3D printing organic chemistry

All 3D printing articles | Chemistry World

-

Research

Quantum dot matrix printer creates 3D structures

2022-09-08T08:30:00Z

Nanocrystals used as 3D printer ink, without the need for an organic matrix

-

Feature

3D printing adds another dimension

2022-05-23T09:16:00Z

Nina Notman learns how 4D printing is opening the door to unique smart materials whose applications may only be limited by our imaginations

-

Research

3D-printed ‘digital ivory’ saves antique artworks – and maybe elephants

2021-05-11T08:30:00Z

‘Digory’ will be invaluable for restoration projects, and could help prevent ivory poaching that threatens the survival of wild elephants

-

Research

Coffee pods and 3D printing combine to create cheap and quick Covid-19 tests

2021-04-12T13:30:00Z

Repurposed aluminium capsules enable a point-of-care test ideal for remote and low-income settings

-

Research

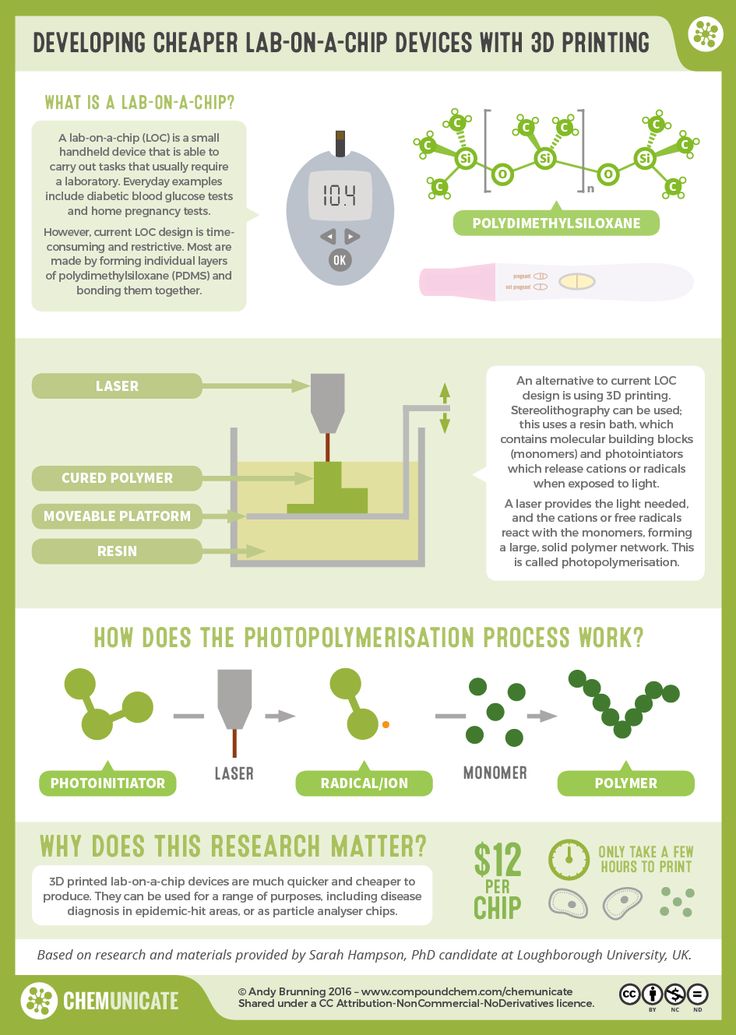

Hybrid resin offers new dimension in flow reactor printing

2021-01-08T09:13:00Z

New resin enables chemical resistance, UV transparency and the potential for surface functionalisation

-

Opinion

Fit to 3D print

2020-02-24T14:54:00Z

Construction from the bottom up has benefits but users must proceed with caution

-

Feature

3D printing the future

2020-02-24T09:46:00Z

Kit Chapman takes a tour of a US Department of Energy lab, where 3D printing is performed on a massive scale

-

Research

Warning that 3D printing pills can stop drugs working

2020-02-03T14:30:00Z

Photoreactive monomers need close scrutiny for production of polypills

-

Business

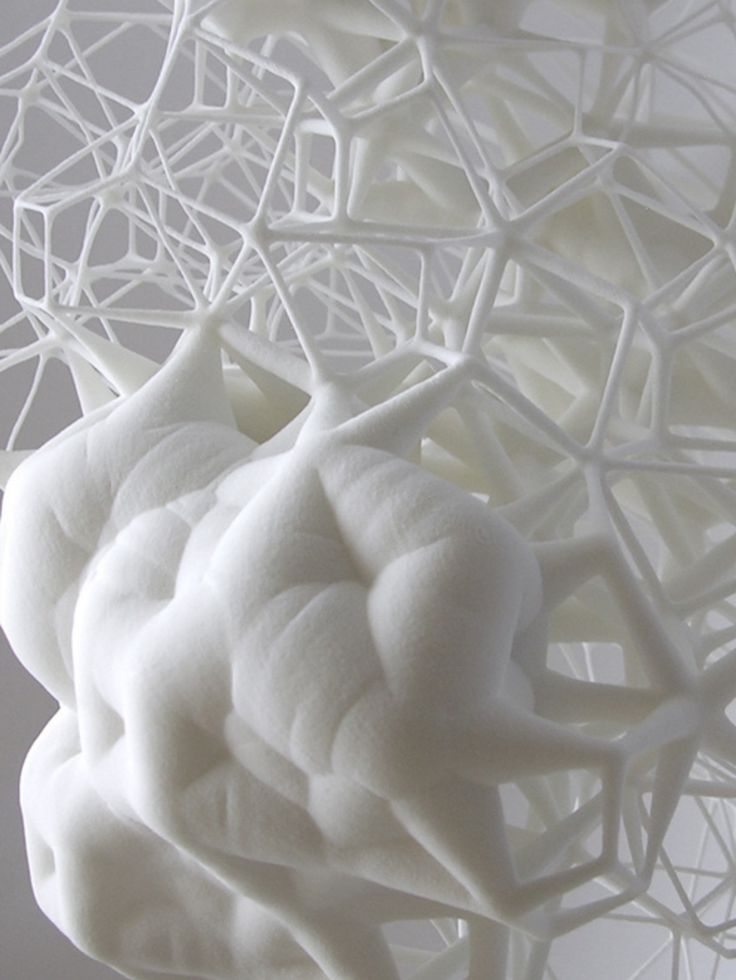

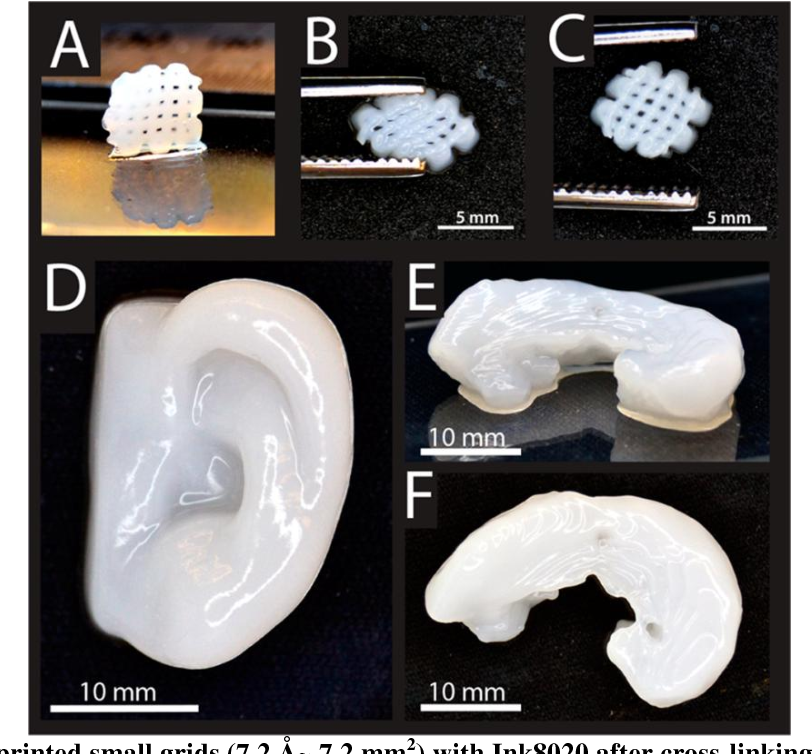

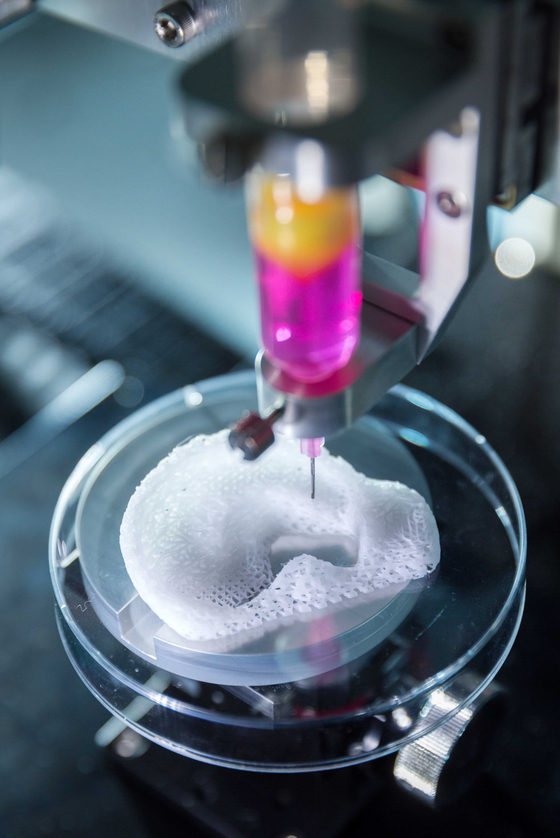

Tissue scaffolds from resin inks

2019-12-20T09:28:00Z

4D Medicine’s biodegradable polymer inks can be 3D-printed into useful biomedical applications

-

Research

High-resolution 3D printing shows promise for lab glassware

2019-11-12T14:30:00Z

New technique that uses phase-separating resins could help in the 3D printing of reactionware

-

Research

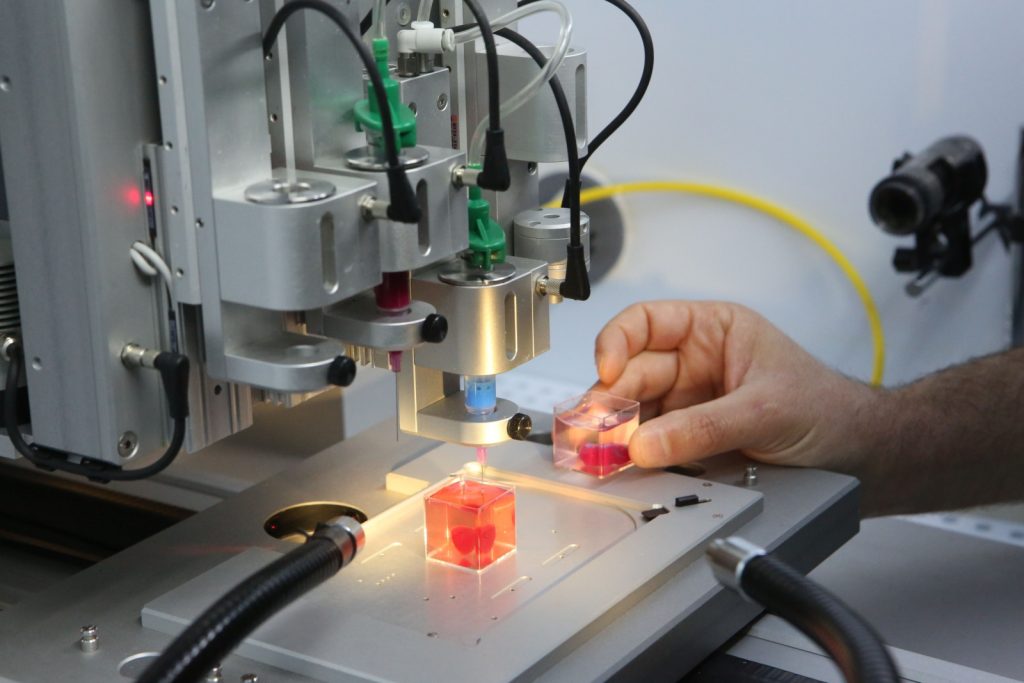

Microgel supports 3D printing technique that builds organs out of stem cells

2019-07-05T10:14:00Z

Internal scaffolds made redundant from tissue engineering process

-

Careers

Making matters: the story of PrintCity

2019-07-04T12:00:00Z

How a 3D printing research centre was built from the bottom up

-

Research

Food colouring paves the way for 3D-printed organs

2019-05-07T14:30:00Z

Tatrazine could overcome biocompatibility problems of printed tissues

-

Research

Reverse gear makes metamaterial stand out

2019-04-09T14:29:00Z

Printed material goes from stiff to soft and back again

-

Research

Doing away with membranes from the chloralkali process

2019-03-22T10:00:00Z

Cost-effective and scalable electrochemical cells rely on inertial separation mechanism, rather than membranes, to keep products separate

-

Research

Printer uses light to carve 3D sculptures out of liquid

2019-01-31T19:00:00Z

CAT scan-inspired printer produces whole objects in seconds

-

Research

Colour changing cup printed using gold nanoparticle ink

2018-10-31T12:03:00Z

Infusing PVA with dichroic nanoparticles gives 3D printed objects interesting optical properties

-

Research

Serrated tail helps microrobot push enormous load

2018-09-10T09:34:00Z

3D-printed catalytic channels furnish microrobot with enough strength to steer object 6500 times its own weight

-

Feature

3D printing in pharma

2018-04-27T10:30:00Z

Nina Notman explores how 3D printing is carving out a niche for itself in the pharmaceutical industry

-

Research

‘Ikea reactionware’ promises to democratise organic chemistry

2018-01-18T19:00:00Z

3D-printed modular reactor that ‘a child could use’ makes a drug in 40 hours

This 3D printer for small molecules might change organic chemistry forever

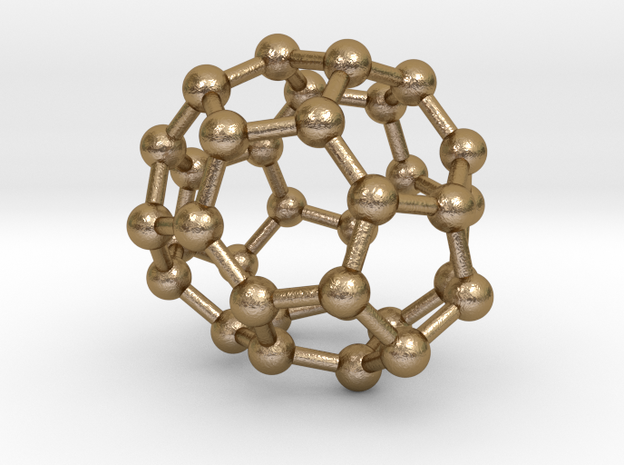

At his lab at the University of Illinois at Urbana-Champaign, Dr. Martin Burke laid the foundation for what he simply calls “The Machine” – an automated small molecule synthesizer that’s set to change the way chemists assemble chemicals forever. It’s like a 3D printer, only for molecules. Starting with some basic chemicals, which Burke and colleagues separate into blocks, the machine assembles all sorts of molecules in a modular fashion, like pinning Lego bricks. Hours and hours of toiling in the lab might now be dedicated to more important business, and molecules yet to be synthesized can now be attempted. These small molecules hold tremendous potential in medicine, but technology is also sure to exploit the machine – anything from LEDs to solar cells.

The machine that builds molecules

Credit: Burke, ScienceSmall molecules and polymers are common components in medicine, food, cosmetics, pesticides, narcotics and research reagents. They can also be found in the human body and in the environment.Small, chemically manufactured molecules (or SMOLs for short) are the classic active substances and still make up over 90 percent of the drugs on the market today. One example is acetylsalicylic acid (ASA), aspirin’s active ingredient with a molecular weight of about 180 g/mol. These small molecules can be processed into easily ingestible tablets or capsules. If the tablet dissolves in the gastrointestinal tract, the dissolved active substance is absorbed into the bloodstream via the intestinal wall. From there, the small molecules can reach almost any desired destination in the body because of their tiny size. Their small structure and chemical composition often also helps them to easily penetrate cell membranes.

One example is acetylsalicylic acid (ASA), aspirin’s active ingredient with a molecular weight of about 180 g/mol. These small molecules can be processed into easily ingestible tablets or capsules. If the tablet dissolves in the gastrointestinal tract, the dissolved active substance is absorbed into the bloodstream via the intestinal wall. From there, the small molecules can reach almost any desired destination in the body because of their tiny size. Their small structure and chemical composition often also helps them to easily penetrate cell membranes.

At the same time, these small small molecules are also very difficult to synthesize. You need a lot of time, going from reaction to reaction which often can involve hundreds of steps and, usually, highly trained personnel is required. The Machine is different. It does all the dirty work for you, providing it has the process uploaded in its software, and almost anyone can do it – even chemistry neophytes.

ADVERTISEMENT

“A lot of great medicines have not been discovered yet because of this synthesis bottleneck,” he says.

With his new technology, Burke aims to change that. “The vision is that anybody could go to a website, pick the building blocks they want, instruct their assembly through the web, and the small molecules would get synthesized and shipped,” Burke says. “We’re not there yet, but we now have an actionable roadmap toward on-demand small-molecule synthesis for non-specialists.”

Nature is very good at building small molecules, but so far chemists’ efforts aimed at mimicking these processes have proven slow or, more often than not, impossible with current tech. Plants, animals, and microbes manufacture many small molecules with protein-like functions, and with some precise chemical modifications. The machine could assemble these sort of small molecules without the need for proteins.

Credit: Burke, ScienceFirst the machine breaks down very complex molecules into their basic chemical building blocks then induces a chemical reaction and washes away the reaction’s byproducts—slowly building each molecule from the ground up. Using this process the machine can utilize over 200 different building blocks along with thousands of other molecules to ‘print’ billions of different organic compounds, many of which make up 14 classes of small molecules, including the ratanhine molecule family.

Using this process the machine can utilize over 200 different building blocks along with thousands of other molecules to ‘print’ billions of different organic compounds, many of which make up 14 classes of small molecules, including the ratanhine molecule family.

“Doing real atomistic modifications to transform nature’s starting points into actual medicines is really, really challenging. The slow step in most cases in the synthesis. As a result, many natural products don’t get worked on in any practical way.”

“Nature makes most small molecules the same way,” Burke says. “There are a small number of building blocks that are coupled together over and over again, using the same kind of chemistry in an iterative fashion.” That means small molecules are inherently modular. So when Burke’s team analyzed the chemical structures of thousands of different natural products, patterns emerged. “There are building blocks that appear over and over again, and we’ve been able to dissect out the building blocks that are most common,” he says.

Burke has now founded a company called Revolution Medicines to further scale his project and receive funding. The company already is working to improve upon an anti-fungal compound known as Amphotericin B, which is found in nature and used to treat patients with life-threatening fungal infections. Check out this awesome interview with Dr. Burke below.

“Perhaps most exciting, this work has opened up an actionable road map to a general and automated way to make most small molecules,” stated Burke. “If that goal can be realized, it will help shift the bottleneck from synthesis to function and bring the power of making small molecules to nonspecialists….A 3D printer for molecules could allow us to harness all the creativity, innovation, and outside-the-box thinking that comes when non-experts start to use technology that used to only be in the hands of a select few.”

ADVERTISEMENT

Tags: 3d printersmall moleculeUniversity of Illinois at Urbana-Champaign

Reactors for photochemistry will be printed on a 3D printer directly in the laboratory and in one day

April 8, 2022, 1:00

3D printing

New techniques

Photochemistry

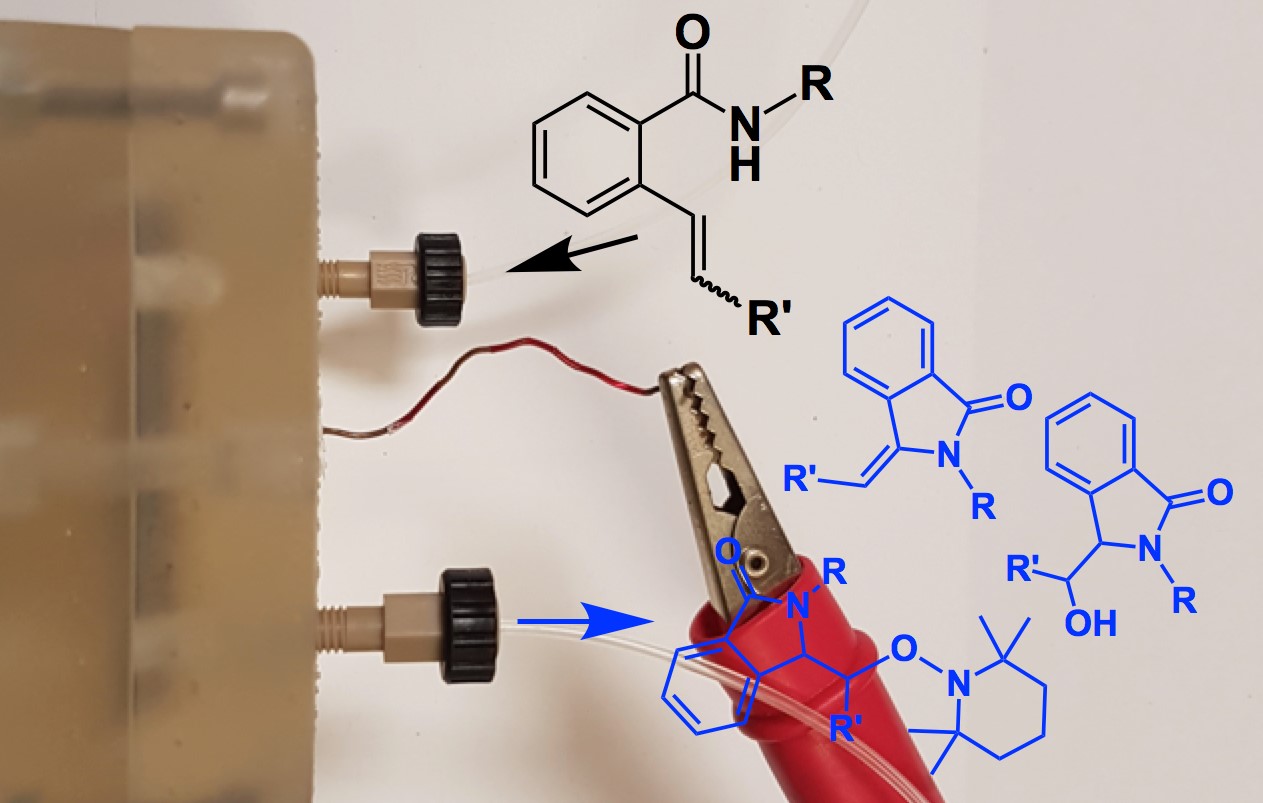

, or 3D printing, to make photoreactors for fine organic synthesis in the laboratory. The devices allow a number of important reactions to be carried out that require a stable temperature and irradiation with light of a certain wavelength. The development of this approach will help speed up and reduce the cost of introducing unique equipment into scientific practice.

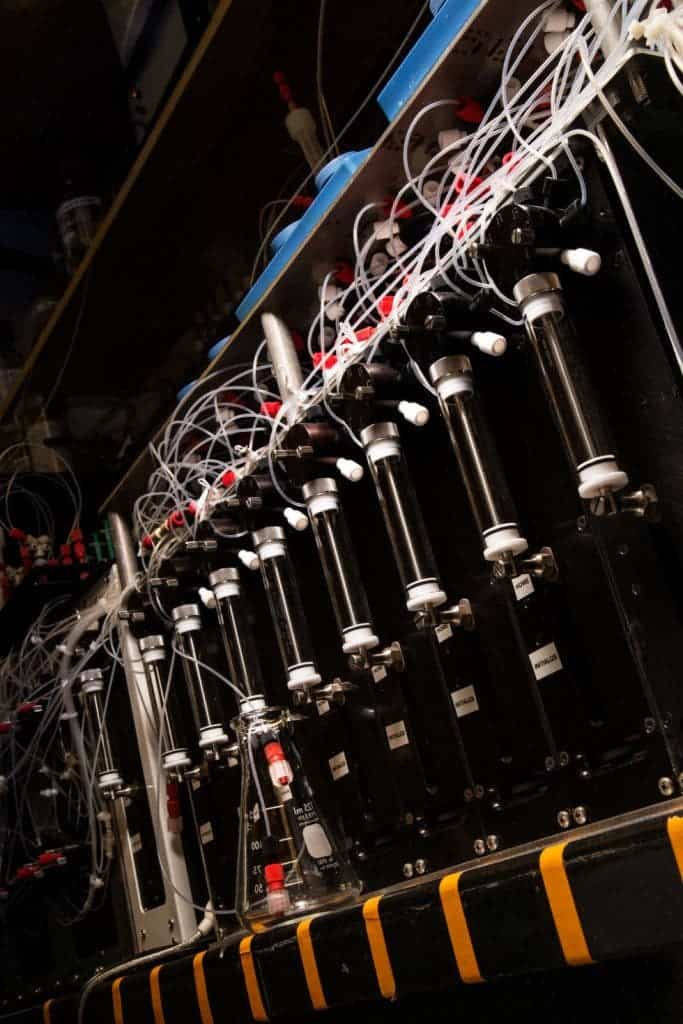

Model illustrating the simultaneous performance of several experiments using compact metal photoreactors (left) and the photochemical synthesis of a large amount of material in a laboratory-fabricated thermoplastic polymer fusing reactor (right)

Source: Evgeny Gordeev

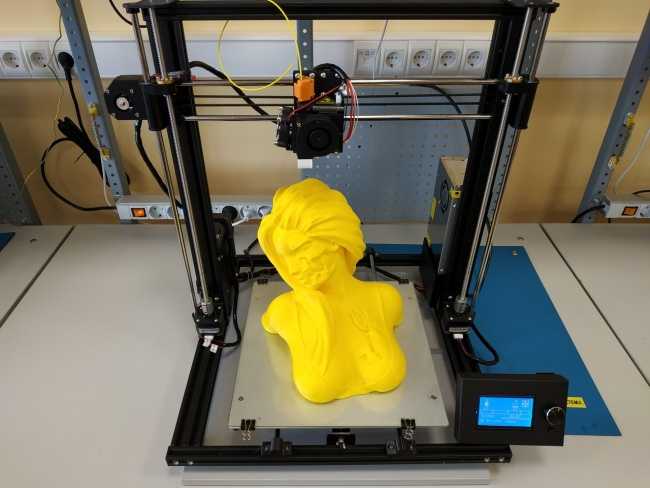

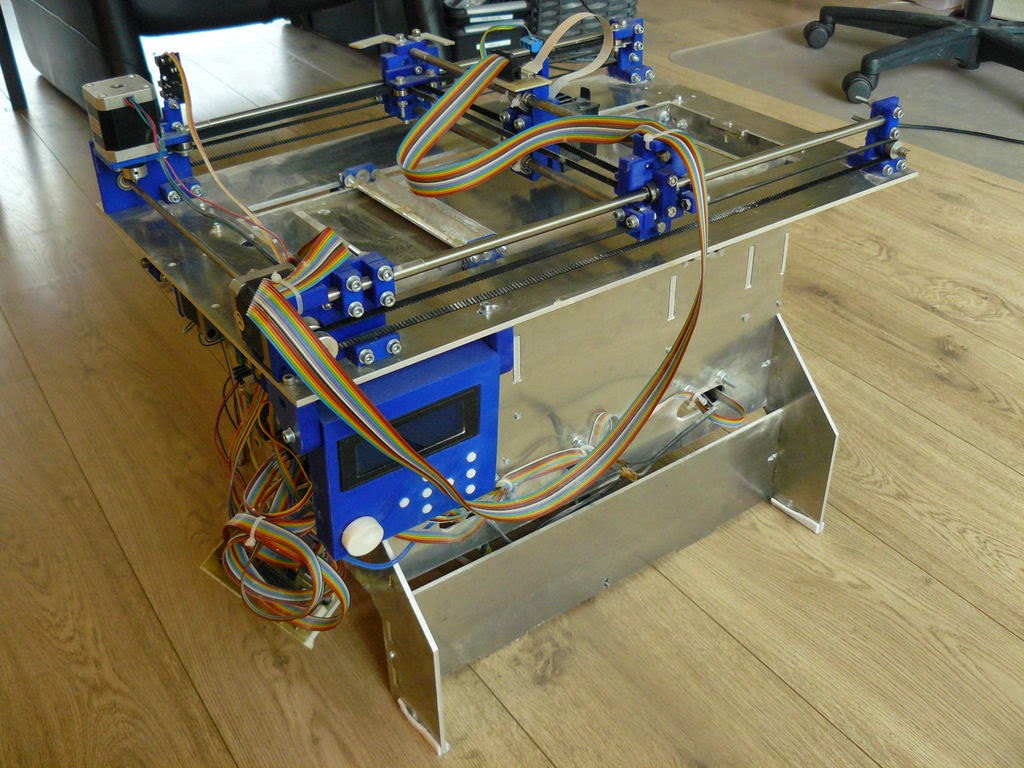

Additive manufacturing methods, known as 3D printing, are actively used in many areas of mechanical engineering, medicine, science and education. Today it is difficult to find a sphere of material production in which there would be no effective application of 3D printing. The huge potential of additive methods is due to their high versatility, almost complete wastelessness, variety of structural materials used and, in many cases, relative ease of use that does not require special engineering skills.

Today it is difficult to find a sphere of material production in which there would be no effective application of 3D printing. The huge potential of additive methods is due to their high versatility, almost complete wastelessness, variety of structural materials used and, in many cases, relative ease of use that does not require special engineering skills.

Russian scientists from the N. D. Zelinsky Institute of Organic Chemistry of the Russian Academy of Sciences (Moscow) have successfully implemented 3D printing in the scientific work of a chemical laboratory. A team of young researchers from the Laboratory of Metal Complex and Nanoscale Catalysts, led by Academician Valentin Ananikov, designed and manufactured compact universal photoreactors for fine photochemical synthesis, which makes it possible to obtain a number of valuable organic compounds. The reactors were fabricated by selective sintering of metal powder and fusing of thermoplastic polymer material. The first approach makes it possible to obtain complex products from a variety of metal alloys, while the second approach has proven to be an inexpensive and efficient way to produce products from a variety of thermoplastic plastics and compositions based on them.

The photoreactors obtained in the project have a number of advantages over traditional photochemical equipment: they can be adapted to light sources of different wavelengths, are characterized by low cost, especially when using plastics, and allow for quick changes to the design. The last feature is one of the fundamental advantages of 3D printing: a reactor with a new, more optimal design can be manufactured directly in a chemical laboratory within one working day and immediately tested in an experiment.

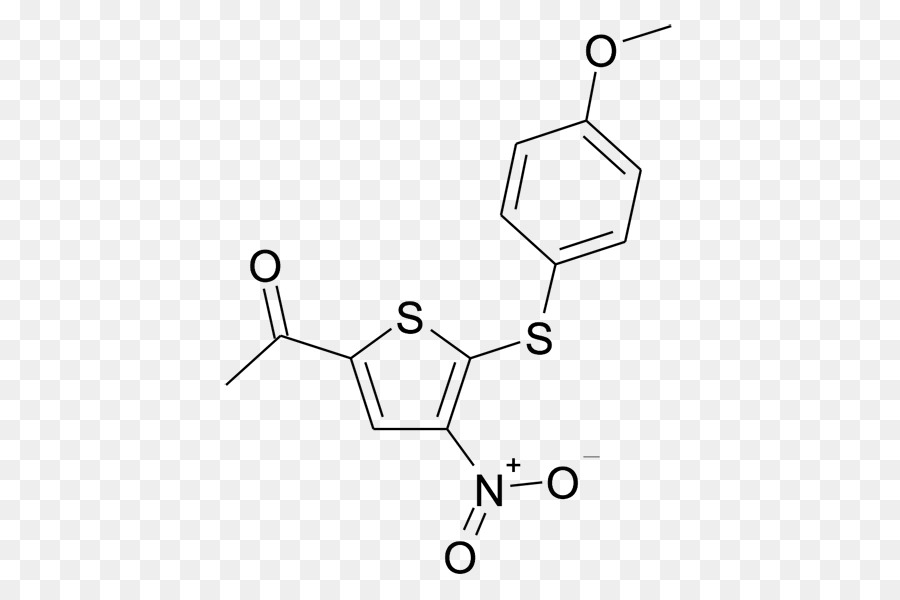

The authors have shown that stainless steel metal reactors can be used for serial experiments with various chemical substrates or photocatalysts. Photoreactors made of plastic, which differ from metal photoreactors in a significantly larger volume, make it possible to scale up organic synthesis to obtain products in significant quantities. Both types of reactors can maintain a given temperature, which is important for increasing the yield and selectivity of chemical synthesis, i. e., the target product will be formed in the process, rather than side compounds. The effectiveness of the new equipment was demonstrated using a number of critical chemical reactions for the formation of carbon-carbon and carbon-sulfur bonds.

e., the target product will be formed in the process, rather than side compounds. The effectiveness of the new equipment was demonstrated using a number of critical chemical reactions for the formation of carbon-carbon and carbon-sulfur bonds.

« We expect our development to become part of everyday laboratory practice in the near future. Additive manufacturing opens up great opportunities for creating new chemical equipment directly in the chemical laboratory ,” says Yulia Burykina, project manager under the grant, Ph.D.

Source: RNF press service

Profiles of scientists from the news

Organizations from the news

Publications from the news

By date

By citation

Exploring metallic and plastic 3D printed photochemical reactors for customizing chemical synthesis

Gordeev E. G., Erokhin K.S., Kobelev A.D., Burykina J.V., Novikov P.V., Ananikov V.P.

G., Erokhin K.S., Kobelev A.D., Burykina J.V., Novikov P.V., Ananikov V.P.

Q1 scientific reports, 2022, citations: 0 ,

open access

Share

Fresh

Reactors for photochemistry will be printed on a 3D printer directly in the laboratory and in one day

892

Bookmark

Russian chemists demonstrated how to make photoreactors for fine organic synthesis in the laboratory using additive technologies, or 3D printing. The devices allow a number of important reactions to be carried out that require a stable temperature and irradiation with light of a certain wavelength. The development of this approach will help speed up and reduce the cost of introducing unique equipment into scientific practice. The results of the project, supported by a grant from the Russian Science Foundation (RSF), are published in Scientific Reports.

The devices allow a number of important reactions to be carried out that require a stable temperature and irradiation with light of a certain wavelength. The development of this approach will help speed up and reduce the cost of introducing unique equipment into scientific practice. The results of the project, supported by a grant from the Russian Science Foundation (RSF), are published in Scientific Reports.

Model illustrating the simultaneous performance of several experiments using compact metal photoreactors (left) and the photochemical synthesis of a large amount of material in a laboratory-fabricated thermoplastic polymer fusing reactor (right). Source: Evgeny Gordeev

Additive manufacturing methods, known as 3D printing, are actively used in many areas of engineering, medicine, science and education. Today it is difficult to find a sphere of material production in which there would be no effective application of 3D printing. The huge potential of additive methods is due to their high versatility, almost complete wastelessness, variety of structural materials used and, in many cases, relative ease of use that does not require special engineering skills.

Russian scientists from the Institute of Organic Chemistry named after N.D. Zelinskiy RAS (Moscow) successfully implemented 3D printing in the scientific work of the chemical laboratory. A team of young researchers from the Laboratory of Metal Complex and Nanoscale Catalysts, led by Academician Valentin Ananikov, designed and manufactured compact universal photoreactors for fine photochemical synthesis, which makes it possible to obtain a number of valuable organic compounds. The reactors were fabricated by selective sintering of metal powder and fusing of thermoplastic polymer material. The first approach makes it possible to obtain complex products from a variety of metal alloys, while the second approach has proven to be an inexpensive and efficient way to produce products from a variety of thermoplastic plastics and compositions based on them.

The photoreactors obtained in the project have a number of advantages over traditional photochemical equipment: they can be adapted to light sources of different wavelengths, are characterized by low cost, especially when using plastics, and allow for quick changes to the design. The latter feature is one of the fundamental advantages of 3D printing: a reactor with a new, more optimal design can be manufactured directly in a chemical laboratory within one working day and immediately tested in an experiment.

The latter feature is one of the fundamental advantages of 3D printing: a reactor with a new, more optimal design can be manufactured directly in a chemical laboratory within one working day and immediately tested in an experiment.

The authors have shown that stainless steel metal reactors can be used for serial experiments with various chemical substrates or photocatalysts. Photoreactors made of plastic, which differ from metal photoreactors in a significantly larger volume, make it possible to scale up organic synthesis to obtain products in significant quantities. Both types of reactors can maintain a given temperature, which is important for increasing the yield and selectivity of chemical synthesis, i.e., the target product will be formed in the process, rather than side compounds. The effectiveness of the new equipment was demonstrated using a number of critical chemical reactions for the formation of carbon-carbon and carbon-sulfur bonds.

« We expect our development to become part of everyday laboratory practice in the near future. Additive manufacturing opens up great opportunities for the creation of new chemical equipment directly in the chemical laboratory ,” says Yulia Burykina, project manager under the grant, Candidate of Chemical Sciences, leading researcher at the N.D. Zelinskiy RAS.

Additive manufacturing opens up great opportunities for the creation of new chemical equipment directly in the chemical laboratory ,” says Yulia Burykina, project manager under the grant, Candidate of Chemical Sciences, leading researcher at the N.D. Zelinskiy RAS.

Information and photos provided by the press service of the Russian Science Foundation

Posted by Irina Usik

3D printing IOC RAS photoreactors

Information provided by the Information Agency "Scientific Russia". Mass media registration certificate: IA No. ФС77-62580, issued Federal Service for Supervision of Communications, Information Technology and Mass Communications on July 31, 2015.

SCIENCE CHILDREN

Valery Kozlov was re-elected Academician-Secretary of the Department of Mathematical Sciences of the Russian Academy of Sciences

13:00 / Mathematics, Science and Society

XVII International Congress "Rational Pharmacotherapy": new times - new opportunities

12:30 / Health, Medicine

Research by Perm Polytechnic University scientists will help prevent equipment breakdowns for oil production

91 :30 / Engineering

Artificial Art: Can AI create a masterpiece?

10:30 / Information technology, New technologies

Birthday of the Minister of Science and Higher Education Valery Falkov

10:00 / Science and Society

10/17/22 — Opening of the conference "Fundamental basis of innovative technologies in the oil and gas industry"

20:30 / Engineering, Geosciences

Record level of accuracy in determining the intensity of molecular spectral lines

18:30 / Physics

US scientists print plant cells on a 3D printer

18:00 / Biology, New technologies

SFedU scientists have proposed a new method for the treatment of bone defects

17:30 / Medicine

Scientists have created a transparent and heavy-duty material for Russian cosmonautics

16:30 / Chemistry

great memory .