China 3d printer house

3D printed house takes shape in rural China »

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

A rural house in north China’s Hebei Province has been catapulted into fame recently for being the first 3D printed house in this rural area of China, built “scan by scan” with giant construction 3D printers.

With vaulted ceilings and concrete outer walls decorated by weave patterns, Zhao Xiujuan’s house in Wujiazhuang Village of Zhangjiakou, the co-host city for the 2022 Winter Olympics, covers an area of 106 square meters and boasts three bedrooms, a kitchen and a restroom.

When Xu Weiguo, a professor with the School of Architecture under Tsinghua University, came up with the idea of building a 3D printed farmhouse in Wujiazhuang, there was an outpouring of concern from villagers.

“How can a big house be printed?” “Is it strong enough?” Regardless of skepticism from her fellow villagers, Zhao asked Xu and his team to rebuild her old house with 3D printing technology.

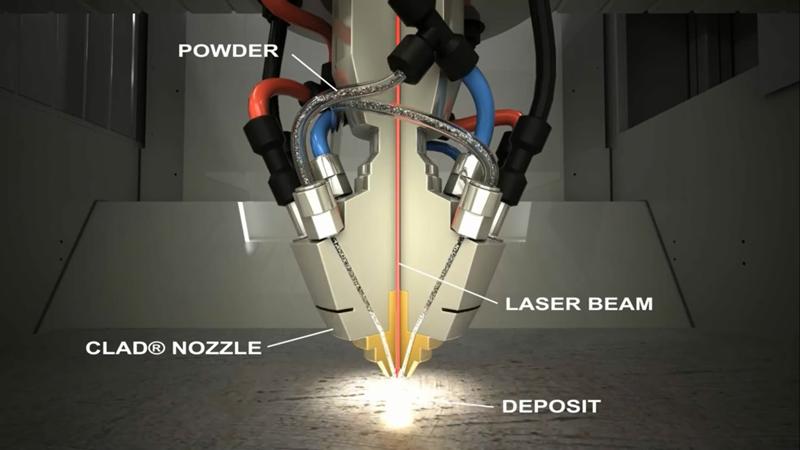

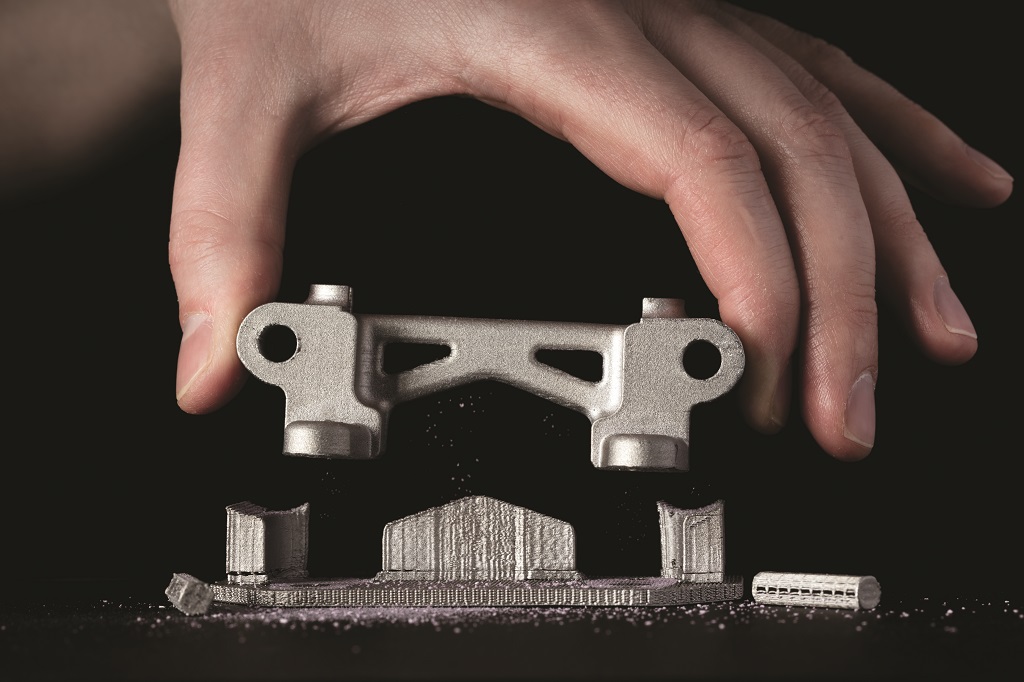

At the construction site, 3D printing robotic arms built up concrete materials layer by layer to form the foundation and walls. After the roof was printed separately, it was put on the wall by a crane.

The construction of the house was completed in two weeks.

The Kickstarter brought success and brushed away concerns. “There were only two people on each device. They pressed the button, then a house was built. It’s amazing,” said a villager without giving his name.

In recent years, China’s 3D printing market has been growing fast, and the technology has been widely used in aerospace, construction, automobile, shipping and other fields.

Experts even tried to take 3D printing to the next level, by building 3D-printed houses in villages, thus improving the rural living environment.

“This technology can save manpower and construction cost while increasing efficiency and quality,” said Xu, adding that it can keep the design and construction of traditional houses while creating beautiful irregular curved surfaces.

Before the 3D printed farmhouse took shape, Xu and his team have applied 3D printing technology to build other structures at home and abroad, including a 26.3-meter-long pedestrian bridge in Shanghai.

China has made continuous efforts in technological innovation to transform and upgrade the traditional construction sector.

In July 2020, a guideline released by 13 central departments called for efforts to integrate intelligent construction technologies into the whole industrial chain, and set short- and long-term targets for the industry’s high-quality development.

“At present, there are still a large number of houses and infrastructure to be built in China. Intelligent technologies can solve the labor shortage problem faced by the construction industry, liberating workers from their heavy labor,” Xu said.

Source: Xinhua

Related Articles

Back to top button

Chinese Construction Company 3D Prints an Entire Two-Story House On-Site in 45 Days - 3DPrint.

com

comHow long does it take to build a house? Obviously it depends on the size of the house and other factors, but somewhere around six or seven months is a good estimate. Chinese construction company HuaShang Tengda thinks that’s pretty funny, and have essentially laughed in the face of traditional construction by 3D printing a 400-square-meter, two-story house in a mere month and a half.

Beijing-based HuaShang Tengda is a major competitor of fellow Chinese construction company WinSun, which we’ve followed in the past since they surprised us with their 3D printed homes, including a six-story apartment building and a mansion. Not long after that, WinSun’s reputation was tarnished by quite of bit of controversy when Dr. Berokh Khoshnevis, creator of the revolutionary Contour Crafting technique of 3D printing buildings, stated that the Shanghai company had blatantly stolen his patented technology and were passing it off as their own. Moreover, Dr. Khoshnevis said, WinSun’s claim that they were 3D printing entire homes was untrue; in fact, they were 3D printing small sections of walls and then cobbling them together on-site using other construction methods.

HuaShang Tengda appears to be something different altogether. Their two-story villa was printed entirely on-site in a unique process that looks quite different from other 3D printed construction techniques we’ve seen. The team first erects the frame of the house, complete with rebar support and plumbing pipes, and then prints over it with their gigantic 3D printer, which only recently completed testing after several years of development. The printer, as seen in the video below, has a sort of forked extruder that simultaneously lays concrete on both sides of the structural material, swallowing it up and encasing it securely within the walls.

The printing material itself is ordinary Class C30 concrete, an extremely tough, durable yet inexpensive material, and HuaShang Tengda states that any cement material can be used with the process, so that other construction firms can take advantage of what is locally available. Twenty tons of the concrete were used to print the 250cm-thick walls of the villa, and seismic testing showed that the structure should be capable of withstanding an earthquake as strong as 8 on the Richter scale – that’s a strength that has flattened cities.

The technology, according to HuaShang Tengda, was developed entirely in-house and is controlled by custom-designed software that consists of four “systems”: an electronic ingredient formulating system, a concrete mixing system, a transmission system and a 3D printing system. The versatile printer, the company says, can be used to print buildings of any size and shape, including high-rise apartment buildings as well as structures with unconventional shapes that wouldn’t be feasible with other construction methods.

“(This technology) will have immeasurable social benefits,” HuaShang Tengda states. “Particularly the use of the new rural construction can now improve farmers’ living conditions. Because of its speed, low cost, simple and environmentally friendly raw materials, (it can) generally improve the quality of people’s lives. If to be used in developing countries, international competitive bidding in a great competitive advantage, the use of mechanical devices to reduce administrative costs and operating costs.

”

I hesitate to use too many superlatives when talking about a new process, machine or material; we’ve heard a lot of 3D printing-related inventions described as being the next thing to turn a particular industry on its head, and that’s not always the case. WinSun’s claims turned out to be too good to be true, but HuaShang’s technology really does look like the real thing. Beyond the speed and low cost of the process, the fact that it can allegedly withstand all but the very strongest of earthquakes could save millions of lives – an idea that should be very appealing indeed to earthquake-prone China and many other regions. Watch the process for yourself below, and discuss further over in the Two-Story 3D Printed Villa forum at 3DPB.com.

[Images: HuaShang Tengda]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D concrete printing • 3d printed architecture • 3d printed building • 3d printed building materials • 3d printed buildings • 3d printed cement • 3d printed concrete • 3d printed construction • 3d printed house • china • concrete 3d printing • HuaShang Tengda • winsun

Please enable JavaScript to view the comments powered by Disqus.

Print me a house - top 7 residential buildings printed on a 3D printer

Currently, there is a real technological breakthrough, thanks to which three-dimensional printers have appeared and the ability to print small architectural forms on them. Moreover, today in many countries of the world you can see printed houses and buildings in which you can really live, and 7 of them deserve special attention.

House of the future in the UAE

The name of this building, built in 2016, speaks for itself. And according to the words of the Government, the "House of the Future" became the first building, every detail of which was created using a printer in China.

The construction took a record 17 days and only 140 thousand dollars.

Like standard buildings, the "House of the Future" is equipped with running water, electricity and even the Internet. Now the office is actively used for various exhibitions and work events of the Future Foundation. nine0003

nine0003

Chinese Villas by WinSun

In 2014, 10 houses built with modern technology appeared in the industrial park of Jiangsu Province in China. Different types of buildings were made for the exhibition by the popular company Shanghai WinSun Decoration Design Engineering Co. Houses have a different type of appearance, but at the same time they are distinguished by a relatively low cost.

So, the most expensive one cost the company 3 thousand pounds sterling.

A year later, WinSun presented two more printed buildings in Suzhou City. In terms of their external decoration, they differed little from the usual buildings, which cannot be said about the material that was used for their construction. The walls were made from building waste, which held its shape thanks to a special hardener.

Yaroslavl project

In 2017, the first residential building in Europe appeared in Yaroslav, which was recreated using 3D technologies. It took 2 years to build the house, but it took only a month to plant the main “box” on the foundation. Most of the work was carried out using a portal printer. nine0003

It took 2 years to build the house, but it took only a month to plant the main “box” on the foundation. Most of the work was carried out using a portal printer. nine0003

Today, the Yaroslavl House looks a little different from the usual living quarters.

It is also equipped with all necessary communications, being ready to move in. The AMT-SPECAVIA company was engaged in the construction of an atypical house, and its main task was to print a building suitable for life, and not at all another exhibition piece.

Fairy Castle in Minnesota

Andrey Rudenko from Minnesota has developed his own 3D printer and decided to try it out by printing a small structure in his backyard. This building was a miniature castle, symbolizing the active development of modern technologies in architecture and construction. nine0003

The building turned out to be truly fabulous.

The miniature castle, like its full-fledged relatives, received pointed towers and graceful arches. In the course of printing, Rudenko used the maximum tuning configurations, declaring that he was going to build a full-fledged living space with his help in the near future.

In the course of printing, Rudenko used the maximum tuning configurations, declaring that he was going to build a full-fledged living space with his help in the near future.

Italian house with a glass roof

In 2018, an atypical building with a glass roof with a total area of 100 sq m appeared in Italy, which was built in just a week. This speed was achieved through the use of a 3D printer to print individual elements. nine0003

Two Italian companies were involved in the reconstruction of the house: Arup and CLS Architetti.

Amsterdam Hut

Natural disasters often cause loss of housing. The Amsterdam architectural studio DUS decided to make the process of restoring the house as comfortable as possible.

In the end, using a 3D printer and durable bioplastic, they printed the "City Cabin", which turned out to be completely habitable. nine0003

The 25 cubic meter building contains a fold-out bed, a table and a window. As for the bathroom, it is located on a small lawn near the house.

As for the bathroom, it is located on a small lawn near the house.

Apartments in the Philippines

Businessman Lewis Yakic decided to expand his hotel in the Philippines, choosing for this not the most standard way. For this purpose, the man invited the already mentioned Rudenko, who printed the apartment on a printer.

His apparatus proved to be suitable for recreating an atypical hotel building. nine0003

Sand and volcanic ash were used as materials, mixing of which made it possible to obtain the most durable mixture.

It is likely that in the near future the bulk of new buildings will be made using 3D printing. Such "construction" is not only more economical, but also the most environmentally friendly. And all because after it there is no usual construction waste, while exclusively recycled waste is used as materials. nine0003

Source

studio DUS, Andrey Rudenko

In China, 10 houses were printed on a 3D printer in a day

April 25, 2014 17:22

nine0002http://www.bbc.com

Every day, 3D printers are increasingly becoming part of our lives. It seems that today with the help of them you can print everything - from weapons to human organs. Chinese engineers decided to use innovative technology to solve the housing problem. Using the printer, they built 10 houses in a day. nine0003

Every day, 3D printers are becoming more and more integral to our lives. It seems that today with the help of them you can print everything - from weapons to human organs. Chinese engineers decided to use innovative technology to solve the housing problem.