3D printer implant

3D Printing Is Ready To Tackle Plastic Body Implants

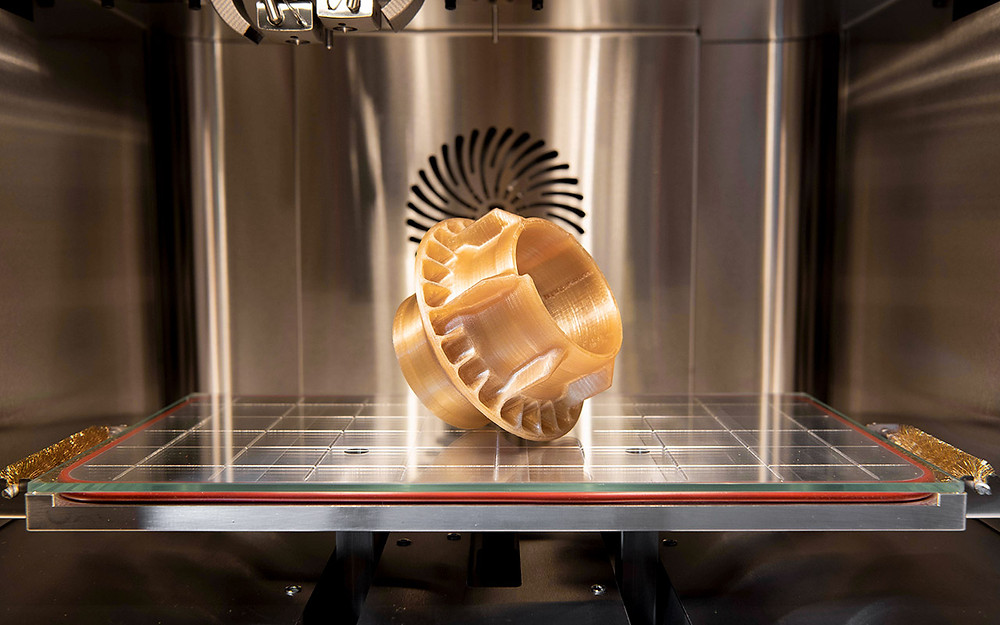

3D-printed skull implant by German MedTech start-up Kumovis.

KumovisAfter an accident left a 40-year-old woman in Sweden with a massive head injury late last year, she received a 3D-printed implant made from a plastic called PEEK to repair her skull.

It was the first time a hospital had designed and 3D printed an implant of this kind on-site, and it could prove a turning point for 3D printing in medical care.

“As far as we know, we are the world’s first to make 3D implants entirely in a hospital, which means that the implants will be better adapted to the patients, right from the start," says Einar Heiberg Brandt, medical engineer in Clinical Physiology at Skåne University Hospital, Sweden. "This will lead to faster surgeries and fewer complications."

In-hospital 3D printing is still in the early stages, but shows great promise, industry experts agree. Although 3D printing has been used in healthcare for more than a decade to manufacture titanium and stainless steel implants, PEEK plastic expands opportunities for the technology to move off the shop floors of medical device manufacturers and into labs at hospitals and clinics worldwide.

In fact, medical facilities represent a vast new market for 3D printing. The healthcare segment of the 3D printing industry, which includes dental and 3D-printed pharmaceuticals, currently is valued at nearly $3 billion.

3D Printing at Hospitals

Institutions, such as the Mayo Clinic in Minn. and VA hospitals nationwide, have extensive 3D printing labs. The work there is mostly patient-specific 3D-printed medical models, surgical training tools, and orthopedic braces. However, in the not too distant future, these hospitals may be 3D printing patient-specific implants in PEEK for all types of surgeries.

MORE FROMFORBES ADVISOR

Kumovis offers a workflow, hardware, and materials for in-hospital manufacturing of PEEK medical ... [+] implants.

KumovisUsing a 3D printer and PEEK filament brings a long list of benefits to hospitals, while still having substantial hurdles. The method, when compared to traditional ways medical devices are made, namely machining and injection molding, can be done on-site at the point of care. This means faster implants, lower costs, and closer coordination between the surgeon and the technicians producing the implant.

This means faster implants, lower costs, and closer coordination between the surgeon and the technicians producing the implant.

By using the patient's data from scans and X-rays, hospitals can 3D print a custom implant that fits precisely into the defect space.

Studies show that patient-specific implants shorten surgery time, lower risks of infection, result in better outcomes, and dramatically reduce the length of a hospital stay. 3D printing the implants as needed also relieves the hospital from having to keep an inventory of expensive implants on hand.

Although, as of today, there are no 3D-printed PEEK implants manufactured at hospitals approved by the FDA, that may soon change.

A German start-up specializing in 3D-printed PEEK skull implants, Kumovis, says it’s completing the final hurdles in the FDA approval process.

"There's a lot of excitement around 3D printing on-site at hospitals and the projects that are driving manufacturing at the point of care and showing what is possible," says Miriam Haerst, co-founder and co-CEO of Kumovis.

South Carolina-based 3D Systems, one of the oldest and largest 3D printer manufacturers in the world, recently announced its plans to acquire Kumovis in order to expand from metal implants to PEEK implants at the point of care.

“As [3D printing] technology becomes more user-friendly for medical professionals, more hospitals will be able to implement end-to-end solutions for personalized surgery,” says Gautam Gupta, vice president and general manager of 3D Systems medical devices practice. “This will disrupt existing healthcare models, improve the quality of care, and crucially, save more lives.”

The Kumovis acquisition fits nicely into 3D Systems' established healthcare business and adds a new focus on decentralizing the production of medical implants.

“Shifting the manufacturing to the hospitals will be a game-changer when it comes to the availability of implants,” says Haerst.

For hospitals to become manufacturers, however, requires technical and engineering staff, regulatory processes, along with equipment. This could be managed on-site in a cooperative agreement by current medical device manufacturers, Haerst says.

This could be managed on-site in a cooperative agreement by current medical device manufacturers, Haerst says.

PEEK Plastic vs. Titanium for Implants

PEEK has had FDA approval as an implant material for years when machined, but not yet when 3D printed. Although PEEK is used in numerous implants on the market today from spinal cages to ankle joints, 3D-printed PEEK still has to prove it has the same weight bearing and wear attributes as milled or molded PEEK.

German materials manufacturer Evonik produces an implant grade, 3D printing filament, VESTAKEEP i4 ... [+]4 G, that can be used in permanent medical implants.

EvonikOverall, this bio-compatible material has several perceived advantages over stainless steel and titanium: it's lightweight, permeable to ultrasound, and practically invisible to CT and MRI scans enabling better post-op monitoring.

Over the years 3D-printed titanium gained a reputation for better bone integration and thousands of joint and spine implants are 3D printed every year by major manufacturers, such as Stryker. But PEEK has changed, says Marc Knebel, head of medical systems at Evonik, which manufactures PEEK for 3D printing as well as injection molding and milling.

But PEEK has changed, says Marc Knebel, head of medical systems at Evonik, which manufactures PEEK for 3D printing as well as injection molding and milling.

"Today, PEEK can be designed with additives to gain new features, such as better osteointegration," says Knebel. "We are working with a couple of hospitals on [3D-printed implants] already. The first ones will be active within the next five years."

A 3D printing lab situated next to the operating room ready to churn out individualized implants designed from patient data at a moment’s notice is still a long way off. Regulatory hurdles remain, clinical studies are still in progress, and building buy-in from hospitals will take time. What we’re seeing today, however, are the innovators taking the first steps.

3D Printed Implants: The Top Applications

3D printing news Medical 3D-Printed Medical Implants: Discover Some of the Most Innovative Projects

Published on October 1, 2021 by Carlota V.

Additive manufacturing in the medical implant sector is expected to reach $0. 27 Billion by 2025. Previously, we presented you with a selection of the most innovative 3D-printed orthoses on the market. 3D printing enables the customization of medical implants that respond to each patient’s specific needs. The solutions created with 3D printing regularly outperform traditional implant methods in terms of design, manufacturing times, associated costs, and often times patient comfort and experience with the implant is improved. Today, we take a look at 3D printed implants—used to repair an organ, treat a disease, or supplement a function, all over a generally long period of time. 3D printing implants today are made of titanium, a metal prized by the medical sector for its biocompatibility. The body generally accepts this material well, a key component when it comes to implant placement. Below you will find some examples of 3D printed implants—this list is not exhaustive so feel free to share your comments at the bottom of the article!

27 Billion by 2025. Previously, we presented you with a selection of the most innovative 3D-printed orthoses on the market. 3D printing enables the customization of medical implants that respond to each patient’s specific needs. The solutions created with 3D printing regularly outperform traditional implant methods in terms of design, manufacturing times, associated costs, and often times patient comfort and experience with the implant is improved. Today, we take a look at 3D printed implants—used to repair an organ, treat a disease, or supplement a function, all over a generally long period of time. 3D printing implants today are made of titanium, a metal prized by the medical sector for its biocompatibility. The body generally accepts this material well, a key component when it comes to implant placement. Below you will find some examples of 3D printed implants—this list is not exhaustive so feel free to share your comments at the bottom of the article!

3D-Printed Silicone Heart Valves

Of course, implants do not just include bones, though those are easier to create and thus more prolific on the market. Recently, we have also seen examples of implants for parts originally made from organic tissue. For example, this case of a bioinspired heart valve prosthesis, which was made using silicone AM. Created in a collaboration between a team of researchers from ETH Zurich and the South African company Strait Access Technologies, these artificial 3D printed heart valves were created as a way to replace valves in an aging population. The researchers decided to create the valve out of silicone as it is compatible with the human body. Additionally, by using 3D printing they would be able to make a valve that is a more perfect match to the patient. It should be noted that though the initial results were promising, they estimate that it will take another 10 years before these 3D printed heart valves could actually be on the market.

Recently, we have also seen examples of implants for parts originally made from organic tissue. For example, this case of a bioinspired heart valve prosthesis, which was made using silicone AM. Created in a collaboration between a team of researchers from ETH Zurich and the South African company Strait Access Technologies, these artificial 3D printed heart valves were created as a way to replace valves in an aging population. The researchers decided to create the valve out of silicone as it is compatible with the human body. Additionally, by using 3D printing they would be able to make a valve that is a more perfect match to the patient. It should be noted that though the initial results were promising, they estimate that it will take another 10 years before these 3D printed heart valves could actually be on the market.

A 3D-Printed Carbon Artificial Retina

An additional application for 3D printed beyond bones is for retinas. In this case, an Australian engineer developed a 3D-printed artificial retina made out of carbon to help people see again. Dr. Matthew Griffith from the University of Sydney made a breakthrough when he realized that essentially, like a computer, a body is just a carbon-based semiconductor. With this knowledge, he determined that he could replicate an eye by creating a carbon (and thus fully bio-compatible) device that absorbed light and then created an electronic charge, exactly like an eye. Furthermore, thanks to low-cost manufacturing with 3D printing, it was entirely possible for him to design this artificial retina himself. Though the device is not actually completed yet and will not even go to clinical studies until the next three to five years, Griffith is hopeful that it will be useful for patients who have lost their sight, even potentially restoring color vision which is not currently possible.

Dr. Matthew Griffith from the University of Sydney made a breakthrough when he realized that essentially, like a computer, a body is just a carbon-based semiconductor. With this knowledge, he determined that he could replicate an eye by creating a carbon (and thus fully bio-compatible) device that absorbed light and then created an electronic charge, exactly like an eye. Furthermore, thanks to low-cost manufacturing with 3D printing, it was entirely possible for him to design this artificial retina himself. Though the device is not actually completed yet and will not even go to clinical studies until the next three to five years, Griffith is hopeful that it will be useful for patients who have lost their sight, even potentially restoring color vision which is not currently possible.

A New Way to Make Knee Replacements

According to statistics, nearly 1 million people undergo knee and hip surgeries every year, making them one of the most common replacement surgeries. And yet, many of these replacements fail, and astonishingly despite this fact, joint reconstruction technology has not changed significantly in the past 50 years or so. American company Monogram Orthopedics is on a mission to change this. They are currently developing a product solution combining 3D printing and robotics to enable mass personalization of orthopedic implants. These implants are designed, according to the company, for maximum cortical contact and stability and designing a part that is as close to the patient’s original anatomy (thanks to a CT scan which will allow for a 3D representation of the original bone structure and 3D printing using a titanium alloy) as possible, making implants less painful and less likely to fail. Though they have not yet commercialized the product, they have reached a number of achievements including raising $16.7M and already completed their first Total Knee Arthoroplasty (TKA) procedure in March 2021.

And yet, many of these replacements fail, and astonishingly despite this fact, joint reconstruction technology has not changed significantly in the past 50 years or so. American company Monogram Orthopedics is on a mission to change this. They are currently developing a product solution combining 3D printing and robotics to enable mass personalization of orthopedic implants. These implants are designed, according to the company, for maximum cortical contact and stability and designing a part that is as close to the patient’s original anatomy (thanks to a CT scan which will allow for a 3D representation of the original bone structure and 3D printing using a titanium alloy) as possible, making implants less painful and less likely to fail. Though they have not yet commercialized the product, they have reached a number of achievements including raising $16.7M and already completed their first Total Knee Arthoroplasty (TKA) procedure in March 2021.

Restorative Oral-maxillofacial Implants

AB Dental uses Selective Laser Sintering (SLS) to create customized Implant Systems and has innovated the technology and application in the oral-maxillofacial field. The company’s system allows doctors to plan dental and facial restoration treatments with more precision compared to traditional methods. The company offers several restorative 3D printed implants for patients, including sinus roof augmentation, orbital bone repair, and a subperiosteal implant for resorbed jaws.

The company’s system allows doctors to plan dental and facial restoration treatments with more precision compared to traditional methods. The company offers several restorative 3D printed implants for patients, including sinus roof augmentation, orbital bone repair, and a subperiosteal implant for resorbed jaws.

Photo Credit: AB Dental

Customized Microporous Bones

With the trademarked motto “We Print Bone”, Particle3D was launched in 2014 by two medical engineering students and their professor with the goal of developing a new solution for replacing destroyed or surgically removed bone. Today, Particle3D is further developing patient-specific bone implants based on a patient’s own CT/MRI scan which results in 3D printed implants that provide uniquely bone-like internal architecture containing micro- and macro porosities—just like real bone.

3D-Printed Spinal Interbody Fusion Implant

NanoHive Medical is a pioneer in 3D printed spinal interbody fusion implants. Using its proprietary, biomimetic Soft Titanium lattice technology, the company offers surgeons and their patient’s biomechanical elastic modulus properties, precise diagnostic imaging, and osteoblast cell attraction and integration—all resulting in less stiffness or discomfort experienced for the patient and faster implant stability when compared to existing PEEK implant methods.

Using its proprietary, biomimetic Soft Titanium lattice technology, the company offers surgeons and their patient’s biomechanical elastic modulus properties, precise diagnostic imaging, and osteoblast cell attraction and integration—all resulting in less stiffness or discomfort experienced for the patient and faster implant stability when compared to existing PEEK implant methods.

Photo Credit: NanoHive Medical

Nexxt Matrixx

The US company Nexxt Spine has been specializing in the manufacture of implants for spinal diseases for several years. With Nexxt Matrixx, the company has achieved another innovation: the 3D-printed titanium implants are intended to support osteogenesis, improve surface topography and promote the production of angiogenic factors. The naming seems to be inspired by the 75% porous grid of the implant, which promotes osteointegration and radiological visualization. The company uses equipment from GE Additive in the manufacture of its implants and thus relies on the DMLM process to manufacture its titanium parts. Andy Elsbury, the founder of Nexxt Spine states that patients and clinics particularly benefit from the strength and biocompatibility of the titanium implants.

Andy Elsbury, the founder of Nexxt Spine states that patients and clinics particularly benefit from the strength and biocompatibility of the titanium implants.

Integration of an Eye Implant

The orbit is the bony cavity in which the eye sits, each one different in shape from person to person. Surgical procedures around the orbit are therefore complex and often long, especially when it comes to implants: doctors must ensure the position of the orbit and its correct insertion. At the Hong Kong Polytechnic University Industrial Center, a team 3D printed models to facilitate these operations. The team starts with the scanner and the patient’s x-ray to create a CAD model. She then prints the upper and lower parts of a mold on a Stratasys machine with a biocompatible thermoplastic and then presses a sheet of titanium into the mold to obtain the shape of the implant. This is not a 3D printed implant per se, but we wanted to present this application case to you which significantly reduces operating times.

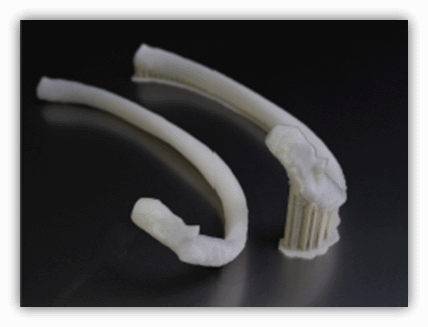

On the left, the mold used to create the shape of the implant; on the right, an orbit model to help surgeons with their operations. (Photo Credit: Stratasys)

The First 3D-Printed PEEK Clavicle Implant

In February 2019, we informed you of a great breakthrough in the medical world: the manufacturer of 3D printers IEMAI 3D and the Kunming University Hospital had successfully implanted a clavicle 3D printed using PEEK, a highly resistant and biocompatible high-performance thermoplastic. The patient who received this 3D printed implant suffered from cancer and, having to undergo chemotherapy sessions, could not receive a metal implant. The device in question was tailor-made: additive manufacturing made it possible to meet patient requirements much more quickly and easily. It seems that PEEK was very well accepted by the latter’s body. The implant was printed on the IEMAI 3D MAGIC-HT-M machine.

Photo Credit: IEMAI 3D

3D-Printed Implants for Ear

The hammer, anvil, and stirrup are three bones located in our ear, the smallest in our human body because they do not grow after birth. Their shape, size, and position are therefore very important for the proper functioning of the ear. However, sometimes these bones break and need to be replaced. This is what happened in South Africa where a patient had 3D printed titanium bones implanted following a car accident. After a 3D scan of his middle ear, the team of surgeons behind the operation was able to model a bespoke implant, which was then printed on a powder bed laser fusion machine. Titanium was favored in this case for its biocompatibility and strength.

Their shape, size, and position are therefore very important for the proper functioning of the ear. However, sometimes these bones break and need to be replaced. This is what happened in South Africa where a patient had 3D printed titanium bones implanted following a car accident. After a 3D scan of his middle ear, the team of surgeons behind the operation was able to model a bespoke implant, which was then printed on a powder bed laser fusion machine. Titanium was favored in this case for its biocompatibility and strength.

Ossicles are among the smallest bones in the human body. The picture shows a real ossicle and not the implant

3D-Printed Jaw Implant After Tumor Removal

Anelia Myburgh, is an Australian woman from Melbourne who improved her quality of life thanks to additive manufacturing technologies. Due to a malignant tumor located in her jaw and teeth, the doctors were forced to remove it, which caused a disfigurement in the woman’s face by losing more than 80% of the jaw. The case of de Myburgh led maxillofacial surgeon George Dimitroulis to explore the possibilities of additive manufacturing for the creation of custom models. Thus, he created a jaw implant with a titanium frame capable of incorporating bone grafts. After more than 5 hours of surgery and several months of recovery, we can affirm that the operation was a complete success and the advances in this technology gave Anelia the security and confidence in her life.

The case of de Myburgh led maxillofacial surgeon George Dimitroulis to explore the possibilities of additive manufacturing for the creation of custom models. Thus, he created a jaw implant with a titanium frame capable of incorporating bone grafts. After more than 5 hours of surgery and several months of recovery, we can affirm that the operation was a complete success and the advances in this technology gave Anelia the security and confidence in her life.

Renishaw’s Rib Cage

Due to breast cancer, 71-year-old Welshman Peter Maggs underwent an 8-hour operation to remove the tumor. In the surgical process, three ribs and part of his sternum were removed, so doctors looked for a way to replace the missing parts. To do this, they turned to metal additive manufacturing, specifically Renishaw solutions, in order to create a high-quality, biocompatible model of the rib cage. Cardiothoracic surgeon Ira Goldsmith explained that one of the main benefits of using a 3D printed prosthesis is that it can be completely customized and tailored to the patient. And he proved it, offering Maggs a fast and efficient solution.

Cardiothoracic surgeon Ira Goldsmith explained that one of the main benefits of using a 3D printed prosthesis is that it can be completely customized and tailored to the patient. And he proved it, offering Maggs a fast and efficient solution.

Flexible Polyamide 3D Printed Implants for Ribs

In 2018, In Bulgaria, Ivaylo Josifov arrived at the hospital with tonsillitis and left with a new 3D-printed rib. A first for the country. Doctors discovered a deformity in his ribs that pressed against the lungs, prompting immediate surgery. And to cure it, in partnership with Polish 3D printer manufacturer 3DGence, doctors have decided to use additive manufacturing. To do this, they first performed a 3D scanner of the patient’s bone and then 3D printed it from flexible polyamide. Thanks to the operation, and the cooperation between 3D printing players and doctors, Ivaylo Josifov is now in good health.

Photo Credit: 3DGence

A Cranial 3D-Printed Implant

Tiffany Cullern is a young woman from Great Britain who suffered the fate of a brain tumor at the age of 20. It was a psammomatous juvenile ossifying fibroma, a benign tumor that had to be removed quickly so that the young woman’s brain was not damaged. So the doctors decided to have Tiffany undergo a 6-hour operation to remove the tumor. Although the operation went well, the girl did not respond two days later: her brain was swollen. In order to reduce the pressure, the doctors, therefore, had to remove part of the skull and the British woman had to live with 12.7 cm fewer skulls for the first three weeks after the operation. She was then implanted with a 3D-printed implant made of titanium, plastic, and calcium that has since replaced the missing part of the skull.

It was a psammomatous juvenile ossifying fibroma, a benign tumor that had to be removed quickly so that the young woman’s brain was not damaged. So the doctors decided to have Tiffany undergo a 6-hour operation to remove the tumor. Although the operation went well, the girl did not respond two days later: her brain was swollen. In order to reduce the pressure, the doctors, therefore, had to remove part of the skull and the British woman had to live with 12.7 cm fewer skulls for the first three weeks after the operation. She was then implanted with a 3D-printed implant made of titanium, plastic, and calcium that has since replaced the missing part of the skull.

Partially 3D-Printed Cartilage Implant to Fight Osteoarthritis

In humans and dogs, a tiny layer of cartilage preserves joint surfaces and allows bones to glide together properly. Unfortunately, over time, this cartilage breaks down, resulting in osteoarthritis and therefore joint pain. To overcome this, researchers at North Carolina State University developed a textile-based implant containing cartilage derived from the patient’s stem cells.:quality(80)/images.vogel.de/vogelonline/bdb/1612700/1612740/original.jpg) Partly 3D printed, this type of implant has been successfully tested on a group of dogs with hip problems. This group was split into two, and one part received the implant and the other did not. As you can imagine, the dogs that received the implant recovered to their full potential 4 months after the operation.

Partly 3D printed, this type of implant has been successfully tested on a group of dogs with hip problems. This group was split into two, and one part received the implant and the other did not. As you can imagine, the dogs that received the implant recovered to their full potential 4 months after the operation.

Photo Credit: Deposiphoto

What did you think of these 3D-printed medical implants? If you want to share some more we might have missed, you can leave a comment in the section below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Spinal implant fabrication using EP-M250 metal 3D printer

May 27, 2020

subscribe subscribe

As additive manufacturing technologies continue to evolve, so do their applications and availability. While rapid prototyping and tooling has always been at the forefront, the ultimate goal was to be able to apply 3D printing to industry. The medical world is no exception. After the first application of 3D printing in the field of medicine was prototypes and templates, technology has finally reached the ability to create customized implants using modern 3D printers.

The medical world is no exception. After the first application of 3D printing in the field of medicine was prototypes and templates, technology has finally reached the ability to create customized implants using modern 3D printers.

SHINING 3D has always remained true to its vision of making customized 3D solutions accessible to everyone. With the latest line of metal 3D printers, SHINING 3D has caught the attention of partners in the medical field who are now using this technology on an incredible scale. One of the pioneers who are paving the way in the creation and use of medical implants is Mantiz.

Mantiz is a manufacturer of medical devices using advanced technical solutions and technologies to ensure a pain-free and active life for all patients with diseases of the spine. The company has received KFDA (Medical Device Approval) certification and is listed on HIRA (Health Insurance Review and Assessment) in South Korea. In 2018, with government approval and funding, Mantiz began developing 3D printed cage implants. May 20191st, the company launched the Partner cage 3D printing system for posterior/transforaminal/oblique lateral/anterior lumbar interbody fusion surgery. The entire process of manufacturing the form of implants is carried out in Mantiz independently. The ability to avoid having to outsource the manufacturing process to a third party saves time, money and reduces the possibility of manufacturing errors.

In 2018, with government approval and funding, Mantiz began developing 3D printed cage implants. May 20191st, the company launched the Partner cage 3D printing system for posterior/transforaminal/oblique lateral/anterior lumbar interbody fusion surgery. The entire process of manufacturing the form of implants is carried out in Mantiz independently. The ability to avoid having to outsource the manufacturing process to a third party saves time, money and reduces the possibility of manufacturing errors.

Cage is a specially designed intervertebral disc replacement placed between the vertebrae to support the spine. Represents a structure for implantation in the form of a small hollow cylinder with many holes. Manufactured from titanium, ceramic, high performance PEEK polymer and filled with an osteoinductive material. It is used in surgery for stabilization and fusion of the vertebral bodies. In the treatment of diseases of the spinal column, a worn-out intervertebral disc is replaced with a cage. This operation is called "interbody fusion".

This operation is called "interbody fusion".

Mantiz uses SHINING 3D's EP-M250 Metal 3D Printer to produce titanium 3D printed cages for use in implant surgery. Cages are designed to specification: size, material, shape and porosity are all vital to implant performance. The finished cage design is loaded into the printer software where it is prepared for printing. Using the entire construction area of the EP-M250 3D printer, more than 50 individual implants can be produced in one printing operation. After implantation, the surrounding bone and muscle tissues begin to fuse with the implant, creating a strong structure in the patient's spine.

Industrial Metal 3D Printer EP-M250

“We have completed the development of a more advanced 3D printed titanium cage using the EP-M250 metal 3D printer. The results of mechanical tests confirm the safety and functionality of our implants. The average closed porosity of a solid titanium 3D printed part is 3%.

This leads to accelerated attachment of proteinaceous and mesenchymal stem cells for bone fusion,"

says Hongwon Yoon, inventor of the Partner 3D printing system and CTO of Mantiz.

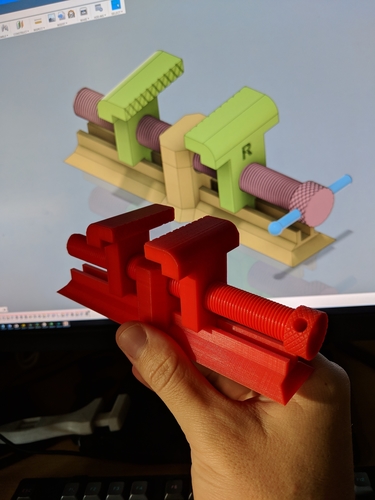

The whole process from design to printing and from printing to implantation can be seen in the images below.

Design and 3D printing process: cage implant design in professional CAD software

Part preparation in 3D printing software

Use 3D printer for EP-M250 metal from ShINING 3D

Process Metal in 3D printer

created using 3D printing Cage

Only after a series of mechanical tests, the 3D printed cage can be used in surgery

After completing the complete design - 3D printing - post-processing - testing cycle, Partner can be used in a surgical operation.

Partner is currently being used in the treatment of patients

Partner is currently being used in the treatment of patients Thanks to 3D printing capabilities, the Partner titanium cage (medium porosity) has been successfully used to optimize bone ingrowth in spinal surgery with an average pore size of 630–730 µm on the surface in contact with the end plate vertebral body, and the average range of porosity of the mesh parts is 70–80%.

Partner Mesh made on EP-M250 3D printer under microscope

The universe of 3D printing is rapidly expanding, and as technologies improve, so do their applications. The ability to manufacture custom parts in-house has never been so accessible. The automotive, aerospace, and medical industries are currently using 3D printing in manufacturing, and in this post, we've only scratched the surface of what additive technologies are capable of. Dipol specialists are ready to share additional information on how 3D printing can be applied in everyday work.

Bone implants are printed by the printer - news from the National Medical Research Center of Radiology

home

News

Branch news

In the department of prognosis of the effectiveness of conservative treatment of the MNII named after. P.A. Herzen - a branch of the Federal State Budgetary Institution "NMITs Radiology" of the Ministry of Health of Russia, two new types of material for bone-replacing implants are being tested. With their help, a breakthrough in the treatment of various infections and tumor lesions of the bone tissue will be provided to a large extent.

- Jointly with the Institute of Metallurgy and Materials Science. A.A. Baikov, Russian Academy of Sciences and the Faculty of Materials Science, Moscow State University. M.V. Lomonosov, we are actively developing a new medical technology for 3D printing of personalized functionalized bone-replacing implants (CBI), - says Professor N.S. Sergeeva, head of the department for predicting the effectiveness of conservative treatment, P. A. Herzen - a branch of the Federal State Budgetary Institution "NMITs Radiology" of the Ministry of Health of Russia.

A. Herzen - a branch of the Federal State Budgetary Institution "NMITs Radiology" of the Ministry of Health of Russia.

- The uniqueness of the project is that the technology of 3D printing of bone-replacing implants allows them to be manufactured individually in accordance with the volume and shape of the bone defect of a particular patient by converting CT analysis data into an STL format for a printer.

Currently, two fundamentally different approaches for prototyping have been created to replace bone defects: extrusion printing and stereolithographic printing. Materials scientists from the Institute of Metallurgy and Materials Science have developed complex compositions of sodium alginate/gelatin/calcium phosphates as "ink" for extrusion 3D printing of bone-replacing implants, which have successfully passed the stage of preclinical trials at the Moscow Research Institute of Orthopedics. P.A. Herzen.

Colleagues from the Faculty of Sciences and Materials of Moscow State University named after M. V. Lomonosov proposed implants based on tricalcium phosphate ceramics (β-Ca3(PO4)2, β-TCP) with bimodal porosity. Most of the pores of this model provide active ingrowth of one's own bone into the implant and the presence of blood flow in the newly formed bone tissue. The other part of the pores of the ceramic scaffold provide the necessary relief and increase its total surface for effective drug adsorption on the surface and in the pores of the ceramic scaffold.

V. Lomonosov proposed implants based on tricalcium phosphate ceramics (β-Ca3(PO4)2, β-TCP) with bimodal porosity. Most of the pores of this model provide active ingrowth of one's own bone into the implant and the presence of blood flow in the newly formed bone tissue. The other part of the pores of the ceramic scaffold provide the necessary relief and increase its total surface for effective drug adsorption on the surface and in the pores of the ceramic scaffold.

In other words, a “charged” implant is implanted into the patient, which contains the necessary medicinal components for subsequent treatment in an “automatic mode” inside the bone itself. The pores of this scaffold model are created using a special mode of heat treatment and sintering printed on a 3D printer.

The task of our biologists is to check the material for biocompatibility with living cells, non-toxicity, the rate of resorption of the artificial material in the bone, the ratio of macro- and micro-sized pores, the mechanical strength of the structure, which should be sufficient to maintain the structure of the bone tissue during the transition period.

Functionalization is one of the leading trends in modern biomaterials science. This term means giving a bone-replacing implant, along with the known osteoconductive/osteoinductive properties, additional characteristics that can significantly expand their therapeutic potential.

For example, to create a bone-replacing implant with antibacterial or antitumor specific activity and prolonged release kinetics at the site of the defect. In other words, such an implant can be charged with the necessary drugs and properties. When discussing the course of testing, the director of the P.A. Herzen, Academician of the Russian Academy of Sciences A.D. Kaprin expressed the idea to include radionuclides in this list of medicinal charges, thus expanding the range of possibilities for the new invention of Russian scientists through the possibilities of nuclear medicine.

The technology of 3D printing of functionalized bone-replacing implants will be in demand in oncology for patients with primary or metastatic bone lesions.