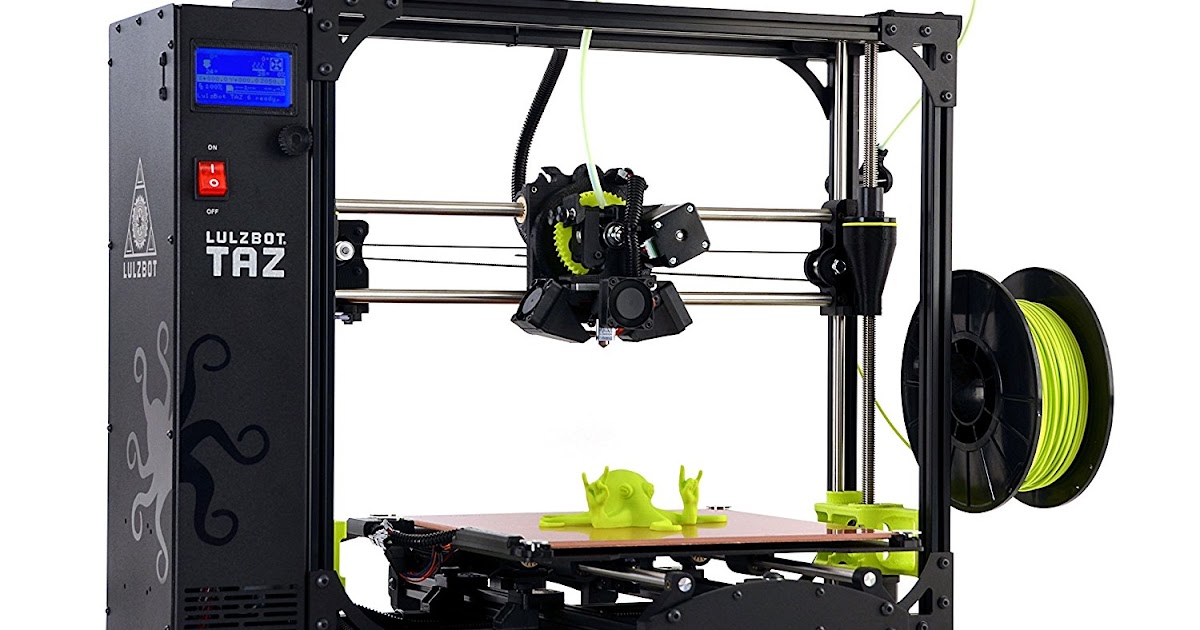

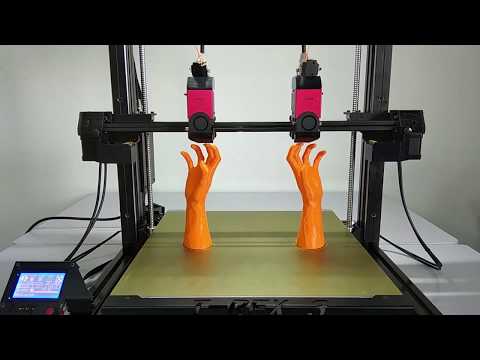

Demonstration of 3d printing

The Best 3D Printing Videos from 2021

Published on January 9, 2022 by Madeleine P.

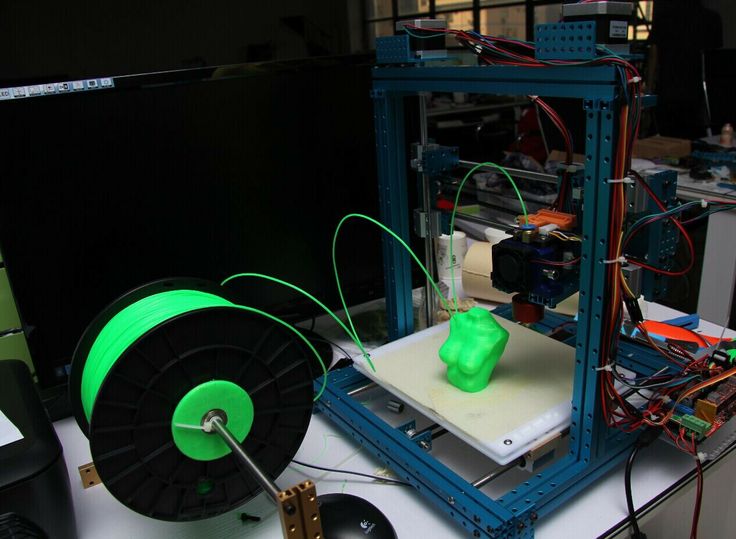

The year 2021 has come to an end and, like every Sunday, 3Dnatives is taking a look at some of the best videos, though this time it’s from the past 12 months rather than the week. Between building houses, bridges, robots or car parts, the technology has developed greatly over the past year. Other industries, such as medical and aerospace have also been impacted by the advancement of the technology. In addition, the return of physical events, such as Formnext, the world’s largest trade show dedicated to 3D printing, has brought industry players together. Through these 10 3D printing videos, relive some of the most outstanding innovations of 2021!

A 3D printed ocular prosthesis

A few weeks ago we learned about the case of Steve Verze, a London resident who became the first person in the world to receive a 3D printed ocular prosthesis. The prosthesis was developed in a collaboration between several agents in the UK and Europe, in a project led by researchers at UCL and Moorfields Eye Hospital NHS Foundation Trust. In this video, see how 3D printing has enabled Steve to regain his self-confidence thanks to the ultra-realistic appearance of the prosthesis, which is also adapted to the shape of the eye socket.

Large format machines at Formnext 2021

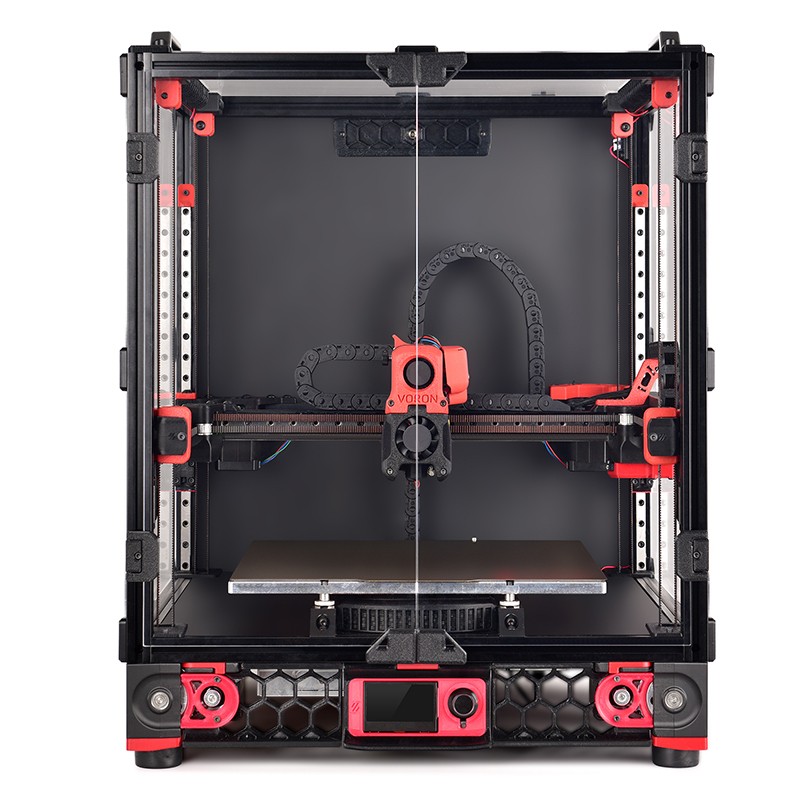

One of the biggest 3D printing events that the industry experienced in 2021 was undoubtedly Formnext. Organized in Frankfurt in mid-November, this event brought together the main players in the industry in one place after several months without the possibility of physical events. And to bring you first-hand all the news of the 2021 event, the 3Dnatives team made a series of videos with the most outstanding machines, applications and innovations of the fair. Specifically, in this video, get to know the 5 large format 3D printers that we saw in Frankfurt, specifically at the CMS, Triton, CEAD, Cubicure and MX3D booths. Discover the features of these five machines below!

Discover the features of these five machines below!

The 3D printed Striatus bridge

Among the various 3D printed bridges from this year, we would like to highlight the Striatus Bridge. The project was carried out by a group of architects from ETH Zurich who, together with Zaha Hadid Architects and Incremental3D technology, managed to design this pedestrian bridge. It is a 12 x 16 meter long bridge that was installed by assembling several individual pieces in a park in Venice. Thanks to 3D printing, the concrete was only applied at certain angles which ensured that the bridge did not need any extra reinforcement. We’ll let you discover the rest of the details in the video!

Trying out the Adidas 4DFWD

The combination of 3D printing, footwear and sport is certainly something we have seen throughout 2021. In fact, the so-called Adidas 4DFWD were launched in May this year by the German manufacturer in collaboration with 3D printing company Carbon. What is striking about these sneakers is that the midsole has been created using resin additive manufacturing. According to those behind the project, this design should allow athletes to generate more thrust when exercising thanks to the lattice structure of the midsole. To learn more about these shoes, see them in action in the video below.

In fact, the so-called Adidas 4DFWD were launched in May this year by the German manufacturer in collaboration with 3D printing company Carbon. What is striking about these sneakers is that the midsole has been created using resin additive manufacturing. According to those behind the project, this design should allow athletes to generate more thrust when exercising thanks to the lattice structure of the midsole. To learn more about these shoes, see them in action in the video below.

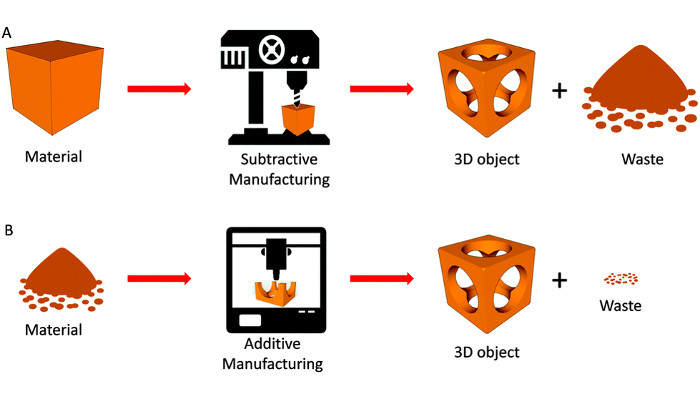

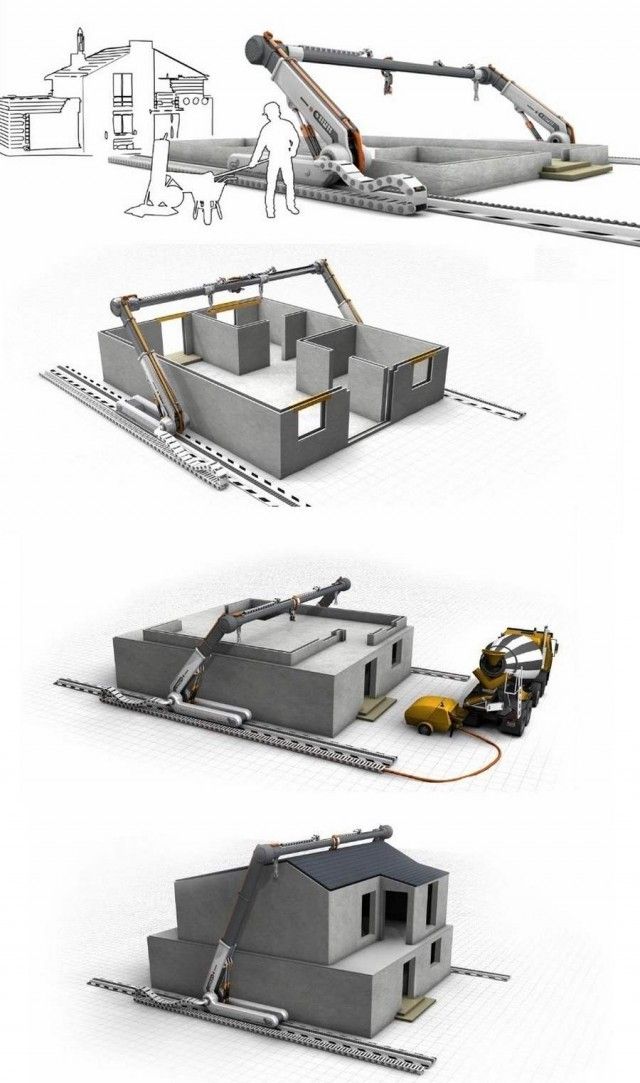

The role of additive manufacturing in construction

As additive manufacturing takes center stage in the construction industry, many companies have started 3D printed house projects. What once seemed like science fiction is now a reality. Thus, companies such as WASP, ICON, Mighty Buildings, TAM and many others have taken advantage of 3D printing to bring their innovative projects to life. To learn more about the rise of the technology in construction, we at 3Dnatives wanted to take a look at some of the most popular 3D printed houses in recent months. Will additive manufacturing be the main method to build houses in the future?

To learn more about the rise of the technology in construction, we at 3Dnatives wanted to take a look at some of the most popular 3D printed houses in recent months. Will additive manufacturing be the main method to build houses in the future?

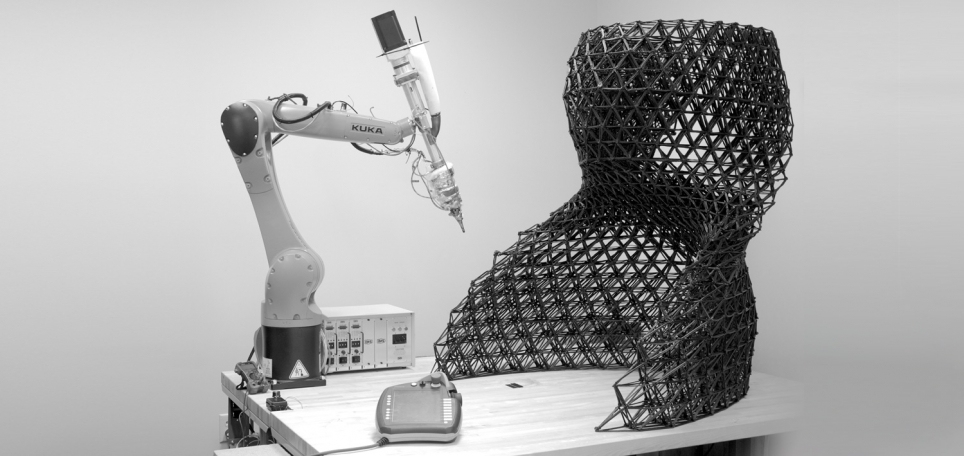

Atlas, the Boston Dynamics robots

This is undoubtedly one of the 3D printing videos that went viral in 2021. It is about an obstacle course performed by the so-called Atlas, 3D printed humanoid robots. The development of the robots was carried out by the company Boston Dynamics, who aim to test the limits of what is possible by combining 3D printing and robotics. Specifically, the Atlas prototypes have certain 3D printed components, such as legs or other parts of the final structure. Don’t miss the amazing video where the robots make all kinds of jumps by itself!

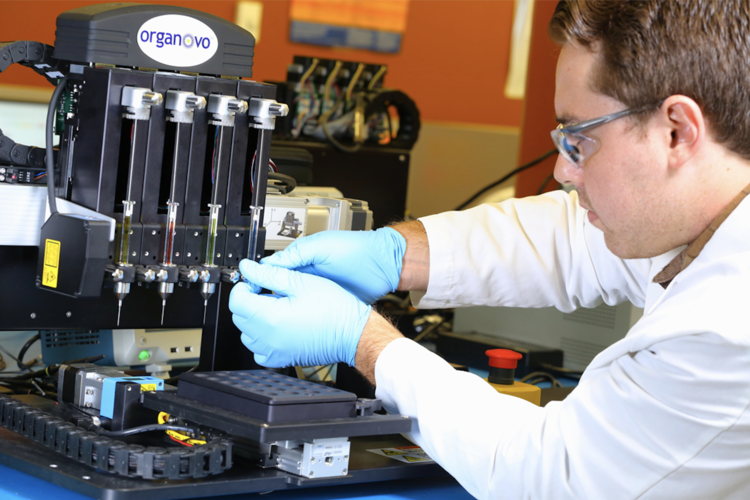

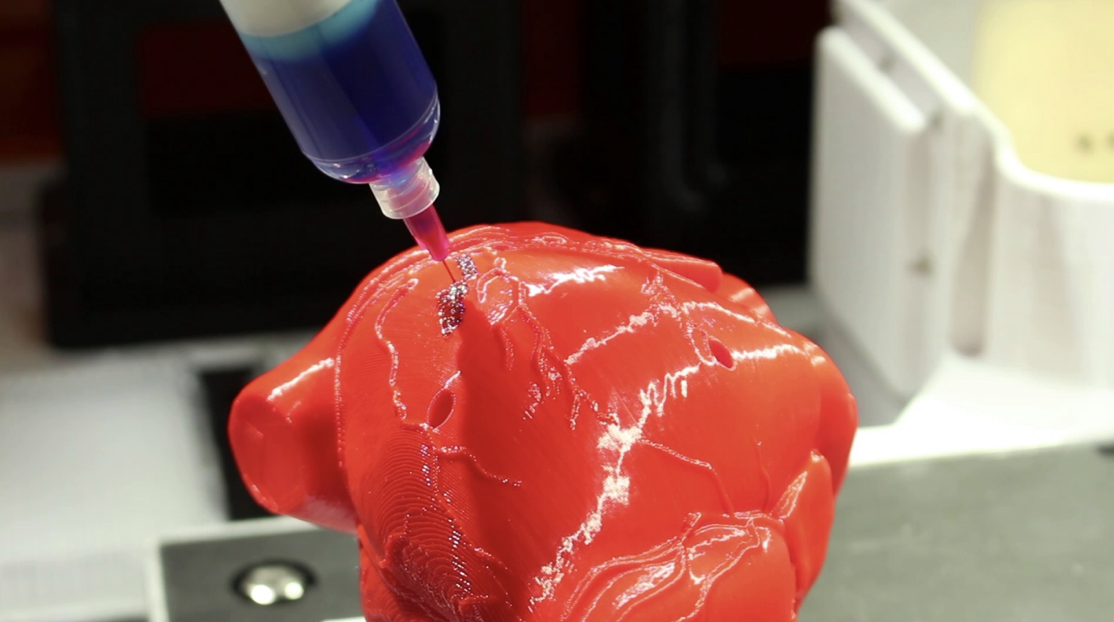

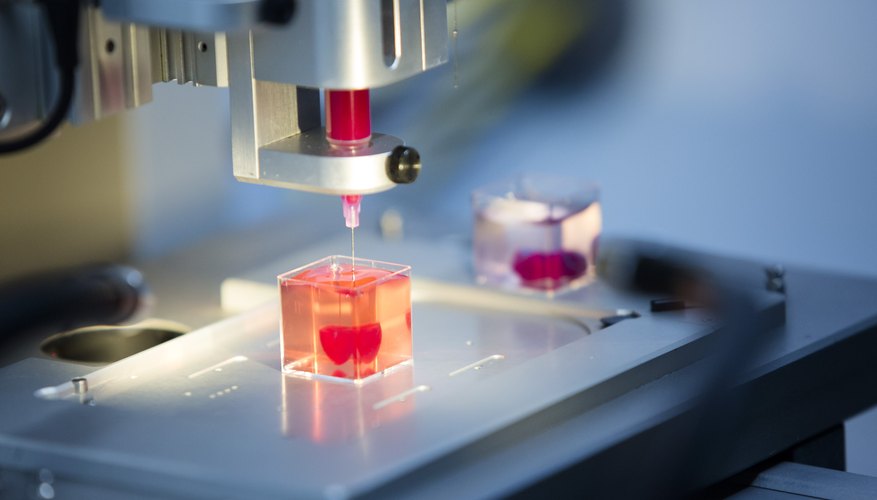

3D printing of bones with living cells

Advances in additive manufacturing in medicine are revolutionizing the industry, enabling the development of exciting projects ranging from prosthetics to 3D printed organs. In this case, we will watch a video in which Kris Kilian, a research doctor at the University of New South Wales in Sydney, explains a new initiative using this technology. Specifically, his research team developed an ink that could allow surgeons to create 3D printed bones using real living cells. If you want to learn more about this project and its impact on the medical sector, don’t miss the video below!

3D printed rockets for space exploration

As time goes on, more and more projects using additive manufacturing are emerging in the aerospace sector, whether for the creation of parts and tooling or large-scale structures. The growing implementation of 3D printed rockets in the industry is enabling companies to reduce the weight of final parts as well as production times. To learn more about the advantages of this technology in space exploration, we have taken a look at the main projects to date. Discover the activity of major companies such as Relativity Space, Hyperganic, SpaceX or SPEE3D!

The growing implementation of 3D printed rockets in the industry is enabling companies to reduce the weight of final parts as well as production times. To learn more about the advantages of this technology in space exploration, we have taken a look at the main projects to date. Discover the activity of major companies such as Relativity Space, Hyperganic, SpaceX or SPEE3D!

The TECLA project uses sustainable resources

Although we have seen several videos from 2021 that use 3D printing in the construction sector, we could not leave out the TECLA project, one of those that has most marked the year 2021. Carried out by the Italian company WASP, these structures have been created with natural and sustainable materials, using their proprietary construction 3D printer. The innovative habitat model created by WASP aims to implement a new circular model of housing created entirely with reusable and recyclable materials, from local soil, carbon neutral and adaptable to any climate and context.

3D scanning of difficult surfaces

Another video that caught our attention during 2021 was offered by HandsOnMetrology. The company published this short video in which it aims to solve a big question that many users in the industry ask themselves on a daily basis: how can you 3D scan the most difficult areas of a part or model? To do so, it shows the case of the IndyCar RLL racing team, who needed to scan the windshield of a racing car, which was complicated because the laser went through the surface. For this, they used a 3D scanning mattifying spray that allowed them to coat the surface, obtaining a much cleaner and higher quality final result.

Ford and BigRep additive manufacturing

Another video highlight of 2021 comes from Ford Motor Company. In this case, the famous automaker used BigRep’s large-format additive manufacturing to optimize tooling production at the factory. With more than 30 years of experience in additive manufacturing, Ford expanded its Cologne prototyping facility with two BigRep solutions. This integration of 3D technology enabled Ford to reduce lead time by 94%, as well as final costs. All these investments in additive manufacturing machinery highlight the growing popularity of the technology in many areas, particularly in the automotive industry.

In this case, the famous automaker used BigRep’s large-format additive manufacturing to optimize tooling production at the factory. With more than 30 years of experience in additive manufacturing, Ford expanded its Cologne prototyping facility with two BigRep solutions. This integration of 3D technology enabled Ford to reduce lead time by 94%, as well as final costs. All these investments in additive manufacturing machinery highlight the growing popularity of the technology in many areas, particularly in the automotive industry.

What do you think of our choices for the best 3D printing videos from 2021? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! And don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Demo best 3D printing files・Cults

Square, Triangle, Circle

€0.86

CASE FOR AS7265X DEMO KIT

€10

Team Fortress 2 | Demoman's Eyelander

€1.88

Specialist Marker Rings - Sniper Scout Comms Combat Veteran Zealot Medic Leader Heavy Demo Commander

€1.41

BUSTE DemoCyborg limited edition

€1.99

SL_ST FLEXURE GAUGE INDICATOR 3-02

Free

Cycloidal Driver V2

Free

DEMO MAN MOTU ESTILO

€3.80

SL_ST FLEXURE GAUGE INDICATOR 2-01

Free

SL_ST FLEXURE GAUGE INDICATOR 2

Free

SL_ST FLEXURE GAUGE INDICATOR 1-04

Free

SL_ST FLEXURE GAUGE INDICATOR-01

Free

The model of the cervical spine C1-C7 with a part of the skull

€7. 53

53

Human Helpers Flame Fighters WITH EXPERIENCE and carbines

Free

HUMAN HELPERS FLAME FIGHTERS WITH EXPERIENCE

Free

Human Helpers Front Breakers with experience

Free

Human Helpers Flame Fighters

Free

Human Helpers Front Breakers

Free

Human Helpers Trail Blazers

Free

Human Helpers Demo

Free

Stepper Motor V1.1

Free

Echo Windwalker Statue from Tech Demo

€4.51

The demo model for endodontics (veterinary medicine)

€5.65

DETONATOR

Free

Preassembled Pliers

Free

Print-in-Place DeLorean benchmark

€1. 41

41

Funduscopy support ophthalmology

€61.96

Library Attention Seekers

Free

Dissolvable Support Gearbox

Free

Polarizing Light Demo

Free

Air Spinner

Free

Lady Alcina Dimitrescu

€0.70

FreeShip Demo Superstructure (cabin)

Free

Mario Bross Mushroom Pot

€0.50

Ring Type Butterfly Style Gotic (Anime: Chūnibyō Demo Koi ga Shitai! or Love, Chūnibyō & Other Delusions)

Free

Infill Visualization Tool

Free

Diamond shape

Free

Falcon 9 Crew Dragon Scale 1:200 (Multi Parts)

Free

Smartphone telescope mount

Free

demogorgon funko pop 2 pieces low poly

Free

Air Spinner

Free

Key Fob / 3D Demo Print - Interlocking rotating gears

Free

Circular Air Spinner

Free

Small Architect House

€12. 24

24

Parametric 27 to 1 Gearset

Free

Electric Motor Demonstration

Free

Spinner keychain

Free

Demonstration of 3D printers and 3D scanners

Globatek experts are ready to demonstrate 3D equipment for you: in our demo hall, at an enterprise in your city or region, using online broadcasting. You will be able to try out 3D printers and 3D scanners, see print samples from different materials, and ask technical experts questions.

01

Own demo hall in Moscow with equipment and samples

02

Organization of visits to Russian enterprises using 3D technologies

03

Visiting plants of 3D equipment manufacturers in Russia and abroad

04

Exit demonstrations of 3D scanners, Test 3D 1,

Demosal in Moscow

In the demosal of Globatek you can ask questions to the equipment for equipping enterprises 3D equipment, see popular models of 3D printers and 3D scanners in action

Demonstration of 3D printers

In the Globatek demo hall you can see how professional 3D printers work, compare the features of different additive technologies

Over 500 3D printed samples in various technologies

Study the properties of 3D printed samples from different materials, compare details, surface quality - so you can understand which material is right for your applications

PhotopolymersMetal powdersWaxPlastic

Test 3D scan your samples

Globatek engineers will explain how 3D scanners work and run a demo scan of your samples, show you the results

EPiCRangeVisionGOMScantech

Expert advice on 3D technology implementation

Globatek experts will study your tasks, select a set of equipment according to the budget and terms of delivery, answer all questions about the implementation of 3D equipment in production and research processes

Examples of 3D printing samples located in the Globatek demo

Examples of 3D printing samples located in the Globatek demo

Road demos

1.

Presentation at your plant

Presentation at your plant 3D scanners

-

We will carry out 3D scan of your samples, show the results

-

We will talk about the role of 3D channers in reverse engineering and quality control

-

Successful cases in your industry

-

We will answer questions

3D printers

-

We will tell you about the types of equipment and 3D printing technologies

-

We will bring samples of 3D printing from the required materials

-

We will show successful applications in your industry

-

We will answer questions

2. Meeting at the enterprise using 3D equipment

at the meeting you can see 3D equipment, built into real equipment, built into real workflows

View samples of 3D printing and 3D scanning

Get feedback from employees using 3D technology at work

Geography

-

more than 300 clients

-

79 cities in 40 regions of Russia

-

5 countries of the Near Foreign

-

sector: production, research, science, education

9007

3D equipment manufacturer's plant

When implementing large-scale projects to equip an enterprise with 3D equipment, as well as in the production of additive systems according to individual parameters, it may be necessary to visit manufacturing plants. Globatek specialists are ready to organize such a trip and act as technical consultants and intermediaries. nine0003

Globatek specialists are ready to organize such a trip and act as technical consultants and intermediaries. nine0003

We will organize a meeting with manufacturers in Russia, Europe, USA, China, South Korea

We will make a trip plan, select convenient tickets, transfer, accommodation options

We will attend the meeting, we will help to negotiate

We will conduct a tour, demonstrate equipment and samples

When implementing large-scale projects to equip an enterprise with 3D equipment, as well as in the production of additive systems according to individual parameters, it may be necessary to visit manufacturing plants. Globatek specialists are ready to organize such a trip and act as technical consultants and intermediaries. nine0003

We will organize a meeting with manufacturers in Russia, Europe, USA, China, South Korea

We will make a trip plan, select convenient tickets, transfer, accommodation options

We will attend the meeting, we will help to negotiate

We will conduct a tour, demonstrate equipment and samples

Sign up for a demo

Leave a request - we will call you back and answer all your questions

Call +7 495 646-15-33

to get advice from Globatech engineers on choosing 3D equipment

Come to our demo hall

to see the best 3D printing and 3D scanning systems in action

I confirm the accuracy of the information I entered and agree to the processing of my personal data in accordance with the privacy policy and user agreement.

Demonstration

As part of the 3D Print Expo exhibition, which was held in Moscow in Sokolniki Exhibition and Convention Center in October, the editors asked what new and interesting things in the field of 3D printing and 3D scanning are offered to the consumer on the Russian market. What did the visitors see? nine0169

3D printers

When asked about the most interesting, most of the exhibitors readily demonstrated the equipment and materials presented at the stands, including novelties from the domestic manufacturer.

The Vortex company from Surgut showed 3D printers of its own design and production: DUAL and GIANT models ( fig. 1 ). The presence of two printheads makes it possible to produce two-color parts or parts with complex supports on them, when the supports are printed with a water-soluble material, and the product is the main one. The small DUAL has a diameter of 320 mm and a print height of up to 55 cm, the large GIANT has a diameter of 55 cm and a print height of up to 95 cm. As innovative components for delta printers were identified: a fairly light head, head height switching system and a fully automated calibration system.

As innovative components for delta printers were identified: a fairly light head, head height switching system and a fully automated calibration system.

Fig. 1.

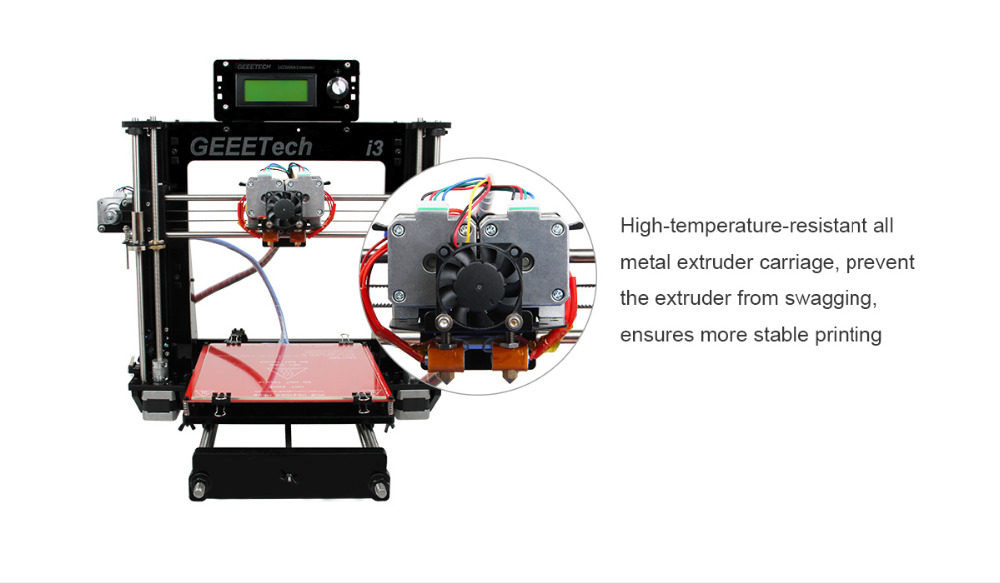

3D printers also with two extruders: Pro2 and Pro+2 by the well-known Chinese developer RAISE3D — were demonstrated at the booth of Tsvetnoy Mir LLC (construction area, respectively, 305 × 305 × 300 mm and 305 × 305 × 605 mm, resolution printing - 0.01 mm). The printers are distinguished by high productivity, as well as a wide range of materials used, which is achieved due to the special design of the extruder and its heating up to 300°C. nine0169 The capabilities of the Her-cules STRONG DUO printer with a new dual-extruder printhead manufactured by IMPRINTA demonstrated a unique motorcycle from Vizuit lab (a motorcycle customization company). Vizui Lab uses printing for two purposes: prototyping and testing parts before final production from metal and for printing parts that are not under load: electronics cases, decorative covers, overlays, etc. As for this printer model, it has new systems automatic calibration from nozzle height position to table plane calibration, increased positioning accuracy, plastic control system in the coil. nine0003

As for this printer model, it has new systems automatic calibration from nozzle height position to table plane calibration, increased positioning accuracy, plastic control system in the coil. nine0003

In the new product from Cyber, the Dragon 3D printer, the benchmark was taken for speed and quality. Printing is implemented by two independent extruders on the same X-axis. In addition to the fast switching of materials, this gave an additional function of parallel printing - two parts in the time of printing one. The closed case with a space frame provides good rigidity and allows printing with structural materials with shrinkage.

Two new models were presented at the Maestro booth. The goal of the little Honey printer was to make it affordable for the home, but like the base Maestro Classic, it has a filament motion sensor and table adjustment. The future flagship with two printheads was also presented. In addition to the technologies mentioned, the model provides a power backup system, a new control controller, a color screen, USB support, and a built-in Wi-Fi module. In the process of developing a remote monitoring and control system via the Internet, it is planned to install a camera to receive slides from a printed table. nine0003

In the process of developing a remote monitoring and control system via the Internet, it is planned to install a camera to receive slides from a printed table. nine0003

New from Picasso - VC Picasso machine has a large print area of 360×360×610 mm, automatic table level, automated profile system, like all X-series printers. So far, printing is carried out with one material, but a two-nozzle version is being prepared.

The new Magnum Creative 2 printer ( fig. 2 ) has improved and simplified the process of printing with two nozzles, the switching time between which is no more than 0.5 s. For ease of use, semi-automatic calibration of the height and distance between the nozzles has been added. The updated software gives you faster speed and better print quality than the PRO model. The size of the construction area is 245×170×170 mm. nine0003

Fig. 2.

The key feature of the new PrintBox3D White 3D printer is the fully enclosed forced draft chamber. Thus, the best temperature balance is created in the 3D printer chamber for printing with high-temperature plastics. For this model, a new extruder was developed, which has become much lighter than its predecessor. Easier cleaning process. There is a filament sensor. Working chamber size: 220×210×230 mm. nine0003

Thus, the best temperature balance is created in the 3D printer chamber for printing with high-temperature plastics. For this model, a new extruder was developed, which has become much lighter than its predecessor. Easier cleaning process. There is a filament sensor. Working chamber size: 220×210×230 mm. nine0003

Elektroprivod presented the SkyOne 3D printer based on the Koskar mechanics ( fig. 3 ). To date, no one in the world produces such printers. What is the main advantage? The printer turned out to be quite compact with standard print settings. Removing the table, you can achieve a minimum dimension for storage. The printer has no components subject to temporary deformation.

Fig. 3 .

A new product on the market - a 3D printer that prints with clay, was presented by the company "Robokinetics". The company also offers Delta 3D printers with a Mixing extruder, which allows you to mix two or three filaments of the same material of different base colors in the required proportions during the printing process. Thus, shades of these colors and new colors can be obtained in the product. nine0003

Thus, shades of these colors and new colors can be obtained in the product. nine0003

At the booth of AM-KOR LLC, the official representative of XYZprinting (Taiwan), they showed the world's first affordable 3D printer with the ability to print in full color daVinci Color ( fig. 4 ), combining the processes of inkjet and 3D printing based on technology FFF (Fused Filament Fabrication). The principle of operation is as follows: an inkjet printhead applies CMYK ink to a special CPLA absorbent filament, allowing you to create products with millions of colors. The print area of this model has dimensions of 200 × 200 × 150 mm, positioning accuracy along the Z axis is 0.4 μm, along the X and Y axes is 12.5 μm, the layer thickness is 100–400 μm, which allows you to create quite voluminous and accurate full-color 3D models. nine0003

Fig. 4 .

Industrial 3D printers using FDM technology were presented by two companies Nissa Digispace — a dealer of Stratasys (the Srtatasys F370 model with a working area of 356 × 254 × 355 mm was demonstrated at the booth) and the Russian manufacturer Total Z (the model was demonstrated at the booth). ANYFORM 450 PRO with working area 450×450 mm - fig. 5 ). In addition, Maker Bot FDM printers, the Replicatior+ and Replicator 9 models, were shown at the Nissa Digispace booth.0169 Mini+ with working areas 295×195×165 mm and 101×126×126 mm respectively.

ANYFORM 450 PRO with working area 450×450 mm - fig. 5 ). In addition, Maker Bot FDM printers, the Replicatior+ and Replicator 9 models, were shown at the Nissa Digispace booth.0169 Mini+ with working areas 295×195×165 mm and 101×126×126 mm respectively.

Fig. 5.

The only SLM printer for metal printing at the exhibition was demonstrated by the domestic company OOO Exclusive Solutions (3DSLA.RU). According to the manufacturer, the platform of its own design allows you to quickly manufacture printers with any reasonable build zones (up to 900 × 900 × 1000 mm), install laser sources of different powers and create solutions with several synchronously operating scanners. These machines work not only with spherical powders, but also with non-spherical ones, which are 2-4 times cheaper. Triangulatica's own software allows you to prepare printing tables, arrange support structures in automatic mode, create printing strategies for various materials, etc.

The ISL group of companies, together with the Moscow State University of Food Production, is developing innovative 3D food printers. Various materials, modes of their supply, temperature parameters are investigated. A concept model was demonstrated at the exhibition, the first 3D printer is expected to be released within a year. Among the materials used: chocolate, icing, dough, puree.

And at the stand of the 3D ARTEL online store, one could already see the results of printing on coffee foam, cocktails and desserts. nine0169 And of course, there were other exhibits and exhibitors, including online stores offering Chinese equipment.

Scanners

Range 3D Vision Scanners manufactured in Russia. The user is offered two models: Spectrum and Pro. The flexible equipment is accurate and detailed and allows you to scan both miniature (less than 3 cm) and large (from 1 m) objects.

Terem3D booth demonstrated the capabilities of THOR 3D scanners ( fig. 6 ). According to the company, this is the first handheld 3D scanner that can digitize almost everything from a coin to a tractor. All you need to do is choose the right lens - one of the three. Patented hardware and software ensure the best results even when scanning complex objects with sharp edges or shiny, thin walls. Mini model accuracy up to 40 µm, Midi up to 70 µm, Maxi up to 150 µm.

6 ). According to the company, this is the first handheld 3D scanner that can digitize almost everything from a coin to a tractor. All you need to do is choose the right lens - one of the three. Patented hardware and software ensure the best results even when scanning complex objects with sharp edges or shiny, thin walls. Mini model accuracy up to 40 µm, Midi up to 70 µm, Maxi up to 150 µm.

Fig. 6 .

In the art gallery area, Texel presented a new version of the 3D scanner, thanks to which you can make a three-dimensional model of a person in 30 seconds. Two models were shown: the compact Texel Portal MX and the full-size Texel Portal BX. nine0169

Materials

At the booth of the REC manufacturing company, attention was paid to promising flexible materials for 3D printing: elastic Flex, similar in properties to the flexible rubber Rubber, as well as the most elastic and wear-resistant in the Sealant line, which also features high chemical resistance to oils, gasolines, alkalis and some acids.

The representative of the Print Product company first of all singled out Flex hard (resistant to ultraviolet, solvents and at the same time machined), ADS V-0 - flame retardant ABS, PC polycarbonate for printing durable products. nine0169 The company Filamentarno demonstrated a new material for printing wax models (wax). Products made from it without changing the technology can be used for any casting process, providing maximum cost reduction in the manufacture of small-scale and single products.

Other interesting materials were also shown here.

TOTAL CF‑5 carbon-filled polyurethane is a material with very low shrinkage, high temperature resistance and high wear resistance, designed for printing final products: gears, parts of mechanism cases. PROFLEX material is specially made for printing art products (such as life-size puppets presented at the exhibition). It is available in two colors and, unlike most FLEX materials, undergoes chemical post-processing. For printing lightweight structures, AEROTEX‑2 carbon-filled composite is suitable, which foams during the printing process. The density of the material after printing is about 0.8 g/cm3. In the process, it is possible to adjust the density and hardness of the structure. nine0003

The density of the material after printing is about 0.8 g/cm3. In the process, it is possible to adjust the density and hardness of the structure. nine0003

Interesting Applications

The company's clients were invited to work at the booth of the Russian manufacturer of materials Print Product, who illustrated various areas of 3D printing. Thus, the My3DSHoes company demonstrated the work of a factory for the production of individual shoes. In addition to printing individual insoles and other parts of shoes, the company has developed original technologies for gluing various materials to printed parts to ensure comfort. nine0003

Fig. 7.

Representatives of the construction industry - the companies 3DSHOP and "DUST NO" at first used additive technologies for their own needs, producing products that were difficult to purchase on the market: a casing for angle grinders for connecting to a vacuum cleaner, separators for grinders, etc. - prefabricated and collapsible products of various form and functionality. Later, a separate direction grew out of this, including an online store and the production of its own large-sized printers. An interesting development of the company was a new composite (printed mesh, covered with a thermally insulating layer such as foamed polyethylene). A sheet of this composite when heated by boiling water or dry exposure to 90 degrees can be molded. Due to the thermally insulated layer, the heated material does not burn (the temperature of the outer layer is 30–35 degrees), heat is stored inside. Moreover, the material remains plastic not for 10–15 seconds, but for a minute and a half. This is sufficient time to, for example, mold it for use in traumatology instead of the usual gypsum or expensive foreign materials.

Later, a separate direction grew out of this, including an online store and the production of its own large-sized printers. An interesting development of the company was a new composite (printed mesh, covered with a thermally insulating layer such as foamed polyethylene). A sheet of this composite when heated by boiling water or dry exposure to 90 degrees can be molded. Due to the thermally insulated layer, the heated material does not burn (the temperature of the outer layer is 30–35 degrees), heat is stored inside. Moreover, the material remains plastic not for 10–15 seconds, but for a minute and a half. This is sufficient time to, for example, mold it for use in traumatology instead of the usual gypsum or expensive foreign materials.

The highlight of the exhibition, of course, were the unusual exhibits of the art gallery: the Onyx dolls, the Reptiloid doll, a dinosaur with a movable jaw, a four-meter statue of a Girl with an oar. nine0169

Winners

As part of the exhibition, the list of winners of the 3D Print Expo Awards, the most influential companies of the year in the field of additive technologies, was traditionally announced. The organizers of this event are Smile Expo and SIU System.

The organizers of this event are Smile Expo and SIU System.

This year the following companies were awarded nominations:

3DSYSTEMS. PRO - brand of the year;

MZTO - the best domestic manufacturer of 3D printers;

VORTEX - the best innovative company of the year;

CYBERON - the best development of the year; nine0169 TEREM 3D is the most demanded manufacturer of consumables;

RANGEVISION - Best 3D Object Scanning Company;

TOP3DSHOP - the best integrator of 3D equipment for additive technologies and digital manufacturing;

MAESTRO Rookie of the Year.

As part of the business program

, the exposition of the exhibition was traditionally supplemented by a rich business program, where one could not only get information, but also acquire new skills. In the lecture area, which was held with the support of RENA SOLUTIONS, they discussed novelties, changes, innovations in the field of additive technologies (Fig. 7). Among the topics of speeches are: intellectual property rights in 3D, integration of additive technologies in production, the use of 3D printing of sand

molds and models for investment casting, modeling of 3D printing processes, 3D printing with composites, etc.