3D printed drop in auto sear

▷ ar15 drop in auto sear 3d models 【 STLFinder 】

AR - 15 Drop in Full Auto Sear

thingiverse

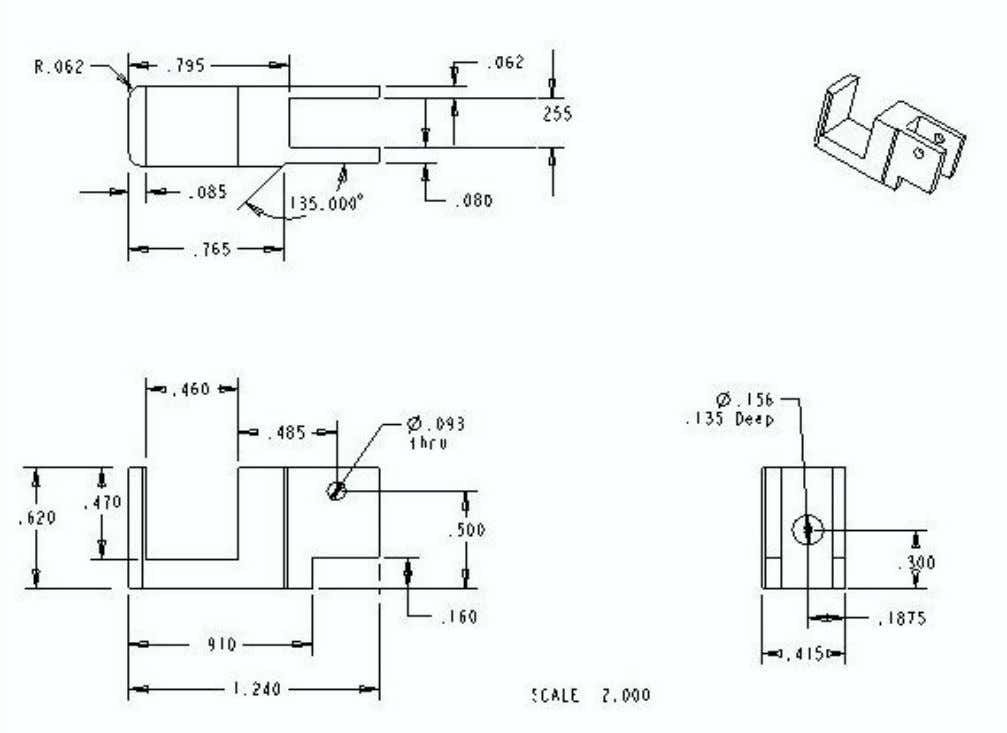

Pulled these specs from some old mag, bear in mind it is illegal to make and or possess one of these...FOR YOUR INFORMATION ONLY! ... To work, this requires a spring and pin to hold the two pieces together to function

AR15 Target Style Sear

grabcad

Sear that accompanies the target style hammer for an AR15

Auto Sear for AKM

grabcad

Auto Sear for AKM

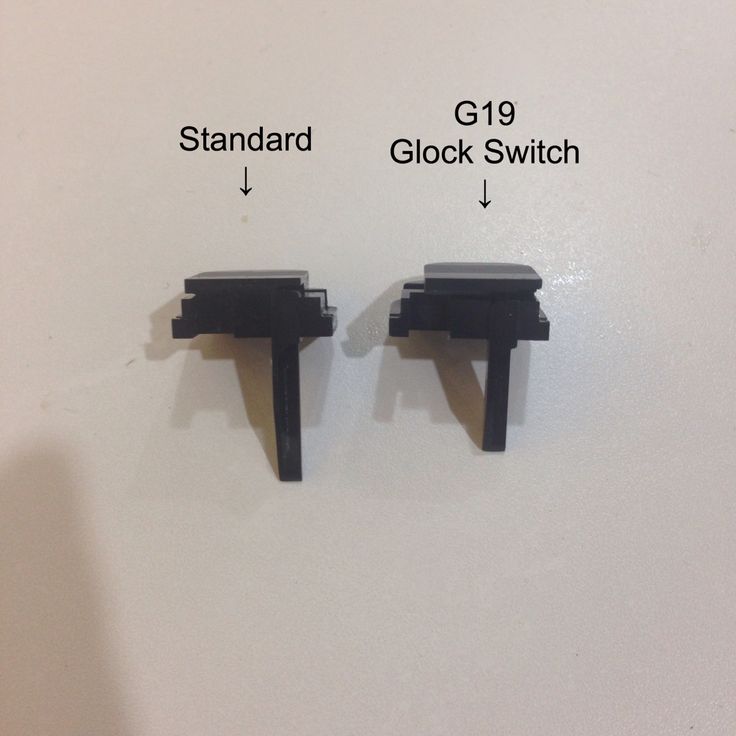

EZ Glock Auto Sear

cults3d

. .. system. The disconnector is to be made from 18 gauge steel. You can keep the backplate on and just screw the auto sear in whenever you want to. You tension the auto sear with the nut in the rear. ...Tighten to engage and loosen to disengage.

hk417 Auto Sear

grabcad

hk417 Auto [email protected]

AR15 Sear

pinshape

Print on its side, 100% infill

SEAR

grabcad

SEAR 3d model

Glock Auto Sear

thingiverse

Four educational purposes only please follow all local laws

switch auto sear

grabcad

Step. StL. ...format files.

StL. ...format files.

AKM Auto Sear

grabcad

Came across some old blueprints, this is pretty close to the real deal other than errors readng dodgy russian drawings.

Glock auto sear

grabcad

For design purposes only...

Sear&Auto Sear SPRING for Ak-47

grabcad

these springs are used for akm or ak-47 based on blueprint

ar15

grabcad

ar15

AR15 Full Auto Link

cults3d

Files you receive with the purchase: -2 Machining Blueprints -2 STL 3D printable files

AR15

grabcad

AR15 built from picked up parts

Drop In Sink

grabcad

Drop in sinkStainless steel hand sink15 x 15

Ar15

sketchfab

Game ready model of a AR15 assault rifle complete with animaitons.

Pencil Holder, Drop-in

thingiverse

This drop-in pencil holder fits the cutouts (cable access) of a HON brand desk. ... Remove the annoying, unwanted hole plug(s) and drop this in instead.

2x4 Drop-in Support

thingiverse

This is a replacement of the 2x4 drop-in support for the Centipede sawhorse.

Drop-in Cup Holder

thingiverse

Designed this simple cup holder for a temporary couch table. ...Just cut a hole 91-99mm wide and drop it in!

Haven't printed it yet, but my biggest concern is the strength of the lip. ...May have to make that thicker.

...May have to make that thicker.

Dishwasher Grid drop-in

thingiverse

When your dishwasher grid for utensils breaks apart, use this to drop it in and fix it! A smaller version can be found here: http://www.thingiverse.com/thing:1568108 Print Settings Printer: Da Vinci 1.1 Plus ...

Drop-in Flashlight holder

thingiverse

I wanted a drop-in light holder for my flashlight. Putting it on the Molle webbing behind my seat of my vehicle. It is designed to clip onto Molle webbing or screwed to something or a single zip-tie. Spots for all kinds of mounts! It should work. ..

..

Y-Stage Drop-In

thingiverse

History x-y lowrider by twotimeshttp://www.thingiverse.com/thing:2845 Drop-In Y-stage for Batch 9 Cupcakes. Printable in 1 sheet (only 6 pieces) Uses minimal hardware (see instructions) Solves issues of: bolts jammed against guide rods Y timing belt...

20x40mm Drop in Nut

cults3d

With the drop in nut any place on the rail can be accessed. The nut fits the slot but when turned it locks in position. At first I had my doubts about making this. It is so small and it may be too weak. I was wrong on both counts. With my Prusa...

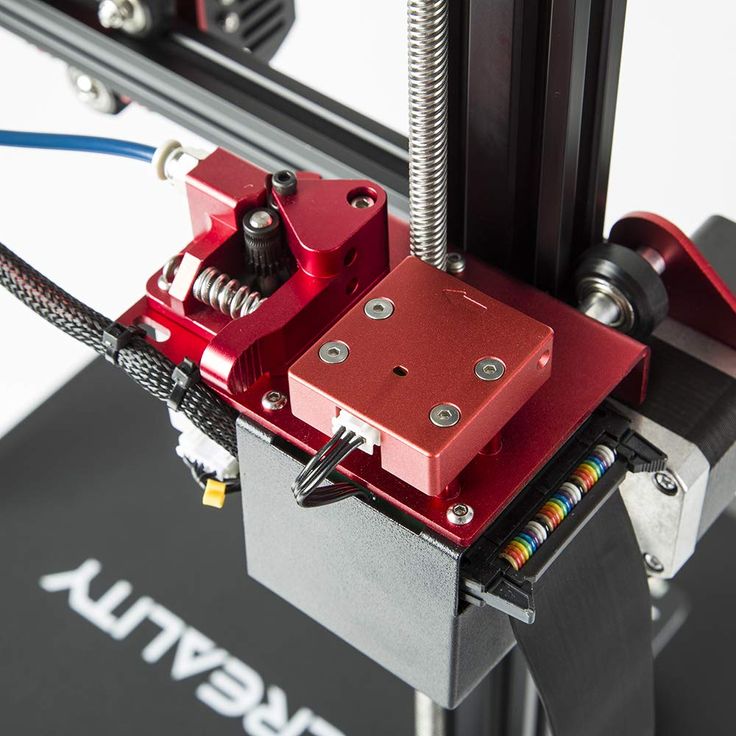

Printable Drop-in Paxtruder

thingiverse

. .. a plunger thing to push against the plastic like the original. Put it together. (Self explanatory, but if you need help head over to www.thingiverse.com/thing:1351) Mount it to your Dinos. Start extruding on your new Printed Drop-in Paxtruder!!

.. a plunger thing to push against the plastic like the original. Put it together. (Self explanatory, but if you need help head over to www.thingiverse.com/thing:1351) Mount it to your Dinos. Start extruding on your new Printed Drop-in Paxtruder!!

20x40mm Drop in Nut

thingiverse

With the drop in nut any place on the rail can be accessed. The nut fits the slot but when turned it locks in position. At first I had my doubts about making this. It is so small and it may be too weak. I was wrong on both counts. With my Prusa...

GoPro Drop In Bracket

thingiverse

I have been using the original go pro bracket housing to film my 3d prints but the original housing doesnt allow for charging while its in the housing as the flap cannot be accessed. So i needed just the face plate with some side support just to rest...

So i needed just the face plate with some side support just to rest...

AR15

sketchfab

Have a look at my comprehensive tutorials and 3D assets on my website at www.chamferzone.com You will also find free tutorials and weapons there that you can use in your projects. Questions? ...Message me through www.facebook.com/chamferzone Cheers!,...

Cerchio in lega auto

grabcad

Cerchio in lega, stile BMW M5

AR15 M4 Full Auto Hammer

grabcad

This part was produced from this mode;

3D Printed AR-15 Part Linked to Extreme Right Boogaloo Group - 3DPrint.

com

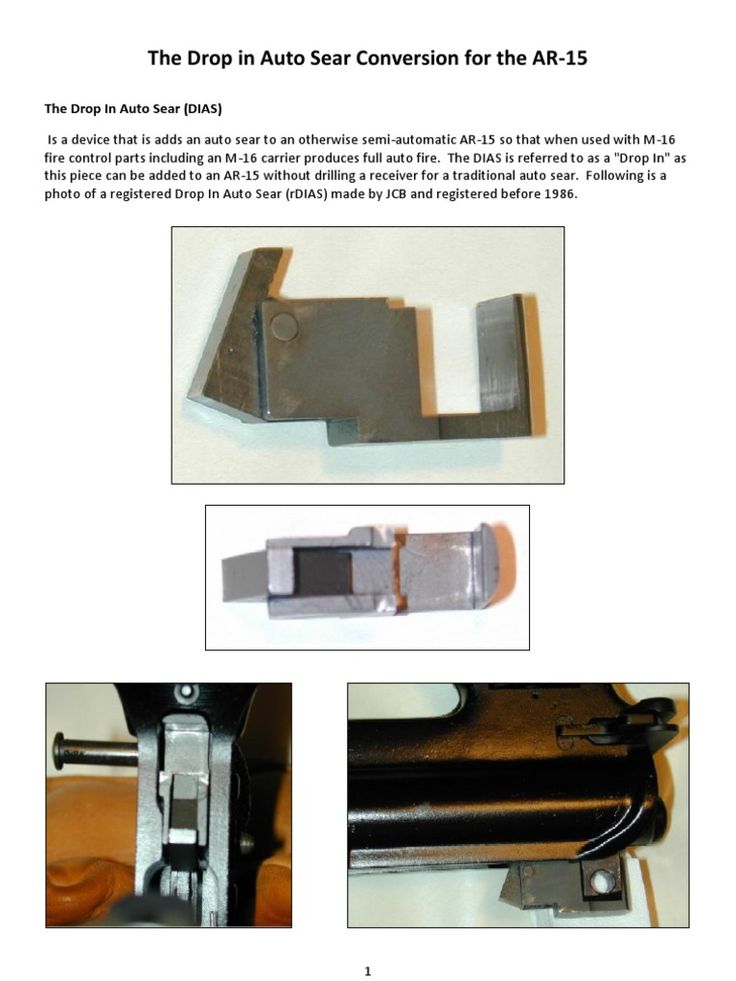

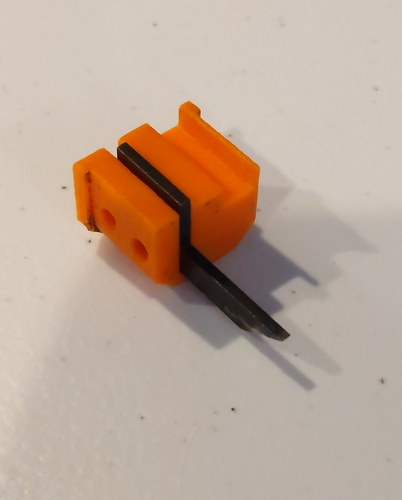

comWhen the topic of 3D printing guns comes up, it’s always difficult to know what to do. On the one hand, we can cover it and add to the scaremongering around the topic. Or we can ignore it and let a potentially newsworthy story slip by. However, as the trend has evolved, it may become increasingly difficult to look past it, as demonstrated by a recent criminal complaint filed against a West Virginia resident accused of selling over 600 3D-printed plastic parts that convert semi-automatics into fully automatic rifles.

The FBI has claimed that Timothy Watson used a website, Portablewallhanger.com, to sell what is known as a “drop-in auto sear” that makes it possible to turn an AR-15 semi-automatic assault rifle, legal in the U.S., into an automatic machine gun, banned in the country for over 20 years. The federal investigators suggest that Watson was disguising the device as a wall hook. Once an extra bit of 3D printed plastic was removed, buyers were left with a 3D-printed auto sear.

An Instagram commenter refers to “red coats”, code for the enemy of the Boogaloo Boys. Image courtesy of Wired.

For the over 600 units Watson sold, customers included multiple members of the Boogaloo group, the FBI claims. The far-right movement is the latest manifestation of newer right-wing extremists that have emerged leading up to the 2016 presidential election in the U.S. The group was said to have been responsible for the murder of multiple police officers. The Boogaloos have been involved in inciting violence at racial justice protests that erupted in the U.S. in the summer of 2020 in response to the police murder of George Floyd.

Most alarmingly, among those Boogaloo customers was Steven Carrillo, according to the FBI. Carrillo is accused of shooting Santa Cruz police officers and two Oakland courthouse security guards in May and June, which resulted in the deaths of one police officer and one guard.

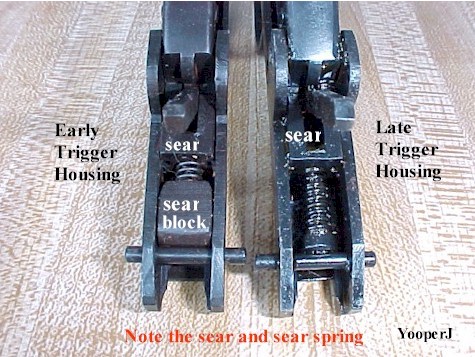

The 3D printed auto sear works by preventing the bolt within an AR-15 from stopping when fired. As a bullet is fired from the weapon, the gases within the chamber push the bolt back to retrieve a new round from the magazine. The bolt pushes a spring in the gun’s stock down before propelling forward. The auto sear stops the bolt and causes the hammer to push the firing pin once more. This allows the gun to continue firing without any further pulling of the trigger.

As a bullet is fired from the weapon, the gases within the chamber push the bolt back to retrieve a new round from the magazine. The bolt pushes a spring in the gun’s stock down before propelling forward. The auto sear stops the bolt and causes the hammer to push the firing pin once more. This allows the gun to continue firing without any further pulling of the trigger.

Once the extra black portion is removed, the red hook fits into an AR-15 to convert it into an automatic rifle. Image courtesy of Wired.

As we’ve covered in the past, 3D printed guns have so far posed little threat to the public at large due to the fact that the plastic parts are easily destroyed by the extreme forces of the weapon upon firing. They have been capable of firing but are dangerous to the users for this reason. However, this latest story represents a growing trend in the 3D printing of arms.

A consultancy group called Armament Research Services published a report in March 2020 noting that the current trend for DIY gun enthusiasts has grown to include individual components and not entire weapons. This has resulted in hybrid guns, made up of a combination of 3D printed and traditionally made or off-the-shelf parts, and market-bought weapons with 3D printed receivers. The report notes:

This has resulted in hybrid guns, made up of a combination of 3D printed and traditionally made or off-the-shelf parts, and market-bought weapons with 3D printed receivers. The report notes:

“At present, the material limitations of consumer-grade 3D printers, and the high cost of those small number of industry-grade printers capable of producing objects in metals, means that certain essential pressure-bearing components must either be fabricated from metals using alternative methods or substituted for commercially made parts. In the case of a Glock-series handgun, for example, the frame and magazine body may be printed from PLA while the slide, barrel and trigger would usually be original, factory-made parts. The emergence of other technologies such as ECM and desktop/micro-CNC milling machines have bridged the technological gap, and now mean that viable, capable self-loading hybrid firearms such as the FGC-9 can be produced by the home gunsmith without using any regulated components.

Other areas for development, such as the production of 3D-printed ammunition, remain in their infancy.”

The auto sear part itself doesn’t take the stress of the bullets being fired, meaning that it can be used successfully even if made out of plastic. The piece would eventually wear away but could easily be replaced. With the price of industrial-grade polymer printers now dropping, it may be increasingly possible to print an auto sear from materials that can withstand the heat and impact of bullets firing.

In some cases, the 3D printing of guns or gun parts may just be a hobby or a means to procure weapons outside of government control. The Ghost Gunner from Defense Distributed, for instance, was focused specifically on CNC machining the lower receiver for an AR-15 so that it might not be traced by government authorities.

Watson was specifically selling a component that would convert an AR-15 into a fully automatic rifle. U.S. legislation frames the auto sear itself as an automatic weapon, making anyone who 3D prints one a potentially culpable in a federal crime. However, groups like Deterrence Dispensed have released their own files for 3D printable auto sears.

However, groups like Deterrence Dispensed have released their own files for 3D printable auto sears.

While there may be a plethora of reasons for crafting guns or procuring guns outside of government scrutiny, 3D printable weapons and guns rights activists have seemingly been aligned with the right wing of the country. Ghost guns have been involved in more than one mass shooting in the US since 2013. Just this October, a far-right terrorist in Halle, Germany used a homemade submachine gun to murder two people following an attempt performing a mass shooting at a synagogue.

One of the key creators of the 3D printed gun movement, Cody Wilson, is a self-identified libertarian that has been described as right wing and founded Hatreon, referred to as an “alt-right crowdfunding platform.” Wilson himself was charged with sexually assaulting a minor when he allegedly met a 16-year-old on a site, SugarDaddyMeet.com, and paid her $500 in exchange for sex. This led him to step down as CEO of Defense Distributed, the leading site for 3D printable gun files. However, news of Timothy Watson’s 3D printed auto sears suggests that the far right and the 3D printed gun movement continue to commingle

However, news of Timothy Watson’s 3D printed auto sears suggests that the far right and the 3D printed gun movement continue to commingle

A screenshot from the Portable Wall Hanger website.

As detailed in a recent Wired article on the subject, the FBI claims that one witness in the case was a Boogaloo member who told the federal agency that he learned of Watson’s product from ads on a Boogaloo Facebook group. Portablewallhanger.com also advertised that it would donate 10 percent of its proceeds to Duncan Lemp, a militia member killed by police in March 2020.

Jon Lewis, a research fellow at the George Washington University Program on Extremism, told Wired:

“To the best of my recollection, there has been very little in the way of tangible evidence that domestic extremist groups have successfully used 3D printing to modify guns, until now. When you have individuals who so strongly support the second amendment—pro-gun, anti-government individuals trying to evade any kind of gun control measure—it makes sense for them to shift to this kind of technology.

”

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print guns • 3D printed AR-15 auto sear • 3d printed gun parts • 3d printed guns • 3D printed weapons component • Boogaloo Boys • cody wilson

Please enable JavaScript to view the comments powered by Disqus.

20 Use Cases for 3D Printing

3D printing has progressed so rapidly in recent years that we will soon stop talking about what can be created using additive manufacturing. It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Fruit

A gift for impatient parents

Young parents often experience an irresistible desire to acquire all sorts of items, one way or another related to their child, even if not yet born. The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level.

The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level.

Although the desire to get such a model may seem a bit strange, there is a perfectly logical explanation. As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

Weapons

Functional 3D printed receiver from AR-15 without any numbers

The possibility of 3D printing of weapons has seriously alarmed law enforcement agencies around the world. After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons.

After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

Clothes

One of Snezhana Gross' designs

Some consumables for 3D printing, especially soft photopolymers, are quite suitable for making clothes and even underwear. The bra in the illustration was laser sintered from nylon. This design from Continuum Fashion aims to showcase the possibilities that 3D printing opens up for couturiers. However, don't think this is an experimental model: the company offers finished products for sale on the Shapeways website.

Russian designers did not bypass the new technology either: Snezhana Gross demonstrated casual wear designs integrating functional 3D printed components.

Art

Easy to print. Take a picture - as lucky

Would you like a replica of the Venus de Milo? No problem, just choose the material and printing method. True, marble is not yet on the menu, but sandstone imitators are already available. Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre.

Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre.

Although, if you are too lazy to make digital models yourself, you can always download them.

Products

What's for breakfast?

Although giant hot dogs are still far away, 3D printers have already learned how to print minced meat. An example of this is the Foodini culinary printer, a simple and practical device using syringe extrusion. Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Characters

Parts of models used to animate ParaNorman's protagonist

Whether it's a miniature version of a giant robot from a favorite manga, a creepy alien creature from Alien, or a Keanu Reeves action figure (as in a black cape and sunglasses, and with a beard and a sandwich sitting on a bench), 3D printing allows you to create replicas of game and movie characters for the delight of fans. And the fact that such souvenirs can be printed even on household 3D printers opens up great opportunities for those who like to collect such models - after all, not all of them are available for sale. Do you want a model of a rare aircraft? Print it.

And what is most interesting, this application has already had the opposite effect. ParaNorman cartoon characters were still printed. Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Home Robots

Early Terminator Prototype

The advent of inexpensive Arduino boards made it possible to design a wide variety of electronic devices at home. Here are your own 3D printed robots. You printed the case, inserted the servos and the board, and you have a new au pair. But what about people who do not understand programming or elementary soldering? Scientists from the Massachusetts Institute of Technology are developing a project aimed at automating the design and construction of domestic robots. Ideally, the user will only have to set the necessary functions for the future device, after which the system will compile the required design and send it to print. A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

Aviation

3D printed part used in Chinese fifth generation fighter aircraft prototypes

The toy airplanes we have already mentioned. What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons.

What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons.

Space

Dragon v2 is Space's latest creation

The space industry is not far behind the aviation industry in its interest in 3D printing. NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

Bioprinting

Biopens can help treat fractures

Vessels, tissues, whole organs - several companies are simultaneously developing the production of organic imitators that are completely similar to natural tissues. Although transplantation of 3D printed organs is still far away, work in this direction is underway. In parallel with the production of organic tissues from scratch, methods are also being developed to restore damaged tissues, such as cartilage or bone. Devices called "biopens" are able to apply living cells to damaged areas, promoting their healing.

Prostheses

Titanium orthopedic prostheses with a porous structure for improved osseointegration

What if the tissues cannot be restored? 3D printing can help with prosthetics. Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Not only that, 3D printed limbs can compete with high-tech designs with one difference - their cost cannot be compared. How many people can afford a tens of thousands of dollars of prosthetic hands? How about a $50 fully functional prosthesis? And it's possible.

An even more common application of additive manufacturing is in dental prosthetics. If you have recently had a crown or bridge placed, it is possible that they were cast from models created with a stereolithography printer that prints with photopolymer resins.

Musical instruments

3D printed musical instruments

Guitars? Flutes? Drums? Easy. Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

It would be fantasy!

Shoes

Luc Fusaro's stylish trainers

Eight-time world sprint champion Usain Bolt is famous for his love of gold. This includes not only medals, but also cars and even shoes. During his contract with renowned manufacturer Puma, Bolt wore signature gold-plated sneakers. And more recently, engineer and designer Luke Fusaro has taken on the development of sports shoes that Usain would like. Its distinctive feature is its golden color. Oh yes - and it's also designed for 3D printing. The use of additive manufacturing has one important bonus, namely the ability to produce shoes that are precisely tailored to the size and contours of the athlete's foot. Such shoes are produced by laser sintering, although this technology has already had a competitor.

Drugs

3D printing can facilitate the production of mixed drugs and help with drug testing on living tissues often in combination with tissue engineering. Thus, the Organovo company directs its efforts to create artificial human liver tissues to test new drugs for toxicity without risk to human health. But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient.

But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient.

Cars

Doc Brown is introduced to 3D printing. That's about the reaction you'd expect.

Most automotive components can be printed, but it's not economically viable when it comes to mass production. But for prototyping new cars, 3D printing is great. As, however, for the production of unique machines or components. For example, you can print replacement parts for low-volume, discontinued models. Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Customization

Maximum glamor at minimum cost

Why not take a finished product and add decorative elements? Turn your bike into a work of art for everyone to envy. Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Furniture

One of Joris Laarman's clever designs

Toy furniture? No, not only. The advent of composite materials for FDM printing makes it possible to print "wooden" furniture, almost indistinguishable from the real thing. Actually, the material Laywoo-D3 could not do without real wood in the form of micro-sawdust. This stuff even smells like wood! Finished products are easily machined and varnished.

Or do you prefer metal furniture? Dutch designer Joris Laarman has created his own machine for metal 3D printing, without the use of expensive powders, vacuum chambers and lasers. The device draws with metal in the air, allowing you to create elegant interlaced designs.

Jewelry

Beautiful and functional

A clear demonstration of the precision of 3D printing is its application in jewelry. It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process.

It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process.

But there is also an option for direct additive manufacturing of jewelry: laser sintering and melting technologies make it possible to create finished products from metal powder, including precious metal powders. True, the cost of such installations and materials is often too high for widespread use even by jewelers.

Construction

3D printing of buildings will help solve housing problems experimenting with the construction of concrete "boxes". True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Which method will be the most practical, time will tell. But if any of them succeeds, the construction industry can make a qualitative breakthrough, expressed in increased savings, safety and speed of building construction.

3D printers

What else can I print with a 3D printer? Another 3D printer! Even if not entirely yet: the necessary electronic and electromechanical components are not yet subject to printing, but this is only a matter of time. Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion.

Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion.

Article prepared for 3DToday.ru

Auto-calibration of the desktop in 3D printers

Auto-calibration of the desktop is a feature available in some FDM 3D printers by default from the factory. In addition, experienced technicians can install the auto-calibration sensor themselves.

In this article, we will tell you what this function is for and how to use it.

Why Calibrate the Platen

Most FDM 3D printers are devices that require the active participation of the master in the process of preparing for printing. One of the features of the devices is the need to regularly check the level of the printed table. Over time, the design of an FDM 3D printer can become loose. And this is due not only to the adjusting screws of the table, but also to the backlash of absolutely all screw connections. Most often this is manifested in vibrations during the printing process.

One of the features of the devices is the need to regularly check the level of the printed table. Over time, the design of an FDM 3D printer can become loose. And this is due not only to the adjusting screws of the table, but also to the backlash of absolutely all screw connections. Most often this is manifested in vibrations during the printing process.

Source: pinshape.com

As a result of the deviation of the table from the set level, the distance between the extruder nozzle and the printing table changes, by different distances at different points. This can lead to deformation of the printed model, distortion of dimensions and proportions, clogging of the extruder (when the nozzle is close to the table and the plastic cannot come out).

This may be caused by a missing thread lock and poor quality platform leveling screws. Also, the error can be caused by the user's actions, for example, if he unevenly pasted adhesive tape on the printed table.

To avoid problems, the user should calibrate the platen regularly. In budget models, this work is done manually. To do this, the table is equipped with adjusting screws. However, there are models of 3D printers on the market with auto-calibration of the print bed, which greatly simplifies the operation of the printer.

The principle of auto-calibration of the 3D printer table

Before printing, the 3D printer determines the position of the print bed relative to the extruder and, if necessary, adjusts the position of the nozzle during printing.

Typically, an auto-leveling 3D printer has a proximity sensor or contact end sensor at the printhead nozzle level that "probes" specific points on the platform when the auto-calibration process is initiated. Sometimes, equipped with a feedback encoder, the extruder itself serves as such a sensor, and the nozzle is its probe.

One of the advantages of auto calibration is that it allows you to print a quality product, even if there are visually imperceptible irregularities on the table. Such a situation may occur during long-term operation of the device at high heating temperatures of the printing table.

Since the 3D printer automatically adjusts the position of the nozzle relative to the plane, the nozzle is always at the optimal distance from the printed model during the operation of the device. This, in particular, improves the adhesion of layers and print quality.

When using non-professional FDM 3D printers, especially from the DIY category (self-assembled, supplied as a kit), there are extensive upgrade options, including the ability to install the sensor required for auto-calibration.

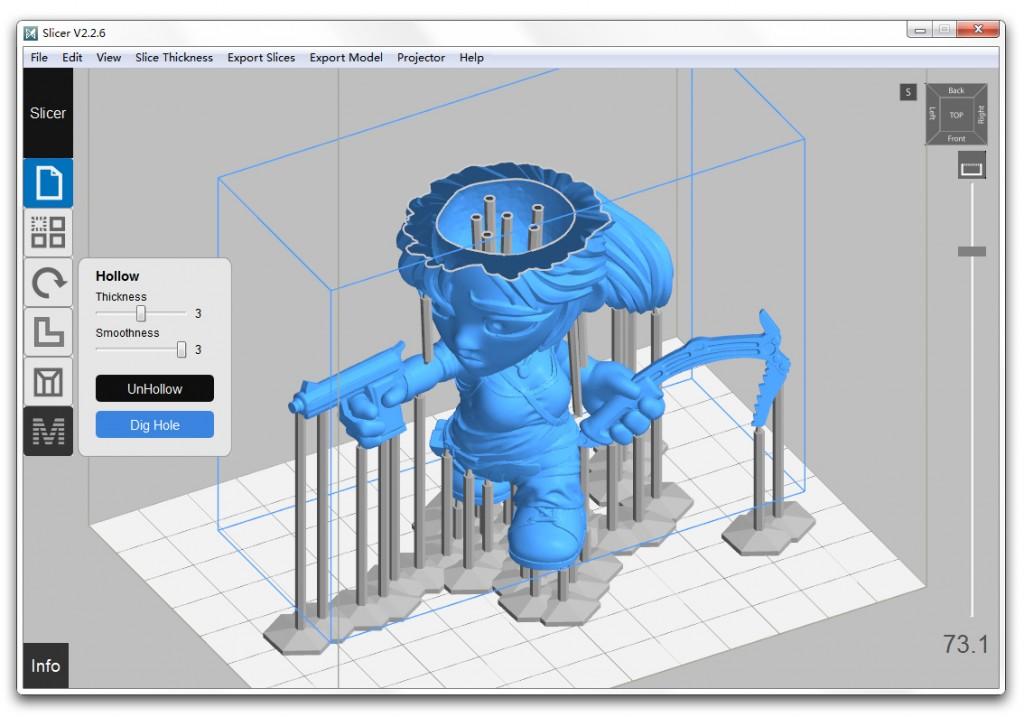

Auto-calibration using the example of Simplify3D

Source: simplify3d.com

Consider setting up auto-calibration using one of the most popular professional 3D printing software, Simplify3D, as an example.

If the 3D printer has an automatic build plate alignment feature, then the Simplify3D profile for the machine must be set to auto-calibrate at the start of each print.

If you are using the printer for the first time, you can download the default Simplify3D profile for a specific device by selecting Help > Setup Assistant in the program. After loading the profile, click "Change process settings", go to the "Scripts" tab and select the startup script. This set of commands defines the actions that the 3D printer will perform at the start of each print.

Source: simplify3d.com

To auto-calibrate the 3D printer, edit the G-code of the script. To do this: at the beginning of the file, you need to add the G29 command, which tells the printer that you need to perform the table auto-calibration process. In this case, the 3D printer must perform a standard homing operation before it starts the alignment process, i.e. the G29 command must be placed after the G28 command (homing command) in the script.

To do this: at the beginning of the file, you need to add the G29 command, which tells the printer that you need to perform the table auto-calibration process. In this case, the 3D printer must perform a standard homing operation before it starts the alignment process, i.e. the G29 command must be placed after the G28 command (homing command) in the script.

Startup scenarios may vary depending on the model. There are several different types of G28 commands, such as the regular "G28" (all-axis coordinate origin), "G28 X0 Y0" (X and Y origin only), or "G28 Z0" (Z-axis origin only). For the script to work correctly, the G29 command must come after the most recent G28 command.

Source: simplify3d.com

After making these changes, you must save the new printer settings. To check if the changes were successful, it is enough to start a new print on the 3D printer and make sure that the table auto-calibration process is performed at the beginning of the print.