Best 3d printer on market

Creality Ender 3 S1 Pro Review: All the Bells and Whistles

When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

No upgrades needed. This Ender 3 has it all.

Editor's Choice

(Image: © Tom's Hardware)

Tom's Hardware Verdict

Creality took its most popular budget 3D printer and decked it out with all the upgrades, saving you time, and even a little money.

TODAY'S BEST DEALS

Pros

- +

Quality prints

- +

Easy assembly

- +

Auto bed leveling

- +

Direct drive

- +

Touch Screen

Why you can trust Tom's Hardware Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Creality Ender 3 S1 Pro deals

$499

$399

View

$479

View

$499

View

The Creality Ender 3 S1 Pro is quite a mouthful, but it’s also quite a printer. Shortly after announcing the deluxe Ender 3 S1, Creality inexplicably added even more features to their trusty workhorse and dubbed it the “pro” version.

None of these new features will make you throw your S1 in the garbage, but they are enticing if you’re stepping up from an Ender 3 Pro or V2 model. Ready to compete with the best 3D printers on the market, the Ender 3 S1 Pro comes with Creality’s first all metal hotend, a PEI flex plate, a touch screen, an improved spool holder and a built-in light kit.

That’s on top of core improvements already introduced in the S1 version, such as a direct drive, dual Z axis, auto bed leveling, and a slot for a full sized SD card.

Retailing at $479 on Creality’s website , this printer is a far cry from its budget minded roots. It’s still $360 cheaper Prusa MK3S+ kit, but nearly twice the price of basic Ender 3s still on the market. Those bargain basement Enders are still popular because they are so easily upgraded. Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

Nearly everything that comes on an Ender 3 S1 Pro can be added to a classic Ender 3, if you’re willing to spend at least $350 in parts and add them to the old printer yourself (which is a hassle and costs more if you don’t already own an Ender 3).

- Creality Ender 3 S1 Pro (Black) at Walmart for $479

Specifications: Ender 3 S1 Pro

Swipe to scroll horizontally

| Machine Footprint | 6490 x 455 x 625 mm (19.2 x 18 x 24.5 inches) |

| Build Volume | 220 x 220 x 270 mm (8.5 x 8.5 x 10.5 inches) |

| Material | PLA/PETG/TPU/ABS |

| Extruder Type | Direct Drive |

| Nozzle | .4mm (Interchangeable) |

| Filament Runout Sensor | Yes |

| Bed Leveling | CR Touch |

| Connectivity | SD card, Type-C USB |

| Interface | Color Touch Screen |

Creality Ender 3 S1 Pro: Included in the box

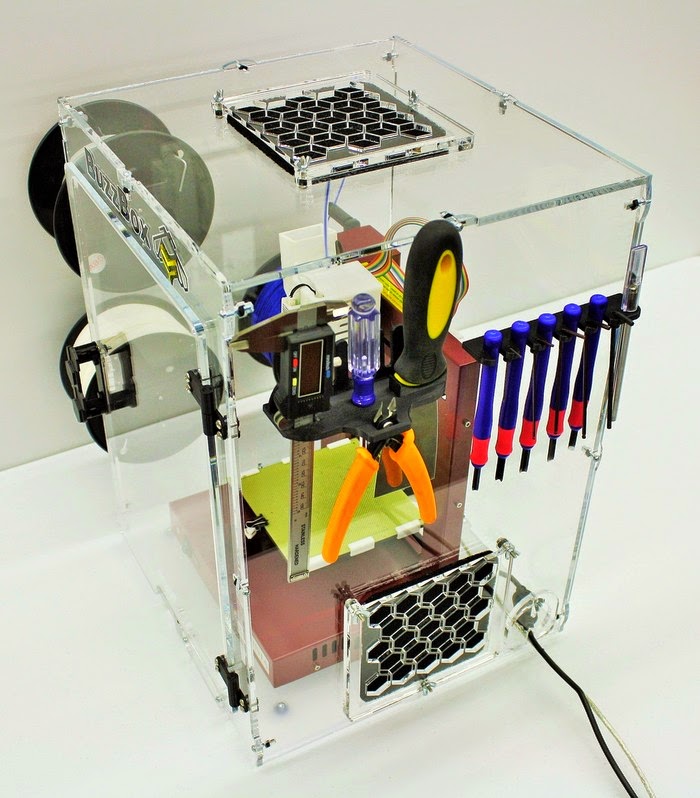

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with everything you need to get your printer set up. You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

You get tools to build and maintain the printer, side cutters, a metal scraper, a nozzle cleaner, a spare nozzle, an extra Z limit switch, and a full sized SD card with a USB adapter. There’s also a small sample of white PLA to print your first model.

The SD card has two short videos, one on assembling the printer, and another on how to level it. You also get a PDF copy of the manual, a copy of Creality Slicer 4.8.0 and models in both pre-sliced .gcode and .stl format.

(Image credit: Tom's Hardware)The Ender 3 S1 Pro is quite a bit flashier than the old Ender 3s, but only slightly different from the previous S1.

The Ender 3 S1 Pro has a modern look, with an all-in-one design, smooth metal frame and flat cables. It has Creality’s newest direct drive, the all metal Sprite, which not only improves performance, but does away with the need for a Bowden tube.

The direct drive is an all metal, dual gear unit that works beautifully. It’s a little industrial looking compared to the rest of the machine, but the lack of plastic housing serves to cut down on weight. It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

It’s a titanium heat break allows it to heat up to a toasty 300 degrees. This allows us to print more materials, but more important, cuts down on nasty clogs from burnt PTFE tubes.

The Creality Sprite extruder is shipped unmounted and attaches with a few easy to reach screws. It’s meant to be simple to remove, so you can swap it with a laser kit , purchased separately. We’ll be reviewing the laser at a later date.

(Image credit: Tom's Hardware)I’m still not loving the awkward front-mounted parts cooling fan, which makes it hard to watch your first layer go down. The machine also comes with a run out sensor mounted near the spool holder and power loss recovery.

Like the S1, the Ender 3 S1 Pro has a CR Touch for auto bed leveling, but kept the bed’s flexible springs and knobs. Should the CR Touch fail completely, or you just hate easy bed leveling, Creality included a Z limit switch you could add to convert it back to manual.

A final intriguing addition is a dual Z axis upgrade, something normally reserved for larger printers. The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

The two lead screws are kept in sync with a belt for added security. The extra Z axis ensures smoother prints by giving the X gantry more support.

I was most excited to see my favorite upgrade – a PEI coated steel flex plate. The PC coated plate on the S1 was both too sticky and too floppy, and damaged a few vase mode prints.

(Image credit: Tom's Hardware)If you’ve used any Creality machine in the past, the new touch screen will throw you for a loop. The layout is completely different from all the old versions with a complex text menu that, honestly, doesn’t make a lot of sense in places. For example, the automatic preheat buttons are hidden under “manual” and bed leveling is stashed under settings.

(Image credit: Tom's Hardware)Assembling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is mostly pre-assembled and comes together with a handful of neatly labeled bolts and screws. Creality learned from the S1 and made the paper manual much larger. If you find video easier to follow, you can watch a good assembly video on the included SD card.

If you find video easier to follow, you can watch a good assembly video on the included SD card.

I installed the gantry first. It fits into slots on the base unit and is held in place with 2 screws and 2 bolts on each side. Then I fitted the hotend assembly onto the X gantry with four screws. The control screen bolts to the side with 3 screws and the spool holder snaps into place on the top.

Wiring is very simple as everything is already attached to the frame and only needs to be plugged in.

Last, flip the power supply switch to match your main household electric, which is 115V in the U.S. Creality placed a giant sticker to make sure you don’t overlook the hidden switch.

(Image credit: Tom's Hardware)Leveling the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a CR Touch installed, Creality’s version of the popular BL Touch. It physically taps the build surface with a metal probe and works with both metal or glass surfaces.

To level the printer for the first time, select Level from the settings menu. Click Start and the printer will immediately go into its leveling routine without preheating and tap 16 points around the bed.

(Image credit: Tom's Hardware)Now go back to the previous menu and click “Auto Level” to set the Z offset by sliding a piece of paper under the nozzle. Move the Z offset up or down until the nozzle just scrapes the paper. The printer I tested did not need to adjust the Z, it was perfect the first time.

If the CR Touch is unable to level the bed, you will need to do a manual level. Directions for this are in the manual.

Loading Filament on the Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Creality Ender 3 S1 Pro is the first Ender to include a filament loading routine in the control panel. This is located under Ready → In/Out. Click the nozzle icon, enter a number of millimeters you’d like to advance. 20 is a good place to start. If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

If the nozzle is not hot, the Ender 3 S1 Pro will automatically warm up to 200 degrees, then advance the filament.

To unload material, just reverse the process.

Preparing Files / Software for Creality Ender 3 S1 Pro

(Image credit: Tom's Hardware)The Ender 3 S1 Pro comes with a copy of Creality Slicer 4.8.0, which is simply an older version of Cura with Creality branding and every printer its ever made pre-loaded. PrusaSlicer is another popular alternative that’s also free and some consider easier to use.

The latest version of Cura (5.0) doesn’t have a profile for the Ender 3 S1 Pro, but you can use the profile for the Ender 3 Pro and adjust the build height to 270. PrusaSlicer has a profile for the Ender 3 S1, which has the same build size.

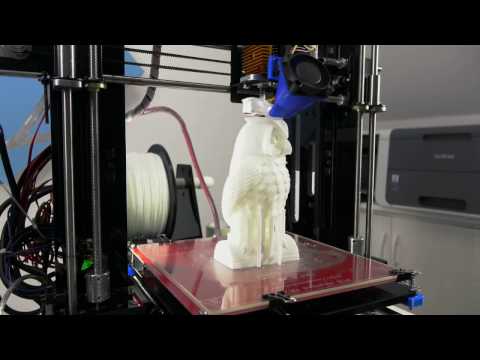

Printing on the Creality Ender 3 S1 Pro

The Creality Ender 3 S1 Pro printed wonderfully right out of the box. My first print was a pre-sliced Cat from the SD card – which was also the test print supplied with the S1. I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

I turned out exactly the same, including the same little stray bit of filament on the mouth. This is printed using the sample filament.

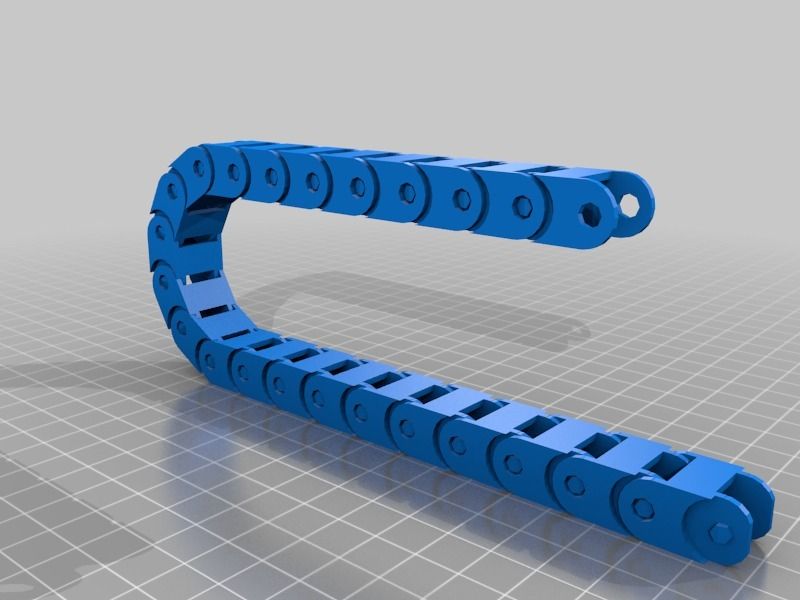

I like to test bed adhesion with a print in place model, like a flexi toy. This dolphin from Flexi Factory fit the bill and printed very cleanly. I did a manual color swap just to use up some final scraps of PLA. This is printed in Inland Turquoise PLA and Matterhackers Pro Series Blue PLA. This took 3 hours and 55 minutes at a .2mm layer height and 60mms speed.

Model by Flexi Factory (Image credit: Tom's Hardware)I wanted to test TPU in an interesting way, so I ran this really cool coaster set from Trilobyte3D. It won a contest on Printables.com for, you guessed it, coasters! This is a three part print, with the leaves printed in TPU laying flat, then the stem and pot printing separately without supports. The leaves are made from Matterhackers Translucent Green TPU and come off the stem to place under your drink. The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

The stem is Emerald City Green Silk from Polyalchemy Elixir and the pot is Protopasta Recycled PLA in Still Colorful 11. Everything was printed individually at a standard .2mm layer height, and the whole project took 19 hours and 45 minutes of printing time.

I’ve been looking for practical prints, and found it with this credit card cutlery model from jq910. I used Keene Village Edge Glow Glass PETG. It’s only a nine layers thick, but still quite sturdy. This printed in 36 minutes with a .2mm layer height and 60 mms speed.

Model by jq910 (Image credit: Tom's Hardware)To see just how big I can print with an Ender 3 S1 Pro, I took this Twisted Cloud Vase by PressPrint and expanded it 200% until it filled the bed. Then I ran it in Blue/Purple Evyone Matte Dual-Color PLA . It’s a vase mode print, so it only took 7 hours and 36 minutes at a .2mm layer height and 60 mms speed.

Model by PressPrint (Image credit: Tom's Hardware)The Ender 3 S1 Pro is a fantastic printer and a refreshing change of pace from its bare-bones beginnings. It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

It’s easy to assemble and the CR Touch leveling system worked perfectly without a need to make any adjustments. The new PEI coated flex plate is great and all the little upgrades from light kit to all metal hotend make this printer feel like a complete consumer grade product. This isn’t a science project to stick out in the shed, it’s a real piece of hardware to sit proudly on your desk.

Retailing at $479, the S1 Pro has everything you need in a 3D printer, and more features than a lot of the competition. However, if you want the deluxe Ender experience and don’t need an all metal hotend, you can save a few bucks by getting the Ender 3 S1. Another feature packed printer we like is the Anycubic Kobra, priced at $319, it’s an Editor’s Choice and our pick for Best Printer for Beginners.

Creality Ender 3 S1 Pro: Price Comparison

$499

$399

View

$479

View

$499

View

powered by

Denise Bertacchi is a Contributing Writer for Tom’s Hardware US, covering 3D printing.

The Best Cheap 3D Printers for 2023

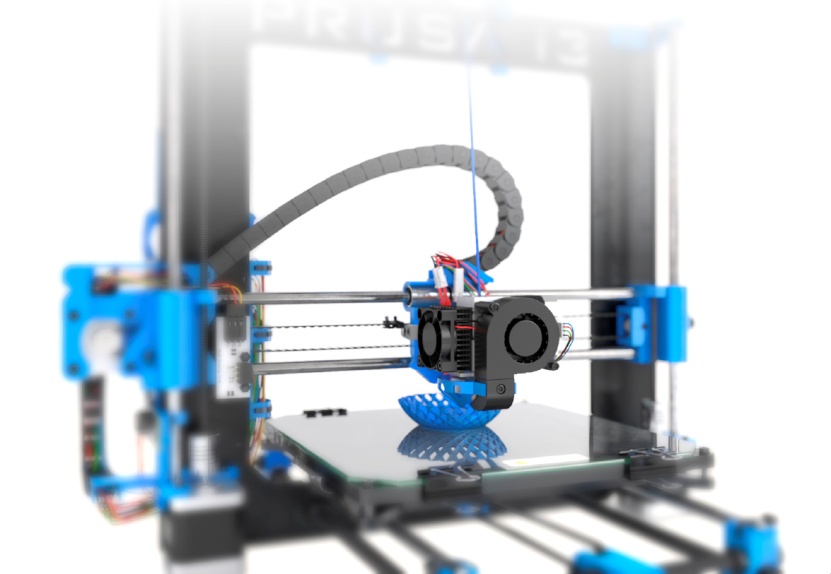

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

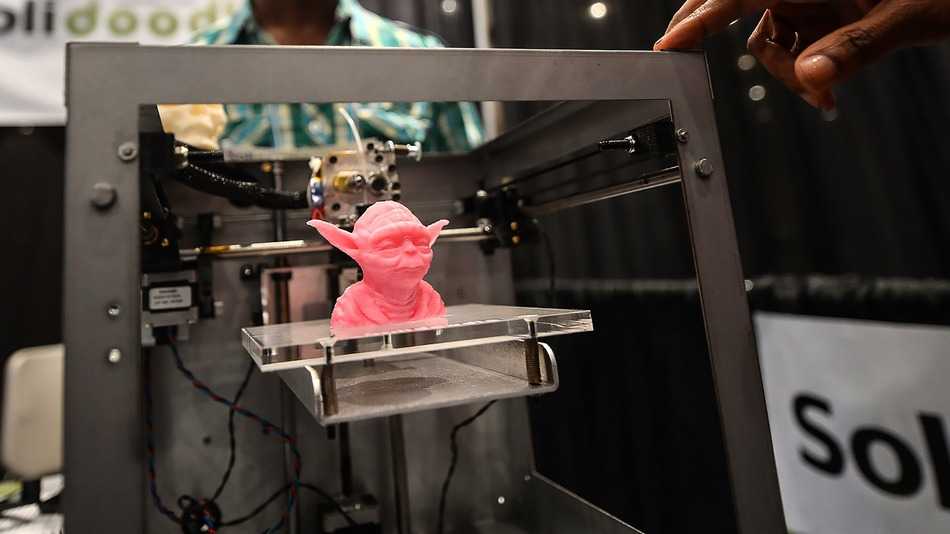

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

| Walmart | $199.95 | $198.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

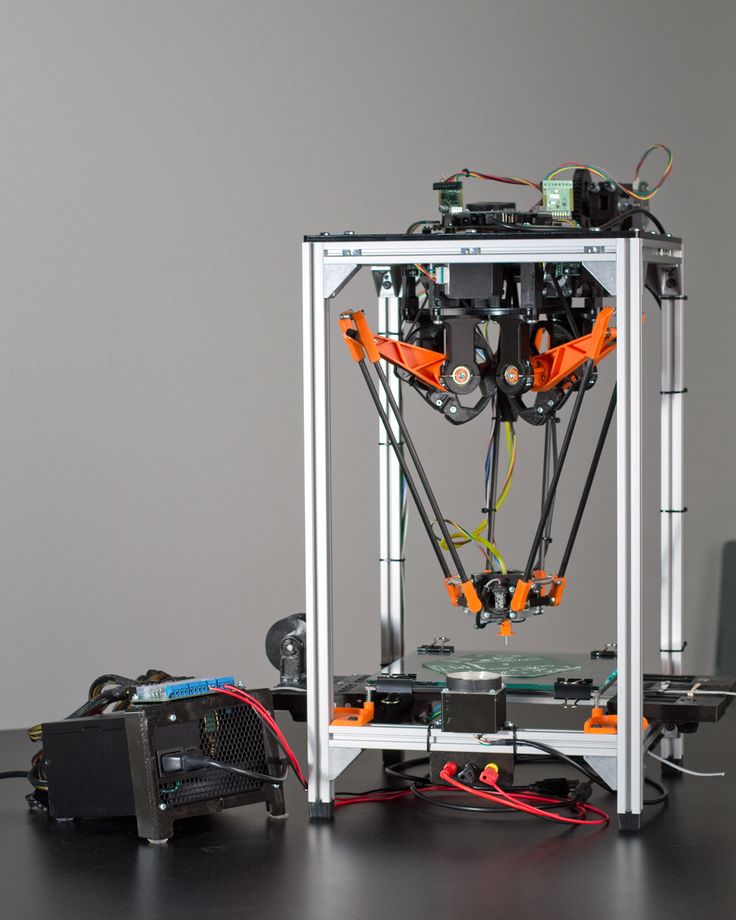

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

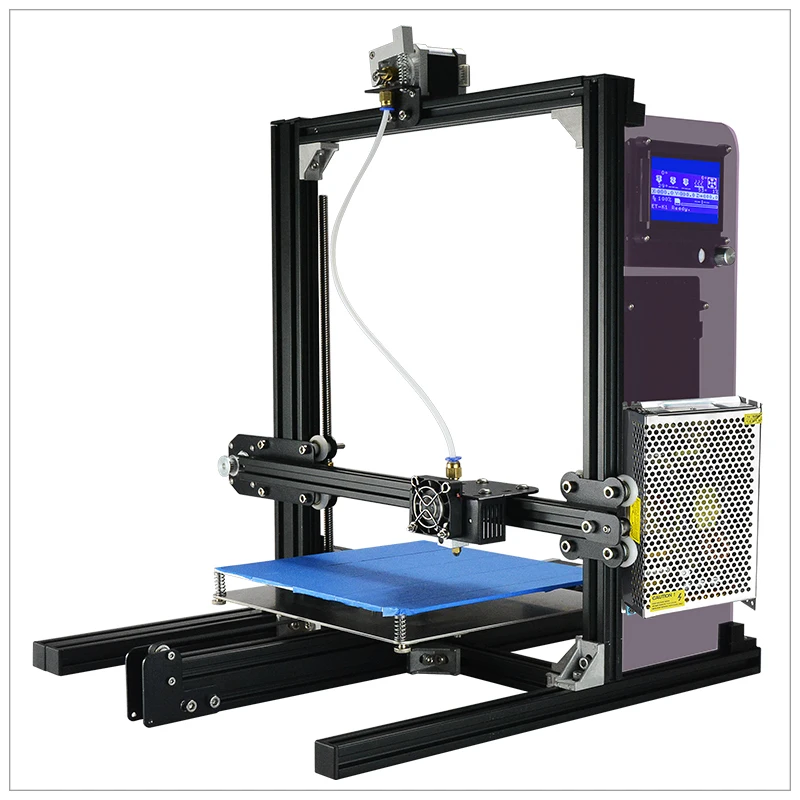

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| AnyCubic | $369. 00 00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $499.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $249.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $583.74 | $583.74 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | Check Stock (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

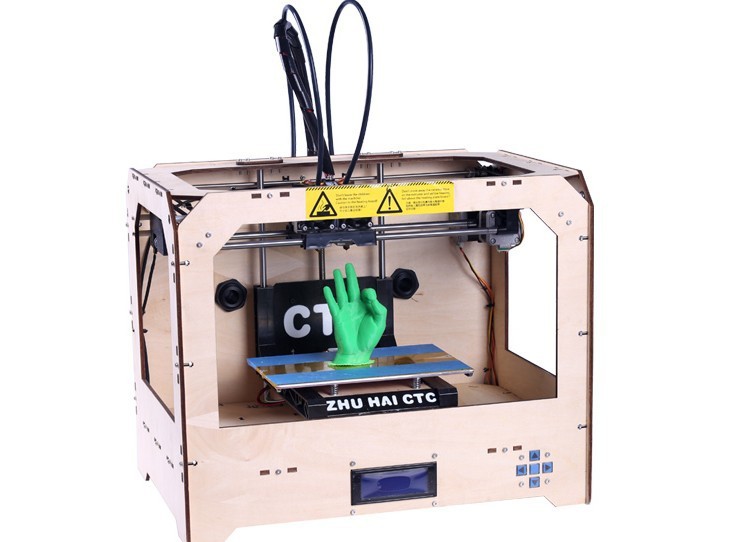

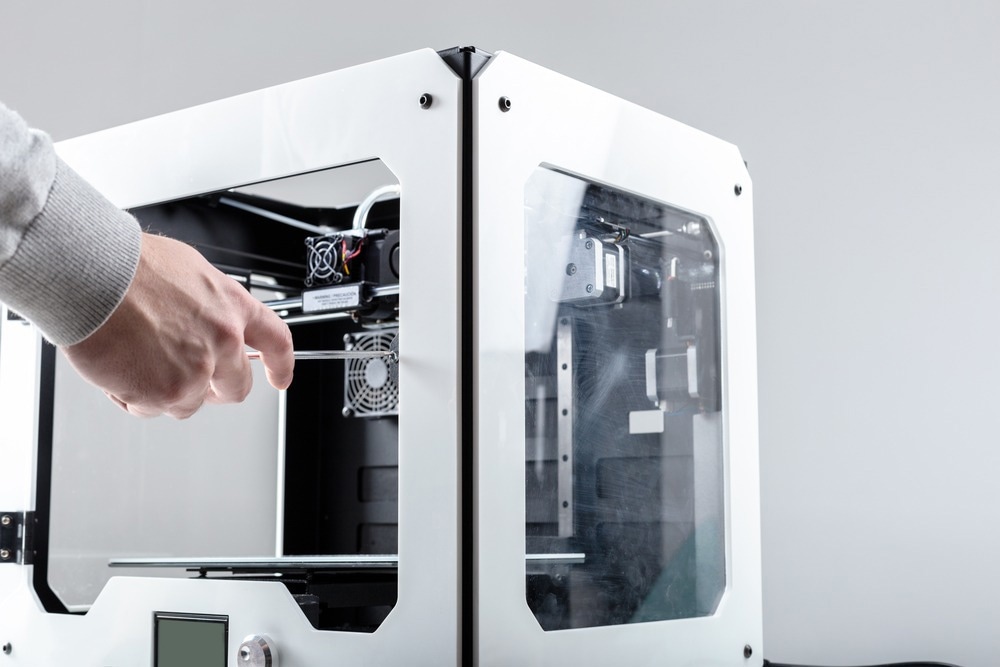

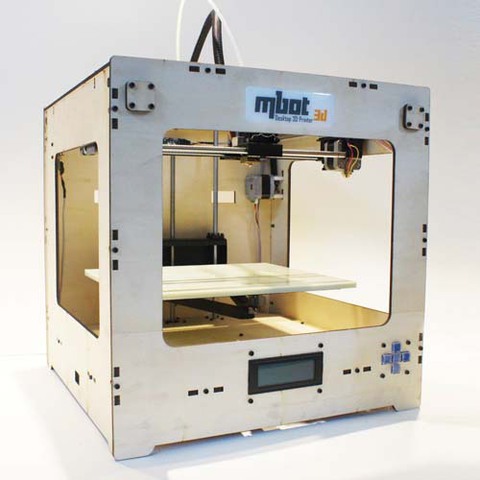

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Best 3D Printers of 2022 | Rating of TOP models of 3D printers for printing

Contents [Show]

The modern market of additive equipment offers many options for 3D printing equipment designed to solve various problems. Devices are in demand in engineering and design, architecture, medicine, industry, education, entertainment, engineering and many other areas.

Devices are in demand in engineering and design, architecture, medicine, industry, education, entertainment, engineering and many other areas.

Let's talk about what you should pay attention to when choosing a 3D printer, and also consider the rating of the best equipment models for amateurs and professionals in 2022.

How to choose the right 3D printer

There are a number of basic parameters that you need to pay attention to when choosing a printer for bulk printing. Let's briefly consider each of them.

Printer type

According to the ISO / ASTM 52900: 2021 standard, approved by the International Organization for Standardization, 3D printers are divided into several categories depending on the characteristics of the printing process (for convenience, we will duplicate the trade names for each category):

- DED (SLS, MJF) - deposition and melting of material using a directed electron or laser beam.

- BJT (CJP, NPJT) - selective jet application of a binder composition to the powder for its sintering.

- MJT (MJP) - layer-by-layer inkjet application of photopolymer resin.

- MEX (FDM, FFF, PJP) - layer-by-layer application of the consumable through a heated nozzle (extrusion).

- VPP (SLA, DLP, LCD, CDLP) - photopolymerization, selective curing of a liquid photopolymer in a bath under the influence of a light source.

- SHL (LOM, Composite Lamination) - gluing (lamination) of sheets of material.

- PBF (SLM, DMLS, EBM) - fusion of certain areas of the powder layer under the influence of thermal energy.

Approval

This parameter largely depends on the printing technology and is standardly described in the vertical and horizontal planes (Z and XY, respectively).

The Z resolution is the height/thickness of the layer. The thinner the layer, the more accurate and detailed the model will be. XY resolution is the smallest possible movement of the print head, which cannot be less than the diameter of the nozzle or laser beam.

The highest resolution is provided by photopolymer 3D printers.

Compatible materials

The choice of consumable depends on the 3D printing technology used. FDM printers use special thermoplastics in the form of filaments (PLA, HIPS, ABS, PET, PETG, Wood, Flex, etc.), while photopolymer printers use various light-sensitive liquid resins. Sintering technology devices are designed to use engineering thermoplastics or metals in powder form.

Many professional printers work with special purpose materials - composites (glass-filled materials, carbon fiber, etc.), metals, wood, concrete, ceramics, dental photopolymers, wax, etc.

Print platform (desktop, build platform)

This is the plate on which objects are printed. A high-quality platform ensures reliable adhesion of models to the surface (adhesion) during printing and at the same time makes it easy to separate them at the end of the process.

Typically, the print bed is made of glass, but other materials can also be used. To improve the contact of the material with the platform, special sprays and adhesives increase adhesion (Adhesion). Professional models of 3D printers usually have features that increase the resistance of printing to failures:

To improve the contact of the material with the platform, special sprays and adhesives increase adhesion (Adhesion). Professional models of 3D printers usually have features that increase the resistance of printing to failures:

- flexible, removable or magnetic platform;

- automatic print area alignment system;

- heated platform for handling high temperature materials.

Security

3D printing can be associated with some risks even when all safety regulations are followed. For example, high-temperature printing increases the risk of burns, and some powder materials or photopolymer resins are harmful to the skin.

To reduce the risk of exposure to toxic substances, some printers recommend the use of protective chambers, air filtration and ventilation systems, protective gloves, and goggles. There are also models of 3D printers designed to be serviced exclusively by trained personnel.

Noise level and motor drivers

Drivers and stepper motors directly affect the noise level during equipment operation. More advanced and expensive drivers, coupled with high-quality stepper motors, contribute to a significant reduction in the noise level during the printing process.

More advanced and expensive drivers, coupled with high-quality stepper motors, contribute to a significant reduction in the noise level during the printing process.

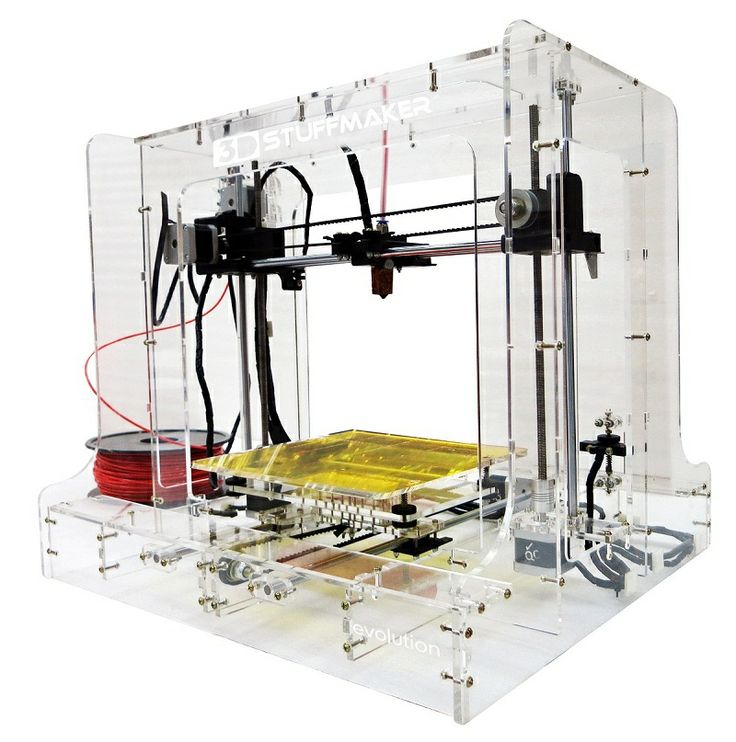

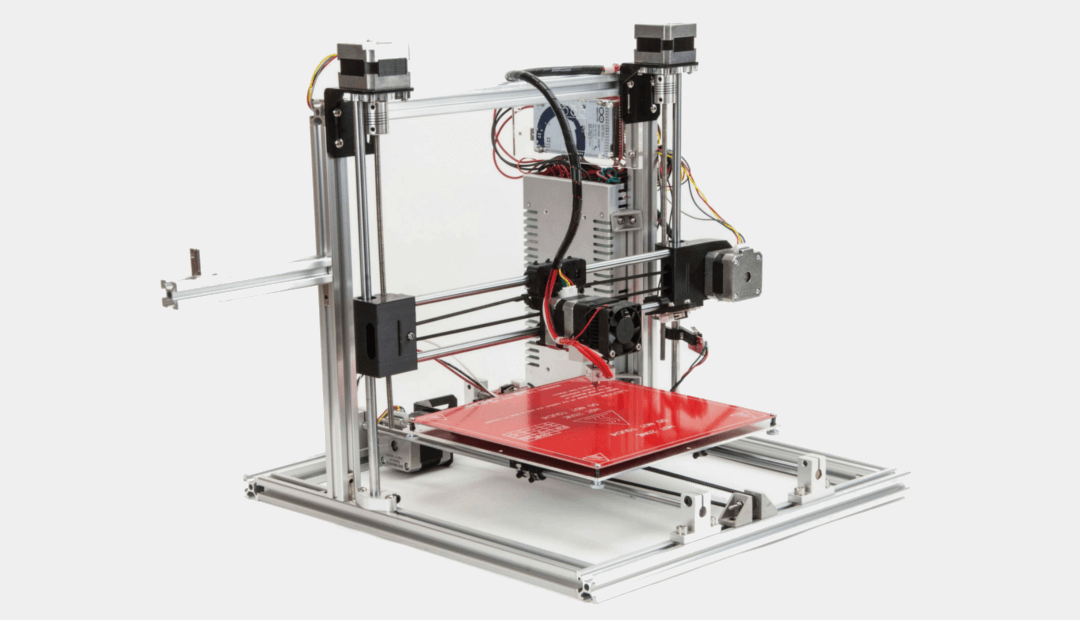

Self assembly

Most manufacturers offer additive devices that are ready to go. But some models of 3D printers are presented as self-assembly kits (DIY kits). When buying, you need to consider that assembling such a device can cause certain difficulties, especially for the first time.

Product size

The choice of the area of the working area of the equipment depends on the dimensions of the parts that are planned to be printed on a 3D printer. For a home, it is enough to purchase a device with parameters up to 200x250x200 (WxHxD). This is enough to solve most problems. For more serious tasks, we recommend considering models with a working area of at least 306x306x610 (WxHxD), such a print volume will allow you to print large objects without subsequent gluing with the same print quality and resolution.

Technology

Let's take a closer look at the main technologies used in the field of 3D printing:

- FDM is a method of layer-by-layer deposition of plastic filament threads. Ideal for creating functional prototypes and parts from high-strength industrial plastics.

- DLP - layer-by-layer curing of photopolymer resins using LED projectors. Allows you to produce ultra-precise, highly detailed objects with a high-quality surface.

- SLA - curing layers of liquid photopolymer using a laser beam. Suitable for printing very precise products with complex geometry and fine details.

Multicolour printing

There are modifications of printers that support the function of printing in two or more colors. Most of these FDM devices are equipped with two presses filled with threads of different colors. A separate file is used to print each color, and sections of different colors are combined with each other like a three-dimensional puzzle. There are also color powder printing technologies, such as CJP or MJM, but the range of their application is limited to simple layout or prototyping.

There are also color powder printing technologies, such as CJP or MJM, but the range of their application is limited to simple layout or prototyping.

Print surface

The surface quality of finished models depends on both the technology used and the print resolution. If necessary, the products are easily amenable to post-processing.

Housing type

Volumetric printers are available in an open or closed case. Open type devices are cheaper, but may have print quality issues and shrinkage of ABS products due to temperature changes. Enclosed printers have a more rigid, stable design and deliver high quality builds because their print surface is protected from dust and other unwanted particles. In addition, they have a low noise level and are safer to operate.

Connection

The majority of modern 3D printers have built-in memory, a port for USB flash drives or are equipped with SD memory cards, which allows you to continue the 3D printing process without a permanent connection to a PC. Some devices may also support wireless technology (Wi-Fi or P2P) or connect via Ethernet. Recently, more and more manufacturers include in their devices the possibility of forming 3D printing farms from a cluster of devices connected by one local network.

Some devices may also support wireless technology (Wi-Fi or P2P) or connect via Ethernet. Recently, more and more manufacturers include in their devices the possibility of forming 3D printing farms from a cluster of devices connected by one local network.

Software

Additive technology comes with special software or is compatible with open-source programs that can be downloaded, for example, from the manufacturer's website. As a rule, the software runs on Windows, Linux or MacOS. The software package may include modules for optimizing 3D models, building automatic supports (supports), controlling the movement of the printing block and desktop, and advanced preparation of layers for printing.

3D printer models

Consider the different models of amateur and professional 3D printers recognized as the best in 2022.

Assembly kits

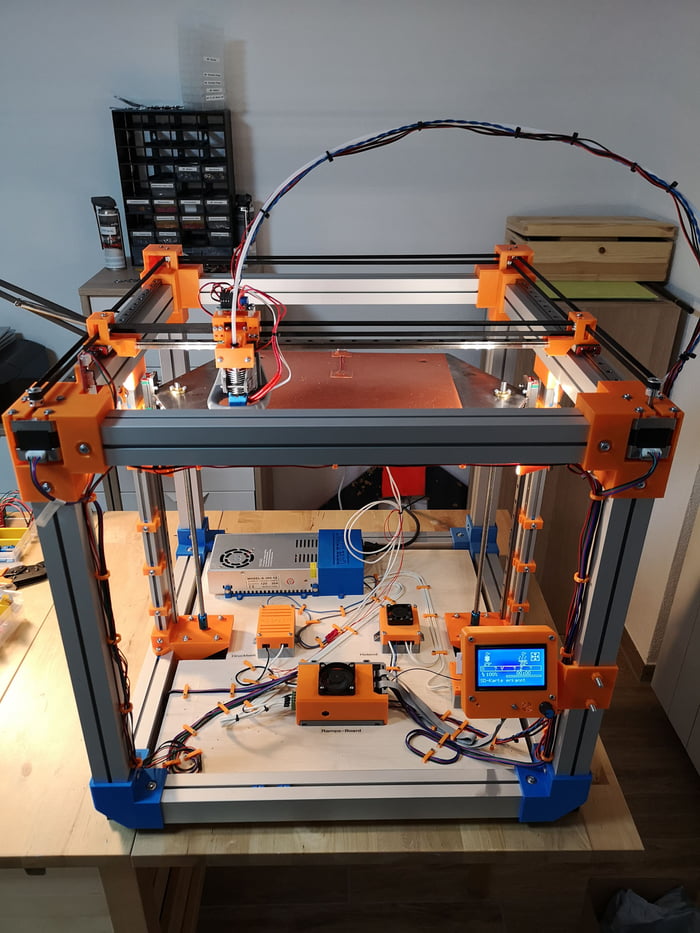

Self-assembly kits (DIY) are the most budgetary and popular variant of FDM/FFF/PJP 3D printers in Russia. The use of such kits allows you to independently assemble, configure, reconfigure and upgrade printing devices to suit your needs.

The use of such kits allows you to independently assemble, configure, reconfigure and upgrade printing devices to suit your needs.

The most popular DIY kits in 2022:

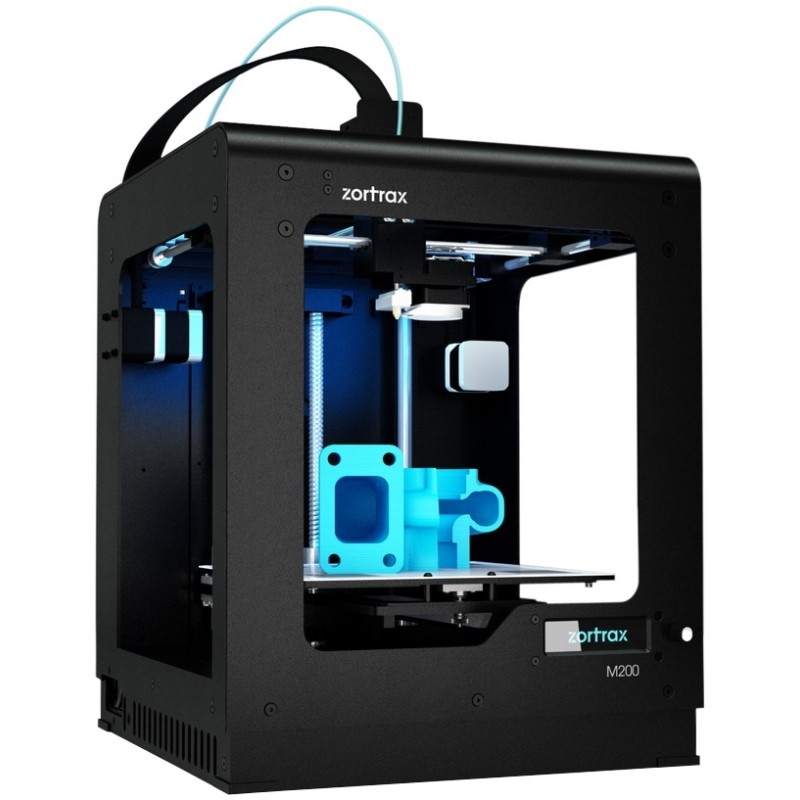

Creality Ender 3

Thoughtfully designed home 3D printer with open chamber, large build area (WxHxD: 220x250x220mm) and high print quality at speeds up to 180mm/s. Works great with PLA, ABS, PETG, TPU, Wood and other plastics. Equipped with a single extruder, a heated worktable, a compact display that shows the main parameters, and an active cooling system. Suitable for printing small functional items, prototypes or decorative figurines. Connects via USB or microSD.

Flying Bear Ghost 5

Equipment for semi-professional use, equipped with an open chamber with dimensions of 255x210x210 mm. Due to the uniform supply of the filament, it allows you to produce high-resolution parts at a speed of up to 150 mm / s and an accuracy of up to 0.01 mm. The model is equipped with one extruder, a heated table, options for adjusting speed and temperature, an active cooling system and a convenient TFT color display. Compatible with HIPS, ABS, Wood, PLA, etc. Reliable, quiet operation. Connects via Usb, SD, Wi-Fi.

Compatible with HIPS, ABS, Wood, PLA, etc. Reliable, quiet operation. Connects via Usb, SD, Wi-Fi.

Creality Ender 5 Plus

A printer with a large working area (350x350x400 mm), one extruder and a filament sensor that prevents printing errors due to tangles or broken threads. It has a magnetic platform with heating up to 100 degrees in 10 minutes, a rigid, reinforced cubic frame and a reliable power supply with overheat protection. Provides fast, high-precision, stable printing with an adjustable layer thickness of 0.1-0.4mm.

Creality Ender 6

Equipment with a closed plastic case, one extruder with a heating temperature of up to 260 degrees, a color touch screen and a build area of 250x250x400 mm. Ideal for small batch production and prototyping. The printer is equipped with a heated bed, connects via SD and is compatible with most of the available filaments. The layer height is 0.1-0.4 mm.

Budget 3D printers

This category includes inexpensive, ready-to-use FDM/FFF 3D printers designed for beginners - ordinary users, students in robotics circles, schools, etc. The devices are endowed with additional options that allow you to achieve excellent results with simple, understandable operation.

The devices are endowed with additional options that allow you to achieve excellent results with simple, understandable operation.

The best budget models of 2022:

Anycubic Mega S

Functional equipment with a working space of 210x210x205 mm and the possibility of resuming the work process after a power outage. The device has a color touchscreen, a heated platform with Ultrabase coating, connects via data cable or SD and prints at speeds up to 100 mm/sec. Layer height - 0.05-0.3 mm.

FlashForge Adventurer 4

A good option for children or teenagers who are fond of 3D modeling. The printer has a working area of 200x200x250 mm, a heated platform, a color touch screen and is connected via USB, Ethernet or Wi-Fi. Construction speed - up to 150 mm / sec. Layer thickness - 0.1-0.4 mm. The model is also equipped with a built-in webcam, a filament end sensor, an auto-calibration function and the possibility of remote control through the application.

Voxelab Aries STEM

A printer with a full range of modern functions, designed to create objects of standard sizes (200x200x200 mm). Prints at speeds up to 80 mm/sec. and a layer thickness of 0.1-0.4 mm. Connection - Usb, SD, Wi-Fi.

QIDI i-Mate S

A device with a working space of 260x200x200 mm, connected via Usb, LAN or Wi-Fi. Layer thickness - 0.05-0.2 mm, construction speed - up to 80 mm/sec. Great for prototyping simple objects.

Budget Large Format 3D Printers

Devices designed to create a large number of small products in one go or to print large objects. These printers are equipped with a capacious platform and have increased reliability and stability.

The most popular low-cost large-format FDM 3D printers in 2022:

Wanhao D12/500

A model with an improved component base and mechanics, updated electronics, a redesigned feed mechanism, a heated platform and two extruders. Construction area - 500x500x500 mm. Layer thickness - 0.1-0.4 mm, build speed - up to 150 mm/sec. Connection - Wi-Fi, MicroSD.

Construction area - 500x500x500 mm. Layer thickness - 0.1-0.4 mm, build speed - up to 150 mm/sec. Connection - Wi-Fi, MicroSD.

Creality Ender 5 Plus

Apparatus with dimensions of the working area 350x350x400 mm. It has a robust construction with a reinforced structural profile frame and a heated platform. Provides the most accurate, stable printing and smooth, stable movement along the axes. Connected via SD. The layer height is 0.1-0.4 mm.

Creality CR-10S Pro V2

A 3D printer that delivers high performance and exceptional print stability. Ideal for creating print trusses that produce large runs of the same type of parts. Construction volume - 300x300x400 mm. Print speed - up to 180 mm / sec. (recommended speed is up to 60 mm/s). Layer height - 0.1-0.4 mm. Connection - SD.

Professional 3D printers

Professional-grade printers are designed to produce complex objects using high-temperature engineering plastics and other consumables. Such equipment has a closed chamber to maintain a certain temperature and ensure stable printing.

Such equipment has a closed chamber to maintain a certain temperature and ensure stable printing.

Best Professional FDM 3D Printers of 2022:

FlashForge Creator Pro 2

Technique with two independent extruders for simultaneous printing of two identical products. The second extruder can be used to create soluble supports for the production of complex models with a quality surface. Construction area - 200x148x150 mm. Layer height - 0.1-0.4 mm, build speed - up to 100 mm/sec. Connection - Usb, SD.

Picaso Designer Classic

A printer designed to solve a wide range of tasks. It has built-in profiles for different types of plastic, which makes it easy to start printing. Chamber size - 200x200x210 mm. Work speed - up to 100 cm3 / h, layer thickness - from 0.01 mm. Connection - Usb, Ethernet.

Anycubic 4Max Pro 2.0

Advantages of the model: dual drive extruder for working with soft, flexible plastics, filament end sensor, silent drivers, color display. The device provides the most accurate, stable printing at speeds up to 150 mm/sec. Camera dimensions - 270x210x190 mm. Layer thickness - 0.05-0.3 mm. Types of connection - Usb, SD.

The device provides the most accurate, stable printing at speeds up to 150 mm/sec. Camera dimensions - 270x210x190 mm. Layer thickness - 0.05-0.3 mm. Types of connection - Usb, SD.

QIDI Tech X-Plus

A printer with a capacious working chamber (270x200x200 mm), one extruder with a heating temperature of up to 300 degrees and a build speed of up to 150 mm/sec. Equipped with a heated platform, connects via Wi-Fi, Usb or LAN, the layer height is 0.05-0.2mm.

Professional single extruder 3D printers

Additive equipment of this kind is designed to solve various problems, from relatively simple to complex.

The most popular models of professional FDM/FFF 3D printers with one print head:

Picaso Designer X S2 (Series 2)

The main difference of this modification is the heating of the extruder up to 430 degrees, which allows working with a wide range of plastics, including engineering ones (ABS, PETG, PLA, PEEK, Nylon, Flex, etc. ). Dimensions of the working chamber - 201x201x210 mm. Connection - Usb, Ethernet. Speed - up to 150 mm / s. Layer thickness - from 10-250 microns. The printer is equipped with a heated bed.

). Dimensions of the working chamber - 201x201x210 mm. Connection - Usb, Ethernet. Speed - up to 150 mm / s. Layer thickness - from 10-250 microns. The printer is equipped with a heated bed.

QIDI X-Max

A 3D printer with a large printable area (300x250x300 mm) and a wide range of useful features. It has a robust design with a strong double Z-rail, a heated platform with a double-sided coating for working with different types of plastic and a 5-inch touch screen. The extruder heats up to 300 degrees. Compatible filaments - PLA, ABS, PETG, PC, Carbon, Nylon, Flex, etc. Connection type - USB storage, LAN, Wi-Fi. Working speed – up to 150 mm/sec. Layer height - 0.05-0.2 mm.

Picaso Designer XL S2

The model is designed for printing with engineering and refractory materials, as the print head heats up to 430 degrees. Robust aluminum body with steel frame guarantees reliability and no vibration during operation. Chamber size - 360x360x610 mm. Speed - up to 130 cm3 / h. Layer thickness - 10-250 microns. Connection type - USB-drive, Ethernet.

Speed - up to 130 cm3 / h. Layer thickness - 10-250 microns. Connection type - USB-drive, Ethernet.

TierTime UP300

It is equipped with three separate extruders for working with different materials (low-temperature, high-temperature, standard), as well as various interchangeable platforms (smooth, perforated, glass). Supports print queue for different users. Dimensions of the working area - 205x255x225 mm, layer height - 0.05-0.4 mm. Connection - Usb, LAN, Wi-Fi.

Bizon 3

An updated version of the Bizon 2 model. Layer thickness - 0.02 - 0.65 mm. Print area size: 300x300x400mm. Print speed: up to 160 mm/s. Layer height: from 0.02 to 0.65 mm. Connection type: USB, SD card.

Mid-range large format 3D printers

This category includes models for universities, specialized colleges and offices of medium-sized companies.

The best mid-range large format FDM 3D printers in 2022:

Raise3D Pro3 Plus

Equipment with a transparent body and two extruders equipped with a lifting mechanism, well-thought-out kinematics, interchangeable nozzles of different diameters and a convenient 7-inch color touch screen. Other options: Low Filament Sensor, Print Resume System, RaiseCloud Firmware, Webcam, IdeaMaker Slicer, RaiseCloud Cloud Service. Printed volume: 300x300x605 mm (for one extruder), 255x300x605 mm (for two extruders). Connection - Wi-Fi, Usb, LAN. Speed – up to 150 mm/sec. Layer thickness - from 0.01 mm.

Other options: Low Filament Sensor, Print Resume System, RaiseCloud Firmware, Webcam, IdeaMaker Slicer, RaiseCloud Cloud Service. Printed volume: 300x300x605 mm (for one extruder), 255x300x605 mm (for two extruders). Connection - Wi-Fi, Usb, LAN. Speed – up to 150 mm/sec. Layer thickness - from 0.01 mm.

Flash Forge Creator 4

High-performance, accurate 3D printer with a system of two independent extruders and an advanced thermal management system inside the chamber (to protect against cracking and deformation of engineering plastics). Robust steel body prevents vibration. Print area - 400x350x500 mm. Speed – up to 200 mm/sec. Layer height - from 0.01 mm. Connection - Usb, Wi-Fi, LAN.

Picaso Designer XL Pro S2

Large-format model with a working area of 360x360x610 mm, a heated platform and two extruders with a heating temperature of up to 430 degrees. The device has a simple automatic calibration, a built-in material spool drying mode and a plastic feed control system. Layer thickness - 0.01 mm, speed - up to 130 cm3/h. Connection type - Usb, Ethernet.

Layer thickness - 0.01 mm, speed - up to 130 cm3/h. Connection type - Usb, Ethernet.

CreatBot D600 Pro

The printer with the largest print area is 600x600x600 mm. Equipped with two extruders with heating up to 260 and 420 degrees respectively (for working with standard or engineering plastics). Other features: heated chamber, platform and compartments, speed - up to 120 mm/s, layer thickness - from 0.05 mm. Connection type - Usb.

Professional Dual Extruder 3D Printers

Professional FDM printers with two extruders are designed to solve the most complex tasks. This technique is equipped with a fully functional slicer and a reliable nozzle lift mechanism or independent extruders.

The most popular professional grade dual extruder 3D printers:

Raise3D Pro2 Plus

The flagship model of the manufacturer, endowed with a full range of useful features. The equipment, enclosed in a transparent case, is connected via Usb, Wi-Fi or LAN and is distinguished by quiet operation. Equipped with an extruder lifting mechanism, a 7-inch color touch screen, a filament end sensor, and a print resume system. Includes RaiseCloud software, webcam, replacement nozzles. Print volume - 305x305x605 mm (for 1 extruder), 280x305x605 mm (for 2 extruders). Speed – up to 150 mm/sec. Layer height - from 0.01 mm. Connection - Usb, Wi-Fi, LAN.

Equipped with an extruder lifting mechanism, a 7-inch color touch screen, a filament end sensor, and a print resume system. Includes RaiseCloud software, webcam, replacement nozzles. Print volume - 305x305x605 mm (for 1 extruder), 280x305x605 mm (for 2 extruders). Speed – up to 150 mm/sec. Layer height - from 0.01 mm. Connection - Usb, Wi-Fi, LAN.

Picaso Designer X Pro S2

A compact device with dimensions of the construction area of 201x201x210 mm, providing excellent print quality. It has a high temperature mode with heating up to 430 degrees for printing with complex filaments. Speed - up to 130 cm3 / h, layer thickness - from 0.01 mm. Connection - Usb, Ethernet.

Raise3D E2

High-performance 3D printer with two independent print heads (IDEX system), heated platform and print speed up to 150 mm/sec. A built-in step-by-step video instruction for site calibration is provided. Layer thickness - 0.02-0.25 mm. Connection - Usb port, Wi-Fi, LAN. Print volume - 330x240x240 mm (1 print head), 295x240x240 mm (2 extruders).

Print volume - 330x240x240 mm (1 print head), 295x240x240 mm (2 extruders).

FlashForge Creator 3 Pro

Model with a large chamber (300x250x200 mm), HEPA filter, built-in webcam, color screen and the ability to install hardened nozzles with a material melting point of up to 320 degrees. The heating speed of the working platform is up to 120 degrees in 3 minutes. Print speed - up to 150 mm / sec. Layer thickness - 0.05-0.4 mm. Connection type - Usb, Ethernet, Wi-Fi.

CreatBot F430 PEEK

3D printer ideal for PEEK and other filaments. Equipped with a closed chamber with temperature support and two printheads with heating up to 260 and 420 degrees, respectively. Construction area - 400x300x300 mm. Layer height - from 0.02 mm. Speed – up to 180 mm/sec. Connection - Usb.

Ultimaker S5

An easy-to-use device that prints with threads of non-standard diameter - 2.85 mm. The size of the working area is 330x240x300 mm. Layer thickness - from 0.02 mm. Speed - 24 mm3 / sec. Connection type - Usb, Ethernet, Wi-Fi.

Layer thickness - from 0.02 mm. Speed - 24 mm3 / sec. Connection type - Usb, Ethernet, Wi-Fi.

Photopolymer desktop 3D printers

Modern models of 3D printing devices using photopolymers are equipped with monochrome displays with a resolution of up to 8K, which provide high speed and quality of building objects of any geometry.

Best photopolymer 3D printers of 2022:

Phrozen Sonic Mini 8K

A compact budget LCD printer with over 2000 hours of uninterrupted operation. Equipped with 8K 7.1” Mono LCD display. Print volume - 165x72x180 mm. Layer height - 0.01-0.3 mm. Resolution along the XY axis - 22 microns.

Phrozen Sonic 4K 2022

Equipment for permanent loads, ideal for dental laboratories and dental clinics. It has a heated chamber 134x75x200 mm with an odor filter and a Mono 4K 6.1” LCD display. Layer thickness - 0.01-0.3 mm.

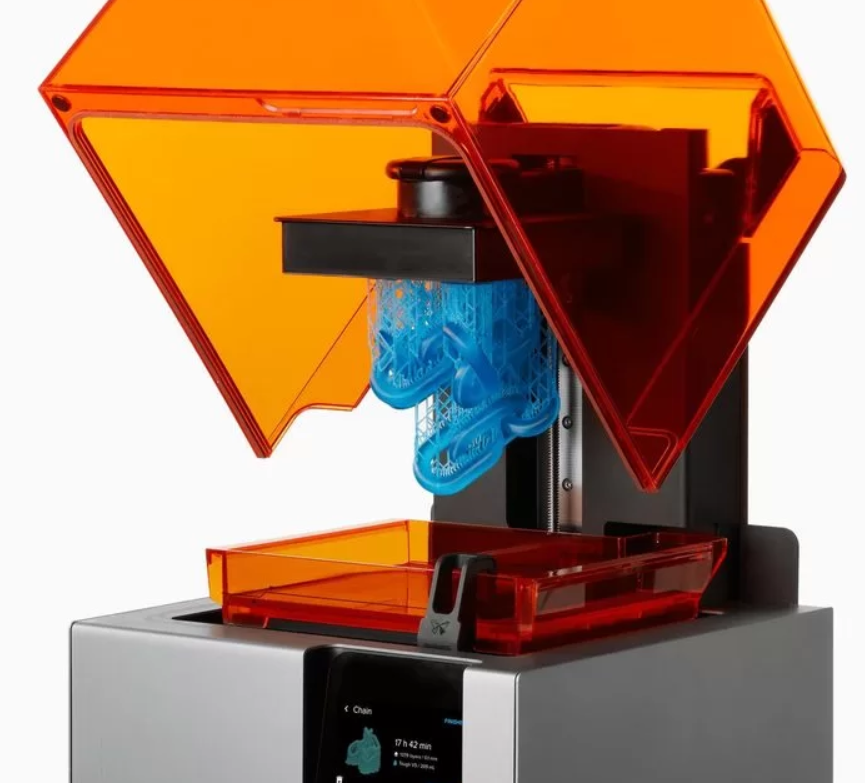

Formlabs Form 3+

LFS printer with an intuitive interface and many special settings. The light source is a 250 mW laser. The size of the working area is 145x145x185 mm. Layer thickness - 0.025-0.3 mm.

The light source is a 250 mW laser. The size of the working area is 145x145x185 mm. Layer thickness - 0.025-0.3 mm.

Anycubic Mono X 6K

3D printer with a working chamber 197x122x245 mm and a high-quality Mono 6K 9.25” LCD screen. Layer height - 0.01-0.15 mm.

XYZ Part Pro 150

Equipped with a 5 inch LCD touch screen. Illumination source: 405 nm UV laser. Print area size: 150x150x200 mm. Layer thickness: 25 to 200 microns (0.025 - 0.2 mm).

Best Large Format Desktop Resin 3D Printers

Phrozen Sonic Mega 8K

The best 3D printer in its segment, capable of solving tasks that usually only an entire farm can handle. Suitable for both mass production of small detailed products, and for printing huge objects and dioramas. It is equipped with a 15-inch Mono 8K LCD display and has a working area of 330x185x400 mm. Resolution - less than 50 microns, layer height - 0.01-0.3 mm.

Formlabs Form 3L

LFS-technique with a construction area of 335x200x300 mm, creating high-precision details using a 2x250 mW laser with a spot diameter of 85 microns. It is possible to install two cartridges at the same time for uninterrupted printing of large models. Layer thickness - from 0.025 mm.

It is possible to install two cartridges at the same time for uninterrupted printing of large models. Layer thickness - from 0.025 mm.

Totals

All 3D printers reviewed have been rigorously tested in practice and tested by experienced engineers. Each of them has its own advantages and disadvantages, therefore, when choosing a model, it is necessary to focus, first of all, on the expected result, equipment functionality and budget.

If you find it difficult to make a choice, please contact 3DTool. Our experts will help you choose the right 3D equipment and consumables for you.

Best 3D printers 2022-2023 for production and business: Expert rating

3D scanners

Analysts and business

The best on the topics

Experts recommend

3D printers

Author: Semen Poladyuk

Author: Semen Popadiuk

Summing up the results of the outgoing year, we tried to choose the most interesting solutions that appeared in 2022 on the global 3D printing and 3D scanning market. Of course, our top is far from covering even a small part of the novelties of the grandiose 3D industry. We have highlighted several developments that have attracted increased attention from users and professional industry experts.

Of course, our top is far from covering even a small part of the novelties of the grandiose 3D industry. We have highlighted several developments that have attracted increased attention from users and professional industry experts.

Note that the best 3D printers and 3D scanners of 2022 roundup does not include the home (consumer) segment. In accordance with the direction of the blog, we are considering professional and industrial equipment that will reduce time, material and labor costs for manufacturing enterprises, research, educational and medical organizations, as well as in the field of business projects. Thanks to such innovations, the locomotive of the industry is moving.

Blog materials will help you navigate the typology of equipment and choose the best solution:

-

Types of 3D printers: technologies, materials, applications

-

Choosing a 3D Printer: Find the Right Solution for You

-

How to choose a 3D scanner

If you have questions about the implementation of 3D technologies, please contact iQB Technologies experts

Top 8 3D printers

HBD E500

© HBD

HBD is one of the Chinese market leaders in metal 3D printing. The manufacturer's portfolio includes more than 15 models of printers with cameras from 150 to 1500 mm. In 2022, the line was replenished with perhaps the most versatile machine - the HBD E500. It's a true workhorse for trouble-free printing of complex custom or prototype designs up to 520mm.

The manufacturer's portfolio includes more than 15 models of printers with cameras from 150 to 1500 mm. In 2022, the line was replenished with perhaps the most versatile machine - the HBD E500. It's a true workhorse for trouble-free printing of complex custom or prototype designs up to 520mm.

The printer is equipped with two or three lasers, depending on customer requirements, equipped with a safe and reliable filtration system and provides a closed powder supply cycle. With its high print speeds of up to 10,000 mm/s, the E500 is well suited for continuous batch production in a variety of industries such as automotive, mechanical engineering, aviation, foundry, education and R&D.

SLM NXG XII 600E

© SLM Solutions

At Formnext 2022, SLM Solutions, the market leader in metal 3D printing, announced its latest development, the largest additive manufacturing machine for selective laser melting technology. Based on the popular NXG XII 600 model, the new model has a larger build area of 1. 5 m in the Z-axis, which is reportedly 50% larger than the equipment of the nearest competitor.

5 m in the Z-axis, which is reportedly 50% larger than the equipment of the nearest competitor.

Metal-to-metal additive manufacturing customers are demanding ever larger parts – and as quickly as possible. Serial production of products of complex geometry can now be implemented in a few hours or days, rather than weeks and months. To meet these expectations, the NXG XII 600E provides an end-to-end manufacturing process to increase machine uptime.

The system platform features an open SLM architecture that allows flexible process parameters for maximum performance at a layer thickness of 90 micron or more (when working with popular materials such as IN718, AlSi10Mg, TiAl6V4 and copper alloys).

IEMAI FAST JET 1500

© IEMAI

-

Technology: FDM/FGF

-

Construction area: 1500 × 1500 × 1500 mm

-

Features: creation of large objects from granulated thermoplastics and remote control of the printing process

The use of polymers in the form of granules in 3D printing makes it possible to save even more on materials and speed up the process of printing large-sized objects compared to filaments. Another well-known Chinese manufacturer, IEMAI, introduced the FAST JET 1500 large-format FGF printer for printing products up to 1.5 meters in length, width and height.

Another well-known Chinese manufacturer, IEMAI, introduced the FAST JET 1500 large-format FGF printer for printing products up to 1.5 meters in length, width and height.

The 3D printer features an elevated extrusion temperature (500°C), a 3-stage extrusion temperature control system, and a closed isolation chamber to handle most thermoplastic pellets available on the market, including PLA, nylon, and high-performance materials such as PEEK and PEKK. .

The FAST JET 1500 also features a proprietary 6-axis control system and a 10″ full color touch screen with remote automatic loading. In addition, the printer is one of the first models to be sold with a built-in IEMAI cloud platform for remote control of material drying, G‑od file uploads, printing at regular intervals, and remote monitoring of the printing process.

F2 Gigantry

© F2 Innovations

The Perm company F2 innovations, which develops and manufactures industrial 3D systems, has introduced a novelty - a granule printer with the largest print area.

The F2 Gigantry is an open gantry with an extruder capable of creating parts up to 4 meters long, 2 meters wide and 1 meter high. The technology allows printing with polymer granules with a capacity of up to 10 kg/h, including recycled materials (recycled granulate).

FGF-printing technology is not new, but F2 Gigantry became the first domestic large-format 3D printer in this category. Today, the question of a quick and high-quality replacement of imported solutions, as well as the acceleration of production with an increase in the number of manufactured products, is acute. The novelty from F2 Innovations will help to solve these problems effectively.

ProtoFab PF‑S300 / PF‑S350

© ProtoFab

Professional Russian users are already familiar with SLA printers from the Chinese company ProtoFab, and this year the manufacturer introduced a series of high-precision industrial units based on selective laser sintering (SLS) technology.

The ProtoFab PF‑S300 and PF‑S350 are equipped with a new dynamic thermal control system that further optimizes temperature distribution monitoring, encapsulation and sensor performance. Nylon, carbon fiber composite nylon powder, glass fiber composite nylon powder and other plastics are used as consumables.

The speed of laser illumination is increased to 3 m/s, which significantly speeds up molding by increasing the speed of powder spraying. The printers are equipped with new, efficient powder removal accessories, which can reduce production costs and lead times. With a cylinder temperature of 220°C, the PF‑S300 and PF‑S350 are capable of sintering materials with a melting point of 225°C or lower.

Sinterit Lisa X

© Sinterit

The Polish company Sinterit sets another record: according to the manufacturer, the new SLS system is ten times faster than its predecessor, the Lisa PRO model. Lisa X is capable of sintering PA12 at speeds up to 14 mm/h and completing a full print session in just 30 hours. Relatively inexpensive and compact, a 3D printer can truly boast the performance of an industrial device and allow companies to speed up product development and time to market.

Relatively inexpensive and compact, a 3D printer can truly boast the performance of an industrial device and allow companies to speed up product development and time to market.

Open source software allows you to customize 32 print settings to suit your individual needs. Media changes can be done in 15 minutes, and printing and cooling can take up to 40% less time than any other compact SLS printer.

Lisa X also features a unique "airblade" system that automatically cleans the glass around the laser during production, meaning users don't have to do it manually in two out of every three sessions, speeding up print preparation.

Massivit 10000

©Massivit 3D

-

Technology: Cast-In-Motion

-

Construction area: 1200 × 1500 × 1650 mm

-

Features: production of molding equipment in the shortest possible time

Another interesting novelty for 2022 is a large-format additive machine from the reputable Israeli manufacturer Massivit 3D. The system uses a hybrid technology of photopolymer 3D printing and thermoplastic injection, called "Cast-In-Motion" (CIM). The printer is designed for the production of molding equipment for the subsequent manufacture of products from composite materials. Two printheads are used respectively to form the photopolymer gel formwork and to fill the internal cavities with thermoplastic. After heat treatment of the printed product, the photopolymer shell dissolves, and the resulting form undergoes finishing machining.

The system uses a hybrid technology of photopolymer 3D printing and thermoplastic injection, called "Cast-In-Motion" (CIM). The printer is designed for the production of molding equipment for the subsequent manufacture of products from composite materials. Two printheads are used respectively to form the photopolymer gel formwork and to fill the internal cavities with thermoplastic. After heat treatment of the printed product, the photopolymer shell dissolves, and the resulting form undergoes finishing machining.

This technology, according to the manufacturer, allows to reduce the number of stages of the production process and reduce the time for the manufacture of molding equipment by 80%.

BMF microArch S350

© Boston Micro Fabrication

-

Technology: projection microstereolithography (PµSL)

-

Construction area: 100 × 100 × 50mm

-

Features: high resolution microscale photopolymer printing

And here is one of the latest new products for 2022 - a photopolymer microprinting machine from Boston Micro Fabrication (BMF). The microArch S350 is the highest performing BMF printer for the final part industry, as it can print not only high-resolution micro-scale objects (up to 10 microns), but also many small objects that require high precision and detail. The 3D printer is suitable for prototyping and additive manufacturing in the amount of one thousand to 30 thousand products and will find its place in enterprises and research laboratories.

The microArch S350 is the highest performing BMF printer for the final part industry, as it can print not only high-resolution micro-scale objects (up to 10 microns), but also many small objects that require high precision and detail. The 3D printer is suitable for prototyping and additive manufacturing in the amount of one thousand to 30 thousand products and will find its place in enterprises and research laboratories.

The microArch S350 is based on BMF's projection microstereolithography (PµSL) technology, which is a form of masked stereolithography (MSLA) using ultraviolet light with microscale resolution.

Top 5 3D Scanners

FARO Focus Premium

© FARO

-

Type: ground laser 3D scanner

-

Distance measurement accuracy: ±1mm

-

Scanning speed: up to 2 million points per second

-

Features: Unsurpassed scanning quality in one minute

The super-hit FARO Focus series has been replenished with improved Premium models. The new line includes three instruments with a scanning range of 70, 150 and 350 meters and features higher speed, increased resolution, hardware noise reduction and the ability to remotely control the instrument from any mobile device.

The new line includes three instruments with a scanning range of 70, 150 and 350 meters and features higher speed, increased resolution, hardware noise reduction and the ability to remotely control the instrument from any mobile device.

Premium is 50% more productive than its predecessors: measurements take an average of one minute using the optional PanoCam, even when scanning in color. Remote control of the scanner and stitching of scans from a mobile device is performed using the Stream application with subsequent integration into the Sphere cloud platform.

New devices are perfect for projects in the field of manufacturing, architecture, civil and industrial construction. And a nice bonus: the official warranty period from the manufacturer has been extended to two years.

Also in 2022, FARO launched the Focus Core, a cost-effective terrestrial scanning solution with an optimal balance of speed and accuracy.

EPiC EasyScan T10

© EPiC

-

Type: terrestrial 3D laser scanner

-

Accuracy: 1cm at 10m, 2cm at 30m, 5cm at 100m

-

Scanning speed: 320 thousand points per second

-

Features: Easy-to-use entry-level device

The appearance of such devices marks a new milestone in the evolution of laser scanning technology, which optimally combines economy, quality and ease of use. The EasyScan T10 from China's EPiC (Wuhan Eleph‑Print Tech Co, Ltd.) will be in demand when processing time and measurement convenience are more important than obtaining high-precision data. The scanner is equipped with a 360 °C panoramic camera, and the signal emission system and sensors are securely and ergonomically integrated into the body.

The EasyScan T10 from China's EPiC (Wuhan Eleph‑Print Tech Co, Ltd.) will be in demand when processing time and measurement convenience are more important than obtaining high-precision data. The scanner is equipped with a 360 °C panoramic camera, and the signal emission system and sensors are securely and ergonomically integrated into the body.

The scanner is launched with one button. A dual scan mode is available, which allows you to combine the simultaneous operation of a panoramic camera and lidar. Data stitching is done on a mobile device. Weighing only 3.2 kilograms, the instrument is one of the lightest geodetic scanners on the market. The package includes everything you need for scanning, including a tripod, batteries and free software for data processing.

Artec Leo 2022

© Artec 3D

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: up to 0.1 mm

-

Scanning speed: up to 35 million points per second

-

Features: The legendary Leo - with double the power and even more accuracy

In the past year, Artec 3D introduced a new version of its popular Leo system, released in 2018. The Artec Leo 2022 Wireless Handheld 3D Scanner offers twice the processing power, improved capture of vibrant colors, an updated built-in touch screen, a multilingual interface, and guaranteed high accuracy. The new Auto Temperature Control feature allows the scanner to regulate its operation and maintain the optimal operating temperature of the components.

The Artec Leo 2022 Wireless Handheld 3D Scanner offers twice the processing power, improved capture of vibrant colors, an updated built-in touch screen, a multilingual interface, and guaranteed high accuracy. The new Auto Temperature Control feature allows the scanner to regulate its operation and maintain the optimal operating temperature of the components.

Powered by an updated NVIDIA Jetson TX2 processor, power consumption is reduced to less than 7.5W. The capture area is 160,000 cm 3 , which means the Leo 2022 can scan objects larger than 200 cm, from auto parts to people and rooms.

peel 3d peel 3

© Peel 3d

-

Type: Handheld Structured Illumination 3D Scanner

-

Accuracy: 0.250 mm/m, up to 0.1 mm

-

Scan speed: 80 sec/m 2

-

Features: A new generation of affordable scanners for reverse engineering