Bibo 3d printer dual extruder laser engraving review

Review: BIBO Dual-Extruder 3D Printer — Does it Live Up to the Hype?

Log inSign up

Please ensure that JavaScript is enabled in your browser to view this page.

BIBO is a little-known Chinese company, but this 3D printer has great reviews on Amazon. The question is if it lives up to the hype.

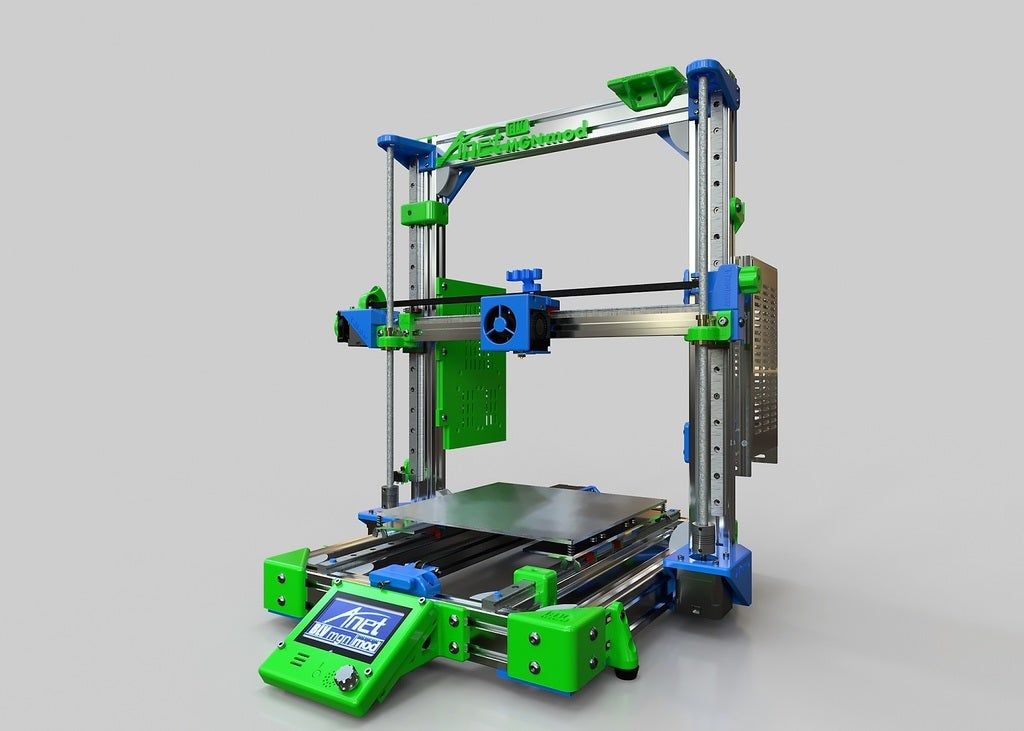

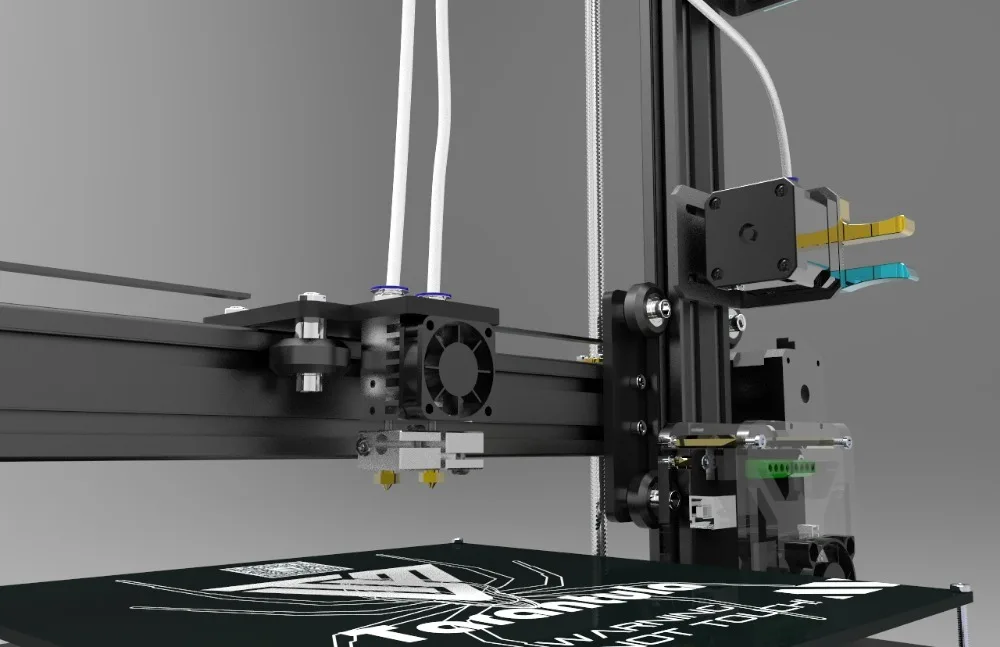

There are a lot of 3D printers on the market, and the selection can be overwhelming. But once you start narrowing them down by the features you require, you end up with only a handful of options. If, like me, you want a sub-$1,000 dual-extruder 3D printer, then you may have come across the “BIBO 2 Touch Laser Dual Extruders 3D Printer.” BIBO is a little-known Chinese company that produces a range of products, but this 3D printer has overwhelmingly good reviews on Amazon. The question is if it lives up to the hype.

To find out, I purchased one for my own personal use — BIBO did not provide me with a printer for this review. I’ve been looking for a decent dual-extruder 3D printer for a while now, mostly because I want to be able to print PVA soluble supports for complex geometry. Nobody likes removing supports, which makes PVA very desirable (I’ll cover how to successfully print them in another article).

In my research, I came across the BIBO 3D printer. I had never heard of the brand, and professional reviews are scant, but it is very well-rated on Amazon. Are those reviews fake, or is this a legitimately good 3D printer being sold at a very reasonable price? I decided to find out.

Before I move on, let me address the somewhat confusing naming scheme that BIBO uses. They really only sell one 3D printer, but it is available with different options. Those include a touchscreen and a laser engraver module. So, the printer sold on Amazon as the “BIBO 3D Printer” is actually the “BIBO 2 Touch Laser Dual Extruders 3D Printer” on their website. That means it comes with the upgraded touchscreen and the laser engraver module.

This 3D printer sells for well under $1,000 on Amazon (with free Prime shipping!), which makes it one of the most affordable dual-extruder 3D printers on the market — even if you completely ignore the laser engraver module. It’s fully-enclosed and has a sturdy aluminum composite panel frame. It has a built-in WiFi module for transferring G-code files, and you can make those using whichever slicing software you prefer.

Here are the basic specifications:

- Build Size: 8.4 x 7.3 x 6.3 inches (214 x 186 x 160 mm)

- Layer Resolution: 0.05-0.3 mm

- Maximum Nozzle Temperature: 270°C

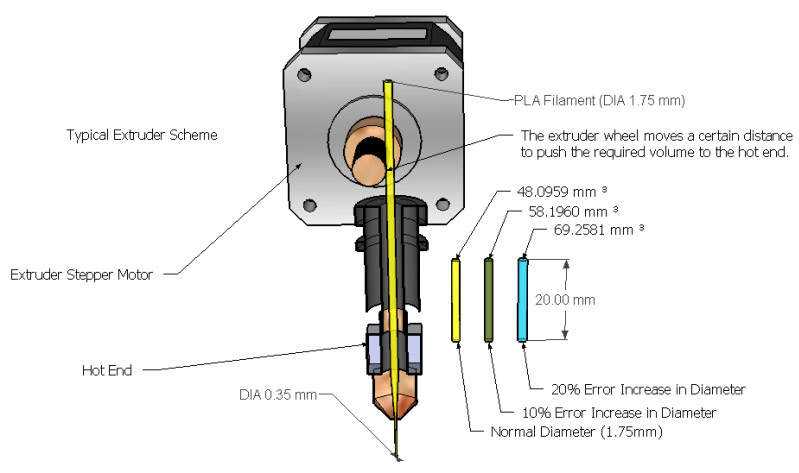

- Filament Diameter: 1.75 mm

- Overall Size: 18.4 x 14 x 14.7 inches (467 x 356 x 373 mm)

Assembly

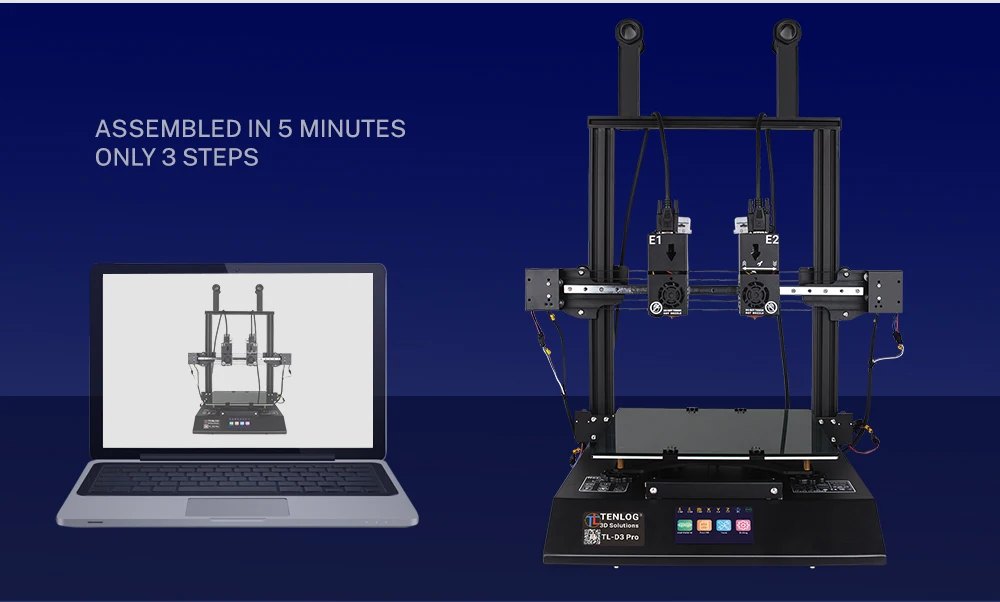

The printer comes from Amazon double-boxed in heavy cardboard, with a solid amount of Styrofoam padding. After unpacking, you’ll find that it is already 95% assembled. The rest of the assembly process took me less than an hour.

Doggo inspecting the condition of the package

That includes mounting the extruder block to the X axis carriage, attaching the front door, assembling the red top cover, mounting the spool holders, and leveling the bed. Unfortunately, there is no automatic leveling, so you have to adjust the wingnuts manually to level the bed. That said, the leveling process is fairly quick and I haven’t had to re-level my bed yet — except after the upgrades I’ve done, which I will discuss at the end of this review.

Unfortunately, there is no automatic leveling, so you have to adjust the wingnuts manually to level the bed. That said, the leveling process is fairly quick and I haven’t had to re-level my bed yet — except after the upgrades I’ve done, which I will discuss at the end of this review.

The BIBO 3D Printer is delivered 95% assembled

Software Setup

As I mentioned before, you can use whatever slicing software you prefer. BIBO does, however, provide configuration settings for Repetier, Cura, and Simplify3D. I’ve been using Cura exclusively, and the standard settings work fairly well. You will probably want to fine-tune them to suit your needs and the filament you’re choosing to use, though.

My only complaint here is that the process for setting up wireless file transfer is convoluted. You have to connect your BIBO 3D Printer to your wireless network, install multiple utilities — one of which is in Chinese by default, and then use those clunky utilities to transfer the files. I’ve found it easier to just copy them to the included SD card, as the wireless transfer process is less convenient for me.

I’ve found it easier to just copy them to the included SD card, as the wireless transfer process is less convenient for me.

Touchscreen Control

The touchscreen is adequately responsive, and the interface is fairly intuitive. But there are still some quirks that are a little bit frustrating. For example, to preheat the bed or extruders, you have to go to that section of the menu and then tap the “temperature increase” button over and over again to set them to the temperature you want. It would be nice to have a preset selection of temperatures that you could jump to.

There also isn’t much configurability. You can’t, for instance, set any kind of Z axis offset. That’s not a big deal, as the bed has to be leveled manually anyway, but it would be a nice feature. Those minor complaints aside, the touchscreen is more pleasant to use than the monochrome LCDs that most budget 3D printers — and even the similarly-priced Prusa i3 MK3S — have.

Printing

Let’s get down to what’s really important: printing. This topic is always going to be subjective, as people measure print quality with different yardsticks. That said, I’ve found the quality to be on-par with most other well-reviewed consumer FFF (Fused-Filament Fabrication) 3D printers. I have noticed more shadowing then on other 3D printers, including the Prusa i3 MK3S that I owned before I purchased the BIBO 3D printer, which is likely due to the additional weight of the extra extruder.

This topic is always going to be subjective, as people measure print quality with different yardsticks. That said, I’ve found the quality to be on-par with most other well-reviewed consumer FFF (Fused-Filament Fabrication) 3D printers. I have noticed more shadowing then on other 3D printers, including the Prusa i3 MK3S that I owned before I purchased the BIBO 3D printer, which is likely due to the additional weight of the extra extruder.

Speaking of the second extruder, I’ve been impressed by how level the two extruders are. A common issue with dual-extruder 3D printers is one extruder nozzle being slightlylower than the other. Even a fraction of a millimeter difference will cause one nozzle to drag across your part. That can ruin your print, or at least leave ugly scars. The BIBO’s extruders were perfectly leveled out of the box, and I have not had to touch them at all.

This isn’t the fastest 3D printer on the market, and I find myself printing at between 60 and 80 mm/s for the outer layers (100 mm/s for infill). It is possible to set it higher, but the print quality deteriorates as the weighty extruder block jerks around. Some printers are faster, but these speeds are pretty average for this market segment.

It is possible to set it higher, but the print quality deteriorates as the weighty extruder block jerks around. Some printers are faster, but these speeds are pretty average for this market segment.

The extruders themselves seem to perform well, and flow has been pretty consistent. I haven’t noticed any under-extrusion or over-extrusion that can’t be explained by flaws in the filament. I also haven’t had any problems with the gears grinding or slipping on the filament.

The Bed

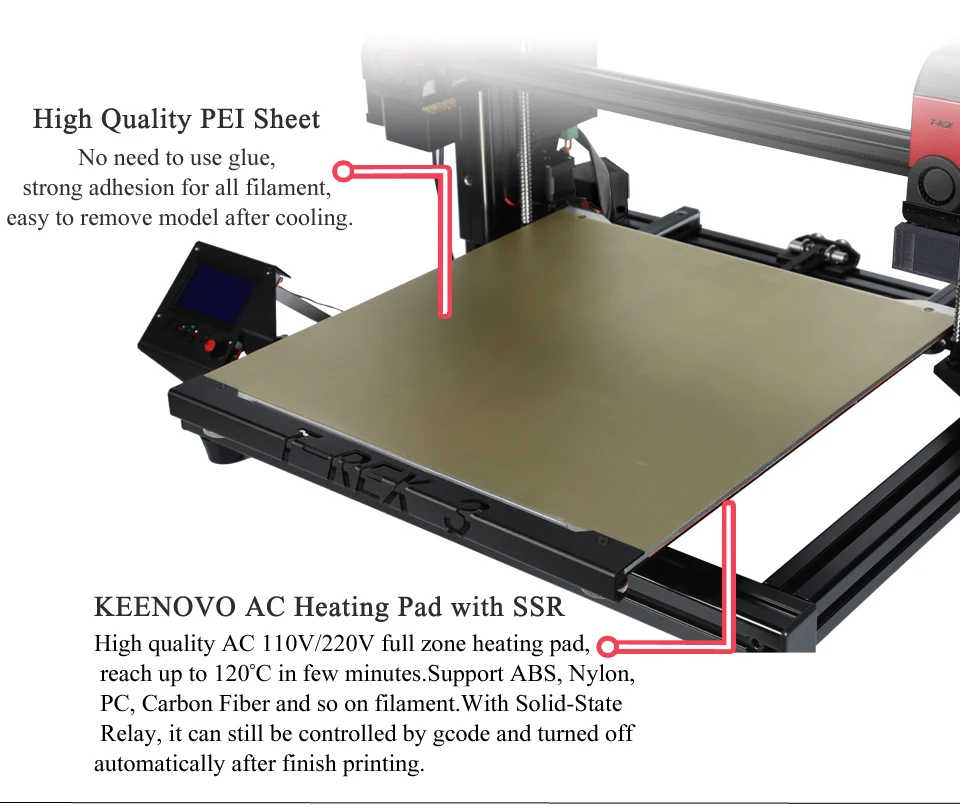

My only significant complaint about the BIBO 3D Printer is the bed, which has a glass build plate. While glass build plates are still very common, they feel outdated to me. You’re forced to use fixes like painter’s tape or glue sticks to get your first layer to adhere, and then the parts become difficult to remove when you’re done. Anyone who has stabbed themselves with a scraper knows how true that is. With other manufacturers, like Prusa, using modern solutions such as spring steel build plates, being stuck with glass seems a bit like taking a technological step backwards.

Fortunately, this is a relatively easy fix. You can upgrade your BIBO 3D printer with a better build plate, and I’ve covered a couple of options for how to do that here. If you do purchase one of these printers, I highly recommend you upgrade your build plate. It’s inexpensive and easy to do, and something that BIBO really should have done themselves.

The Conclusion

If you’re looking for a dual-extruder 3D printer under $1,000, the BIBO 3D Printer is one of the best options I’ve come across — maybe even the best. With the exception of the build plate, which can be upgraded, I don’t have any complaints that aren’t just minor nitpicks. BIBO has also proven to have extremely responsive and helpful support, which is nearly unheard of when it comes to Chinese 3D printer manufacturers.

If you’re like me and want that second extruder for printing PVA soluble supports, then stay tuned. After a lot of trial and error, I’ve finally got PVA printing reliably and will have a guide posted soon on how to achieve good results.

Cameron Coward

Writer for Hackster News. Maker, retrocomputing and 3D printing enthusiast, author of books, dog dad, motorcyclist, and nature lover.

Latest articles

Read moreRelated articles

Bibo Dual Extruder 3D Printer In-Depth Review

ADVERTISEMENT

7.6Expert Score

Bibo Dual Extruder 3D Printer

Like every other machine, Bibo also has few limitations apart from all the good things in place.

Affordability

7

Quality

8

Speed

7

Capability

8

Practicality

7

User Expectations

6

PROS

- It possesses dual extruder

- Multi-color printing is possible

- Metal frame for extra reliability

- Removable glass bed

- Support for multiple filaments

CONS

- Build space isn’t very large

- Unavailability of automatic bed leveling before the print starts

Being a 3D printer that is known for its laser engraving capabilities, the Bibo Dual Extruder 3D printer has evolved by carrying its distinguished . ..

..

Add to wishlistAdded to wishlistRemoved from wishlist 1

Add to compare

|

Table of Contents

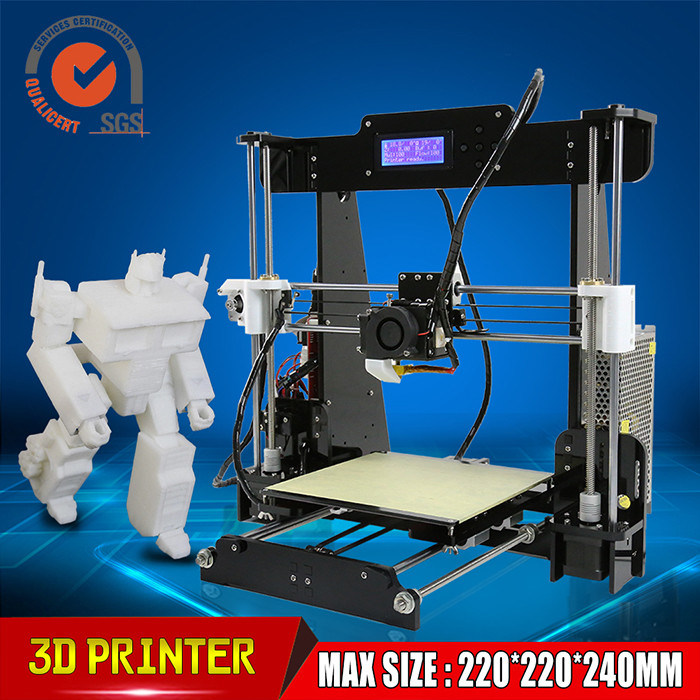

If you are looking for a 3D printer with laser engraving capabilities, you must go for Bibo Dual Extruder 3D printer which is also known as Bibo 2.

The 3D printer has evolved carrying its distinguished set of features that make it stand out from other variants. The machine has been manufactured a company based out in China named Shaoxing Bibo Automatic Equipment Co.

The looks of Bibo 2 is very similar to that of Makerbot Replicator. However, it has set its own example in terms of operation and results when it comes to 3D printing.

The 3D printer is a cartesian design and is very thoughtfully designed. One can find four versions of this 3D printer, however, the standard one is almost capable of serving most of the user base.

A very competitive machine that exhibits some of the most wonderful features to tag along. With many satisfied users, the 3D printer has gathered huge popularity.

ADVERTISEMENT

Features of the Bibo Dual Extruder

Among all the various versions of Bibo 2, there are certain core features that make it a great option for users. Backed with some of the most advanced features, Bibo can be a useful technology for lots of applications.

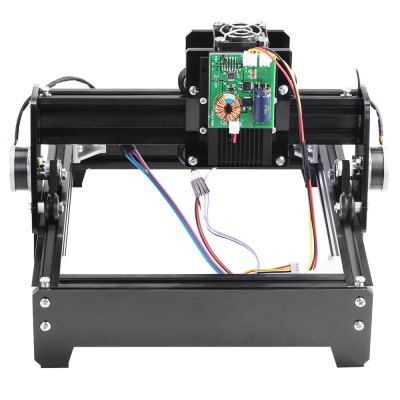

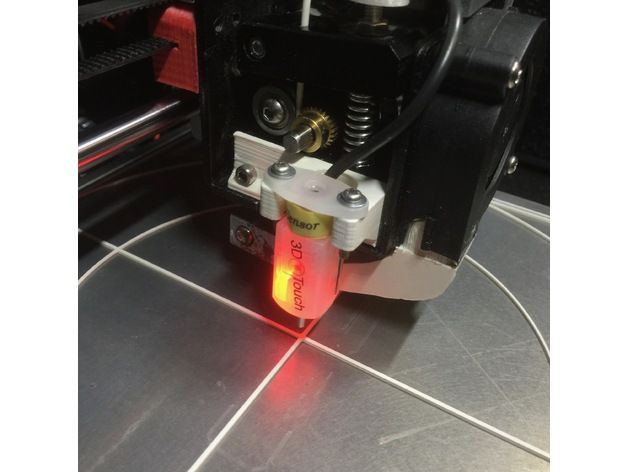

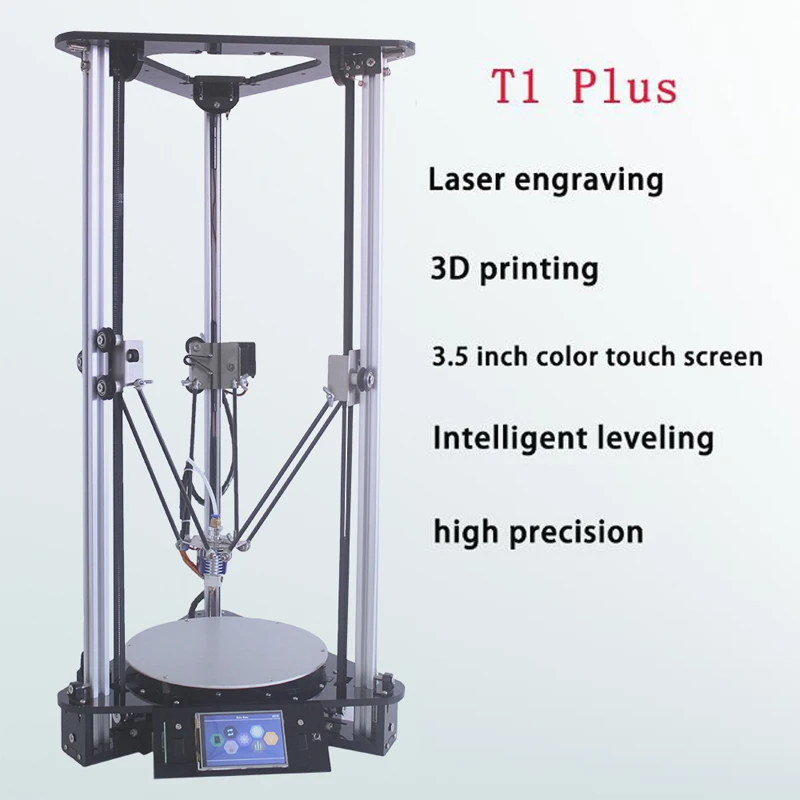

✔ Laser Engraving

Many users may not find it appealing but a lot will. And, this is the reason why this 3D printer has made such an important place in the 3D printing niche.

In short, it does not just print what is fed as a 3D design but can help engrave as well.

Although it may be disheartening to expect too much from laser engraving add-on, as the engraver isn’t very powerful, however, one can use it on light materials including wood.

You can engrave with this laser on paper, wood, cardboard, and also on a few of the plastic materials. The 3D printer exhibits 500 mW laser engraver that can easily be swapped out for the extruders when necessary. And, it easy to install and use.

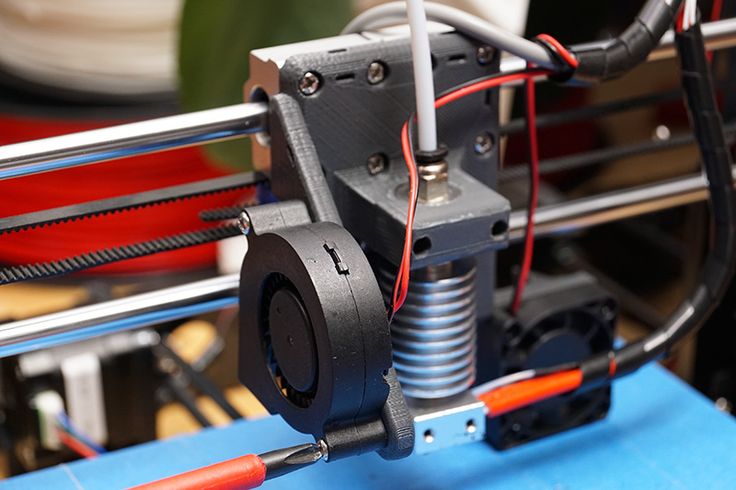

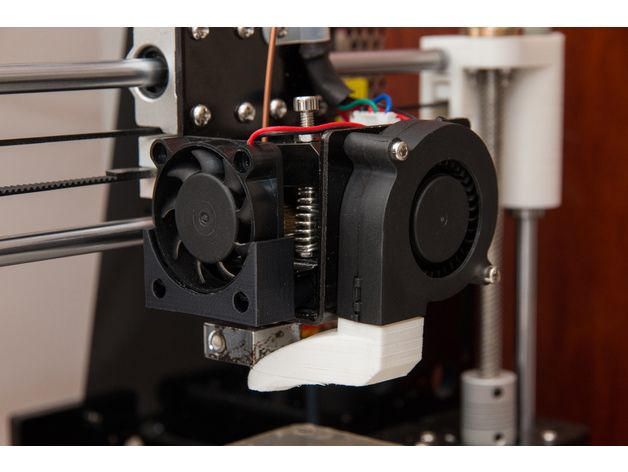

✔ Powerful Cooling Fans

The Bibo 2 touch and laser printer is what it is called, is equipped with two nozzle cooling fans. One of these fans has been installed in the front and the other one goes in the back of the machine.

With powerful cooling, printing with materials that require high temperature becomes easy and helps in providing precise prints.

The fan setting is easy to manage and can be controlled anytime during the print process.

Either you can use the touch screen control panel in the front of the 3D printer, or you can also utilize the Wi-Fi connected device including smartphones.

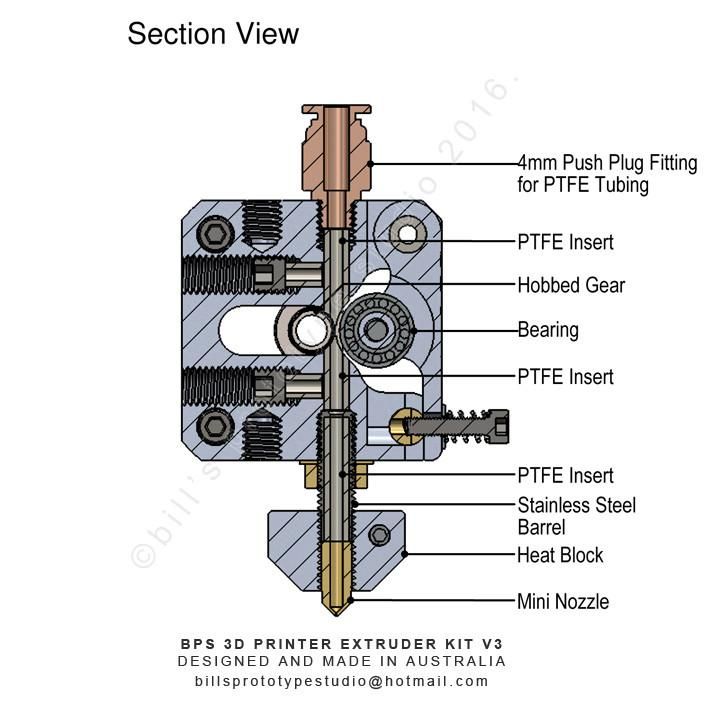

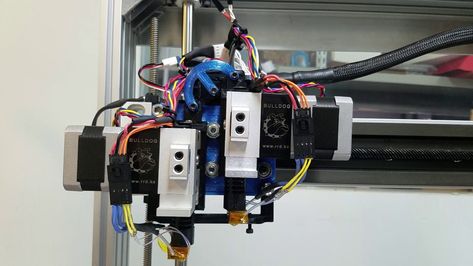

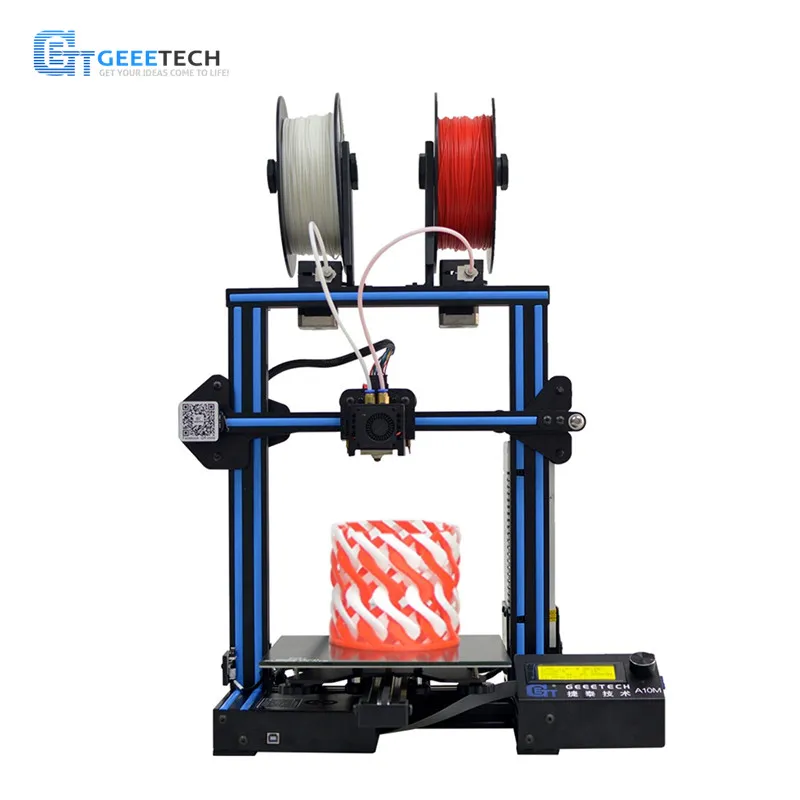

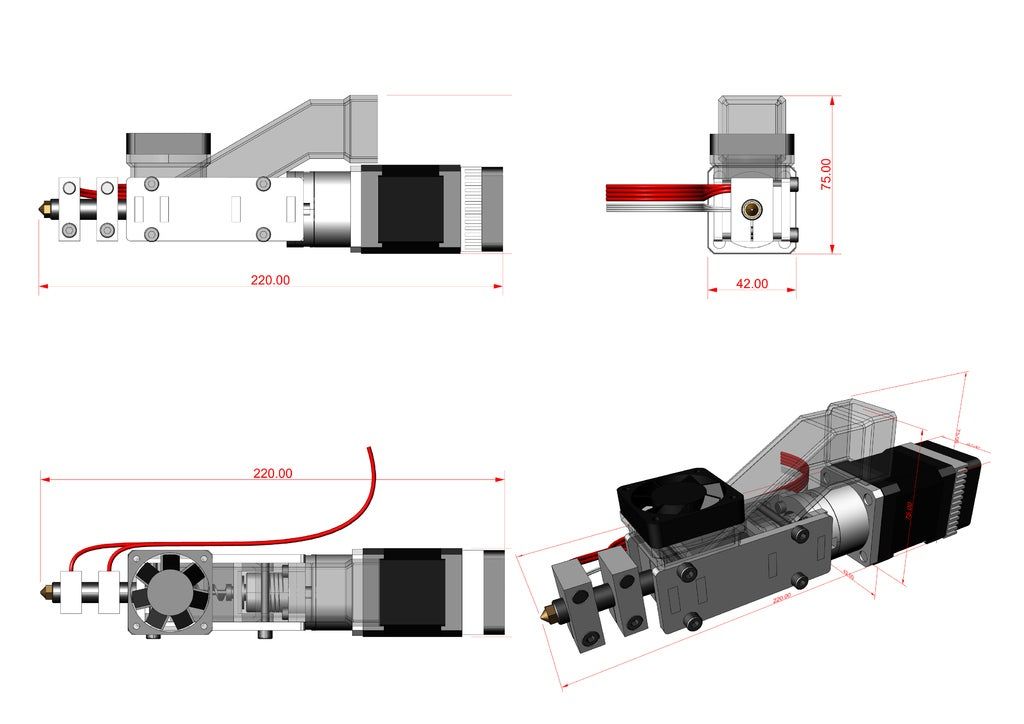

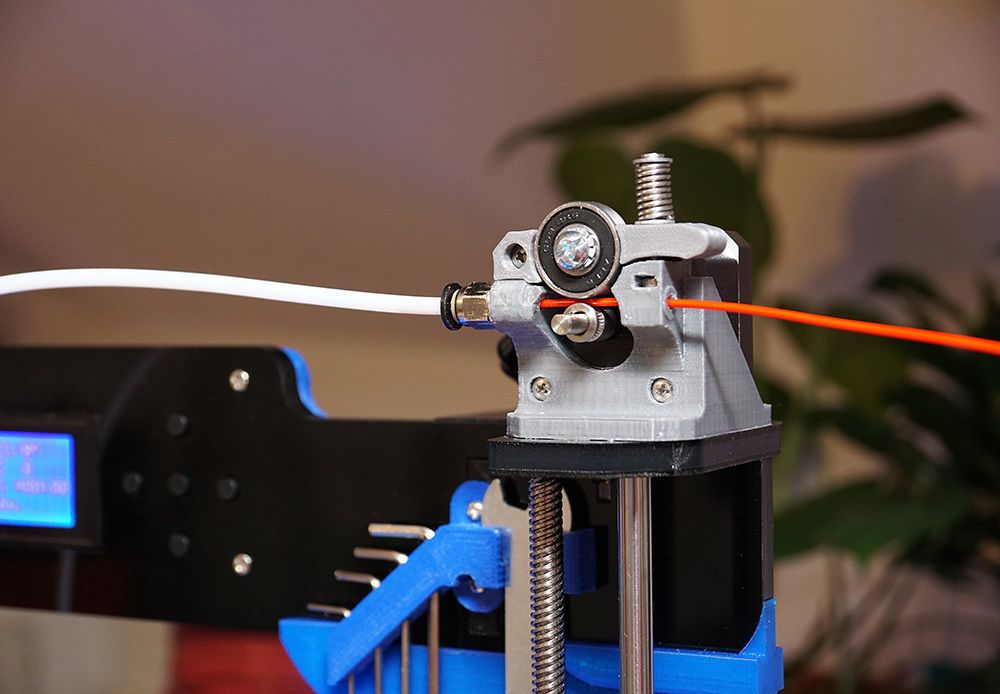

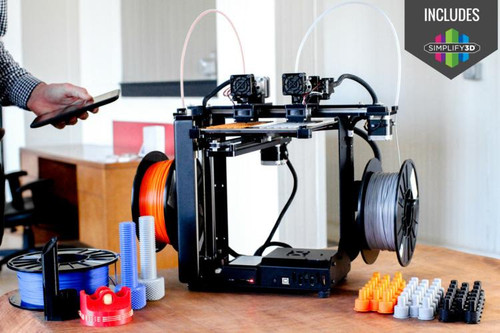

✔ Dual Extruders

Dual extruders add unimaginable strength to the printing possibilities of a 3D printer. And, there is no way one can ignore the fact that the inclusion of an extra extruder is becoming mainstream.

It is no more a hassle to be able to print in two different colors. Or, to print support that is easily removable when dissolved in water.

The reliability also increases when working with a dual extruder. You can print faster when working with two extruders.

With so many machines offering dual extruder nowadays, what is so special about Bibo extruders?

The reason that these are highly stable and offer unmatched precision to the 3D printed objects, Bibo clears its intention of staying at the top.

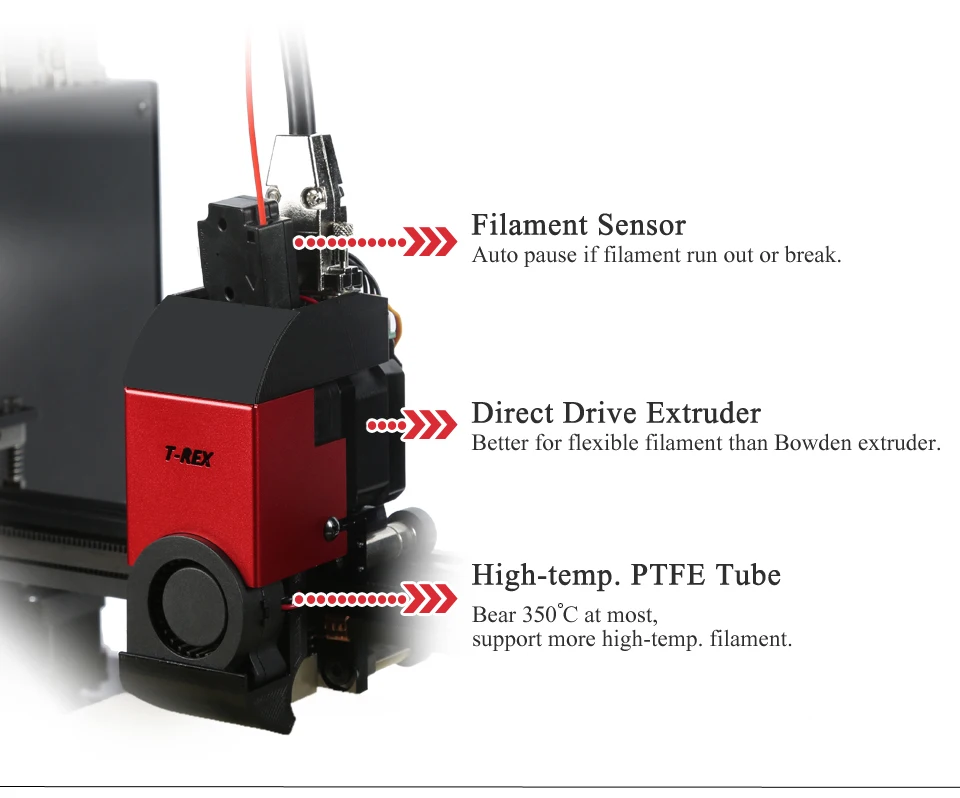

Moreover, the use of direct drive extruder technology Bibo is able to prevent the bending of filament inside the transmission tube.

✔ Power Detection

3D printing isn’t just a matter of seconds. Sometimes it can take almost an entire day to print an object.

That is when the problem of power outage comes into play. Ever been bothered by frequent power losses when printing with a 3D printer?

If yes, you would know the pain unless your 3D printer can recover from a power outage. Because of a power outage, a lot of times users have to start the printing all over again.

Some may lose the entire work completed before the power outage. But there is nothing to worry about when working with Bibo 2.

This printer can save work and pause the printing process until the power comes back. Hence, you can start from where you left. Isn’t that too crucial?

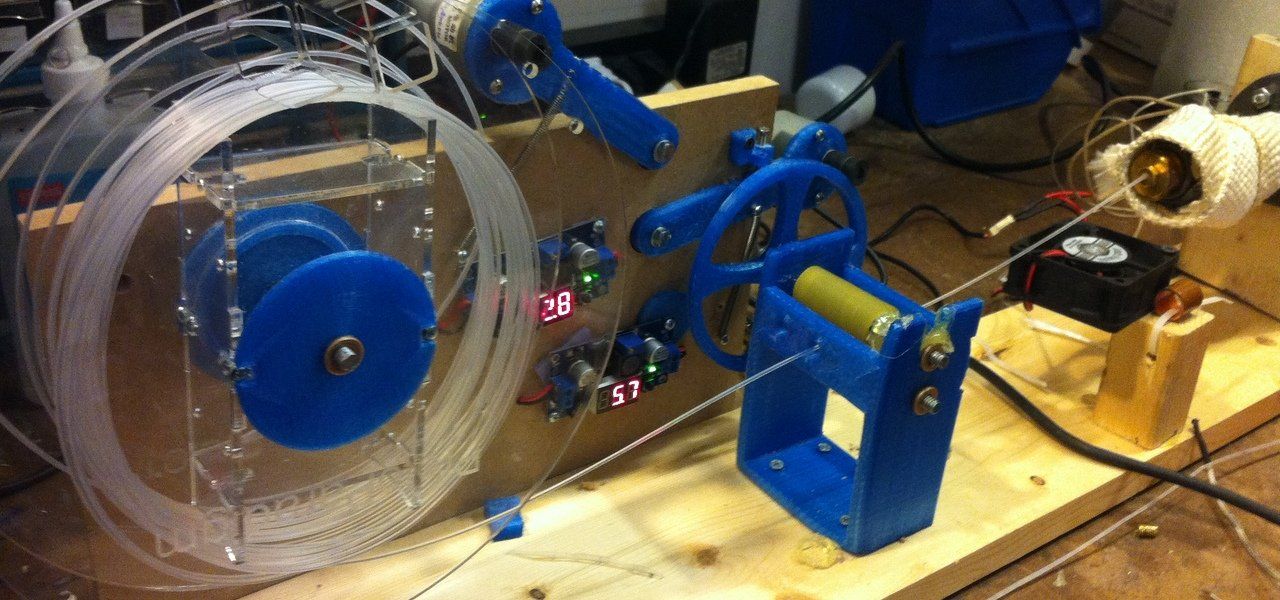

✔ Filament Detection

The problems aren’t limited to a power outage. There are times when you may not be around and the filament exhausts. You may even lose your prints.

There are times when you may not be around and the filament exhausts. You may even lose your prints.

To avoid such a mess, this 3D printer offers filament detection technology. This means that if you ever happened to run out of filament during a print, the printer would pause and save the work until you reload the filament.

Once you do that, the print would automatically start from where it was paused. Saving you a lot of unnecessary loss. On top of that, you will get a flawless print with no sign of mismanagement that ever happened during the print.

✔ Full-Color Touch Display

The 3D printer has a color touch display for helping users utilize the machine as a standalone solution.

Most of the settings can be altered using the touch display on the front.

With an easy interface, one can make use of this display to the fullest. It does vouch for the easy operation to completely another level.

✔ WIFI Connection

The 3D printer can be connected to a smartphone or a laptop using the WIFI controls. So, if you are away and still wanted to print, you can do that using the WiFi controls.

So, if you are away and still wanted to print, you can do that using the WiFi controls.

Apart from all these awesome features, the 3D printer also boasts a removable heated bed for easing the operation of the machine even further.

ADVERTISEMENT

Specifications

The 3D printer comes with a build size of 214 x 186 x 160 mm which is not too great but decent to accomplish most of the print jobs.

One can print with resolution ranging between 0.05 mm to 0.3 mm and the maximum nozzle temperature allowed is 270 degrees Celsius.

Bibo offers great precision and comes with two extruders with a nozzle diameter of 0.4 mm and 1.75 mm.

Apart from WIFI connectivity, users can upload the 3D designs using an SD card slot and USB slot. Using this 3D printer, one can achieve a maximum print speed of 350 mm/s which is quite fast.

Bibo Dual Extruder 3D Printer Price

The Bibo 3D printer is not very expensive and can come for almost $680. This is the price of the standard version.

The price may change when choosing the other variants of the machine.

However, it falls very much in the budget for most enthusiasts and home users. Looking at its results, even professionals can use this 3D printer.

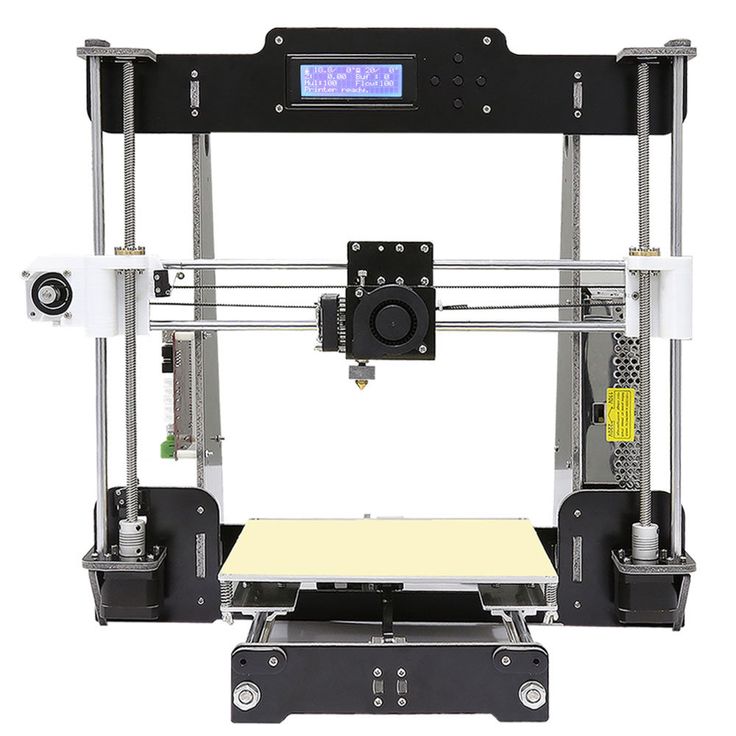

First Impressions

As mentioned before, the printer resembles a lot like Makerbot Replicator, however, it does differ in its operation in a lot many ways. But, at first, you may find it very close to the Makerbot series.

The most attractive part is its sturdy frame made of 6 mm thick aluminum composite panel. One may not understand the importance of the aluminum frame yet, but once you start working with it, you would.

The aluminum frame adds stability to the entire design making the precision go one level higher.

The enclosed structure is also appealing. With acrylic All models acrylic lid and door, one can expect to work with difficult filaments with ease such as ABS that require controlled temperature throughout the print process.

Alongside every positive detail, the printer also is compact in many terms. It occupies around 467 x 357 x 374 mm of space and weighs around 13 kgs. All in all, this is a nice-looking machine.

ADVERTISEMENT

Bibo Dual Extruder Setup

A lot of users may think it a fully assembled machine, however, it does come with few setup requirements.

The machine is packaged with many parts installed, however few pieces that must be stuck in for starting the print process.

For example, the extruder must be screwed inside, the red acrylic lid and a few other parts.

Depending on the experience of the users, the machine may take around an hour to start operating after taking out of the box.

Also, the bed leveling isn’t easy and one must invest some time to accurately set that up before starting to print from the machine.

Printing Type/Cost

The 3D printer is an FDM printer with the ability to print with two materials simultaneously.

It supports a lot of materials such as ABS, PLA, Dissolvable filament (HIPS), Flexible filament (TPU) and others. Talking about the cost of the printer and printing operation, the printer is within the affordable range.

With printer cost and support for PLA and other cheap filament options, one can keep the printing cost to the minimum side.

Bibo Dual Extruder Print Quality

Credit: 3dhubs.comThere have been issues with the second extruder coming in the way of the print process when not in use. However, this can be corrected using the best oozing avoidance practice.

Apart from that, the printer is smooth and very accurate. Being an FDM printer, the speed is not an issue. It prints with fast speed and an extra extruder adds to that benefit.

The complex geometries are also easily printable using this machine. One needs to take care of proper printing practices when trying to achieve the best results.

ADVERTISEMENT

Software

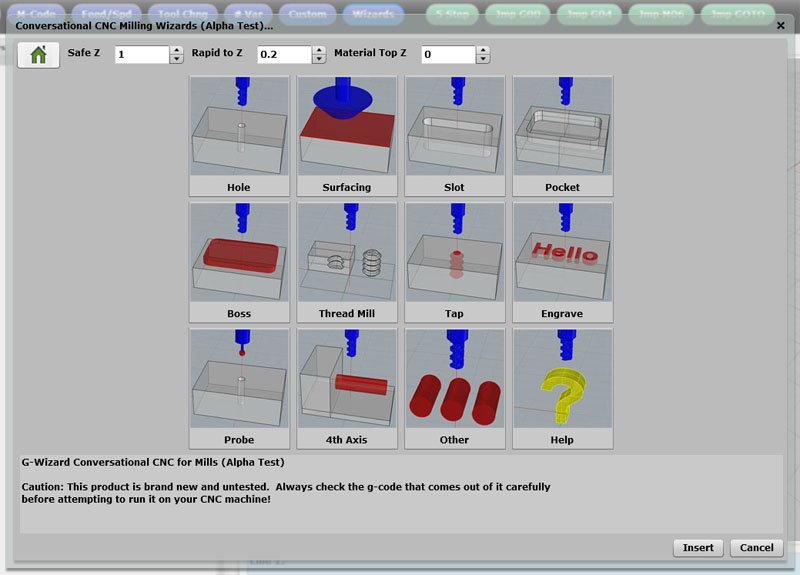

There is are a bunch of software that users can make use of. The company recommends using Repetier-Host, Cura, Simplify3D. Each of the software is easy to use and boasts a friendly interface.

The company recommends using Repetier-Host, Cura, Simplify3D. Each of the software is easy to use and boasts a friendly interface.

The printer is compatible with various slicing applications and one can very well choose as per convenience. Hence, giving users the freedom to opt for the application that they like to work with.

Customer Service

The company provides one year warranty on the product and the customer service is also amazing. With 12*7 hours of response time, users get the assistance needed as fast as possible.

As per the reviews from other users, the company excels at providing prompt guidance. Moreover, the help and instructions provided through documents and videos are also very helpful.

These are easy to understand and help users resolve most of the problems at hand without a need for an expert opinion.

Factors Governing the Buying Decision of Users

There are many factors that one must keep in mind before spending on a 3D printer. Here are a few major points to note before planning on buying Bibo 2.

Here are a few major points to note before planning on buying Bibo 2.

3D Printer cost: The printer, with all kinds of amazing features, can be counted as one of the most affordable options. However, if you are not using it for any specific purpose, you may choose to go with cheaper ones. But it is best for hobbyists, enthusiasts, and professionals. And, also for those who love to know the best possibilities from a 3D printer.

3D Print quality: The print quality is top-notch. One can expect to print accurate parts using this printer.

3D Print speed: It offers great speed. With such a price package, you are getting a workhorse. However, speed depends on a lot of other factors, such as the size and design complexity of the model, the resolution chosen, the material used, etc.

3D Printer capability: The printer can print complex geometries and very difficult designs with great speed.

3D Printer Practicality: This printer isn’t all just words. But can be utilized for many artistic and crucial applications within various niches. A great affordable printer for businesses.

But can be utilized for many artistic and crucial applications within various niches. A great affordable printer for businesses.

3D Printer User expectations: Users may expect a few more features with that price tag and the most important one is the auto bed leveling. However, it does fit right for most of the requirements. Hence, is very popular among users from different niches.

Verdict

Bibo has proved that a small machine can do wonders too. The unlimited benefits and features that the machine is packed with are difficult to chase.

It would not be incorrect to term it more than just a 3D printer. It adds more to the job list including laser engraving and is highly reliable, powerful, accurate and stable.

Top 5 3-in-1 3D printers of 2022 (with laser engraving and CNC!)

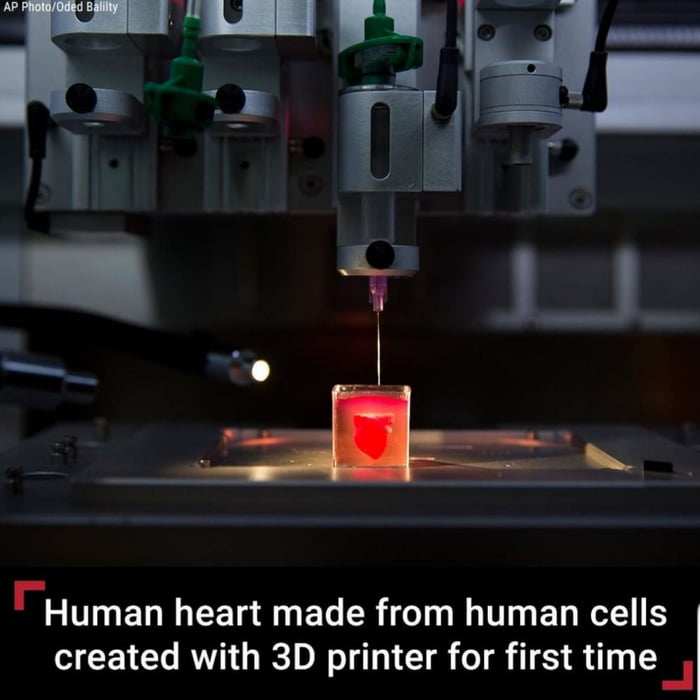

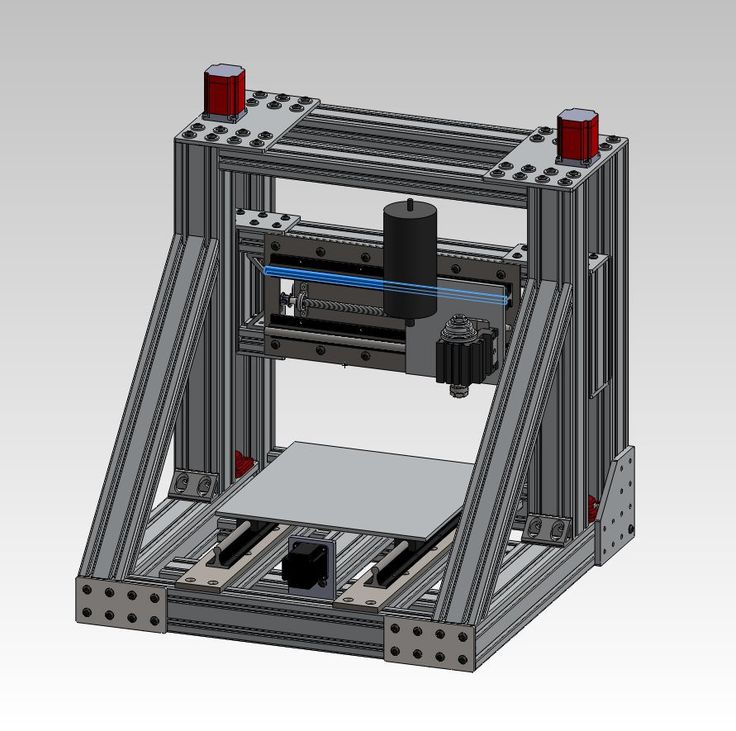

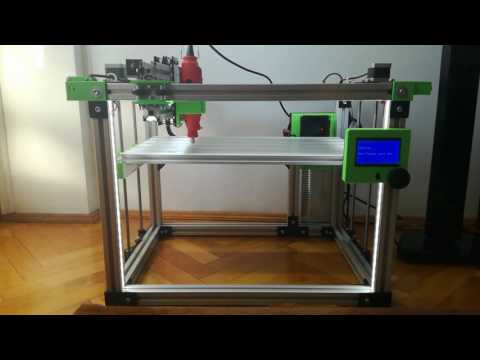

Ideally, we would all have one machine that could perform all the necessary production tasks - a laser 3D printer that would print , laser cut, CNC engraved and much more. 3-in-1 3D printers aren't perfect yet, but they offer versatility in 3D printing, CNC machining, and laser engraving - at different levels.

3-in-1 3D printers aren't perfect yet, but they offer versatility in 3D printing, CNC machining, and laser engraving - at different levels.

Sometimes referred to as multifunction 3D printers or AIO 3D printers, these printers feature removable tool heads that can be swapped to change their functions. If you want to prototype and cut out a wooden model first, use a CNC machine and then switch to a 3D printer extruder to create the final plastic prototype. nine0003

After testing dozens of 3D printers over the years, including our top pick, the Snapmaker 2.0, we've compiled our findings into our top 3-in-1 3D printer recommendations to help you make the best choice for you.

Contents

- How good are all-in-one 3D printers?

- The criteria we used to rate the best 3 in 1 3D printers

- When ranking the 3 in 1 3D printers we recommend below, we compared:

- Best all-in-one 3D printers

- Snapmaker 2.0 - comes in 3 shapes: A150, A250 & A350

- Snapmaker Original - good starter laser engraver 3D printer

- ZMorph Fab - 4 in 1 3D printer Creality CP-01

- 5axismaker - Excellent CNC 3D Printer

- Diabase H-Series - Powerful CNC Router 3D Printer

- Ecubmaker TOYDIY - 4 in 1 3D Printer

one"?

Naturally, focusing on being good enough at everything means losing quality in some areas. Elite athletes can't compete at the top of the NBA, NFL, and NHL at the same time - not even Michael Jordan could beat baseball - and the same is true for less specialized all-in-one 3D printers. nine0003

Elite athletes can't compete at the top of the NBA, NFL, and NHL at the same time - not even Michael Jordan could beat baseball - and the same is true for less specialized all-in-one 3D printers. nine0003

This is not to say that the 3D printer/laser hybrids we recommend don't work well. For hobby projects, laser 3D printers are great, but we don't recommend starting a full-service manufacturing company after purchasing a desktop 3D laser printer and CNC laser engraver.

The criteria we used to rate the best 3 in 1 3D printers

When ranking the 3 in 1 3D printers we recommend below, we compared:

- 3D Printer Quality: Most of these 3 in 1 3D printers are made by 3D printer companies and are mainly focused on additive manufacturing. Therefore, the quality of a 3D printer is a key factor.

- CNC Router Power: Some CNC machines cannot fully mill but only engrave. More powerful CNC machines rotate faster, can engrave harder materials, work more accurately and last longer.

nine0012

nine0012 - Laser engraver power: As with CNC machine, some all-in-one 3D printers can only engrave while others can cut materials.

- How easy it is to change heads: It's good to have powerful heads that work great, but if they're too hard or difficult to change, they can only do one thing.

- Software Efficiency: most of our recommendations contain specialized software that allows you to cut models for 3D printing, prepare designs for CNC and laser. The best software is easy to use, yet effective and reliable in all functions. nine0012

Best All-in-One 3D Printers

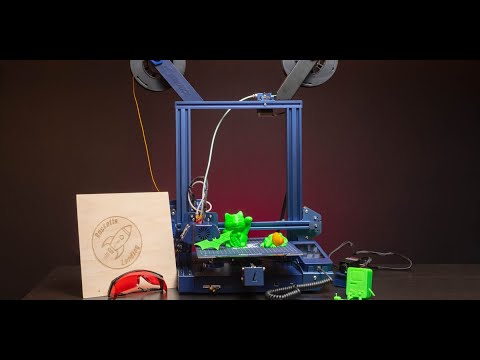

Snapmaker 2.0 - Available in 3 shapes: A150, A250 & A350

- Price: $1,199 to $1,799

- Assembly volumes: A150 = 160 x 160 x 145 mm / A250 = 230 x 250 x 235 mm / A350 = 320 x 350 x 350 mm

- Type: 3D in 1 3D printer: 3D printing, CNC and laser engraving

The original Snapmaker has already made a splash with over $2. 2M on Kickstarter, but Snapmaker 2.0 has completely surpassed all expectations, becoming the most funded tech project in Kickstarter history, raising an astounding $7.85M. Thousands of enthusiastic fans who love Snapmaker Original , are back to support the new version, and it has remained the most popular all-in-one 3D printer since its full release. nine0003

2M on Kickstarter, but Snapmaker 2.0 has completely surpassed all expectations, becoming the most funded tech project in Kickstarter history, raising an astounding $7.85M. Thousands of enthusiastic fans who love Snapmaker Original , are back to support the new version, and it has remained the most popular all-in-one 3D printer since its full release. nine0003

We've tested and reviewed Snapmaker 2.0 and talked about how great it is. It is undoubtedly the best 3-in-1 3D printer, offering fantastic 3D printing experience as well as excellent CNC carving and laser processing. You could even call it a 4-in-1 3D printer, as you can purchase an optional 4-axis rotary module that turns the laser and CNC heads into 4-axis versions with a 360-degree field of view. We've carved cylindrical chess pieces, engraved cylindrical gift boxes, and more with this add-on. nine0003

The 3D printer can print with PLA, ABS and flexible filaments such as TPU, and with WiFi and USB connectivity, you can print remotely online or offline using USB. The portable and movable touch screen used to control the printer looks and acts like a smartphone, simplifying workflow and making it easier to control and manage projects.

The portable and movable touch screen used to control the printer looks and acts like a smartphone, simplifying workflow and making it easier to control and manage projects.

What's more, the low filament sensor automatically pauses printing when it runs out, giving you time to load more filament and resume printing without ruining it, and if you purchase an extra housing, you can print ABS more easily to prevent warping - and save money. CNC from dust, and laser brightness from your eyes. nine0003

Snapmaker 2.0 3D printed vase

A vase that we 3D printed with Snapmaker 2.0.

The laser engraver creates high contrast images on fabrics, leather, plywood and acrylic materials. The built-in camera allows you to monitor the design remotely and make sure everything runs smoothly. This is an efficient low cost laser 3D printer. We also tested it as a laser cutter and were able to cut and assemble a gift box from a 1.5mm thin sheet of softwood. nine0003

Snapmaker 2. 0 laser 3d printer with laser cutter

0 laser 3d printer with laser cutter

Snapmaker 2.0 also works as a laser cutter as well as a 3D printer.

The CNC machine can carve designs on walnut, PCB wood, as well as carbon fiber sheets, acrylic and hard wood. A key enhancement to Model 2.0 is increased speed, which means that large projects can be created in record time.

Overall, we highly recommend the Snapmaker 2.0 models, of which we tested the largest version, the Snapmaker 2.0 A350. You can optionally purchase a body, a 4-axis rotary module, and a powerful new 10W laser head, but we haven't tried the 10W laser head. nine0003

We recommend purchasing a body for safer and more consistent manufacturing, as well as replacement CNC bits.

Snapmaker Original is a good starter laser engraver 3D printer

- Price: $719

- Assembly volume: 125 x 125 x 125 mm

- Type: 3 in 1 3D printer: 3D printing, CNC and laser engraving

Snapmaker went public and made headlines when it raised an incredible $2. 2 million on Kickstarter for its first all-in-one 3D printer, the Snapmaker Original. Functioning as a small 3D printer, as well as being able to carve wood and engrave images into phone cases and other materials, the Snapmaker Original captured the hearts of many crafters around the world and became a wild success. nine0003

2 million on Kickstarter for its first all-in-one 3D printer, the Snapmaker Original. Functioning as a small 3D printer, as well as being able to carve wood and engrave images into phone cases and other materials, the Snapmaker Original captured the hearts of many crafters around the world and became a wild success. nine0003

The heated bed of the 3D printer can reach 80C, allowing both ABS and PLA to be printed. It is accurate, with layer resolution down to 50 microns. The heavy metal frame secures the printer and improves stability and durability, while the heavier frame is less prone to vibrations that can affect print quality and surface quality.

The CNC cutter can create intricate parts up to 90 x 90 x 50 mm, while the laser engraver works up to 125 x 125 mm.

Snapmaker's 3-in-1 software, Snapmaker Luban, allows you to do 3D printing, CNC and laser engraving on the same platform and seamlessly switch between each tool head.

Snapmaker claims that a 3D printer can be assembled in just 10 minutes, and switching between tool heads to change the functions of an all-in-one 3D printer is very easy. Highly acclaimed by manufacturers as one of the best 3-in-1 3D printers in its price range, Snapmaker recently upgraded the Original with the Snapmaker 2.0, with a higher build volume and higher price tag. nine0003

Highly acclaimed by manufacturers as one of the best 3-in-1 3D printers in its price range, Snapmaker recently upgraded the Original with the Snapmaker 2.0, with a higher build volume and higher price tag. nine0003

A selection of wood and other materials cut with the Snapmaker Original CNC tool head. Source: snapmaker.com

ZMorph Fab 4 in 1 3D Printer

- Price: $3,999 for a complete set of

- Assembly volume: 250 x 235 x 165 mm

- Type: 4 in 1 3D printer with CNC milling, laser cutting and engraving, and thick paste extruder.

- Home country: Poland

Poland's ZMorph makes some of the most versatile all-in-one 3D printers: Fab can print, CNC, engrave and laser cut, and can even turn into a food 3D printer with ZMorph's thick paste extruder . This edible material can print chocolate as well as other similar materials such as icing and pastry. nine0003

ZMorph 3D printers are renowned for their reliability and workhorse quality, and the Fab is no exception. This is a great 3D printer with a high quality heated bed that can comfortably print ABS, HIPS and other stiffer materials like nylon. The printer can automatically align and easily transform from a 3D printer to a laser engraver or CNC router.

This is a great 3D printer with a high quality heated bed that can comfortably print ABS, HIPS and other stiffer materials like nylon. The printer can automatically align and easily transform from a 3D printer to a laser engraver or CNC router.

Also, with the dual head option, the ZMorph works well as a dual extruder 3D printer, capable of printing multiple colors or soluble support materials such as HIPS and PVA, and even mixing two colors together to produce multiple different shades in one details. The hybrid CNC laser 3D printer can be configured to print with both 1.75mm and 3mm 3D printer filaments, and has a large enough build area to print even the largest projects. nine0003

When used with a CNC tool head, the ZMorph becomes a powerful 3D printer with a CNC router that can mill and engrave almost any type of wood, as well as other materials such as acrylic glass and EVA foam. The 300W power allows you to mill at speeds up to 120mm/s, while ZMorph recommends a cutting depth of up to 0. 5mm.

5mm.

The Laser PRO attachment turns the Fab into a 3D laser engraver capable of burning and engraving plywood and many other types of wood, cardboard, leather and acrylic glass with a powerful yet compact 2.8W blue laser. Although the default speed is 15mm/s, the laser can run up to 120mm/s for faster engraving. nine0003

ZMorph's Voxelizer 2 software works as a 3D slicer for 3D printing parts, and offers the features of CAD CAM software for CNC and laser cutting models, all in one. All in all, this is a fantastic and extremely versatile all-in-one 3D printer and the closest thing to a machine with a complete manufacturing facility.

zmorph vx cnc wood carving printer

ZMorph CNC tool head creates design from wood. Source: ZMorph on Medium. nine0003

Creality CP-01

- Price: $819

- Assembly volume: 200 x 200 x 200 mm

- Type: 3 in 1 3D printer: 3D printer, CNC and laser engraving

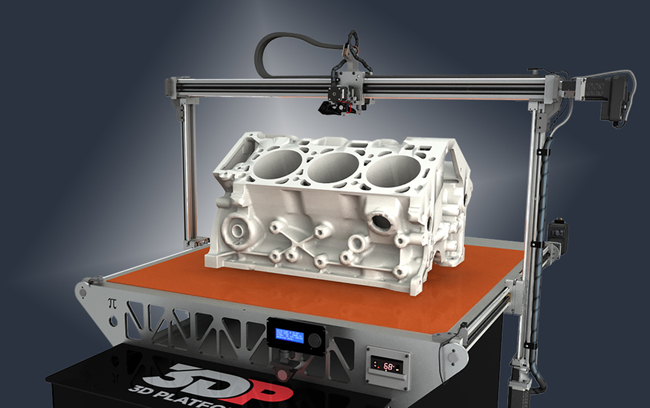

Creality makes the world's most popular affordable 3D printers today, including the Ender 3, Ender 5 and CR-10 series. The Creality CP-01 is their all-in-one 3D printer venture offering CNC engraving and laser engraving along with a 3D printer.

The Creality CP-01 is their all-in-one 3D printer venture offering CNC engraving and laser engraving along with a 3D printer.

As a 3D printer, it has a good print volume of 200 x 200 x 200mm and comes with a heated bed that can reach 100C. Such temperatures mean that 3D printing on ABS, HIPS and TPU shouldn't be a problem, and in theory you could even try printing on materials like polycarbonate and carbon fiber. nine0003

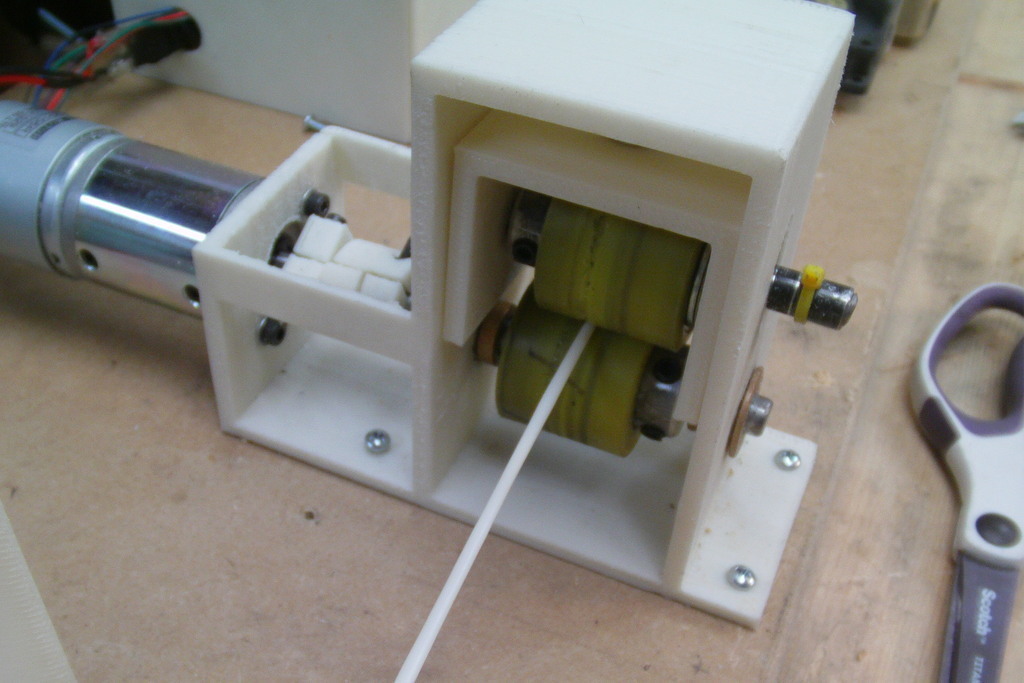

The textured glass plate should promote adhesion and reduce warping, and the direct drive extruder also makes flex filament 3D printing easier in most cases.

As a laser engraver, the Creality CP-01 3-in-1 3D printer is equipped with a 0.5W laser tool that can engrave areas up to 100 x 90mm. The engraver can create contrasting halftone patterns on paper, plastic and wood.

As a CNC cutter, the CP-01 is equipped with a 4800 rpm CNC rotating spindle, capable of cutting plastic, wood and circuit boards. It can cut sections of the same size as a 3D printer - 200 x 200mm. nine0003

nine0003

The CP-01 comes with Creality Workshop's own 3D printer software that supports engraving and CNC functions. The offline Creality Slicer software is well suited for 3D printing.

Overall, it's similar to the Snapmaker and seems to offer similar specs and features, so it remains to be seen if the kings of cheap 3D printers can compete in the all-in-one 3D printer sector.

Each of Creality CP-01 tool heads for 3D printing, CNC cutting and laser engraving. nine0003

5axismaker - great CNC 3D printer

- Price: £5,500 / £6,800 depending on size

- Assembly volume: 5xm400 = 400 x 400 x 400 mm / 5xm600 = 600 x 600 x 400 mm

- Type: 2 in 1 CNC 3D printer

London-based 5axismaker has developed a great multi-functional CNC 3D printer that comes in two main sizes to meet your production needs:

- 5axismaker 5xm400 model: 400 x 400 x 400 mm building volume

- model 5axismaker 5xm600: 600 x 600 x 400 mm

As a 3D printer, the 5axismaker comes with a default 0. 6mm nozzle - although you can go to 0.4mm if you're used to smaller nozzles, and up to 1.2mm nozzles if speed is important to you and you are willing to sacrifice some precision. 5axismaker can print to PLA or ABS.

6mm nozzle - although you can go to 0.4mm if you're used to smaller nozzles, and up to 1.2mm nozzles if speed is important to you and you are willing to sacrifice some precision. 5axismaker can print to PLA or ABS.

As a CNC machine, 5axismaker offers a fast spindle speed of 10,000-15,000 RPM on a powerful 500-1000W brushless motor capable of milling foam, hardwood, carbon fiber, engineering plastics, processable wax, etc. .d. There is also a touch sensor option - but for this head and any other custom tools you need to contact 5axismaker directly. nine0003

5axismaker has also developed its own CAM software to support CNC milling and NC code generation called 5xmonkey. 5axismaker focuses primarily on CNC machining, preferring not to offer laser engraving with a 3D printer, but it is well suited as a 2 in 1 3D printer.

- Price: from $9,750

- Assembly volume: depends on the number of axles

Another 2 in 1 3D printer focused on 3D printing and CNC milling, Diabase offers three different H-series options:

H5-400A Hybrid: no tool plate, 5 or 4 axis upgradeable , but can mill printed parts.

H5-400A CNC Lite: offers 4 and 5 axis upgrades.

H5-400B CNC Full: offers 4 material printing, 14 tool changes and a powerful spindle. nine0003

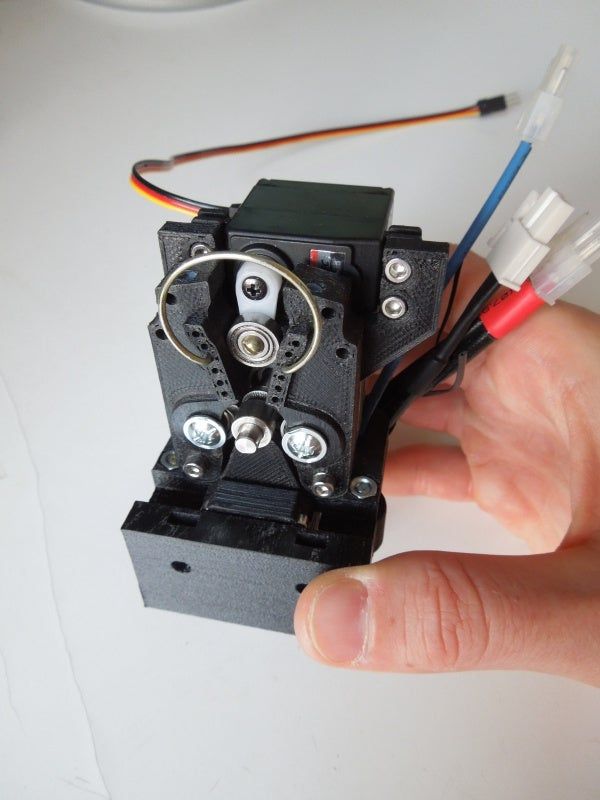

Diabase is already well known for its excellent 3D printer extruders focused on making 3D printing as reliable as possible with flexible filaments that were previously considered difficult to print - especially on Bowden extruders.

Now they offer a complete manufacturing solution: their multifunctional 3D printers can print and mill parts in a single workflow with each tool head.

h-series diabase CNC 3D printer

H-series hybrid 3D printer with CNC cutter offers 5-axis CNC production and 12,000 RPM rotation speed to create very complex and intricate parts. As a 3D printer, it allows 3D printing in multiple materials such as TPU and PVA, with PVA's solubility making it ideal for later easy removal of PVA supports. The CNC milling part can machine soft metals up to 75 HRB hardness, truly a full service solution. nine0003

nine0003

Diabase H-series rotary axes provide fantastic detail complexity and complex geometries for production.

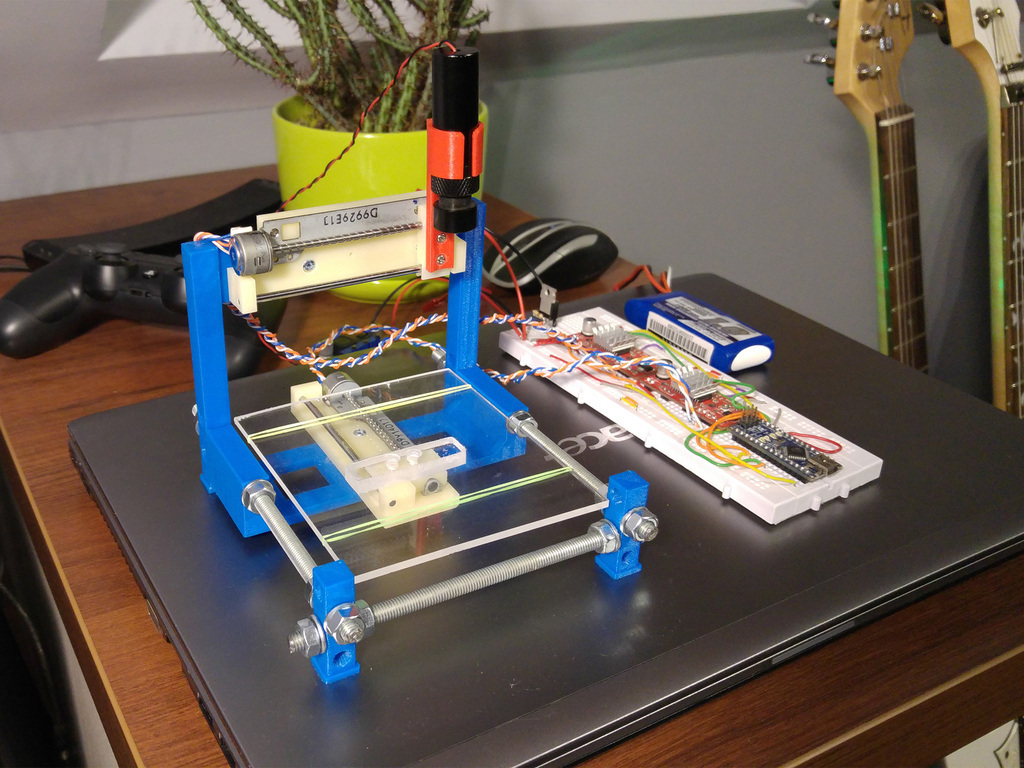

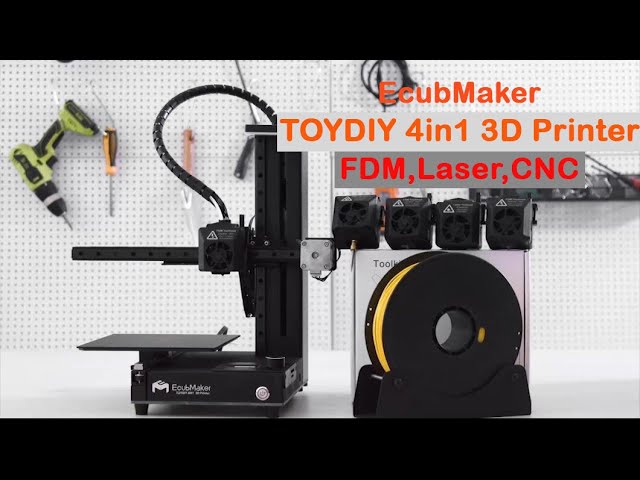

Ecubmaker TOYDIY - 4 in 1 3D Printer

- Price: $549

- Case volume: 180 x 180 x 180 mm

- Type: 4 in 1 3D printer: FDM, dual color, CNC engraving and laser engraving

- Country of manufacture China

Although it calls itself a 4 in 1 3D printer, this statement implies the division of the 3D printing part into standard FDM 3D printing and two-color 3D printing, which both belong to 3D printing. In reality Ecubmaker TOYDIY is a 3 in 1 3D printer but with four easily interchangeable tool heads for 3D printing, CNC engraving or laser engraving. nine0003

For 3D printing, the extruder can reach up to 240C and the heated bed up to 50C. Therefore, printing with higher temperature materials such as ABS and HIPS is not possible and you are limited to using the Ecubmaker TOYDIY as a PLA 3D printer only. (Testing has been done to use a dual extruder for PVA printing as a support, although the company does not recommend this). So when using the dual extruder 3D printing option, you can only print two different colors of PLA, not soluble support materials. nine0003

So when using the dual extruder 3D printing option, you can only print two different colors of PLA, not soluble support materials. nine0003

ecubmaker toydiy 4 in 1 3d printer

Each of four Ecubmaker TOYDIY modes.

For a laser 3D printer that doesn't specialize in any one measurement, it's surprisingly accurate - with layer thicknesses down to 0.05mm. The foldable three-layer plate also makes it easier to remove finished prints and helps reduce buckling, although PLA rarely warps.

As a laser engraver, TOYDIY 3D printer is equipped with a 1500MW violet laser, which can engrave wood, plastic, leather, cardboard and some other materials. However, this is purely a laser engraver and cannot cut materials. nine0003

The CNC tool head is equipped with a 385DC motor that rotates at 8,000 to 10,000 rpm. The CNC printer can engrave and cut wood, plastic, acrylic and most non-metal materials, but cannot be used with transparent materials such as glass. Ecubmaker also emphasizes that the CNC head should not be used for more than 3 hours at a time.

Ecubmaker also emphasizes that the CNC head should not be used for more than 3 hours at a time.

TOYDIY comes with Ecubmaker Ecubware 4 in 1 3D Slicer software for any type of application. The 3D laser printer comes with an SD card containing tutorials on how to use the 3D printer, engraver and CNC cutter to help you get started, and if you have any serious problems, you can return the printer within the warranty period. nine0003

Snapmaker Multifunctional 3D Printer Overview / Sudo Null IT News

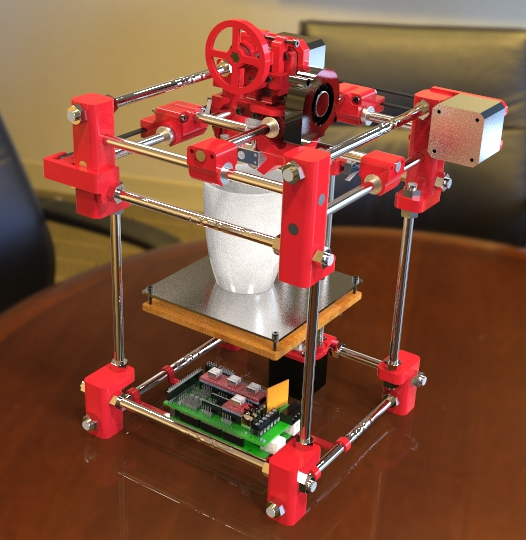

Snapmaker is a multifunctional device with replaceable modules. In the simplest configuration, this is a compact desktop 3D printer made of metal, and with additional blocks it acquires the capabilities of a laser engraver and a small milling machine.

Features:

Materials: PLA, PVA, ABS, Nylon and other plastics up to 250°C

Nozzle temperature: 180-250 °C

Platform temperature: 20-100°C

Layer thickness: from 50 to 300 microns.

Print area: 125x125x125 mm.

External dimensions: 289x272x332 mm.

Price: from $199 to $699, depending on configuration and excluding shipping and handling charges, subject to early backing on KickStarter.

The retail price of the series is not yet known, but you can pre-order and be the first to receive up-to-date price information. nine0003

What is interesting?

Strength and stiffness

Snapmaker is made of metal - it has no responsible or load-bearing plastic parts. At the same time, the use of sheet steel for massive parts would significantly increase the weight of the design and make the printer more expensive, because aluminum alloys are used.

Precision

The accuracy of work is ensured, along with the rigidity of the structure, also by the fact that in the linear modules, a screw gear is used as a drive mechanism. nine0003

nine0003

Modularity

The device consists of replaceable modules, which allows not only to quickly switch functionality, but also to easily repair and upgrade. Replacing the working head turns a 3D printer into a laser engraving machine or a software-controlled router.

Simplicity

The ease of handling of the device is also associated with the modularity of the design. The linear modules responsible for the movement of the working heads cannot be confused - they are the same and interchangeable. nine0003

Snapmaker assembles and disassembles for transport, also in minutes.

Operation via easy-to-use Snap3D software and detachable 3.2" touch terminal.

No need for a special varnish or film to fix the product during printing or processing - the design provides a reusable self-adhesive heated platform.

Due to the design features and Snap3D, manual platform calibration is also not needed. nine0003

nine0003

What can?

3D printing

Snapmaker prints PLA, PVA, ABS, Nylon and other materials with print temperatures up to 250 degrees Celsius. The maximum size of a possible printout is a cube with a 125 mm edge.

This vase, for example, 8 cm high and 6.45 cm in diameter, was printed with standard 1.75 mm PLA, with a layer thickness of 0.2 mm, in about 1 hour and 20 minutes.

Other printouts:

Laser engraved

One of the supplied modules is a laser for engraving on wood, plastic and other surfaces.

The laser power is 0.5 watts, which is enough to apply any image on wood and wood composites, polymers, fabrics, leather.

Milling

The milling module, with a spindle speed of 2000 - 7000 rpm, is able to reproduce relief images on any surfaces suitable for hardness - mainly wood and plastics. nine0003

nine0003

Hong Kong Electronics Fair video:

Uncompressed bamboo engraving video (1 hour 10 minutes):

Yes, not too fast, but accurate and accurate.

Total:

So why are we interested in Snapmaker?

First of all, this compact and easy-to-handle device, which can easily fit on any table, can replace an entire workshop. He alone will print, and burn, and cut out. An irreplaceable thing. nine0003

Not surprisingly, he raised $2,277,182 on KickStarter, out of the $50,000 requested at the start of the campaign.

There are unconditional disadvantages.

First of all, this, of course, is the size of the workspace. Seriously, 12.5 centimeters may be enough for 3D printing, but for laser engraving and milling, this is quite modest.

Nevertheless, the device is certainly interesting. We will closely monitor the completion of the crowdfunding campaign and the launch of mass production.

75 mm 0.07 in

75 mm 0.07 in