Conveyor belt 3d printer diy

The 5 Best Belt 3D Printers for Infinite Printing (2022) – Clever Creations

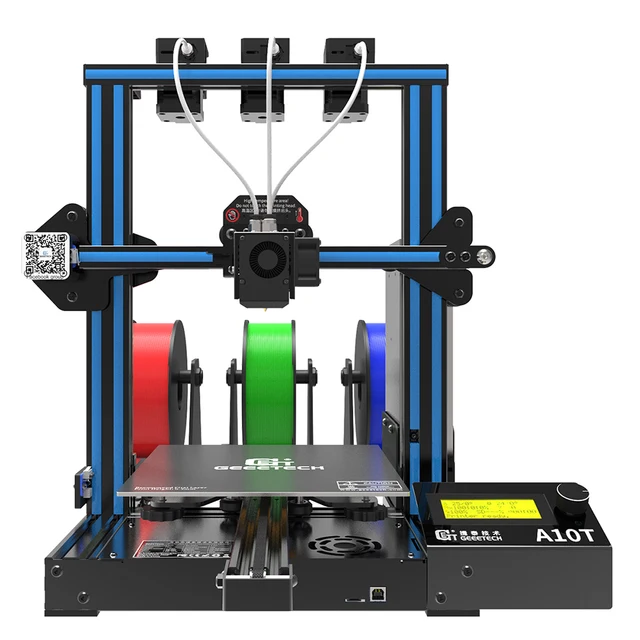

3D printer designs have evolved a lot since their inception in the 1980s. Cartesian, CoreXY, and Delta 3D printers are the standard norm in the hobby 3D printing space. Recently, we have seen the introduction of conveyor belt 3D printers.

These 3D printers have the belt embedded into the build platform, essentially creating a printer with an infinite Z-axis. This is an interesting design and raises the question: is a belt 3D printer viable for your 3D printing needs?

Read on to learn more about continuous printing and see the best belt 3D printers that are currently available on the market.

| Belt 3D Printer | Build Volume | Inclination | Price (~) | Best Offer |

|---|---|---|---|---|

| Creality CR-30 3DPrintMill | 200 x 170 x ∞ mm | 45° | $1049 | Creality |

| Blackbelt 3D Printer | 340 x 340 x ∞ mm | 15°/25°/35°/45° | $10450 | Blackbelt 3D |

| IdeaFormer IR3 | 250 x 250 x ∞ mm | 45° | $499 | Amazon |

| SainSmart INFI-20 | 200 x 180 x ∞ mm | 45° | $849 | SainSmart |

| White Knight Belt Printer | 400 x 430 x ∞ mm | 45° | $2000 | GitHub |

What is a Belt 3D printer?

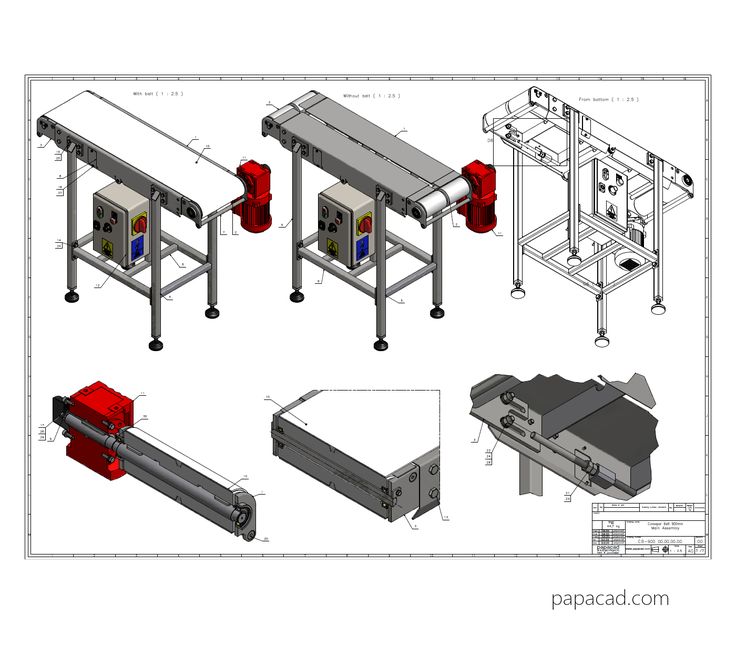

Originally invented by the Dutch company Blackbelt in 2017, rolling conveyor belt 3D printers are a radical take on the existing 3D printer designs. Belt 3D printers consist of a moving belt that lets you print long objects in the Z-axis without any limits (infinite Z printing).

You can use a belt 3D printer to carry out bulk printing and print continuously without the need to stop the 3D printing process.

The original Blackbelt 3D printer had a price tag of over $9000, limiting its user base to professional users. Subsequently, Creality’s CR-30 3DPrintMill brought continuous printing technology to the masses. Several other conveyor belt printers have appeared on the market after that.

How do belt 3D printers work?

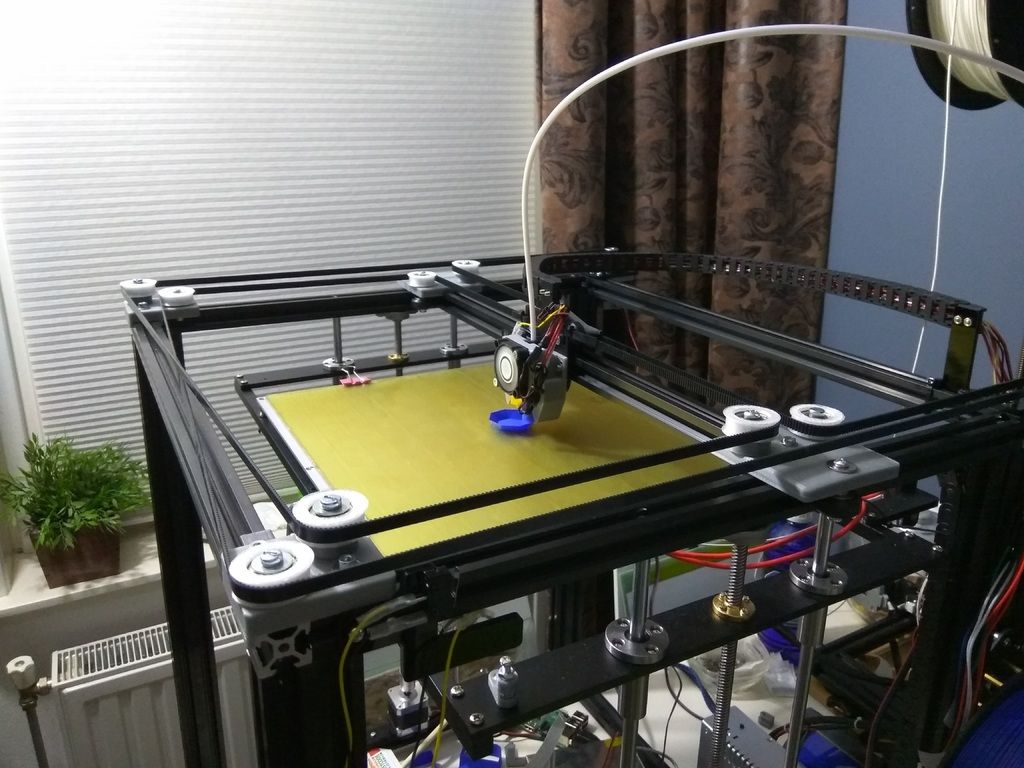

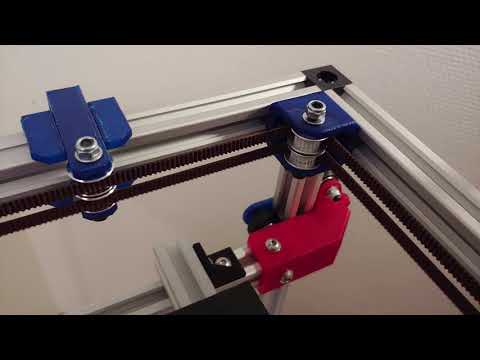

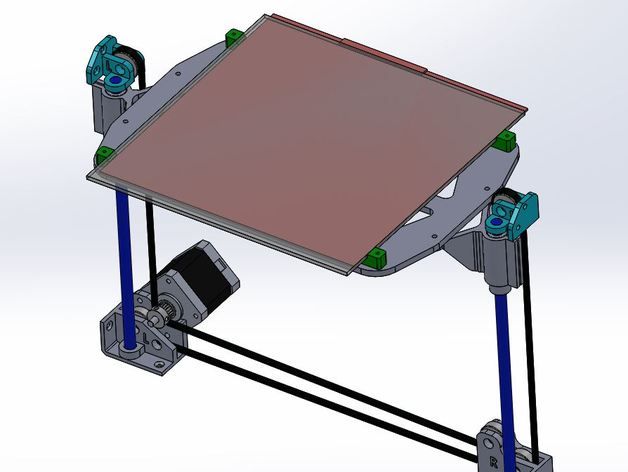

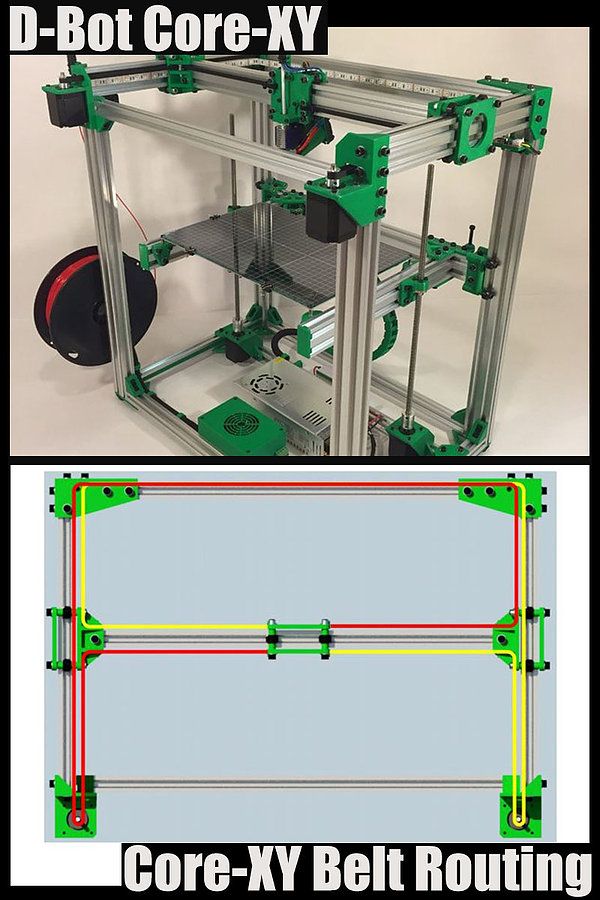

A conveyor belt 3D printer is a drastic modification over your typical Cartesian or CoreXY 3D printer. Its stand-out feature is a continuously moving belt instead of a fixed print bed.

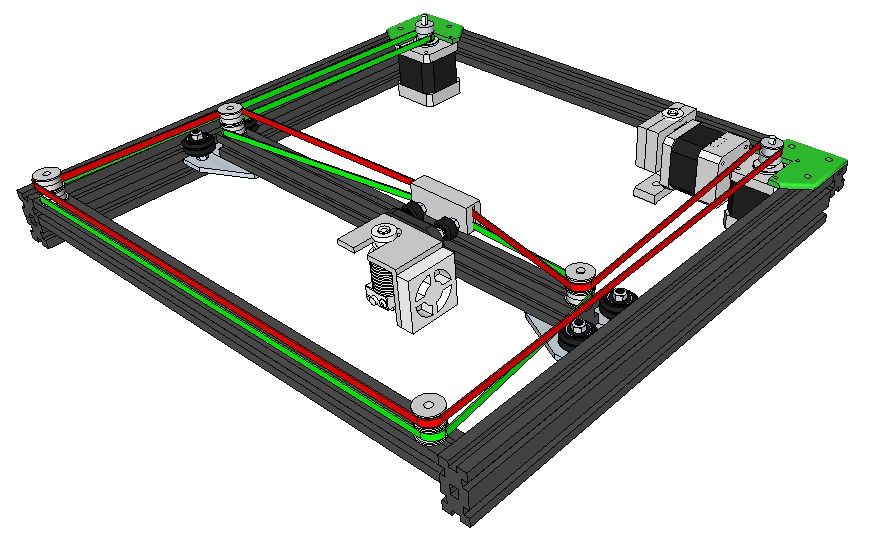

On a belt 3D printer, a Core XY motion gantry is positioned inclined to the belt, usually at a 45° angle. The belt is used as the Z-axis for your 3D prints, whereas the inclined print head constitutes the X and Y axes.

The print head prints the objects in an inclined plane. While doing so, the belt moves ahead or backward, depending on your object’s design. The printing process is pretty much like that of a standard CoreXY 3D printer, albeit on an inclined plane.

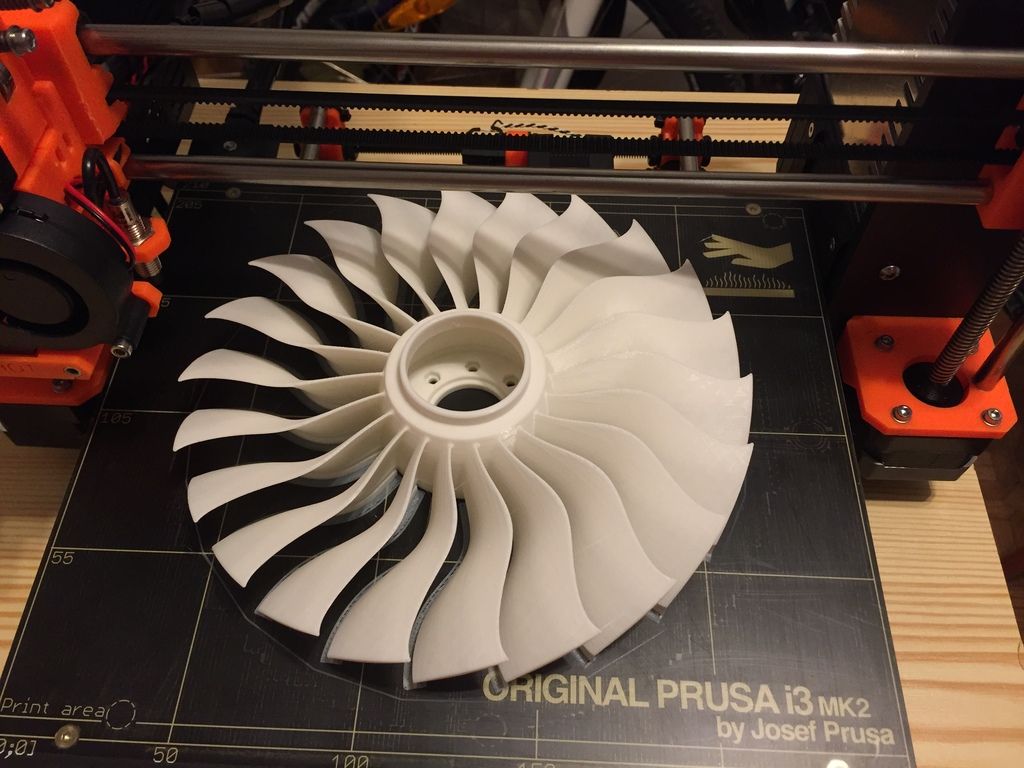

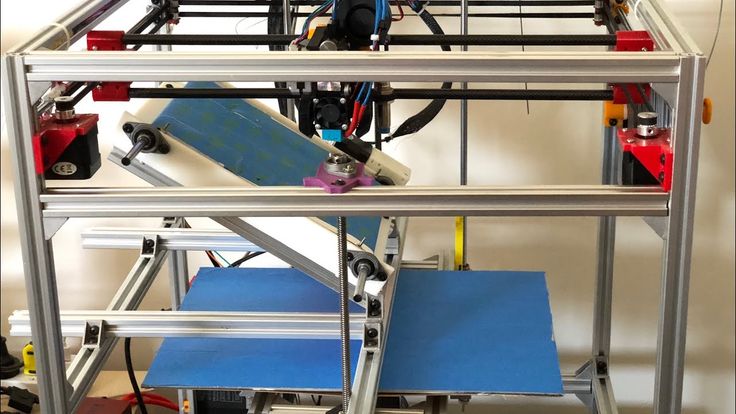

3D prints fall off the belt’s far end once they’re done printing. Because of this, you can use belt 3D printers to print large production runs of your designs without any intervention.

Technically, there’s no restriction on the object’s height that you can print on belt 3D printers. Here is an example of a CR-30 3D printer printing a 6-meter extended model on the conveyor belt.

Why use a belt 3D printer?

One of the biggest advantages of a conveyor belt 3D printer is that it lets you 3D print long objects. As the 3D printer has no actual limit in the Z direction, you can 3D print swords, large model buildings, and other prints that would not fit the print volume of traditional FDM printers.

As long as you can support your parts beyond the belt’s length, you can print models as long as you want. For that reason, some belt 3D printers come with a removable extension bracket accessory.

For that reason, some belt 3D printers come with a removable extension bracket accessory.

Alternatively, you can use belt 3D printers to automate your printing process. If your work consists of 3D printing numerous parts, you might not want to go through the effort of removing them from the print bed, cleaning the bed, and starting a new 3D print each time.

Advantages:

- Infinite z-axis offers infinite length 3D prints

- Cost-efficient bulk 3D printing

Disadvantages:

- No belt 3D printers with enclosure

- Rougher surface finish than glass print beds

- Limited slicer options

- Requires additional support structures

The Best Conveyor Belt 3D Printers in 2022

Creality CR-30 3DPrintMill

Best overall

Check Price

AmazonCrealityCreality3DOfficial

Creality’s CR-30 3DPrintMill is probably the best-known conveyor belt 3D printer at the moment of writing. It carries a similar design to the Blackbelt 3D printer, but comes at a considerably more attractive price. At a price tag of $1049, it provides a great set of features and easy accessibility to spare parts.

It carries a similar design to the Blackbelt 3D printer, but comes at a considerably more attractive price. At a price tag of $1049, it provides a great set of features and easy accessibility to spare parts.

The CR-30 comes with a CoreXY gantry inclined at 45°. This lets the 3D printer have a rigid triangular frame that aids in print quality. The design is similar to other Creality 3D printers with V-slot extrusions, a dual gear Bowden extruder, and a spring adjustable bed platform.

The wear-resistant nylon belt surface and partially heated print area both promote print adhesion. The printer’s belt can be easily removed for cleaning or replacement.

Keep in mind that you will need to spend time fine-tuning it to get the best quality results. Nonetheless, the CR-30 Print mill opens up many avenues for cosplay 3D printing and is one of the best belt 3D printers for hobbyists looking for an endless printing solution.

Standout Features

- Nylon conveyor belt

- Dual metal gear extruder

- Silent stepper drivers

Technical Details | |

|---|---|

| Build volume | 200 x 170 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 240°C |

| Overall dimensions | 535 x 656 x 410 mm |

| Weight | 16. 5 kg 5 kg |

What We Like

- Easy to assemble

- Add-on rollers and replacement belts available

- Great community support

Could Be Better

- Sub-par print quality out of the box

- Poor quality control

Find Creality CR-30 3DPrintMill at

AmazonCrealityCreality3DOfficial

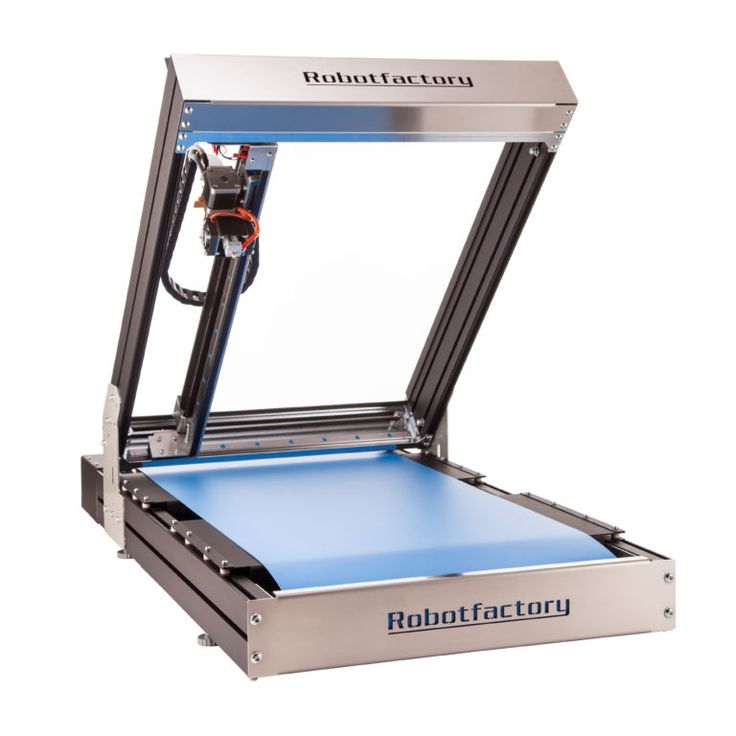

Blackbelt 3D Printer

Best high-end

Check Price

Blackbelt 3D

The Blackbelt 3D printer was the first commercial solution to realize infinite Z-axis 3D printing. Its revolutionary design and high-end components brought belt 3D printing to industrial applications.

The belt is made up of a durable carbon fiber composite material and holds your prints firmly in place. It features a modular design letting you quickly change the printhead assembly to print flexible filaments. Additionally, the Blackbelt team can customize the printer to fully suit your 3D printing workflow.

The industrial linear guides on the printer facilitate a smooth motion, and you get the option to adjust the inclination angle of the printer frame as well. It certainly has a premium design and a rugged build quality and is developed with industrial applications in mind.

It certainly has a premium design and a rugged build quality and is developed with industrial applications in mind.

If you have the budget for a >$10,000 conveyor belt 3D printer, the Blackbelt will be the best choice for you.

Standout Features

- Modular design

- Carbon-fiber composite belt

- Adjustable print angles

Technical Details | |

|---|---|

| Build volume | 340 x 340 x ∞ mm |

| Inclination angle | 15°/25°/35°/45° |

| Max hot end temperature | N/A |

| Overall dimensions | N/A |

| Weight | N/A |

What We Like

- Industrial build quality

- Customizable to your needs

- Large build volume

Could Be Better

- Expensive

- Outdated user interface

Find Blackbelt 3D Printer at

Blackbelt 3D

IdeaFormer IR3

Best on a budget

Check Price

AmazonAliExpress

The IdeaFormer IR3 is a desktop-sized conveyor belt 3D printer catered to budget 3D printer users. It has a simple design and comes with typical features of a budget 3D printer but in a belt printer package.

It has a simple design and comes with typical features of a budget 3D printer but in a belt printer package.

The printer features a CoreXY structure with a PU polyester belt as the print surface. You get linear guides on the XY axes for smooth and precise movement. The hot end on the printer is exclusive to it and has the addition of a dual gear extruder and a filament breakage detector. These key features are designed to provide reliable 3D printing over long periods of time.

As the printer is focused on novice users, it is easy to assemble, You will be able to put it together within half an hour.

The lack of a heated bed makes it most suitable for 3D printing low-temperature filaments like PLA. Similarly, its non-triangular frame is less rigid than the one you can find on the CR 30.

If you can handle its limitations and want to experience printing with a budget belt 3D printer, the IdeaFormer I3 is an excellent option.

Standout Features

- Easy to assemble

- Linear rail guides on X and Y axes

- Exclusively designed hot end

Technical Details | |

|---|---|

| Build volume | 250 x 250 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 250 °C |

| Overall dimensions | 575 x 436 x 506 mm |

| Weight | 16. 8 kg 8 kg |

What We Like

- Beginner-friendly design

- Low-cost

- Good printing volume

Could Be Better

- Separate control unit takes up extra space

- Limited community support

Find IdeaFormer IR3 at

AmazonAliExpress

SainSmart INFI-20

Most rigid

Check Price

AmazonSainSmart

The Sainsmart INFI-20 is one of the most compact and modern-looking conveyor belt 3D printers. Its spec sheet is comparable with that of the CR-30. At a slightly lower cost, the Sainsmart still delivers a decent printing experience and is an excellent alternative to the CR-30.

The INFI-20 comes with TMC 2208 stepper drivers for silent 3D printing. You also get a textured nylon belt surface designed for durability and good print adhesion. To help with setup, the included layer test model lets you quickly level your print bed.

The sleek brush metal finish display with a rotary knob on the control panel adds a touch of modernity to the printer. And with the inbuilt Wi-Fi capabilities, you can print wirelessly through the Octoprint app.

And with the inbuilt Wi-Fi capabilities, you can print wirelessly through the Octoprint app.

Reviews of the INFI-20 aren’t as positive as those of the CR-30. While it comes packed with nice features in a small form factor, you can expect to do a lot of tinkering before you get good results.

That said, if you get it dialed in correctly, the SainSmart INFI-20 conveyor belt 3D printer can be a decent belt printer for beginners, and hobbyists to print multiple models at once.

Standout Features

- Compact form factor

- Modern user interface

- Wi-Fi printing

Technical Details | |

|---|---|

| Build volume | 200 x 180 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 240 °C |

| Overall dimensions | 630 x 530 x 290 mm |

| Weight | 18. 5 kg 5 kg |

What We Like

- Easy to set up

- Silent 3D printing experience

- Integrated Octoprint support

Could Be Better

- Requires considerable fine-tuning

- Inconsistent Z-axis homing

Find SainSmart INFI-20 at

AmazonSainSmart

White Knight Belt Printer

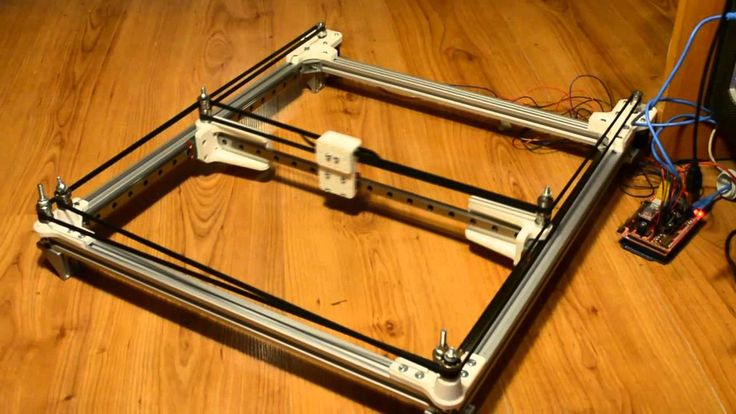

Best DIY Conveyor Belt 3D Printer

GitHubThingiverse

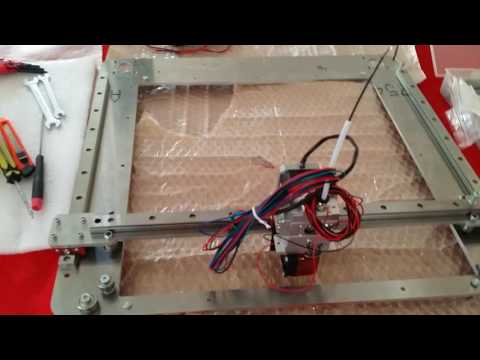

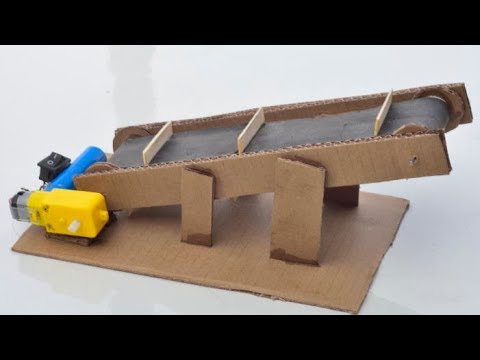

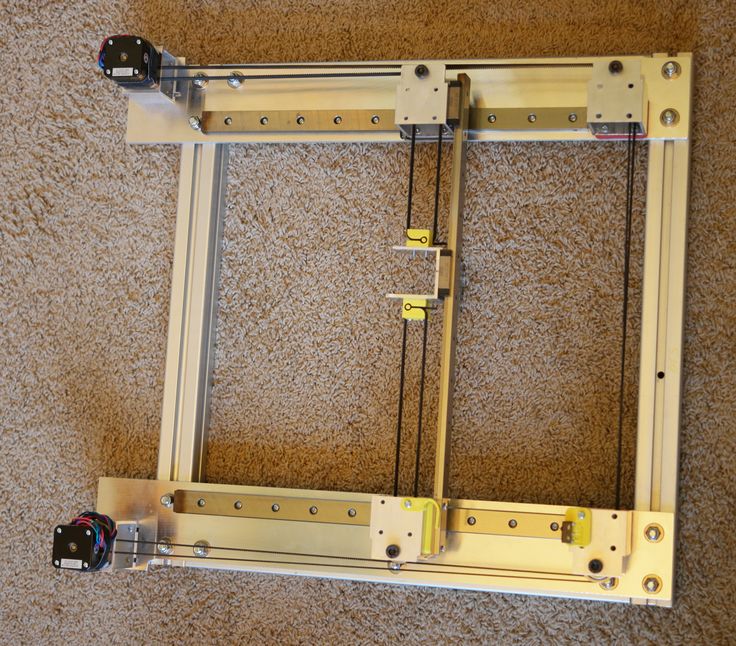

If you’re looking for a DIY belt 3D printer, the White Knight Belt 3D Printer is certainly worth looking at. Built by NAK 3D Designs, it is an entirely open-source conveyor belt 3D printer. It uses premium components but costs considerably less than its ready-to-buy counterparts.

The White Knight has a 400 mm x 430 mm print area with its CoreXY structure. It is designed to use a Duet WiFi 3D printer controller board along with an all-metal hot end. The Bondtech Extruder and the BuildTak printing surface are additional aids in delivering excellent 3D printing quality.

You can find all the files and instructions to build the 3D printer on its GitHub page. It is definitely not for beginners, and it will be helpful to have prior knowledge about assembling a 3D printer. Yet, the White Knight is a testament to the open-source and 3D printing community and is a great addition to your 3D printing setup if you’re up for building it.

Standout Features

- Large build area

- Duet WiFi motherboard

- BuildTak print surface

Technical Details | |

|---|---|

| Build volume | 400 x 430 x ∞ mm |

| Inclination angle | 45° |

| Max hot end temperature | 450 °C |

| Overall dimensions | N/A |

| Weight | N/A |

What We Like

- Excellent features

- Open-source design

- Customizable to your specifications

Could Be Better

- Long Bowden tube may lead to issues

- Needs considerable 3D printing expertise

Key Factors When Buying a Belt 3D Printer

Slicer support

Conveyor belt 3D printers have a unique design. Their inclined printing angle makes traditional slicer software setups unusable for slicing models. As these printers are relatively new, slicing support for belt 3D printers is very limited in popular slicers.

Their inclined printing angle makes traditional slicer software setups unusable for slicing models. As these printers are relatively new, slicing support for belt 3D printers is very limited in popular slicers.

When choosing a conveyor belt 3D printer, you need to consider its slicer compatibility. It is a crucial aspect of all the belt printers and will dictate your software experience with the printer. You need to ensure that you have alternative slicer options available if one of them doesn’t work out for you.

The Blackbelt 3D printer comes with its Blackbelt slicer based on an older version of Cura. The Creality CR-30 works on the Creality Belt slicer, another old version of the Cura Slicer. But it has extensive support and profiles available with the Ideamaker Slicer software.

Build quality

Build quality is often neglected in budget 3D printers. However, in the case of belt 3D printers, solid build quality is absolutely essential. A stable structure will help provide good support to the prints and is helpful in long-duration 3D prints.

Belt 3D printers have an inclined printing angle, and even a slightly wobbly structure can lead to disastrous results. In the best-case scenario, only print quality is affected. In the worst-case scenario, a large print can come loose and ruin hours of work.

A sturdy frame will help avoid these issues. A triangular frame typically creates the best support structure for the 3D printer.

The Creality CR-30 and the BlackBelt 3D printer come out on top in terms of build quality. The White Knight belt 3D printer, too, has some high-end components and an all-metal frame to keep up with the extended demands of long 3D printing objects.

Filament sensor

The filament sensor is an integral part of any belt 3D printer. Its function is to inform you about your filament feed to the printer. If your filament spool empties or the filament breaks in the middle of a 3D print, the sensor will notify the printer and stop the printing process.

This can save your current model from failing due to a lack of filament. You can quickly load up a new filament spool and resume printing your model. Considering a belt printer’s objective of printing long-duration prints, a filament sensor becomes almost a necessity to avoid any print failures.

You can quickly load up a new filament spool and resume printing your model. Considering a belt printer’s objective of printing long-duration prints, a filament sensor becomes almost a necessity to avoid any print failures.

Almost all the 3D printers mentioned in the list have a smart sensor for filament embedded in their hardware. Even if the conveyor belt 3D printer you are looking at does not have a filament sensor, it is typically fairly easy to add one.

Belt surface

Unlike typical FDM printers, which can use a glass bed, PEI-coated spring steel, BuildTak surfaces, and more, belt 3D printers come with limited build platform options. There simply aren’t many options available to swap out the belt with. This is why choosing a belt 3D printer with a high-quality belt surface is vital.

You’ll find the Creality CR-30 and the SainSmart INFI-20 have Nylon as their belt surface material. The Nylon belt material is used for long-term durability and offers excellent print adhesion. It also helps to keep the overall cost of the 3D printer down.

It also helps to keep the overall cost of the 3D printer down.

The top-end BlackBelt 3D printer comes with a special infinite Z belt made up of carbon fiber composite. It has a low coefficient of friction and high stiffness. This reduces expansion during the heating process and ensures maximum print adhesion. Additionally, the material adds to the aesthetic of the 3D printer and gives it a premium feel.

While carbon fiber will give you the best printing performance, you need to consider the cost aspect of the belt too. In that aspect, a Nylon surface delivers the best balance between cost and bed adhesion.

Filament Support

It is important that the belt 3D printer you buy can print with all filament materials you need it to. The type of 3D printer extruder you need and the belt surface you choose will heavily depend on the kind of filaments you want to use.

The most popular 3D printing filament is PLA. It is easy to print with and does not require a heated bed. As a result, it is ideal for belt 3D printers that don’t have a heated belt.

As a result, it is ideal for belt 3D printers that don’t have a heated belt.

You can use other materials like ABS, PETG, and TPU as well. However, you will need a belt material and an extruder that can handle the higher temperatures required to print with these filaments.

The ability to print with different materials gives you a lot of freedom when it comes to choosing the right belt 3D printer for your needs. It is always better to have more options rather than be limited by the printer you choose.

Repairability

The belt 3D printer you choose should be easy to repair and maintain. This is important because, with extended use, things are bound to break down. When they do, you want to be able to quickly fix them. If you want to make money with your 3D printer, reducing downtime is key.

Frequently Asked Questions

Can 3D printing be automated?

Yes, 3D printing can be automated with a conveyor belt 3D printer. These can print objects continuously without the need for the user to manually remove 3D prints. This type of printer is perfect for mass production because it can print large quantities of objects quickly and efficiently.

This type of printer is perfect for mass production because it can print large quantities of objects quickly and efficiently.

Can you run a 3D printer continuously?

Yes, you can run a 3D printer continuously, but it will depend on the type of printer you have. If you have a belt 3D printer, then you should be able to run it continuously without any issues.

However, if you have a traditional 3D printer, then you will need to remove finished prints by hand.

Regardless of the type of 3D printer, it is important that it is properly designed and components don’t get too hot when used for longer periods of time. This helps prevent any potential issues with overheating or jamming.

Conclusion

Belt 3D printers are still relatively new to the 3D printing world. While they don’t provide the most extraordinary printing experience, their unique design opens up a new approach to printing long objects. Infinite length printing is an excellent solution for printing long swords, knives, and cosplay items.

Printing many smaller objects non-stop is also a great way of using belt 3D printers. Combined with large spools of filament, belt 3D printers can run for days unattended.

Within the limited available options, we found that the Creality CR-30 is the overall best belt 3D printer that you can buy right now. It has a rugged build quality and a compact form factor with a slightly modern design. Once you configure it correctly, you should have no issues printing the swords in your wishlist in a single piece.

The White Knight belt 3D printer is an excellent alternative. While you need to source the components and assemble them yourself, this belt 3D printer DIY project offers a lot of potential. If you are an experienced user, then the challenge of building and configuring this machine might be an excellent option for you.

What are your thoughts on the belt 3D printers? What would be the first object you’d 3D print if you were to use one? Let us know your thoughts in the comments below.

5 Best Belt 3D Printers In 2022

- Last Updated: October 19, 2022

- Jackson O'Connell

3D printers have come a long way from their beginnings. In fact, conveyor belt technology is a recent addition to the field of 3D printing. The first generation of conveyor belt printers only came out in 2017, so don’t worry if you’re not familiar with them!

What exactly are belt 3D printers? The main difference from regular 3D printers is that belt 3D printers have a belt embedded into the build platform creating an infinite Z-axis. Basically, you can print continuously, whether you’re printing multiple prints or one very long print (cosplay swords anyone?).

Things to consider before purchasing a belt 3D printer include print speed, build quality, the printer’s motherboard, the different electronic features, and the extruder.

We’ll go more into our favorite belt printers, exploring these various features. Keep reading to understand how the printer works and explore the versatile uses of belt printers.

SainSmart Infi-20

Get Discount Now

Check Latest Price

Creality CR-30: 3DPrintMill

Get Discount Now

Check Latest Price

Blackbelt 3D

Check Latest Price

Table of Contents

- Best Belt 3D Printers At A Glance

- 1. Creality CR-30: 3DPrintMill (Best Choice)

- 2. SainSmart Infi-20 (Best Value)

- 3. Blackbelt 3D (Premium Choice)

- 4. The White Knight (Best for DIY Enthusiasts)

- 5. iFactory3D One Pro

- What Is a Belt 3D Printer?

- How Does a Belt 3D Printer Work?

- Advantages and Disadvantages of a Belt 3D Printer

- Advantages

- Disadvantages

- Uses of a Belt 3D Printer

- Print Farm

- Cosplay (Long Prints)

- Regular Printer

- Conclusion

Best Belt 3D Printers At A Glance

1. Creality CR-30: 3DPrintMill (Best Choice)

Creality CR-30: 3DPrintMill (Best Choice)

2. SainSmart Infi-20 (Best Value)

3. Blackbelt 3D (Premium Choice)

4. The White Knight (Best for DIY Enthusiasts)

5. iFactory3D One Pro

3D Printer Type: FDM | Materials: PLA, PLA+, TPU & PETG | Build Volume: 200 x 170 x ∞ mm

First up we have the Creality CR-30, also known as the 3DPrintMill. This belt 3D printer is one of the most well-known belt 3D printers out there.

It can be a little tricky to get the printer working, but once you get over the initial learning curve, the printer is amazing. It’s packed with numerous features. From a 32-bit motherboard to a filament runout sensor and an all-metal dual drive extruder, Creality makes sure that the CR-30 is one of a kind.

The 3DPrintMill also holds features like a full-size SD card slot and a fast heating hot end. The printer’s solid frame is large enough for you to print relatively wider prints. The printer also comes mostly assembled and ready to print, making your job easier.

The printer’s solid frame is large enough for you to print relatively wider prints. The printer also comes mostly assembled and ready to print, making your job easier.

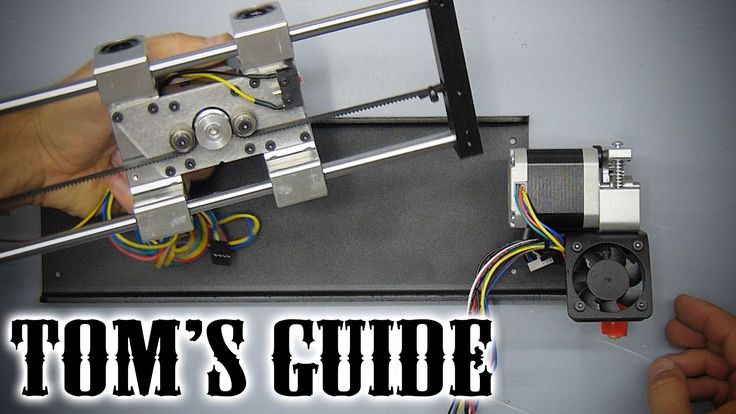

The Stable Core-XY structure ensures that you have a great printing experience. This motion system allows for faster motion and greater accuracy. Because the CoreXY system moves the X and Y plane together, overall mass is reduced, increasing the print speed of the printer.

The Creality CR-30 stands out for its low price point among other belt printers. Even with its lower price, the printer is known for its great build quality, sturdiness, and overall strength. The printer is also compatible with many materials, including PLA, PETG, and TPU.

Overall, the capabilities of CR-30 are well worth the investment. If you don’t mind spending time making the machine work for you and getting the best results, this printer is perfect for you. You will be able to play around with it, making adjustments to the hardware as you like!

- Super stable Core-XY structure

- Relatively affordable

- Stable frame

- All-metal extruder

- Filament runout sensor

- Durable nylon belt

- Takes time to get it working

- User Interface feels outdated (chunky)

Get Discount (Official Store)

Check Latest Price

2. SainSmart Infi-20 (Best Value)

SainSmart Infi-20 (Best Value) 3D Printer Type: FDM | Materials: PLA & PETG | Build Volume: 200 x 180 x ∞ mm

The Sainsmart Infi-20 is similar to the Creality 3DPrintMill as Sainsmart is actually partnered with Creallity. While this belt 3D printer is slightly bulkier than other printers, it’s extremely affordable and a great option.

The user interface on this printer is really nice and has a modern look to it. It comes with a straightforward interface that allows you to keep track of the printer’s status easily. The SainSmart Slicer software that comes with this printer gives you a boost in your infinite 3D printing journey.

The Infi-20 is also really easy to set up. Even though the printer isn’t fully assembled, the simple design of the printer on top of the built-in layers provides an easy start for you with the belt printer.

Another feature of this printer includes the stable CoreXY structure. This feature ensures great print adhesion and smooth print quality. With this belt 3D printer, you print a model that is as long as you want or as many times as you want. Your only true limit is how much filament you have.

This feature ensures great print adhesion and smooth print quality. With this belt 3D printer, you print a model that is as long as you want or as many times as you want. Your only true limit is how much filament you have.

- Large print area

- Modern user interface

- Filament runout sensor

- Stable frame

- Affordable

- Bulky design

- Not a very visually-appealing look

Get Discount (Official Store)

Check Latest Price

3. Blackbelt 3D (Premium Choice)

Blackbelt 3D (Premium Choice) 3D Printer Type: FDM | Materials: ABS, PLA, TPU, Co-Polyester & PETG | Build Volume: 340 x 340 x ∞ mm

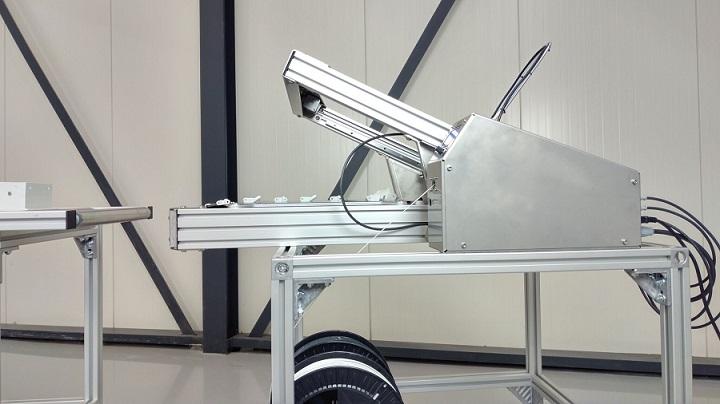

Although a bit pricier in comparison to other belt 3D printers, the Blackbelt 3D is extremely versatile. This printer provides customers with three versions of the conveyor belt: a desktop version, a frame version, and a frame version with a roller table.

The Blackbelt 3D is also not compromised to a single degree. Its E3D V6 hot end can print at an angle of 15°, 25°, 35°, or 45° on the heated conveyor belt. The printer supports various filaments, including PLA, PETG, ABS, TPU, and XT, among many others.

The printer also comes assembled and mostly ready. There are some accessories and features that are sold separately, such as the Blackbelt Server and the Filament Runout Sensor. Still, the printer boasts many other features.

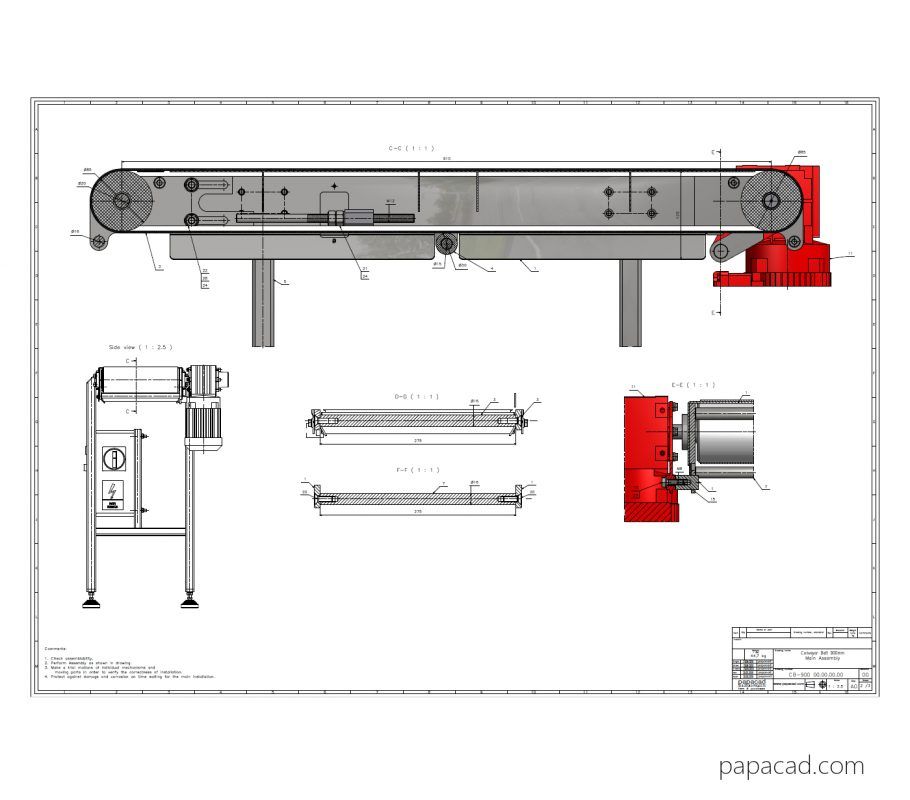

The Blackbelt has a large XY build area which allows for larger-sized prints. For 3D prints 1300mm or longer, it’s recommended to use a roller table to provide additional support during the 3D printing process. Additionally, this belt 3D printer is able to print overhangs without using any support material.

For 3D prints 1300mm or longer, it’s recommended to use a roller table to provide additional support during the 3D printing process. Additionally, this belt 3D printer is able to print overhangs without using any support material.

The motherboard and power supply unit are located together in a separate box, saving space and making the machine frame larger. The printer also comes with many fans and linear rails to create a smooth printhead motion for large prints.

With so many features, the Blackbelt proves to be an exceptionally high-quality machine. But, it’s not cheap. Considering the price, the machine is great for the industry and business environment. If you are looking for a belt 3D printer for hobbyist reasons, the Blackbelt may not be the best option for you.

- Large build volume

- Adjustable print angles

- Super reliable

- High-quality prints

- Well-developed and looks great

- Pricey

- Bulky/Heavy

- Outdated User Interface

Check Latest Price

4. The White Knight (Best for DIY Enthusiasts)

The White Knight (Best for DIY Enthusiasts) 3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 400 x 430 x ∞ mm

The White Knight is different from the printers we’ve touched on so far. This 3D belt printer is an open-source DIY project in which you can build the printer yourself!

The quality is not as great as a Creality or a Blackbelt 3D belt printer, but there’s no doubt regarding the exciting challenge the White Knight comes with. Considering you can build the printer yourself, the printer consists of many 3D printed parts and hardware pieces which reduces the overall costs. Still, you will have a large but sturdy frame.

As a DIY 3D belt printer, the White Knight is an open-source design, downloadable at no charge from Thingiverse. The community surrounding the White Knight is a huge part of this printer’s success. There’s a large community behind this project that can assist you through the build process.

Even though you can probably add any feature you would like to the White Knight, the printer holds many features by itself. There are linear rails for smooth printhead motion, a high-temperature hot end, and an extruder for consistent filament flow.

Still, there are some things to watch out for. The White Knight is known to be difficult to level the bed, which is definitely not ideal for many users. The bed also isn’t heated, meaning you’ll probably only be able to print PLA filament.

- Huge build volume (bigger than Blackbelt)

- Allows for customization

- Customizable with features

- Very helpful community

- No heated bed

- Can be tricky getting the printer assembled

iFactory3D One Pro

iFactory3D One Pro 3D Printer Type: FFF | Materials: PLA, PETG, TPU, With Additional Enclosure: PC, ASA, Nylon & ABS | Build Volume: 290 x 180 x ∞ mm

Finally, we have the iFactory3D One Pro. This 3D belt printer is the upgraded version of the original iFactory One. The printer is loaded with numerous features and is priced great for all that it comes with.

While it isn’t a DIY printer like the White Knight, the iFactory3D does require a good bit of assembly to get it running. This belt 3D printer is known for its variety of unique features.

The printer comes with an onboard camera that monitors your prints and makes sure everything is running smoothly. There’s even an AI-enabled failure detection software built into this system to prevent mistakes.

Other features include the dual-gears, direct extrusion E3D Hemera print head, and a high-temperature heated bed. The printhead provides reliable and precise extrusion. The printer also has linear rails, a Duet 3D motherboard, a touchscreen LCD, and a Wi-Fi-enabled Raspberry Pi4.

The printer also has linear rails, a Duet 3D motherboard, a touchscreen LCD, and a Wi-Fi-enabled Raspberry Pi4.

- Large build area

- AI failure detection software

- Linear rails

- E3D Hemera direct drive hot end

- Built-in Raspberry Pi 4 (OctoPrint)

- Easy-to-use LCD

- More assembly required

- Does not look as well constructed as printers by larger companies

Check Latest Price

What Is a Belt 3D Printer?

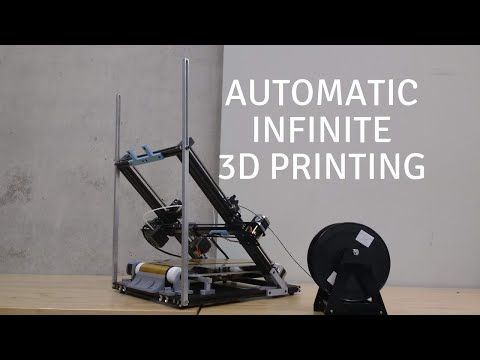

Source: Youtube Aurora TechTo recap, a belt 3D printer is a 3D printer with unique features allowing it to print continuously or in a series (part-after-part production). There are many advantages to this type of technology.

There are many advantages to this type of technology.

Automatic 3D print removal allows for the 3D printer to immediately start the next job, increasing overall productivity. Infinite 3D printing allows belt 3D printers to print objects beyond what fits on the printer’s build platform. This type of printer can print an infinitely long object in the Z direction.

As an FDM/FFF 3D printer, a belt 3D printer can print at an overhand up to about 45°. Depending on what is being printed, a conveyor belt 3D printer can minimize the overall support material needed making impossible overhangs possible.

How Does a Belt 3D Printer Work?

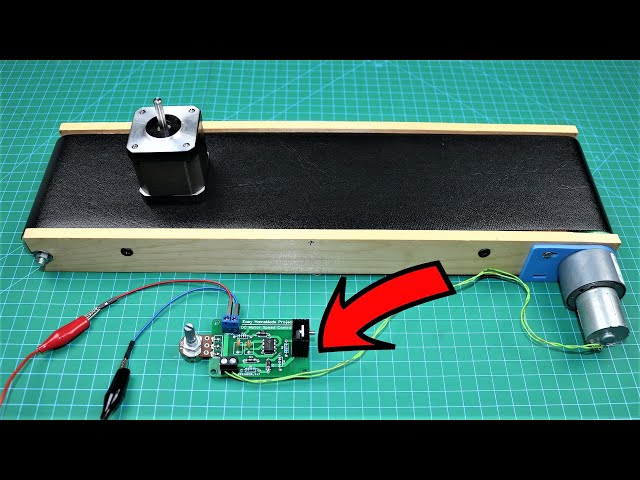

Source: Youtube Teaching TechAs mentioned before, belt 3D printers have a belt embedded in their build platform. But the belt alone doesn’t make infinite Z-axis printing possible. That goes to the 45-degree printing angle of belt printers, which enables infinite printing along one axis.

Conveyor belt 3D printers used FDM technology (Fused Deposition Modeling). Materials are fused together and layered on top of each other to create an object.

Materials are fused together and layered on top of each other to create an object.

While printing, the belt pulls prints away from the nozzle. Prints do eventually fall off the belt, but this could be avoided easily by having a support structure. Support structures can be anything from a table to a set of rollers in front of the bed that meet the printer’s height.

Touching on bed adhesion, as of right now, you can’t have a fully heated conveyor belt bed, but painter’s tape does the job.

For a belt 3D printer to function appropriately, the x and y axes are rotated at an angle instead of being parallel to the build plate. The z-axis conversely is replaced with a conveyor belt. The conveyor belt allows prints to not be limited by the size of the build platforms, unlike regular 3D printers.

Advantages and Disadvantages of a Belt 3D Printer

Source: Youtube The 3D Print GeneralBelt 3D printers hold numerous advantages over other 3D printers, but there are also some disadvantages to consider.

Advantages

Considering that belt 3D printers can be used for continuous printing, these printers are great for automated or even semi-automated production. They make mass-production and printing really large models simple.

Even with the belt printer’s large print volume capacity, there is no loss in average speed. Additionally, print removal is automatic and hassle-free. It’s also possible to have a partially heated bed with these printers.

Considering these features, belt 3D printers are great for professionals working in the business industry as it is suited great for large, expensive projects. It’s also a great option for hobbyists.

Disadvantages

There are some limitations to keep in mind if you are considering buying a belt 3D printer. Belt 3D printers are relatively more expensive than other 3D printers. Belt 3D printers can also require additional support structures, which adds to the overall costs.

On top of costs, belt 3D printers can’t print certain types of materials depending on the printer. You also can’t use a glass print bed. The print speeds are noticeably slower compared to other 3D printers.

You also can’t use a glass print bed. The print speeds are noticeably slower compared to other 3D printers.

Another factor to consider is that belt printers can take up a lot of space. Especially since you may need additional structures to support prints that are longer than the print bed. Additionally, belt 3D printers are still in development (new tech) and may result in lower print quality.

Uses of a Belt 3D Printer

Source: Youtube 3D Printing NerdBelt 3D printers are extremely versatile when it comes to their uses. Keep reading to find out the different ways you can use your own belt 3D printer.

Print Farm

Print farms are groups of 3D printers that run together continuously to increase overall production rates.

Given the endless Z-axis, which allows for mass production and the printing of very large parts, it’s clear to see that a print farm made completely out of belt 3D printers is a game changer.

Unlike a print farm with regular 3D printers, a print farm with belt 3D printers completely addresses the single-volume problem that comes with 3D printing, as belt 3D printers can print multiple prints continuously.

Cosplay (Long Prints)

Belt 3D printers also work for cosplay purposes. With a belt printer, you can create any 3D printed prop you want.

By printing your own cosplay props, there’s no doubt that you will enjoy faster printing times, better quality products, and the flexibility to make it your own!

There is no limit to what you can make with a belt 3D printer.

Regular Printer

At the end of the day, a belt 3D printer can still do everything a regular 3D printer can do. You can print regular-sized models. Think of a belt 3D printer as a 2-in-1! You’re not limited to the dimensions of a standard 3D printer.

Conclusion

It’s no doubt that belt printers offer some super incredible benefits, like infinite printing capabilities and part-after-part production. But what belt printer to get is the question?

My personal favorite and #1 rec is the Creality 3DPrintMill, AKA the CR-30. This printer has a large following, with many optional upgrades available. Additionally, the machine is loaded with many cool features, like a durable nylon belt, sturdy frame design, filament runout sensor, and all-metal extruder; this makes the print quality spectacular.

Additionally, the machine is loaded with many cool features, like a durable nylon belt, sturdy frame design, filament runout sensor, and all-metal extruder; this makes the print quality spectacular.

And, if you want an even more professional belt printer, then definitely check out either the iFactory3D One Pro or the Blackbelt 3D. The One Pro is loaded with many advanced consumer features, like linear rails for smooth motion, an E3D Hemera direct drive hot end, and even a built-in Raspberry Pi 4 for OctoPrint control. And the Blackbelt 3D, while very expensive, is super reliable due to its frame design and many sensors.

If you’re shopping on a budget, though, and are trying to get the most bang for your buck, then I’d point to the Sainsmart Infi-20 as it’s reasonably priced and has a few cool features like a filament sensor and sturdy frame.

Lastly, if you’d rather DIY your printer, then check out The White Knight. While this printer is definitely a pretty complicated build, it gives you the opportunity to fully customize the features on your printer. Plus, many of the parts are common hardware that can be picked up at your local hardware store.

Plus, many of the parts are common hardware that can be picked up at your local hardware store.

News

Subscribe to

Subscribe

Z. The desktop additive system can be used for both oversized 3D printing and small-scale additive manufacturing.

This 3D printer has already been featured in several reviews under the designation CR-30. In the additive community, the idea of conveyor 3D printers has been floating around for a long time, at least twelve years, but commercial versions have only recently begun to appear: Blackbelt in 2017, Powerbelt Zero in 2019, from the open source versions, the White Knight project can be mentioned. Another promising option called Printrbelt was never brought to market due to the untimely demise of Printrbot.

It was only a matter of time before an analogue appeared in the assortment of leading Chinese manufacturers of 3D printers, and already on November 18, everyone will be able to apply for Creality's system, called 3DPrintMill. The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538. nine0003

The development of our own version of a conveyor 3D printer was promoted by Naomi Wu (a.k.a. SexyCyborg), a DIYer familiar to our community members, who has been collaborating with Creality for a long time. Perhaps the main factor was the cost: the price range among the above offers is wide, reaching up to €12,500, and Creality offers a very affordable option: early Kickstarter campaign participants can place orders for as low as $538. nine0003

As you can see in the illustrations, the distinguishing features of these 3D printers are the guides mounted at an angle of 45 ° to the surface along the X and Y axes, as well as the conveyor belt. You can get confused with the coordinate system, but imagine that a slightly skewed 3D printer is lying on its back - then the CoreXY kinematics are mounted on the portal with the appropriate coordinates, and the belt moves along the Z axis. The tilt of the portal, coupled with the translational movement of the belt, provides the ability to build parts in height without the need to rollback the entire model. In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window. nine0003

In other words, this scheme allows you to print parts of theoretically unlimited length - just remember to attach the roller table and open the window. nine0003

Alternatively, this 3D printer can be used for in-line production, printing one part after another and allowing the models to separate themselves from the tape at the end and fall into a container. From an economic point of view, serial 3D printing will be justified as long as we are talking about relatively small batches of products, measured in hundreds or thousands of pieces.

Polylactide, PET-G, and TPU are listed as consumables, but there is a heated platform in the work area under the belt. The wear-resistant conveyor belt is made on a nylon base, apparently with the addition of carbon fibers. The system is calibrated at the factory, equipped with quiet drivers, a massive airflow with three fans is installed on the head. Additional features include a filament sensor, save and resume function, plus a card capture reader for offline operation. Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt. nine0003

Frame made of aluminum profiles with V-shaped rollers and guides reinforced with corners. Given the unusual coordinate system, the preparation of machine code requires special software - for this purpose, the company offers a specialized slicer CrealityBelt. nine0003

Specifications of 3DPrintMill 3D Printer (CR-30):

- Print technology: FDM

- Number of extruders: 1

- Construction area size: 200x170x∞ mm

- Printing accuracy: ±0.1 mm

- Nozzle diameter: 0.4 mm

- Layer thickness: 0.1-0.4 mm

- Hot end temperature: ≤240°C

- Heating temperature: ≤100°C

- Power consumption: 350W nine0042

- Power supply: AC 100-120V / 200-240V, DC 24V

- Consumables: PLA, PET-G, TPU

- Filament diameter: 1.75 mm

- Interface language: English

- Data transfer: USB, SD card

- Software: CrealityBelt Slicer

- Dimensions: 535x656x410 mm

- Weight: 16.

5 kg (net), 20.5 kg (gross)

5 kg (net), 20.5 kg (gross)

The start of accepting orders is scheduled for November 18, 19:00 Moscow time.

You can subscribe to the notification about the start of the campaign here.

FFF fdm CREALITY 3DPrintMill CR-30 conveyor

Follow author

Subscribe

Don't want

11

3D printer running like a pipeline with the new Blackbelt 3D device

Continuous 3D printer operation

is still beyond a lot of things, but 3D printing is still capable of much beyond its functionality. Although the operation of a 3D printer seriously affects the production process in enterprises, it is not yet able to completely replace industrial methods. However, everything can change thanks to the unique development of the Dutch startup Blackbelt 3D, which has transformed the very idea of a 3D printer. nine0003

Although the operation of a 3D printer seriously affects the production process in enterprises, it is not yet able to completely replace industrial methods. However, everything can change thanks to the unique development of the Dutch startup Blackbelt 3D, which has transformed the very idea of a 3D printer. nine0003

The idea is to create a conveyor device for 3D printing, one of the possibilities of which will be the production of products of unlimited length. In theory, of course. On top of that, this device can print at an angle of up to 45 degrees, which will avoid the need for building supports. The operation of a 3D printer of this design could completely transform traditional FDM 3D printing. Now more

What is special about the technique

This is a unique type of industrial equipment of a new category, which is able to produce extremely long parts, as well as carry out assembly line production. A separate advantage is the ability to produce parts without building supporting structures. This effect is achieved due to the unique design of the device. The operation of a 3D printer is based on the principle of FDM 3D printing with some differences. nine0003

This effect is achieved due to the unique design of the device. The operation of a 3D printer is based on the principle of FDM 3D printing with some differences. nine0003

The playback process is carried out on a moving conveyor belt that functions as the Z axis. With each new layer, it moves horizontally. At the same time, the layers are superimposed at a certain angle, which can be adjusted in the device settings. The default angle is 45˚, you can choose the angle of 15˚, 25˚ and 34˚. The material used is a plastic thread with a diameter of 1.75 mm.

Advantages

The main advantages include the modular design of the device, due to which it is possible to adapt the 3D printer to your own needs. That is, if necessary, the operation of a 3D printer can be carried out both in industrial and at home conditions. The device is available in two versions: desktop and standalone. The conveyor belt is made of high-quality carbon composite and provides reliable adhesion and 3D printing accuracy. nine0003

nine0003

In addition, the device is equipped with three print heads with interchangeable nozzles with a diameter of 0.4 mm, 0.6 mm and 0.8 mm. It is planned to expand this list in the future. And, of course, the ability to produce components of unlimited length is extremely interesting. In practice, however, for parts longer than 1300 mm, the developers recommend providing additional support using a roller table.

Operation of a 3D printer in mass production

We are sure that the news about such an unusual device has excited everyone interested in mass production. Indeed, the work of a 3D printer as a conveyor in both industrial and desktop versions will be incredibly useful for this area. After all, the device is able to continuously produce products one after another. And due to the conveyor belt, you do not need to manually separate them. Just place the container in front of the printer and they will fall into it when printing is finished. nine0003

And, of course, the design of a 3D printer provides for the creation of elements of complex geometry, inaccessible with traditional 3D printing.