Best 3d printer hot end

The 7 Best 3D Printer Hot Ends (All-Metal!) – Clever Creations

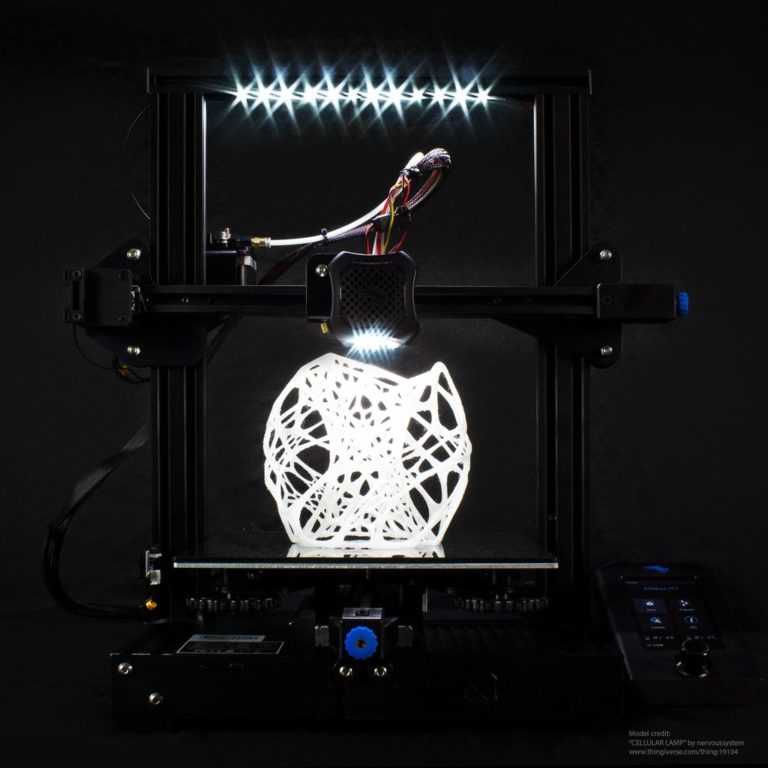

When it comes to 3D printing, the hot end is one of the most important components. It’s responsible for melting and extruding the filament, so it’s crucial that you have a good one.

In this article, we’ll discuss some of the best 3D printer hot ends on the market. We’ll also give you a few tips on how to choose the right one for your needs. So, without further ado, let’s get started!

| 3D Printer Hot End | Max. Temp | Filament Dia. | Voltage(s) | Price (~) | Best Offer |

|---|---|---|---|---|---|

| E3D V6 | 300 °C | 1.75 mm, 2.85 mm | 12V, 24V | $59 and up | Amazon |

| Micro Swiss All Metal Hotend Kit | 300 °C | 1.75 mm | 24V | $63 | MatterHackers |

| E3D RapidChange Revo | 300 °C | 1.75 mm | 12V, 24V | $88 and up | E3D |

| Slice Engineering Mosquito | 500 °C | 1. | 12V, 24V | $145 | MatterHackers |

| E3D Supervolcano Upgrade Kit | 300 °C | 1.75 mm, 2.85 mm | 12V, 24V | $96 and up | E3D |

| DyzEnd PRO | 500 °C | 1.75 mm | 12V, 24V | $130 | MatterHackers |

| Phaetus Dragonfly Hot End | 500 °C | 1.75 mm | 12V, 24V | $69 | BIQU |

What is the hot end in a 3D printer?

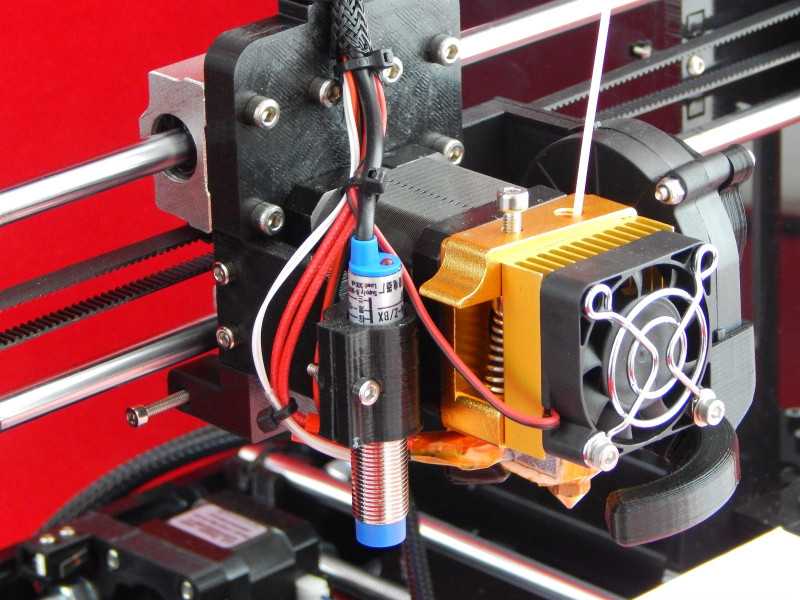

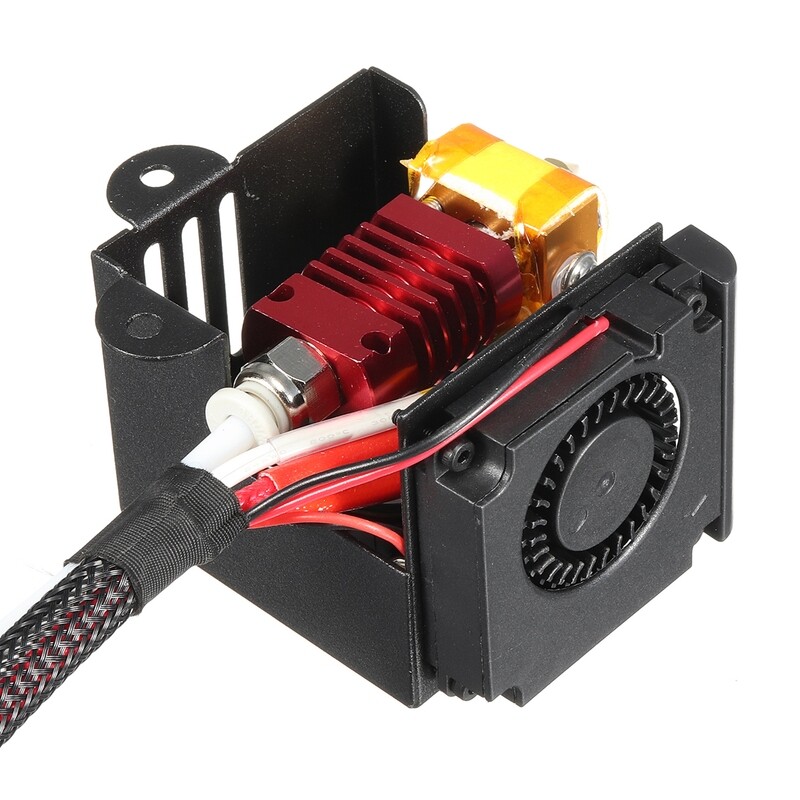

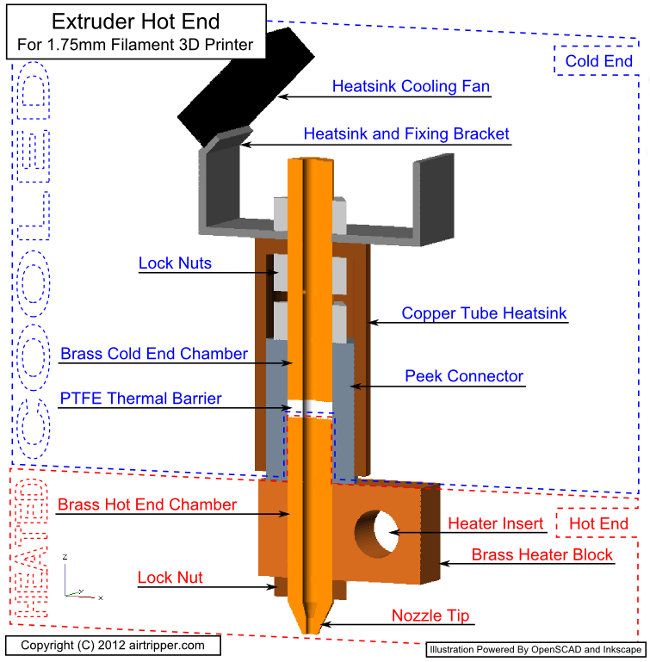

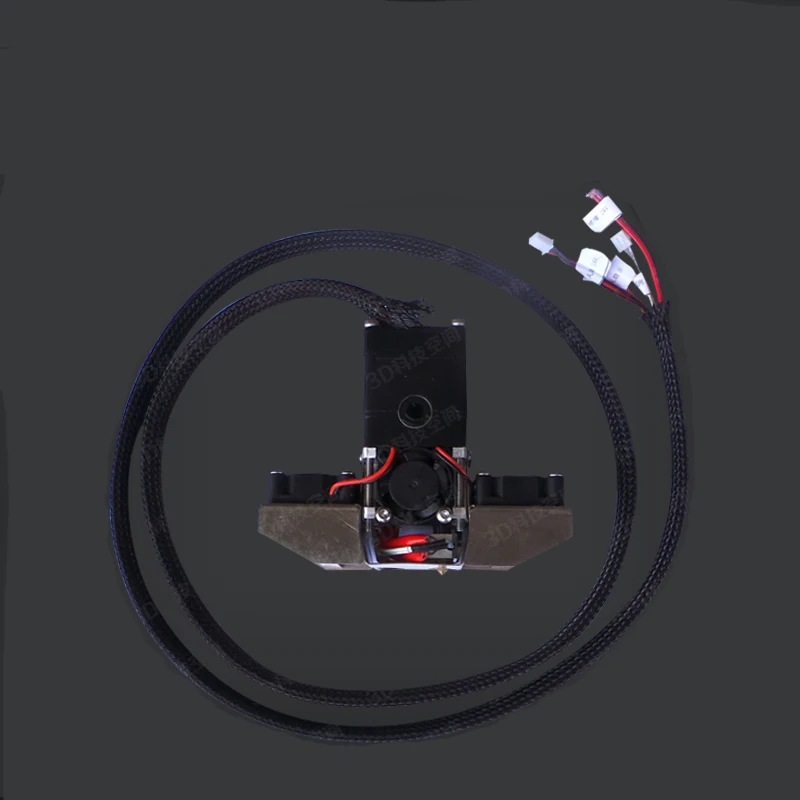

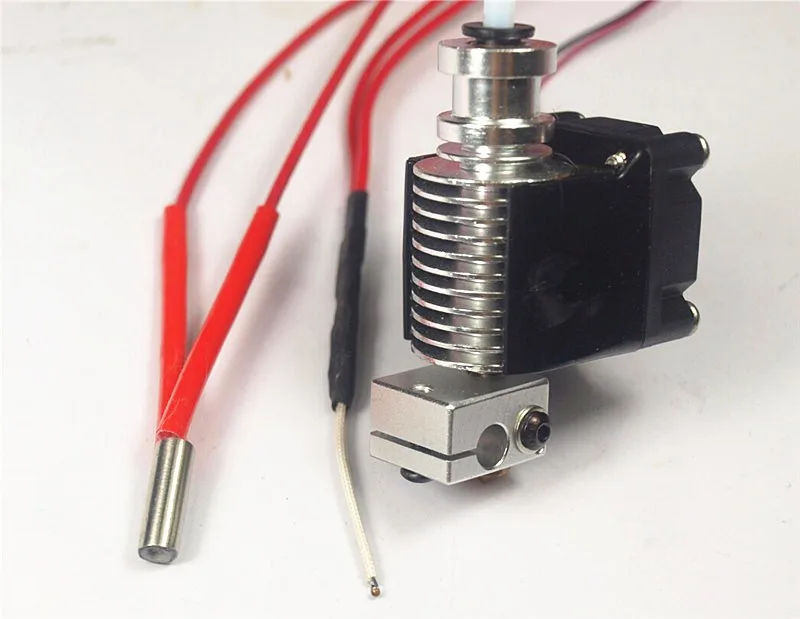

A hot end is the heating element in a 3D printer. It comprises several parts, including the heating element, nozzle, heat sink, and heat break.

The heating element is responsible for heating the filament to its melting point. The nozzle is a small hole through which the molten filament is extruded. And finally, the heat break limits the amount of heat that transfers to the heat sink.

These elements work together to provide an even flow of melted material and give you a smooth 3D printing experience.

What makes a good hot end?

The best 3D printer hot ends have good heat management, durability, material compatibility, and material flow rate. They minimize heat creep and maintain a stable printing temperature during extended 3D printing times. A stable hot end temperature reduces the chances of the hot end clogging up and prevents print failures.

A hot end with a high flow rate lets you print at faster print speeds and larger layer heights. This reduces print times and creates a strong 3D printed part.

Another aspect you need to consider is the material composition of the hot end. 3D printer hot ends with brass nozzles are not the best for printing with abrasive materials. Instead, you should look for hot ends with stainless steel or hard-coated nozzles. These nozzles are more wear-resistant and can handle abrasive materials better.

Similarly, if you want a hot end for 3D printing high temperature (>300°C) filaments, you are best off with a hot end with a copper-plated heater block, a high-powered heater cartridge, and a thermocouple. These hot ends can handle the higher temperatures required for printing with polycarbonate, PEEK, and other engineering-grade filaments.

These hot ends can handle the higher temperatures required for printing with polycarbonate, PEEK, and other engineering-grade filaments.

The Best All-Metal 3D Printer Hot Ends in 2022

E3D V6

Best overall

Check Price

AmazonE3DMatterHackers

E3D manufactures some of the highest quality hot ends and the E3D V6 is one such example of that. It is simple yet effective and delivers excellent printing performance. It is suitable for both direct and Bowden drive extruders, and you can further customize it for your 3D printer directly through E3D’s website.

The E3D V6 is an all-metal hot end capable of reaching temperatures of up to 300 °C in the standard configuration. The cartridge-style heating block facilitates the easy removal of heater cartridges and thermistors for easy installation and maintenance. Its heatbreak is designed to maintain consistent and accurate temperature in longer prints.

As with all E3D products, the V6 has excellent community support, ensuring that you can quickly resolve any issues. Overall, it is a superb hot end that will take care of most of your printing needs and is suitable for hobbyists and professionals alike.

Overall, it is a superb hot end that will take care of most of your printing needs and is suitable for hobbyists and professionals alike.

Standout Features

- All-metal heatbreak

- Cartridge style heating block

- Simple design

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1.75 mm, 2.85 mm |

| Available voltages | 12V, 24V |

What We Like

- Excellent printing performance

- Available in several configurations

- Excellent community support

Could Be Better

- Big form factor

Find E3D V6 at

AmazonE3DMatterHackers

Micro Swiss All Metal Hotend Kit

Best hot end for Ender 3

Check Price

AmazonMatterHackers

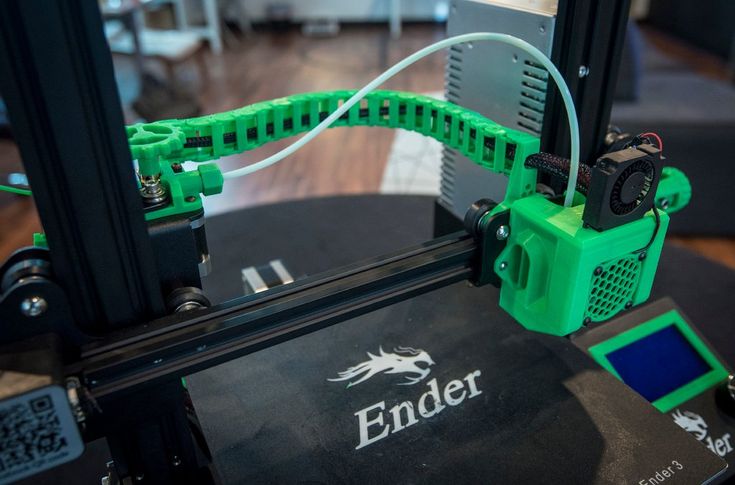

The Micro Swiss hot end is an upgraded version of the stock hot end for Creality 3D printers. You can install it directly on the default setup of CR-10 and Ender 3 series 3D printers without any extra mounting systems and brackets.

You can install it directly on the default setup of CR-10 and Ender 3 series 3D printers without any extra mounting systems and brackets.

The Micro Swiss comes with a similar appearance to the stock Ender setup, albeit delivering improved performance. You get a titanium heat break that does an excellent job in thermally separating the hot and cold regions of the hot end resulting in a more defined melt zone.

You will need to recalibrate your retraction settings and ensure proper assembly of this hot end, however. Set it up correctly, and the Micro-swiss hot end is an excellent upgrade for anyone who wants to print high-temperature materials on a budget.

Standout Features

- Aluminum heater block

- Titanium heat break

- Brass plated MK8 nozzle

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1. 75 mm 75 mm |

| Available voltages | 24V |

What We Like

- Easy to use with Creality printers

- Good build quality

- Good customer support

Could Be Better

- Requires tweaking

- Potential retraction and leakage issues

Find Micro Swiss All Metal Hotend Kit at

AmazonMatterHackers

E3D RapidChange Revo

Best high-end

Check Price

E3DMatterHackers

Swapping out a 3D printer nozzle can be a labor-intensive process and result in significant downtimes in your 3D printing process. To speed this process up, the E3D Rapid Change Revo comes with a unique design that lets you quickly change your nozzles without any tools.

It features a design similar to the E3D V6 hot end but in a more compact and lightweight form factor. The hot end comes with a redesigned heating block that is engineered for safety and maximum heating performance. The Revo is compatible with most high-temperature materials and delivers superb print quality out of the box.

The Revo is compatible with most high-temperature materials and delivers superb print quality out of the box.

You can get the hot end in three configurations – Revo Micro, Revo Six, and the Revo Hemera. Each version is developed for different use cases. Together, the Revo Rapid change system covers a wide range of 3D printing applications.

A RapidChange Revo hot end is well-suited for professional users who are looking for the best hot ends with easy maintenance.

Standout Features

- Quick-swappable nozzles

- Lightweight design

- Fast heating times

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 12V, 24V |

What We Like

- Compact form factor

- Faster print speeds

- Easy maintenance

Could Be Better

- Limited nozzle options

- Pricy nozzles

- Not compatible with 2.

85 mm filament

85 mm filament

Find E3D RapidChange Revo at

E3DMatterHackers

Slice Engineering Mosquito

Best for high-temperature filaments

Check Price

AmazonMatterHackers

The Slice Mosquito hot end comes with a unique design that separates it from other hot ends. The heater block is entirely separated from the frame of the hot end with the help of four support rods. It helps to eliminate heat creep and improves thermal performance.

This design allows the hot end to be highly compact and lightweight, resulting in extra vertical height and faster print speeds. Its rigid construction allows for one-handed nozzle changes making maintenance an easy task.

In contrast to the previously mentioned hot ends, the Slice Mosquito is rated to print at high temperatures of up to 500 °C, covering filaments such as PEEK, ULTEM, and PPSU.

At a starting price point of $144.99, it is certainly not for budget 3D printer users. However, the Slice Engineering Mosquito hot end is ideal for professionals who need a high-performance hot end that delivers excellent print quality and broad material compatibility.

Standout Features

- Unique design

- High printing temperatures

- High structural rigidity

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 12V, 24V |

What We Like

- Lightweight and compact design

- No heat creep

- Compatible with majority of FDM 3D printers

Could Be Better

- No liquid cooling option

Find Slice Engineering Mosquito at

AmazonMatterHackers

E3D Supervolcano Upgrade Kit

Best for large 3D printers

Check Price

AmazonE3DMatterHackers

The E3D Supervolcano upgrade kit is specifically designed for fast printing of large objects. It delivers up to 11x more volumetric flow rate than regular E3D V6 hot ends. This lets you 3D print at higher speeds with large layer heights and widths.

This lets you 3D print at higher speeds with large layer heights and widths.

Wider layers allow for better interlayer adhesion resulting in a stronger 3D printed part. While 3D print strength is something you can also increase by choosing the strongest infill pattern and strongest filament, printing wider layers gives you another option to do so.

The Supervolcano can reach a maximum print temperature of 300 °C, letting you print with materials like PLA, ABS, PETG, and TPU. It is fully compatible with various other E3D hot ends and extruders, so you can easily upgrade your default setup to a Supervolcano.

This is the best 3D printer hot end for a large format 3D printer to carry out high-volume printing. If your printing workflow consists of large-scale and high-volume 3D printed parts, the Supervolcano kit is crucial in reducing your 3D printing times.

Standout Features

- 11x volumetric flow rate (compared to V6)

- Copper plated heat break

- Readily compatible with E3D hot ends

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1. 75 mm, 2.85 mm 75 mm, 2.85 mm |

| Available voltages | 12V, 24V |

What We Like

- High filament melting rate

- Suitable for large objects

- Option for second thermistor

Could Be Better

- Reduces print height

- Increased chances of thermal runaway and safety issues

Find E3D Supervolcano Upgrade Kit at

AmazonE3DMatterHackers

DyzEnd PRO

Most durable nozzle

Check Price

MatterHackers

The DyzEnd Pro hot end is a high-performance hot end developed for a professional workflow. It comes in a lightweight and compact design that takes up less space.

This hot end comes with a tungsten carbide nozzle with excellent wear resistance. This means you can use the DyzEnd PRO for 3D printing abrasive materials, like carbon fiber or glow-in-the-dark filament, without fear of it wearing out.

Its all-metal heat zone and steel heater block ensure that you can print materials up to 500°C with ease. You can also quickly cold swap the nozzle on the DyzEnd Pro for less downtime and easy repairability.

You can also quickly cold swap the nozzle on the DyzEnd Pro for less downtime and easy repairability.

It is a superb hot end meant for serious professionals who regularly print with high-temperature materials. If you’re looking for a lightweight, robust and good quality hot end for your 3D printing workflow, the DyzEnd Pro is one of the best hot ends available.

Standout Features

- Cold swappable nozzle design

- High maximum temperature

- Liquid cooling ready

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 12V, 24V |

What We Like

- Fast printing speeds

- Increased durability with abrasive filaments

- Compatible with different temperature sensors

Could Be Better

- Limited nozzle sizes

- Requires considerable fine-tuning

Find DyzEnd PRO at

MatterHackers

Phaetus Dragonfly Hot End

Check Price

AmazonBIQU

The Phaetus Dragonfly hot end is an all-metal hot end designed for hobbyists and professionals. It uses copper alloy material for its heat sink for better heat dissipation. The Dragonfly also lets you print at up to 500 °C, making it one of the cheaper 3D printer hotends that can reach these high temperatures.

It uses copper alloy material for its heat sink for better heat dissipation. The Dragonfly also lets you print at up to 500 °C, making it one of the cheaper 3D printer hotends that can reach these high temperatures.

This hotend has a smooth inner surface that aids in getting an uninterrupted filament flow. Its conical heat break designs allow fast heat dissipation, maintaining good thermal separation and a stable melt zone.

Compared to the other hot ends that can reach 500 °C on this list, the Dragonfly is reported to come with more quality control issues. This is something that can be expected given its low price but it is still something we think you should be aware of.

The Dragonfly Hot end comes in two variations suitable for Creality and Prusa 3D printers. It is ideal for individuals who need a high-temperature hot end that’s easy to use and comes at a budget price.

Standout Features

- All-metal design

- Conical heat break

- Copper alloy construction

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1. 75 mm 75 mm |

| Available voltages | 12V, 24V |

What We Like

- Excellent heat dissipation

- High printing temperature

- Relatively low price

Could Be Better

- Quality control issues

- Inconsistent printing performance

Find Phaetus Dragonfly Hot End at

AmazonBIQU

Buyer’s Guide – How to Choose a 3D Printer Hot End

3D Printer CompatibilityHot ends are not a generic component and are often designed for a specific set of 3D printers. Checking the hot end’s compatibility with your 3D printer is essential for getting the best results. It will ensure that you get the right hot end that supports your 3D printer’s hardware and electronics.

One of the things to look for is the heater cartridge voltage on the hot end. It has to match the printer’s voltage to ensure proper heating of the hot end.

You also need a mounting system for the hotend. Any additional mounting plates and hardware will translate to an increase in the cost, even though you can 3D print these yourself sometimes.

Any additional mounting plates and hardware will translate to an increase in the cost, even though you can 3D print these yourself sometimes.

Material Compatibility

A hot end with wide material compatibility is always a good thing to have. This allows you to experiment with different materials and find the ones that work best for your needs.

The most important thing to look for is the maximum temperature that the hot end can reach. This number will give you a good idea of the range of materials that the hot end can work with.

Typical all-metal hot ends can reach up to 300 °C and can easily print most thermoplastics. This range covers PLA, ABS, PETG, Nylon, and flexible filaments like TPU and TPE.

If you need to print high-performance plastics such as PEEK, ULTEM, Polycarbonate, and PEI, you will need a hot end that has a maximum printing temperature of 500 °C.

High-performance hot ends will be more expensive than the basic ones and might not yield good results when printing at lower temperatures. If you primarily print with materials that melt below the 300 °C points, basic all-metal hot ends like the E3D V6 and the Microswiss should be enough for you.

If you primarily print with materials that melt below the 300 °C points, basic all-metal hot ends like the E3D V6 and the Microswiss should be enough for you.

Nozzle Compatibility

A nozzle is an important component of the hot end assembly. Nozzles are designed with their hot end’s specifications in mind. The nozzle you use defines the printing capability and material compatibility of your hot end.

A larger nozzle size will let you print fast and with large layers, while a fine nozzle is suitable for printing detailed parts. Both can be properties to look for when looking to make money with your 3D printer.

Similarly, a nozzle’s material will also affect the print quality. Nozzles made from stainless steel can handle higher temperatures and are more wear-resistant. As a result, they can last longer, but they might not be the best choice for printing with PLA.

On the other hand, brass nozzles are a good all-around choice and can be used with most materials. If you are unsure about the material of the nozzle, always check with the hot end’s manufacturer.

If you are unsure about the material of the nozzle, always check with the hot end’s manufacturer.

Due to the hot end’s design, nozzles aren’t interchangeable between 3D printer hot ends from different brands. For example, the DyzEnd nozzle is specific to the DyzEnd Pro hot end. Similarly, the E3D Supervolcano exclusively supports E3D nozzles of sizes 0.6 mm – 1.2 mm.

If you 3D print with parts of varying layer heights and with different materials, you need to ensure that you get a hot end that’s compatible with various nozzle sizes and materials.

Build Quality

A hot end is the critical component of the 3D printer and is responsible for extruding the filament smoothly. A poorly manufactured hot end will lead to many issues down the line.

Nozzle clogs, hot end jamming, filament leakage, and improper filament flow all indicate poor hot end build quality. These issues can be frustrating and time-consuming to deal with. Checking the user reviews before you purchase the hot end will give you a better idea about its build quality.

Cheaper hot ends tend to have poor overall quality and while they might work well in the beginning, they can experience many issues after prolonged use.On the other hand, a well-manufactured hot end will have a high upfront cost and give you consistent printing performance and a high-quality experience.

Should You Buy an All-Metal Hotend or Not?

All-metal hot ends are helpful for printing materials like ABS, PETG, and Nylon. Where PTFE-lined hotends are only suitable for printing up to around 250°C, an all-metal hot end typically reaches temperatures of either 300°C or 500°C

These temperatures are more than enough for printing a wider variety of materials. The all-metal design also eliminates the need to replace the PTFE liner in the hotend over time, as the PTFE tube is no longer exposed to extreme temperatures.

However, the all-metal design can create more filament jamming issues when not configured correctly. A shorter retraction distance helps to minimize stringing and consequently prevent filament jams, however.

If you plan on printing with a lot of different materials or if you want to experiment with higher temperatures, an all-metal hot end is a good investment. Otherwise, a PTFE-lined hot end will suffice for most applications.

That said, you can’t ever go wrong with an all-metal hotend upgrade. If you simply want the best 3D printer hot end for your machine, all-metal is the way to go.

FAQ

When should I replace my 3D printer hot end?

There’s no need to replace your 3D printer hot end unless you’re looking for an upgrade to get better performance. You might have to periodically replace certain components, like the nozzle, when they wear out, however.

If you are experiencing issues with your prints, then it may be time to check your hot end for any damage or debris that may be causing problems.

Is an all-metal hot end good for PLA?

Yes. While all-metal hotends are ideal for higher-temperature filaments, they can also be used with lower-temperature filaments like PLA. Some users find that they get better results using an all-metal hotend with PLA than they do with a standard hotend with PTFE lining.

Some users find that they get better results using an all-metal hotend with PLA than they do with a standard hotend with PTFE lining.

What type of hotend does the Ender 3 use?

The Ender 3 uses a PTFE-lined hot end, which allows for smoother filament flow and reduced clogging. PTFE is a low-friction material that is resistant to wear and tear, making it an ideal choice for a hot end.

If you want to upgrade your Ender 3 hot end, the Microswiss is one of the best hot ends to swap the stock one out with.

Which hot end is best?

In our opinion, the E3D V6 hotend is currently the overall best hot end on the market. It is made of high-quality materials and has a modular design that makes it easy to assemble and maintain. It also has a wide range of compatibility with different types of printers, making it a popular choice for both beginners and experienced users.

Conclusion

Choosing the right hot end for your 3D printer will extend your printing potential. The best 3D printer hot end minimizes heat creep while maintaining a stable printing temperature. However, you need to check that the hot end you select fits your 3D printing needs and is compatible with your 3D printer.

The best 3D printer hot end minimizes heat creep while maintaining a stable printing temperature. However, you need to check that the hot end you select fits your 3D printing needs and is compatible with your 3D printer.

The E3D V6 hot end ranks on the top as the best 3D printer hot end. It is one of the most reliable hotends that has been well-tested over the years and is suitable with a good of materials. It has an all-metal design, broad 3D printer compatibility, and excellent build quality at a reasonable price.

Its only drawback is its limited range of printing materials. With a maximum temperature of 300°C, it won’t handle true engineering materials like PEEK.

This is where the Slice Engineering Mosquito and the DyzEnd Pro hot end step in. These are rated to print up to 500 °C and come with unique designs with elegant features.

So, what is the best 3D printer hot end for you? It depends on your specific needs. Consider the type of materials you want to print with, your budget, and your 3D printer compatibility when making your decision.

Let us know your experience if you’ve used any of these hot ends. We’d love to hear if you have anything else to add in the comments below.

The Best 3D Printer Hot Ends Buyer's Guide 2022

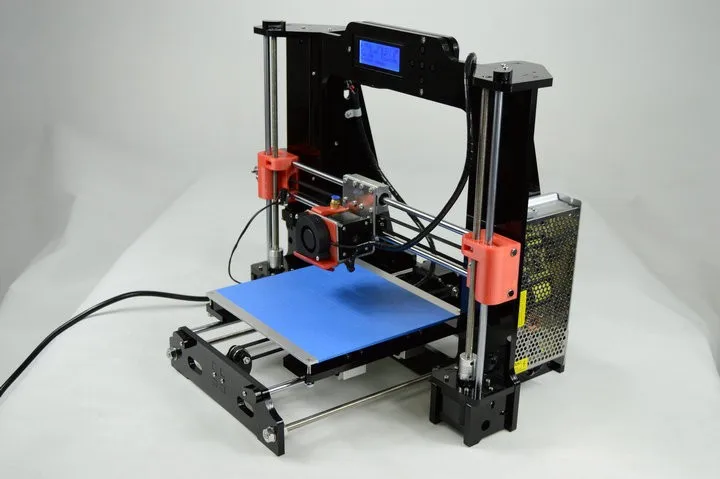

A 3D printer hot end makes up part of the extruder, probably the single most important part of an FDM 3D printer. The hot end melts plastic filaments that are then deposited on the print bed to create your 3D model.

In a direct drive extruder set up, the hot end is directly below the cold end for direct access. In a Bowden extruder however, the hot end is separate from the cold end, which is mounted on the printer’s frame and is commonly seen in delta 3D printers.

Investing in a good quality hot end is one of the best investments you can make in 3D printing, as they are so integral to print quality and efficiency. A sign of a good hot end is that there are many copies or clones – though we strongly recommend spending the extra $20 and picking up the real deal, ensuring a great 3D printing experience.

- We also have a guide to all the parts of a 3D printer.

How a 3D Printer hot end affects 3D printing:

- Reliability: A good hot end reduces the likelihood of prints failing and helps prevent filament clogging.

- The materials you can use: Some hot ends are made of fully metal parts and therefore can handle higher temperatures. This allows you to print with tougher filaments such as Nylon or PETG. Always check what temperature your hot end can manage.

- 3D printing speed: a lightweight hot end can mean a faster 3D printer with less chance of overshooting.

- Print quality: hot ends are key for precise, crisp finishes on prints. A hot end that effectively melts filament to deposit it at the perfect temperature reduces chances of warping.

- Nozzle size: some hot ends are compatible with different 3D printer nozzle sizes, which affect accuracy and speed.

Top 5 Best 3D Printer Hot Ends / Extruders

| Name | Price | Best place to buy: | Other purchase option: |

|---|---|---|---|

| E3D V6 | $61 | Amazon here | Matterhackers here |

| E3D Lite6 | $37 | Amazon here | Matterhackers here |

| Micro Swiss MK10 All Metal Hot End | $63 | Amazon here | |

| Diabase Flexion Single Extruder | $150 | Amazon here | |

| Diabase Flexion Dual Extruder | $250 | Amazon here | |

| E3D Titan Aero | $140 | Amazon here |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Choosing the Best Hot End for You

When considering buying a hot end, consider:

- What materials you want to print with – some hot ends can reach 400C and can melt and print with anything, while others can only print PLA.

Metal hot ends can reach higher temperatures than PEEK hot ends, and are therefore compatible with more materials. You’ll need a high-quality hot end for tougher materials such as Nylon, and should consider a special extruder for flexible filaments.

Metal hot ends can reach higher temperatures than PEEK hot ends, and are therefore compatible with more materials. You’ll need a high-quality hot end for tougher materials such as Nylon, and should consider a special extruder for flexible filaments. - How much you are willing to invest – saving money on a cheaper hot end can cost you more money in the long run if they keep breaking and need to be replaced. We have picked hot ends with a reputation for reliability and durability which we recommend below.

- What 3D printer do you currently have – only buy a hot end compatible with your 3D printer or that is easily modifiable to fit with it. The best hot ends, such as those made by E3D, are compatible with almost every 3D printer.

- Size of filament you want to print with – many hot ends are compatible with both 1.75mm and 3mm filament, but make sure you don’t buy the wrong size for you.

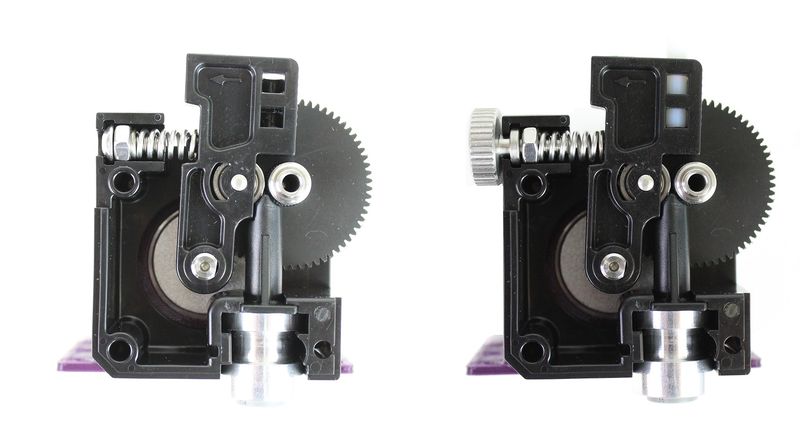

Metal vs PEEK / PTFE Hot Ends

Hot ends are usually either made of PEEK, PTFE or metal. Metal hot ends are more versatile and can reach higher temperatures, and are therefore compatible with more filament material types. They are also considered more reliable, so for any maker looking for reliable printing and the option to print materials beyond the standard ABS or PLA, we recommend a metal 3D printer hot end.

Metal hot ends are more versatile and can reach higher temperatures, and are therefore compatible with more filament material types. They are also considered more reliable, so for any maker looking for reliable printing and the option to print materials beyond the standard ABS or PLA, we recommend a metal 3D printer hot end.

PEEK is good enough for standard filaments such as ABS or PLA, but for tougher filaments it is not best suited.

The materials you can print doesn’t just depend on the hot end, however. Other factors such as whether your 3D printer has a heated bed affect whether you can print ABS, PETG, Nylon and several other filaments.

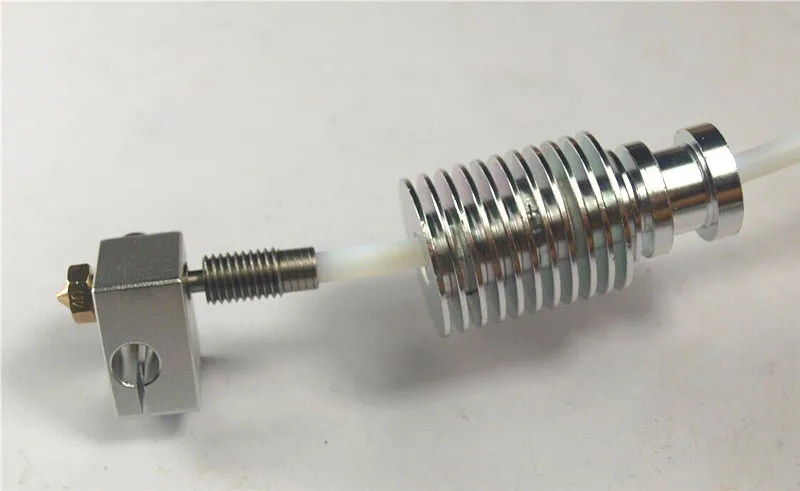

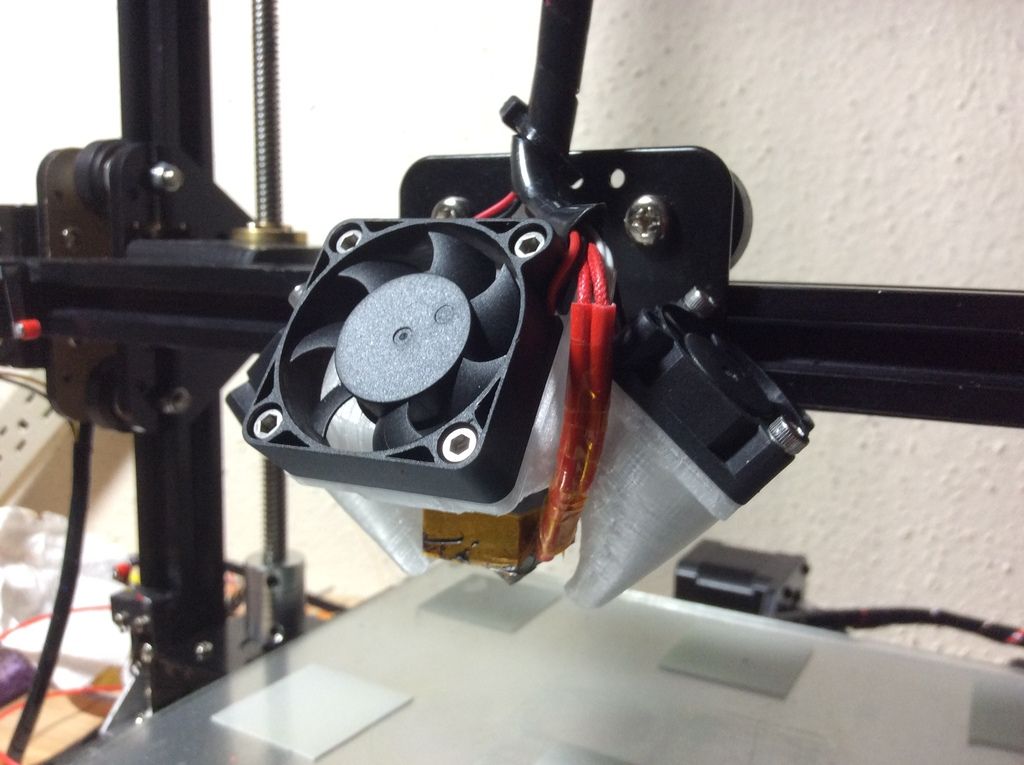

A PEEK hot end and a metal hot end, side-by-side comparisonParts of a 3D Printer Hot End

- Nozzle – lets filament out, and on to the print bed to form the model. The size of your nozzle affects precision, as smaller nozzles can print more precise details. However, there is a trade-off: you can either print more quickly with a larger nozzle but at lower quality, or more slowly at a higher quality with a smaller nozzle.

The standard nozzle size is 0.4mm, but varies. They can easily be switched out if you want to print with a larger or smaller nozzle. A smaller nozzle is important for 3D printing miniatures.

The standard nozzle size is 0.4mm, but varies. They can easily be switched out if you want to print with a larger or smaller nozzle. A smaller nozzle is important for 3D printing miniatures. - Heat Block – keeps the heater cartridge and thermistor in place, and connects the heat break and nozzle together. This part produces the heat which melts filament so it can be extruded.

- Thermistor – monitors the heater block’s temperature.

- Heat Break – connects the heat block to the heat sink, and is where the filament moves from normal temperature to the high temperatures that will melt it.

- Heat Sink – cools down the cold side of the break, usually with a fan to help cool it.

5 of the Best 3D Printer Hot Ends

E3D V6 — best overall 3D printer hot end

- Price: $62 — Available on Amazon here / Available on Matterhackers here

Considered the best hot end around by makers and 3D printer companies alike, the E3D V6 is a customizable all-metal hot end that works great even with tougher filaments like Nylon. As with all E3D hot ends, parts can easily be replaced and switched out.

As with all E3D hot ends, parts can easily be replaced and switched out.

It comes as a DIY kit that you will need to assemble yourself, unless you’d prefer to pay more to have it ship assembled. Building it yourself gives you the flexibility you need, as you may want to turn it into a direct or Bowden extruder, or change it to take either 1.75mm or 3mm filaments.

E3D hot ends are extremely versatile, and compatible with almost any FDM 3D printer you can think of. It’s built to be lightweight and precise, meaning you can print with no overshooting at good speeds. Overall, we highly recommend the E3D V6 as one of the best 3D printer hot ends.

E3D Lite6 – best 3D printer hot end for beginners

- Price: $37 — Available on Amazon here / Available on Matterhackers here

The E3D V6’s baby brother, the Lite6 is one of the best hot ends for beginners to 3D printing. It’s only compatible with 1.75mm filament, so for the minority of makers who prefer 3mm this won’t work for you.

For the lower price, you lose some of the benefits of the E3D V6. Instead of being fully metal, a small number of parts are PTFE-lined, so the Lite6 can’t take on the same high temperatures as the E3D V6. For that reason, it is mostly limited to standard filaments such as ABS and PLA.

Being less customizable than the V6 shouldn’t be a problem for beginners, and it is easier to assemble and mount than its bigger brother. Overall, we recommend it for newer makers and those who want to save time, prefer a less complex hot end, and want to save some money.

Compressed by jpeg-recompressMicro Swiss MK10 All-Metal Hot End

- Price: $63/£37 — Available on Amazon here

This all-metal hot end is similar in price to the E3D V6 and is a great upgrade on the standard MK10 hot ends ever-present on printers such as the Creality CR-10, Flashforge, Qidi Tech and Dremel 3D printers.

The Micro Swiss MK10 is compatible with a variety of different nozzle sizes, and can be used with dual extruder 3D printers as well as single extruders. In effect, the MK10 all-metal upgrade replaces some PTFE parts with metal ones to improve printing conditions and results.

In effect, the MK10 all-metal upgrade replaces some PTFE parts with metal ones to improve printing conditions and results.

Unlke E3D hot ends, you don’t get every part to your hot end, just the necessary parts to replace the non-metal parts of existing standard MK10 hot ends.

Diabase Flexion Extruder — best 3D printer hot end for flexible filament

- Price: $149 single, $249 dual extruder

- Single extruder version available on Amazon here

- Dual extruder version available on Amazon here

The Diabase Flexion is specifically designed for printing flexible filaments, and is by far the most effective hot end for flexibles – able to print at higher speeds and with less clogging and errors.

Designed to prevent errors that can occur often with flexible filament printing due to clogging or the squeezing of flexible materials into positions or areas where they are not supposed to go. The specially-designed feeder can more effectively grip flexible filament to travel through to be printed without issue and avoid jams.

Coming in both dual extruder and single kits, but only compatible with 1.75mm filaments, this is the ideal hot end we recommend if you want to avoid the stress of filament jams. Overall, for flexible filaments, you can’t get much better.

E3D Titan Aero

- Price: around $140 — Available on Amazon here

Designed for direct drive extruders and with the heat sink attached to the hot end, the Titan Aero is a hybrid hot end built for efficiency.

Since the heat sink is attached to the hot end, there is a far shorter distance to travel from the heater block to the extruder. This makes it great for fast printing, and the E3D Titan Aero also has great grip to prevent filament jams, and is designed to be extremely easy to clean. It’s also compatible with both 1.75mm and 3mm filament.

Though minor, it is important to remember that the attached heat sink will add a small amount of weight to the hot end, so it will struggle to reach the precision of the E3D V6 at the same faster speeds.

Related articles:

- Ender 3 hot ends – best options

- 3D printer nozzles – the best and tips and tricks

- 3D printer nozzle size – the pros and cons of smaller and larger nozzles

- Best 3D printer extruders

- Best dual extruder 3D printers

Top 5 extruders for 3D printer Anet A8

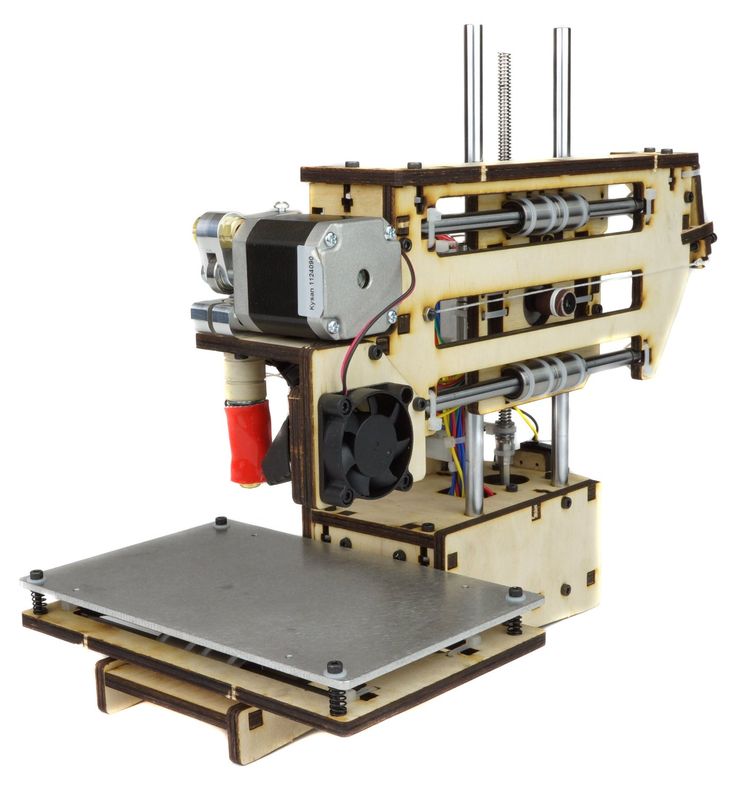

TheAnet A8 is a very popular 3D printer due to its affordability and wide customization options. This is certainly an interesting project that you can assemble yourself or buy as a set. Thanks to its affordable price and clear design, Anet A8 has long been the "people's 3D printer" and a great option to get acquainted with the intricacies of 3D printing.

Due to the extensive modification options, 3D printing results on the Anet A8 can vary greatly. And some modifications simply turn this model into an analogue of expensive 3D printers in terms of 3D printing quality. There are a lot of modifications on the Internet, and in this article we will touch on the modifications of one node - the extruder. Believe me, there are a lot of modifications to the Anet A8 extruder and they are worth discussing.

Believe me, there are a lot of modifications to the Anet A8 extruder and they are worth discussing.

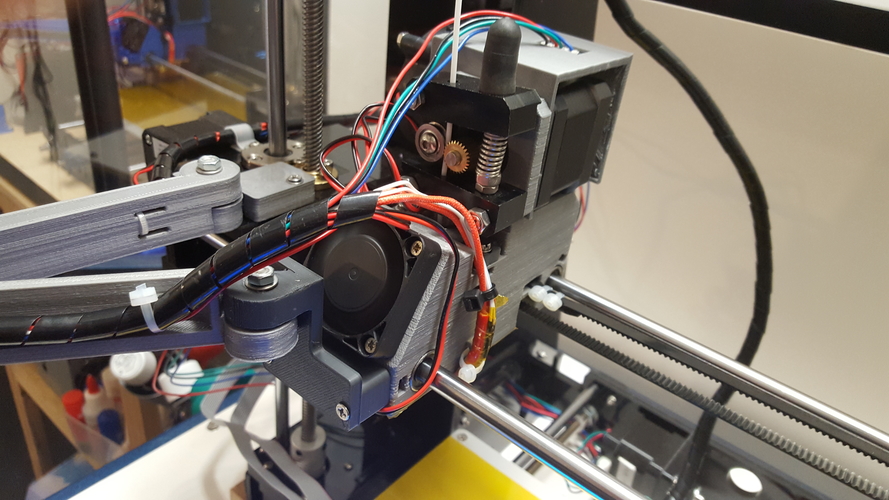

For example, the original design of this 3D printer does not include a duct fan to help direct air from the Anet A8 extruder fan to the nozzle. And air is needed to cool the extruded plastic and keep the 3D printer in proper working order. But there is also good news - Thingiverse already has a lot of mods for blowing. Here's a great one from a user named Arjjck.

One of the simplest mods is adding an extruder button to make it easier to use the 3D printer. This 3D printed button is definitely better than the standard extruder screw, which is almost impossible to press with your fingers. Such a simple 3D printed Anet A8 extruder button will save you the pain of changing 3D printing material.

The extruder replacement is one of the Anet A8 upgrades that can greatly improve the quality of 3D printing, so let's take a look at the interesting options.

E3D Titan extruder

The E3D Titan extruder is ideal for those who want to print using different materials, not just PLA plastic. Lightweight E3D Titan reduces clogging and features specially machined teeth that are curved to grab fibers at right angles. The teeth improve the grip of the thread and increase the accuracy of its feeding.

Lightweight E3D Titan reduces clogging and features specially machined teeth that are curved to grab fibers at right angles. The teeth improve the grip of the thread and increase the accuracy of its feeding.

This extruder has been manufactured to increase torque, reduce clogging and 3D print at higher resolutions. It is designed for use with the E3D v6 hotend, allowing you to print at higher temperatures, and the 3:1 gear ratio ensures more precise movement.

According to the manufacturer, this ratio gives the E3D Titan extruder the best performance in terms of accuracy and speed. Obviously lower gear ratios run too slow while higher gear ratios run too fast. Thus, the manufacturer concluded that a ratio of 3:1 is the best option, allowing the extruder to cope with the required degree of extrusion. The gear ratio increases resolution and promotes smooth 3D printing at low layer heights.

The extruder supports 3D printing with 1.75 mm and 3 mm filaments and allows the use of materials such as abrasive carbon fiber, TPU, TPE and a number of other harder plastics. The E3D Titan has a solid construction thanks to injection molded parts. Unlike other more clumsy extruders, the design details eliminate the possibility of wiggle and improve accuracy. In addition to being lightweight for more torque, the E3D Titan has been built to be easy to assemble or disassemble.

The E3D Titan has a solid construction thanks to injection molded parts. Unlike other more clumsy extruders, the design details eliminate the possibility of wiggle and improve accuracy. In addition to being lightweight for more torque, the E3D Titan has been built to be easy to assemble or disassemble.

LulzBot Taz Single Extruder Tool Head v2

LulzBot TAZ Single Extruder Tool Head v2 comes with a solid metal hex and can withstand temperatures up to 300°C (572°F). Thus, you will not have problems with materials such as ABS, PLA and HIPS. You can also use materials such as T-Glase, polycarbonate, nylon, as well as various types of threads filled with stone and wood.

The extruder comes with two fans, one for the nozzle to help produce highly detailed prints, and one for the heatsink. The LulzBot Taz has gone through countless hours of testing and is a suitable replacement for the Anet A8 extruder.

Single Flexion Retrofit Kit Extruder

This extruder is much better than the standard Anet A8 extruder and guarantees high resolution and fewer failures. The Extruder Upgrade Kit includes precision machined components that give you the ability to print at full speed on flexible materials, using adjustable fine filament tension to maintain high 3D printing accuracy.

The Extruder Upgrade Kit includes precision machined components that give you the ability to print at full speed on flexible materials, using adjustable fine filament tension to maintain high 3D printing accuracy.

The Flexion extruder pushes the filament harder and the self-cleaning drive ensures no clogging during long 3D prints. This extruder uses a high rigidity lever to compress the filament, and an adjustable screw and cam is used to control the compression - for precise tension control. The Flexion extruder will work well with TPU, TPE, flexible PLA, Filaflex and Ninjaflex in addition to standard materials like PLA, PETG or ABS.

Flex3Drive Extruder

The Flex3Drive extruder is compatible with a wide range of hot ends and has a ratio of 40:1. With this ratio, it will print great first layers. It provides a direct feed to the hotend, but the motors are spaced apart to reduce moving mass and lighten the extruder. This results in smoother print head movement and reduces vibration.

This shaft-driven extruder is compact, small and fairly light. The extruder is equipped with cam-lock tensioners for constant material tension without the use of springs or screws. This is particularly suitable for tough materials, but there is an adjustable thread tension lever that does not require a firm grip.

Material loading is greatly simplified and the filament can be changed without stopping the 3D printing process.

Mounting the Flex3Drive hot end on the bottom of the extruder can be a pain, but worth it. This extruder is suitable for working with nozzles of the widest diameter. The drive gears are made on high-precision CNC machines, so there are no questions about the quality of the manufacture of these extruders.

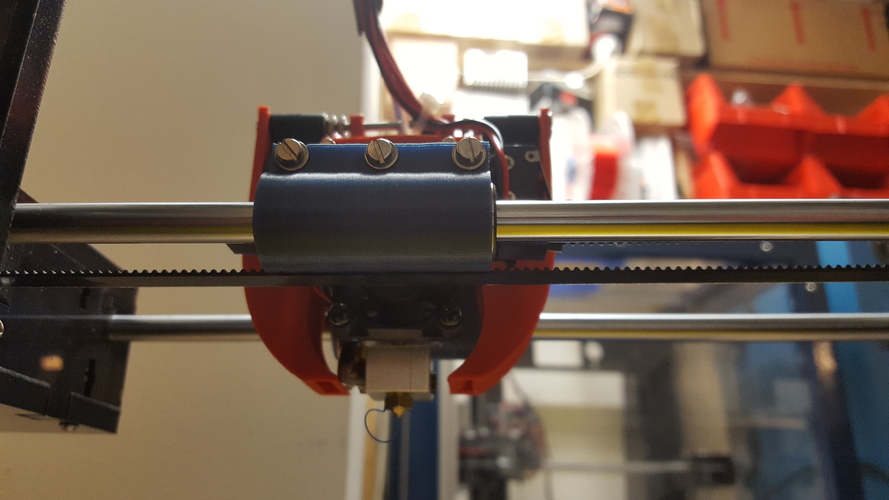

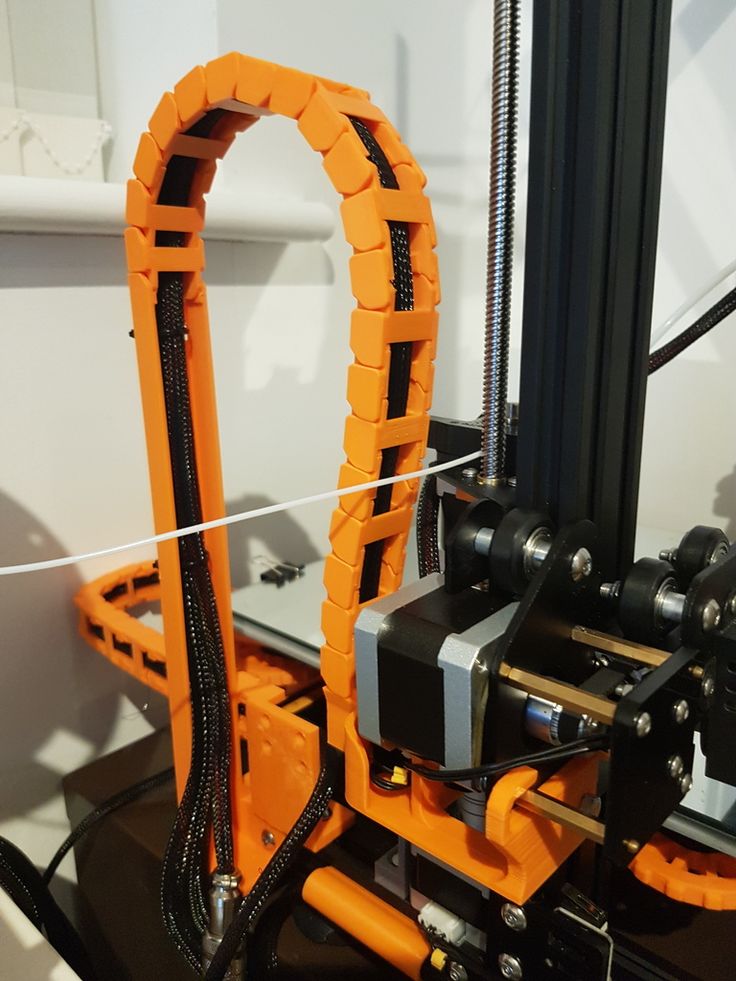

Bowden Type Extruders

Well, here's the holi comrade on our list of the best Anet A8 extruders. Bowden type extruder. An extruder in a Bowden layout means that the hot end is physically separate from the extruder. Typically the extruder is mounted on the inside or back of the Anet A8 3D printer and works like a "remote" extruder in the same way as a direct extruder: grabs the material and pushes it. However, the main difference is that the thread must pass through the tube before it reaches the hot end.

Typically the extruder is mounted on the inside or back of the Anet A8 3D printer and works like a "remote" extruder in the same way as a direct extruder: grabs the material and pushes it. However, the main difference is that the thread must pass through the tube before it reaches the hot end.

The Bowden Extruder significantly reduces the weight that the carriage needs to move during 3D printing and reduces carriage vibration, backlash and twitching. This is because when the extruder (with its mounts and motor) is out of the way, only the hot end can move. Therefore, less momentum needs to be overcome, and this makes Bowden designs the best choice for 3D printing complex parts.

But this type of extruder has a downside. The separation of the hot end and extruder usually causes a delay or hysteresis. A longer material path means longer contact and more friction that the extruder must counteract. Therefore, the motors will need more torque to deliver the filament to the hot end. This makes it difficult to use Bowden extruders with flexible filaments. The longer path also means that the filament can warp, shrink, or stretch, resulting in inconsistent 3D printing.

This makes it difficult to use Bowden extruders with flexible filaments. The longer path also means that the filament can warp, shrink, or stretch, resulting in inconsistent 3D printing.

While the Bowden extruder may work well on the Anet A8 3D printer, it may require some technical knowledge to install as the above issues may require certain settings in the 3D printer firmware. Hence, buying a Bowden type extruder can cause problems if you are not a true 3D printing enthusiast.

On the other hand, if you are confident in your skills and have no problem setting up your 3D printer, the Bowden Extruder may come in handy. With the right settings, you can get cleaner and smoother 3D models.

Direct extruder for a 3d printer: an overview of the best types and types, which one is better to choose

The extruder is called the working head of a 3D printer. The plastic thread passes through it, melts and is squeezed out through the nozzle onto the work table. This is how objects are built layer by layer.

This is how objects are built layer by layer.

Types of extruders for 3D printer

There are two types of extruders: direct and bowden. They are slightly different in design and have their pros and cons.

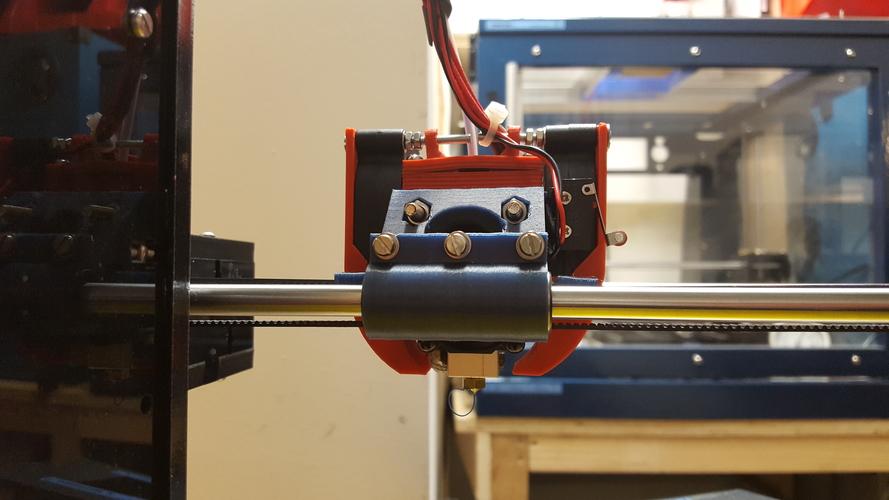

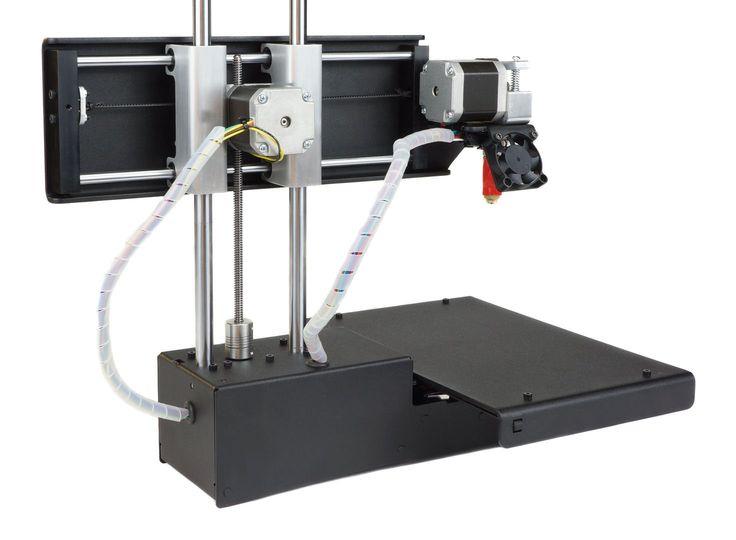

Direct extruder

Direct extruders are located directly above the hot end. Due to this, the distance from the gear train is minimal, which ensures more reliable work with flexible threads.

If a direct head is installed on the printer, this does not mean that it will print well with flexible filaments. In order for the print to be of high quality, it is necessary to monitor the position of the clamp, as well as pay attention to the gear device.

Direct extruders have more precise retraction control compared to Bowden. Positioning above the hot end significantly reduces the distance between the thread and the clip. Therefore, the thread has less room for bending.

The direct printhead is bulkier. Because of this, inertia increases. Good print quality requires a solid rail design. Also, large head sizes affect print speed.

Because of this, inertia increases. Good print quality requires a solid rail design. Also, large head sizes affect print speed.

Main advantages of direct extruders:

- Media can be changed quickly and easily;

- minimum feed distance reduces error;

- can use flexible heads at relatively high speeds.

Disadvantages:

- increased weight compared to bowden;

- head design is more complex.

Bowden Extruder

When using the Bowden Extruder, the gear train and the motor are assembled on the machine frame. The weight of such a print head is less than with a direct extruder.

Bowden's main disadvantage is that as the thread travels through the Teflon tube that connects the hot end and the feed mechanism, it can deviate. The amount of deflection depends on the length of the tube. This disadvantage is especially pronounced during the use of flexible plastics. The print settings and the amount of retraction must be selected empirically.

The print settings and the amount of retraction must be selected empirically.

The problem of friction must also be solved. The thread must be pushed through the tube. It is important that the torque is sufficient to carry out this process.

REFERENCE. Most home delta 3D printers come with bowden extruders.

Advantages:

- reduced weight of the carriage due to the fact that the engine is located on the frame;

- The print head is small.

Disadvantages:

- Printing with flexible plastic is difficult;

- needs a powerful motor to feed material;

- Printer error increases in proportion to tube length.

What is the best filament extruder to buy?

Now the cost of 1 kg of the cheapest thread is about $20. And the price of plastic from trusted manufacturers can reach up to 50% per 1 kg. Therefore, the issue of self-manufacturing of the filament is very relevant.

Therefore, the issue of self-manufacturing of the filament is very relevant.

Filament extruders:

- Liman extruder. This device was invented by Hugh Liman. It can make filament with a diameter of 1.75 and 3 mm with an error of 0.01 mm and saves about 80% on the purchase of filament.

- Fischer extruder or STRUdittle. This is a compact device that allows you to make thread from ABS plastic. The speed of work is 30-60 cm per minute. The error does not exceed 0.05 mm if the filament is freely output. If you use a spool that automatically winds the thread, then the error is reduced to 0.03 mm.

- Filabot Original. The most famous development, which has good performance. Can work with ABS, HIPS and PLA. The starting material can be granulated plastic or plastic waste. If waste is used, the particle size should not exceed 5 mm.

- FilaMaker. The device combines the functions of a crusher and an extruder.

It has a neat design, high functionality and good performance. Can produce up to 1 m of filament per minute with an accuracy of 0.05 mm. The only drawback is the high price - $1200.

It has a neat design, high functionality and good performance. Can produce up to 1 m of filament per minute with an accuracy of 0.05 mm. The only drawback is the high price - $1200. - Filastruder. Relatively cheap extruder, with which you can get 1 kg of thread in 12 hours. The speed of work is from 15 to 60 cm per minute. Speed depends on operating temperature, nozzle diameter and material used. The device is designed for ABS, but it can also be used for PLA, HIPS and nylon.

Overview of 3D printer extruders

Below are the most popular 3D printer extruders with detailed specifications.

MK8

This is the most popular direct extruder. It is easy to install and easy to use, suitable for most 3D printers. Costs approximately $15.

Device specifications:

- Thread diameter 1.75 mm;

- nozzle diameter can be from 0.2 to 0.5 mm;

- 12 V and 40 W heater;

- operating speed - 4 cm per second;

- device weight 450 g;

- operating temperature - from 190 to 250 degrees.

E3D TITAN AERO

Key features of the E3D TITAN AERO:

- direct drive;

- all-metal thermal barrier;

- maximum temperature - 285 degrees;

- gear ratio - 3 to 1;

- is suitable for flexible plastics.

The device is easy to install and easy to use. The original costs about $170, but you can buy a Chinese equivalent for about $40.

Includes:

- standard or mirror housing;

- heat sink;

- mounting connectors;

- fan;

- heating block;

- nozzle;

- Teflon tube;

- thermal grease;

- idle lever;

- thermistor cable and cartridge.

About the dual extruder on the Ender 3 pro

The dual extruder allows you to print with two filaments at once.