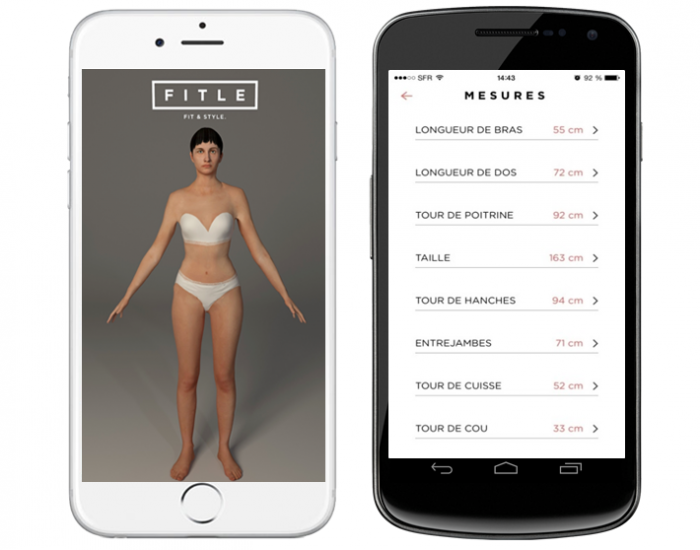

- 3D body scanners: a guide

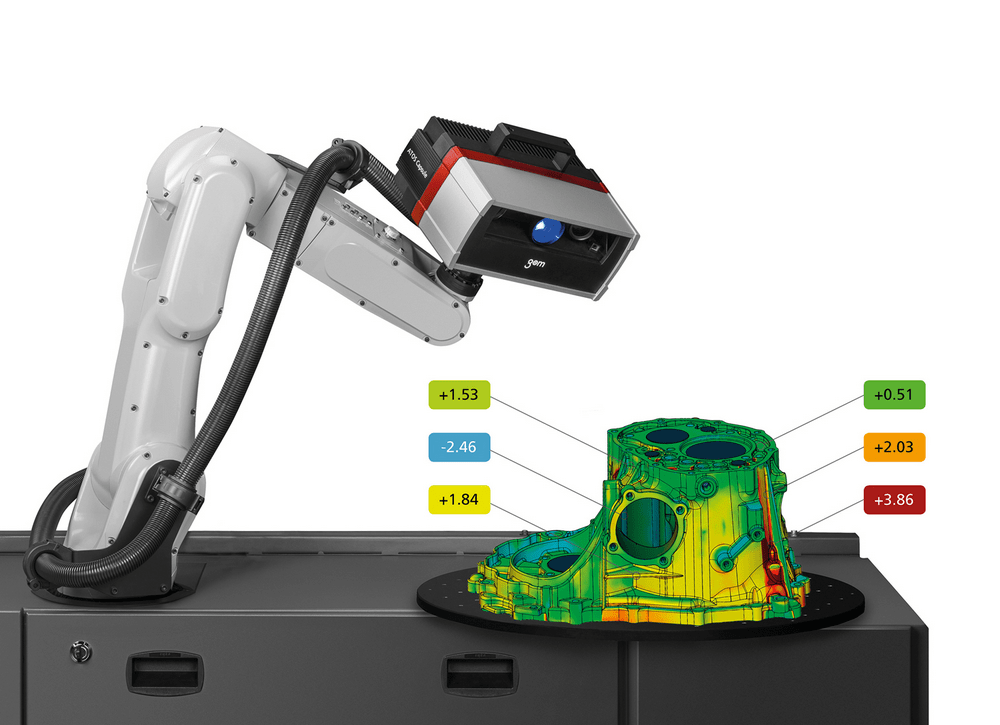

- Industrial 3D scanners

review of the 10 best programs for 3D scanners: the most popular software for 3D scan

04/30/2021

Content

-

- PhotoModler Scanner

- Rapidform 9000 Rangevision Scancenter

- GEOMAGIC CONTROL CONTROL CONTROL

- FARO Scene

- 3DF Zephyr

- Colmap

- PolyWorks

- Vxmodel

- Artec Studio

- Conclusion

-

by setting the parameters manually;

-

automatically, from already laid beacons;

-

from a point cloud from overlapping images.

-

XOS - designed to regulate and control 3D scanning, as well as processing the resulting images.

nine0003

nine0003 -

XOR - widely used in design, as it has a huge number of tools for 3D modeling. With its help, you can create high-precision three-dimensional models (from a point cloud) of almost anything.

-

XOV - allows you to control the quality of the resulting three-dimensional image, which makes it possible to maximize its detail. nine0003

1 3D printers have long ceased to be a curiosity for Russians. Increasingly, these devices can be found not only in manufacturing plants and in companies involved in engineering and design. They are actively used by consumers both for personal needs (creating souvenirs, figurines) and for work purposes, moreover, in various fields - medicine, construction, science, car manufacturing, etc. However, all this would be impossible without 3D scanners that transfer data about a physical object into digital format and, using special computer programs, create a three-dimensional model, which can later be sent for printing. Scanning, in fact, is only the first stage of work, but the main part of it falls on the processing of the collected information. nine0003

However, all this would be impossible without 3D scanners that transfer data about a physical object into digital format and, using special computer programs, create a three-dimensional model, which can later be sent for printing. Scanning, in fact, is only the first stage of work, but the main part of it falls on the processing of the collected information. nine0003

Specialized software not only analyzes the information received and creates a virtual copy based on it, but also helps to eliminate possible errors and errors made during the scanning process and much more.

Today we will talk about the most popular programs for 3D scanners that allow you to solve almost any user task.

Photomodeler Scanner

Very simple and functional software that can create 3D models of varying degrees of complexity. Almost everyone can understand it and learn how to use it to recreate virtual copies of anything, even a person. nine0003

You can set the characteristics of a future object in Photomodeler Scanner using 3 methods:

In the latter version, the user will also need to indicate the position of the camera during the shooting process and mark control points on the images, linking them together. nine0003

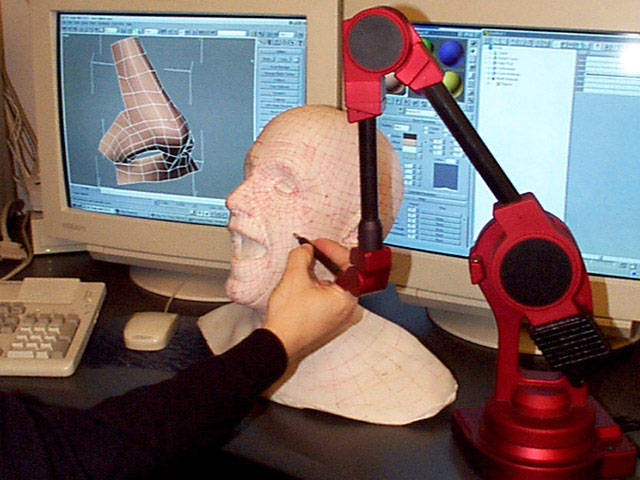

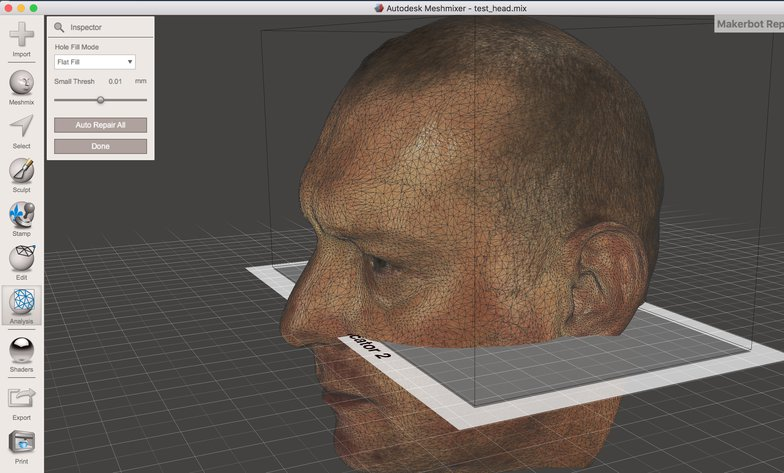

Creating a 3D model with Photomodeler Scanner

With Photomodeler Scanner, you can create all kinds of diagrams, graphs, different planes, expand a 3D line, and much more.

This application is very affordable and at the same time allows you to get professional results with a minimum of effort.

RapidForm

One of the most frequently used and convenient programs. Distinguished by its quality and versatility, as it is suitable for many models of 3D printers. nine0003

It analyzes the data received using a 3D scanner and creates an accurate three-dimensional model. If you need to make any changes, then it will be quite easy to do this, since the program is very simple and straightforward to use.

Example of work in Rapid Form

RapidForm has several types of programs:

RangeVision ScanCenter

Software that provides the user with a huge selection of functions and tools for creating a high-precision digital three-dimensional copy of an object of any complexity. For data analysis, unique algorithms are used that make it possible to convey as clearly as possible not only the geometry of the scanned object, but also its color (up to shades, including white) and texture. At the same time, anyone can understand the RangeVision ScanCenter, as it is intuitive and easy to use. nine0003

Screenshot of the process of creating a 3D model in Range Vision

It can work in various scanning modes: free, with markers and on a turntable. The resulting file can be exported to all popular formats.

The resulting file can be exported to all popular formats.

All actions of the program are automated as much as possible (calibration, adjustment, analysis of the quality of scans), which greatly simplifies the task and at the same time gives the best result at the output. nine0003

Geomagic Control X/Design X/Wrap

Geomagic professional 3D scanning software is available in 3 versions: Wrap, Control X, Design X. They use the latest topological shape recognition technologies. They can not only project a three-dimensional image of an object, but also analyze the degree of its possible wear and deviations. Often used in reverse engineering.

Geomagic Design X 3D reverse design software. Provides the ability to combine CAD processing and 3D scan data based on a design, resulting in detailed CAD models. This can be done both automatically and manually by setting parameters and editing the processing of point clouds and polygonal meshes. nine0003

nine0003

Geomagic Control X - software for quality control and geometry of 3D models. Provides users with a wide range of tools to enhance their scanning experience with reporting and data analysis capabilities.

Wrap : Used for processing point clouds and meshes, used in modeling and design. It works quickly and accurately, making it possible to optimize the resulting model without losing the original properties of the object, such as texture and texture. After processing the scan data with Wrap, the created 3D project can be printed. Suitable for both small and large items. nine0003

How to create a 3D model in Geomagic Wrap

The Geomagic software package, like other analogues, allows you to control the quality of scans and export 3D models created on their basis to various formats.

FARO Scene

Faro is a world famous manufacturer of 3D scanners, which also produces one of the most advanced software for them. One such program is Faro Scene. It is suitable for working both with "native" devices of the same brand, and for many others. nine0003

One such program is Faro Scene. It is suitable for working both with "native" devices of the same brand, and for many others. nine0003

Faro Scene is widely used to create 3D models of various buildings

It is very effective in processing scans: it can combine them, carry out all kinds of measurements, visualize data, etc. In addition, thanks to the advanced functions of the program, it is possible to transfer color from a photo to a finished model by overlaying and further balancing it.

3DF Zephyr

Perhaps the most popular program among users, due to its convenience and simplicity. The interface is so clear that it is not difficult to understand it. nine0003

3D-Zephyr will not cause problems even for beginners

Suitable for both amateurs and professionals. The latter will especially like a large selection of tools and settings, including the ability to transfer the resulting three-dimensional model to CAD software.

Colmap

Indispensable in cases where you need to quickly and easily create a 3D copy of an object. Colmap makes it possible to use a 3D mesh both from one camera and from several. This approach is very convenient where you need to scan a large number of items in a short time. nine0003

Colmap example

The “minus” is that editing 3D models will not work without additional software. However, the quality of such 3D images is quite acceptable.

PolyWorks

The capabilities of the program allow you to analyze the accuracy of the resulting three-dimensional copy, as well as its quality.

3D object created in PolyWorks

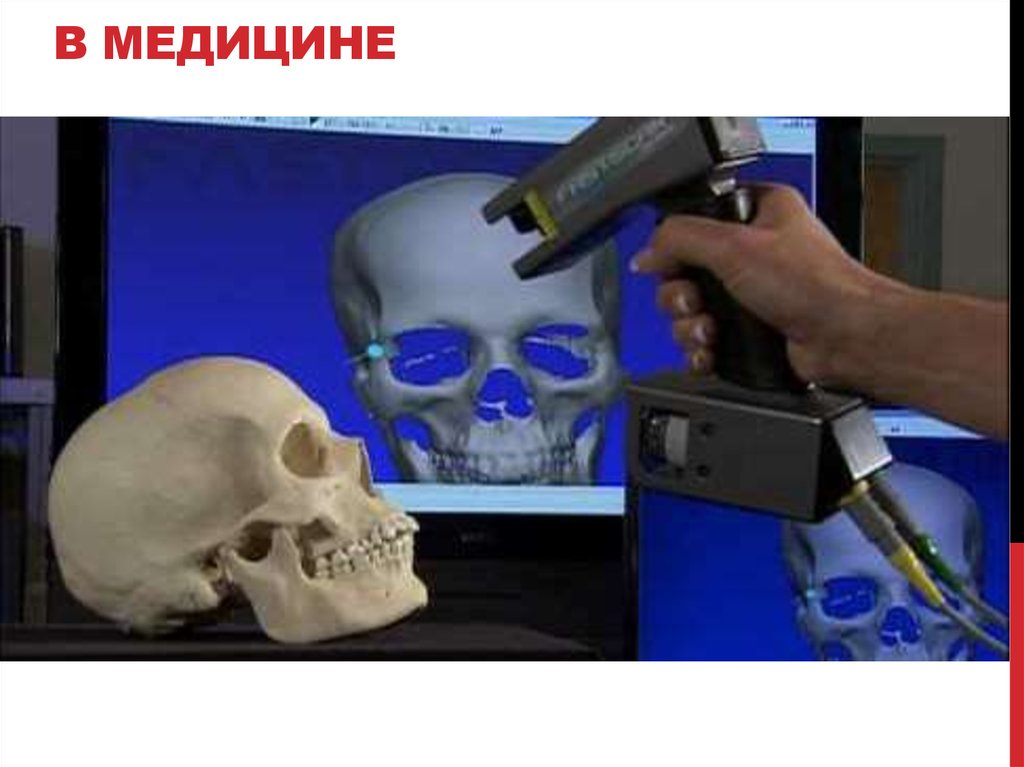

PolyWorks is widely used in areas where maximum detail of a 3D object and its accurate reproduction are required: medicine, automotive, construction, design, etc.

Vxmodel

Software created specifically for reverse engineering products, as well as finalizing 3D scan data. It has the function of editing a polygonal model, its alignment, extraction of primitives, construction of surfaces and export of objects. nine0003

It has the function of editing a polygonal model, its alignment, extraction of primitives, construction of surfaces and export of objects. nine0003

Vxmodel can create 3D models of various parts

It can process information from any 3D scanners and translate it into CAD and prepare it for 3D printing, so it is very convenient to use. Manufactured by Creaform.

Artec Studio

Quality software with a wide range of tools. At the same time, you can use it even if you do not have the skills to work with such programs. Especially for such users, the "Autopilot" mode was developed, which simplifies the process of processing 3D scanning data as much as possible, independently selecting algorithms based on the user's answers. nine0003

3D model obtained with Artec Studio

Allows you to control the quality of the 3D model not only at the processing stage (compatible with Geomagic Control X), but also in the process, giving a color signal about how close / far the operator is from the object when scanning.

The program itself is able to select the degree of sensitivity of the scanner, as it can analyze the type and complexity of the surface. This makes it possible to digitize even dark and shiny objects. nine0003

Well determines the colors and configuration of the scanned object, making it unnecessary to apply markers. Suitable for formatting scans for CAD.

Artec Studio easily handles large amounts of data, making it ideal for 3D scanning of various buildings and structures, etc. All operations are performed very quickly and efficiently.

Conclusion

All the programs for 3D scanning discussed above have good tools and a sufficient amount of options to perform tasks of any degree of complexity. They are suitable for both professionals and ordinary users who do not have experience with such software, since they have a high degree of automation and have a fairly understandable interface. nine0003

Each major manufacturer of 3D scanners releases its own software for them, which is constantly updated and improved. However, many of these programs can easily be used on third-party devices without loss of quality. You can use any of the listed 3D modeling software.

However, many of these programs can easily be used on third-party devices without loss of quality. You can use any of the listed 3D modeling software.

If you need equipment for 3D printing, but it is difficult to make a choice on your own, contact Tsvetnoy Mir. The specialists of our company know absolutely everything about the process of creating three-dimensional models and will help you choose a 3D printer or scanner based on your tasks and capabilities. It is important to us that our customers get exactly what they need. nine0003

Call: +7 (495) 287-41-45, 8(800) 550-02-09 and we will answer any of your questions!

Add to compare

Product added to compare Go

| Manufacturer | Shining 3D |

Add to compare

Product added to compare Go

nine0249Add to compare

Product added to compare Go

| Manufacturer | Range Vision |

Add to compare

Product added to compare Go

| Manufacturer | nine0251 Range Vision

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

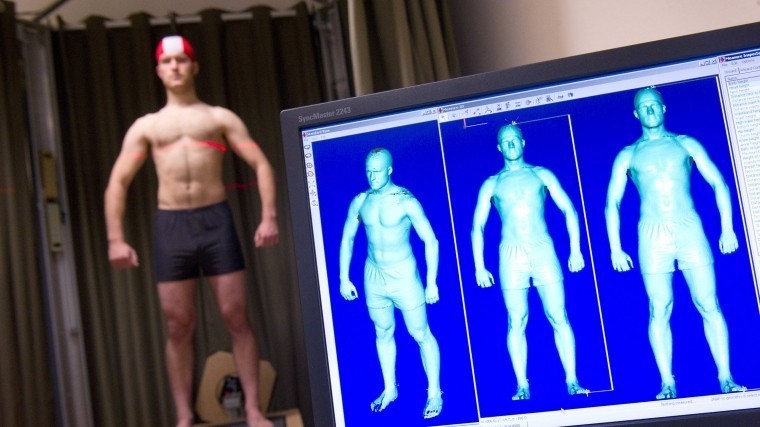

Almost DIY 3d scanner for home / Sudo Null IT News high-quality scanning is out of the question. nine0003

But the main plus that I took out from the article is the David-3D scanning program, which really has a good manual in Russian and, importantly, buying a license is the last thing required, since the free version is limited only to saving the scan result. Everything else works in full, which means that it is quite possible to test the program, settings and your hardware as much as you like. And if you don’t need the result with high accuracy, then you can do without buying a license at all. nine0063

I needed accuracy, since the main thing I wanted to scan was miniatures from the Warhammer board game (so that later I could change them as I wanted and print them :)). The height of these "soldiers" is only 3 cm, but this does not prevent them from being very detailed.

If you do not need to shoot such small objects, then your equipment requirements will be lower, which means that it will be much easier to assemble a similar scanner for yourself.

The principle of the program, and accordingly scanning, is well described in the article, which was linked above (I think it is not necessary to duplicate this). It is advisable to read that article first, as this one will be in some way its logical continuation. nine0003

But let's start in order. What you need to try 3D scanning at home:

1 - projector.

2 - webcam.

That's all, the short list turned out surprisingly well. However, if you want to get very accurate and high-quality scans, then you will have to modify some things with pens. Of course, you can’t do without additional costs, but in the end it will still cost less than buying any of the commercially available 3D scanners, and the quality of the result can be obtained much better. nine0003

Now, in order and in detail.

PROJECTOR.

My first experiments on scanning, like the author of the previous article, I started with a laser pointer, but they immediately showed how inconvenient this method is. There are several disadvantages here at once:

There are several disadvantages here at once:

- the impossibility of obtaining a beam with a sufficiently thin line. Moreover, when you turn the pointer, the distance from the lens to the object changes, which means the focus is lost.

- if you need to scan regularly, turn the laser pointer with sufficient accuracy and smoothness by hand is very difficult, and tiringly easy - the hands are not such a stable tool when it comes to a long time. nine0063 - you have to scan in the dark so that only the laser line is visible and nothing more.

And if the second drawback can still be dealt with by creating a special rotary mechanism (although this is already not such an easy task, in any case, this cannot be done in 5 minutes on the knee), then getting rid of the first drawback is more expensive.

When I realized all this, I decided to try scanning with a projector, for which I borrowed some simple model from a friend. nine0003

A small clarification should be made here - in the last article the author mentioned the possibility of scanning with a projector, although the proposal was, in my opinion, very strange -

A projector with a powerful lamp will do, the light of which must be directed through a narrow slit to the object being scanned

This may have been the only option in earlier versions of the program, but in version 3 that I experimented with, the projector was used much better, because there's a feature called Structured Light Scanning (SLS). Unlike laser scanning, the projector immediately projects a grid of vertical and horizontal lines of various thicknesses onto the object, which reduces the scanning time by an order of magnitude and allows you to automatically shoot the color texture of the object. Well, with good focus, a 1 pixel wide line is much thinner than you can get from an inexpensive laser pointer. nine0003

Unlike laser scanning, the projector immediately projects a grid of vertical and horizontal lines of various thicknesses onto the object, which reduces the scanning time by an order of magnitude and allows you to automatically shoot the color texture of the object. Well, with good focus, a 1 pixel wide line is much thinner than you can get from an inexpensive laser pointer. nine0003

Unfortunately, I didn’t take pictures from those first experiments, and there wasn’t much to take pictures of - the projector is on the table, next to it is a webcam, all of this looks in one direction :) However, even such a simple design showed that this option much better both in terms of scanning speed and quality. Then I decided to buy myself a projector for these purposes.

The criteria for choosing a projector were simple - higher resolution, lower price and dimensions :)

The choice settled on IconBit Tbright x100 - an ultra-compact DLP LED projector, 1080 resolution - at that time it seemed to me that you couldn’t imagine better, but as it turned out later, I was wrong, although while working with it, I got a lot of interesting experience. nine0003

nine0003

The first problem that occurs when scanning a small object with a projector is that for best results, the size of the projected grid should roughly match the size of the object being scanned. This projector made it possible to obtain the smallest screen diagonal at the closest focus - about 22 cm. Agree that against such a background, a miniature 3 cm high is far from the concept of "approximately equal sizes." The answer was found on the official forum - people in such cases install camera lenses on the projector for macro photography. Given the small size of the projector lens, I opted for marumi lenses with a thread diameter of 34mm. nine0003

Using two of these kits, I managed to get a projector screen with a diagonal of only about 3 cm. Which turned out to be quite enough to make my first microscan -

This is a single scan, therefore there are “holes” on the model, torn edges and etc. By turning the coin and scanning from different angles, you can get several of these scans, which are subsequently combined into one object (the scanning program itself allows you to correctly combine different scans, stitch them together and save them as a single object). In the process of stitching, the shape of the object is also specified. But saving the results of such stitching is possible only after purchasing a license. nine0003

In the process of stitching, the shape of the object is also specified. But saving the results of such stitching is possible only after purchasing a license. nine0003

And now the moment has come for the first thing that is not necessary for scanning, but with it the process is much more convenient - this is a stand for a projector with a camera. The calibration process itself is needed not only for the program to recognize the parameters of the equipment - the software must also calculate the relative position of the camera and the projector. In the course of work, their change is not allowed (as well as changing the focus of the camera), which means that it is necessary to firmly fix all this, because the number of scans can be large even for one object. nine0003

David's main page shows a similar system - it is nothing complicated. Yes, and looking through the forum and seeing how different people organize it for themselves, I realized that nothing complicated is required here.

For these purposes, a stand was taken from a burned-out LCD monitor, and plexiglass from it, cut and glued like this design, as it looked in the first version , which allowed changing the screen diagonal and scanning objects of different sizes. nine0063 It should also be mentioned that scanning with a projector does not require the constant presence of calibration panels in the field of view. After the calibration is done, they can be removed. This allows, having calibrated the installation, to easily transfer it, move it, etc.

That is, you can use a large calibration template to calibrate at home on the walls, and then go outside with this stand and laptop and scan your car, for example. We took a smaller template, put a couple of lenses - and you can scan jewelry. nine0003

Recently, the company has released an improved scanning kit, here the stand looks much more serious and interesting -

2000 euros is not entirely justified, it is not difficult to assemble something like this yourself and much cheaper.

Let's go back to the projector. As it turned out, this projector had one major disadvantage for being used in a scanner, namely its native resolution (854*480). And everything would be fine if it produced the same output, but alas, the picture was converted to standard resolutions (such as 1024 * 768), and as a result, a line one pixel wide was somewhere brighter in different parts of the screen, where - something dimmer, somewhere already and somewhere wider ... All this had a negative effect on the quality of scanning, expressed in the form of ripples and stripes on the resulting model. nine0063 By that time, I was already thinking about buying a projector for a stereolithographic 3D printer (http://geektimes.ru/post/245590/). After considering several options, I settled on the Acer P1500 model, because. it does not need any modifications to be used in a printer (this projector, without any lenses, is able to give a focused image on a screen of about 4 * 7 cm). So, for the scanner, it will fit perfectly. At the same time, the resolution of 1920 * 1080 is real. And so it happened, I still use this projector and am completely satisfied with the results. nine0003

At the same time, the resolution of 1920 * 1080 is real. And so it happened, I still use this projector and am completely satisfied with the results. nine0003

CAMERA.

The criteria for choosing a camera were the same as when choosing a projector. Having gone shopping, I stopped at the Logitech C615. The scan of the coin was made from it, without any modifications. But when I tried to scan the figurine, I ran into a problem called "depth of field". When the object is so small, then in fact we get macro photography, and sharpness with such shooting is achieved only in a small segment, literally just a couple of millimeters (which is why the coin was scanned well - the relief fit perfectly into the sharpness area). It was decided to convert the camera to a different lens. Several different lenses were ordered on Ebay for testing, and a new case was cut out for the camera board. The plan was like this0003

The final result was slightly different

The main idea, I think, is clear. And now, both on Thingiverse and on the forum of the program, you can download stl for printing cases for different types of webcams.

And now, both on Thingiverse and on the forum of the program, you can download stl for printing cases for different types of webcams.

I had to remove the standard lens from the camera board, and as it turned out later, the IR filter was removed along with it, so be careful in this matter. The filter will then come in handy for use with other lenses, although you can buy them separately - the price is cheap. nine0003

Thus, I have formed such a collection of lenses.

While I was waiting for the lenses to arrive, I was reading various photography forums. Studying the issue with depth of field, I found out that you can increase it by closing the lens aperture more. This means that the lens was required one in which it was possible to adjust the aperture (alas, among those ordered, not everyone had such an opportunity, but luckily I got a couple of them). In general, to improve the camera, it is desirable to have a varifocal lens with a zoom and an adjustable aperture. In practice, everything turned out the way it was in theory - closing the aperture, an increase in the depth of field was immediately visible, which made it possible to scan three-dimensional, but small objects. nine0003

In practice, everything turned out the way it was in theory - closing the aperture, an increase in the depth of field was immediately visible, which made it possible to scan three-dimensional, but small objects. nine0003

The main lens I use is mounted on the camera in the photo above. The second, with an adjustable aperture, is the largest, in the center. I use it for very very small objects. The rest are without a diaphragm, so I don’t use them - it turned out that these two were quite enough.

Now I plan to either find a webcam with a higher resolution (the quality and detail of the scans directly depends on the resolution of the camera), or try to use some digital camera for this purpose with the ability to shoot video - usually you can get a lot more resolution in them, and lenses are better. nine0003

Actually, this could be the end - it seems that he told about everything. I also thought that this was the end of my scanner assembly, but the farther into the forest . .. While studying the forum of this program, I often came across various schemes of turntables - fortunately, the software allows you to automate the scanning process. After one scan, a command is sent to the com port, the turntable rotates, turning the object by a given number of degrees, and gives a command to the next scan. As a result, with one click of the mouse, we have circular scans of the object - it would seem, what more could you want? I tried this system with interest, but alas, I absolutely did not like this approach, and there are a couple of reasons for this. nine0003

.. While studying the forum of this program, I often came across various schemes of turntables - fortunately, the software allows you to automate the scanning process. After one scan, a command is sent to the com port, the turntable rotates, turning the object by a given number of degrees, and gives a command to the next scan. As a result, with one click of the mouse, we have circular scans of the object - it would seem, what more could you want? I tried this system with interest, but alas, I absolutely did not like this approach, and there are a couple of reasons for this. nine0003

1 – if the object has a complex shape, then simply rotating it will not be enough – you also need to tilt it in different directions so that the camera with the projector reaches all the depressions and other hard-to-reach places.

2 - even if there are no such places, and considering all the scans that were made, there are no parts left on the object that did not fall into the scan, the question of the accuracy of the scan remains.

Let's say that some part of the model on one of the scans came out perfectly. But this does not mean that on all the scans in which this part fell, it also looks perfect, and when stitching scans from different angles, the result will be averaged, which cannot please. The program allows you to slightly edit the received scans (you can cut out the unnecessary part). If we rotate the model by 20 degrees, then after a full rotation we will have 18 scans, the part we need may well be present on half of them, therefore, in order to leave the best result, we will need to remove this piece from 8 scans ... And such pieces with a complex There can be many models, as a result, almost half will be cut off from each scan, which is very laborious and time consuming. nine0003

Instead, it is better to immediately scan adjacent areas after the first scan and check the result. As soon as a piece is ready, we move on to scanning the next one, and so on, until the entire model is in perfect shape. This approach gives the best results in less time.

This approach gives the best results in less time.

But the question of convenience arises. Agree, it’s inconvenient to manually try to rotate an object, looking not at it, but at the monitor - in order to control the hit on the lens without changing the distance to the camera and the projector at the same time (so as not to lose focus). With the next similar balancing act, I accidentally touched the camera, which accordingly knocked down the entire calibration, and the whole process had to be started anew. I categorically did not like this alignment, and after some thought I came up with a plan for such a design (which, as you understand, I subsequently assembled). nine0003

This is not a turntable in the usual sense of the term. Thanks to this design, I can not only rotate the model, but also tilt it as I need. In this case, the center of the model remains in the plane of focus, but even if not, you can move the mount with the model back and forth.

All this was assembled on arduino, a small control program was written, and as a result, now I don’t have to get up from the computer when scanning - using the program, I change the position of the object being scanned, and at the same time, right there, in the window cameras I choose the best angle for scanning. nine0003

nine0003

Insides

In the program, I put the possibility of automatic scanning, as well as scanning not only in a circle, but with inclinations of 45 degrees in one direction and the other, which gives three times more scans. Nevertheless, in the end, I still never use this opportunity - it's too inconvenient to sort through the resulting pile of scans and clean them from unsuccessful pieces.

We should also mention some nuances of scanning.

1 - it is impossible to scan shiny and mirror surfaces. The light from them is reflected, or gives such a glare that the program cannot correctly recognize the line. If there is a need to scan such an object, then such parts will have to be masked with something (washable paint, paper tape, etc.). nine0063 2 - it is more convenient to scan monotonous objects, since when the camera is set to a light color, the projector's brightness is not so high, the exposure is low, etc. And a dark-colored object needs more brightness, so if you have a multi-colored object, then different parts of it require different settings to get the best result. Here, too, it is more convenient to use scanning the object in parts.

Here, too, it is more convenient to use scanning the object in parts.

3 - if you want to immediately get a color texture, then please note that the settings of the camera and the projector for scanning do not affect the settings for removing the texture (the scan is generally done in black and white mode), so play around with the settings in the texture mode just as you would do in scan mode. nine0003

My scanning process now looks like this:

- Focusing the projector and camera

The projector's light is too bright and the projected grid is not visible in the photo, but here is the view from the camera in the program

- scanner calibration

printed on magnetic paper - so you can very quickly adjust to different sizes of scanned objects. nine0003

Software view

It is recommended that the combined angle between the beam of the projector and the camera be around 20 degrees. Therefore, such a stand is used - when scanning large objects (for example, a person), the camera should be set aside much further from the projector, but here they are close to me. The location of the camera relative to the projector can be only vertical, or only horizontal, depending on the geometry of the object. In this case, the arrangement is diagonal (13 degrees vertically and 36 degrees horizontally). nine0003

The location of the camera relative to the projector can be only vertical, or only horizontal, depending on the geometry of the object. In this case, the arrangement is diagonal (13 degrees vertically and 36 degrees horizontally). nine0003

Scan results from different angles. These are already cleaned up scans, i.e. all unsuccessful and unnecessary parts (figure stand, mount that got into the frame) parts have been removed.

Combining scans for subsequent merging into one object

Due to the fact that each scan has its own color, it is convenient to control the correct alignment.

Well, after combining the scans from different angles, we get the following models

Miniature of Boromir from Lord of the Rings. nine0063

When scanning a multi-colored object, the result is slightly worse if you don't bother too much. But then you can get an object immediately with a texture :)

Original models

In the gallery of user works on the developer's website (http://www. david-3d.com/en/news&community/usergallery) you can find many more interesting scans , even fingerprints people scan. And there are even scans of the same miniatures from Warhammer

david-3d.com/en/news&community/usergallery) you can find many more interesting scans , even fingerprints people scan. And there are even scans of the same miniatures from Warhammer

In conclusion, I would like to say that no matter what hardware you use, no matter what expensive 3D scanner you buy, this is not a panacea for printing anything. Theoretically, of course, you can send the resulting object to the slicer and print, but there are several reasons why you should not do this, but in any case, you should study 3D graphics packages. nine0003

1 - The resulting scans, with good scan quality (and we want to get the best quality) have a lot of polygons. No, even is VERY a lot. The scan of Boromir after the merger contained more than 8 million polygons - not every slicer will be able to work with such an object.

2 - Any objects bear traces of assembly and manufacture. And if in reality needle files and sandpaper are used to fix this (and sometimes there are still inaccessible places where it is impossible to use tools), then working with a digital copy of an object, we can change it as we like - remove defects, improve detail, etc.