Common 3d printing plastics

3D Printing Materials Guide: Plastics

Published on June 8, 2020 by Alexandrea P.

A plastic is a material made of synthetic or semi-synthetic compounds that has the property of being malleable (capable of changing its shape). Most plastics on the market are completely synthetic (most commonly derived from petrochemicals). However, given the growing environmental concern, plastics derived from renewable materials such as Polylactic Acid (PLA) are also popular on the market. Due to their low cost, ease of manufacture, versatility and water resistance, plastics are used in a multitude of products and sectors. In the AM sector, 3D printing plastics are also very popular.

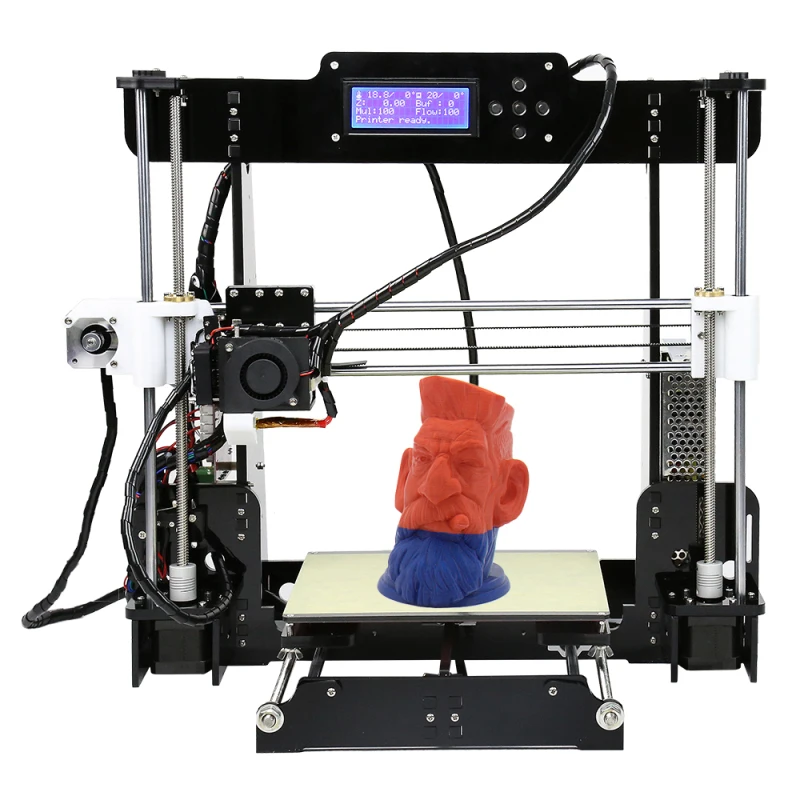

In the following guide, we will take a look at the most common 3D printing plastics. As you may know, the most popular and affordable 3D printing process, FDM, produces parts through the extrusion of plastic filaments. However, the precision on FDM machines is not the same as other AM processes such as SLS or SLA. Plastics are often used with this technology to create prototypes. Therefore, for industrial and end-use parts, manufacturers might decide to opt for SLS (using plastic powders) or SLA (using plastic resins) technologies that offer more accuracy and part quality. Two other technologies that can print with plastics are Material Jetting and Multi Jet Fusion.

What plastics can be used in additive manufacturing? In filament or powder form, the plastic should melt to form the object you are printing layer by layer. In resin form, it should solidify to form the object. Each plastic will require different 3D printing parameters during the building process, and will give parts varying properties.

ABS

ABS filament is the most commonly used 3D printing plastics. It is used in the bodywork of cars, appliances, and mobile phone cases. It is a thermoplastic which contains a base of elastomers based on polybutadiene, making it more flexible, and resistant to shocks. ABS can also be found in powder form for powder bed processes such as SLS, and liquid form for SLA and PolyJet technologies.

ABS is used in 3D printing when heated between 230ºC and 260ºC. It is a tough material, able to easily withstand temperatures of -20ºC to 80ºC. In addition to its high strength, it is a reusable material and can be welded with chemical processes. However, ABS is not biodegradable and shrinks in contact with air, so the printing platform must be heated to prevent warping. Moreover, it is recommended to use a closed chamber 3D printer to limit particle emissions when printing with ABS. Learn more about ABS in our dedicated guide.

PLA

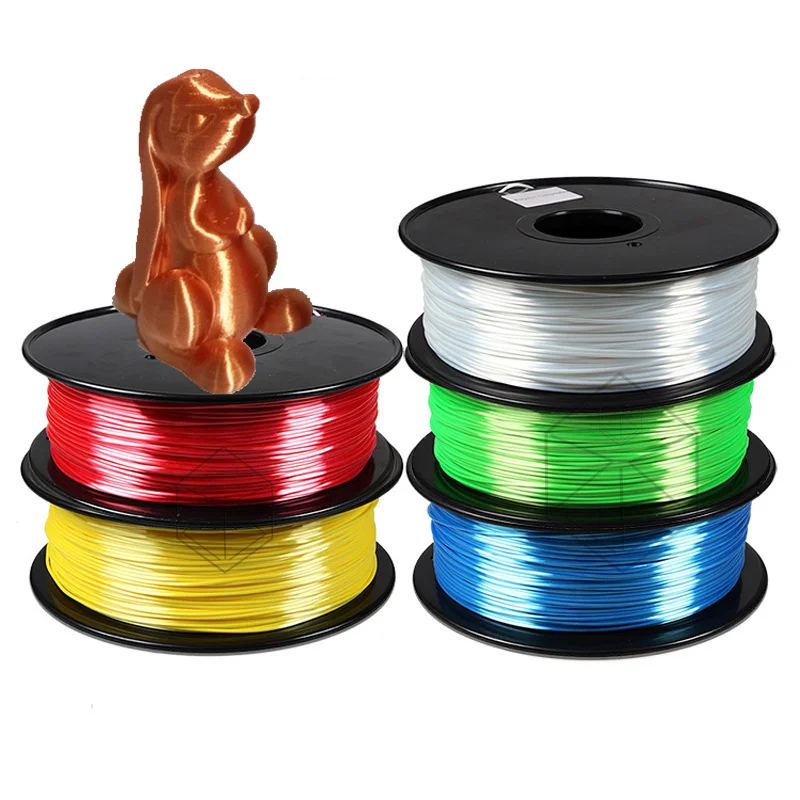

Known as polylactic acid, or PLA, this material has the benefit of being biodegradable, unlike ABS. PLA is manufactured using renewable raw materials such as corn starch. PLA is one of the easiest materials to print, though it does have a tendency to shrink slightly after 3D printing. You don’t require a heated platform when printing in PLA, unlike with ABS. PLA also prints at a lower temperature than ABS, between 190ºC to 230ºC.

PLA is a more difficult material to manipulate due to its high cooling and solidification speed. It is also important to mention that models can deteriorate when in contact with water. However, the material is consistent, simple to use, and comes in a wide variety of colors, making it suitable for FDM 3D printing. Learn more about PLA in our dedicated guide.

It is also important to mention that models can deteriorate when in contact with water. However, the material is consistent, simple to use, and comes in a wide variety of colors, making it suitable for FDM 3D printing. Learn more about PLA in our dedicated guide.

PLA 3D printing filament spools

ASA

ASA is a material that has similar properties to ABS, but has a greater resistance to UV rays. As with ABS, it is advised to print the material with a heated bed platform to prevent warping. When printing with ASA, similar print settings are used to ABS, but extra care must be taken to print with a closed chamber due to styrene emissions.

PET

Polyethylene terephthalate, or PET, is commonly seen in disposable plastic bottles. PET is the ideal filament for any pieces intended for contact with food. Moreover, the material is fairly rigid and has good chemical resistance. To obtain the best results when printing with PET, print between 75 – 90ºC. PET is commonly marketed as a translucent filament, with variants such as PETG, PETE, and PETT also sold. Advantages of PET include that the material doesn’t release any odours when printing, and is 100% recyclable.

Advantages of PET include that the material doesn’t release any odours when printing, and is 100% recyclable.

PETG

PETG, or glycolized polyester, is a thermoplastic widely used in the additive manufacturing market, combining both the simplicity of PLA 3D printing and the strength of ABS. It is an amorphous plastic, which can be 100% recycled. It has the same chemical composition as polyethylene terephthalate, better known by its acronym PET. Glycol has been added to reduce its brittleness and therefore its fragility. Learn more about PETG in our dedicated guide.

Polycarbonate (PC)

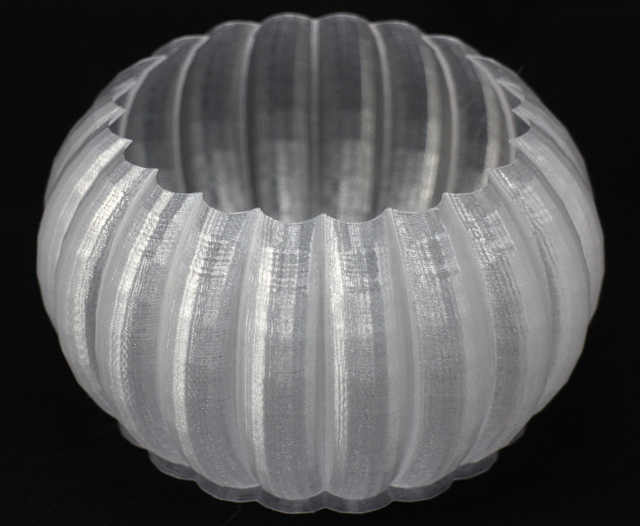

Polycarbonate (PC) is a high strength material designed for engineering applications. The material has good temperature resistance, able to resist any physical deformation up to around 150ºC. However, PC is prone to absorbing moisture from the air, which can affect performance and printing resistance. Therefore, PC has to be stored in airtight containers. PC is highly valued by the AM industry for its strength and transparency. It has a much lower density than glass, making it particularly interesting for designing optical parts, protective screens or decorative objects. Learn more about PC in our dedicated guide.

It has a much lower density than glass, making it particularly interesting for designing optical parts, protective screens or decorative objects. Learn more about PC in our dedicated guide.

A 3D printed part made from PC

High Performance Polymers (PEEK, PEKK, ULTEM)

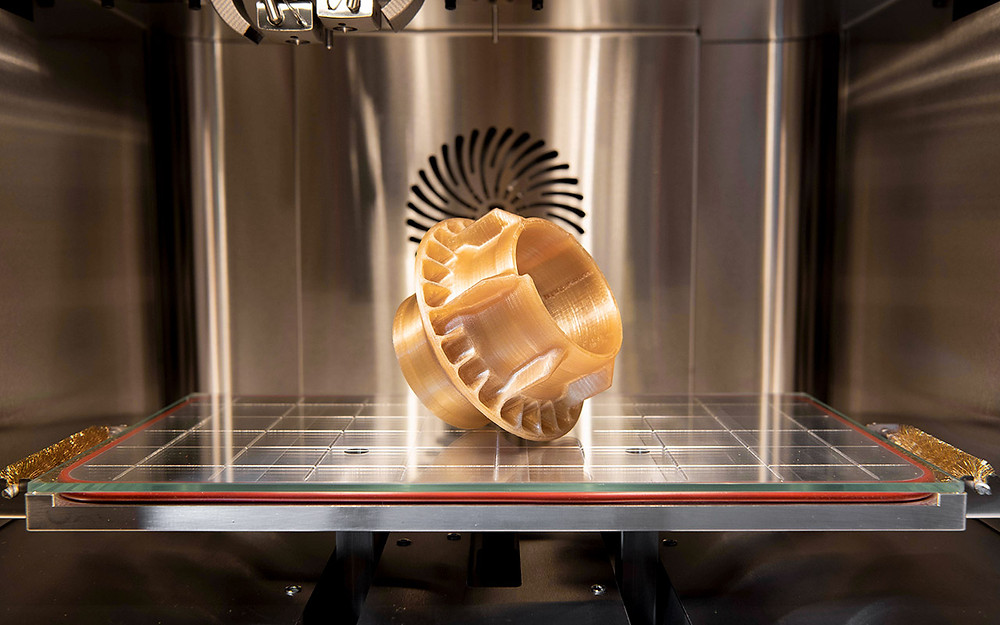

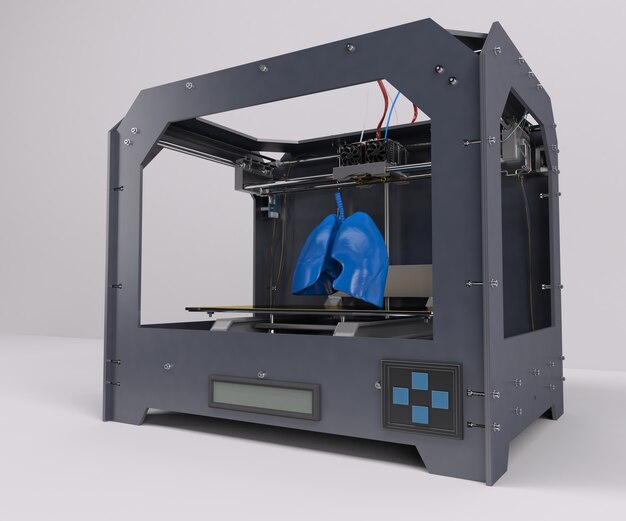

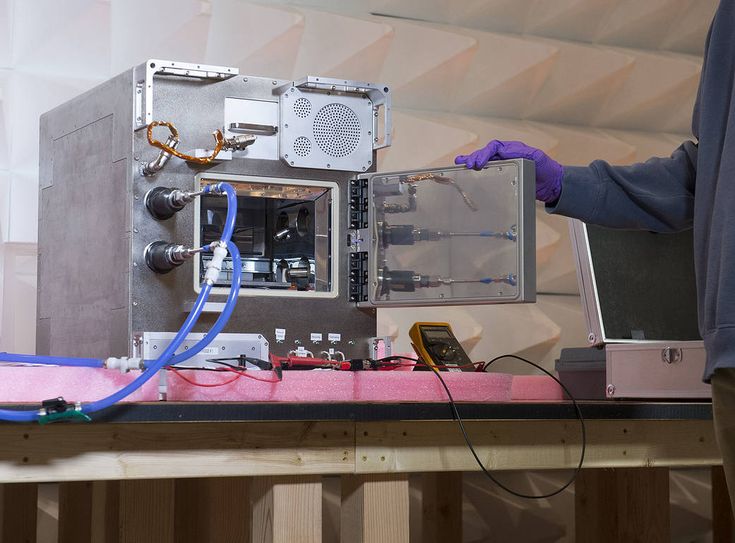

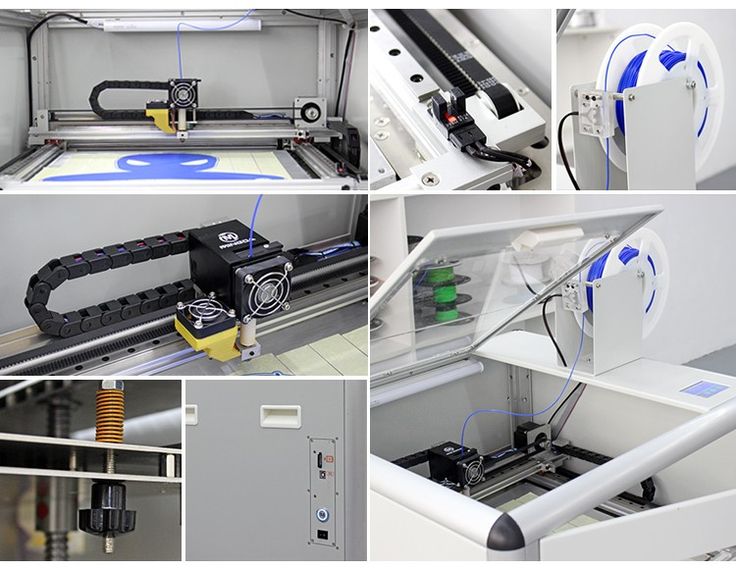

The evolution of 3D printing technologies has led to extensive research work on printing materials, enabling the development of a whole range of high-performance filaments with mechanical characteristics similar to those of metals. There are several types of high-performance 3D printing plastics such as PEEK, PEKK or ULTEM – they are distinguished by family such as polyaryletherketones (PAEK) or polyetherimides (PEI). These filaments have a very high mechanical and thermal resistance, are very strong and at the same time much lighter than some metals. These properties make them very attractive in the aerospace, automotive and medical sectors.

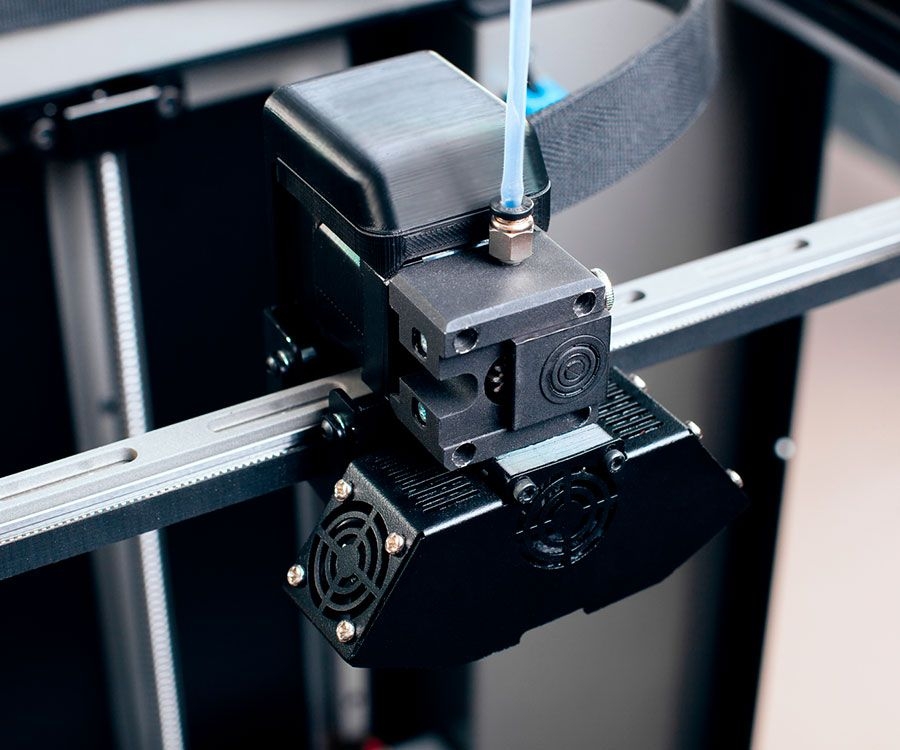

Due to their characteristics, high performance polymers cannot be printed on all FDM machines on the market. Indeed, the 3D printer must have a heating plate capable of reaching at least 230°C, an extrusion at 350°C and a closed chamber. Today, about 65% of these materials are printed with FDM technology, but they are also found in powder form, compatible with SLS technology. Learn more in our dedicated guides on PEEK and PEKK.

Indeed, the 3D printer must have a heating plate capable of reaching at least 230°C, an extrusion at 350°C and a closed chamber. Today, about 65% of these materials are printed with FDM technology, but they are also found in powder form, compatible with SLS technology. Learn more in our dedicated guides on PEEK and PEKK.

Image via VisionMiner

Polypropylene (PP)

Polypropylene is another thermoplastic widely used in the automotive sector, professional textiles sector, and in the manufacturing of hundreds of everyday objects. PP is known for its resistance to abrasion and its ability to absorb shocks, as well as relative rigidity and flexibility. However, drawbacks of the material include its low temperature resistance, and sensitivity to UV rays which can cause it to expand. Due to this, several manufacturers have developed alternative types of PP, simili-propilenos, that are stronger both physically and mechanically.

Nylon

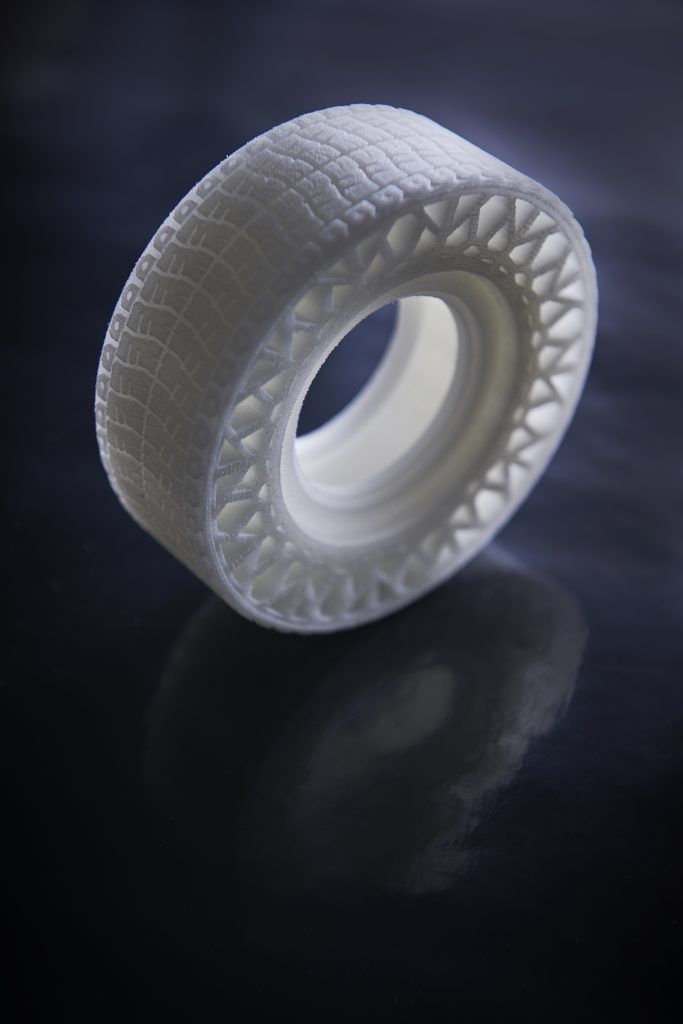

Objects made from polyamides (nylon) are usually created from a fine, white, granular powder with SLS technology. There are however some variants of the material such as nylon that are also available in filaments used in fused deposition modeling (FDM). Due to its biocompatibility, polyamides can be used to create parts that come into contact with food (except foods that contain alcohol).

There are however some variants of the material such as nylon that are also available in filaments used in fused deposition modeling (FDM). Due to its biocompatibility, polyamides can be used to create parts that come into contact with food (except foods that contain alcohol).

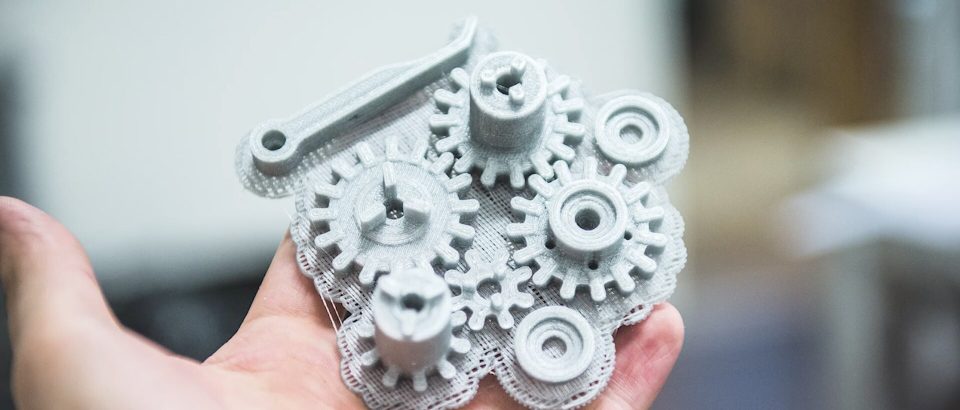

Constituted of semi crystalline structures, polyamides have a good balance of chemical and mechanical characteristics that offer good stability, rigidity, flexibility, and shock resistance. These advantages mean that the material has many applications across sectors and offers a high level of detail. Due to its high quality, polyamides are used in the manufacture of gears, parts for the aerospace market, automotive market, robotics, medical prostheses, and injection molds. You can learn more in our dedicated guide on Nylon.

Image via Sculpteo

Composites

Composites are extremely beneficial when making lightweight yet strong parts. The fibers add strength to a part without adding weight, which is why we also refer to composites as fiber reinforced materials. There are two types of reinforcements, short fiber or continuous fiber. In the first case, chopped fibers, which consist of segments less than a millimeter in length, are mixed into traditional 3D printing plastics to increase the stiffness and to a lesser extent the strength of components. Chopped fibers can be mixed with thermoplastics such as nylon, ABS or PLA.

There are two types of reinforcements, short fiber or continuous fiber. In the first case, chopped fibers, which consist of segments less than a millimeter in length, are mixed into traditional 3D printing plastics to increase the stiffness and to a lesser extent the strength of components. Chopped fibers can be mixed with thermoplastics such as nylon, ABS or PLA.

Alternatively, the fibers can be added to the thermoplastics continuously to arrive at a stronger part. The main fiber used in the 3D printing sector is carbon fiber, but there are also other fibers such as glass fiber or Kevlar. You can find more information in our dedicated guide.

Carbon fiber reinforced filament spool

Hybrid Materials

There are a variety of hybrid materials that mix base plastics with powders to give them a new color, finish or additional material properties. Often based on PLA, these materials are usually made of 70% PLA and 30% hybrid material. For example, wood-based filaments ranging from bamboo, cork, wood dust, and more are available. These wood-based materials mixed with PLA give the hybrid filament a more organic texture. Additionally, some hybrid materials incorporate metal powders to work with FDM-based technologies, to give parts a metal finish. They can be based on copper, bronze, silver, and more.

These wood-based materials mixed with PLA give the hybrid filament a more organic texture. Additionally, some hybrid materials incorporate metal powders to work with FDM-based technologies, to give parts a metal finish. They can be based on copper, bronze, silver, and more.

3D filaments based on wood.

Alumide

Alumide plastic objects are manufactured from a combination of polyamides and aluminium powder using the SLS process. The material has a large, slightly porous surface and a gritty, grainy appearance offering great strength and good temperature resistance (up to 172°C). However, some post-processing treatments are necessary, such as grinding, sanding, coating, or milling.

Alumide is used for complex models, design pieces, or for small series production of functional models that need high rigidity and an appearance similar to aluminium. This technique involves few geometric limits.

Soluble Materials

Soluble materials are materials printed with the intention of being dissolved in a future stage of the manufacturing process. The two most common soluble filament materials are HIPS (High Impact Polystyrene) and PVA (Polyvinyl Acetate). HIPS is associated with ABS, and can be dissolved with limonene, whereas PVA is associated with PLA and can be dissolved using just water.

The two most common soluble filament materials are HIPS (High Impact Polystyrene) and PVA (Polyvinyl Acetate). HIPS is associated with ABS, and can be dissolved with limonene, whereas PVA is associated with PLA and can be dissolved using just water.

There are also BVOH filaments which are becoming increasingly popular, especially in dual extruder printers. This is because the material is soluble in water, and according to experts has a higher solubility than PVA.

Flexible Materials

A newer type of filament, and one of the most successful, are flexible filaments. They are similar to PLA, but usually made out of TPE or TPU. The advantage of using these filaments for 3D printing is they allow for the creation of deformable objects, widely used in the fashion industry. Generally, these flexible filaments have the same printing characteristics as PLA, though they come in a variety of ranges based on their stiffness. It is worth finding out which type of extruder is best suited to the material to avoid jams when 3D printing.

Flexible materials are widely used in fashion and design

Resins (for photopolymerization-based 3D printing)

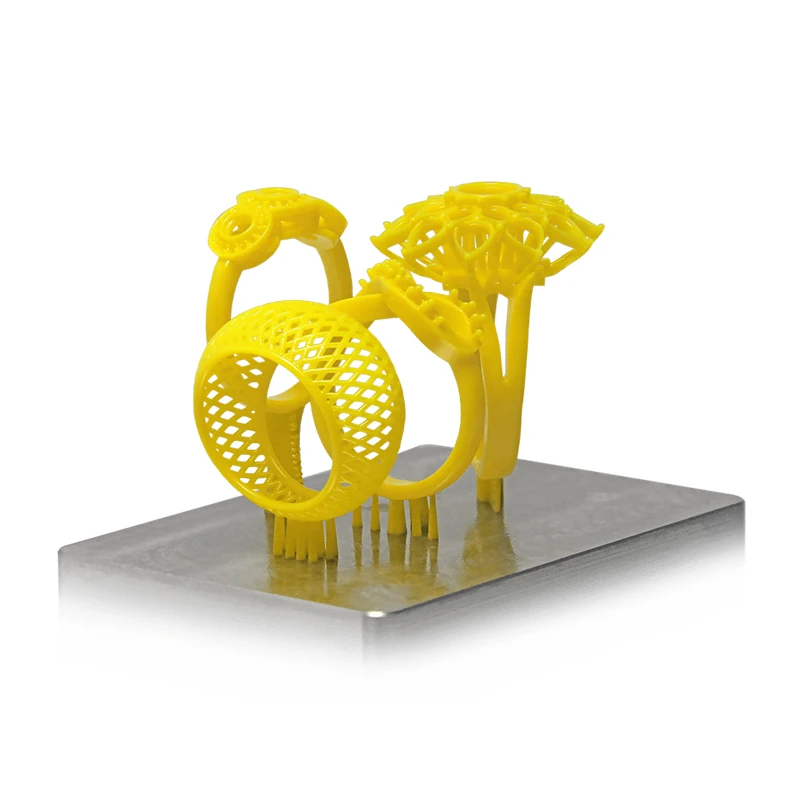

3D printing technologies based on photopolymerization use UV-sensitive resins to create objects layer by layer. In other words, they use a light source such as a laser or LCD screen to solidify a liquid photopolymer. Technologies include SLA, DLP, and even Material Jetting (PolyJet). Creating parts using resins results in high detail and smooth surface objects, nevertheless, the color range is still quite limited using this process. What differentiates resins from FDM filaments is that it is impossible to mix resins to obtain different results quite easily.

Standard resin has properties similar to ABS: the surface finish of the part will be good given the photopolymerization process, however mechanical properties will be moderate. More advanced resins do exist for technical applications such as in dentistry (also need to be biocompatible), or engineering. Additionally, flexible resins that offer greater flexibility and deformation can be used to make jewelry. Over the years, manufacturers have expanded their range of liquid photopolymers to answer manufacturing needs from various sectors. Therefore, you should be able to find resins that have high-temperature resistance, can withstand large impacts, or that have high elongation properties.

Additionally, flexible resins that offer greater flexibility and deformation can be used to make jewelry. Over the years, manufacturers have expanded their range of liquid photopolymers to answer manufacturing needs from various sectors. Therefore, you should be able to find resins that have high-temperature resistance, can withstand large impacts, or that have high elongation properties.

The 3D printing resin is poured in a tank

What do you think of our explanation of these 3D printing plastics? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Guide to 3D Printing Materials: Types, Applications, and Properties

3D printing empowers you to prototype and manufacture parts for a wide range of applications quickly and cost-effectively. But choosing the right 3D printing process is just one side of the coin. Ultimately, it'll be largely up to the materials to enable you to create parts with the desired mechanical properties, functional characteristics, or looks.

This comprehensive guide to 3D printing materials showcases the most popular plastic and metal 3D printing materials available, compares their properties, applications, and describes a framework that you can use to choose the right one for your project.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

There are dozens of plastic materials available for 3D printing, each with its unique qualities that make it best suited to specific use cases. To simplify the process of finding the material best suited for a given part or product, let’s first look at the main types of plastics and the different 3D printing processes.

There are the two main types of plastics:

-

Thermoplastics are the most commonly used type of plastic.

The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles. Thermoplastics can be heated and formed into the desired shape. The process is reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible. A common analogy for thermoplastics is butter, which can be melted, re-solidify, and melted again. With each melting cycle, the properties change slightly.

The main feature that sets them apart from thermosets is their ability to go through numerous melt and solidification cycles. Thermoplastics can be heated and formed into the desired shape. The process is reversible, as no chemical bonding takes place, which makes recycling or melting and reusing thermoplastics feasible. A common analogy for thermoplastics is butter, which can be melted, re-solidify, and melted again. With each melting cycle, the properties change slightly. -

Thermosetting plastics (also referred to as thermosets) remain in a permanent solid state after curing. Polymers in thermosetting materials cross-link during a curing process that is induced by heat, light, or suitable radiation. Thermosetting plastics decompose when heated rather than melting, and will not reform upon cooling. Recycling thermosets or returning the material back into its base ingredients is not possible. A thermosetting material is like cake batter, once baked into a cake, it cannot be melted back into batter again.

The three most established plastic 3D printing processes today are the following:

-

Fused deposition modeling (FDM) 3D printers melt and extrude thermoplastic filaments, which a printer nozzle deposits layer by layer in the build area.

-

Stereolithography (SLA) 3D printers use a laser to cure thermosetting liquid resins into hardened plastic in a process called photopolymerization.

-

Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of thermoplastic powder.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

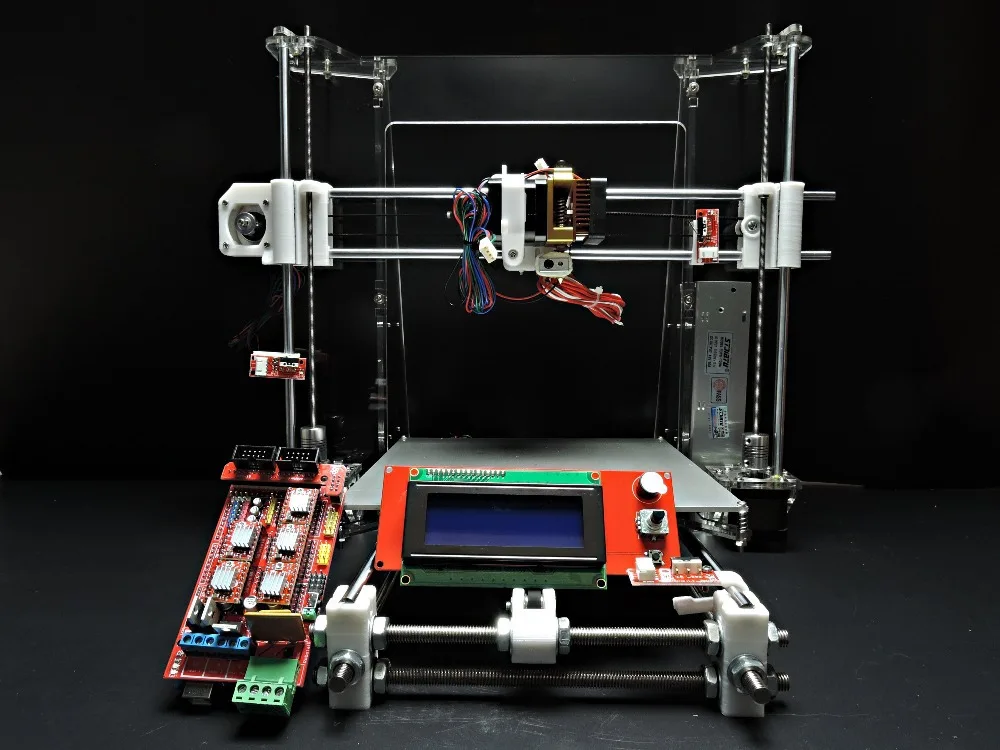

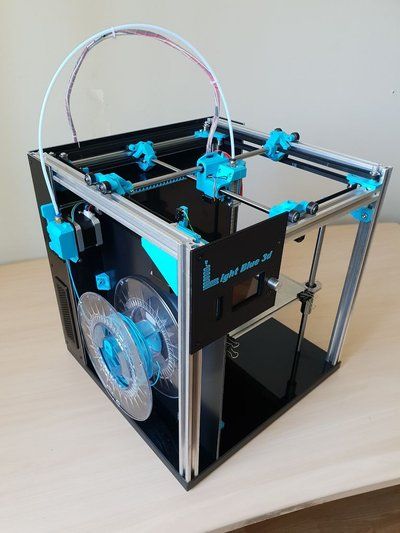

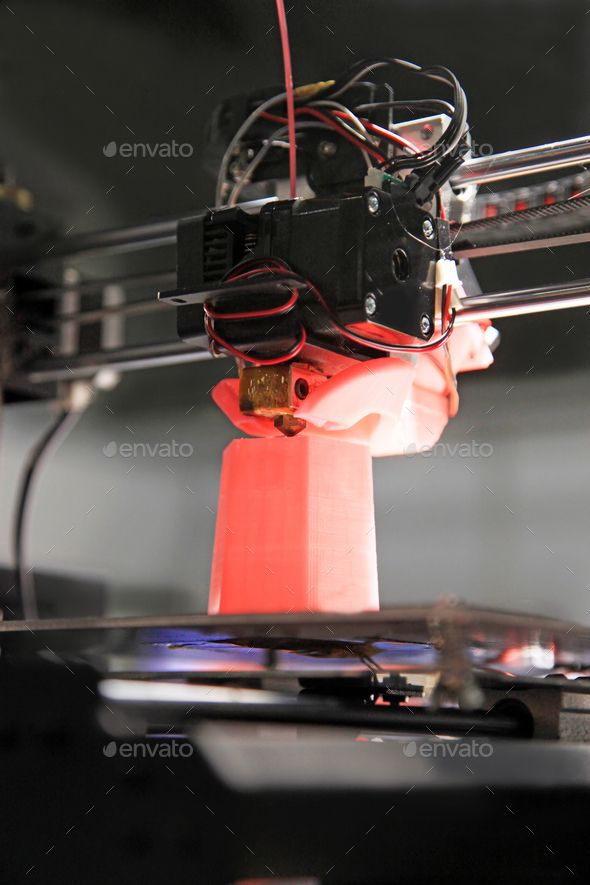

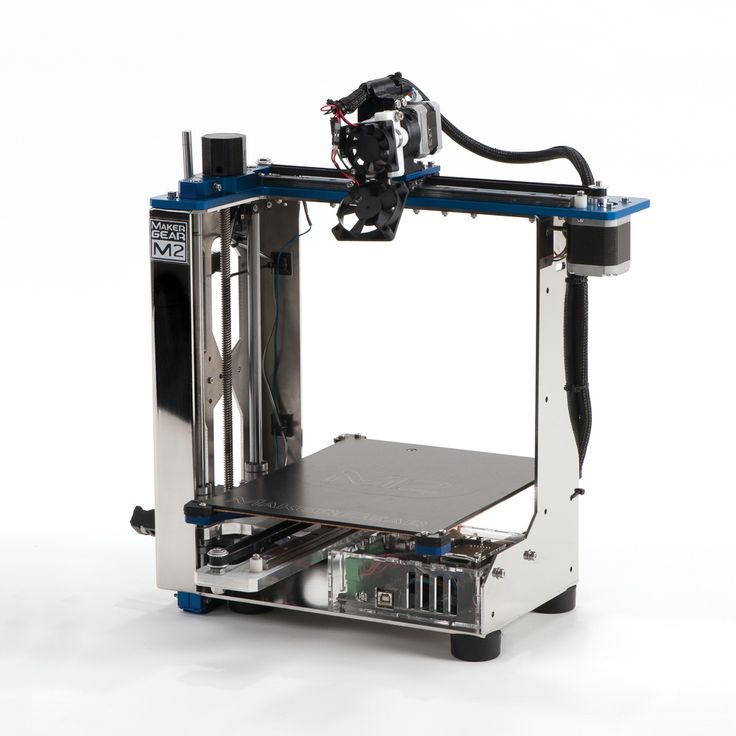

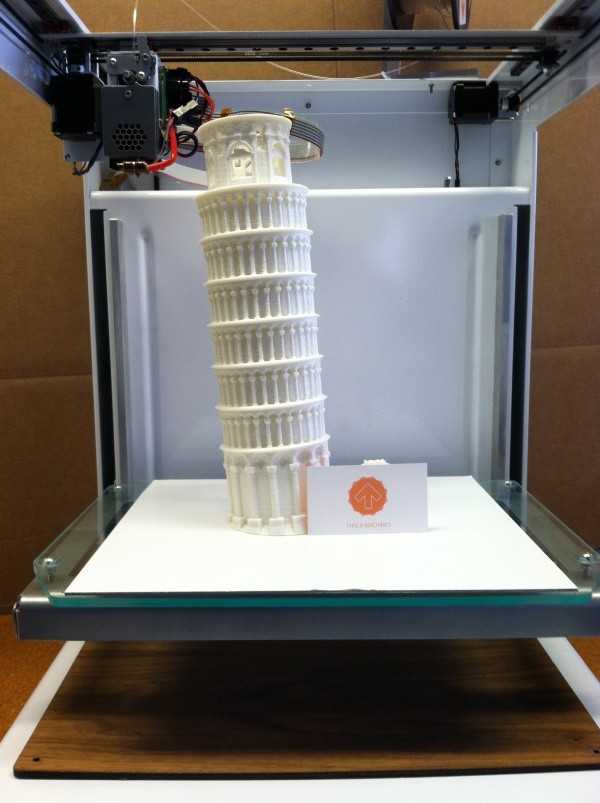

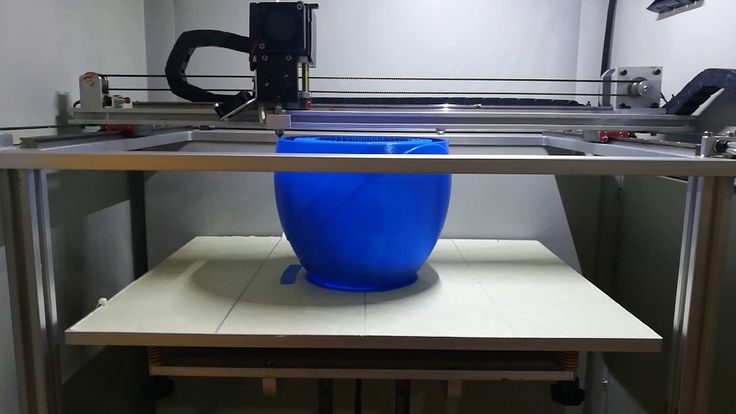

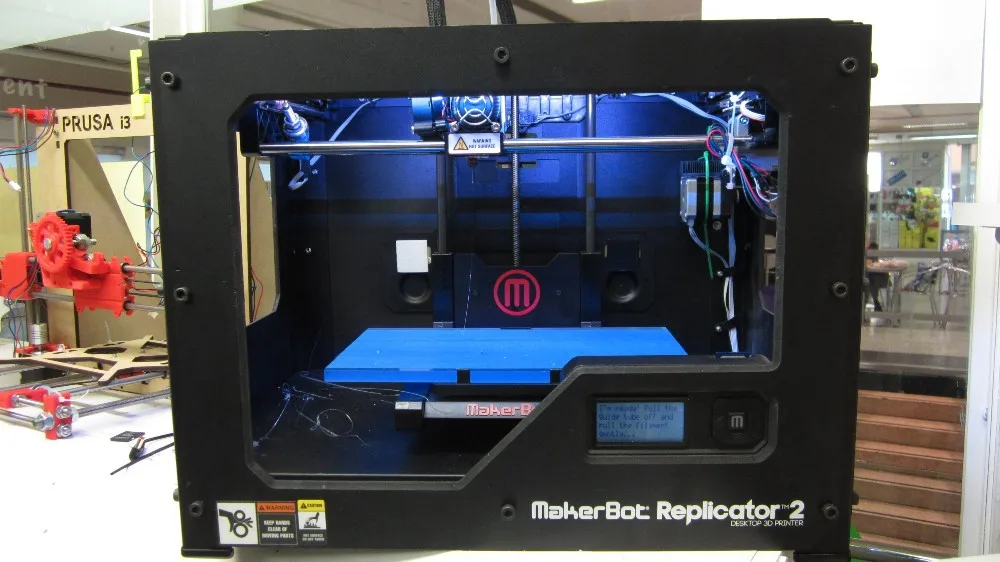

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

This technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

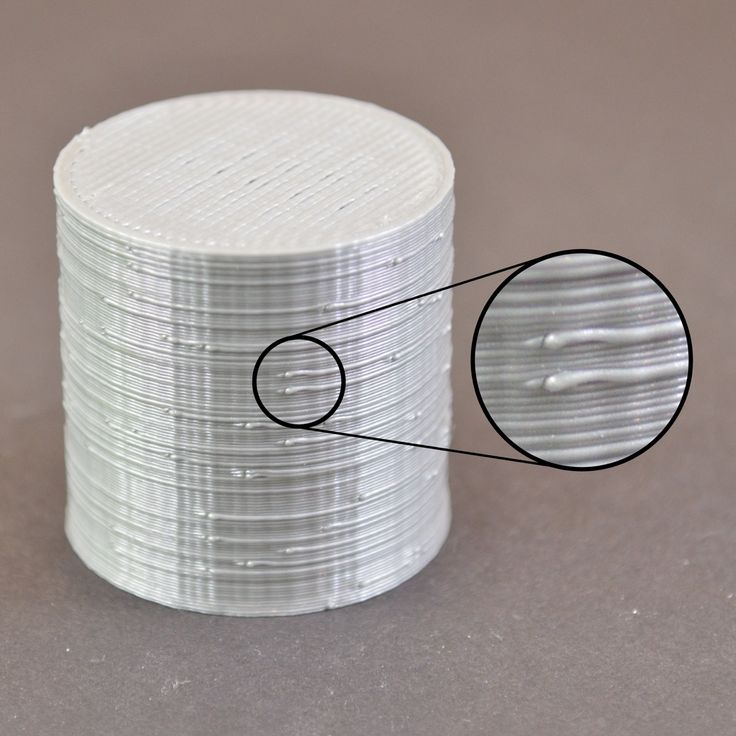

Consumer level FDM has the lowest resolution and accuracy when compared to other plastic 3D printing processes and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics or even composites, but they also come at a steep price.

As the melted filament forms each layer, sometimes voids can remain between layers when they don’t adhere fully. This results in anisotropic parts, which is important to consider when you are designing parts meant to bear load or resist pulling.

FDM 3D printing materials are available in a variety of color options. Various experimental plastic filament blends also exist to create parts with wood- or metal-like surfaces.

The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials that offer properties like higher heat resistance, impact resistance, chemical resistance, and rigidity.

| Material | Features | Applications |

|---|---|---|

| ABS (acrylonitrile butadiene styrene) | Tough and durable Heat and impact resistant Requires a heated bed to print Requires ventilation | Functional prototypes |

| PLA (polylactic acid) | The easiest FDM materials to print Rigid, strong, but brittle Less resistant to heat and chemicals Biodegradable Odorless | Concept models Looks-like prototypes |

| PETG (polyethylene terephthalate glycol) | Compatible with lower printing temperatures for faster production Humidity and chemical resistant High transparency Can be food safe | Waterproof applications Snap-fit components |

| Nylon | Strong, durable, and lightweight Tough and partially flexible Heat and impact resistant Very complex to print on FDM | Functional prototypes Wear resistant parts |

| TPU (thermoplastic polyurethane) | Flexible and stretchable Impact resistant Excellent vibration dampening | Flexible prototypes |

| PVA (polyvinyl alcohol) | Soluble support material Dissolves in water | Support material |

| HIPS (high impact polystyrene) | Soluble support material most commonly used with ABS Dissolves in chemical limonene | Support material |

| Composites (carbon fiber, kevlar, fiberglass) | Rigid, strong, or extremely tough Compatibility limited to some expensive industrial FDM 3D printers | Functional prototypes Jigs, fixtures, and tooling |

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. Resin 3D printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA parts can also be highly polished and/or painted after printing, resulting in client-ready parts with high-detailed finishes.

Parts printed using SLA 3D printing are generally isotropic—their strength is more or less consistent regardless of orientation because chemical bonds happen between each layer. This results in parts with predictable mechanical performance critical for applications like jigs and fixtures, end-use parts, and functional prototyping.

SLA offers the widest range of material options for plastic 3D printing.

SLA 3D printing is highly versatile, offering resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

| Formlabs Materials | Features | Applications |

|---|---|---|

| Standard Resins | High resolution Smooth, matte surface finish | Concept models Looks-like prototypes |

| Clear Resin | The only truly clear material for plastic 3D printing Polishes to near optical transparency | Parts requiring optical transparency Millifluidics |

| Draft Resin | One of the fastest materials for 3D printing 4x faster than standard resins, up to 10x faster than FDM | Initial Prototypes Rapid Iterations |

| Tough and Durable Resins | Strong, robust, functional, and dynamic materials Can handle compression, stretching, bending, and impacts without breaking Various materials with properties similar to ABS or PE | Housings and enclosures Jigs and fixtures Connectors Wear-and-tear prototypes |

| Rigid Resins | Highly filled, strong and stiff materials that resist bending Thermally and chemically resistant Dimensionally stable under load | Jigs, fixtures, and tooling Turbines and fan blades Fluid and airflow components Electrical casings and automotive housings |

| Polyurethane Resins | Excellent long-term durability UV, temperature, and humidity stable Flame retardancy, sterilizability, and chemical and abrasion resistance | High performance automotive, aerospace, and machinery components Robust and rugged end-use parts Tough, longer-lasting functional prototypes |

| High Temp Resin | High temperature resistance High precision | Hot air, gas, and fluid flow Heat resistant mounts, housings, and fixtures Molds and inserts |

| Flexible and Elastic Resins | Flexibility of rubber, TPU, or silicone Can withstand bending, flexing, and compression Holds up to repeated cycles without tearing | Consumer goods prototyping Compliant features for robotics Medical devices and anatomical models Special effects props and models |

| Medical and dental resins | A wide range of biocompatible resins for producing medical and dental appliances | Dental and medical appliances, including surgical guides, dentures, and prosthetics |

| Jewelry resins | Materials for investment casting and vulcanized rubber molding Easy to cast, with intricate details and strong shape retention | Try-on pieces Masters for reusable molds Custom jewelry |

| ESD Resin | ESD-safe material to improve electronics manufacturing workflows | Tooling & fixturing for electronics manufacturing Anti-static prototypes and end-use components Custom trays for component handling and storage |

| Ceramic Resin | Stone-like finish Can be fired to create a fully ceramic piece | Engineering research Art and design pieces |

Explore Formlabs SLA Materials

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts. Low cost per part, high productivity, and established materials make the technology ideal for a range of applications from rapid prototyping to small-batch, bridge, or custom manufacturing.

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Just like SLA, SLS parts are also generally more isotropic than FDM parts. SLS parts have a slightly rough surface finish due to the powder particles, but almost no visible layer lines.

SLS 3D printing materials are ideal for a range of functional applications, from engineering consumer products to manufacturing and healthcare.

The material selection for SLS is limited compared to FDM and SLA, but the available materials have excellent mechanical characteristics, with strength resembling injection-molded parts. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

| Material | Description | Applications |

|---|---|---|

| Nylon 12 | Strong, stiff, sturdy, and durable Impact-resistant and can endure repeated wear and tear Resistant to UV, light, heat, moisture, solvents, temperature, and water | Functional prototyping End-use parts Medical devices |

| Nylon 11 | Similar properties to Nylon 12, but with a higher elasticity, elongation at break, and impact resistance, but lower stiffness | Functional prototyping End-use parts Medical devices |

| TPU | Flexible, elastic, and rubbery Resilient to deformation High UV stability Great shock absorption | Functional prototyping Flexible, rubber-like end-use parts Medical devices |

| Nylon composites | Nylon materials reinforced with glass, aluminum, or carbon fiber for added strength and rigidity | Functional prototyping Structural end-use parts |

Explore Formlabs SLS Materials

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Different 3D printing materials and processes have their own strengths and weaknesses that define their suitability for different applications. The following table provides a high level summary of some key characteristics and considerations.

| FDM | SLA | SLS | |

|---|---|---|---|

| Pros | Low-cost consumer machines and materials available | Great value High accuracy Smooth surface finish Range of functional materials | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility High cost industrial machines if accuracy and high performance materials are needed | Sensitive to long exposure to UV light | More expensive hardware Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models Select end-use parts with high-end industrial machines and materials | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Models and props | Functional prototyping Short-run, bridge, or custom manufacturing |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends on consumer level machines. High performance composites on high cost industrial machines High performance composites on high cost industrial machines | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites, thermoplastic elastomers such as TPU. |

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but use extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

SLM and DMLS printers work similarly to SLS printers, but instead of fusing polymer powders, they fuse metal powder particles together layer by layer using a laser. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

-

Titanium is lightweight and has excellent mechanical characteristics. It is strong, hard and highly resistant to heat, oxidation, and acid.

-

Stainless steel has high strength, high ductility, and is resistant to corrosion.

-

Aluminum is a lightweight, durable, strong, and has good thermal properties.

-

Tool steel is a hard, scratch-resistant material that you can use to print end-use tools and other high-strength parts..

- Nickel alloys have high tensile, creep and rupture strength and are heat and corrosion resistant.

Compared to plastic 3D printing technologies, metal 3D printing is substantially more costly and complex, limiting its accessibility to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

Another alternative is electroplating SLA parts, which involves coating a plastic material in a layer of metal via electrolysis. This combines some of the best qualities of metal—strength, electrical conductivity, and resistance to corrosion and abrasion—with the specific properties of the primary (usually plastic) material.

Plastic 3D printing is well-suited to create patterns that can be cast to produce metal parts.

With all these materials and 3D printing options available, how can you make the right selection?

Here’s our three-step framework to choose the right 3D printing material for your application.

Plastics used for 3D printing have different chemical, optical, mechanical, and thermal characteristics that determine how the 3D printed parts will perform. As the intended use approaches real-world usage, performance requirements increase accordingly.

| Requirement | Description | Recommendation |

|---|---|---|

| Low performance | For form and fit prototyping, conceptual modeling, and research and development, printed parts only need to meet low technical performance requirements. Example: A form prototype of a soup ladle for ergonomic testing. No functional performance requirements needed besides surface finish. | FDM: PLA SLA: Standard Resins, Clear Resin (transparent part), Draft Resin (fast printing) |

| Moderate performance | For validation or pre-production uses, printed parts must behave as closely to final production parts as possible for functional testing but do not have strict lifetime requirements. Example: A housing for electronic components to protect against sudden impact. Performance requirements include ability to absorb impact, housing needs to snap together and hold its shape. | FDM: ABS SLA: Engineering Resins SLS: Nylon 11, Nylon 12, TPU |

| High performance | For end-use parts, final 3D printed production parts must stand up to significant wear for a specific time period, whether that’s one day, one week, or several years. Example: Shoe outsoles. | FDM: Composites SLA: Engineering, Medical, Dental, or Jewelry Resins SLS: Nylon 11, Nylon 12, TPU, nylon composites |

Once you’ve identified the performance requirements for your product, the next step is translating them into material requirements—the properties of a material that will satisfy those performance needs. You’ll typically find these metrics on a material’s data sheet.

| Requirement | Description | Recommendation |

|---|---|---|

| Tensile strength | Resistance of a material to breaking under tension. High tensile strength is important for structural, load bearing, mechanical, or statical parts. | FDM: PLA SLA: Clear Resin, Rigid Resins SLS: Nylon 12, nylon composites |

| Flexural modulus | Resistance of a material to bending under load. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. Good indicator for either the stiffness (high modulus) or the flexibility (low modulus) of a material. | FDM: PLA (high), ABS (medium) SLA: Rigid Resins (high), Tough and Durable Resins (medium), Flexible and Elastic Resins (low) SLS: nylon composites (high), Nylon 12 (medium) |

| Elongation | Resistance of a material to breaking when stretched. Helps you compare flexible materials based on how much they can stretch. Also indicates if a material will deform first, or break suddenly. | FDM: ABS (medium), TPU (high) SLA: Tough and Durable Resins (medium), Polyurethane Resins (medium), Flexible and Elastic Resins (high) SLS: Nylon 12 (medium), Nylon 11 (medium), TPU (high) |

| Impact strength | Ability of a material to absorb shock and impact energy without breaking. Indicates toughness and durability, helps you figure out how easily a material will break when dropped on the ground or crashed into another object. | FDM: ABS, Nylon SLA: Tough 2000 Resin, Tough 1500 Resin, Grey Pro Resin, Durable Resin, Polyurethane Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Heat deflection temperature | Temperature at which a sample deforms under a specified load. Indicates if a material is suitable for high temperature applications. | SLA: High Temp Resin, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Hardness (durometer) | Resistance of a material to surface deformation. Helps you identify the right “softness” for soft plastics, like rubber and elastomers for certain applications. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

| Tear strength | Resistance of a material to growth of cuts under tension. Important to assess the durability and the resistance to tearing of soft plastics and flexible materials, such as rubber. | FDM: TPU SLA: Flexible Resin, Elastic Resin, Durable Resin SLS: Nylon 11, TPU |

| Creep | Creep is the tendency of a material to deform permanently under the influence of constant stress: tensile, compressive, shear, or flexural. Low creep indicates longevity for hard plastics and is crucial for structural parts. Low creep indicates longevity for hard plastics and is crucial for structural parts. | FDM: ABS SLA: Polyurethane Resins, Rigid Resins SLS: Nylon 12, Nylon 11, nylon composites |

| Compression set | Permanent deformation after material has been compressed. Important for soft plastics and elastic applications, tells you if a material will return to its original shape after the load is removed. | FDM: TPU SLA: Flexible Resin, Elastic Resin SLS: TPU |

For even more details on material properties, read our guide to about the most common mechanical and thermal properties.

Once you translate performance requirements to material requirements, you’ll most likely end up with a single material or a smaller group of materials that could be suitable for your application.

If there are multiple materials that fulfil your basic requirements, you can then look at a wider range of desired characteristics and consider the pros, cons, and trade-offs of the given materials and processes to make the final choice.

Try our interactive material wizard to find materials based on your application and the properties you care the most about from our growing library of materials. Do you have specific questions about 3D printing materials? Contact our experts.

Recommend Me a Material

90,000 types of plastic for 3D printerBlog / Useful / Plastic types for 3D printer

09.04.2021

Content

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

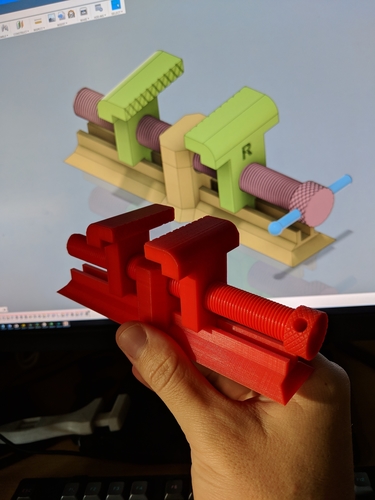

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage.

Because of this, it can be problematic to manufacture overall products.

Because of this, it can be problematic to manufacture overall products. -

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

-

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags. It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

#Useful

Expert in additive technologies and 3D printing with over 5 years of experience.

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

3D Printing Plastics Selection Guide

Contents:

- Common 3D Printing Materials

- PLA plastic: benefits and uses

- ABS plastic

- PETG, PET, PETT

- Nylon

- TPE, TPU, TPC

- Wood

- Metal

- Biodegradable, BioFila

- Glow in the dark

- Conductive

- Magnetic

- Color-Changing

- Professional approach

- Carbon Fiber

- PC ABS

- HIPS

- PVA

- Wax, MOLDLAY

- ASA

- PP

- Acetal, POM

- PMMA, Acrylic

- Features of Cleaning

- FPE

- Ceramic, Clay

Affordability, ease of use, and an active open-source movement have allowed 3D printers to be used almost everywhere. They are successfully used in production, in offices and at home. Consumers have well-founded questions, since it is correct to use the device, and what properties of the material to pay attention to in each individual case. Today we will present an overview of plastics for 3D printing, as well as their main differences.

They are successfully used in production, in offices and at home. Consumers have well-founded questions, since it is correct to use the device, and what properties of the material to pay attention to in each individual case. Today we will present an overview of plastics for 3D printing, as well as their main differences.

The most common types of plastic used for 3D are PLA and ABS. However, their varieties are huge, thanks to the use of impurities of wood, nylon, metal, carbon and many additional components, they can demonstrate various performance characteristics, for example, they can glow in the dark and serve as conductors of electricity.

We will tell you how to choose the best plastics, what properties they may have. Obviously, when choosing which one is better to use for a 3D printer, it is necessary to determine the purpose of the finished product.

Varieties of plastic for <3D printers allow you to recreate beautiful and functional things of high quality. Check out PLA, ABS, Nylon, PETG, Conductive and 20 other popular printables right now.

Check out PLA, ABS, Nylon, PETG, Conductive and 20 other popular printables right now.

Standard 3D printing materials

In addition to detailed information about all types of materials, our section proposes to consider how they differ from each other. This will help you better understand the cases in which they are used.

PLA: advantages and features of use

The most popular for home printing is PLA. Many compare it to ABS, which is also the leader in 3D technology. However, when comparing competitive advantages, PLA wins in many ways. First of all, it is much easier to print, since its temperature index is noticeably lower than that of its counterparts. The PLA moves away from the base, which eliminates the urgent need for a heated table. Also, it does not have an unpleasant odor during operation. This plastic is the most environmentally friendly type.

Important characteristics of PLA for 3D printing:

- Easy to use;

- Good strength;

- Minimum deformation;

- Print - 180 to 230 pp.

Given the properties of PLA for 3D technology, experts recommend not to use them for objects that will be affected by high temperatures, because PLA loses its original characteristics at 60C and above.

What should I do if the 3D device does not stick to the table?

First of all, it is necessary to set the gap again and heat it up, or use the reverse thrust, and when moving, the retract will pull the filament to a customizable length.

ABS

When choosing a plastic to work with a 3D device, it is very common for consumers to purchase ABS. This decision is partly justified: despite the fact that the process is more laborious, it is successfully used in the production of LEGO and motorcycle equipment.

The main advantages of ABS plastic are durability and resistance to high temperatures. for working with a 3D printer, temperature: 210°C - 250°C. It is the best choice for creating phone cases and structural elements for electrical appliances. It has an advantage over other types, as it is the strongest plastic, which makes it a universal solution.

It has an advantage over other types, as it is the strongest plastic, which makes it a universal solution.

How to clean the table of a 3D printer from plastic?

It is recommended to heat the table to 60°C–70°C, prepare warm water and wipe the plastic with a cloth.

PETG, PET, PETT

These types of plastic for 3D printing are familiar to every consumer, since this one is used for the manufacture of bottles and containers. Consumers are more likely to use PETG because it is more practical.

The printing temperature range is 220°C - 250°C. The plastic shrinks during the printing process. The advantage of PETG is durability and high strength. The good rigidity makes it possible to manufacture machine and mechanical parts, protective items and housings from PETG. An important feature is that PETG scratches to a greater extent than ABS, but at the same time demonstrates greater strength.

Nylon

Relative to other printed samples, nylon has the most optimal parameters of rigidity, durability and flexibility. The shrinkage is small. The temperature regime is 240°C - 260°C (table - 70°C - 100°C).

The shrinkage is small. The temperature regime is 240°C - 260°C (table - 70°C - 100°C).

In accordance with the advantages of nylon, it is in demand in the manufacture of bearings and other components. For quality printing, it is not recommended to use nylon with impurities, as this will contribute to increased wear.

TPE, TPU, TPC

A special group of plastics are those that demonstrate a high level of moisture resistance. The types of plastics presented in this section are capable of withstanding heavy loads. Manufactured products are used both in everyday life and industry. This plastic is ideal for medical devices, cases, shoes, toys or clothing.

The presented types of plastics for have one characteristic feature - the difficulty of extruding through an extruder.

What is used to make original products?

In this section, the types and properties of plastic for a 3D device are selected taking into account aesthetics, composition and unusual effects.

Wood

Despite the fact that artificial components are used, printing with two PLA plastics looks as natural as possible. This effect can be achieved using wood shavings. The recommended ratio is 1:1. Wood is especially in demand by consumers due to the fact that the products are aesthetically appealing. Decor items, awards and scalable models of real architectural objects are made from it under the tree.

Metal

Would you like to create products that are visually similar to those made of steel? Then the best solution is to use a special powder with If you do not know which plastic is better for a 3D printer from an environmental point of view, then pay attention to this particular type. Would you like to create an original item that stands out in the dark? Then carefully study the Glow in the Dark printing method. In production, phosphorescent elements are used in combination with PLA / ABS. In the field of electronics and computers, products capable of conducting current are needed. And today, thanks to special technologies, it has become possible to perform these tasks. Electrical circuits can be made using a mixture of carbon fiber and PLA\ABS. Magnetic properties make it possible to manufacture products based on PLA or ABS plastics, as well as metal powder. In fact, it is a ferromagnet, which means the absence of its own magnetic field. Simply put, the resulting models are attracted to magnets, but they themselves are not a magnet. Do you like original solutions where the color changes depending on the temperature? Today, this is still relevant and easily implemented. One color will easily replace another, giving the product unusualness. The basis of colored plastic is PLA or ABS. It can be used to produce phone cases, watches, containers, toys and other products that are in demand in everyday life. This group is most often applicable for industrial and commercial purposes and in isolated cases in everyday life. The essential difference from those types that have been described above is that they can provide very specific functions, not always related to the manufactured product itself. Very often they are necessary for high-quality maintenance of equipment, for example, they are suitable for processing plastic for a 3D printer. Due to its rigid structure and low weight, carbon fiber is optimal for use, for example, in automotive or aircraft parts. The printing process is difficult, but the hardness level is large enough, which is why PC ABS is so popular. Used in the automotive and electronics industries. Printing from 260°C. HIPS is comfortable, it combines flexibility while retaining its shape perfectly. This allows it to be used in the manufacture of various types of packaging. It has a higher degree of hardness than ABS and PLA, shrinkage is less than that of ABS, it is well processed and glued, and it absorbs paint well. An individual feature of PVA is dissolution in water, so storage requirements are especially stringent. If the product is damaged due to moisture, then drying the plastic for the 3D printer using an oven (40-45 ° C) or a dehydrator (fruit dryer) will help. Printing steps: The method will help to print the likeness of pewter and brass models. The primary field of operation is mechanical engineering. Advantages: resistance to chemicals, heat, color and shape changes. Durability allows you to create birdhouses and decorative items for home and garden. ASA may become brittle during printing due to excessive cooling. Not the most comfortable printing plastic, with low layer adhesion and shrinkage. Also subject to possible processing into an updated sample. ROM is actively used for the manufacture of various elements. An important feature is the maximum manufacturing precision. This category of parts may include camera focusing mechanisms, bearings, etc. When trying a ROM, you need to take into account the possibility of a problem with the test layer. If the plastic does not stick to the 3D printer table, the gap between the nozzle and the table will help in the first place. For the most part, PMMA is used as an analogue to glass, as a lightweight and blast-resistant raw material. Cleaning is not used for the printing process, but its importance lies in the fact that it provides a good cleaning of the extruder from the remnants of the material used previously. Peculiarities: Biodegradable, bioFila

The main plus lies in biodegradability, which makes it possible to avoid environmental pollution. The best way to apply is to create things that are not expected to be highly mechanically loaded.

The main plus lies in biodegradability, which makes it possible to avoid environmental pollution. The best way to apply is to create things that are not expected to be highly mechanically loaded. Glow in the dark

Conductive

Magnetic

A fair choice for refrigeration ornaments, including some kinds of toys and tools.

A fair choice for refrigeration ornaments, including some kinds of toys and tools. Color-Changing

Professional approach

Carbon Fiber

PC ABS

HIPS

PVA

Wax, MOLDLAY

ASA

PP

Pros: Acetal, POM

It will be necessary to use auxiliary means of stabilizing the adhesion of the printing table.

It will be necessary to use auxiliary means of stabilizing the adhesion of the printing table. PMMA, Acrylic

It’s definitely not worth making things out of it that tend to bend, it’s worth taking a closer look at those that let in light - from window replacement to bright toys. Features of Cleaning

Learn more

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance.

Performance requirements include strict lifetime testing with cyclic loading and unloading, color fastness over periods of years, amongst others like tear resistance.