Indiegogo 3d printer

Rapide 3D to Launch Indiegogo Campaign for Rapide Lite 200XL This March - 3DPrint.com

Last September, a company called Rapide 3D launched an Indiegogo campaign to fund the Rapide Lite 200 3D printer. It was touted as an ‘affordable high resolution 3D printer’, and was priced at just $999 for early backers. When all was said and done, the campaign raised a total of $329,262, allowing Rapide 3D to begin full scale production.

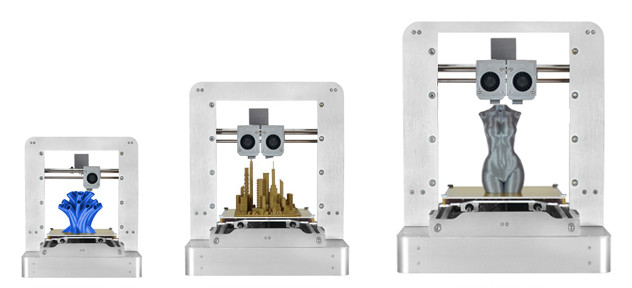

Vase printed on Rapide Lite 200 (left) at max size and one printed on 200XL (right)

Today, Ethan Hunt, CEO of Rapide 3D, has informed 3DPrint.com that they plan to launch yet another Indiegogo campaign for another 3D printer this coming March.

“Following our highly successful campaign on Indiegogo for Rapide Lite 200, we will be going for a second round of funding for our latest creation, the Rapide Lite 200XL, a commercial quality desktop 3D printer with a build height of 400mm,” Hunt tells 3DPrint.com. “The Rapide Lite 200 campaign raised over $300,000 in just over 30 days, and less than 3 months later more than 700 of the 200 version have been delivered to contributors with rave reviews for the quality of build and precision of the printer.

”

The new 3D printer, which offers a massive 16,000 cubic cm build volume, with a footprint of just 350×380 mm, will also be priced starting at just $999 for super early bird contributors. For those who don’t get in early enough, the price will still remain low at just $1199, including shipping.

As for the specifications of the new 200XL, they are as follows:

- Footprint: 360 x 350 x 380mm

- Build Size: 200 x 200 x 400mm

- Build Volume: 16,000cm3

- Control Board: ARM 32bit

- Control Interface: 2.8” Full Color Touch Screen

- Printing Material: PLA, ABS, PVA, HIPPS, Lay, Polymax

- Filament Size: 1.75mm and 3.0mm

- Minimum Layer Height: Up to 50 microns

- Print Speed: Up to 150mm per second

- Material Type: Non- Proprietary ($25kg)

- Mechanism: Core XY

- Positioning Accuracy: 10 micron X and Y

- Total Weight: 15kg (approx)

- Operating System: Window, Mac, Linux

- Print Bed: Precision Heated Aluminum (3mm)

- Connection: USB, SD Card

- LCD Screen: 2.

8” Full Color Touch Screen

8” Full Color Touch Screen - Extruder Type: Rapide 3D Q Extruder

- Number of Extruders: 1 (.04mm)

- X Axis: X Wing Technology

- Chassis: Anodized 5026 Aluminum

- Frame: Anodized 5026 Aluminum

- Components: Anodized 5026 Aluminum

If you are interested in being notified of the launch of the Indiegogo campaign, you can sign up to the Rapide 3D notification email list today.

“The last campaign was highly successful and we expect this one to exceed the last one, based on the fact we delivered on time and with a substantially better printer than first promised,” said Hunt. “The response has been awesome from contributors who are all raving about the print quality and comparing Rapide Lite 200 to many other brands.”

It should be interesting to see how the upcoming campaign performs. Rapide 3D has made quite a good name for themselves with the way in which they handled things with their initial campaign. The Rapide Lite 200 3D printer has proven to be the high quality, affordable printer that they promised. What do you think about this latest 3D printer from Rapide 3D? Will you be backing it when their campaign when it launches in the middle of March? Discuss in the Rapide Lite 200XL forum thread on 3DPB.com.

The Rapide Lite 200 3D printer has proven to be the high quality, affordable printer that they promised. What do you think about this latest 3D printer from Rapide 3D? Will you be backing it when their campaign when it launches in the middle of March? Discuss in the Rapide Lite 200XL forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: crowdfunding • indiegogo • rapide 3d • rapide lite 200 • rapide lite 200xl

Please enable JavaScript to view the comments powered by Disqus.

3ders.org - $99 palm-sized PocketMaker 3D printer launches on Indiegogo

Nov 4, 2016 | By Alec

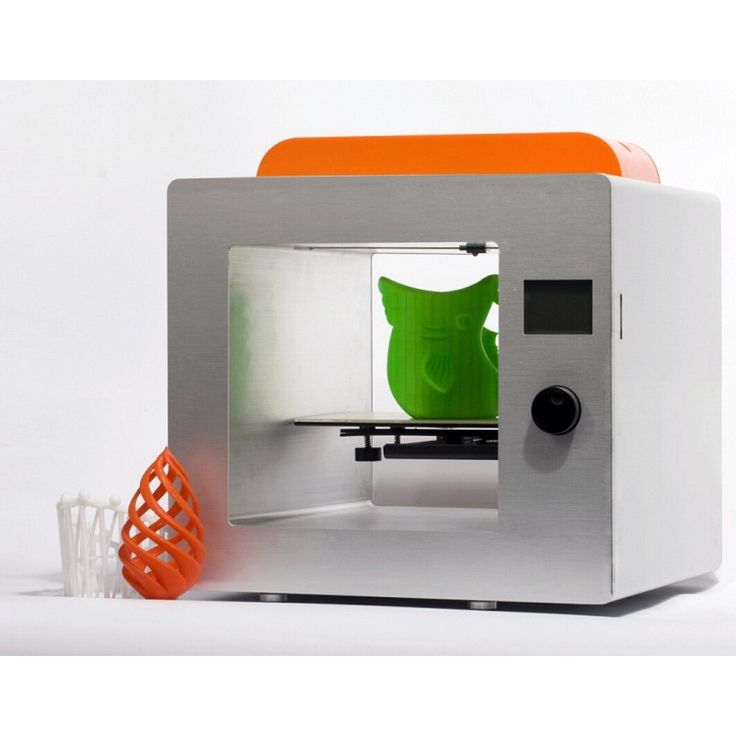

While 3D printers do honestly come in all shapes and sizes, the vast majority of models feature roughly the same desktop size – with size differences usually being negligible. While the dream is always to go bigger and wider to facilitate larger prints and more ambitious projects, there’s a lot to be said for downsizing as well. Aside from the obvious benefit of making your 3D printer extremely portable, it also means 3D printing smaller, more efficient objects and optimally using your build volume. Why be tempted to go bigger if smaller means becoming more efficient? If this sounds appealing, then the palm-sized PocketMaker might be something for you.

Aside from the obvious benefit of making your 3D printer extremely portable, it also means 3D printing smaller, more efficient objects and optimally using your build volume. Why be tempted to go bigger if smaller means becoming more efficient? If this sounds appealing, then the palm-sized PocketMaker might be something for you.

The 3D printer itself has been developed by a team of students from the Central Academy of Fine Arts in Beijing, including engineers Hu Biao and Sun Ran, industrial designer Lang Qiyue and visual designer Xu Shiwen. They have just launched an Indiegogo crowdfunding campaign for this palm-sized piece of hardware, which is true to its name in every way. Just 10.8cm × 12.8cm × 14.2cm in size, it very nearly fits into your pocket – while the $99 price tag means that you could actually afford one using nothing but pocket money. Though if you’re only starting to save up now, it’s good to know that the price will actually be raised to $149 upon the conclusion of the crowdfunding campaign.

What’s more, it looks like the Chinese developers have made the most out of the very small volume that is available to them. A very efficient design means that nearly the entire hardware volume is also the build volume, and the final 8cm × 8cm × 8cm build space can still house quite a list of 3D printing projects. As they revealed, going small and low-cost seemed like a perfect way to bring 3D printing to everyone. “Our mission was to make 3D printing simple and affordable. We redesigned and customized the motor while leaving only the essential structure needed for stable, quality 3D printing to make it truly affordable and completely effortless to use. We know that some point in the future 3D printing must be a part of everyone’s lives,” they say.

What’s more, the actual build platform is removable and bendable, making it very easy to remove 3D printed objects from the plate. Say goodbye to putty knives, ruined prints and filament residue – all you have to do is bend the bed slightly and the print just pops off. The process can be seen in the Indiegogo preview clip visible below. Along with the price tag and build volume, this makes the PocketMaker a perfect educational 3D printer option for kids and classrooms.

The process can be seen in the Indiegogo preview clip visible below. Along with the price tag and build volume, this makes the PocketMaker a perfect educational 3D printer option for kids and classrooms.

This mini-3D printer also supports both PLA and ABS, and works with custom ‘pocket filament’ spools and other standard 1.75 mm spools. “We specially designed pocket PLA filament spools so that people can print with more materials and color choices,” the Chinese developers add. For optimal accessibility, the PocketMaker is further supported by a one-touch-print app and a forthcoming model library.

That level of accessibility is further supported by a clever replaceable nozzle design. Of course nozzle clogging is a common problem that haunts 3D printer users throughout the world, and not something beginning users want to be confronted with. Few teachers and parents would feel comfortable with letting young children deal with clogged nozzles either. In an attempt to overcome this problem, the PocketMaker is compatible with magnetic nozzle modules, that simply slide into place and are replaced in a moment’s notice. Clogging never has to get in the way of 3D printing fun ever again. It’s just another feature that makes the palm-sized PocketMaker 3D printer a very appealing entry-level option. For more, check out the Indiegogo crowdfunding campaign here.

In an attempt to overcome this problem, the PocketMaker is compatible with magnetic nozzle modules, that simply slide into place and are replaced in a moment’s notice. Clogging never has to get in the way of 3D printing fun ever again. It’s just another feature that makes the palm-sized PocketMaker 3D printer a very appealing entry-level option. For more, check out the Indiegogo crowdfunding campaign here.

PocketMaker specifications:

- Print volume: It's a cube, 80 mm (3.15 in) per side.

- It is lightweight, roughly 850g (1.87 lb).

- Replaceable nozzle.

- Removable Print Bed.

- Print accuracy:0.2mm.

- Wireless connection.

- USB-Compatible connection.

- It can be used with Android, iOS, Windows, or Mac.

- Filament: standard 1.75mm. Nearly 160g (0.35lb) rolls.

- Supports many different materials: PLA, ABS, and more.

- Other standard 1.

75 mm filament spools on the market also supported.

75 mm filament spools on the market also supported. - PocketMaker APP for an effortless, plug-and-play experience.

- Supports and uses open source software (for advanced users).

Posted in 3D Printer

Maybe you also like:

- SpiderBot announces ABSolute 2 3D printer capable of printing at a blistering 500°C

- US Marines test Invent3D printer in the field

- Microlay unveils high resolution DLP based DentalFab 3D printer

- Desktop 3D printers drive 14% global 3D printer market growth in first half of 2016

- Sterne Elastomere launches SiO-Shaping 1601 silicone 3D printer, targets medical device sector

- Trumpf to unveil Truprint 3000, a new LMF metal 3D printer at Formnext 2016

- Titan Robotics: new pellet extrusion system makes 3D printing 90% cheaper, 3x faster

- Ultimaker unveils ground-breaking dual-extrusion desktop Ultimaker 3 3D printer

- Meet ONO, the smartphone-powered 3D printer that costs just $99

- Highly anticipated all-metal Trinus 3D printer/laser engraver ready for shipping

- Ilios Beam 3D printer promises high-quality SLA printing for under $2,700

ajith wrote at 2/7/2018 6:27:32 PM:

when it was launching from where to buy hw to proceed

Dinos wrote at 11/6/2016 5:03:58 AM:

This seems, all too familiar and a bit too good to be true. If this 3D printer is genuinely legitimate than I wish it the best of luck.

Ps. I love this awesome site, I visit it nearly every day, Keep up the great work.

If this 3D printer is genuinely legitimate than I wish it the best of luck.

Ps. I love this awesome site, I visit it nearly every day, Keep up the great work.

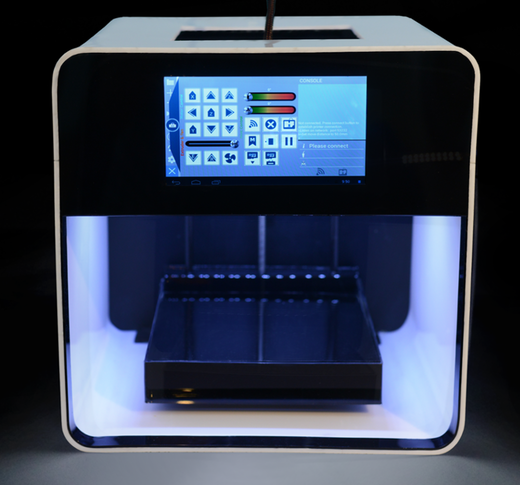

Campaign launched on Indiegogo to support Stalactite 102, a foldable 3D printer powered by DLP technology

Archive

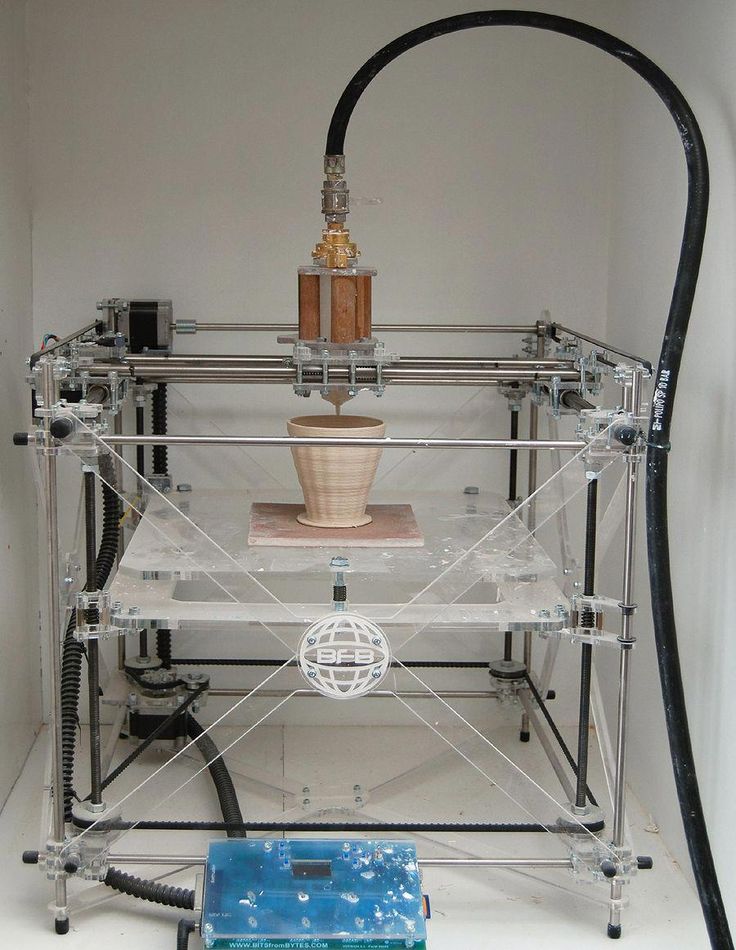

with 3D printers. This time, let's talk about the Stalactite 102 3D printer based on DLP (Digital Light Processing) technology, printing with liquid photopolymer.

DLP projector based printers have become popular in the last few years. With the help of a projector, often used for PowerPoint presentations, such a 3D printer can turn a liquid substance into products with many small details. The projector illuminates the surface of a liquid polymer, which hardens under the influence of radiation with a certain wavelength. So layer by layer appears until the model is ready.

Stalactite, a young company from Barcelona, wants to raise 50,000 euros on indiegogo. For 1850 euros (there are only five printers available) or 1999 euros (for the very first investors) you will receive a fully assembled 3D printer based on SLA (Laser Stereolithography) technology. The Stalactite 102 is a compact, foldable device that anyone can use to bring their ideas to life. The printer comes with a proprietary program for fast model cutting, automatic support and a patented dual cleaning system.

For 1850 euros (there are only five printers available) or 1999 euros (for the very first investors) you will receive a fully assembled 3D printer based on SLA (Laser Stereolithography) technology. The Stalactite 102 is a compact, foldable device that anyone can use to bring their ideas to life. The printer comes with a proprietary program for fast model cutting, automatic support and a patented dual cleaning system.

Specifications:

- Working area: 102 mm x 76.8 mm x 180 mm

- Minimum layer thickness: up to 25 microns

- High resolution X/Y (100 microns in NORMAL mode, 50 microns in FINE mode)

- Machined aluminum and laser-cut steel parts

The company also has its own printed materials. At the time of the printer's launch, four different materials will be on the market at the most affordable prices.

STANDARD: base material, suitable for general purposes.

PROTOTYPING: a material similar in properties to ABS or Nylon plastic. Ideal for making cases for electronic devices and stands for Iphone.

Ideal for making cases for electronic devices and stands for Iphone.

ELASTIC: elastic and flexible resin.

WAXY: is similar in properties to model casting wax. You can resort to the lost wax casting method and cast your product from bronze, silver, gold.

Last October, the STALACTITE 3D printer was among the 10 winning projects that outperformed 5,000 entrants in the HighTech XL Start-Up BootCamp Accelerator competition held in Eindhoven, the Netherlands.

The company plans to ship the printers in August 2014. For more information, check out the Stalactite Campaign page on Indiegogo.

Article prepared for 3DToday.ru

7

Subscribe to the author

Subscribe

Don't want

Volgograd schoolboy Mikhail Kozenko joined the ranks of 3D-makers by designing his own 3D-. ..

..

Read more

5

Subscribe to the author

Subscribe

Don't want

Alexander Gessler wrote a small handy program to convert 40+ 3D file formats (OBJ, S...

Read more

four

Subscribe to the author

Subscribe

Don't want

One of the most promising and least developed areas of 3D printing is bioprinting. Whole a...

Read more

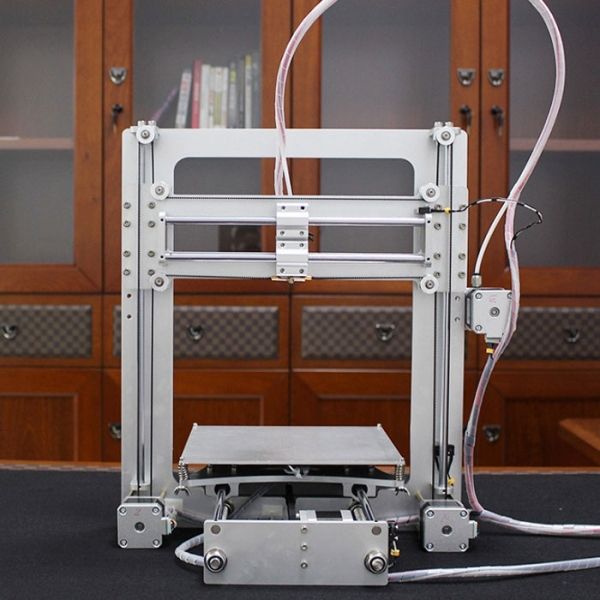

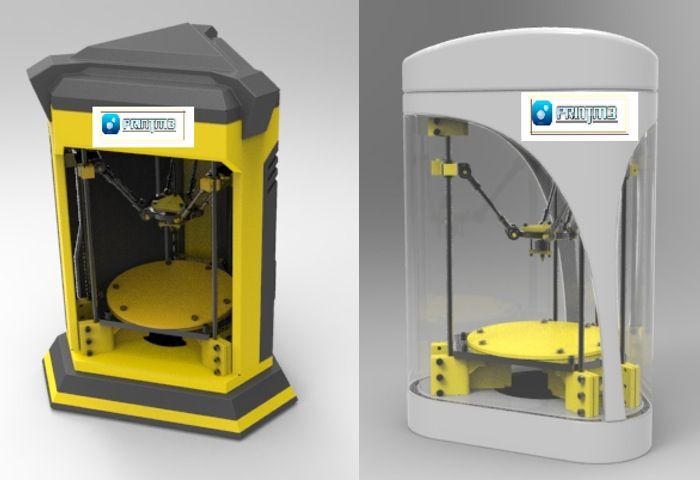

3D printer Maximus XL is looking for sponsors on Indiegogo

Archive

Sign up for

Subscribe

I do not want

1

MYTECHNO3D from Mangle, used by Mikhaele Ipas, used by Mikhaele Ipas. Maximus XL large 3D printer with an incredible 430mm x 330mm x 250mm working volume. Now she wants to raise 20,000 euros on the Indiegogo crowdfunding platform to move on to full-scale production. Ipas claims that the printer prototype performed well. He plans to start producing kits for self-assembly as soon as he collects the required amount. Below are the main features of the Maximus XL 3D printer:

Ipas claims that the printer prototype performed well. He plans to start producing kits for self-assembly as soon as he collects the required amount. Below are the main features of the Maximus XL 3D printer:

- Dimensions: 500 mm x 500 mm x 500 mm

- Working volume: 430 mm x 330 mm x 250 mm

- Electronics: Rambo board and Nema 17 stepper motors

- Fiber type: Nylon, ABS, PLA, Laywood (minimum thickness 0.2 mm)

- Auto leveling function: yes

The creators of the printer offer sponsors two options to choose from. On the one hand, you can invest 875 euros ($1170) and get a complete Maximus XL kit plus a 1kg PLA spool. On the other hand, one can invest 9€50 ($1270) and get a full Maximus XL 3D printer with graphic LCD, Rambo and Raspberry Pi adapter for remote printer access.

Includes the following: electronics, frames, motors, print head, wires and power supply. Ipas also promises free updates to all backers for the first year after purchase. This means that if he decides to improve the design of his device, then all sponsors will have the opportunity to receive new equipment for free (you will only have to pay for shipping).

This means that if he decides to improve the design of his device, then all sponsors will have the opportunity to receive new equipment for free (you will only have to pay for shipping).

The Indiegogo campaign will run until September 24th. Shipping of the first printers is scheduled for October. Below you can see the Maximus XL in action.

Article prepared for 3DToday.ru

Article comments

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

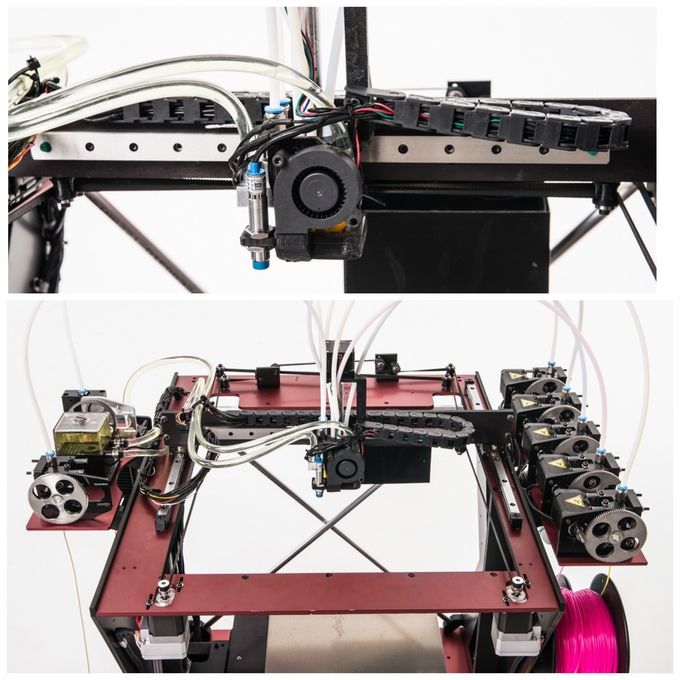

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

If yesterday 3D printing was the lot of boys of different age groups trying to adapt new.