High temp 3d printing

High-Temperature 3D Printers | Vision Miner

Designed for PEEK, ULTEM, and other High-Performance Polymers, these machines are all open-filament, open-source and cutting-edge in their respective categories.

Which Printer Do You Need?

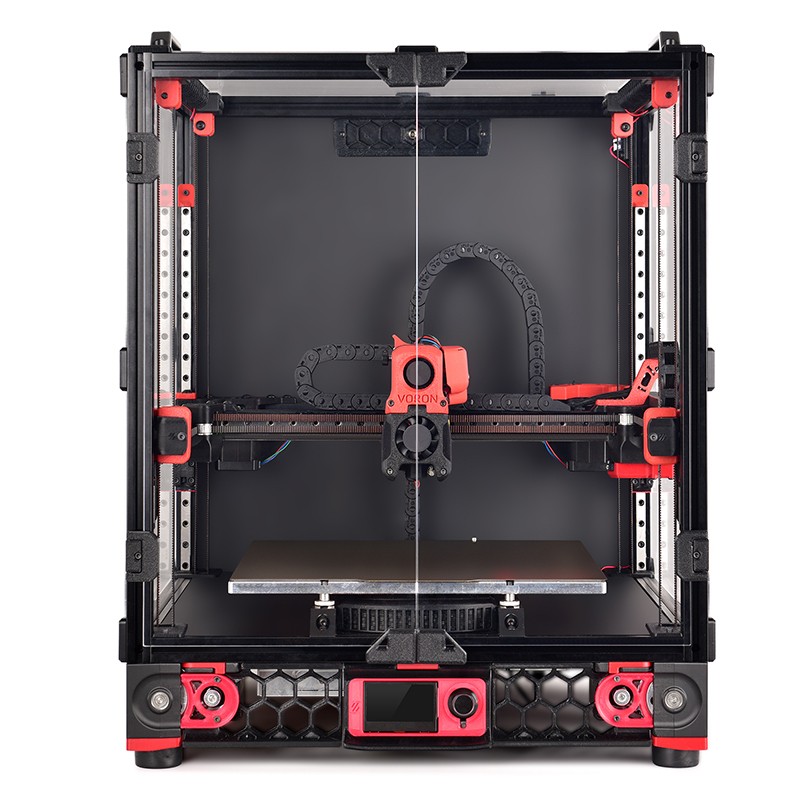

With dual independent extruders capable of 500ºC, an actively-heated chamber reaching 90ºC, and a triple-motor, true-self-leveling 200ºC bed, coupled with the fully open material system, the 22 IDEX is unlocking the potential of in-house additive manufacturing, at a price that disrupts everything the industry has seen before.

LEARN MORE

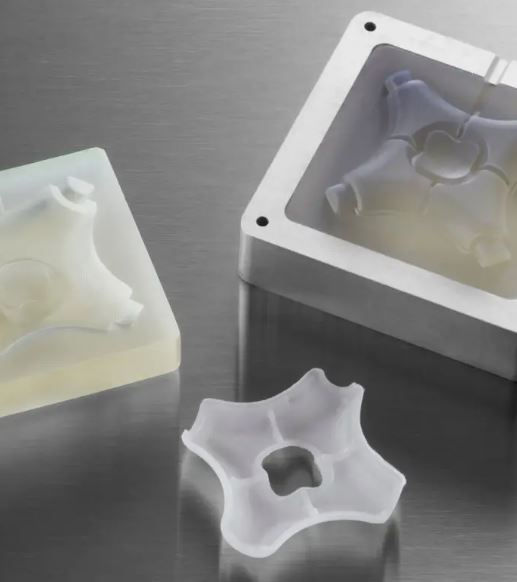

High-Quality Selective Laser Sintering 3D Printers -- with 9 different polymers to choose from, and a totally open material platform, the Sinterit line of SLS machines are the best we could find on the market, and now, they're available to you and your business.

LEARN MORE

The AON-M2+ is a high temperature, industrial 3D printer that can fabricate the highest performance thermoplastics. Print bigger and better with its actively heated build chamber and large build volume.

Choose from materials that can replace metals, with properties that can withstand the harshest operating conditions.

Avoid getting tied down with costly proprietary polymers, and experience the freedom of choosing between leading chemical companies.

AON M2 ⤑

Essentium is fundamentally changing how things are made. As innovators in both materials and production platforms, Essentium is disrupting traditional manufacturing processes by bringing strength and speed together, at scale, with a no-compromise material set.

At 5-15x faster than the competition, Essentium's High Speed Extrusion (HSE) 3D Printing Platform is built to transform manufacturing floors and solve the issues of strength, speed and cost. You can finally harness the power of 3D printing at scale without sacrificing accuracy or speed.

Did we mention it's all Made in the USA?

ISO 9001:2015 and AS9100D Certified + ITAR Registered

Essentium HSE 180•S Platform

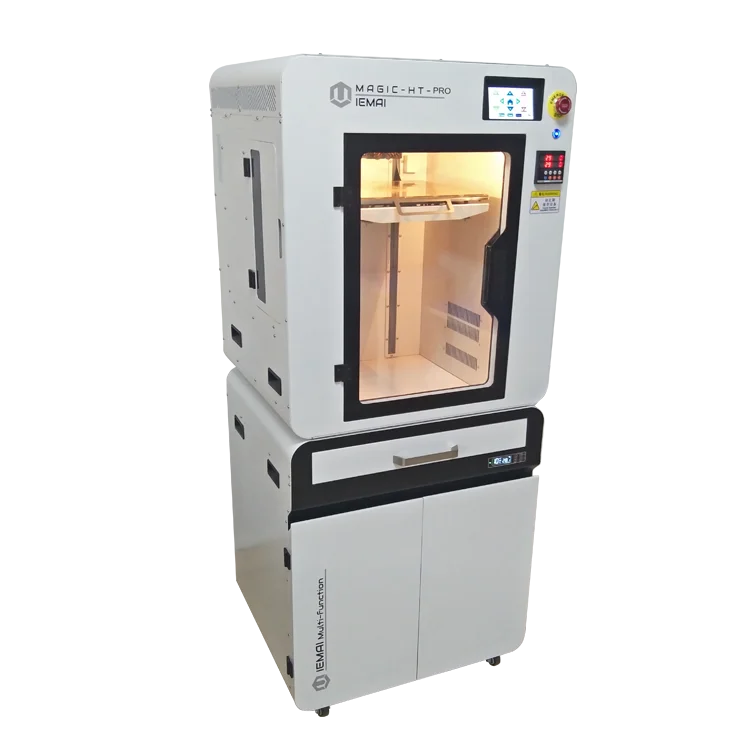

The Intamsys Funmat HT Enhanced is designed specifically to 3D print high-performance functional materials like PEEK, PEI and PPSU, in addition to a broad range of engineering thermoplastics. Users can achieve 50-micron, high-resolution, industrial-quality 3D printing with the Intamsys Funmat HT.

Users can achieve 50-micron, high-resolution, industrial-quality 3D printing with the Intamsys Funmat HT.

The Enhanced version includes a new build platform, ceramic-glass build plates, updated extruder design, auto bed-leveling, independent motor drivers, and more.

FUNMAT HT ⤑

The FUNMAT PRO 410 is an industrial additive manufacturing 3D printer designed for PEEK, PEI & PEI Blends, PPSU and other High-Performance Polymers.

For the very first time, the INTAMSYS FUNMAT PRO 410 features a dual extruder which operate in a large 305 x 305 x 406 mm build chamber (12 x 12 x 16 inch).

FUNMAT PRO 410 ⤑

This printer has been discontinued by Cincinnati, Inc. We have kept this page live for archival purposes.

The SAAM High-Temperature 3D Printer by CINCINNATI can print with virtually any material, from PEEK to Nylon, at a resolution of 11 microns.

Reaching temperatures of 500°C in the printing head, 250°C heated bed, and a heated chamber capable of reaching 160°C, the SAAM HT can print nearly any material on the market. SAAM HT is optimized for fabrication of tooling, fixtures, prototypes, and functional parts.

SAAM HT is optimized for fabrication of tooling, fixtures, prototypes, and functional parts.

Cincinnati SAAM HT ⤑

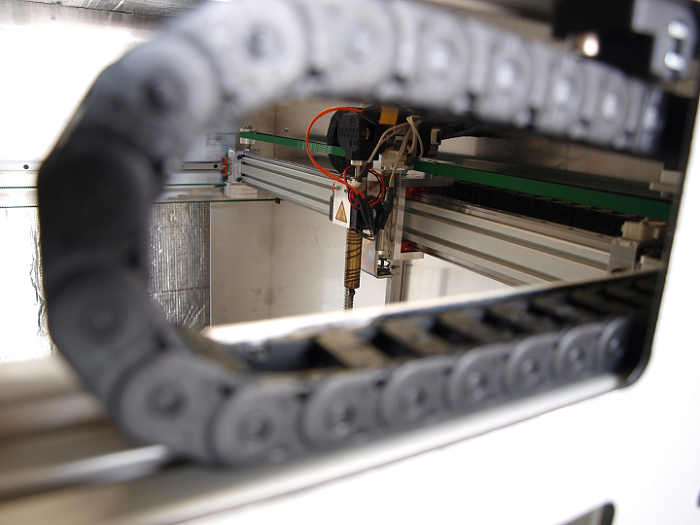

MAAM (Medium Area Additive Manufacturing) is an industrial sized additive machine built for production manufacturing. A rigid welded frame, CNC controls, and the latest extruder technology are combined in this machine to print parts accurately and consistently at speeds that are unmatched in the filament 3D printer market.

Its dual print head allows for multi-material printing. Its open source material solution, along with its temperature capabilities in the chamber, print bed and nozzle allow for 3D printing the industry’s most highly engineered thermoplastics, even PEEK and ULTEM™.

Cincinnati MAAM ⤑

Cincinnati Incorporated, in partnership with Oak Ridge National Labs, has developed the world's first industrial size 3D printer and taking additive manufacturing to a large scale.

BAAM (Big Area Additive Manufacturing) is an industrial sized, additive machine. The machine uses the proven design and technology from our laser platform, including the machine frame, motion system, and control, and has been adapted with an extruder and feeding system. BAAM was designed to allow 3-D printing to be used for production manufacturing. The size and speed allow large parts to be made quickly. The ability to use commodity thermoplastic materials means that the cost per part will be reasonable. By designing a system with an open architecture for material vendors, material costs will be kept lower and with more options.

The machine uses the proven design and technology from our laser platform, including the machine frame, motion system, and control, and has been adapted with an extruder and feeding system. BAAM was designed to allow 3-D printing to be used for production manufacturing. The size and speed allow large parts to be made quickly. The ability to use commodity thermoplastic materials means that the cost per part will be reasonable. By designing a system with an open architecture for material vendors, material costs will be kept lower and with more options.

REQUEST QUOTE

The Colossus 3D printers are the first FGF printing systems designed with a special accent on materials for furniture, construction applications and large size 3D objects. It also prints with recycled materials, combining cutting-edge technology to give plastics a second life.

Colossus wants to break down the barrier of entry for designers to sell not only their designs but make their vision into objects without current limitations. They also develop 3D technology for the commercial markets, like Furniture, Art, Molds, Automotive, prototyping, small series designs --everything is possible.

They also develop 3D technology for the commercial markets, like Furniture, Art, Molds, Automotive, prototyping, small series designs --everything is possible.

REQUEST QUOTE

High Temperature 3D Printers | MatterHackers

3D printers that are capable of reaching higher temperatures are able to print with advanced, engineering grade materials that require higher temperatures, like polycarbonate 3D printing filament and polypropylene 3D printing filament. 3D printing at higher temperatures allows manufacturers to use stronger, more functional materials to create the parts necessary for practical applications. High-temperature additive manufacturing for rapid prototyping in industries like aerospace, architecture, engineering, and design allows for minimal downtime during the product development process.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

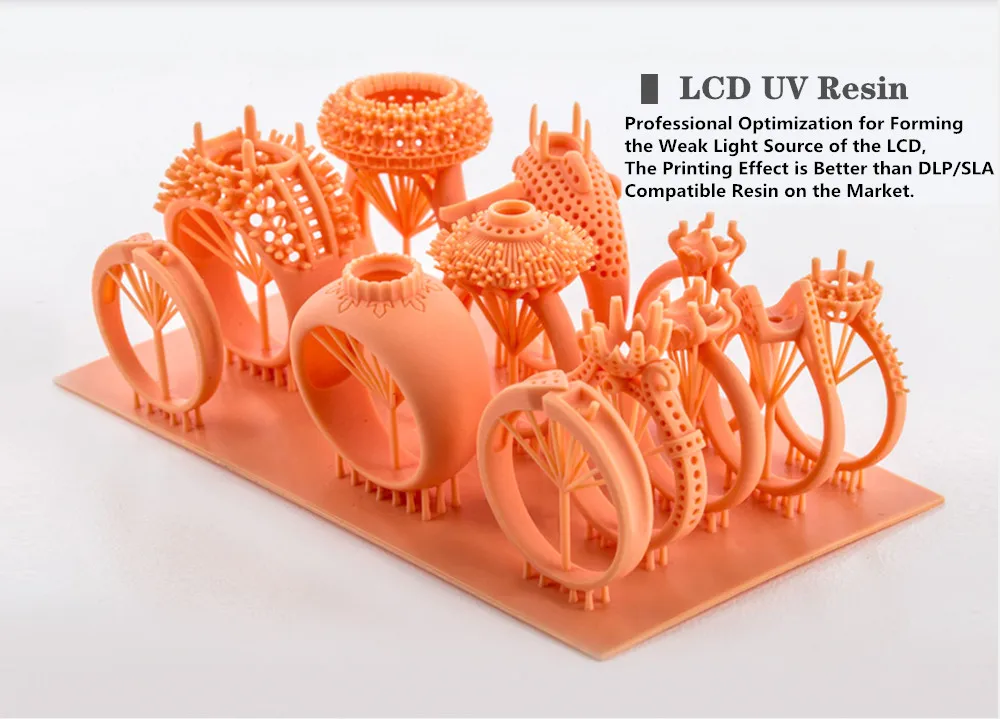

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

High Temperature 3D Printing to the Masses / Sudo Null IT News

There is an impressive variety of thermoplastics that can be printed on consumer grade desktop 3D printers. But, despite this, most often users turn to polylactide (PLA) threads. This is not only the cheapest of materials, but also the easiest to work with. Its extrusion can already be carried out at a temperature of 180 °C, and good results can be obtained even without preheating the table. The disadvantage of PLA-printed objects is that they are relatively brittle and do not tolerate high temperatures well. For prototyping or printing low-stress components, PLA is great. However, many users quickly go beyond its capabilities. nine0003

Polyethylene terephthalate (PETG) is usually the next step. It is not much harder to work with compared to PLA, while it is more reliable and can withstand higher temperatures. In general, it is better suited for creating mechanically loaded parts. But if you need to make even stronger and more heat resistant parts, you can switch to acrylonitrile butadiene styrene (ABS), polycarbonate (PC) or nylon. And this is where the problems begin. These materials are extruded at temperatures over 250°C and closed chambers are recommended for best results. These printers are at the top of the budget range that hobbyists are willing to work with. nine0005

It is not much harder to work with compared to PLA, while it is more reliable and can withstand higher temperatures. In general, it is better suited for creating mechanically loaded parts. But if you need to make even stronger and more heat resistant parts, you can switch to acrylonitrile butadiene styrene (ABS), polycarbonate (PC) or nylon. And this is where the problems begin. These materials are extruded at temperatures over 250°C and closed chambers are recommended for best results. These printers are at the top of the budget range that hobbyists are willing to work with. nine0005

Industrial 3D printers like this one, the Apium P220, start at around $30,000. (PAEK, PEEK, PEKK). Components made from these plastics are suitable for aerospace applications as they can replace metal while remaining much lighter.

Such plastics need to be extruded at temperatures of around 400°C, and a sealed chamber is required for operation, the temperature in which constantly exceeds 100°C. The cheapest printers of this kind cost tens of thousands of dollars, and some models even cost six figures. nine0003

The cheapest printers of this kind cost tens of thousands of dollars, and some models even cost six figures. nine0003

Naturally, not so long ago, the same could be said about all 3D printers. Once used only by well-equipped research labs, these machines now sit on the workbenches of hackers and hobbyists the world over. It is difficult to predict whether the same price-cutting race will start for high-temperature 3D printers, but the first steps to democratize the technology have already been made.

Engineering difficulties

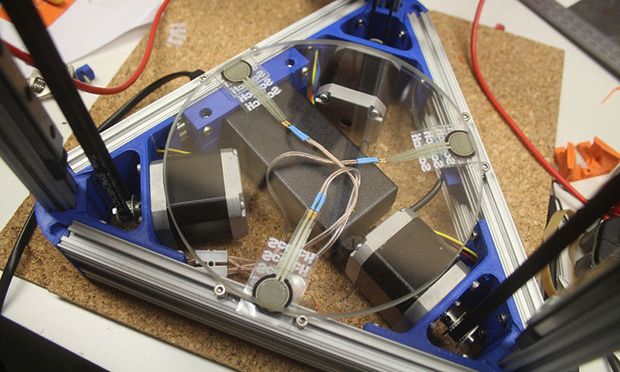

Simply put, a machine that supports these so-called. "engineering plastics", you need to be a hybrid of a 3D printer and a stove. This, of course, is the main problem. The printer itself - of the type and quality we are accustomed to seeing on our desks - will not survive in such conditions. In order for a consumer printer to produce PEI and PEEK plastic parts, it needs to be seriously redesigned. This is exactly what NASA did with the LulzBot TAZ 4 in 2016. nine0003

nine0003

LulzBot TAZ 4 redesigned to support high temperature printing

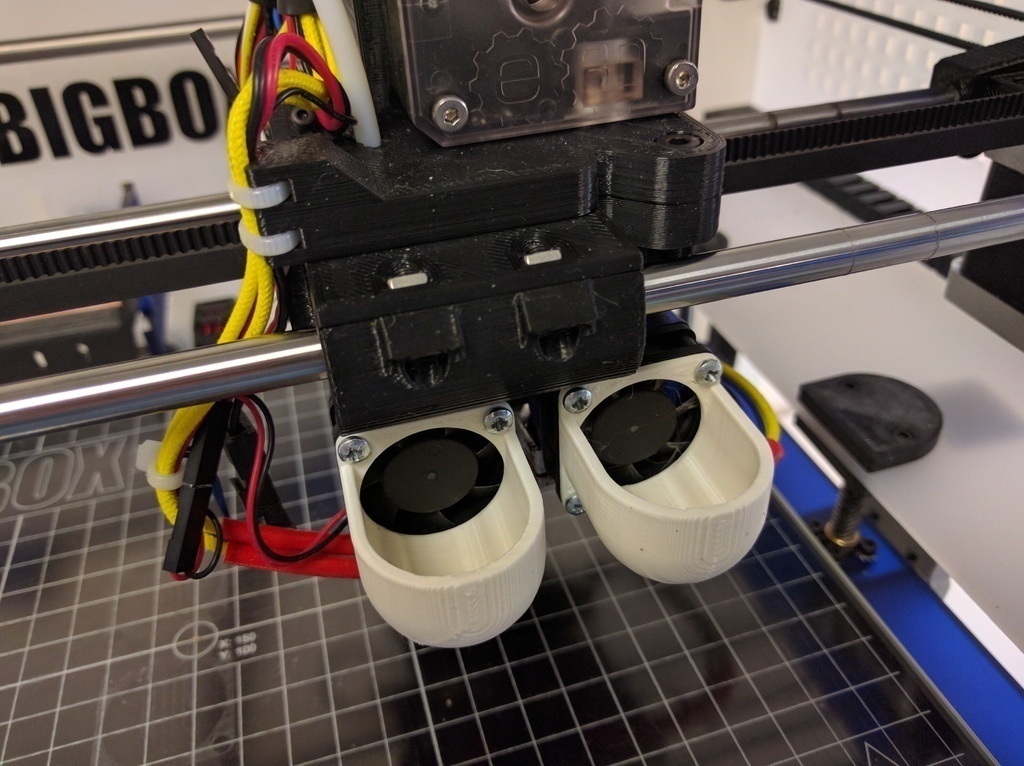

The first step was to design an insulated housing to fit the TAZ 4 and install a set of 35W infrared lamps for heating. Under such conditions, the printer's electronics would naturally overheat - so it had to be taken outside.

Stepper motors would also overheat. But instead of taking them out, the team at the Langley Research Center decided to build cooling shrouds on each of the motors through which the compressed air must circulate. nine0003

Like many desktop 3D printers, the TAZ 4 uses several printed components. Since they are ABS, they would quickly break down in a chamber designed to support PEEK. They were printed from PC, but even this material was not resistant enough for permanent use. In classic RepRap tradition, the team printed the last, third set of components on their most modified printer, in PEI plastic, commercially named Ultem.

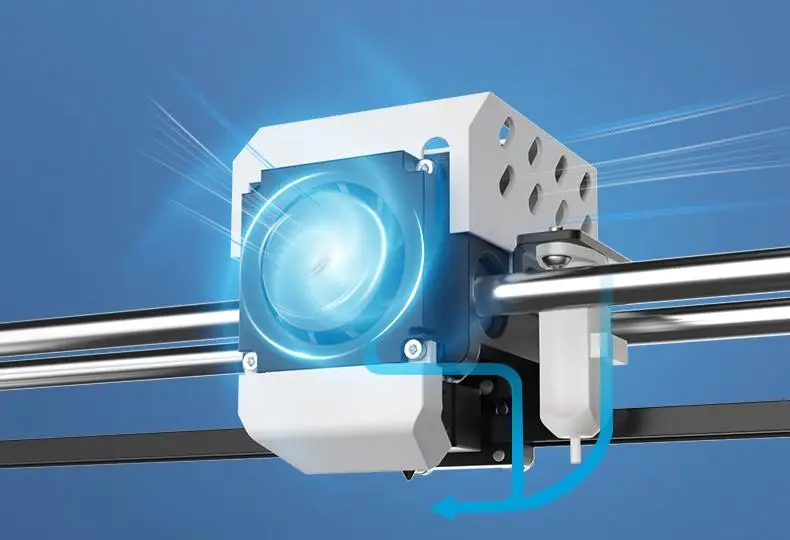

Surprisingly, the team had no trouble changing the printer's nozzle to one that could extrude plastic at 400°C. The popular E3D-v6 extruder costs less than $100 and has been shown to be able to maintain this temperature. True, the team had to replace the thermistor with a better one, as well as edit the Marlin firmware so that it allowed it to reach high temperatures. For conventional printers, too high a temperature should cause an emergency shutdown. nine0003

The popular E3D-v6 extruder costs less than $100 and has been shown to be able to maintain this temperature. True, the team had to replace the thermistor with a better one, as well as edit the Marlin firmware so that it allowed it to reach high temperatures. For conventional printers, too high a temperature should cause an emergency shutdown. nine0003

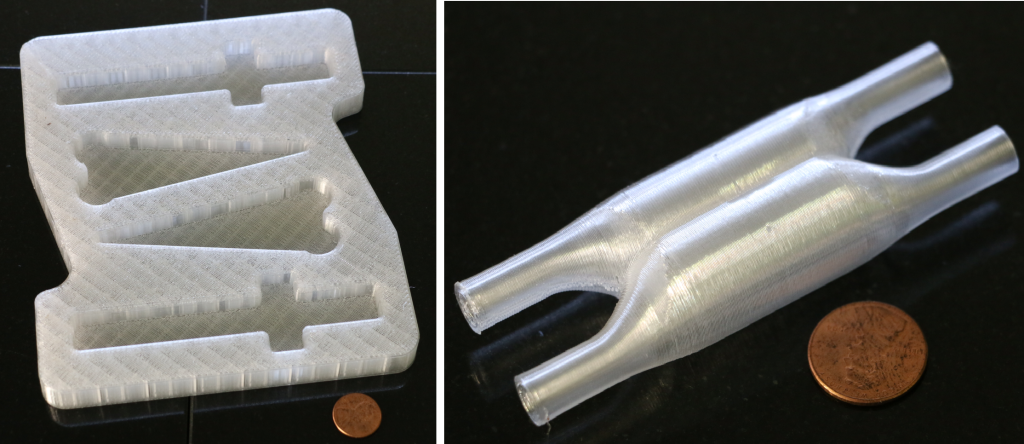

Printing results from Ultem 1010 plastic on a redesigned LulzBot TAZ 4.

In the end, the NASA report indicated that the redesign of the LulzBot TAZ 4 was a complete success. They noted that an attempt to print PEI with infrared lamps turned off ended in failure - delamination and distortion of the model, which was to be expected. They did not specify the cost of the conversion, but given that at that time the TAZ 4 cost $2200, the entire project could cost 10 times cheaper than similar commercial proposals. nine0003

Starting from zero

A NASA experiment has shown that an existing desktop 3D printer can be converted to print with high-temperature engineering plastics, and quite inexpensively. But hardly anyone believes that this approach is the ideal solution. There are too many repetitive operations involved here, and NASA engineers had to abandon some of the decisions made by the LulzBot developers. Still, the experiment provided a valuable baseline for other projects built from scratch. nine0003

But hardly anyone believes that this approach is the ideal solution. There are too many repetitive operations involved here, and NASA engineers had to abandon some of the decisions made by the LulzBot developers. Still, the experiment provided a valuable baseline for other projects built from scratch. nine0003

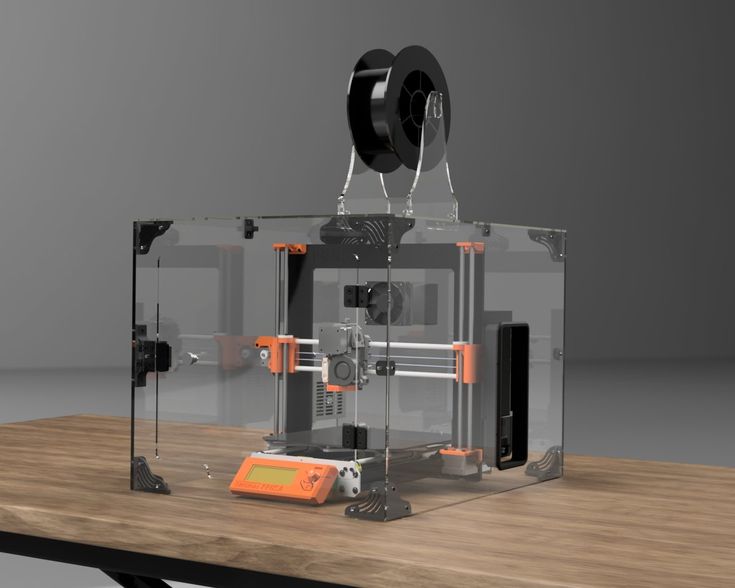

In September 2020, a team from Michigan Technological University demonstrated the Cerberus, an open-source, high-temperature 3D printer capable of creating items from PEI and PEKK, that costs as little as $1,000 to build. Without trying to adapt existing designs, the team started development from scratch, aiming for high temperature printing. All electronics are housed separately from the sealed chamber, which uses a kilowatt heating element to quickly raise the temperature in the chamber to operating temperature. nine0003

All stepper motors are also outside the chamber. Because of this, the kinematics become more complex than in desktop 3D printers, but Cerberus no longer requires a special motor cooling system.

Building a Cerberus is quite affordable for the aspiring hobbyist. It has a simplified circuit, ready-made control electronics based on the Arduino Mega 2560 and RAMPS 1.4, and the same E3D-v6 extruder as the TAZ 4. In addition, the team posted clear and detailed instructions for assembling the printer - this is not in the NASA report. meet. nine0003

Expanding possibilities

Whether it's NASA's redesign of the TAZ 4, or the new Cerberus-type circuits, it's clear that the technical capabilities of PEI and PEEK printing in the home workshop are already available for those who really need them. So far, it's not as easy as buying a $200 3D printer on Amazon, but if there is demand, cheaper machines based on the same principles will appear on the market. The situation is not much different from the current wave of affordable laser cutters hitting the markets in the past few years. nine0003

Fans all over the world print PPE

Is there a demand for such machines? A year ago, the answer might have been different from today. But in the fight against the coronavirus pandemic, there is a new demand for the rapid production of personal protective equipment (PPE) that no one could have foreseen.

But in the fight against the coronavirus pandemic, there is a new demand for the rapid production of personal protective equipment (PPE) that no one could have foreseen.

print PPE that can be sterilized at high temperatures. The team believes that masks printed from PEKK can be reused rather than thrown away. nine0003

Components that can be printed and re-sterilized will obviously have other potential medical applications. A portable, low-cost machine capable of producing such components has the potential to save lives in places on the planet where supplies and equipment cannot be quickly accessed.

Critics of 3D printing have often said that the main disadvantage of these machines is that the reliability of the items they make rarely allows them to be used for anything other than rough prototyping. But when a $1,000 printer starts making aerospace-grade components, we seem to be moving toward a manufacturing revolution at an unprecedented rate. nine0003

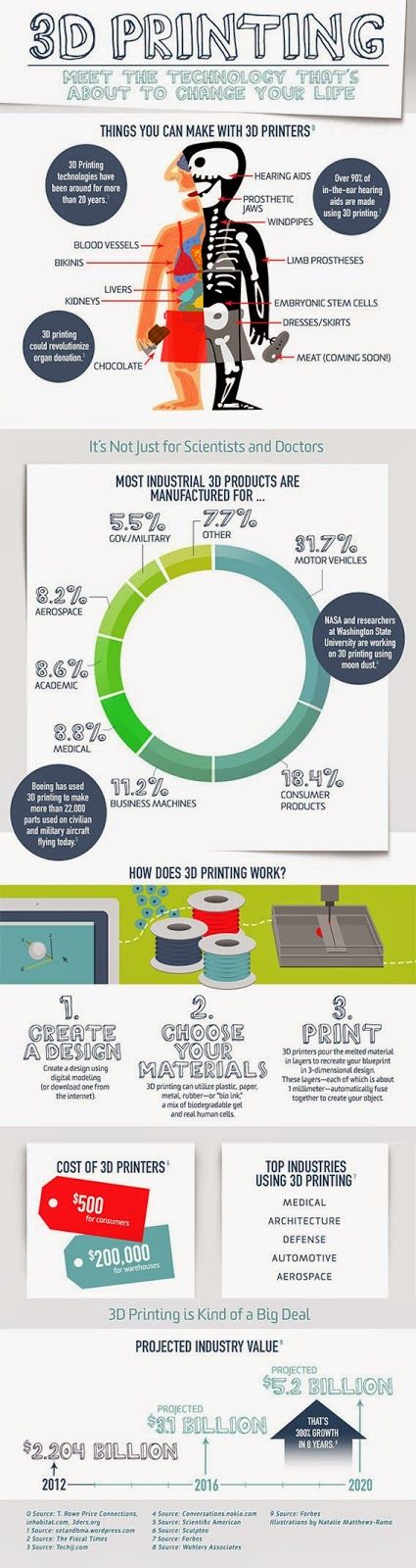

Overview of high-temperature FDM plastics for industrial 3D printing

The scope of application of additive technologies is wide: on one extreme - desktop printers "only PLA", for decorative applications, on the other - installations for direct printing with metals, between them - equipment and materials in assortment. To understand what materials are needed to obtain a strong and lightweight part, we are moving from personal printing to industrial printing. PLA, ABS, SBS are consumables that are familiar to all printers. PETG, nylon, polycarbonate - rather exotic. But these are far from the most serious materials. nine0003

To understand what materials are needed to obtain a strong and lightweight part, we are moving from personal printing to industrial printing. PLA, ABS, SBS are consumables that are familiar to all printers. PETG, nylon, polycarbonate - rather exotic. But these are far from the most serious materials. nine0003

Where are superplastics needed?

Plastics with outstanding properties are very useful in space. No, it’s not yet possible to print a rocket engine out of plastic, the heat resistance is not even close to the same, but it is ideal for various parts around. An example is Stratasys and the "climate control" of Atlas V rockets. 16 printed parts instead of 140 metal parts - faster, lighter, cheaper. And this is not a theoretical project, it has already flown into space.

Another example is aviation. The flight altitude is lower, but the application is more massive. Here, too, there is a reason to reduce the mass of parts, switch to plastic where possible. It is used in the aircraft industry and direct metal printing, when it comes to engine components or fuselage frame parts, but less loaded structural elements, such as cabin ventilation and interior elements, are best made from plastic. This direction is being developed, for example, by Airbus. nine0003

It is used in the aircraft industry and direct metal printing, when it comes to engine components or fuselage frame parts, but less loaded structural elements, such as cabin ventilation and interior elements, are best made from plastic. This direction is being developed, for example, by Airbus. nine0003

We are descending from heaven to earth: here the mass is no longer so critical, other properties of engineering plastics are interesting. Resistance to aggressive chemicals and elevated temperatures, the ability to create structures inaccessible to classical methods. At the same time - a lower price, in comparison with metal printing. Printed products are used in medicine, oil and gas industry, chemical industry. As an example, a mixing block with a complex channel structure, made for illustration in a section. nine0003

Difference from conventional plastics

Why not launch PLA into space and make ABS air vents in aircraft cabins? A number of requirements are applied to engineering plastics related to resistance to high and low temperatures, fire resistance, mechanical strength. Usually all at once. So, it is undesirable to launch PLA “floating” when interacting with the environment or perfectly burning ABS into the sky. Now - to what, in fact, plastics are used in industrial printing using FDM / FFF technology. nine0003

Usually all at once. So, it is undesirable to launch PLA “floating” when interacting with the environment or perfectly burning ABS into the sky. Now - to what, in fact, plastics are used in industrial printing using FDM / FFF technology. nine0003

Polycarbonate filaments

Polycarbonate is a common industrial plastic with high impact resistance and transparency, also produced for the needs of FDM printing. The material holds temperature better than ABS, is resistant to acids, but is sensitive to UV radiation and is destroyed by oil products.

Clear polycarbonate, PC

The operating temperature limit for polycarbonate products is 130°C. Polycarbonate is biologically inert, products made from it can withstand sterilization, which makes it possible to print packaging and auxiliary equipment for medicine. nine0003

- Stratasys PC, PC-ISO for Fortus printers. The first is general purpose, the second is certified for biocompatibility, for medical use.

- Intamsys PC;

- Esun ePC;

- SEM PC;

- PrintProduct PC;

ABS/PC

Polycarbonate/ABS alloy combines the sanding and painting capabilities of ABS with higher impact resistance and operating temperature. Retains strength at low temperatures down to -50 °C. Unlike pure PC, it is better applicable in cases where it is necessary to eliminate the layered structure of the part by grinding or sandblasting. Application: production of housings and elements of controls for piece and small-scale production, replacement of mass-produced plastic parts in equipment, parts for which have ceased to be produced. nine0003

- Stratasys PC/ABS;

- Roboze PC-ABS;

- SEM ABS/PC;

- BestFilament ABS/PC.

Polyamide based filaments

Polyamides are used in the manufacture of synthetic fibers, a popular material for laser selective sintering (SLS) printing. For printing using FDM / FFF technology, polyamide-6 (kapron), polyamide-66 (nylon) and polyamide-12 are mainly used. Common features of polyamide-based filaments include chemical inertness and anti-friction properties. Polyamide-12 is more flexible and resilient than PA6 and PA66. Operating temperature approx. 100 °C, some modifications up to 120.

For printing using FDM / FFF technology, polyamide-6 (kapron), polyamide-66 (nylon) and polyamide-12 are mainly used. Common features of polyamide-based filaments include chemical inertness and anti-friction properties. Polyamide-12 is more flexible and resilient than PA6 and PA66. Operating temperature approx. 100 °C, some modifications up to 120.

First of all, gears are printed from polyamide. The best material for this purpose, which can be worked with on a regular 3D printer with a closed chamber. Abrasion resistance allows you to make rods, cams, sliding bushings. In the line of many manufacturers there are composite filaments based on polyamide, with even greater mechanical strength.

- Stratasys Nylon 6, Nylon 12, Nylon 12CF. The latter is filled with carbon fiber.

- Intamsys Nylon, PA6.

- Taulman Nylon 618, Nylon 645 based on PA66 and PA6 respectively. Nylon 680 is approved for use in the food industry. Alloy 910 is a low shrinkage polyamide alloy.

- PrintProduct Nylon, Nylon Mod, Nylon Strong;

- REC Friction;

- BestFilament BFNylon.

Moving on to the fun part

You can work with polycarbonate or polyamide on a regular 3D printer. With the filaments described below, it is more difficult, they require other extruders and maintaining the temperature in the working chamber, that is, you need special equipment for printing with high-temperature plastics. There are exceptions - for example, NASA, for the sake of experiment, upgraded the Lulzbot TAZ popular in the USA to work with high-temperature filaments. nine0003

Polyetheretherketone, PEEK

Working temperature of PEEK products reaches 250 °C, short-term heating up to 300 is possible - indicators for reinforced filaments. PEEK has two disadvantages: high price and moderate impact resistance. The rest is pluses. The plastic is self-extinguishing, heat-resistant, chemically inert. Medical equipment and implants are produced from PEEK, abrasion resistance makes it possible to print parts of mechanisms from it.

Medical equipment and implants are produced from PEEK, abrasion resistance makes it possible to print parts of mechanisms from it.

- Intamsys PEEK; nine0110

- Apium PEEK;

- Roboze PEEK, Carbon PEEK. The second is reinforced with carbon fiber.

Polyetherimide, PEI

aka Ultem. A family of plastics developed by SABIC. The characteristics of PEI are more modest than those of PEEK, but the cost is noticeably lower. Ultem 1010 and 9085 are Stratasys' primary materials for printing functional parts. PEI is in demand in the aerospace industry - the mass is much less compared to aluminum alloys. Operating temperatures of products, depending on the modification of the material, reach 217 ° C according to the manufacturer and 213 - according to the results of tests by Stratasys. nine0003

The advantages of PEI are the same as those of PEEK - chemical and temperature resistance, mechanical strength. It is this material that Stratasys is promoting as a partial replacement for metal in the aerospace industry, for drones, the manufacture of tooling for molding, the rapid printing of functional parts in pilot production.

The cooling system components for the Atlas V rocket and the plastic parts for the Airbus jetliners shown at the beginning of this review are made of Ultem 9085.

- Stratasys Ultem 1010 and 9085, for Fortus 450mc and 900mc printers.

- Intamsys Ultem 1010 and 9085;

- Roboze Ultem AM9085F;

- Apium PEI 9085.

Polyphenylsulfone, PPSF/PPSU

Another material that combines temperature resistance, mechanical strength and chemical resistance in its properties. Stratasys PPSF is certified for aerospace and medical applications. Positioned as a raw material for the production of auxiliary medical devices, it can be sterilized in steam autoclaves. It is used in the production of parts for laboratory installations in the chemical industry. nine0003

- Stratasys PPSF;

- 3DXTech Firewire PPSU.

Polysulfone, PSU

Less common than PPSU, similar physical properties, chemically inert, self-extinguishing. 175°C operating temperature, up to 33% cheaper than PPSU.

175°C operating temperature, up to 33% cheaper than PPSU.

- 3DXTech Firewire PSU

Filament performance comparison

* Baked for 2 hours at 140°C.

** Apium PEEK 450 natural, no similar impact test results available. Temperature resistance is specified for unfilled PEEK.

Data shown for Stratasys filaments, excluding PEEK. If a range of values is indicated, then the tests were carried out along and across the layers of the part.

About Composite Filaments

Most FDM materials have composite versions. If we talk about PLA, then metal or wood powders are added to it to change the aesthetic properties. Engineering filaments are reinforced with carbon fiber to increase the rigidity of the part. The influence of such additives on the properties of plastic depends not only on their quantity, but also on the size of the fibers. If a fine powder can be considered a decorative additive, then the fibers already significantly change the characteristics of the plastic. By itself, the word Carbon in the name of the material does not yet mean outstanding properties, you need to look at the test results. For example: Stratasys Nylon12CF has almost twice the tensile strength, when tested along the layers, than Nylon12. nine0003

By itself, the word Carbon in the name of the material does not yet mean outstanding properties, you need to look at the test results. For example: Stratasys Nylon12CF has almost twice the tensile strength, when tested along the layers, than Nylon12. nine0003

Exotic variant - implementation of continuous reinforcement from Markforged. The company offers a reinforcing filament for co-FDM printing with other plastics.

Other specific properties

Engineering plastics are not only high temperature resistance and mechanical strength. For housings or boxes for storing electronic devices, and in environments where flammable volatile liquids are used, materials with antistatic properties are required. In the Stratasys line, this is, for example, ABS-ESD7. nine0003

- Stratasys ABS-ESD7;

- Roboze ABS-ESD.

Conventional ABS is not UV resistant, limiting its outdoor use without a protective coating. As an alternative, ASA is offered, which has characteristics similar to ABS, except for the UV resistance.

As an alternative, ASA is offered, which has characteristics similar to ABS, except for the UV resistance.

- REC Eternal;

- SEM ASA;

- BestFilament ASA.

Original alternative

Plastic can replace metal in many areas, as it surpasses it in lightness, thermal and electrical insulation, resistance to reagents. But printouts from the best FDM filaments do not reach the physical indicators of metal products.

Chemical giant BASF offers Ultrafuse 316LX FDM filament with 80% stainless steel by weight. The part is printed on an FDM printer and then placed in an oven where the binder plastic is burned off and the metal is sintered. The part obtained in this way is much cheaper than the one made by direct metal printing. With an FDM printer and a suitable oven, no new equipment is needed at all. nine0003

Note that Virtual Foundry offers a similar solution - its Filamet, with bronze or copper powder, is baked in a similar way. The choice of metal hints at decorative rather than engineering applications.

The choice of metal hints at decorative rather than engineering applications.

AIM3D has its own implementation of this principle - the ExAM 255 printer does not work with filament, but with granules. This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. For sintering the part, the company offers an ExSO 9 furnace0. It is also possible to print with plastic granules, which is usually cheaper than using traditional filament.

Special machinery for engineering plastics

To recap. In a nutshell: the considered consumables differ from the usual materials in high printing temperature, which requires the use of special equipment, and serious heat resistance and mechanical strength of the manufactured parts. To work with such filaments, 3D printers with an extruder operating temperature of 350 °C and a heat-stabilized working chamber are required. Top 3D Shop specialists will help you with the selection of an industrial 3D printer and plastics for solving the most interesting tasks.