Composite 3d printers

3D Printing Carbon Fiber and Other Composites

Composite materials, on the other hand, are parts made up of more than one material that, when combined, have properties different from their original materials. Materials like concrete and particleboard can be considered composites, because they are mixtures of a variety of materials. However, when we talk about composites from an engineering standpoint, we usually refer to composites with reinforcing fibers. Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti - thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves - they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Fiberglass strands being laid down in a mold and cured with a thermoset resin.

Carbon fiber has one of the highest strength-to-weight ratios out there, making it very valuable for creating lightweight, strong parts. The fibers themselves are made up of carbon atoms whose crystal structure is aligned into strands, making the strands incredibly strong in tension. Traditionally, thermoset resins are used as the bonding agent to set these fibers into a designated shape, cured around a matrix material like foam. So you can create a sandwich panel by “sandwiching” the foam between to sheets of fiber weave, and curing it all with resin. In the context of 3D printing, the fiber can take two different forms:

Chopped Fibers are short-length fibers chopped into segments less than a millimeter in length and mixed into traditional thermoplastics to form what is called a filled plastic. These can be printed with an FDM printing process.

Continuous Fibers require a slightly different 3D printing method, in which continuous fiber strands are coated in a curing agent and laid down into a thermoplastic matrix extruded via a secondary print nozzle. This process is called Continuous Fiber Fabrication (CFF).

This process is called Continuous Fiber Fabrication (CFF).

Two forms of 3D printed carbon fiber: on the top is a chopped fiber 3D printing filament, and below is a continuous strand of carbon fiber.

Either way you add fiber, the addition of the fibers boosts part strength and other material properties, but the amount it helps differs depending on the way that fiber is used, and what fiber it is. Generally speaking, a continuous carbon fiber 3D print is stronger than chopped carbon fiber 3D because the continuity distributes any applied loads.

Chopped Fiber 3D Printing Materials

Chopped fiber filled plastics are the most common type of composite 3D printed plastics. The most widely used chopped composite 3D printing material is chopped carbon fiber - where carbon fiber pieces are mixed with traditional 3D printing plastics like nylon, ABS, or PLA. Adding this “filling” to thermoplastics is a material booster pack. The fibers take on some of the stresses of the part, like how concrete is added to cement to boost its strength. The fibers handle some of the applied stresses on the part, boosting the properties of typically lower-grade materials. The addition of carbon fiber also improves the thermal stability of mechanical properties, which widens the range of operating temperatures and improves predictability of material behavior in both high and low temperatures.

The fibers handle some of the applied stresses on the part, boosting the properties of typically lower-grade materials. The addition of carbon fiber also improves the thermal stability of mechanical properties, which widens the range of operating temperatures and improves predictability of material behavior in both high and low temperatures.

A close-up of chopped carbon fibers used in 3D printing, taken on an SEM.

These fibers are chopped up into fine pieces and mixed into the plastic before it gets extruded into a spool for use with material deposition-based 3D printers. In this case, the 3D printing process remains the same, because the fibers are just suspended in the thermoplastic - so it gets heated, extruded, and cooled into the part just like any other FFF style 3D printed. Chopped composite 3D printing materials take normal plastic that may be lacking in certain properties and boost it. In the case of carbon fiber, the fibers boost the strength, stiffness, and dimensional stability of the part to make it higher-performing than its base plastic.

Chopped carbon fiber 3D printing materials can be used like normal 3D printing plastics, boosting some material properties.

The quantity of fibers and the length of chopped segments impacts the strength and quality of the part. Different vendors blend different amounts of fiber into their plastic, yielding materials with different strengths. Below a certain threshold, and the fibers boost surface finish, print quality. Above that threshold, mixing in a large quantity of longer fibers, and you get a stronger material, but you sacrifice surface finish and part accuracy because there is a smaller percentage of plastic in the material overall. The thermoplastic is essential to the mixture because it makes the printing process work well, so your parts can only get so strong.

Continuous Fiber 3D Printing

Continuous fiber 3D printing adds continuous strands of fiber reinforcement to the part (think back to fiber strands), to achieve metal-strength properties at a fraction of the weight. Using two print nozzles, the printer builds the matrix material out of a thermoplastic, and irons down continuous strands of continuous fibers into the part. This process is called Continuous Fiber Fabrication (CFF).

Using two print nozzles, the printer builds the matrix material out of a thermoplastic, and irons down continuous strands of continuous fibers into the part. This process is called Continuous Fiber Fabrication (CFF).

Continuous Kevlar strands are ironed into this part to increase its impact resistance with a composite fiber printing nozzle. A thermoplastic matrix material forms the skin and core of the part.

The power of CFF comes from the continuity of the strands. Unlike chopped fibers, continuous strands can absorb and distribute loads across their entire length. When placed within a thermoplastic matrix, the part can handle higher loads and absorb larger impacts. This allows these parts to achieve the strength of metal at a fraction of the weight.

Continuous fibers form the backbone of a 3D printed part, because the loads distribute along their length, rather than into the plastic.

The CFF 3D printing process consists of two steps per layer - first, a thermoplastic is extruded to form the infill and shells of the part - this serves as the “matrix” material of the composite. Next, the continuous fiber is ironed into that matrix, fusing with the thermoplastic by use of a compatible resin coating. This process repeats layer by layer, forming the fibers into the backbone of the 3D printed part, while the thermoplastic acts as a skin. This process is also similar to how rebar can be laid down inside concrete to reinforce it.

Next, the continuous fiber is ironed into that matrix, fusing with the thermoplastic by use of a compatible resin coating. This process repeats layer by layer, forming the fibers into the backbone of the 3D printed part, while the thermoplastic acts as a skin. This process is also similar to how rebar can be laid down inside concrete to reinforce it.

The fibers form the "backbone" of the part and can be laid down in specific patterns to optimize a part’s strength for its weight and material consumption. You can place fiber in specific areas based on how the part will experience load, putting the strength exactly where you need it. This is very different from standard deposition-based 3D printers, including with chopped fibers, because these methods have an even distribution of properties throughout the entire part. Different fiber reinforcement options can be used for different loading conditions and behaviors. You can learn more about the different reinforcement strategies in Fiber Reinforcement Strategies.

A variety of different fibers can be used for reinforcement as well, depending upon what material properties your part needs to have. Markforged 3D printers offer a few different fiber materials so that you can choose the strength behavior of the reinforcement:

Carbon Fiber is a stiff and strong fiber that behaves like 6061 Aluminum, so it can be used for lightweight components that support heavy loads.

This 3D printed carbon fiber can match the strength of aluminum when continuous. Both are supporting a 27.5 lb load.

Fiberglass is a sturdy, cost-effective reinforcing material with some compliance to it. It boosts part strength above that of plastics and is a good starting point for printing with reinforcement.

Fiberglass is a robust 3D printing fiber option, exceeding the strength of chopped fiber, ABS, and PLA when supporting a 7.5 lb weight.

Kevlar has high toughness and shock resistance, making it ideal for shock-loading and high-impact conditions. It bends instead of breaking.

It bends instead of breaking.

PLA, ABS, and Kevlar reinforced 3D printed parts getting shock-loaded with some big hammer hits!

High Strength High Temperature (HSHT) Fiberglass maintains its strength and stiffness at high temperatures because of its high heat-deflection temperature. Its heat resistance allows it to hold up in more extreme environments.

This test was performed after heating each beam to 300 degrees Fahrenheit in an oven. HSHT does not lose strength at high temperatures, so it still supports the 5 lb load.

So between selecting different fiber types for certain material needs, and controlling where the fiber can be placed layer by layer, you can control the behavior and performance of your parts. This is one of the primary advantages continuous 3D printed composites have over chopped fiber materials. Not only do you get stronger parts, but you also can produce parts optimized for their application.

Continuous Composites | Continuous Fiber 3D Printing

HomeTechnologyAboutNewsContact

HomeTechnology

Partners

Partners

Arkema / SartomerSiemens

NewsAboutCareersContact

A fundamental shift in composites manufacturing.

Explore CF3D®

Unlimited Possibilities

with CF3D®

CF3D® combines high-performing composite materials with rapid curing thermoset resins to create complex parts on demand. With the ability to print both structural and functional fibers, Continuous Composites presents a new future for additive manufacturing with composites.

See our latest partnerships with Arkema and Siemens

Continuous Fibers

Revealed

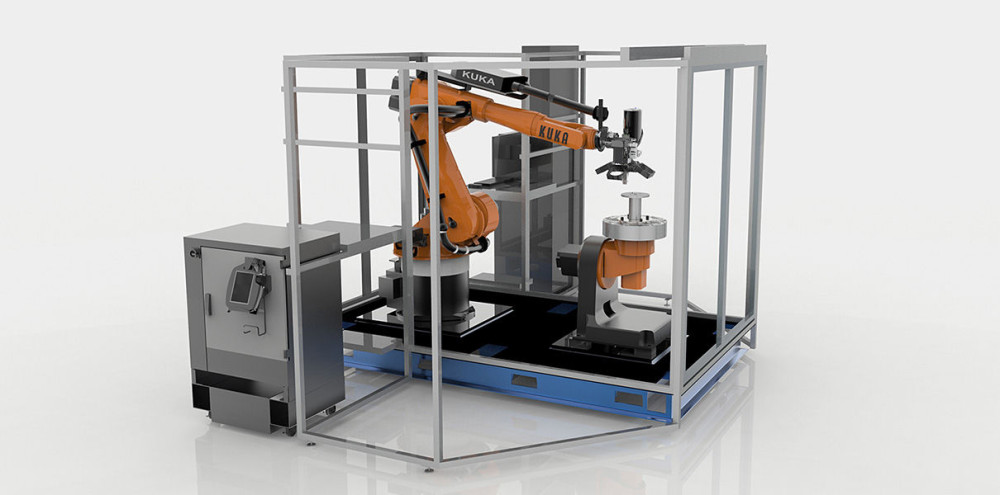

CF3D® is comprised of hardware, materials, software, and configurable motion platforms to harness the power of composites without the constraints of traditional manufacturing. Composites manufacturing is now affordable with limitless material combinations, net shape printing, and part optimization across all industries.

Interested in our tech?

Explore More

All The Benefits

None of The Constraints

As the additive manufacturing landscape continues to expand, CF3D® shifts the standard by making 3D printing a viable, end-part manufacturing solution. CF3D® is fully automated, scalable, efficient, and tailorable to the user’s applications.

CF3D® is fully automated, scalable, efficient, and tailorable to the user’s applications.

Freedom of Design

Prints fibers in all three dimensions with continuous anisotropic material, enabling complex geometries.

Low Cost

Fully automated, affordable raw materials, high material yield, and elimination of extensive labor resulting in lower manufacturing costs.

Scalable

Build volume of machines can be increased or decreased for part application.

Limitless Material Combinations

Tailorable fiber + library of resins to create endless material combinations specific to user’s application.

Learn more. View All Benefits

Hot Off The Press

Continuous Composites Selected by NASA for Additive Manufacturing of Low CTE Open Isogrid Composite Structure

This NASA award will demonstrate CF3D’s robotic steering of individual, continuous carbon fiber tows to print and test a flat 1.6- x 3.3-foot open isogrid rib structure, which will have a low CTE.

Read More

Continuous Composites Selected by NASA for Additive Manufacturing of Low CTE Open Isogrid Composite Structure

This NASA award will demonstrate CF3D’s robotic steering of individual, continuous carbon fiber tows to print and test a flat 1.6- x 3.3-foot open isogrid rib structure, which will have a low CTE.

Read More

Continuous Composites Closes $17m Series A Financing

Continuous Composites, a developer of composite 3D printing technology, has successfully closed a $17 million Series A financing round.

Read More

Continuous Composites Closes $17m Series A Financing

Continuous Composites, a developer of composite 3D printing technology, has successfully closed a $17 million Series A financing round.

Read More

Continuous Composites Files Patent Infringement Lawsuit Against Markforged

Continuous Composites files patent infringement lawsuit against Markforged asserting the infringement of four patents that include process and hardware claims, which are core to the underlying operation of Markforged’s flagship continuous fiber printers.

Read More

Continuous Composites Files Patent Infringement Lawsuit Against Markforged

Continuous Composites files patent infringement lawsuit against Markforged asserting the infringement of four patents that include process and hardware claims, which are core to the underlying operation of Markforged’s flagship continuous fiber printers.

Read More

Continuous Composites Selected by NASA for Additive Manufacturing of Low CTE Open Isogrid Composite Structure

This NASA award will demonstrate CF3D’s robotic steering of individual, continuous carbon fiber tows to print and test a flat 1.6- x 3.3-foot open isogrid rib structure, which will have a low CTE.

Read More

Continuous Composites and Siemens Energy Partner to 3D Print Generator Components

Continuous Composites, a developer of composite 3D printing technology, has 3D printed power generator components for energy technology firm Siemens Energy. Using Continuous Composites’ proprietary Continuous Fiber 3D Printing (CF3D) process, the partners were able to manufacture the generator parts with drastic cost and lead time reductions.

Read More

View More News

Companies We Work With

A New Way to

Create Awaits

Connect with our team to explore how CF3D® can accelerate your industry.

Reach our team. Inquire

3D printing with thermoplastic polymers: 12 domestic projects

Implementation stories

Rapid prototyping

Experts recommend

Author: Semyon Popadyuk

Author: Semyon Popadyuk

Thermoplastics and composites - what is it? | How are composites made? | Who are the main consumers of 3D printing resins? | What plastics are the most popular? | How is 3D printing with thermoplastics and composites applied? Examples of finished products

We are often asked the question: do they make high-quality, reliable and safe materials for 3D printing in Russia? Of course, there are such manufacturers, moreover, significant experience and know-how have been accumulated in this area. One of the pioneers in the domestic market for the production of plastics for the additive industry was REC. It is directly involved in the production of filaments, and its 3D Solutions division conducts R&D on the creation of composite materials.

It is directly involved in the production of filaments, and its 3D Solutions division conducts R&D on the creation of composite materials.

REC and 3D Solutions in facts and figures:

-

8 years of work with thermoplastics in the field of additive technologies;

-

22 different types of FFF filament material are mass-produced;

-

in 2020 and 2021, more than 130 different compositions based on thermoplastics were produced and tested;

-

own production equipment and laboratory complexes for the production and testing of thermoplastic compositions both in molding and in 3D printing;

-

the most recognizable brand in the field of FDM printing materials.

Dmitry Miller © youtube.com / JsonTV

Today, in our blog, REC and 3D Solutions Executive Director Dmitry Miller shares his experience in the development and application of thermoplastics and composite materials and talks about the most interesting FDM technology implementation projects.

Check if a 3D printer will solve your problems - order a free test 3D printing service from iQB Technologies!

Thermoplastics and composites - what is it?

A thermoplastic is a polymer that can become plastic when subjected to temperature. Based on thermoplastics, composites are produced - pure plastics in combination with other materials, for example, ABS with polycarbonate or reinforced with carbon fiber. There can be a huge number of such variations.

For eight years on the market, we have managed to work with most of the existing plastics, including ABS, ASA, SBS, SEBS, PA, PP, PSU, PPSU, PEEK, PC, TPU, TPEE, PET, PETG, PEI, PLA, PS, PTFE, PVA, PMMA, PBT. And this is not a complete list - some materials, such as PVC, could not be brought to an adequately usable state, because there are all sorts of difficulties with processing.

How are composites made?

We take the necessary polymer base and, depending on the task and the required properties of the material, we modify it with certain components. These include:

These include:

A wide range of fillers with different properties is also used. These are the most familiar carbon fibers, and fiberglass, and basalt fiber, and Kevlar fibers. To obtain certain properties, it is possible to fill the polymer with hollow glass spheres and carbon nanotubes.

We also have metal-filled polymers used in MIM (Metal Injection Molding) molding technology. It is more correct to call them metal-polymer compositions, since they contain more than 93% metal and at least 7% binder. A product is molded from such a composite material using casting or 3D printing, then the binder is chemically etched, the resulting model is baked in an oven, and finally we get an all-metal part.

In addition, compositions exhibiting ferromagnetic properties can be obtained. They are in demand in tasks related to radiography and radio electronics.

iQB Technologies experts recommend the article: Additive Manufacturing of Molding Tooling from Polymer and Composite Materials

Who are the main consumers of 3D printing resins?

Our main consumer is production, since additive methods create either the final product, or some part of it, or tooling for its production. A large number of orders is due to the regularity, systematic repetition and stability of the production process.

A large number of orders is due to the regularity, systematic repetition and stability of the production process.

Slightly more than a quarter of the volume of production is engineering companies that are engaged in 3D printing of prototypes for assembly testing, visual models and the like.

A large layer, accounting for 25%, is the sphere of education. Thanks to federal programs such as "Point of Growth", 3D printers are supplied to many educational institutions, and additive technologies are an educational subject. Teaching the basics of 3D printing makes a huge difference as it helps students change the way they think. When we use classical subtractive technologies - turning a blank or cutting it with a laser, cutting something out of a flat sheet - this is one way of thinking. Additive manufacturing removes many restrictions, thinking is completely different, and the next generation will think in technical terms much more freely.

The next segment is occupied by personal consumption, which can affect absolutely any area. These are people, as well as small businesses, using 3D printers for their own purposes, hobbies.

These are people, as well as small businesses, using 3D printers for their own purposes, hobbies.

And finally, medicine. So far, the amount of work we have in this area is small, but there are precedents for application. Polymers are used for the additive production of orthoses (devices for fixing limbs), prosthetics, and, together with educational institutions, for the manufacture of anatomical models for various medical needs.

What plastics are the most popular?

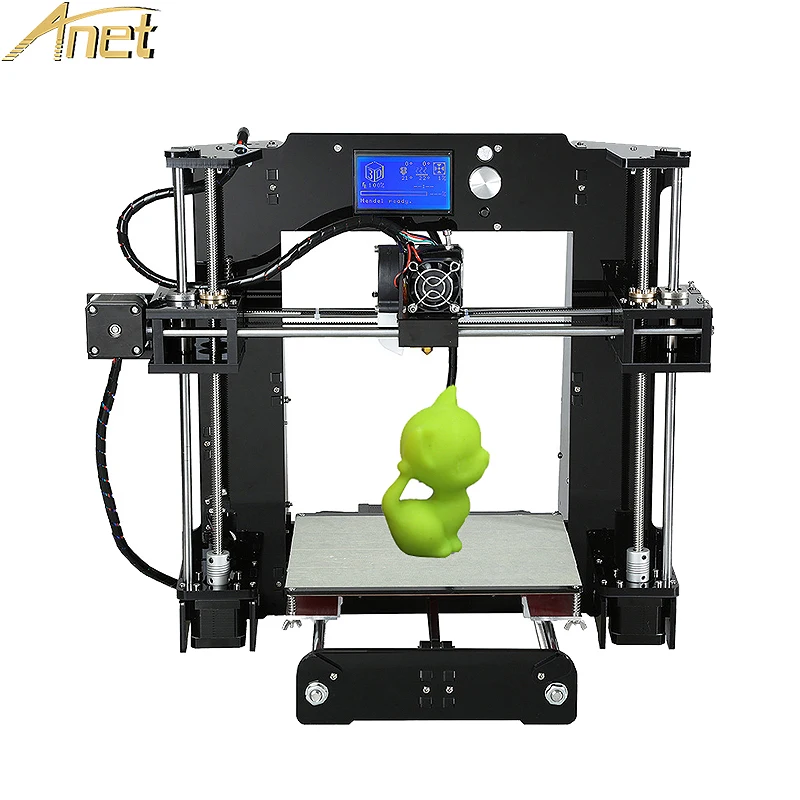

For clients of REC and 3D Solutions, PLA occupies the first place in terms of consumption. This is well deserved, as it is easier to print than any other plastic, and it is the least demanding on equipment. Any simplest personal 3D printer will work fine with this material, and there will be no difficulties.

The second place is approximately equally divided by ABS and PETG materials. They are used in functional prototyping, where PLA is far from always applicable due to its extremely low heat resistance: at 50 degrees it is already soft.

Next come various composite materials, and this segment is growing from year to year. In the next five years, they are likely to come out on top due to the ability to achieve any desired properties.

And a very small segment (4%) is made up of polyurethanes, ester elastomers - any flexible and elastic polymers. They are used by customers of all other materials, but for certain tasks that require elasticity and flexibility.

How is 3D printing with thermoplastics and composites applied? Examples of finished products

1. The prototype of an unmanned taxi and its components printed using FDM technology

Before you (Fig. 1) is a functional prototype of an unmanned taxi, containing a huge number of details. To make each of them by classical factory methods is quite difficult, expensive and time consuming. Thanks to 3D printing, the manufacturing company has optimized the process of creating many parts - reflectors for front optics, brackets, holders, decorative elements, etc. Models drawn on a computer were immediately printed and installed on the spot - so, as quickly and simply as possible, project of a fully functional working prototype vehicle.

Models drawn on a computer were immediately printed and installed on the spot - so, as quickly and simply as possible, project of a fully functional working prototype vehicle.

2. Grip for the robotic arm

An interesting example is when materials are combined for 3D printing. In the photo above, you can see the grip for the arm of the robotic arm. The claws themselves are printed from hard PETG plastic, while the inner pads are made from elastic material. It ensures that objects will not slip out of the manipulator's hand.

3. Model of the fuel system of the Angara rocket. Printed from ABS plastic, used to test the assembly of a complex device

Let's move on to complex systems. Figure 3 shows a real layout of the Angara space rocket power supply system, printed from ABS plastic, on which the assembly was checked. It was necessary to test whether the developed device with a large number of components can be assembled without damage.

4. Elements of LED lamps (medium runs)

Elements of LED lamps (medium runs)

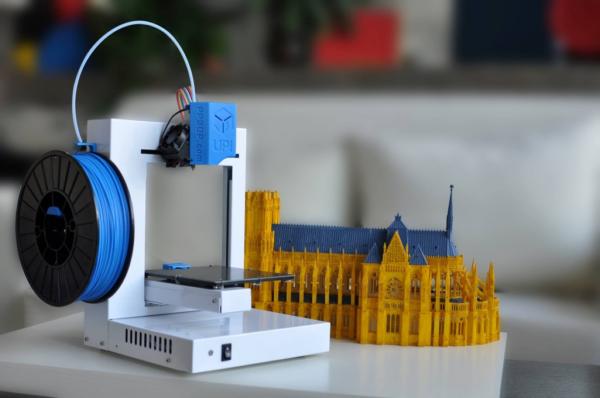

And here you see how it is possible to produce complete end products using 3D printing. The company is engaged in the manufacture of LED lamps in small series. Some models have plastic elements - plugs, light diffusers. All products are designer, original, it turns out to be more expensive to make a thousand pieces by casting into silicone, not to mention the classic casting of molds: in such a run, the mold will not pay off at all, the parts will turn out to be “golden”. In this case, 3D printing is an extremely profitable solution. Unlike casting in silicone, additive manufacturing allows more freedom in geometry and a batch can be produced very cheaply and quickly.

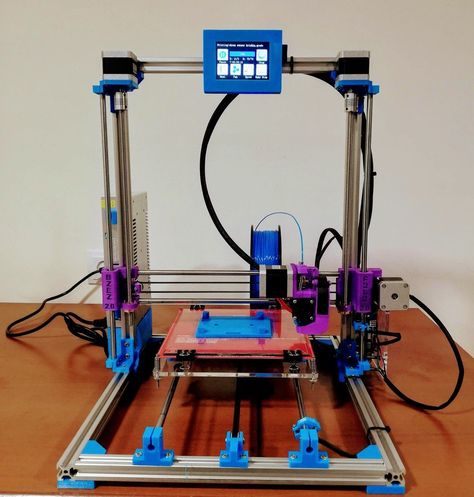

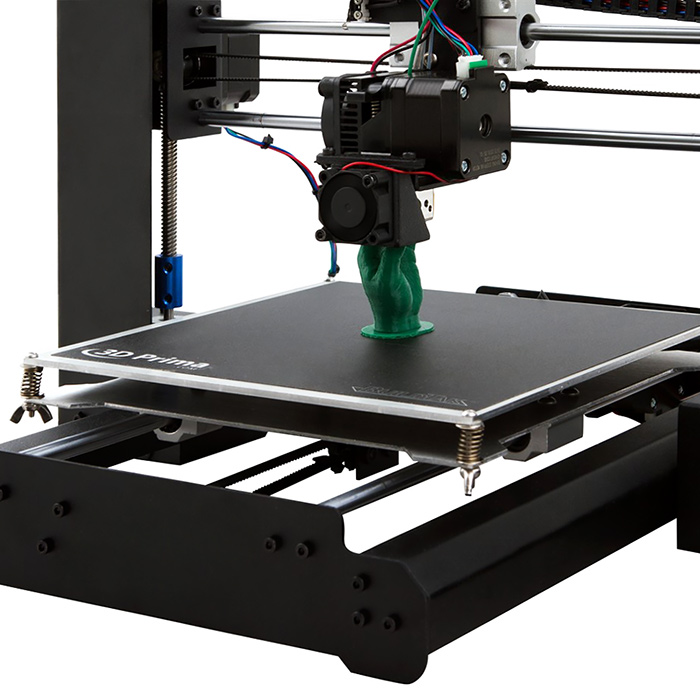

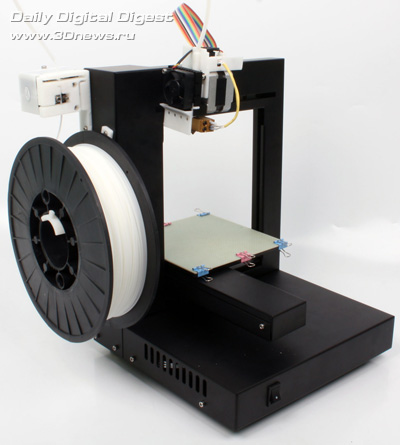

The production speed is determined by the capacity of the 3D printer farm. As a rule, when we integrate 3D printing into production, we do not limit ourselves to one machine and create a farm. This is a whole fleet of identical additive installations to which the job is sent, and they immediately start printing together. In this way, we can significantly increase productivity. It is easily scalable and quite cheap, especially if FDM is used - the most affordable of all 3D printing technologies.

In this way, we can significantly increase productivity. It is easily scalable and quite cheap, especially if FDM is used - the most affordable of all 3D printing technologies.

5. Pots for levitating plants (small runs)

A curious startup project that specializes in levitating plants (Fig. 5). A tree in a pot flies over a wooden block, a magnet device works. So, the task was to make a planter. It should be light, not clay, so that it is easier to make a magnet, and not be afraid of such environment as earth, fertilizers and water. At first, there were attempts to produce wooden pots, but the wood, even with protective coatings, eventually deteriorated from the internal environment. Therefore, it was decided to introduce 3D printing with plastics. The company ordered 3D printing from us, but when it became clear that the production was profitable, it purchased equipment and materials and began to produce pots of various designs on its own.

6. Model of the foot, made according to CT

Medicine cannot be overlooked. The photo shows a foot model printed from white plastic based on the results of computed tomography. The 3D model was obtained from CT and sent to the 3D printer. The product has two uses:

The photo shows a foot model printed from white plastic based on the results of computed tomography. The 3D model was obtained from CT and sent to the 3D printer. The product has two uses:

-

students with the help of such realistic models can practice, identify pathologies, since the use of real bones is very limited;

-

using this model, it is much easier for surgeons to plan an operation strategy and make it more accurate on the patient.

7. Prototype of endoprosthesis

Another medical device is a prototype endoprosthesis (Fig. 7). This is a preliminary model made of plastic, which is used to check the accuracy and correctness of the prosthesis. The final product is also created on a 3D printer, but already from metal, using SLM technology, obtaining a high-precision model of an individual endoprosthesis on the first attempt. Medical metal has a high cost and, in order to eliminate errors, prostheses are initially printed from plastic.

Read on: Plastic works wonders: how a 3D printer imitates human organs

8. Figures in the Olympic Museum in Sochi, printed on a 3D printer

Now let's see what benefits you can get using large format resin 3D printing. One of the most common areas of application today is the production of small architectural forms: sculptures, statues, decorative elements, architectural decorations (Fig. 8). Using a 3D printer, such models are created easily and quickly, and this is one of the cheapest ways to manufacture. In addition, there is the possibility of a wide choice of materials, adding optical effects, translucency (for example, to build a luminous element inside the sculpture for a greater effect).

9. An example of the texture of a printed product of large dimensions

As you know, FDM printing has one feature: due to the layered construction, the parts are “striped”. However, this disadvantage can be turned into an advantage and interesting textures can be created using a large-format 3D printer, as in Fig. 9. Of course, first of all, this is the production of designer furniture and various decorative elements and architectural forms.

9. Of course, first of all, this is the production of designer furniture and various decorative elements and architectural forms.

10. 3D printing with foam composite

For 3D printing of large objects using FGF technology using polymer granules, there is a separate layer of composite materials. On fig. 10 shows the process of printing with a material resembling polyurethane foam. The similarity is not accidental - a foaming composite is used here. One cubic meter of raw material yields 25 cubic meters of foamed material. And, as you can see, this technology allows you to achieve very large layer heights, and the thicker the layer, the faster the 3D printing. And a slight decrease in density facilitates the entire structure as a whole.

Learn more about large-format 3D plastic printing: solutions, challenges, case studies

FDM/FGF printing has a very low accuracy. Moreover, materials have different shrinkage, and in the case of different geometry of parts, shrinkage will be non-linear, unequal simply because of the peculiarities of the technology itself - because of how the material is laid, what temperature loads are applied. In the case of tooling production, as a rule, hybrid technologies are used - the model is printed, and then the working surface is milled. In this way, we obtain the desired roughness and precision.

In the case of tooling production, as a rule, hybrid technologies are used - the model is printed, and then the working surface is milled. In this way, we obtain the desired roughness and precision.

Different equipment requires different materials. Somewhere high heat resistance is needed, somewhere high strength, and somewhere the lowest possible price is a priority. There is an optimal material for each task.

And there is a huge field for optimizing production in order to produce large enough objects cheaply and in an incredibly short time - literally in a matter of hours.

Screensaver photo © zbulvar.ru

Article published on 11/12/2021, updated on 09/20/2022

Technique: Science and Technology: Lenta.ru

In Russia, 3D printing technologies are becoming more and more widespread, allowing the creation of raw materials and parts that cannot be obtained in the usual way. These include special composite materials with unique properties that are useful for developing new types of spacecraft, machines, and even medical prostheses. On the eve of the international startup conference Startup Village 2019Lenta.ru talked to the head of Anisoprint (Skolkovo resident) Fyodor Antonov and talks about the prospects that additive technologies open up for domestic companies.

On the eve of the international startup conference Startup Village 2019Lenta.ru talked to the head of Anisoprint (Skolkovo resident) Fyodor Antonov and talks about the prospects that additive technologies open up for domestic companies.

Lenta.ru: What developments in the field of 3D printing are being done in your company?

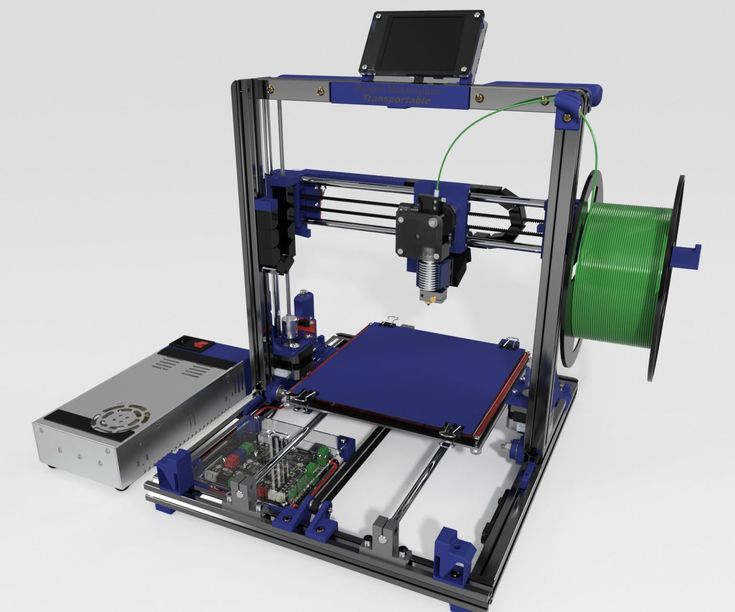

Fedor Antonov: We are developing a technology for 3D printing of composite materials reinforced with continuous fibers. Such materials are ten times stronger than plastic, twice as strong and lighter than aviation aluminum alloys. Our technology includes, first of all, equipment - a 3D printer, or, as we call it, a CFC printer (from Composite fiber co-extrusion - composite fiber co-extrusion).

The material for it is a composite reinforcing fiber, which is introduced into the polymer melt during printing, giving the material unique physical and mechanical properties. There is also software - the so-called slicer - Anisoprint Aura. With its help, a 3D model is prepared for printing, the necessary reinforcement trajectories are set, the internal structure of the material is adjusted, and the strength and rigidity of the structure are optimized. We conduct both development and production in all three areas ourselves.

We conduct both development and production in all three areas ourselves.

General Director of Anisoprint Fedor Antonov.

Photo: Mikhail Tereshchenko / TASS

What types of 3D printing exist, what are their advantages and disadvantages?

3D printing is a huge layer of different technologies. There is 3D printing for engineering, construction, living tissue printing, even confectionery printing. We are engaged in engineering printing - printing of parts and structures for machines and units or their layouts, models and prototypes.

There are also many different technologies in engineering printing, which can be conditionally divided according to the materials used - polymer printing and metal printing. There are also different combinations of them. As a rule, polymer printing technologies, of which there are also several dozen, are used for prototyping - making mock-ups or models of real products. This is due to the low strength of the materials used. They, with rare exceptions, cannot be used for the manufacture of important functional parts.

They, with rare exceptions, cannot be used for the manufacture of important functional parts.

Metal printing (which also includes dozens of different technologies) is a more complex and expensive process. However, the resulting products can already withstand significant operational loads and be used in the details of machines and assemblies. But due to the high cost of equipment and materials for metal printing, it is in demand only in very narrow niche markets, such as, for example, astronautics or prosthetics. But we believe that composite printing, with the benefits of both, will eventually become one of the most sought-after 3D printing technologies. But there is still a lot to be done.

Back to your project. What directions in additive technologies are the most promising now?

Today, in additive technologies, the main emphasis is on the transition from prototyping to the production of functional elements. Therefore, all the main trends are now aimed at reducing the cost of production of final parts. This can be achieved both by reducing the cost of equipment and materials, and by increasing productivity.

This can be achieved both by reducing the cost of equipment and materials, and by increasing productivity.

So far, there has been no significant breakthrough in these areas. We see how the number of players in the metal printing market is growing, new technologies are emerging. New niches are gradually opening up. Composites are the trend of the last few years, and the rapid growth of this segment is yet to come. I am sure that composites will be able to seriously push out metals in the fight for new markets.

How good is additive technology in Russia compared to the rest of the world? Do you have competitors?

There are not so many players on the 3D market in Russia. Those who offer new solutions and are competitive in the world market are few.

If we talk about the volume of the Russian market, it reaches two percent of the world. The same is true for manufacturers. Although we have competitors in Russia, today only we and one other manufacturer in the world have a ready-made market product, a ready-made solution for 3D printing of composites with continuous reinforcement.

What are composite materials and what are they used for?

Composites are materials that consist of at least two components: a reinforcing filler and a binder. The reinforcing filler gives the material the desired properties, and the binder makes the individual parts of the filler work together. Composites can be structural, that is, used as a material that can withstand the loads that act on the structure. In such composites, the most important properties are strength, stiffness and weight. Among them, the most common are the so-called polymer composites, in which polymers are used as a binder filler, and as a reinforcing, as a rule, structural fibers made of carbon fibers, glass or aramids (aromatic polyamides - approx. "Tapes.ru" ).

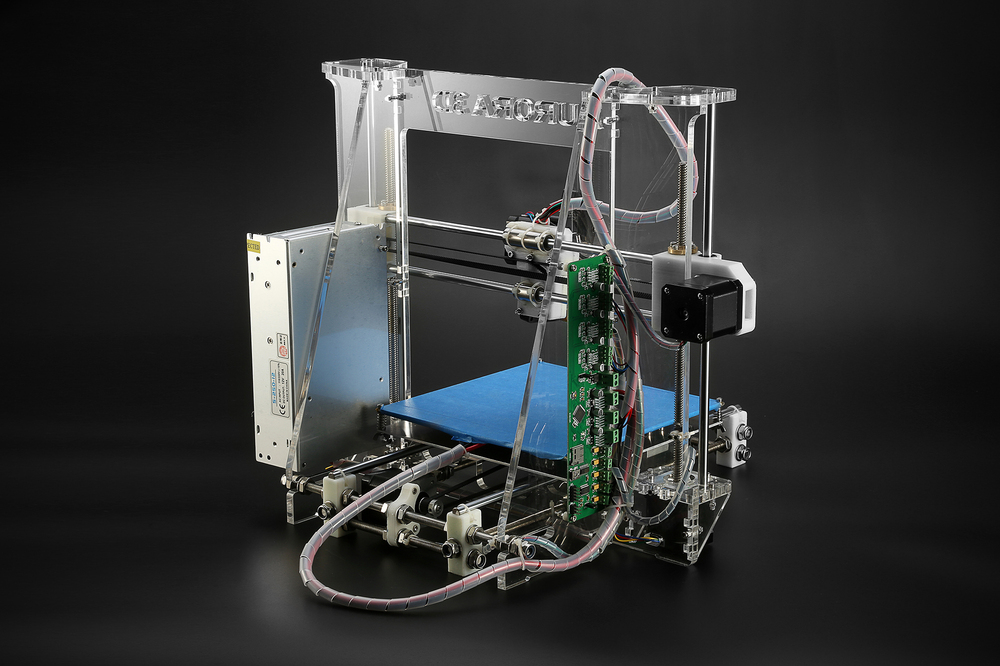

Anisoprint's 3D printer at the Skolkovo Technopark

Photo: Mikhail Tereshchenko / TASS

Carbon fiber-based polymer composites are called carbon fiber plastics (colloquially, carbon fiber). CFRP can be called the king of structural composites. It consists of the thinnest carbon threads, each of which is ten times stronger than steel. The threads are interconnected by special polymer resins, light and durable. In terms of specific characteristics (strength or rigidity related to weight), carbon fiber is several times superior to any metal.

It consists of the thinnest carbon threads, each of which is ten times stronger than steel. The threads are interconnected by special polymer resins, light and durable. In terms of specific characteristics (strength or rigidity related to weight), carbon fiber is several times superior to any metal.

As a rule, composites are used where high strength and stiffness are required, while at the same time low weight: in aviation, space, racing cars, yachts, sports products. Cheaper but less durable fiberglass (a polymer composite based on glass fibers) is used in the manufacture of windmill blades, small boat hulls, and in construction.

How does 3D printing technology solve the problems of composite materials production?

Existing technologies for the manufacture of composites, as a rule, are not automated. They require manual labor, involve work with toxic resins. Specialized tooling is required for the manufacture of parts, and their shape for most composite technologies is limited to plates, shells or profiles. Details of complex shape cannot be manufactured using traditional technologies.

Details of complex shape cannot be manufactured using traditional technologies.

Composite 3D printing is a fully automated, clean, one-step process that helps produce free-form parts with complex internal reinforcement systems. This makes it possible to match the direction of the fibers inside the part with the directions of internal forces acting in the part. In this way, the properties of the material can be focused exactly in the direction in which the internal forces act. This allows you to make parts that more closely match the conditions of work, and therefore, ultimately, lighter, more reliable and cheaper.

What is the uniqueness of the technologies used in Anisoprint? What is your advantage over domestic and global competitors?

Our main innovation is CFC technology, i.e. composite fiber co-extrusion. This is a unique patented technology. In a nutshell, the main stage in creating a composite is the combination of a reinforcing filler and a binder. It is at this moment that the composite is born. In the case of fibrous fillers, this process is called impregnation. The impregnation must be of high quality, it must provide low porosity and good adhesion of the components to each other.

In the case of fibrous fillers, this process is called impregnation. The impregnation must be of high quality, it must provide low porosity and good adhesion of the components to each other.

Impregnation can be carried out either directly during the printing process or beforehand. In the first case, the printing process is more flexible - you can change the binder materials, the volume fraction of the fiber, and control the process more flexibly. In the second, the impregnation is of better quality, the characteristics of the material are higher, but that flexibility is no longer there.

Composite fiber co-extrusion technology combines the advantages of both approaches. We pre-impregnate the reinforcing thread with a special polymer, which ensures low porosity and good adhesion between the fiber and the binder. Then we use the already impregnated fiber in the printing process together with plastic.

The result is a so-called two-matrix composite, in which one polymer binds the finest threads inside the fiber to each other, thereby providing high-quality impregnation. The second material - plastic - connects such composite fibers to each other directly in the printing process, which allows you to select different types of plastics and vary the volume fraction of the fiber on the fly.

The second material - plastic - connects such composite fibers to each other directly in the printing process, which allows you to select different types of plastics and vary the volume fraction of the fiber on the fly.

Detail created on the Anisoprint 3D printer.

Photo: Mikhail Tereshchenko / TASS

This, in particular, allows us to print the so-called mesh structures, like the Shukhov Tower. They cannot be made if pre-impregnated fibers are used, since the volume fraction of the fiber increases sharply at the intersections of the ribs. Thus, Anisoprint technology is both flexible and provides good properties.

How do you imagine the development of additive technologies in Russia in the near future? Tell us about your future plans.

I would not consider Russia separately. We are still in a global context. The market for our products is, first of all, global, and therefore we think within the framework of the global market.

Now additive technologies occupy a very modest share of this market, but it is growing very rapidly.